Page 1

LLooaaddiinngg PPaappeerr UUssiinngg tthhee LLoowweerr PPuusshh TTrraaccttoorr aanndd tthhee RReeaarr PPuullll TTrraaccttoorr

((ooppttiioonn))

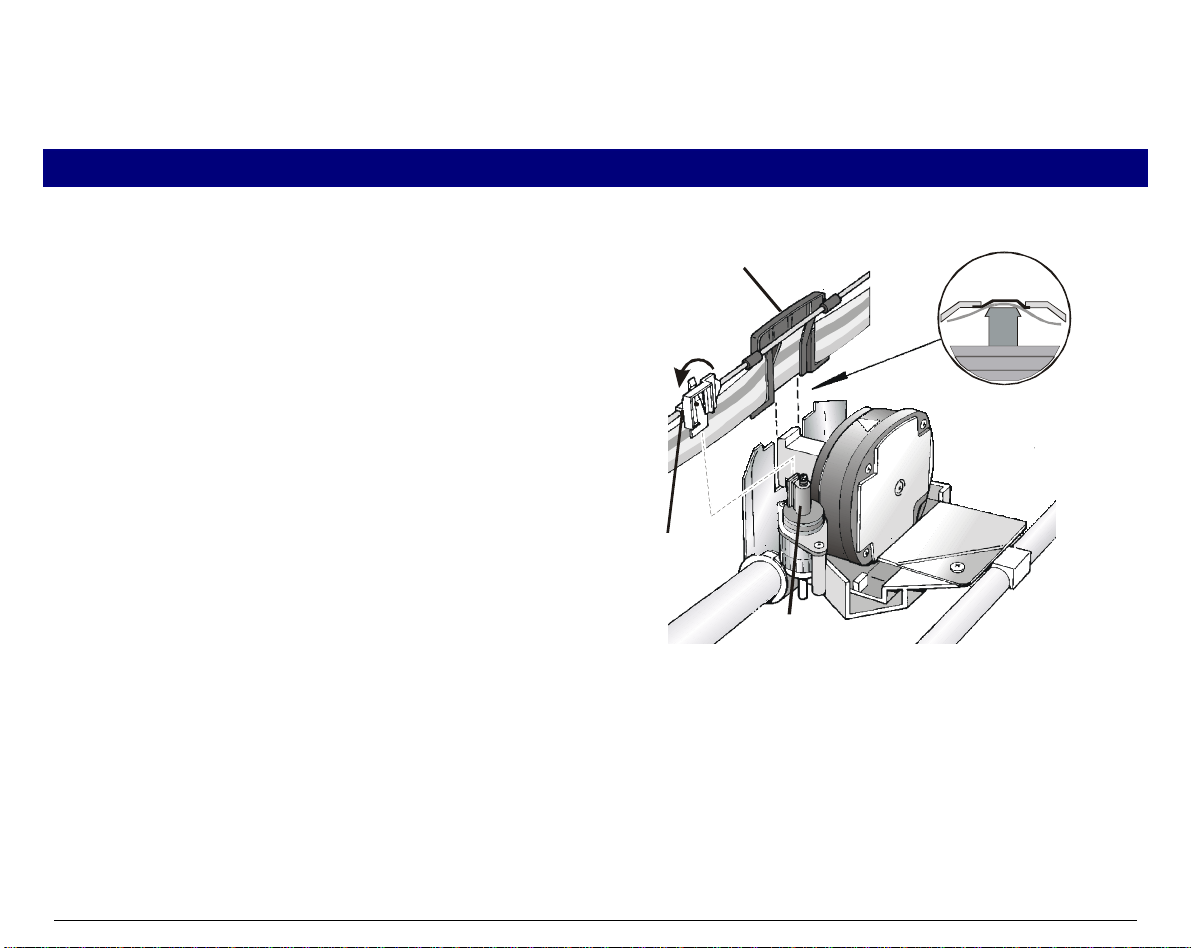

For loading paper in this way, it is necessary to install the optional rear pull tractor. See later

With this paper path confi gura tio n pa per is l oaded contempora neously with the l owe r front push

tractor and the rear pull tractor. In this way it is possible to handle stronger paper.

Once the rear pull tractor is installed, the fanfold paper can be loaded only in push-pull mode.

