Page 1

SFC4200/SFC1275G

Synthesized Frequency

Downconverter

Installation and Operation Manual

TM054 - Rev. 4.0

March, 2002

- NOTICE -

2002, Radyne ComStream Corporation. This

manual may not in whole or in part be copied,

reproduced, translated or reduced to any

electronic or magnetic storage medium without

the written consent of a duly authorized officer

of Radyne ComStream Corporation.

Radyne ComStream Corporation •• 3138 E. Elwood St. •• Phoenix, AZ 85034 •• (602) 437-9620 •• Fax: (602) 437-4811

Page 2

Page 3

Latest Software Revision Confirmation

When new features are added to Radyne ComStream Corporation

equipment, the control parameters are appended to the end of the

Non-Volatile Section of the Remote Communications Specification,

and status of the features, if any, are added at the end of the Volatile

Section. If a remote M&C queries two pieces of Radyne ComStream

Corporation equipment with different revision software, they could

respond with two different sized packets. The remote M&C MUST

make use of the non-volatile count value to index to the start of the

Volatile Section. If the remote M&C is not aware of the newly added

features to the product, it should disregard the parameters at the end

of the Non-Volatile Section and index to the start of the Volatile

Section.

Before creating any software based on the information contained in

this document, contact the Radyne ComStream Corporation Customer

Service Department (602-437-9620) to find out if the software revision

for that piece of equipment is current and that no new features have

been added since the release of this document.

Page 4

Warranty Policy DM240 Synthesized Frequency Downconverter

2

Page 5

SFC4200/SFC1275G Synthesized Frequency Downconverter Warranty Policy

Radyne ComStream Corporation Warranty Policy

Warranty and Service

Radyne ComStream Corporation (Seller) warrants the items manufactured and sold by Radyne

ComStream Corporation to be free of defects in material and workmanship for a period of two (2) years

from date of shipment Radyne ComStream Corporation's obligation under its warranty is limited in

accordance with the periods of time and all other conditions stated in all provisions of this warranty.

This warranty applies only to defects in material and workmanship in products manufactured by Radyne

ComStream Corporation. Radyne ComStream Corporation makes no warranty whatsoever concerning

products or accessories not of its manufacture. Repair, or at Radyne ComStream Corporation's option,

replacement of the Radyne ComStream Corporation products or defective parts therein shall be the sole

and exclusive remedy for all valid warranty claims.

Warranty Period

The applicable warranty period shall commence on the date of shipment from Radyne ComStream

Corporation's facility to the original purchaser and extend for the stated period following the date of

shipment. Upon beginning of the applicable Radyne ComStream Corporation warranty period, all

customer's remedies shall be governed by the terms stated or referenced in this warranty. In-warranty

repaired or replacement products or parts are warranted only for the remaining unexpired portion of the

original warranty period applicable to the repaired or replaced products or parts. Repair or replacement of

products or parts under warranty does not extend the original warranty period.

Warranty Coverage Limitations

The following are expressly not covered under warranty:

1. Any loss, damage and/or malfunction relating in any way to shipping, storage, accident, abuse,

alteration, misuse, neglect, failure to use products under normal operating conditions, failure to

use products according to any operating instructions provided by Radyne ComStream

Corporation, lack of routine care and maintenance as indicated in any operating maintenance

instructions, or failure to use or take any proper precautions under the circumstances.

2. Products, items, parts, accessories, subassemblies, or components which are expendable in

normal use or are of limited life, such as but not limited to, bulbs, fuses, lamps, glassware, etc.

Radyne ComStream Corporation reserves the right to revise the foregoing list of what is covered

under this warranty.

Warranty Replacement and Adjustment

Radyne ComStream Corporation will not make warranty adjustments for failures of products or parts which

occur after the specified maximum adjustment period. Unless otherwise agreed, failure shall be deemed to

have occurred no more than seven (7) working days before the first date on which a notice of failure is

received by Radyne ComStream Corporation. Under no circumstances shall any warranty exceed the

period stated above unless expressly agreed to in writing by Radyne ComStream Corporation.

Liability Limitations

This warranty is expressly in lieu of and excludes all other express and implied warranties, Including but

not limited to warranties of merchantability and of fitness for particular purpose, use, or applications, and

all other obligations or liabilities on the part of Radyne ComStream Corporation, unless such other

warranties, obligations, or liabilities are expressly agreed to in writing by Radyne ComStream Corporation.

All obligations of Radyne ComStream Corporation under this warranty shall cease in the event its products

or parts thereof have been subjected to accident, abuse, alteration, misuse or neglect, or which have not

been operated and maintained in accordance with proper operating instructions.

TM054 – Rev. 4.0 iii

Page 6

Warranty Policy SFC4200/SFC1275G Synthesized Frequency Downconverter

In no event shall Radyne ComStream Corporation be liable for Incidental, consequential, special or

resulting loss or damage of any kind howsoever caused. Radyne ComStream Corporation’s liability for

damages shall not exceed the payment, if any, received by Radyne ComStream Corporation for the unit or

product or service furnished or to be furnished, as the case may be, which is the subject of claim or

dispute.

Statements made by any person, including representatives of Radyne ComStream Corporation, which are

inconsistent or in conflict with the terms of this warranty, shall not be binding upon Radyne ComStream

Corporation unless reduced to writing and approved by an officer of Radyne ComStream Corporation.

Warranty Repair Return Procedure

Before a warranty repair can be accomplished, a Repair Authorization must be received. It is at this time

that Radyne ComStream Corporation will authorize the product or part to be returned to the Radyne

ComStream Corporation facility or if field repair will be accomplished. The Repair Authorization may be

requested in writing or by calling:

Radyne ComStream Corporation

3138 E. Elwood St.

Phoenix, Arizona 85034 (USA)

ATTN: Customer Support

Phone: (602) 437-9620 Fax: (602) 437-4811

Any product returned to Radyne ComStream Corporation for examination must be sent prepaid via the

means of transportation indicated as acceptable to Radyne ComStream Corporation. Return Authorization

Number must be clearly marked on the shipping label. Returned products or parts should be carefully

packaged in the original container, if possible, and unless otherwise indicated, shipped to the above

address.

Non-Warranty Repair

When a product is returned for any reason, Customer and its shipping agency shall be responsible for all

damage resulting from improper packing and handling, and for loss in transit, not withstanding any defect

or nonconformity in the product. By returning a product, the owner grants Radyne ComStream

Corporation permission to open and disassemble the product as required for evaluation. In all cases,

Radyne ComStream Corporation has sole responsibility for determining the cause and nature of failure,

and Radyne ComStream Corporation's determination with regard thereto shall be final.

iv TM054 - Rev. 4.0

Page 7

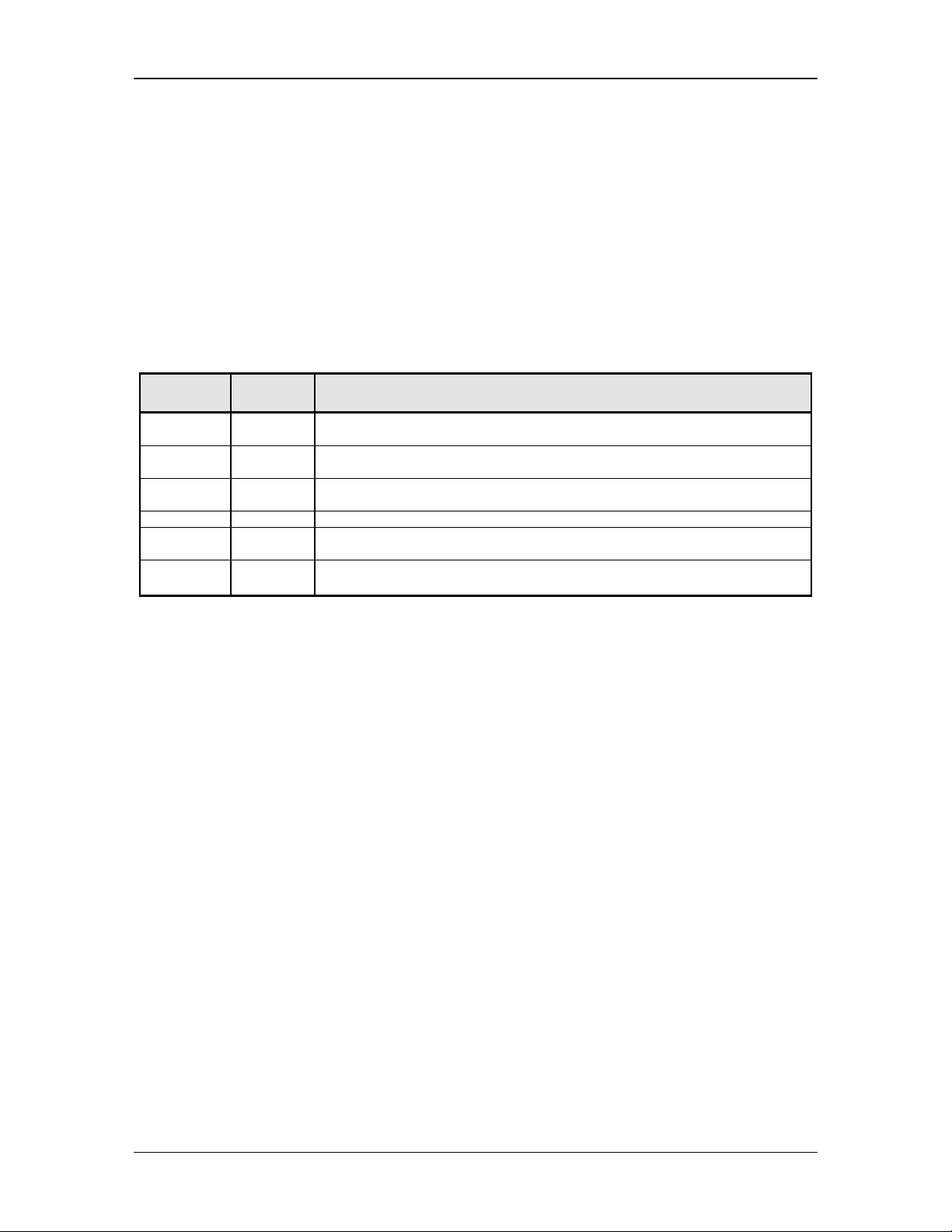

SFC4200/SFC1275G Synthesized Frequency Downconverter Record of Revisions

SFC4200/SFC1275G Synthesized Frequency Downconverter

Installation and Operation Manual

TM054 – Record of Revisions

Radyne ComStream Corporation is constantly improving its products and therefore the

information in this document is subject to change without prior notice. Radyne ComStream

Corporation makes no warranty of any kind with regard to this material, Including but not limited

to the implied warranties of merchantability and fitness for a particular purpose. No responsibility

for any errors or omissions that may pertain to the material herein is assumed. Radyne

ComStream Corporation makes no commitment to update nor to keep current the information

contained in this document. Radyne ComStream Corporation assumes no responsibility for use

of any circuitry other than the circuitry employed in Radyne ComStream Corporation systems

and equipment.

Revision

Level

1.0 7-15-96 Initial Release

2.0 12-01-96 Added interconnection diagram, redefined connector pinouts, updated serial

2.1 12-16-96 Updated Operation Section, updated Serial Protocol and added additional

3.0 2-03-97 Updated Operation Section, added 1:1 and 1:8 Serial Protocol data.

3.1 4-24-97 Added Extended Band data, additional 1:8 operation data and backup 1:8

4.0 3-4-02 Merged with Rev. 4.0, TM062, SFC1275G Global Ku-Band Synthesized

Date Reason for Change

protocol, enhanced operation section, added remote serial I/O operation.

figures to Appendix C.

flow chart

Frequency Downconverter.

TM054 - Rev. 4.0 v

Page 8

SFC4200/SFC1275G Synthesized Frequency Downconverter

This Page is Intentionally Left Blank

vi TM054 - Rev. 4.0

Page 9

SFC4200/SFC1275G Synthesized Frequency Downconverter Table of Contents

Table of Contents

Section 1 - Introduction

1.0 Description______________________________________________________1-1

1.1 Protection Switch Versatility_________________________________________ 1-2

Section 2 - Installation

2.0 Installation Requirements __________________________________________ 2-1

2.1 Unpacking ______________________________________________________ 2-1

2.2 Removal and Assembly____________________________________________2-1

2.3 Mounting Considerations___________________________________________2-1

2.4 Initial Power-Up __________________________________________________2-1

2.5 SFC Downconverter Interconnections _________________________________ 2-2

Section 3 - Operation

3.0 Theory of Operation_______________________________________________3-1

3.1 Signal RF Assembly ______________________________________________3-1

3.1.1 AS/4010 Converter First Mixer C-Band Downconverter (SFC4200) _________ 3-2

3.1.2 AS/4011 Converter Second Mixer C-Band Downconverter (SFC4200) ______ 3-2

3.1.3 AS/4007 Converter First Mixer Ku-Band Downconverter (SFC1275G)_______3-3

3.1.4 AS/4012 Converter Second Mixer Ku-Band Downconverter (SFC1275G) ____3-3

3.2 AS/3048 M&C Controller Assembly___________________________________3-4

3.3 Synthesizer Modules ______________________________________________3-4

3.3.1 Synthesizer Module (SFC4200) ____________________________________3-5

3.3.2 Synthesizer Module (SFC1275G)___________________________________3-5

3.4 AS/3072 Frequency Reference Assembly______________________________ 3-7

3.5 AS/3228 Power Supply System______________________________________3-7

3.5.1 AS/3228 Output Board ___________________________________________3-7

3.6 Frequency Accuracy ______________________________________________ 3-8

3.7 Amplitude Accuracy_______________________________________________3-8

TM054 - Rev. 4.0 vii

Page 10

Table of Contents SFC4200/SFC1275G Synthesized Frequency Downconverter

Section 4 – User Interfaces

4.0 User Interfaces __________________________________________________ 4-1

4.1 Front Panel User Interface__________________________________________4-1

4.1.1 Front Panel LED Indicators________________________________________4-1

4.1.2 Front Panel LCD Display _________________________________________ 4-2

4.1.3 Front Panel Keypad _____________________________________________4-4

4.1.3.1 Soft Reset ___________________________________________________4-4

4.1.4 Monitoring Ports ________________________________________________ 4-4

4.2 Menu Screens ___________________________________________________4-4

4.2.1 Root Menu ____________________________________________________4-8

4.2.1.1 Status ______________________________________________________ 4-9

4.2.1.2 Set/Change Status ___________________________________________4-10

4.2.1.3 Frequency __________________________________________________ 4-10

4.2.1.4 Gain_______________________________________________________ 4-11

4.2.2 Converter Type Menu___________________________________________4-11

4.2.3 Switch Fault Menu _____________________________________________4-11

4.2.4 Converter Faults Menu __________________________________________ 4-12

4.2.5 Utility Access Menus____________________________________________4-13

4.2.6 Switch Configuration Menu_______________________________________4-14

4.2.7 Learn Menu (Backup Converter Only) ______________________________ 4-14

4.2.8 Learn Status Menus (Backup Converter Only) ________________________4-14

4.2.9 Configuration Menu ____________________________________________ 4-15

4.2.10 Reference Menu______________________________________________4-16

4.2.10.1 Reference Offset____________________________________________4-17

4.2.10.2 Reference Stability __________________________________________4-17

4.2.11 Output Attenuator Calibration Menu _______________________________ 4-18

4.3 Serial Protocol __________________________________________________ 4-19

4.4 Command Structure______________________________________________4-19

4.5 Control Commands ______________________________________________4-20

4.5.1 Set Current Channel Frequency Command (S, P1:1, P1:8)______________4-20

4.5.2 Set Current Channel Gain Command (S, P1:1, P1:8) __________________4-20

4.5.3 Set Channel Command (S, P1:1, P1:8) _____________________________4-21

4.5.4 Store Current Channel Settings (S, P1:1, P1:8) _______________________4-21

4.5.5 Remote Help Menu (All) _________________________________________ 4-21

4.5.6 Status Command ______________________________________________4-21

viii TM054 - Rev. 4.0

Page 11

SFC4200/SFC1275G Synthesized Frequency Downconverter Table of Contents

4.5.7 Clear Faults Command (All) ______________________________________4-22

4.5.8 Auto Mode Command (P1:1, B1:1, B1:8) ____________________________4-22

4.5.9 Manual Mode Command (P1:1, B1:1)_______________________________ 4-23

4.5.10 Manual Backup Command (B1:8)_________________________________4-23

4.5.11 Set Stored Gain For a Specified Channel (S, P1:1, P1:8) ______________4-23

4.5.12 Set Stored Frequency For a Specified Channel (S, P1:1, P1:8)__________4-23

4.5.13 Erase (All)___________________________________________________ 4-23

4.5.14 Restart (All)__________________________________________________4-24

4.5.15 Data (All)____________________________________________________4-24

4.5.16 Learn (B1:1, B1:8) ____________________________________________4-24

4.5.17 Show Priority (B1:8) ___________________________________________4-24

4.5.18 Set Priority (B1:8) _____________________________________________4-24

4.6 SFC Downconverter Operator Quick Reference Guide___________________4-25

Section 5 – Electrical Interfaces

5.0 SFC Downconverter Connections ____________________________________ 5-1

5.1 Power _________________________________________________________5-1

5.2 RF In (J1)_______________________________________________________5-1

5.3 IF Out (J2) ______________________________________________________5-1

5.4 10 MHz Ref Out (J3) ______________________________________________5-1

5.5 10 MHz Ref In (J4)________________________________________________5-1

5.6 B. U. Switch Interface (J5)__________________________________________5-1

5.7 Equipment RS-485 (J6)____________________________________________5-2

5.8 Test/Fault (J7) ___________________________________________________5-3

5.9 Operation Serial I/O (J8) ___________________________________________5-4

5.10 Coarse VCXO Adjustment_________________________________________5-7

5.11 Monitor Ports ___________________________________________________5-8

5.11.1 RF Monitor Port _______________________________________________5-8

5.11.2 IF Monitor Port ________________________________________________5-8

5.11.3 LO Monitor ___________________________________________________5-8

TM054 - Rev. 4.0 ix

Page 12

Table of Contents SFC4200/SFC1275G Synthesized Frequency Downconverter

Section 6 - Maintenance

6.0 Periodic Maintenance _____________________________________________6-1

6.1 Failure Analysis __________________________________________________6-1

Section 7 - Technical Specifications

7.0 Introduction _____________________________________________________7-1

7.1 Input Characteristics ______________________________________________7-1

7.2 Output Characteristics_____________________________________________7-1

7.3 Transfer Characteristics____________________________________________7-1

7.4 Frequency Synthesizer ____________________________________________ 7-2

7.5 Single Side Band Phase Noise ______________________________________7-2

7.6 Rx Signal Strength Detection________________________________________7-2

7.7 Mechanical______________________________________________________ 7-2

7.8 Operator Interface ________________________________________________7-3

7.9 Environmental Characteristics_______________________________________7-3

Section 8 – Appendices

x TM054 - Rev. 4.0

Page 13

SFC4200/SFC1275G Synthesized Frequency Downconverter Introduction

Section 1 - Introduction

1.0 Description

This manual discusses the Radyne ComStream Corporation SFC Synthesized Frequency

Downconverter family of products (Figure 1-1). These include the SFC4200 C-Band, and the

SFC1275G Ku-Band Synthesized Frequency Downconverters. They are high quality, rack

mounted satellite Downconverters that are intended for use in medium-to-large earth station

installations where multiple carrier uplinks need to be established. The SFC Downconverters are

ready to be configured into a variety of backup switch configurations which include 1:1, and 1:N

(to a maximum of N = 8) configurations.

The SFC4200 Downconverter is a C-Band, 125 kHz resolution synthesized satellite

downconverter capable of converting a C-band downlink in the range of 3.620 to 4.2 GHz or

3.400 to 4.2 GHz extended band, to either a 40 MHz bandwidth 70 MHz IF output or optionally to

an 80 MHz bandwidth 140 MHz carrier.

The SFC1275G Downconverter is a Ku-Band 125 KHz resolution synthesized satellite

downconverter capable of converting a Ku-Band downlink in the range of 10.95 to 12.75 GHz to

either a 40 MHz bandwidth 70 MHz IF output or optionally to an 80 MHz bandwidth 140 MHz

carrier.

Gain can be controlled to 0.1 dB step resolution. Control of frequency and gain can be

accomplished through the Front Panel Controls or remotely via an RS-232 Serial Interface.

The units monitor local oscillator (LO) phase-locked loop faults in the converter at all times

during operation. If a fault is detected, the converter immediately goes into the Off Line Mode.

If multiple converters are configured to provide backup protection switching, a summary fault will

signal the backup and put itself online thus restoring the failed circuit.

The RF Hardware consists of a broadband synthesizer, a fixed frequency phase locked oscillator,

and the first and second converter modules. The broadband synthesizer provides the

synthesized local oscillator for the conversion from RF to L-Band. The LO that tunes from

4.6645 – 5.2425 GHz or 4.485 – 5.335 GHz (SFC4200), or from 8.88 – 10.68 GHz (SFC1275G)

performs this conversion. The second mixer converts the L-Band Signal to either the 70 or 140

MHz IF Output. A fixed frequency IFLO performs this frequency conversion.

A 40 dB gain control output attenuator at the IF controls the power out of the converter. This

attenuator is capable of 0.1 dB resolution through a software linear interpolation of 1 dB

calibration values.

The internal IF is converted by the second mixer LO to 70 or 140 MHz. The 70/140 MHz IF

chain also performs filtering and phase equalization via an all-pass network. The gain calibration

process also provides gain slope across all bands to be within the specified ± 0.5 dB. Additional

gain compensation due to changes in ambient temperature provide for high gain stability over

various operating conditions.

Figure 1-1. SFC Downconverter Front Panel

TM054 - Rev. 4.0 1-1

Page 14

Introduction SFC4200/SFC1275G Synthesized Frequency Downconverter

The SFC Downconverters have been designed to provide performance that meets or exceeds all

industry standards in effect today for satellite communications earth station frequency converter

equipment found worldwide. In addition to providing robust performance, the SFC

Downconverters are loaded with features that will provide ease of integration and operation.

1.1 Protection Switch Versatility

Radyne ComStream Corporation SFC family of Converter Products feature ‘plug-and-play’ ease

of installation with the RCU101 1:1 or the RCU108 1:8 Redundancy Control Units. All converters

can be plugged into the backup slot and assume the role of protection switch controller. The

backup converter learns and stores the frequency, gain and channel settings of the primary

converters. If the stored setting of the primary converter is changed, the backup converter will

notify the user via the front panel and the RS-232/RS-485 interface.

All circuits are protected upon installation of the switch and completion of the learning process.

This eliminates the need for complicated software configurations that might otherwise leave a

circuit vulnerable. Likewise, replacing a failed converter is as simple as plugging in a

replacement.