1. To select the push-pull tractor paper path press the

• If you have been using a different path, the display shows:

9078 plus model

"Options" section.

LOAD PUSH-PULL

PATH CHANGING

9078D plus model

PATH

key until the display shows:

• If you have been using fanfold paper in the upper tractor paper path, the printer

automatically starts the parki ng procedure. The display shows alternately:

TEAR IF NECESS.

and PARK PAPER

117

Page 2

• Tear off the fanfold loaded with the upper tra ctor (if it is l onger than 18 i nches) and press

the

key. The display shows:

PARK

PARKING

followed by

LOAD PUSH-PULL

2. To load the fanfold paper on the l ower push tra ctor, foll ow the sequence Loading Paper Using

the Lower Tractor described before.

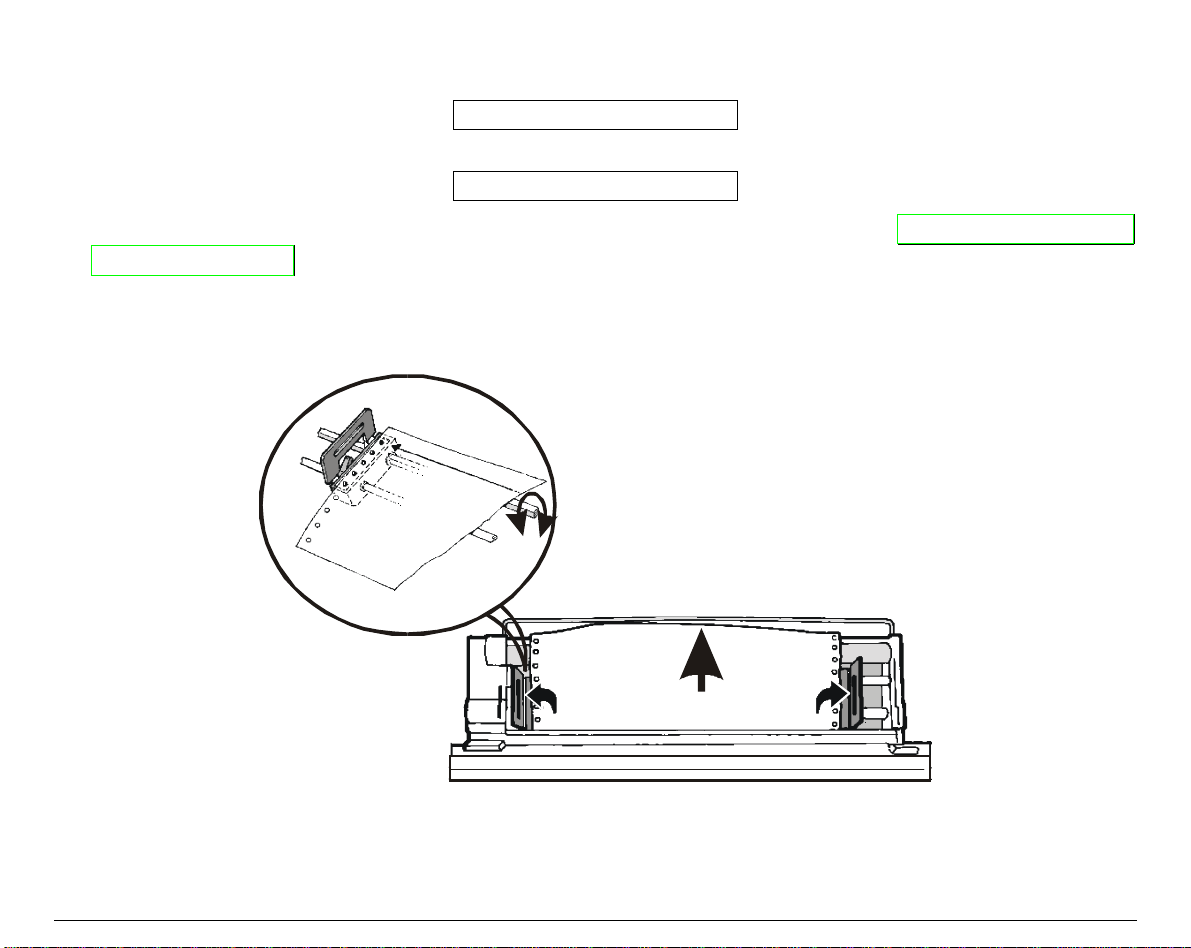

3. Ta ke up the slack of the paper exiti ng from the rear paper slot an d rotate the sprocket bar to

align the sprocket pins of the rear tractor with the paper perforation.