1-2 TM054 - Rev. 4.0

Page 15

SFC4200/SFC1275G Synthesized Frequency Downconverter Installation

Section 2 - Installation

2.0 Installation Requirements

SFC Downconverters are designed to be installed within any standard 19 inch equipment cabinet

or rack, and requires 1 Rack Unit (RU) mounting space (1.75 inches) vertically and 19 inches of

depth. Including cabling, a minimum of 20 inches of rack depth is required. The rear panel is

designed to have power enter from the right and cabling enter from the center and left when

viewed from the rear of the unit. Data and control cabling can enter from either side. The unit

can be placed on a table or suitable stable surface if required.

Before initially applying power to the unit, it is a good idea to disconnect

the transmit output from the operating station equipment. This is

especially true if the current SFC Downconverter configuration settings are

unknown, where incorrect setting could disrupt existing communications

traffic.

2.1 Unpacking

The SFC Downconverter was carefully packaged to avoid damage and should arrive complete

with the following items for proper installation:

SFC Downconverter Unit

Power Cord, 6 foot with applicable AC Connector

Installation and Operation Manual

2.2 Removal and Assembly

Carefully unpack the unit and ensure that all of the above items are in the carton. If the Prime

AC power available at the installation site requires a different power cord/AC connector, then

arrangements to receive the proper device will be necessary before proceeding with the

installation.

SFC Downconverters are shipped fully assembled and do not require removal of the covers for

any purpose in installation. Should the AC Power Connector Cable be of the wrong type for the

installation, either the cable or the power connector end should be replaced. The power supply

itself is designed for universal application using from 100 to 240 VAC, 50 – 60 Hz.

2.3 Mounting Considerations

When mounted in an equipment rack, adequate ventilation must be provided. The ambient

temperature in the rack should be between 10°C and 35°C, and held constant for best equipment

operation. The air available to the rack should be clean and relatively dry.

2.4 Initial Power-Up

Turn the unit ‘ON’ by placing the rear panel switch (above the power entry connector) to the ‘ON’

position. Upon initial and subsequent power-ups, the SFC Downconverters will test themselves

and several of its components before beginning its main Monitor/Control program. These powerup diagnostics show no results if successful. If a failure is detected, the Fault LED is illuminated.

TM054 - Rev. 4.0 2-1

Page 16

Installation SFC4200/SFC1275G Synthesized Frequency Downconverter

2.5 SFC Downconverter Interconnections

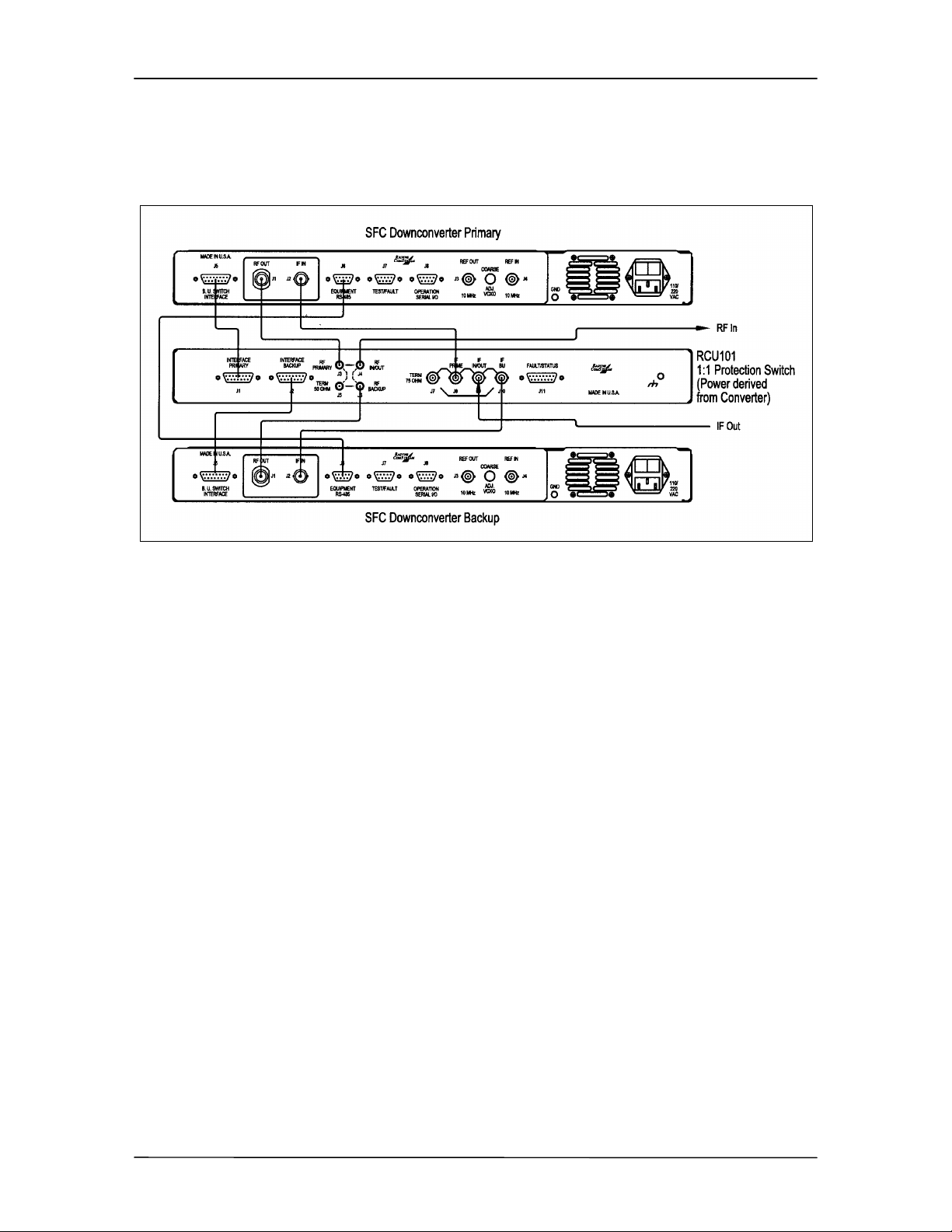

Figure 2-1 illustrates a typical interconnection of a SFC Downconverter with an RCU101 1:1

Protection Switch.

Figure 2-1. RCU101 Typical Interconnection with SFC Downconverters

2-2 TM054 - Rev. 4.0

Page 17

SFC4200/SFC1275G Synthesized Frequency Downconverter Operation

Section 3 - Operation

3.0 Theory of Operation

The SFC Downconverters have been designed to minimize the amount of hardware in the

system while maximizing performance. Spurious performance in the Downconverter is critical

and in particular, LO related spurious In-Band is nonexistent.

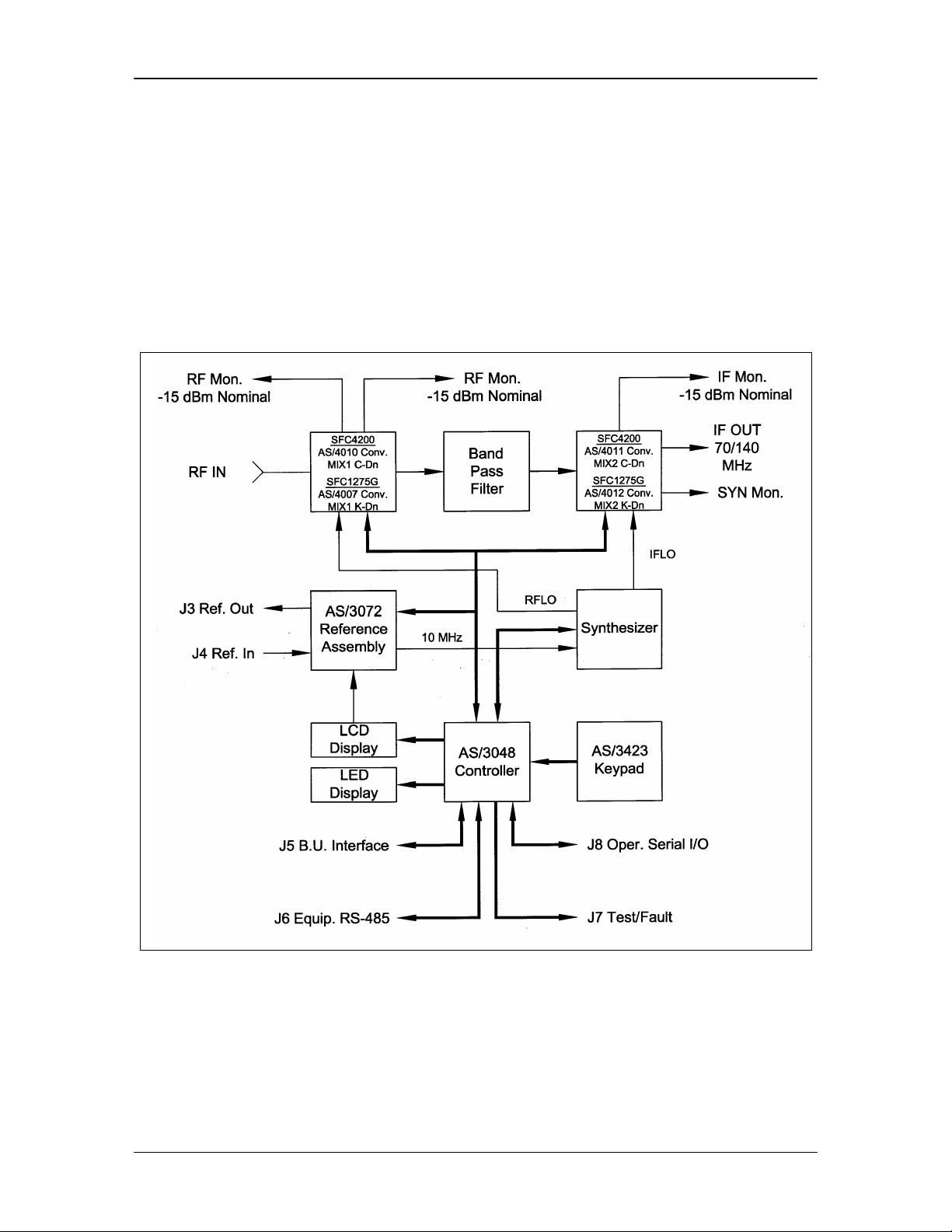

The SFC Downconverters are double conversion microwave Downconverters. The block

diagram (Figure 3-1) of the system includes the Signal RF Assembly, the Synthesizer Assembly,

the Reference Assembly, the Monitor and Control (M&C) Microcontroller, and Power Supply

Subsystem.

Figure 3-1. SFC Downconverter Block Diagram

3.1 Signal RF Assembly

The Signal RF Assembly is a subassembly that holds the first and second mixer converter

modules, and the IF Cavity Filter. The first and second mixer modules for the SFC4200 and

SFC1275G Downconverters are described below.

TM054 - Rev. 4.0 3-1

Page 18

Operation SFC4200/SFC1275G Synthesized Frequency Downconverter

3.1.1 AS/4010 Converter First Mixer C-Band Downconverter (SFC4200)

The First Mixer module of the C-Band Downconverter accepts the input and has 30 dB of digital

gain control. Performance specifications for the First Mixer are listed on Table 3-1.

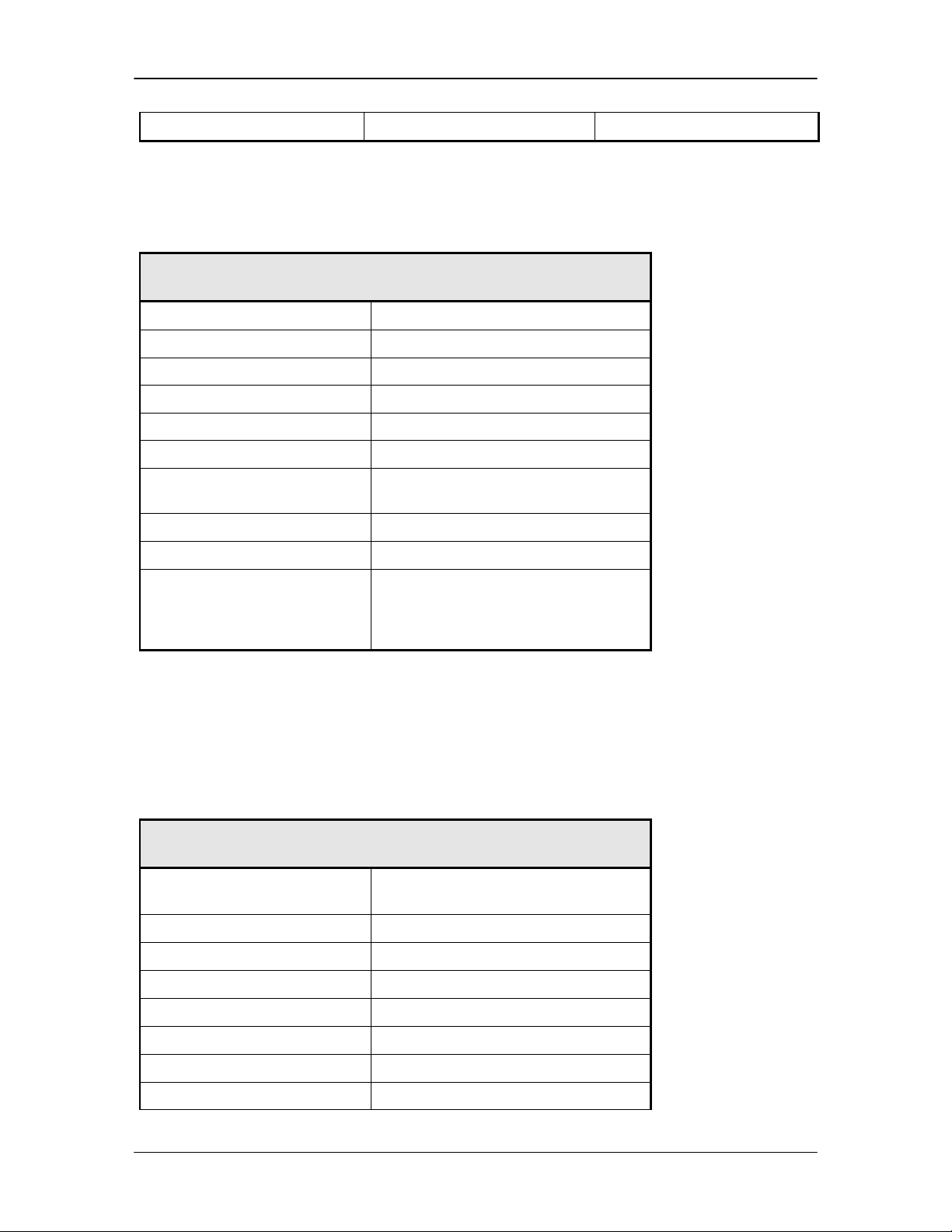

Table 3-1. AS/4010 Converter First Mixer C-Band Downconverter (SFC4200)

Standard Band Extended Band

Input Frequency 3.62 – 4.2 GHz 3.400 – 4.200 GHz

Input Power -40 dB Nominal -40 dB Nominal

Input Return Loss > -20 dB > -20 dB

Input Impedance 50Ù 50Ù

Gain 8 – 10 dB 8 –10 dB

Gain Control None None

Output Frequency 1.0225 – 1.0626 GHz

(70 MHz)

0.9325 – 1.0125 GHz

(140 MHz)

P

Nominal -30 to –32 dBm -30 to –32 dBm

out

1.135 – 1.175 GHz

(70 MHz)

1.045 - 1.125 GHz

(140 MHz)

Output Impedance 50Ù 50Ù

LO Input 4.6625 – 5.2425 GHz @

+13 dBm for 70 MHz IF

4.5925 – 5.1725 GHz @

+13 dBm for 140 MHz IF

4.555 – 5.355 GHz @

+13 dBm for 70 MHz IF

4.485 – 5.285 GHz @

+13 dBm for 140 MHz IF

3.1.2 AS/4011 Converter Second Mixer C-Band Downconverter (SFC4200)

The Second Mixer module of the C-Band Downconverter accepts the IF from the First Mixer and

converts and amplifies it to the 70/140 MHz, 75Ù IF Output. The Second Mixer has 40 dB of

gain control. Performance of this converter assembly is listed in Table 3-2.

Table 3-2. AS/4011 Converter Second Mixer C-Band Downconverter (SFC4200)

Standard Band Extended Band

Output Frequency 50 – 90 MHz Standard

(100 – 180 MHz [Option 01])

50 – 90 MHz Standard

(100 – 180 MHz [Option 01])

Impedance 75Ù 75Ù

Output Return Loss

P

P1 dB +20 dBm +20 dBm

out

≥ 23 dB ≥ 23 dB

Gain 30 – 32 dB 30 – 32 dB

Input Frequency 1.0225 – 1.0625 GHz (70 MHz)

0.9325 – 1.0125 GHz (140 MHz)

Detected Output 0 - 10 VDC

(10 VDC @ -10 dBm Out)

3-2 TM054 - Rev. 4.0

1.135 – 1.175 GHz (70 MHz)

1.045 – 1.125 GHz (140 MHz)

0 - 10 VDC

(10 VDC @ -10 dBm Out)

Page 19

SFC4200/SFC1275G Synthesized Frequency Downconverter Operation

0 – 10 VDC (10 VDC @ -10 dBm In with

LO 1.1125 GHz @ +13 dB 1.225 GHz @ +13 dB

3.1.3 AS/4007 Converter First Mixer Ku-Band Downconverter (SFC1275G)

The First Mixer module of the Ku-Band Downconverter accepts the 10.95 – 12.75 GHz Downlink

and converts it to L-Band IF. Performance specifications for the First Mixer are listed on

Table 3-3.

Table 3-3. AS/4007 Converter First Mixer Ku-Band Downconverter

(SFC1275G)

Input Frequency 10.95 – 12.75 GHz

Input Power -40 dBm

Input Return Loss > -18 dB

Input Impedance 50Ù

Gain -5 to 6 dB

Gain Control None

Output Frequency 2.050 – 2.070 GHz (70 MHz) 2.100 –

2.180 GHz (140 MHz)

P

Nominal -34 to -35 dBm

out

Output Impedance 50Ù

LO Input 8.88 – 10.68 GHz @ +13 dBm for 70

MHz IF

8.81 – 10.61 GHz @ +13 dBm for 140

MHz IF

3.1.4 AS/4012 Converter Second Mixer Ku-Band Downconverter

(SFC1275G)

The Second Mixer module of the Ku-Band Downconverter accepts the IF from the First Mixer

and converts and amplifies it to the 70 MHz, 75Ù IF Output. The Second Mixer has 40 dB of

gain control. Performance of this converter assembly is listed in Table 3-4.

Table 3-4. AS/4012 Converter Second Mixer Ku-Band

Downconverter (SFC1275G)

Output Frequency 50 – 90 MHz Standard (100 – 180

MHz [Option 01])

Impedance 75Ù

Output Return Loss < -23 dB

P

P1 dB +20 dBm

out

Gain 34 – 35 dB

Input Frequency 2.050 – 2.090 GHz (70 MHz)

Pin Nominal -34 to 35 dBm

Detected Output

TM054 - Rev. 4.0 3-3

Page 20

Operation SFC4200/SFC1275G Synthesized Frequency Downconverter

0 dB Attenuation)

LO 2.0 GHz @ +13 dB

3.2 AS/3048 M&C Controller Assembly

The Controller PWB Assembly is the controller, which monitors the Operator Front Panel, and

Remote Input used to control the frequency, gain and provide the fault detection functions of the

converter. The AS/3048 hardware features an Intel 80C32 microprocessor (Refer to Figure 5-2).

Peripherals on the controller include the following:

12 Bit Digital to Analog Converter (DAC)

8 Channel/8 Bit Analog to Digital Converter (A/D)

RS-485 UART

RS-232, -422, -485 UART

LCD Port

8 Bit Addressable Synthesizer Bus

5 Bit Addressable Converter Bus

Static Memory

Nonvolatile Memory

Serial Nonvolatile Memory

Read-Only Memory (ROM)

The 12 Bit DAC provides the precise current to the PIN Diode Attenuators in the converter. The

value of attenuation is determined through look-up of calibration data stored in non-volatile

memory. 000 to FFF written to the DAC provides an output voltage of 0.3 V – 8.50 V

respectively.

The 8-channel A/D Converter allows the AS/3048 to monitor various voltages within the

converter. The input to the A/D is 0 to 5 VDC. Voltages monitored by the A/D include the

square-law voltages from the IF and Fault of the synthesizer which allows the controller to

calculate signal strengths.

The Equipment RS-485 UART is independent from the Operator UART. Dual UARTS allow

equipment to be tied together as a system while giving the operator a single remote point of

contact. The operator serial interface is configurable via jumpers found on the AS/3048. Refer

to Figure 5-3 for the location of the jumpers.

The various memories found in the AS/3048 provide for program storage and calibration value

storage. In the event that the operator is requested to perform a software revision, replacement

of the PROM (U11) will be required. This operation should be performed with the power off and

in a static-free environment.

3.3 Synthesizer Modules

The Synthesizer module used in SFC Downconverters are stand-alone modules that provide the

synthesized local oscillator and the fixed IF local oscillator for the first and second mixers in the

converter.