118

Page 3

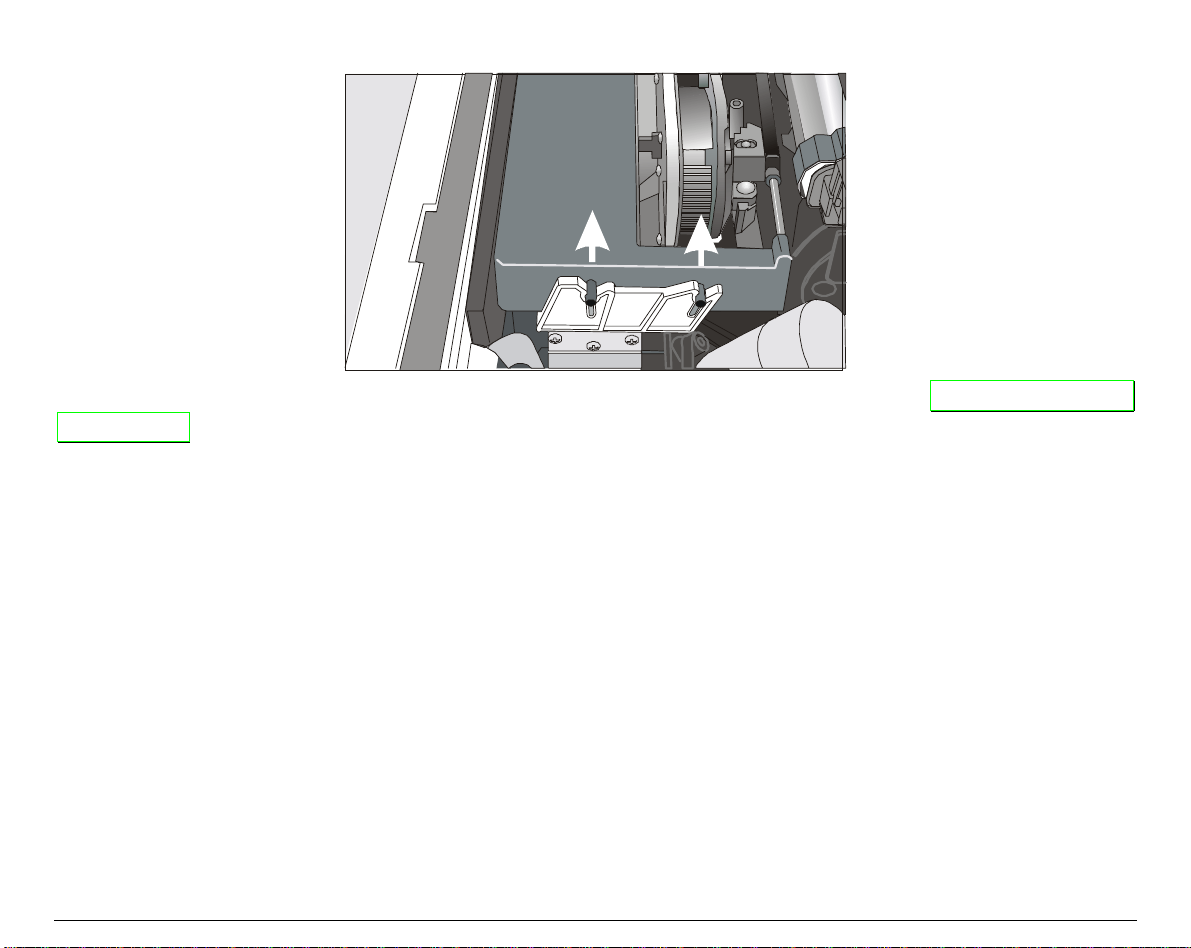

4. Lock the sprocket covers and lower the sprocket levers.

5. Press the

ON LINE

key to confirm that the paper loading is finished. The rear tractor engages.

6. The figure shows the correct paper loading.

119

Page 4

PPrriinntteerr MMaaiinntteennaannccee aanndd TTrroouubblleesshhoooottiinngg

CClleeaanniinngg tthhee PPrriinntteerr

Make sure the printer has been turned off for at least 15 minut es before start ing any cleaning

Periodic cleaning will help keep your printer in top condition so that it will always provide

optimal performance.

• Use a neutral detergent or water solution on a soft cloth to clean dirt and grease from the

cabinet of the printer.

• Do not use an abrasive cloth, alcohol, paint thinner or similar agents because they may cause

discoloration and scratching.

• Be especially careful not to damage the electronic and mechanical components.

operations.

120

Page 5

RReeppllaacciinngg tthhee RRiibbbboonn CCaarrttrriiddggee

1. Make sure that the printer is turned off for at least 15 minutes.

Pay attention to the print head because it becomes hot during operation

2. Open the top printer cover.

3. Slide the ribbon guide out of the print head.

If the color kit is installed on the printer,

unlock the white slider pressing and

holding the lever on the slider towards the

back of the printer and contemporaneously

lifting the slider off the color mechanism.

Ribbon Guide

Color Slider

Color Kit

.

121

Page 6

4. Remove the used ribbon cartridge by lifting it up.

Now, you are ready to insert the new ribbon cartridge. See before "Ribbon Cartridge

Installation"

PPrriinnttiinngg tthhee SSeellff TTeesstt

If you need to know any printer setting, and to check if the printer is working well, print the selftest.

Proceed as follows:

1. Keep the

RELEASE KEY.

2. When you release the key, the printer starts the self-test printout.

3. To stop the self-test printi ng, press the

ON LINE

key pressed while powering on the printer until the display shows

ON LINE

key again. The printer is offline.

122

Page 7

EErrrroorr HHaannddlliinngg

When an error condition occurs:

• the printer is disabled;

• the first message on the display indicates the error, while the second message gives more

details concerning the error conditions.

Press always the ON LINE key to reset the error condition.

123

Page 8

Error Message Description

Messages Indication

A.G.A NOT OPER

ADJUST THE GAP

BUFFER OVERFLOW

CHARACTER LOST

The automatic gap

adjustment (A.G.A) is

not enabled.

A buffer overflow

condition occurred (for

the serial interface).

Solution

Press the

ON LINE

key to reset the error

condition. Adjust the print head gap to a fixed

distance. Select the print head fixed ga p

adjustment function in the

Press the

•

disabled (

Program Setup

Press the ↓ key until the

•

PROGRAM

READY

indicator unlit) to enter the

Program Menu.

key when the printer is

USER MACRO

function is displayed. Press the → key until

the desired macro is displayed (

MACRO#

).

x

Press the → key to enter the macro parameters.

Press the ↓ key until the

FIXED GAP

parameter is displayed. P ress the → o ← keys to

select the fixed gap adjustment values. From

FIXED GAP 1

GAP 4

(multipart fanfold paper).

(simple fanfold paper) to

FIXED

Turn the printer off and on again, or press the

PROGRAM

and

ON LINE

key successively to

clear the buffer.

CUT NOT ALLOWED

NUM. LINES < 12

An error occurred with

the optional cutter.

The paper to be cut is shorter than 12 lines.

Turn the printer off and on again. If the error

is not solved, call the Customer Support.

124

Page 9

Messages Indication

DATA SET OFF

The DSR Signal is not

connected to the printer and

is not ready for data transfer

(if the serial interface is

selected). This condition may

happen in a remote

connection (via modem) and

the DSR (DATA SET

) signal is missing.

INTERLOCK ERROR

CHECK INSERTION

READY

Neither the rear tractor nor

the tractor cover are

installed on the printer.

JAM LOWER PATH

CHECK PAPER

JAM UPPER PATH

CHECK PAPER

A paper jam error condition

occurred in the paper path

A paper jam error condition

occurred in the paper path

Solution

Press the

ON LINE

key to reset the error

condition.

Install the rear tractor or the tractor cover

on the printer.

Check the paper path and remove the

jammed paper. Press the

ON LINE

key to

reset the error condition.

Check the paper path and remove the

jammed paper. Press the

ON LINE

key to

reset the error condition.