3-4 TM054 - Rev. 4.0

Page 21

SFC4200/SFC1275G Synthesized Frequency Downconverter Operation

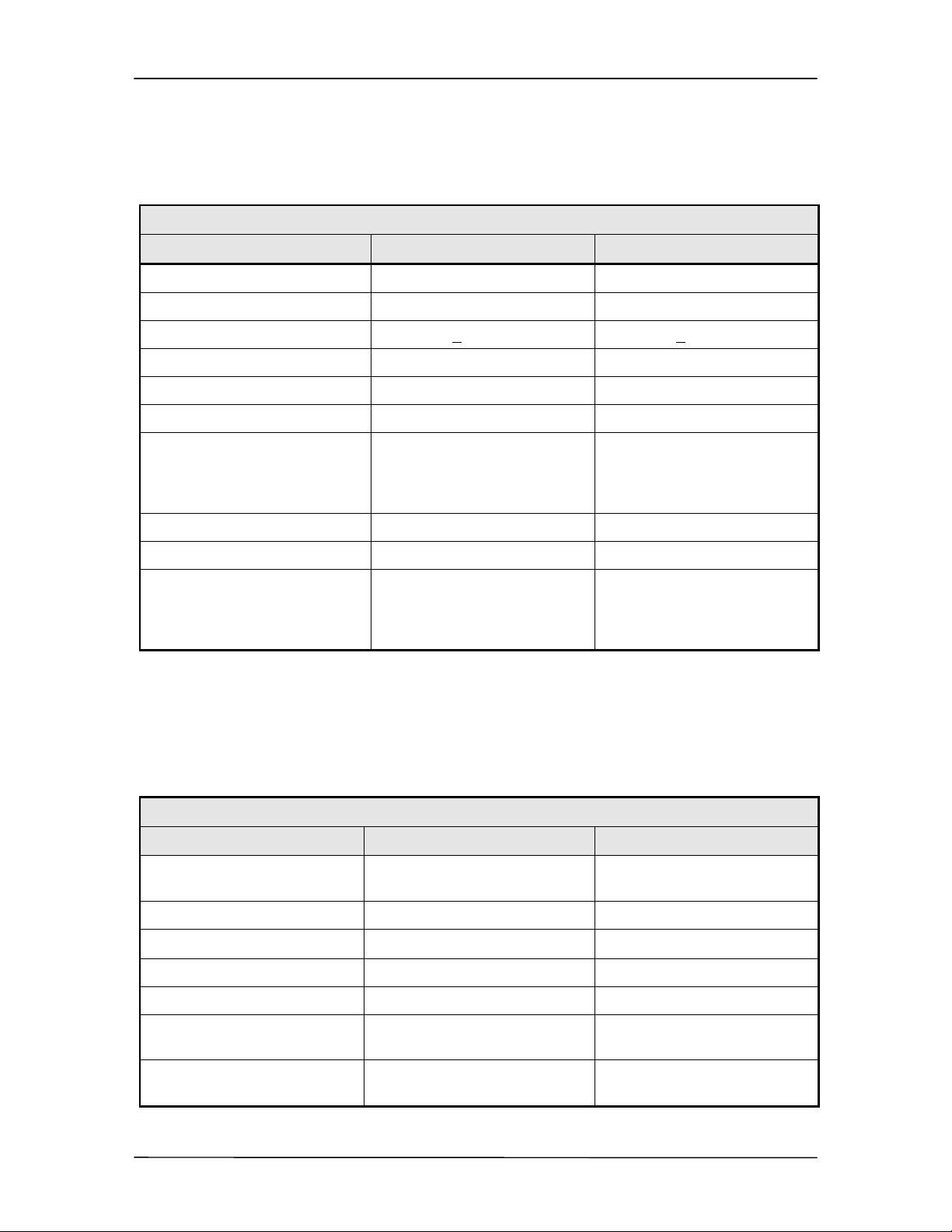

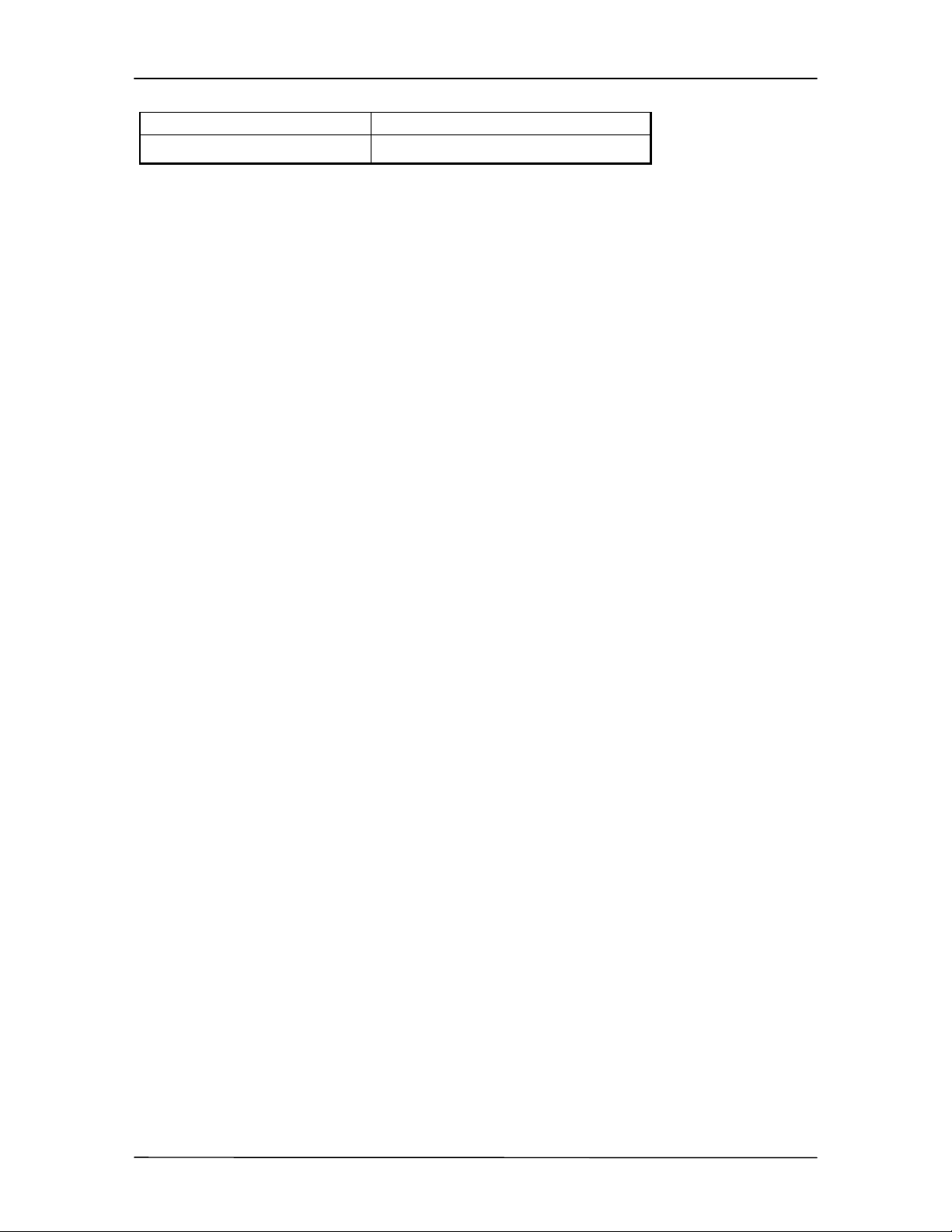

3.3.1 Synthesizer Module (SFC4200)

The 10 MHz reference to the synthesizer is provided by the AS/3072 Reference Assembly.

Performance of the synthesizer is listed in Table 3-5.

Table 3-5. Synthesizer Module (SFC4200)

Standard Extended

RF LO Output Frequency 4592.5 - 5242.5 MHz 4.48 – 5.355 GHz

Step Size 125 kHz 125 kHz

Power Out +13 dBm +13 dBm

Spurious -70 dBc -70 dBc

Harmonics -20 dBc -20 dBc

Phase Noise

Note: Typical readings are 3

to 8 dB better than shown.

IF LO Output Frequency 1112.5 MHz 1.225 GHz

Spurious -70 dBc -70 dBc

Harmonics -20 dBc -20 dBc

-70 dBc @ 100 Hz

-80 dBc @ 1 kHz

-88 dBc @ 10 kHz

-95 dBc @ 100 kHz

-110 dBc @ 1 MHz

-70 dBc @ 100 Hz

-80 dBc @ 1 kHz

-88 dBc @ 10 kHz

-95 dBc @ 100 kHz

-110 dBc @ 1 MHz

3.3.2 Synthesizer Module (SFC1275G)

The 10 MHz reference to the synthesizer is provided by the AS/3072 Reference Assembly.

Performance of the synthesizer is listed in Table 3-6.

Table 3-6. Synthesizer Module (SFC1275G)

RF LO Output Frequency 11.91 – 12.73 GHz

Step Size 125 kHz

Power Out 13 – 15 dBm

Spurious -70 dBc In-Band

-82 dBc Out-of Band

Harmonics -20 dBc

Phase Noise

Note: Typical readings are 3

to 5 dB better than shown.

IF LO Output Frequency 2.0 GHz

Spurious -70 dBc

Harmonics -20 dBc

TM054 - Rev. 4.0 3-5

-60 dBc @ 100 Hz

-80 dBc @ 1 kHz

-84 dBc @ 10 kHz

-94 dBc @ 100 kHz

-110 dBc @ 1 MHz

Page 22

Operation SFC4200/SFC1275G Synthesized Frequency Downconverter

As shown in Figure 3-2, the phase noise plots showing synthesized and IF LO SSB Phase Noise

are representative of the actual phase noise of the SFC4200.

Figure 3-2. Phase Noise Plots

3-6 TM054 - Rev. 4.0

Page 23

SFC4200/SFC1275G Synthesized Frequency Downconverter Operation

3.4 AS/3072 Frequency Reference Assembly

The Frequency Reference Assembly provides high-stability, low-noise reference signals to the

synthesizer in the converter system. The assembly also provides a reference output signal and

a means of synchronizing the internal synthesizer to an external 10 MHz source.

Contained within the reference assembly is a 10 MHz SC-cut overtone ovenized frequency

standard. When an external reference is applied to the reference assembly, the internal

oscillator is turned off and the synthesizer attempts to phase-lock to the external 10 MHz.

The RF Signal to the reference assembly includes the following:

EXT REF IN: 10 MHz external reference signal input.

REF-OUT: 10 MHz OXO signal out, or when an external reference

is present, the external reference signal is available for

daisy chaining. In this manner, a single 10 MHz

reference can be supplied to the external reference of

one converter. In turn, the externally supplied 10 MHz

becomes available at the RF Output Port where it can

be supplied to the Reference Input of the next converter.

Int 10 MHz: 10 MHz signal for the synthesizer. Analog & Digital

Signal to the reference assembly includes the following:

Synthesizer Interface: 16-Pin Synthesizer Bus provides control of serial DAC

for the purpose of fine- tuning the 10 MHz Frequency

Reference.

Power Connector: 10-Pin Synthesizer Power Bus provides voltage for

operating the reference assembly.

3.5 AS/3228 Power Supply System

Power for the converter system is derived from a single 75-Watt 15 V switching regulator. With

15 VDC as the secondary voltage for the entire system, it is possible to operate the converter

from a wide range of primary voltages especially DC or battery supplies. In addition, the 15 VDC

can be heavily filtered with a single computer-grade capacitor. This will allow a high degree of

isolation from dirty primary power systems.

3.5.1 AS/3228 Output Board

The other voltages that are required in the system include +9 VDC and +5 VDC. All of these

voltages are filtered but unregulated. The +9 VDC, and –9.5 VDC are all derived from the

+15 VDC supply through DC/DC converters.

Power budgets in the converter are listed in Table 3-7.

TM054 - Rev. 4.0 3-7

Page 24

Operation SFC4200/SFC1275G Synthesized Frequency Downconverter

Table 3-7. SFC 1275G/SFC4200 Power Supply

+9 VDC +15 VDC +5 VDC

3048 Controller 300 ma 50 ma

3072 Ref. Assy 100 ma 300 ma

1st Mix U/C 120 ma 150 ma

2nd Mix U/C 350 ma 90 ma

Synthesizer 500 ma 850 ma

LCD Display 180 ma

Total Current 1.05 A 1.09 A 850 ma

Power 9.45 Watts 16.35 Watts 4.25 Watts

Total Power: 28 Watts * 85% Conversion Efficiency = 33 Watts Primary

Consumption

3.6 Frequency Accuracy

The 10 MHz reference in the SFC4200 was factory set for an accuracy of 1x10 E-9. The aging

specification of the reference is 5x10 E

-10

per day. In one year, the frequency may drift as much

as 6x10 E-9.

To correct an error in frequency, the operator should use the Reference Menu and adjust the

Frequency Offset in PPB. Scaling of the PPB Offset allows for ± 999 PPB of adjustment. An

increment of 1 PPB of the Reference Menu Offset will provide approximately 4.6 Hz correction in

the synthesizer frequency.

3.7 Amplitude Accuracy

The frequency response stability of the converter is not expected to vary more than the specified

accuracy of the converter over its normal life. In the event that the accuracy of the converter

gain should exceed an acceptable level, it is recommended that the unit be returned to the

factory for gain calibration. Calibration of the converter is performed under computer control.

Manually performing a calibration in the field is possible but may be considered impractical.

3-8 TM054 - Rev. 4.0

Page 25

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

Section 4 – User Interfaces

4.0 User Interfaces

The Front Panel may be used to monitor and control the SFC Downconverters.

4.1 Front Panel User Interface

The Front Panel of the SFC Downconverters allows for complete M&C (including but not limited

to operation, calibration, and testing) of all parameters and functions via a Keypad, LCD Display

and Status LEDs.

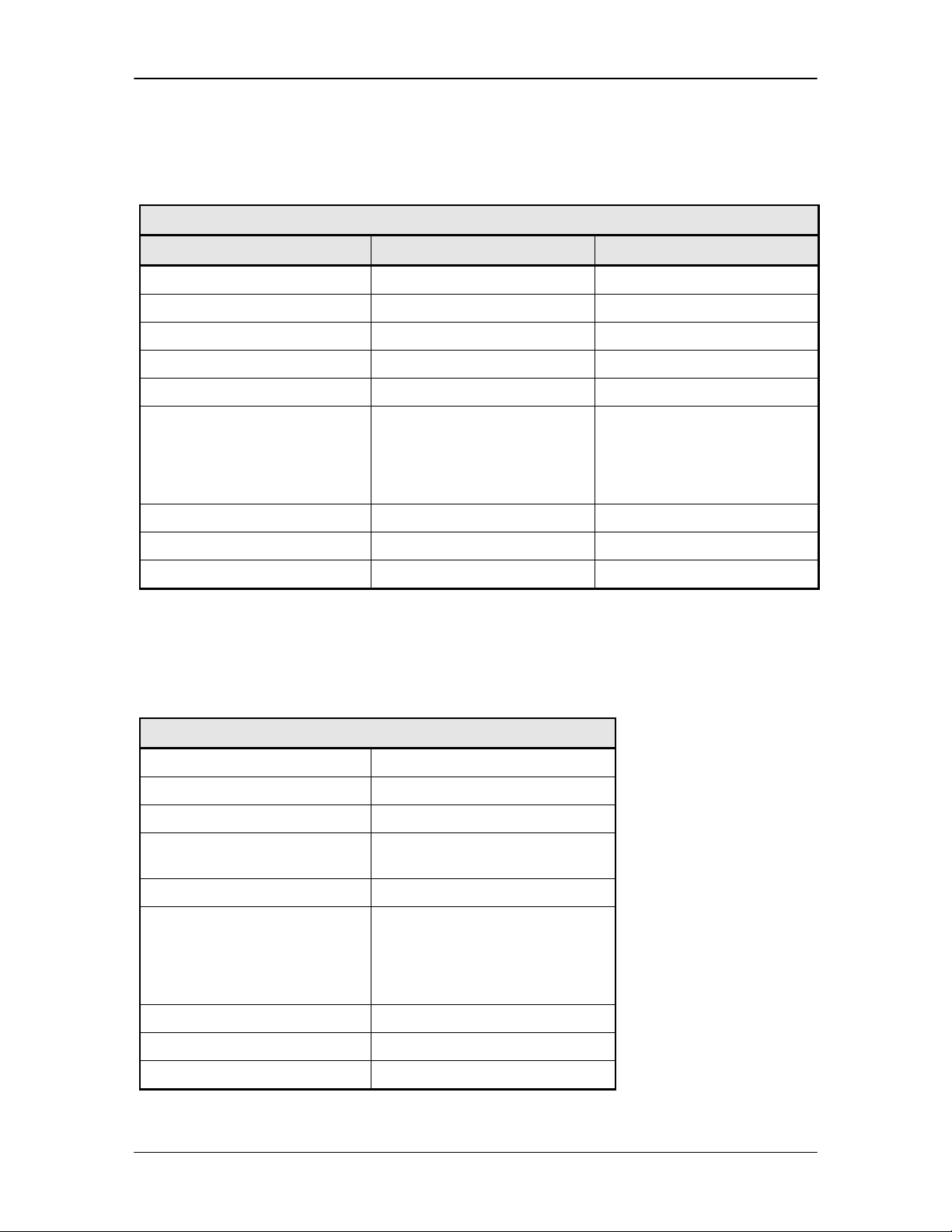

The front panel layout is shown in Figure 4-1, showing the location and labeling of the front

panel. The front panel is divided into four functional areas: Front Panel LED Indicators, Front

Panel LCD Display, Front Panel Keypad, and Monitoring Ports, each described in Table 4-1.

Figure 4-1. SFC Downconverters Front Panel Controls and Indicators

Table 4-1. Front Panel User Interface

Item No. Description Function

1 Front Panel LED

Indicators

2 Front Panel LCD Display Displays SFC Downconverter operating

3 Front Panel Keypad Controls the up, down, left, and right movement

4 Monitoring Ports Allows the monitoring of the LO, and RF and IF

Refer to Section 4.1.1 for an itemized description

of these LEDs.

parameters and configuration data.

of the cursor in the Front Panel LCD Display.

Signals.

4.1.1 Front Panel LED Indicators

There are six LEDs on the SFC Downconverter Front Panel to indicate the operation status

(Table 4-2). The LED colors maintain a consistent meaning. Green signifies that the indication

is appropriate for normal operation, Yellow indicates operation status, and Red indicates a fault

condition that will result in lost communications.

TM054 - Rev. 4.0 4-1

Page 26

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

Table 4-2. Front Panel LED Indicators

LED Color Function

POWER Green Indicates the presence of primary power and that the On/Off

Switch located on the rear of the chassis is in the On

Position.

EXT REF Green This LED indicates that an external 10 MHz reference signal

has been applied to the converter. A LO fault may occur

when the external reference is applied or removed. This

indicates that a change in the reference has occurred. This

fault can be cleared with a soft reset.

REMOTE Green The Remote LED indicates that the converter has been

addressed via the operator RS-232 Serial Interface, and that

a command has been received.

STANDBY Yellow This LED, when illuminated, indicates that the converter is

waiting to be off-line.

LO FAULT Red If the Synthesized LO or IFLO System of the converter

indicates an out-of-lock condition, the LO Fault LED will

illuminate. At this time, the Summary Fault Relay Contacts

will latch. If the LO Fault was due to an Intermittent Fault

Condition, the LO Fault will flash at one second intervals,

and fault checked may be reset.

SIG FAULT Yellow Signal Faults are used in switch configuration to indicate

switch status (when in the Backup Mode).

4.1.2 Front Panel LCD Display

The front panel display is a 2 line by 24-character LCD display that is capable of displaying five

fields of information in each menu window. While at the Root Menu, the Front Panel LCD

Display displays five fields, which are depicted by text captions around the display bezel. These

fields are listed below. The LCD display is a single entry window into the large matrix of

parameters that can be monitored and set from the front panel.

RX Frequency: The RX Frequency Field shows the frequency of the

selected input signal that will be converted to

70/140 MHz. When the cursor is placed in the

Frequency Field, and the Converter is in ‘SETUP’ Mode,

the frequency operation can be modified.

STATUS: The Status Field indicates the Mode of Operation or

Status of the Converter. The Modes of Operation

include ‘SINGLE’, ‘PRIMARY’, ‘BACKUP’, ‘SETUP’, and

‘OFF LINE’. The Single, Primary or Backup Status

indicates that there are no faults. It also identifies the

current configuration of the Converter. The Off Line

Status indicates that the Converter is off line due to a

fault condition.

Note: Because the backup ‘Learns’ the Frequency, Channel and Gain from the Prime,

changes to these fields are not allowed in the Backup converter.

4-2 TM054 - Rev. 4.0

Page 27

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

CHANNEL: The Channel Field indicates which of 30 User-

Programmable (frequency and gain) Channels is

currently active.

GAIN: The Gain Field indicates the gain of the Converter. By

placing the cursor in the Gain Field, the gain can be

changed. Gain can be varied from +40 dB to 0 dB, and

may also be adjusted when the Converter is online.

RX SIGNAL: The Received Signal Field in the lower right-hand corner

of the display represents the signal strength of the RF

Input. The signal strength is displayed in dBm. The

Received Signal Strength Display is active when the

display is locked. Received signal strength accuracy is

± 3 dB.

Online Menus:

Single: Indicates that the converter is a standalone converter.

Backup: Indicates that the converter is the backup converter in a

redundancy system, either a 1:1 or a 1:8 system.

Primary: Indicates that the converter is the primary converter in a

Other Menus:

Setup: Allows the user to modify the fields from the Front Panel

Offline: Indicates that the converter is offline as a result of a

redundancy system, either a 1:1 or a 1:8 system.

Note: The online menus indicate no faults.

Display. To accomplish this:

1. Press <Enter> to obtain the cursor.

2. Move the cursor to the desired field.

3. Make the necessary modification.

4. Depress <Enter> to store the data.

5. Depress the <↑↑> Key to bring the converter to

an online status

6. Depress <Enter> again to turn the RF On.

Note: A faulted condition does not allow the

converter to be placed online. To access the Fault

Menu, press the Menu Button until the Converter

Status Menu is displayed.

fault condition.

Gain: The Gain Field indicates the gain of the converter. By

placing the cursor in the Gain Field, the gain can be

changed. Gain can be varied from +40 dB to 0 dB.

TM054 - Rev. 4.0 4-3

Page 28

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

Note: Because the backup converter ‘Learns’ the Frequency, Channel, Gain and Input

Attenuation from the Prime Converter, changes to these fields are not allowed for the

Backup Converter.

4.1.3 Front Panel Keypad

The pushbutton keypad consists of (↑↑), (↓↓), (→→), (←←) keys, a Menu, and an Enter Key. Use of

these buttons is listed on Table 4-3.

Table 4-3. Front Panel Keypad

Key Function

Left/Right

Arrow Keys

(→→), (←←)

Up/Down

Arrow Keys

(↑↑), (↓↓)

ENTER The Enter Key will cause changes to Frequency, Status, and other operator-

MENU The Menu Key toggles the screens of the Front Panel LCD Display through

The Left/Right Arrow Keys are used to place the cursor in the desired field or

under the specific digit when moved to a number field. No changes in the

values or status can be executed from the left/right cursor movement.

The Up/Down Arrow Keys execute changes to numeric digits and can scroll

the status fields. To execute an actual change in status, gain or frequency,

the new number must be entered by depressing the enter pushbutton. Actual

operation to control frequency gain and status will be covered in detail below.

selected parameters to be executed. <Enter> also causes the status of the

converter to be saved into non-volatile memory.

the various menus (refer to Section 4.2).

4.1.3.1 Soft Reset

The microprocessor can be reset from the front panel by simultaneously depressing the

<MENU> and <ENTER>. This will cause the controller to reinitialize. The previously stored

Frequency, Gain and Input Attenuation information will be used during initialization.

4.1.4 Monitoring Ports

Refer to Section 5.11.

4.2 Menu Screens

The following Menu Screens are available on the SFC Downconverters (refer to Figure 4-2

through 4-4).

Root Menu: The Root Menu is the default screen showing

Frequency, Status, Gain, Rx Signal, and

Current Channel.

Converter Type: Displays Converter Model Number, Software

Revision and Serial Number.

Fault Menu: This menu shows latched fault conditions. It is

this menu that must be accessed to clear a

stored fault.

4-4 TM054 - Rev. 4.0

Page 29

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

Utility Menu: Allows the operator to access the various utility

submenus described below:

Learn Menu (Backup Converter Only): Allows the operator to tell the Backup Converter

to ‘Learn’ about the Primary Converter.

Learn Status Menu (Backup Converter Only):Informs the operator of the status of the learning

process; successful or failed. If failed,

additional submenus inform the operator why.

Unit Configuration Menu: Allows operator selection of unit address (1 -

99), serial port baud rate (1200, 2400, 4800, and

9600 baud), Echo On/Off, specifies converter

configuration (Single, 1:1 or 1:8) and indicates

backup/primary configuration.

Reference Menu: This menu allows the operator to adjust the

reference source in PPB and to view the

number of hours the converter has been in

operation.