NO PATH AVAILABLE

PATH CHANGING

An electromechanical failure

occurs in the lower tractor

paper path. The printer

changes automatically to the

cut sheet paths (Manual or

ASF).

125

Call Service.

Page 10

Messages Indication

NVM CHANGE

REMOVE PAPER

If this error is displayed

during the printer power on,

an NVM error condition

occurred.

PAPER JAM

CHECK ALL PATHS

A paper jam error condition

occurs in one of the paper

paths.

PRINT INTEGRITY

Anomalous print out because

of a possible print carriage

blocking

RIBBON BLOCKED

CHECK RIBBON

UNKNOWN TRACTOR

The ribbon of the cartridge is

blocked

A tractor type that is not

recognized has been

mounted on the printer.

Solution

Turn the printer off and then on again. If

the problem is not solved call Service

Check all the paper paths and remove the

jammed paper. Press the

ON LINE

key to

reset the error condition.

¬ Do not move the platen knob.

Press the

ON LINE

key to reset the error

condition

Check that the ribbon is correctly inserted.

Turn the tension knob to make sure that

the ribbon is not jammed. Press the

key to reset the error condition.

LINE

ON

Check that the installed tractor is

compatible with the printer.

126

Page 11

OOppttiioonnss

TThhee RReeaarr PPuullll TTrraaccttoorr

The rear pull tractor is useful to handle particularly heavy paper.

IInnssttaalllliinngg tthhee RReeaarr PPuullll TTrraaccttoorr

1. Turn the printer off.

2. Remove the ASF cover, the rear tractor area cover and the two small tractor fixing area

covers.

Re ar tractor

area cover

ASF area cover

Tractor fixing

area s cov ers

Keep the covers in a safe place, as they must be reinstalled if the rear t ractor is removed.

3. Replace the ASF cover.

127

Page 12

4. Open the top cover, free (1) the paper bail and remove (2) it from the hooks on both sides of

the printer. Then install the rear pull tractor. Close the top cover

1

1

2

5. Insert the rear pull tra ctor and the corresponding fixing area cove rs (with the slot) as shown

in figure.

6. Turn the printer on.

The paper can be loaded in push-pull mode. See before "Loading Paper Using the Lower Push

Tractor and the Rear Pull Tractor".

128

Page 13

RReemmoovviinngg tthhee RReeaarr PPuullll TTrraaccttoorr

1. Push the lever on the rear pull tractor down and lift the tractor out of the printer.

2. Insert the rear tractor cover and make sure that the interlock connector is correctly inserted.

If the cover is not inserted, the printer is blocked.

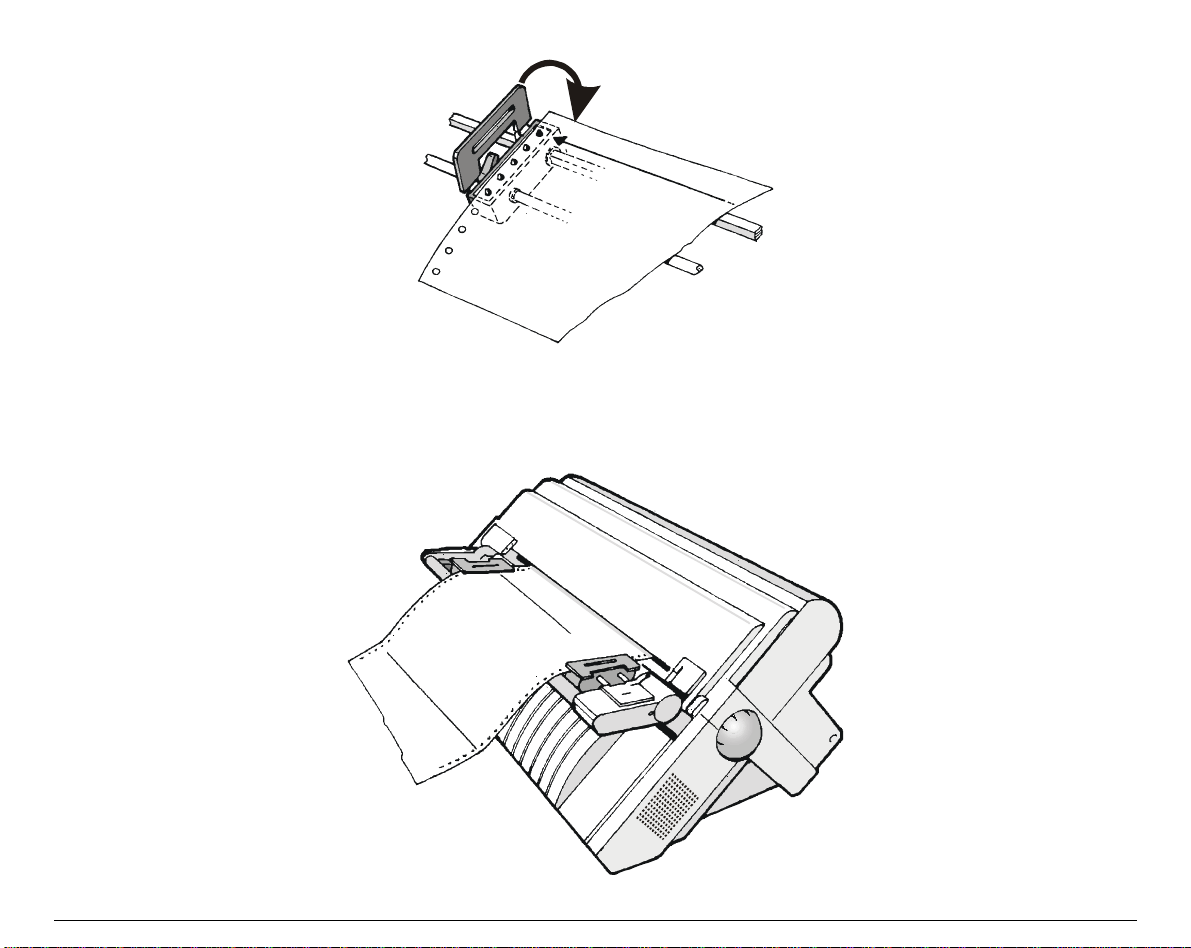

3. Open the top cover. Move the print carriage to the right most position, then insert (1) the

paper bail pi ns into the hooks on both si des of the printer. Rotate (2) the paper bai l upwards

and gently push it on both sides towa rds the back of the printer until it clicks into place.

1

2

1

129

Page 14

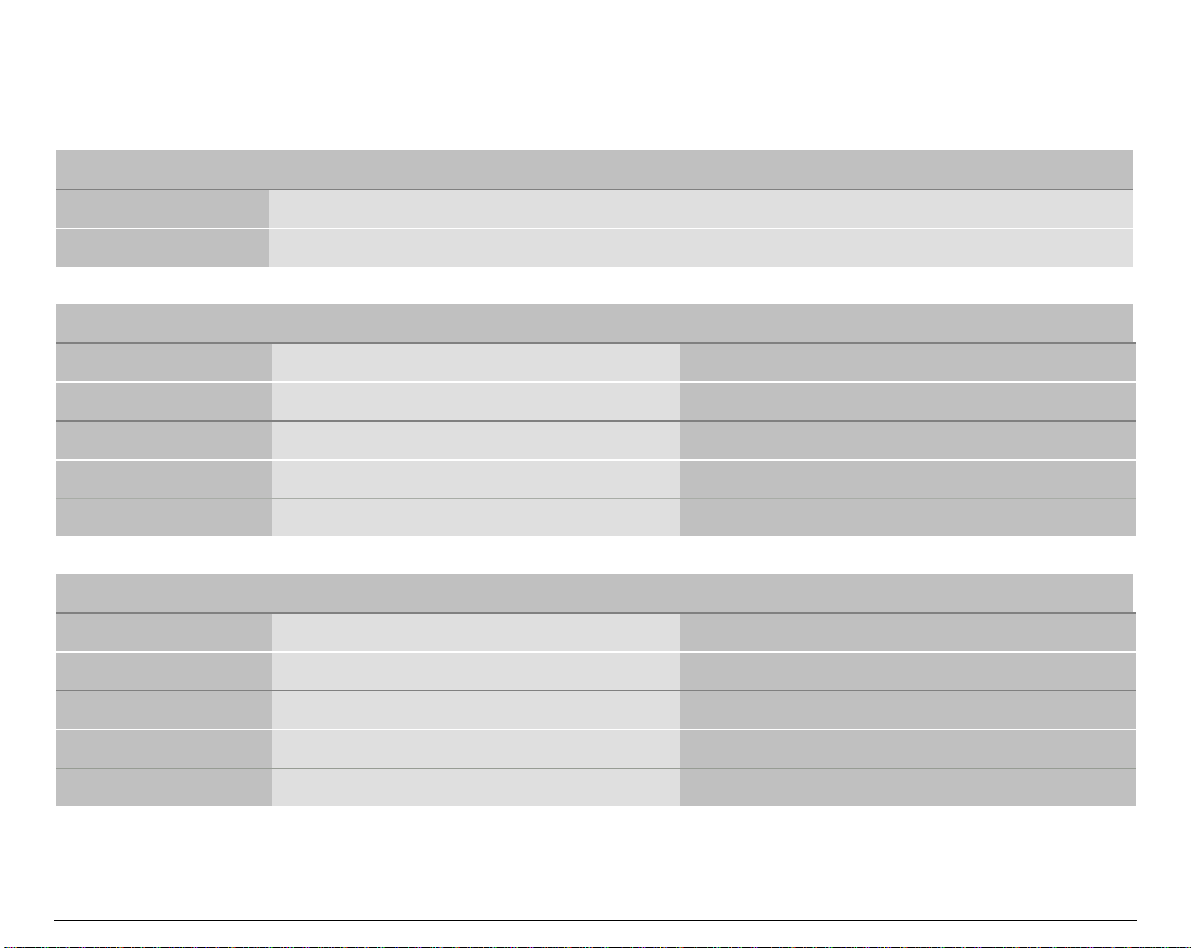

Printing Characteristics

PPrriinntteerr SSppeecciiffiiccaattiioonnss

Print Head

Matrix 24 pins - 0.25 mm

Print Head Life 700 mil characters (draft)

Print Speed (cps)

Draft Quality

10 cpi Normal 700 LQ 133

Best 400 NLQ 266

Best LQ 200

Best NLQ 400

Throughput (pages/hour)

ECMA 132 Draft Quality

10 cpi Normal 540 LQ 220

Best 470 NLQ 310

Best LQ 290

Best NLQ 430

134

Page 15

Print Matrix (horizontal x v ertica l)

Draft Quality

10 cpi 12 x 12 36 x 24

12 cpi 10 x 12 30 x 24

15 cpi 12 x 12 24 x 16

17.1 cpi 12 x 12 36 x 24

20 cpi 12 x 12 30 x 24

24 cpi 12 x 12 24 x 16

Print Density (characters per inch)

Normal 10 - 12 - 15 - 17.1 - 20 - 24

Enlarged 5 - 6 - 7.5 - 8.55

Proportional

Line Length (number of characters)

10 cpi 136 17.1 cpi 233

12 cpi 163 20 cpi 272

15 cpi 204 24 cpi 326

135

Page 16

Vertical Spacing

6, 8, 12 lpi

3, 4, 6, 8, 12 lines/30 mm

N/72, n/144, n/216, n/360

Print Styles

Draft, Courier, OCR -B, Goth ic , OCR -A, S crip t

Print Attrib utes

Sub-Superscript, Underline, Overscore, Italics, Emphasized

Graphic Resolution (dots per inch)

horizontal 60, 80, 90, 120, 180, 240, 360

vertical 60, 72, 180

136

Page 17

Characters Sets

International character sets ASCII Normal and Slanted

Standard PC IBM Character Sets CS1 and CS2

EPSON National Variations USA, France, G ermany, United Kingdom, Denmark -1, Sweden, Italy, Spain-

IBM and EPSON Character Sets USA (CP437), Greek (CP437-G), Multilingual (CP850), Greek (CP851),

ISO Character Sets 8859/1 (Latin1), 8859/2 (Latin2), 8859/3 (Latin3), 8859/4 (Latin4), 8859/5

1, Japan, Norway, Denmark-2, Spain-2, Latin America

Eastern Europe (CP852), Turkish (CP 853), Cyrillic (CP855), Turkish

(CP857), Euro PC Multilingual (CP858), Por tugal (CP860), Hebrew (CP862),

Canada/France (CP863), Arabic (CP864), Denmark/Norway (CP865),

Russian (CP866), Turkish2 (CP867), OCR-A (CP876), OCRB (CP877),

Central Europe (CP1250), Cyrillic (CP 1251), Windows Latin 1 Ansi (CP

1252)

96 GREEK, GOST, TASS, MAZOWIA

(Latin/Cyrillic), 8859/6 (Latin/Arabic), 8859/7 (Latin/Greek), 8859/8

(Latin/Hebrew), 8859/9 (Latin5). 8859/15 (Latin9)

Bar Codes

EAN-8, EAN-13, UPC-A, UPC-E, UPC/EAN 2, UPC/EAN 5, Code GP, C25-3BAR, Code BCD, MSI Plessey,

Code 11, Code 93, 2/5 Bidirectional, 2/5 Interleaved, 2/5 Industrial, 2/5 Matrix, Code 39, Codabar, Code 128,

Postnet

Emulations

- EPSON LQ 1050-2550 (ESC/P) - IBM Proprinter XL24E/XL24 AGM

- IBM Personal Printer 2391+

137

Page 18

Paper Handling

9078 plus model Base Configuration

Fanfold Paper

1 LOWER PUSH TRACTOR

Fanfold width: 76 to 432 mm (3 to 17 inches)

Copies: 1 original + 7 copies Max. thickness 0,635 mm

Cut Sheets (loaded through the manual slot)

Sheet width: 114 to 432 mm (4,5 to 17 inches)

Standard formats: A5 - A4 - A3 - A 2 i n po rtrai t

Letter - Legal - Executive

Copies: 1 original + 7 copies Max. thickness 0,635 mm

9078D plus model Base Configuration

Fanfold Paper

1 LOWER PUSH TRACTOR

Fanfold width: 76 to 432 mm (3 to 17 inches)

Copies: 1 original + 7 copies Max. thickness 0,635 mm

1 UPPER PUSH TRACTOR

Fanfold width: 76 to 432 mm (3 to 17 inches)

Copies: 1 original + 7 copies Max. thickness 0,635 mm

138

Page 19

With the pull tractor option

Push-Pull Feeding

Front fanfold insertion with lower tractor in front push mode and rear tractor in pull mode.

Automatic Sheet Feeder Option

First tray Single sheets, envelopes and postcards

Second and third tray Single Sheets

Paper stacker

- Tray capacity 120 sheets (80 g/m2)

- Sheet width 88,9 to 304,8 mm (3,5 to 12 inches)

Copies 1 original + 2 copies

Coexisting with manual sheet (9078 plus model only)

Coexisting with fanfold in push mode

Standard Functions

•

Automatic print head gap adjustment (AGA)

•

Automatic paper path switching via operator panel or S/W commands

•

Paper parking

•

Plug & Play capability

•

Bar Code printing

•

Automatic fanfold positioning for tear-off

•

Setting and storage of paper format and print conditions for each paper path in the non volatile memory

139

Page 20

Physical and Electrical Characteristics

Interfaces

Parallel Centronics Compatible Bi-directional (IEEE-1284) nibble and byte modes - 36 pin

Amphenol connector

Receive Buffer: max. 64 Kbytes

Serial RS-232/C and RS-422/A - dB 25 connector

Baud Rate: 300 to 38400 bps

Automatic interface sw itch ing

Reliability

MTBF Mean Time between failure: 10000 hours at 25% DC

MTTR Mean Time To Repair: 30 minutes

Workload 43000 pages/month (ECMA 132 - 4 hours for 20 days)

Power Supply

120 V/ 60 Hz USA power cable

220 - 240 V / 50 Hz European power cable

UK power cable

Power Consumption Standby: 28W ---- Average Printing: 90 W

Noise Level

54 dBA

140

Page 21

Environment Conditions

Storage Conditions

Temperature -40° to 50° C

Relative Humidity 10%t o 90% RH (non condensing)

Operating Conditions

Temperature 10° to 38° C

Relative Humidity 10 % to 90 % RH (non condensing)

Paper Conditions

Temperature 16° to 24° C

Relative Humidity 40% to 60% RH (non condensing)

Physical dimensions

Height 315 mm (12,21 inches)

Width 670 mm (26,18 inches)

Depth 390 mm (15,35 inches)

Wei gh t 18 kg (44,15 lbs)

141

Loading...

Loading...