Output Attenuator Calibration Menu: The calibration menu allows a qualified operator

to calibrate the 20 dB output attenuator.

Note: Access to the Service Menu and the Calibration menus is denied when the

converter is online, as these submenus allow direct access to the synthesizer tuning.

TM054 - Rev. 4.0 4-5

Page 30

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

Figure 4-2. Prime and Single SFC Downconverter Front Panel Menu Flowchart. SFC

Downconverter Menu Flow Charts (Prime and Single, Backup 1:1, and Backup 1:8)

4-6 TM054 - Rev. 4.0

Page 31

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

Figure 4-3. Backup 1:1 SFC Downconverter Front Panel Menu Flowchart

TM054 - Rev. 4.0 4-7

Page 32

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

Figure 4-4. Backup 1:8 SFC Downconverter Front Panel Menu Flowchart

4.2.1 Root Menu

The Root Menu appears after the Model Identification Screen, after power-up of the converter.

The four fields of this menu include Receive Frequency, Status, Gain Receive Signal (refer to

Figure 4-5).

4-8 TM054 - Rev. 4.0

Page 33

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

Figure 4-5. Root Menu

The operation of these four fields is as follows:

4.2.1.1 Status

The Status field in the Root Menu provides an indication of the status of the selected channel.

The Status fields indicate the converter’s configuration (Single, Primary, Backup) if the converter

is Online; Setup, if the converter is in setup mode; or Offline if there is a fault in the converter

which would prevent it from being placed online. The Status field also indicates under which

channel number the Frequency and Gain information is being stored.

The Root Menu will appear by default upon power-up. Prior to putting a converter online, the

correct frequency should have been selected. A properly functioning converter that has no faults

and is ready to be placed online will have the status indicated at ‘Setup.’ The structure of the

Status prompt is as follows:

{Status}{Channel No.}

SINGLE: Indicates that the converter is in a standalone

configuration and that when presented with an input

signal of the specified frequency, will generate an output

signal with the specified conversion gain.

PRIMARY: Indicates that the converter is in a switched

configuration, and that when presented with an input

signal of the specified frequency, is capable of

generating an output.

BACKUP: Indicates that the converter is in a switched

configuration, and that when presented with an input

signal of the specified frequency, is capable of

generating an output.

SETUP: Indicates that the front panel is unlocked and the

operator has free control of the Gain and Frequency

fields.

OFF LINE: The converter has experienced a fault and has placed

itself off line. Off Line Status is the same as out-ofservice. The fault will have to be cleared and/or the

failed component replaced.

The ‘Channel No.’ field of the Status prompt includes the numbers from 01 to 30 to indicate

which stored channel is being programmed or recalled with Frequency and Gain information.

TM054 - Rev. 4.0 4-9

Page 34

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

4.2.1.2 Set/Change Status

Status manipulation is performed via the cursor position and the <ENTER> Key. To modify the

operating status of the converter, first determine if the cursor is blinking. If the cursor is not

blinking, press <ENTER> to turn on the blinking cursor and position it under the first letter of the

status field. This is the ‘home’ position in which the cursor is placed in order to execute a change

in status.

For example, to place the converter online (single) from setup, insure that the cursor is present.

Press either the (↑↑) or (↓↓) Keys and scroll through the selections which will include Single

Indicator or Setup. When the selection for Single Indicator has been reached, depress

<ENTER>. The flashing cursor will turn off, and the Standby LED will turn off and the unit

placed in service.

The gain of the online converter can be changed by depressing <ENTER>, using the (→→) or (←←)

Keys to position the blinking cursor in the Gain Field and then using the (↑↑) or (↓↓) Keys to

change the gain. Once the cursor is in the Gain Field, it cannot move into any other field. This

prevents a change of frequency while online. Depressing <ENTER> will save the selected gain,

turn the cursor off, and lock the front panel.

To place a single or a primary converter in setup, from online and front panel locked (no blinking

cursor visible), depress <ENTER>. A blinking cursor will be positioned in the Status Field. Use

the (↑↑) or (↓↓) Keys to select ‘SETUP’ (the Standby LED is on). Use the (↑↑) or (↓↓), and the (→→) or

(←←) Keys to select and change the desired control field. Depress <ENTER>. The Standby

Indicator will be turned off, the changed parameter will be stored to memory, and the cursor will

be placed in the Status Field. Use the (↑↑) or (↓↓) Keys to select the online indicator and depress

<ENTER>. The new converter settings will be executed, the RF will be turned back On, and the

front panel will be locked.

Note: The Backup Converter ‘Learns’ about the Prime(s) and therefore cannot be placed

in Setup Mode.

An optional method of changing the Frequency and Gain is to use the programmed channels.

To select a programmed channel, move the cursor to the Channel Number part of the field after

the unit has been placed into Setup, and scroll through the selections. As the number changes,

the Frequency and Gain Fields will change to indicate the stored values (Note that no changes to

the Frequency or Gain will take place unless the operator depresses the <ENTER> Key). If

<ENTER> is depressed, the new channel will be selected as the default channel. To modify or

to program the stored values, move the cursor to the appropriate field and make the change. To

store the value to non-volatile memory, depress <ENTER>. An asterisk (*) will be displayed to

the right of the channel field to indicate a Channel Store Operation has taken place. In case of a

power failure, the current operating parameters are stored in non-volatile memory for automatic

Downconverter configuration, which takes place upon power restoration.

4.2.1.3 Frequency

To set or to change the Frequency, perform the steps listed in Section 4.2.1.2 to place the

converter into Setup Mode. Select the Channel Number that contains the programmed

frequency, or is the channel for which a previously programmed frequency needs to be changed.

While at the desired channel number, move the cursor to the Frequency Field. Position the

cursor under the desired digit to be changed and make the change with the (↑↑) or (↓↓) Keys. To

store the new frequency into memory for the selected channel, depress <ENTER>.

4-10 TM054 - Rev. 4.0

Page 35

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

The cursor will move to the Status Field. Place the unit back in service by selecting the Single

Indicator in the Status Field and then depressing <ENTER>. An asterisk (*) will be displayed to

the right of the Channel Field to indicate a Channel Store Operation has taken place. Otherwise,

upon power-up or recalling the desired channel will cause the frequency to revert to the stored

frequency value. The frequency selection to the synthesizer is executed when <ENTER> is

depressed. The LO Fault Circuitry is active so that an LO Fault associated with a specific

frequency of operation can be determined while the converter is in Setup Mode.

4.2.1.4 Gain

The Gain of a single or primary converter can be changed while the converter is both Online and

in Setup mode. To change the Gain at any time, position the cursor under the digit to be

changed in the Gain field and increment or decrement the number using the (↑↑) or (↓↓) Keys.

The Gain change will be made at this time. To store the new Gain into the non-volatile memory

for the currently selected channel number, depress <ENTER>. An asterisk (*) will be displayed

to the right-hand corner of the Channel Field to indicate a Channel Store operation has taken

place. Otherwise, upon power-up, or recalling the desired channel causes the Gain to revert to

the Stored Gain value. To prevent data errors while the unit is online, changes as directed from

the front panel are dampened in execution to the actual hardware so as not to generate an

abrupt jump in power.

4.2.2 Converter Type Menu

The Converter Type Menu (Figure 4-6) displays the Converter Type, Software Revision Level.

Figure 4-6. Converter Type Menu

4.2.3 Switch Fault Menu

This menu is applicable to the Backup 1:1 and Backup 1:8 Converters. If there are no switchrelated faults, the menu will say so. If there are switch-related faults, using the (↑↑) Key will scroll

through the various reasons for the Switch Fault (refer to Figure 4-7).

Figure 4-7. Switch Fault Menu

TM054 - Rev. 4.0 4-11

Page 36

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

These include the following:

Prime Not Learned: The Backup has not learned about the Prime(s).

Prime Polling Error: Either the Prime did not respond to the Backup’s

periodic polling, or something in the Prime’s

configuration has changed since the last time the

backup was told to ‘Learn.’

Note: Changing the Prime after the Backup has ‘Learned It’ will cause a Switch Fault until

the Backup is told to ‘Relearn’ the Prime(s).

Prime Relay Fault: The Backup has detected that the Switching Relay did

not switch when told to do so.

Note: Any Switch Fault will cause the Signal Fault LED on the Backup to illuminate. It

will also cause the Error LED on the 1:8 Switch to illuminate.

4.2.4 Converter Faults Menu

To access the Converter Faults Menu, depress <ENTER>. If there are no stored faults, the fault

menu will indicate ‘Stored Faults, None.’ If there are stored faults, the menu will indicate that

stored faults have been recorded.

To interrogate the nature of the stored faults, depress <ENTER> again. The stored fault screen

format is as shown in Figure 4-8.

Figure 4-8. Stored Faults Menu

The Fault descriptions are indicated as follows:

LO: Indicates a fault in the synthesizer and the number of fault detections

(up to 255).

SIG: N/A

To clear the faults, depress <ENTER>.

4-12 TM054 - Rev. 4.0

Page 37

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

4.2.5 Utility Access Menus

Depress <Menu> from the Fault Menu to access the Utility Access Menu. To gain access to the

various utility menus of the converter, depress <ENTER>. The Utility Access Menu will appear

as shown in Figure 4-9.

Figure 4-9. Utility Access Menu

Pressing <ENTER> will scroll to the first Utility Menu which is the Configuration Menu for

Primary and Single Converters, or the Learn Menu for Backup Converters. Depressing <MENU>

again will scroll to the second Configuration Menu. Use <MENU> to scroll through the

Reference Menu, Status Menu, and Output Attenuator Calibration Menu. Calibration Menus

represent those alignments, settings and various operating parameters that are set in nonvolatile memory. Most calibration is done via the RS-232 Interface, but those same parameters

can be accessed via calibration menus.

Note: The Calibration Menu is denied when the converter is online, as these submenus

allow direct access to the synthesizer tuning.

For a 1:1 Backup, the menu will appear as shown below in Figure 4-10.

Figure 4-10. Menu for a 1:1 Backup

For a 1:8 Backup Converter, the Menu will appear as shown below in Figure 4-11.

Figure 4-11. Menu for a 1:8 Backup

TM054 - Rev. 4.0 4-13

Page 38

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

4.2.6 Switch Configuration Menu

This Menu (refer to Figure 4-12) is applicable for a 1:8 Backup Converter. It allows the operator

to specify the priority of the various converters. The priority is as follows: 1 (Highest Priority)

through 8 (Lowest Priority), and 0 (No Priority, the Backup will ignore the Prime).

Figure 4-12. Switch Configuration Menu

The Arrow Keys are used to move left and right, and increase or decrease a converter’s priority.

When all of the priorities have been set, pressing the <ENTER> causes the Backup to accept the

entries and store them in Non-Volatile RAM. Pressing <MENU> will scroll to the next menu.

4.2.7 Learn Menu (Backup Converter Only)

Depressing <MENU> will scroll to the Configuration Menu. Depressing <ENTER> will cause the

Backup Converter to ‘Learn’ about the Primary Converter (Figure 4-13).

Figure 4-13. Learn Menu

The screen automatically scrolls to the Learn Status Menu

4.2.8 Learn Status Menus (Backup Converter Only)

The Automatic Learning in Progress Window (Figure 4-14) indicates that the Backup Converter

is polling the Prime Converter in order to learn about it.

Figure 4-14. Automatic Learning in Progress Window

4-14 TM054 - Rev. 4.0

Page 39

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

The window shown in Figure 4-15 indicates that the Backup Converter was successfully able to

‘Learn’ about the Primary Converter.

Figure 4-15. Automatic Learning Successfully Completed Window

The following window (Figure 4-16) indicates that the Backup Converter was not able to learn

about the Prime Converter.

Figure 4-16. Automatic Learning Failed Window

When the <Menu> key is pressed, the Backup Converter will provide more information about the

failure. This information includes the following:

No Response: The Prime Converter did not respond.

Invalid Response: The Prime Converter responded, but the Backup

Converter did not receive the message clearly.

Incompatible Converter: The Backup Converter is not capable of backing up the

Prime Converter.

4.2.9 Configuration Menu

The ID # Field allows the operator to establish an ID Number for the Operator Serial Interface.

Move the cursor to this field and increment or decrement to change the ID Number. Press

<ENTER> to store the value.

The field for Baud Rate allows the operator to select baud rates from 1200 to 9600 bps. Move

the cursor to this field and increment or decrement the value. Depress <ENTER> to store the

value and reinitialize the serial port.

Note: Serial data format is fixed to provide 8 data bits, 1 start bit, 1 stop bit, no parity.

The Echo Field is for the Operator Serial Port Interface. When the Echo is in the On State, the

converter will echo all the data it receives back to the Host Terminal. When more than one

converter is connected to the same bus (RS-485), the Echo must be Off. Move the cursor to this

field to change the Echo On/Off Status. Press <ENTER> to store the value.

TM054 - Rev. 4.0 4-15

Page 40

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

The Config Field (Configuration) indicates the status of the converter and is defined as follows:

SNGL: Indicates that the converter is a standalone unit.

1:1: Indicates that the converter is in a one-for-one backup

configuration.

1:8: Indicates that the converter is in a one-for-eight backup

configuration.

Figure 4-17. Configuration Menu

4.2.10 Reference Menu

The Reference Menu (Figure 4-18) allows the operator to fine-tune the 10 MHz ovenized

frequency standard over a range of ±999 PPB. This menu also contains a clock that indicates

the total number of hours the unit has been in operation since the reference oscillator was first

installed.

The Reference Menu is as follows:

Figure 4-18. Reference Menu

OPPB: This field contains the offset of the 10 MHz frequency

standard in PPB. When the oscillator is first installed, or

when the oscillator has been coarse-calibrated, this

value will first be set to 000 PPB offset. The operator

can change the offset manually by placing the cursor in

this field and incrementing or decrementing the value.

Press <ENTER> to store the value.

ELAPSED HOURS: This field indicates the number of hours the converter

has been in operation since the frequency standard was

first installed.

4-16 TM054 - Rev. 4.0

Page 41

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

4.2.10.1 Reference Offset

The Reference Offset Field of the Reference Menu allows the operator to adjust the frequency of

the 10 MHz High Stability Internal Reference and vary the output of the Synthesized RF LO by ±

999 Parts per Billion (PPB). One part per billion represents a change of 1 Hz per GHz (1 billion

Hz) of output frequency. Measured at the LO MON port, 1 PPB represents 4.6 Hz change in

frequency for a LO Output of 4.6625 GHz. Note that 1 PPB changes the frequency of the LO

MON or Converted IF or RF Output by 4.6 Hz as well. Thus, each unit of PPB will allow a

change in accuracy of the converter of 1 x 10-9.

The exact frequency of the LO Output can be calculated from the displayed frequency on the

converter front panel as follows:

C-Band Downconverter (70 MHz IF): LO MON = Rx Freq. + 1042.5 MHz

C-Band Downconverter (140 MHz IF): LO MON = Rx Freq. + 972.5 MHz

C-Band Downconverter Extended (70 MHz IF): LO MON = Rx Freq. + 1155 MHz

C-Band Downconverter Extended (140 MHz IF): LO MON = Rx Freq. + 1085 MHz

Ku-Band Downconverter (70 MHz IF): LO MON = Rx Freq. – 2070.0 MHz

Ku-Band Downconverter (140 MHz IF): LO MON = Rx Freq. – 2140.0 MHz

The RF Monitor output can be measured with a frequency counter of known calibration.

4.2.10.2 Reference Stability

The stability of the 10 MHz Reference is related to the temperature of 10 MHz crystal inside the

unit. A proportionally controlled oven around the crystal maintains the temperature in the oven

to 0.1°C. In addition, the precise temperature that the oven maintains has been determined

empirically for each crystal during manufacturing. As long as the ambient temperature stays

within limits (0 - 50°C) the reference will maintain stability of greater than 1 x 10

4-18).

-8

(refer to Figure

Figure 4-19. Typical Reference Aging vs. Time

TM054 - Rev. 4.0 4-17

Page 42

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

Long term stability of the reference is affected by factors other than temperature. Over days and

months, the frequency of the reference will drift at a rate specified as aging. Typical aging rates

of 1 to 5 parts in 10

-10

per day are typical in a crystal that has been stabilized for a few weeks.

The first month of operation for any crystal is a time where drift due to aging can be excessive.

The typical aging curve provides insight into the exponential decay in aging rate for a 10 MHz

Reference. Converters shipped from the factory have had their reference oscillator aged for a

minimum of 30 days and in addition, the aging rate has been verified in the final week to within

tolerance. However, converters that have been in storage or powered off for a period of several

weeks will exhibit a phenomenon whereby the aging curve return to the slope shown for zero

days of aging. This aging reset in not well understood but the manufacturers of crystals believe

it to be related to a gradual relaxation of the molecular makeup of the quartz substrates and the

conductive films deposited on the quartz.

The rule of thumb when checking the frequency accuracy of the converter is to make sure that

the crystal has stabilized before attempting any adjustment. For units that have been in storage

or shipment for more than a week, allow several days of operation before verifying the accuracy.

For this reason, converters shipped from Radyne ComStream Corporation are typically poweredup until the final day before shipment. In addition, the accuracy and aging rate are verified

immediately prior to shipment.

For a converter that has been powered-up for several months, the operator can assume an aging

rate of several PPB per month. If the aging rate has been established, the station operator can

make calculated adjustments from the reference offset menu at timed intervals.

4.2.11 Output Attenuator Calibration Menu (locked, not user accessible)

The Output Attenuator (Figure 4-20) can be calibrated over 0 – 40 dB of attenuation in 1 dB

increments over frequency bands centered 50 MHz apart.

Figure 4-20. Output Attenuator Calibration Menu

Freq: Shows the 50 MHz Frequency Band that is currently

being calibrated. While in this menu, selecting or

changing a Frequency Cal Band will cause the

synthesizer to change to that center frequency. The

frequency band selection can be incremented or

decremented by placing the cursor on the current

frequency and depressing the Up or Down cursor

buttons.

Atten: This number, located under the Status Field

nomenclature, indicates the location for or value of

attenuation for which the operator is calibrating the

Digital-to-Analog Converter (DAC) Value. The Atten

value can be increased by depressing <ENTER>.

When <ENTER> is depressed, the DAC Value displayed

is stored into non-volatile memory and the Atten digit is

increased to the next value. At 20, this digit rolls over to

0.

4-18 TM054 - Rev. 4.0

Page 43

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

DAC Value: Place the cursor in the DAC Value Field and use the (↑↑)

and (↓↓) Keys to increment or decrement the DAC Value.

Simultaneously, the display will indicate the DAC

Voltage. In a normal calibration arrangement, the

operator will be monitoring the power output of the

converter with a Spectrum Analyzer. When the desired

value of calibration is reached, the operator will depress

<ENTER> which stores the value and increments the

Atten Level to the next number. The DAC value will

revert to the stored value for that location. This keypad

arrangement is designed to allow for manual calibration

with limited wear-and-tear on the operator who may be

attempting manual calibration of the attenuator in the

field.

To perform the calibration, the technician needs to apply

an RF signal to the Downconverter at the frequency

indicated in the Freq. Field. A spectrum analyzer or

power meter is connected to the output and the DAC

Value is incremented up or down until the required gain

is indicated by the spectrum analyzer. Finally, the

correct DAC is stored by depressing <ENTER>. The

attenuator setting is incremented to the next location, or

in this case, 01 dB. The process is repeated until 20 dB

is reached and then the next frequency is selected. The

frequency of the signal generator must be changed and

the process repeated. This menu is not displayed when

the converter is online.

4.3 Serial Protocol

The SFC Downconverter Serial Protocol allows a remote operator to gain control the converter.

Through the serial protocol described, the remote operator can control gain, frequency,

calibration, status and fault isolation. The Serial Port is factory-set to communicate as the DCE

at 9600 baud with 8 data bits, 1 start bit, 1 stop bit and no parity bits.

4.4 Command Structure

The serial command structure uses an ASCII character string format that enables serial control

through the use of a ‘dumb terminal.’ To differentiate a proper command string from noise, all

serial commands have a header followed by the specific command characters, followed by

numeric values where required, and are terminated by a character return <cr>. The basic

command structure is as follows:

@{Unit Address/}{command}{numerical value(s)}<cr>

For the following examples, a unit address of 01 is assumed.

TM054 - Rev. 4.0 4-19

Page 44

User Interfaces SFC4200/SFC1275G Synthesized Frequency Downconverter

4.5 Control Commands

Control Commands are those commands that alter the setup or operating parameters of the

converter. These commands primarily control Frequency and Gain. Frequency and Gain can be

altered on the current channel number that is indicated on the front panel, or the other channels

0-30 which are not selected can be programmed without affecting the current operating channel.

The final method to change Frequency and Gain is by remotely recalling the Gain and

Frequency Settings that have been programmed in another channel. The various Control

Commands are applicable for a variety of converter configurations. After each of the following

control commands appears an abbreviation in parenthesis that identifies which converter

configurations are valid for that particular control command. The applicable converter

configurations are as follows:

S: Single Converters

P1:1: Primary Converter 1:1 Switch

B1:1: Backup Converter 1:1 Switch

P1:8: Primary Converter 1:8 Switch

B1:8: Backup Converter 1:8 Switch

ALL: All Converters

4.5.1 Set Current Channel Frequency Command (S, P1:1, P1:8)

The Set Current Channel Frequency Command alters the stored frequency of the current

channel. The set frequency command is as follows:

@01/SETFREQffff.t<cr>

The frequency numerical values include four digits for MHz and one digit "t" which indicates the

resolution in 125 kHz steps. The values of "t" are as follows:

t Frequency

0 000 kHz

1 125 kHz

2 250 kHz

3 375 kHz

4 500 kHz

5 625 kHz

6 750 kHz

7 875 kHz

Valid frequency ranges are 3400.000 though 4200.000 kHz (SFC4200), and 10950.000 MHz

through 12750 MHz (SFC1275G). Frequencies outside this range, or frequencies that are of an

invalid form will be responded to by the ‘illegal frequency’ prompt. If the synthesizer is unable to

tune to the desired in-band frequency, the converter will indicate a LO Fault Condition status

indication and will change to an off-line or out-of-service indication.

4.5.2 Set Current Channel Gain Command (S, P1:1, P1:8)

To permanently change the programmed gain of the current channel, use the Set Current

Channel Gain Command. The command is as follows:

@01/SETGAINsgg.g<cr>

The numeric value ‘s’ indicates the ‘plus’ sign (+). The numeric value ‘g’ consists of three digits

indicating gain from 0 to 40 dB.

4-20 TM054 - Rev. 4.0

Page 45

SFC4200/SFC1275G Synthesized Frequency Downconverter User Interfaces

4.5.3 Set Channel Command (S, P1:1, P1:8)

The Set Channel Command allows the remote operator to change the Channel and thus the

Gain and Frequency of the converter to one of the 30 preprogrammed channels. To change

channels, use the following format:

@01/SETCHANcc<cr>

Where ‘cc’ represents a channel number from 01 through 30.

4.5.4 Store Current Channel Settings (S, P1:1, P1:8)

After altering the Frequency or Gain of the currently selected channel, the remote operator can

store these settings into non-volatile memory by issuing the Store command as follows: