Page 1

Compuprint

6314/6414

User Manual

rel. -002

Page 2

Compuprint 6314/6414 - User Manual

Safety Instructions

Never use the printer, if the mains values do not correspond to those given on the rating plate of the printer. The rating

plate is located inside the printer.

The printer must be used only in environments corresponding to the instructions given in this manual.

Do not operate the printer parts, unless it is indicated inside this manual. Any intervention on the printer must be

performed strictly following the given instructions.

If the printer smokes, is particularly hot or produces unusual noise or smell, turn off the printer immediately and

remove the power cord. Do not use the printer and call Customer Service.

When moving the printer, hold it only at its base. Do not raise the printer holding it at the side grip, because the printer

cover may open, the printer fall harming the user and/or damaging the printer itself.

Sferal wwt srl

Via Martiri d'Italia, 26

10014 Caluso (TO)

Italy

©2007 Sferal wwt and the identifying product names and numbers herein are trademarks of Sferal wwt.

Copyright protection claimed includes all forms and matters of copyrightable materials and information now allowed by

statutory or judicial law or hereinafter granted, including without limitation material generated from the software

programs which are displayed on the screen such as icons, screen display tools, etc. Products names used in this manual

may be trademarks or registered trademarks of their respective companies and are hereby acknowledged. All non Sferal

brands and product names are trademarks or registered trademarks of their respective companies.

2

Page 3

Compuprint 6314/6414 - User Manual

Contents

1 Introduction _________________________________________________________________ 6

1.1 Warnings And Special Information____________________________________________________ 6

1.2 Important Warranty Information _____________________________________________________ 6

1.3 Features___________________________________________________________________________ 7

1.4 Thermal Printer Technology _________________________________________________________ 8

1.4.1 The Printing Process ______________________________________________________________________ 8

1.5 Thermal Consumables _______________________________________________________________ 8

1.5.1 Media Selection __________________________________________________________________________8

1.5.2 Ribbons ________________________________________________________________________________9

1.6 Thermal Features___________________________________________________________________ 9

1.6.1 Emulations______________________________________________________________________________9

1.6.2 Hardware Options ________________________________________________________________________9

1.7 Setting Up The Printer _____________________________________________________________ 10

1.7.1 Unpacking The Printer____________________________________________________________________10

1.7.2 Check List _____________________________________________________________________________11

1.8 Installation _______________________________________________________________________ 12

1.9 Installing The Print Head ___________________________________________________________ 14

1.9.1 Installing The Print Head__________________________________________________________________14

2 Operation___________________________________________________________________ 17

2.1 Using The Printer__________________________________________________________________ 17

2.1.1 Controls And Indicato rs___________________________________________________________________17

2.1.2 Powering The Printer On __________________________________________________________________18

2.2 Loading Media And Ribbon _________________________________________________________ 18

2.2.1 Loading Labels Inside The Printer___________________________________________________________ 19

2.2.2 Loading Labels From Outside The Printer_____________________________________________________22

2.2.3 Adjusting The Print Head Pressure __________________________________________________________ 23

2.2.4 Loading The Ribbon _____________________________________________________________________24

2.3 Printer Options____________________________________________________________________ 25

2.3.1 Tear-Off And Tear-Off Stri p _______________________________________________________________ 25

2.3.2 Label Peel Off (Optional)__________________________________________________________________26

2.3.3 Label Batch Rewind (Optional)_____________________________________________________________28

2.3.4 Installing The Cutter (Optional)_____________________________________________________________29

2.3.5 Installing The NIC Board (Optional)_________________________________________________________30

2.4 Printing Adjustments_______________________________________________________________ 31

2.4.1 Label Variations And The TOF/Paper Out Sensor_______________________________________________31

2.4.2 Media Sensor Horizontal Adjustment ________________________________________________________31

2.4.3 Running The Calibrate Via The Menu________________________________________________________32

2.5 Cleaning _________________________________________________________________________ 34

2.5.1 General________________________________________________________________________________34

2.5.2 Print Head _____________________________________________________________________________34

3 Configuring the printer _______________________________________________________ 36

3.1 Control Panel _____________________________________________________________________ 36

3.1.1 Function Keys And LEDs _________________________________________________________________37

3.2 Configuring The Printer ____________________________________________________________ 38

3.2.1 Overview ______________________________________________________________________________38

3.2.2 Menu Navigation ________________________________________________________________________40

3

Page 4

Compuprint 6314/6414 - User Manual

3.2.3 Setting Printer Configuration Parameters _____________________________________________________ 40

3.2.4 Moving Within The Configuration Menu _____________________________________________________ 41

3.3 File Menu_________________________________________________________________________43

3.3.1 Factory Reset Functions___________________________________________________________________ 44

3.3.2 Others Parameters _______________________________________________________________________ 45

3.4 Enabling and Modes ________________________________________________________________46

3.4.1 Emulation Selection______________________________________________________________________ 46

3.4.2 Set Printer Mode ________________________________________________________________________ 47

3.4.3 Paper Sensor Mode ______________________________________________________________________ 47

3.4.4 Print Method Mode ______________________________________________________________________ 47

3.4.5 Password Selection ______________________________________________________________________ 48

3.4.6 Power Up Configuration __________________________________________________________________ 48

3.4.7 Closing Head Action _____________________________________________________________________ 48

3.5 Printer Settings ____________________________________________________________________49

3.5.1 Vertical Offset Adjustment ________________________________________________________________ 50

3.5.2 Backfeed Adjustment_____________________________________________________________________ 50

3.5.3 Form Length Selection____________________________________________________________________ 50

3.5.4 Maximum Label Length Selection___________________________________________________________ 51

3.5.5 Maximum Label Width Selection ___________________________________________________________ 51

3.5.6 Print Speed Selection_____________________________________________________________________ 51

3.5.7 Slew Speed Selection_____________________________________________________________________ 51

3.5.8 Backfeed Speed Selection _________________________________________________________________ 52

3.5.9 Print Head Heat Selection _________________________________________________________________ 52

3.5.10 Cut Cycle Selection _____________________________________________________________________ 52

3.5.11 Paper Rewinder Torque__________________________________________________________________ 52

3.5.12 Ribbon Rewinder Torq ue_________________________________________________________________52

3.5.13 Horizontal Offset Adjustment _____________________________________________________________ 53

3.5.14 Set Time And Date _____________________________________________________________________ 53

3.5.15 Override Print Parameters ________________________________________________________________ 53

3.6 Emulation Parameters CDL Menu ____________________________________________________54

3.6.1 Vertical Offset __________________________________________________________________________ 54

3.6.2 Backfeed Offset_________________________________________________________________________ 55

3.6.3 Reference Offset ________________________________________________________________________ 55

3.6.4 Row Offset_____________________________________________________________________________ 55

3.6.5 Column Offset__________________________________________________________________________ 56

3.6.6 Select Final Character ____________________________________________________________________ 56

3.6.7 Control Codes __________________________________________________________________________ 56

3.7 Emulation Parameters CZL Menu ____________________________________________________57

3.7.1 Set Format Prefix________________________________________________________________________ 57

3.7.2 Set Control Prefix _______________________________________________________________________ 57

3.7.3 Set Delimiter Character___________________________________________________________________ 58

3.7.4 Resolution Mode ________________________________________________________________________ 58

3.7.5 Label Length ___________________________________________________________________________ 58

3.7.6 Restore Unit Identifie r____________________________________________________________________ 58

3.8 Emulation Parameters CPL Menu ____________________________________________________59

3.8.1 X – Y Starting Point______________________________________________________________________59

3.8.2 Error Report____________________________________________________________________________ 60

3.9 Diagnostic Menu ___________________________________________________________________61

3.9.1 Run Automatic Adjustment________________________________________________________________ 62

3.9.2 Paper Sensor Mode ______________________________________________________________________ 62

3.9.3 Paper Sensor Control_____________________________________________________________________62

3.9.4 Run No Paper Calibration _________________________________________________________________ 62

3.9.5 Run Manual Adjustment __________________________________________________________________ 63

3.9.6 Run Automatic Present Sensor Calibration ____________________________________________________ 63

3.9.7 Printhead Type Detected __________________________________________________________________ 63

3.9.8 Counters Menu__________________________________________________________________________63

4

Page 5

Compuprint 6314/6414 - User Manual

3.10 Communication Parameters Menu __________________________________________________ 64

3.11 Serial Interface___________________________________________________________________ 65

3.11.1 Baud Rate_____________________________________________________________________________65

3.11.2 Parity ________________________________________________________________________________ 65

3.11.3 Data Bits Number_______________________________________________________________________66

3.11.4 Stop Bits Number_______________________________________________________________________66

3.11.5 Xon/Xoff Protoc. Selection _______________________________________________________________ 66

3.12 NIC Interface ____________________________________________________________________ 67

3.12.1 IP Assignment _________________________________________________________________________68

3.12.2 IP Address ____________________________________________________________________________68

3.12.3 Subnet Mask___________________________________________________________________________68

3.12.4 Gateway Address_______________________________________________________________________68

3.12.5 Host Name ____________________________________________________________________________68

3.12.6 Workgroup Name_______________________________________________________________________68

3.12.7 Enabling SMTP ________________________________________________________________________ 68

3.12.8 Mail Server Address_____________________________________________________________________69

3.12.9 Email Notification Address _______________________________________________________________69

3.12.10 Email Printer Address __________________________________________________________________ 69

3.12.11 Contact______________________________________________________________________________ 69

3.12.12 Location _____________________________________________________________________________69

4 Troubleshooting _____________________________________________________________ 70

5 Printer Specifications_________________________________________________________ 72

6 Conformity Declaration_______________________________________________________ 75

6.1 EEC Regulations __________________________________________________________________ 75

6.2 FCC Part 15 Class A _______________________________________________________________ 75

7 Serial Port Wiring ___________________________________________________________ 76

8 Index Of Figures_____________________________________________________________ 77

9 Index Of Tables______________________________________________________________ 78

5

Page 6

Compuprint 6314/6414 - User Manual

1 INTRODUCTION

Our new offer now includes a new line of thermal and thermal transfer printers that can provide the best

solution for every labeling need.

Highly responsive to our customers’ needs, we have introduced an unique innovation in the field of thermal

technology. The installation of memory units makes it possible to increase printer speed.

As a result, you no longer have to buy a new printer if your printing needs change.

Another exclusive system permits the operator to change the head simply and quickly, avoiding wasteful

downtime. CPG printers are also the best investment thanks to their robust and compact design, key features

when space is limited.

CPG thermal technology is ideal for anyone who wants to introduce or expand their own barcode

applications in virtually any field: tracking progress on the production line; tracking outflows, shipping and

receiving, and inventory in the warehouse; labeling of test tubes in medical and pharmaceutical laboratories;

code labeling of property, documents, invoices, and delivery notes in administrative offices.

1.1 Warnings And Special Information

For your safety and to protect valuable equipment, it is very important that you read and comply with all

information highlighted under special headings:

WARNING! Conditions that could harm you as well as damage the equipment.

IMPORTANT! Information vital to proper operation of the printer.

NOTE! Information and helpful tips about printer operation.

1.2 Important Warranty Information

Printer Warranty

CPG International warrants to purchaser that under normal use and service, this printer (excluding the

thermal print head) purchased hereunder shall be free from defects in material and workmanship for a period

of ninety (90) days from the date of shipment from CPG International.

Consumable items such as media and ribbons are not covered under this warranty. This warranty does not

cover equipment or parts that have been misused, altered, or used for purposes other than those for which

they were manufactured. This warranty also does not cover loss, shipping damage, damage resulting from

accident or damages resulting from unauthorized service.

Thermal Print Head

CPG International warrants the print head for a period of ninety (90) days, or 1,000,000 linear inches

(Thermal Transfer/Direct Thermal) of use, whichever comes first. The warranty does not cover print heads

that have been misused, damaged due to improper cleaning, or damaged due to use of improper ribbons or

media.

Supplies

To reorder CPG International supplies, you can complete the reorder form that comes with your printer, or

call your local CPG International office.

6

Page 7

Compuprint 6314/6414 - User Manual

1.3 Features

- Thermal transfer and Direct thermal printing.

- Supports over 17 types of bar codes.

- Download forms, fonts and graphics to printer memory.

- High-resolution print head for sharp graphics and text.

- Optional Built-in label rewinder for label Peel-Off operation.

- Label Taken Sensor for detecting removal of labels in Peel-Off or Tear-Off modes.

- Peel-Off mode for peeling off labels one at a time, before printing the next label.

- Tear-Off mode for positioning the label at the tear-off position and detecting its removal before

printing the next label.

- Tear-Off Strip mode for printing a specified number of labels and positioning the last label at the

tear-off position.

- 8MB DRAM memory.

- 4MB Flash memory.

The printer can be connected to communicate with the host via RS-232 and USB ver 2.00,

Centronics

Ethernet

The interface cables needed to connect the printer to the host device is supplied by the user.

®

-compatible parallel, IEEE

®

10/100 Base-T.

®

1284 compliant parallel, and, optional connections of

7

Page 8

Compuprint 6314/6414 - User Manual

1.4 Thermal Printer Technology

Quiet and fast, with excellent print quality, your multifunction thermal printer uses an inline thermal

print head. The operation of a thermal printer is different from that of a line-matrix or laser printer.

The thermal printer uses a print head with heating elements and special paper or ribbon.

1.4.1 The Printing Process

The thermal print head allows two modes of operation:

- Direct Thermal

During direct thermal printing, the thermal print head selectively heats small, rectangular thermal

dots. When these contact the coated thermal paper, the dyes and developers in the coating react

to the heat and develop an image. This mode of printing is generally used for short-term labeling

applications.

- Thermal Transfer

During thermal transfer printing, the heated thermal dots contact a thermal ribbon. The heat

reacts with the ribbon and bonds the image to the paper. This method is used especially for

abrasive, long-storage applications and for specialized applications, such as in extreme

environmental conditions or where tamper-proofing is required.

1.5 Thermal Consumables

1.5.1 Media Selection

Since there are two print modes of operation, there are two kinds of thermal media:

- Direct thermal media.

- Thermal transfer media.

Direct thermal media is paper coated with special chemicals that act as an accelerator, acceptor dye

and binder. During direct thermal mode, the heat from the thermal print head contacts the paper and

causes a chemical reaction to take place.

There is a wide range thermal transfer media available, such as film or synthetic paper substitutes

that are excellent in their ability to transfer an image (print quality) and others in scratch resistance

(long storage). Most of these media options can be die-cut for easy label applications.

NOTE!

The term “media” used in this manual refers to all the different kinds of paper or tag stock that can be used in the

printer.

8

Page 9

Compuprint 6314/6414 - User Manual

1.5.2 Ribbons

CPG International offers a range of ribbons that have been specifically engineered to enhance

printing capabilities and to prevent premature print head wear. Therefore, it is strongly

recommended that you use a CPG International Thermal Ribbon in your printer.

1.6 Thermal Features

1.6.1 Emulations

Your thermal printer has the standard CZL emulation which provides direct compatibility with

Zebra printers. In addition, the printer has co-resident: CDL emulation which provides direct

compatibility with Datamax printers and CPL emulation.

1.6.2 Hardware Options

Ask your authorized representative about the following options, which can enhance the versatility

of your printer.

- Fonts

A selection of fonts is available to extend the capabilities of the standard resident fonts.

- Media Cutter

The cutter is used to automatically cut printed media when the media exits the printer.

- Media Catcher Tray

Used with the Media Cutter option to catch the cut media and collect it away from the Media

Cutter Assembly.

- Peel Option

The Peel Option is used to peel adhesive labels from the liner.

- Powered Rewind Option

Used to automatically rewind the printed label and liner back on a roll for use at a later time.

- Network Interface Card (NIC) Servers

Allows the user to attach the printer to a LAN (Local Area Network) rather than attaching it

directly to a host system. NIC servers support Ethernet only. NIC servers are available as an

internally installed, mounted inside the printer with the 10/100Base-T (UTP) connection only.

9

Page 10

Compuprint 6314/6414 - User Manual

1.7 Setting Up The Printer

1.7.1 Unpacking The Printer

The printer is shipped in a carton and protective bag. Keep all packing material in case you need to

move or re-ship the printer. Avoid touching the electrical connectors to prevent electrostatic

discharge damage while setting up the printer.

WARNING!

The discharge of electrostatic energy that accumulates on the surface of the human body or other surfaces can damage

or destroy the print head or electronic components used in this device.

WARNING!

Damage to the printer interface connector may result from placing the printer on its backside during unpacking or

handling.

10

Fig. 1 – The 6314-6414 printer

Page 11

1.7.2 Check List

Your thermal printer kit contains the items listed below.

- The thermal printer.

- AC Power cord.

- User’s Manual.

- Quick Reference Manual.

- Software Starter Kit CD.

- Ribbon Take-Up Core (mounted in printer).

NOTE!

If any items are missing, contact your dealer for replacement parts.

Compuprint 6314/6414 - User Manual

11

Page 12

Compuprint 6314/6414 - User Manual

1.8 Installation

The following sections will guide you through the installation of the printer.

- Place the printer in a suitable location on a flat level surface that allows easy access to all sides

of the printer. The printer should never be operated while resting on its side or upside down.

- Check that the printer power switch is in the OFF (O) position.

2

1

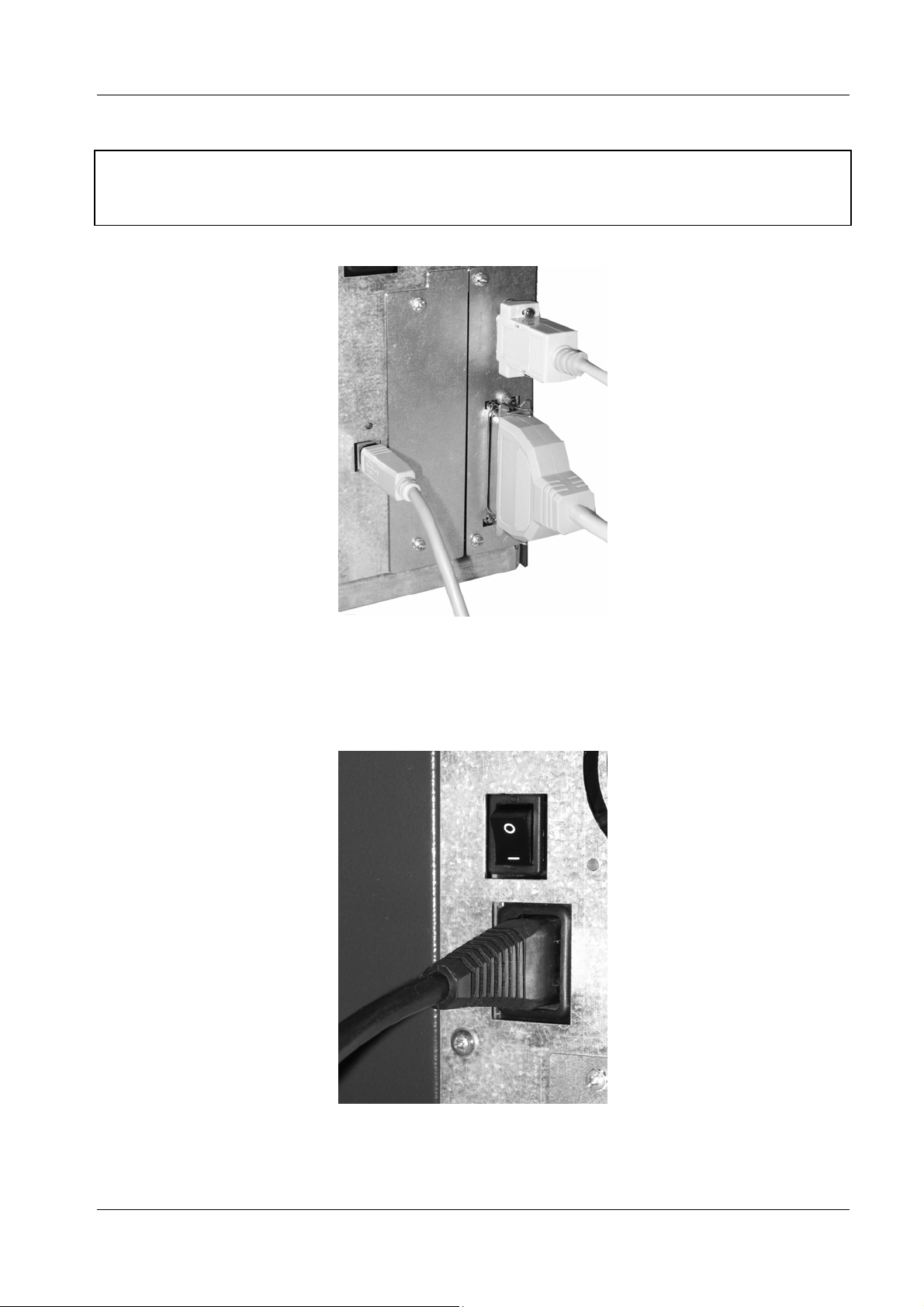

Fig. 2 – Power inlet and ON/OFF switch

Legend:

1) AC Power Receptacle

2) ON/OFF Power Switch

- Attach Interface (Fig. 3):

A. Parallel Interface

Attach a suitable parallel printer cable from the computer to the Centronics

®

interface connector

at the back of the printer. Snap the bail locks to the Centronics connector to secure the interface

cable to the printer.

B. Serial Interface

Attach a suitable serial printer cable from the computer to the DB-9 RS-232 Serial interface

connector at the back of the printer. For additional information on serial cable wiring, refer to

“Serial Port Wiring” section on page 76.

C. USB Interface

Attach a suitable USB cable from the computer to the USB interface connector at the back of the

printer.

12

Page 13

Compuprint 6314/6414 - User Manual

NOTE!

The printer supports simultaneous connection of all available interfaces using the AUTOMATIC feature. The

AUTOMATIC feature is described on page 64.

B

C

A

Fig. 3 – Printer Interfaces

- Attach the AC power cord to the AC power receptacle in the rear of the printer (Fig. 4).

Fig. 4 – Connection of power cord and ON/OFF swi t ch

13

Page 14

Compuprint 6314/6414 - User Manual

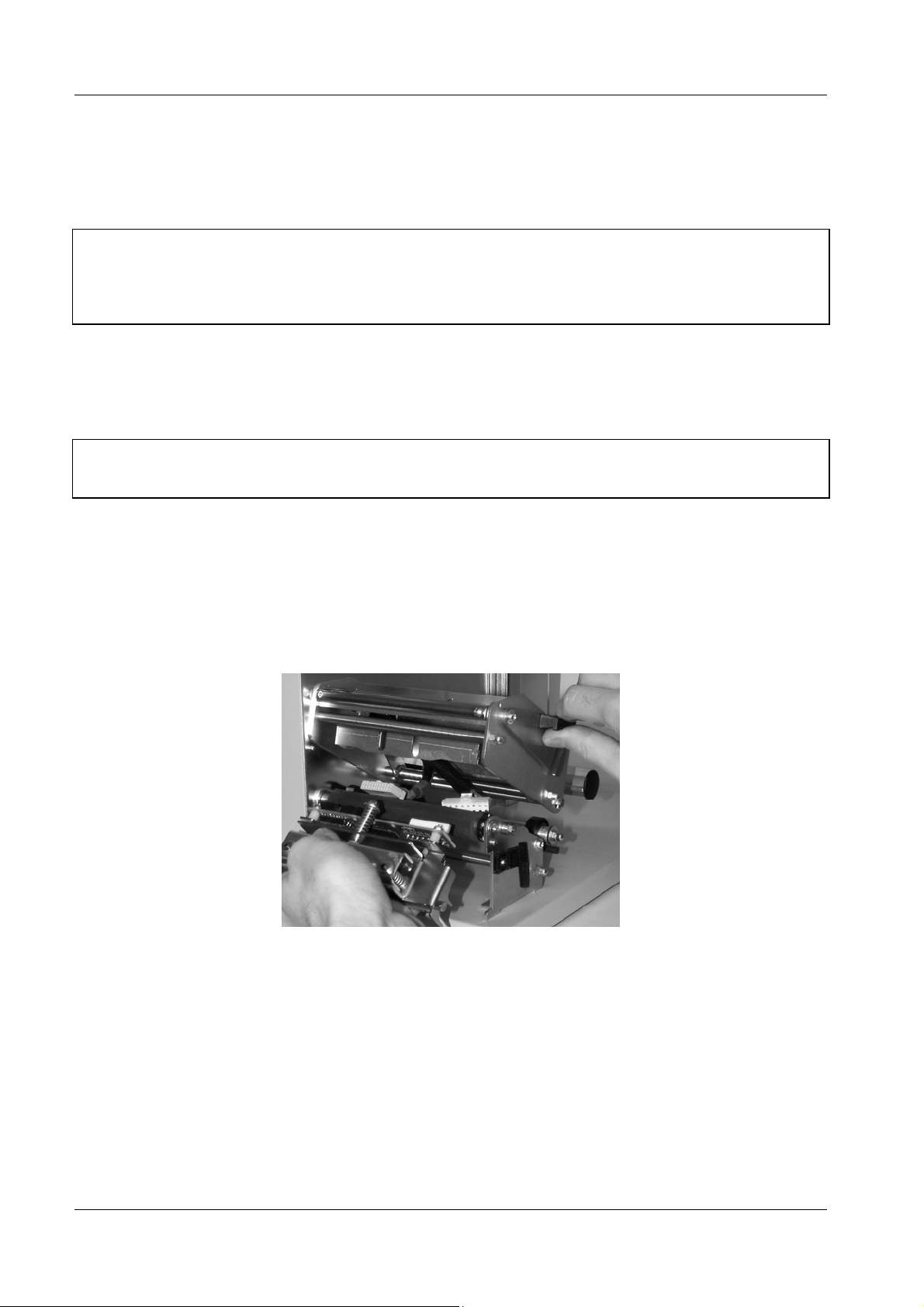

1.9 Installing The Print Head

WARNING!

When the print head is already installed in the printer, it is fixed with a plastic latch.

Before using the printer cut this latch.

1.9.1 Installing The Print Head

WARNING!

Make sure that the printer is turned off before installing the print head.

The first step in setting up the printer is to install the thermal print head, if this has not already been

done.

Please follow the instructions below:

- Turn off the printer.

- Open the label loading area lifting the cover on the right side of the printer.

- Lift the print head group with the corresponding lever (see Fig. 5).

14

Fig. 5 – Lifting the print head group

Page 15

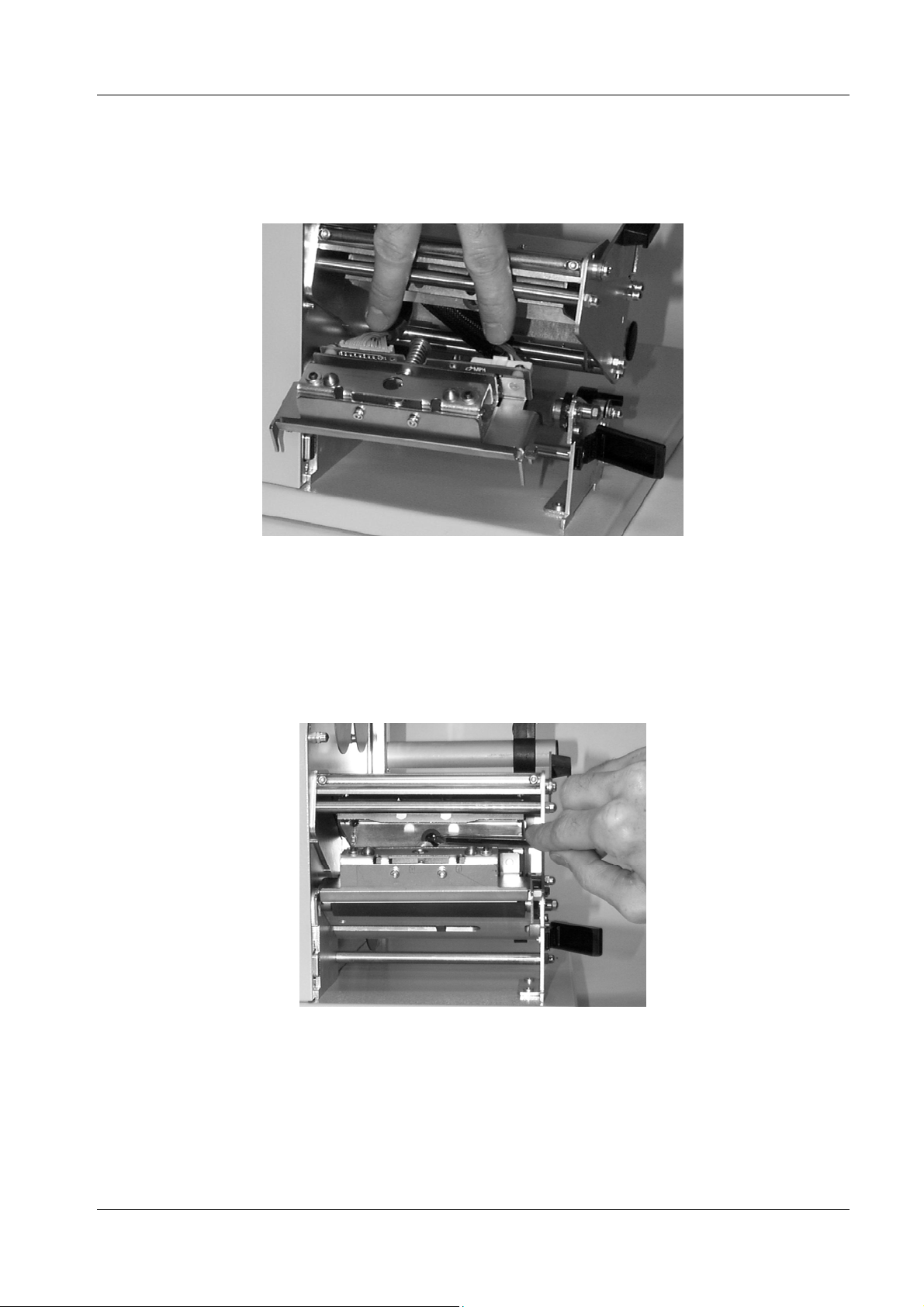

- Place the print head next to the connection cables.

- Attach all cables to the corresponding connectors (see Fig. 6).

Compuprint 6314/6414 - User Manual

Fig. 6 – Connecting the print head

- Insert the guide pin in the corresponding hole on the print head group (see Fig. 7).

Fig. 7 – Guide hole

15

Page 16

Compuprint 6314/6414 - User Manual

- Push the print head in and match the two markers on the top of the print head with the guide

holes on the print head group (see Fig. 8).

- Close the print head group.

Fig. 8 – Front guide markers on the print head

16

Page 17

2 OPERATION

2.1 Using The Printer

2.1.1 Controls And Indicators

Compuprint 6314/6414 - User Manual

Fig. 9 – Controls and indicators

All printer controls and indicators, except for the power switch, are located on the front panel of the

printer. The power switch is located on the left hand panel at the rear of the printer.

The Control Panel is located at the top left of the printer. The panel has a back-lighted LiquidCrystal Display (LCD) with 2 rows of 16-characters each.

The Control Panel also contains the printer control keys. A summary of each key’s function is

provided on the following pages. Detailed descriptions of key functionality are provided in Chapter

3.

17

Page 18

Compuprint 6314/6414 - User Manual

2.1.2 Powering The Printer On

When all cables have been connected and the labels and ribbon have been loaded as described

below, the printer is ready to be powered on.

The power switch is located on the back side near the power cable socket.

When powering the printer on, the display shows the message starting… and all three LED’s light

up. After a few seconds, the Check LED’s turn off, while the Ready remains lit together with the

Power LED; the display shows the

ON LINE message.

2.2 Loading Media And Ribbon

The term “media” used in this manual refers to all the different kinds of paper, label, or tag stock

material that can be printed on by the printer. This section explains how to load roll media, fanfold

media, and transfer ribbon. Your thermal printer can print on continuous paper, adhesive backed

labels or non-adhesive tags packaged in roll or fanfold form.

WARNING!

DO NOT TOUCH the print head or the electronic components unde r the Print Head Assembly. The discharge of

electrostatic energy that accumulates on the surface of the human body or other surfaces can damage or destroy the

print head or electronic components used in this device.

IMPORTANT!

Adhesive backed labels that DO NOT lay flat on the backing liner may jam the printer. This can cause the label to peel

off the liner. The exposed edges may stick to the label guides and rollers inside the printer.

If you run out of labels while printing, do not turn the power switch to the OFF position while reloading labels. Lost

data may result.

18

Page 19

Compuprint 6314/6414 - User Manual

2.2.1 Loading Labels Inside The Printer

You can open the label loading area by lifting the hinged media cover on the right side of the

Printer. Fig. 10 is affixed on the inside of the cover and illustrates the various parts of the printer

involved in labels and ribbon handling.

Fig. 10 – Paper and ribbon handling scheme

Legend:

1) Ribbon rewinder 8) Paper sensor group

2) Ribbon unwinder 9) Fastener for front option devices

3) Paper unwinder 10) Paper rewinding way

4) Paper roll lock lever 11) Print head lock lever (CLOSE)

5) External paper way 12) Paper exit front

6) Paper rewinder 13) Print head lock lever

7) Paper guide 14) Print head lock lever (OPEN)

To install the labels roll, proceed as follows:

- Move the label roll lock lever (4) to the horizontal position and move it towards the external end

of the roll shaft, according to the width of the roll that will be installed.

19

Page 20

Compuprint 6314/6414 - User Manual

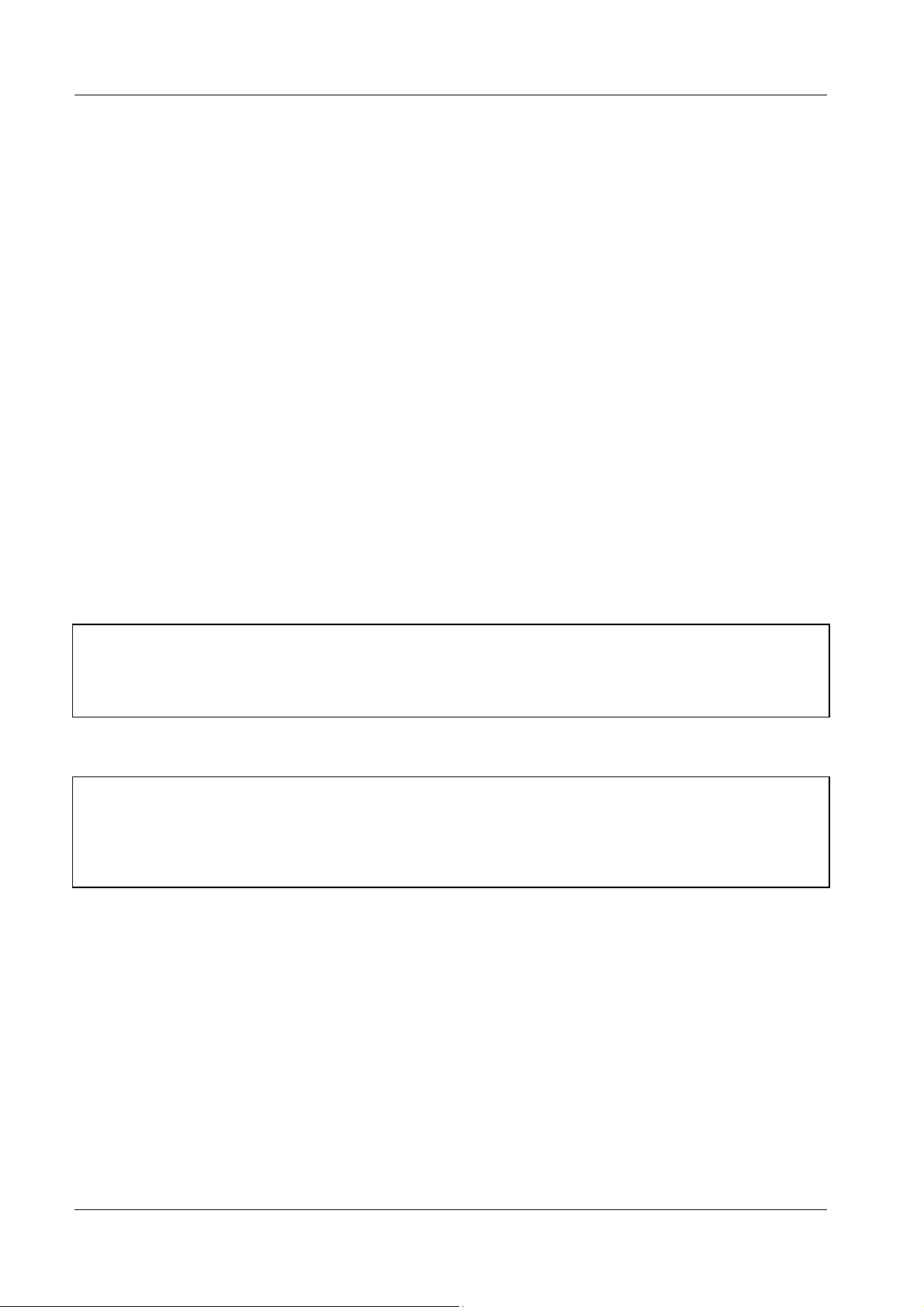

- Move the print head lock lever (11) to the open position (14) (see Fig. 11).

4

11

14

Fig. 11 – Preliminary steps in loading label roll

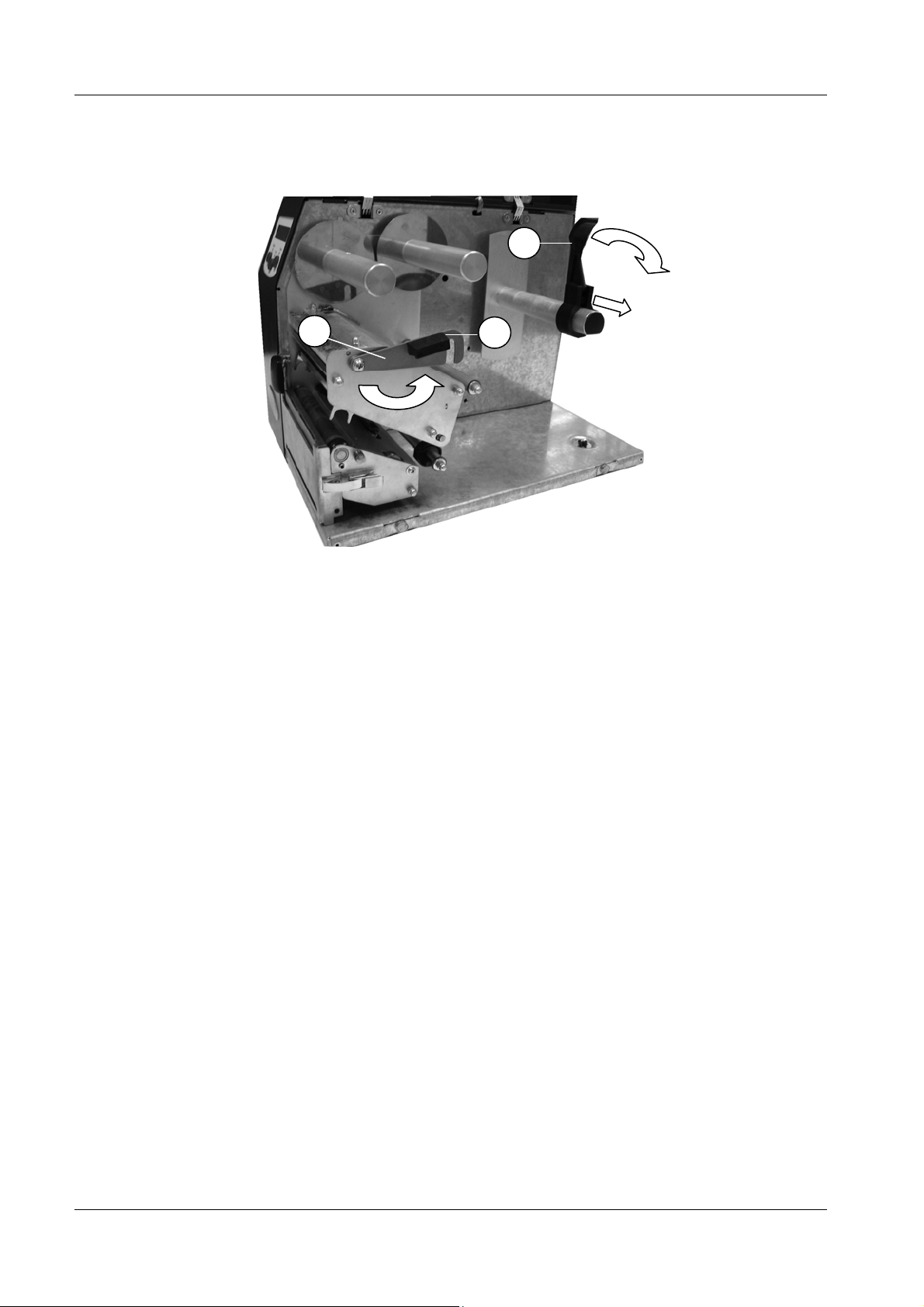

- Insert the label roll (3) onto the corresponding roll shaft.

- Move the label roll lock lever (4) to the vertical position. Be careful not to block the movement

of the label roll itself.

- Then pass the free end of the label roll over the first media roller and under the second one, on

which the paper guide (7) is installed, then between the two sides of the paper sensor (see Fig.

12), and finally under the print head group through the label output (12).

20

Page 21

12

Compuprint 6314/6414 - User Manual

4

3

7

Fig. 12 – Label roll insertion and detail of p aper path/sensor

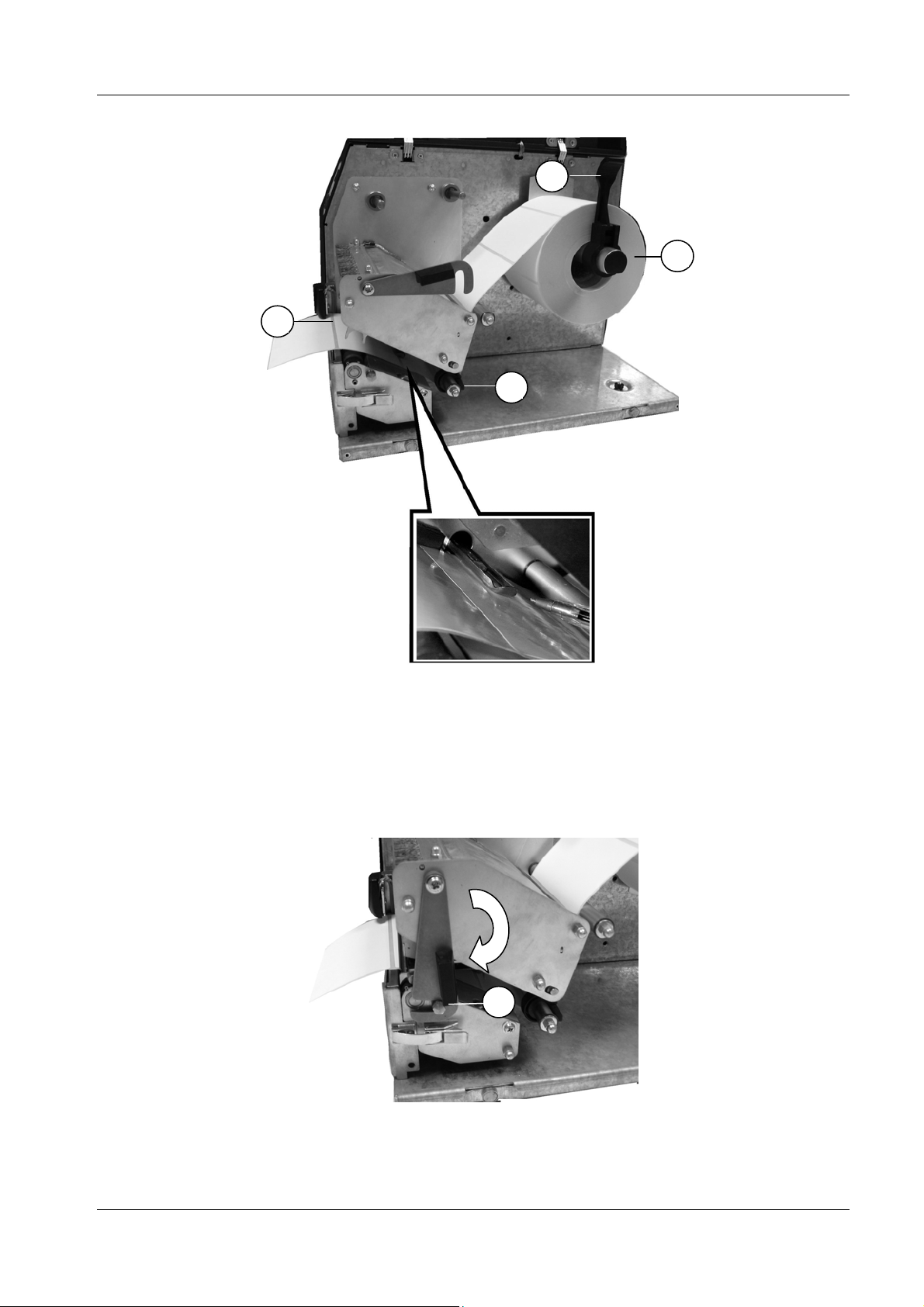

- Move the print head lock lever (11) to the closed position (13) (see Fig. 13).

11

Fig. 13 – Closing the print head assembly

21

Page 22

Compuprint 6314/6414 - User Manual

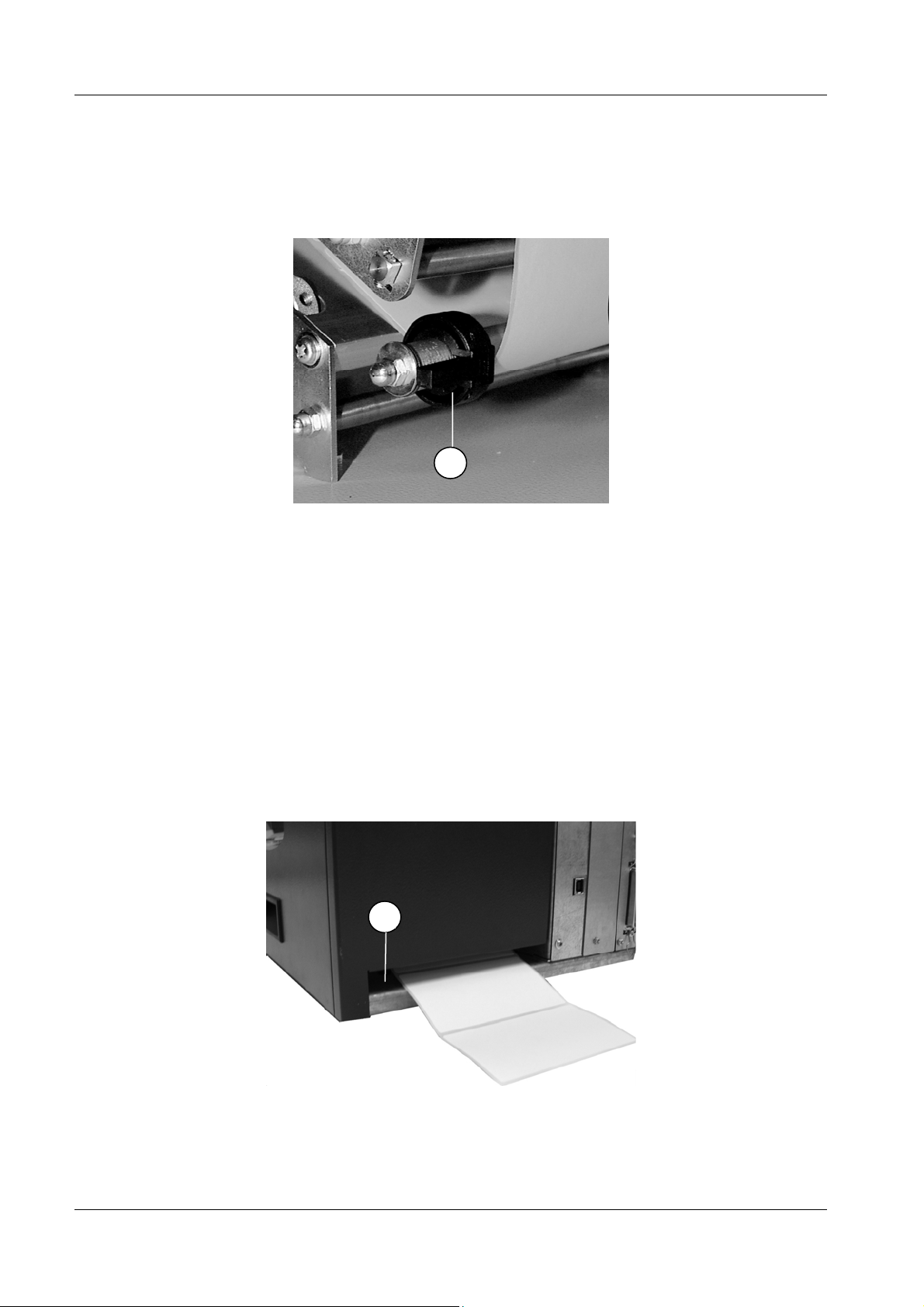

- Slide the paper guide (7) into the printer until it touches the edge of the labels without blocking

their movement, as shown in Fig. 14.

7

Fig. 14 – Detail of the paper guide

- Close the loading area.

-

2.2.2 Loading Labels From Outside The Printer

If the label roll does not meet specifications or if the labels are on a continuous form, they are

loaded from outside the 6314/6414 printer (if a continuous form is used, they are stacked), and their

free end is fed through the rear paper input slot (see Fig. 15).

5

22

Fig. 15 – Rear paper input slot

Page 23

Compuprint 6314/6414 - User Manual

For correct operation of the printer, perform the following steps after opening the label loading area

and studying the figure mounted inside the cover (see Fig. 10 on page 19):

- Move the print head lock lever (11) to the open position (14) (see Fig. 11 on page 20).

- Then insert the free end of the labels into the rear paper input slot (5). Pass it over the roll shaft,

over the first media roller, under the second one on which the paper guide (7) is mounted, and

then between the two sides of the paper sensor (see Fig. 12 on page 21), and finally under the

print head group and out of the label output (12).

- Move the print head lock lever (11) to the closed position (13).

- Slide the paper guide (7) into the printer until it touches the edge of the labels without blocking

their movement, as appears in Fig. 14 on page 22.

- Close the loading area and check that the paper passes unhindered through the rear paper input

(5).

2.2.3 Adjusting The Print Head Pressure

When labels less than 118 mm in width are used, the print head does not operate properly because

the right part of the print head, which is not covered by the labels, gets in direct contact with the

rubber roller and is thus subject to abrasion.

Therefore, the 6314/6414 printer is equipped with a numbered ratchet that can be used to adjust the

pressure of the print head on the right side (see Fig. 16).

Fig. 16 – The adjustment ratchet at position 0

The pressure decreases as the number on the ratchet increases, and therefore progressively narrower

labels require steadily higher numbers. The best adjustment position is the highest possible number

compatible with the print quality. The number 0 corresponds to labels with a width of 118 mm.

23

Page 24

Compuprint 6314/6414 - User Manual

2.2.4 Loading The Ribbon

When printing by thermal transfer, the ribbon must be loaded as follows, after opening the label

loading area and studying the figure on the inner side of the cover (see Fig. 10 on page 19):

- Move the print head lock lever (11) to the open position (14) (see Fig. 11 on page 20).

- Insert the ribbon roll in the new ribbon unwinder (2).

- Insert an empty cardboard core in the printed ribbon rewinder (1).

- Then feed the free end of the ribbon under the first and second media rollers, under the print

head, and then onto the cardboard core installed on the printed ribbon rewinder (1), taking care

not to block the paper sensor.

- Manually wind the free end of the ribbon onto the printed ribbon rewinder (1) and manually turn

it until the ribbon is taut and straight.

- Move the print head lock lever (11) to the closed position (13) as shown in Fig. 17.

1

11

- Close the loading area.

2

2

1

11

Fig. 17 – Loading of ribbon

24

Page 25

Compuprint 6314/6414 - User Manual

2.3 Printer Options

2.3.1 Tear-Off And Tear-Off Strip

Tear Off mode is where each label is printed and then positioned over the tear bar and waits for the

user to remove it before the next label is printed.

In Tear-Off Strip mode, labels are printed until the print buffer is empty and then the last label is

positioned over the tear bar for removal.

When using Tear-Off or Tear-Off Strip media handling, the user will need to tear the label

downward against the tear bar.

Fig. 18 – Front tear off plate

25

Page 26

Compuprint 6314/6414 - User Manual

2.3.2 Label Peel Off (Optional)

The printer can be set up to automatically peel labels off the backing liner and dispense them one at

a time while rewinding the liner. This configuration requires routing the liner through the rollers on

the Peel/Tear assembly and the use of the printer’s internal rewinder.

- Open the media cover.

- Remove the tear bar assembly.

- To install the label peel-off system, remove the two screws on the back of the tear bar assembly

and tear blade by rotating the tear off plate. Replace the cutting blade with the peel-off system.

Fig. 19 – Removing the cutting blade

- Thread the liner over the peel bar and then through the slot of the front plate just below the

platen roller and into the printer.

26

Page 27

Compuprint 6314/6414 - User Manual

Fig. 20 – Detail of the paper path in the peel-off system

- Manually position the leading edge of the first label to just behind the peel bar of the Peel/Tear

assembly.

- Thread the liner counterclockwise around the rewinder, and insert the liner end into one of the

slots in the rewinder.

- Rotate the rewinder release lever counterclockwise so it forms a ridge along the rewinder (rotate

the rewinder release lever clockwise to remove media.)

- With one hand holding the liner in the slot, rotate the rewinder counterclockwise until the liner is

taut on the rewinder spindle. Verify the leading edge of the first label is still behind the tear bar

of the Peel/Tear assembly.

- Close the print head.

27

Page 28

Compuprint 6314/6414 - User Manual

Fig. 21 – Installed peel-off system

- Close the media cover.

- Under the Set Printer Mode in the Enabling And Modes Menu, set the printer to Peel Off Mode.

2.3.3 Label Batch Rewind (Optional)

The label batch rewind option enables you to print media and have it wrap around the rewinder.

To do this, route the media around the front of the media guide, between the paper path guides, and

slide the media through the opening below the front plate of the printer.

Adjust the paper path guides on the media guide to the width of the media. Attach the labels to the

rewinder as described in Label Peel Off.

28

Page 29

Compuprint 6314/6414 - User Manual

Fig. 22 – Detail of the paper path in the rewinder guide

Under the Set Printer Mode in the Enabling And Modes Menu, set the printer to Rewinder Mode.

2.3.4 Installing The Cutter (Optional)

- Set the printer power switch to O (OFF).

- Remove the Peel/Tear Assembly, and replace it with the automatic cutter, taking care that the pin

and connector mounted on the side of the printer corresponds to the respective hole and

connector on the cutter itself.

Fig. 23 – The automatic cutter

29

Page 30

Compuprint 6314/6414 - User Manual

When powering the printer on, the automatic cutter is automatically enabled and opens for paper

insertion. If the cutter is removed, it is automatically disabled.

You can disable the cutter, while it is installed. In this case it simply does not cut.

The automatic cutter cuts after n labels, where n is the parameter CUT CYCLE in the Configuration

Menu under Printer Settings Menu.

2.3.5 Installing The NIC Board (Optional)

How to installing the NIC board (networking interface communication).

- Set the printer power switch to O (OFF).

- To remove the two screw and the optional board mask. Insert the NIC board and to block it by

the screw. Insert the LAN cable in the NIC board connector and power on the printer. The NIC

board is automatically enabled and available for use.

30

Fig. 24 - Installing NIC board

Page 31

Compuprint 6314/6414 - User Manual

2.4 Printing Adjustments

2.4.1 Label Variations And The TOF/Paper Out Sensor

Your printer is equipped with a sensor that is used to detect the TOF (Top-of-Form) position as well

as a paper out condition. Depending on the type of media used, the sensor will either “see through”

the label liner, index hole or notch in the media (Transmissive sensing) or detect a black horizontal

stripe on the media with reflective label backing (Reflective sensing).

In either case, the correct option must be selected under the Paper Sensor Mode of the Enabling

And Modes Menu of the Configuration Menu.

When Transmissive is selected, the TOF position is based on the trailing edge of the gap, notch, or

hole.

When Reflective is selected, the TOF position is based on the leading edge of the black stripe.

A third option, Continuous, is also available under the Paper Sensor Mode. The Continuous option

must be selected when continuous media with no gap, notch hole, or black stripe is installed. The

TOF will be based on the Max Label Length value set under the Maximum Label Length Selection

of the Printer Settings Menu of the Configuration Menu.

Length command is sent via host computer software.

NOTE!

When Gap Sense = Continuous, Calibrate should still be performed to automatically establish the optimum Paperout

Threshold value.

2.4.2 Media Sensor Horizontal Adjustment

In order to accurately detect the gap, hole, notch or narrow width black stripe, the Top-of-Form

sensor can be moved along the width of the media from the inner media edge to within 65 inches

from the maximum media width or the right side.

The position of the sensor is changed by using the knurled dial just behind the Print head Pressure

Adjustment ratchet to adjust the sensor to the desired position.

The actual location of the sensor is indicated by the Black Mark on the sensor finger when the print

head is in the open position.

31

Page 32

Compuprint 6314/6414 - User Manual

Fig. 25 – Paper sensor adjustment knob

Perform the TOF sensor Calibrate procedure described below whenever a different type of media

sensing will be required (Transmissive or Reflective), when installing never-before-tried media, or

when the printer is experiencing loss of TOF position. Loss of Top-of-Form is usually followed by

a fault message on the LCD, such as “PAPER FAULT” or “PAPER OUT”.

2.4.3 Running The Calibrate Via The Menu

Sequence Of Operations

The printer is equipped with a paper sensor which is necessary for perfect alignment of the paper

under the print head.

Sequence of operations necessary for a correct calibration:

- To select what the paper sensor must be calibrate (Transmissive / Reflective).

- Remove paper and Run No Paper Calibration.

- Insert paper

- To move the paper sensor, using the appropriate knob, in a label zone where there aren’t any

printed logos or bar code etc.

- Run Automatic Adjustment.

-

NOTE!

Run No Paper Calibration function is necessary only:

1) at the first time we install the printer.

2) when we update the firmware.

3) when the printer come back from the repair center.

See the chapter 3.9 (Diagnostic Menu) for details.

32

Page 33

Compuprint 6314/6414 - User Manual

Calibration

Calibration is enabled via the front panel by using the Enter key and navigating through the menu.

NOTE!

Verify that the media installed in the printer matches the Paper Sensor Mode option (Transmissive, Reflective, or

Continuous).

Verify that the Media sensor is horizontally positioned to permit sensing of the notch, gap, or black

stripe (see “Media Sensor Horizontal Adjustment” on page 31).

- Power On the printer.

- Press the Enter key once to take the printer Off Line.

- Press the Scroll and Esc keys simultaneously together to enter the “CONFIGURATION

MENU”.

- Press the Enter key once (FILE MENU).

- Press the Scroll key until “DIAGNOSTICS MENU” is displayed.

- Press the Enter key once.

- Press the Scroll key until “PAPER SENSOR MENU” is displayed.

- Press the Enter key (RUN AUTOMATIC ADJUSTMENT).

- Press the Scroll key until “RUN NO PAPER CALIBRATION” is displayed.

- Press the Enter key; the display will show “REMOVE PAPER….AND PRESS A KEY”

- Remove paper, press a key and wait. At the end of operation the display will show “RUN NO

PAPER CALIBRATION”.

- Insert the paper and press the Scroll key until “RUN AUTOMATIC ADJUSTMENT” is

displayed.

- Press the Enter key (the printer will display “RUNNING PAPER SENSOR ADJUST” and starts

to feed the paper until it detects the gap, notch, hole or Black Mark and then feeds 2 label

lengths).

- Wen the printer displays “ADJUSTMENT DONE” or “ADJUST FAILED”, press the Esc key

until “ON LINE” is displayed.

If calibration fails to determine the proper values and ends with a fault message displayed

“ADJUST FAILED”, you can either try it again or manually change the Gain and/or Threshold

values under the Diagnostic menu.

33

Page 34

Compuprint 6314/6414 - User Manual

Manual Adjustment

This function enables the printer to calibrate the paper sensor manually. This function is useful in

problematic cases (e.g. transparent labels).

Refer to chapter 3 paragraph 3.9.3 (Paper Sensor Control).

Once the correct values are determined and the Max Label Length setting in the Printer Settings

Menu is equal to or slightly less than the physical label length, press the Scroll key to advance

media and determine if it consistently stops at the correct TOF position each time.

2.5 Cleaning

Depending on the media used, the printer may accumulate residues (media dust, adhesives, etc.) as

a by-product of the normal printing process. To maintain top printing quality, these residues should

be removed by a periodic cleaning of the printer.

2.5.1 General

Periodic cleaning should be performed on all rollers, guides, and assemblies.

Low pressure air can be used to remove dust in the printer. Isopropyl alcohol and a cotton swab

should be used to clean any areas where media dust, adhesives, etc. have accumulated. This general

cleaning will insure that all parts are free of residue which may degrade print quality. The media

path and print head should be cleaned each time a new roll of media is installed in the printer.

2.5.2 Print Head

As you use your printer, the print head may become dirty resulting in poor print quality. You should

clean the print head when replacing the ribbon or installing new media. Clean the print head with

the print head Cleaning Pen supplied with the printer. The print head heating elements (light brown

area) is most important. Keeping your print head clean will help to maintain its life.

- Open the Media access door and slide the Ribbon to one side.

34

Page 35

Compuprint 6314/6414 - User Manual

Fig. 26 – Front of the printer with ribbon pushed to the side

- Gently rub a cotton swab with Isopropyl alcohol across the print head heating elements (light

brown area).

Fig. 27 – Front of the printer with the print head being cleaned

- Allow the print head to dry for one minute before reloading the labels.

35

Page 36

Compuprint 6314/6414 - User Manual

3 CONFIGURING THE PRINTER

3.1 Control Panel

The printer is equipped with a control panel (see Fig. 28) containing three function keys, three

LEDs, and an alphanumeric display (2 lines x 16 characters) for operating messages.

Fig. 28 – Control panel

36

Page 37

Compuprint 6314/6414 - User Manual

3.1.1 Function Keys And LEDs

The function of the keys and LEDs are indicated by the words printed next to them.

When the menu mode is enabled, the function of each key is indicated in the Table 1 below.

Function key Condition

Pressing this function key, the printer switches between the on line and off line condition.

When the printer is switched off line, it finishes the printout of current label and stops printing until it is brought

back on line.

Enter

Scroll

Esc

In menu mode, this key perform the enter function to confirm the current parameters or to pass on the next menu

level.

In power off condition, if you press this key and hold it while power on the printer, enters the printer communication

menu.

This key advances the label.

In menu mode, this key permits scrolling through the various headings of each menu or the numbers of numerical

parameters.

In off line mode, pressing this key and Esc key together, enters the printer configuration menu.

This key is used to cancel the current job and is always enabled. If it is pressed, the printer finishes the printout of

current label and cancels the remaining print job.

In menu mode, this key performs the esc function. Press it to exit from the menu item without saving the current

parameters or to return to the previous menu level.

In off line mode, pressing this key and Scroll key together, enters the printer configuration menu.

Table 1 – Function key functions

In addition to the three function key on the front panel of printer, there are three LEDs, which,

together with the display, indicate machine status as explained below in Table 2.

LED Condition

Lit: the printer is on line. In this condition, the printer is ready to receive and print information, the display shows the

ON LINE message.

Ready

Check

Power

Blinking: the printer is off line. In this condition, the printer stores the received data in its memory, and prints it out

when brought back on line. The message OFF LINE appears on the display.

Off: the printer is in the off line following a check function (in this case the Check LED flashes) or the printer is in

menu mode.

Off: normal operation condition.

Blinking: the printer is performing a check due to an error condition (e.g. out of paper). The printer goes off line, the

Ready LED turns off and the display shows a blinking error message (e.g. PAPER END).

Lit: normal operating condition.

Off: the printed is off or the power cable is not properly connected.

Table 2 – LED functions

37

Page 38

Compuprint 6314/6414 - User Manual

3.2 Configuring The Printer

3.2.1 Overview

The configuration process is carried out using the printer configuration keys on the control panel

and includes the following:

- Configuring the printer for different host interface options.

- Customizing label formats.

- Checking printer status.

- Running various maintenance tests.

NOTE!

Control codes sent by the host system will override the control panel settings.

38

Page 39

Fig. 29 shows the menu map.

(off line mode)

SCROLL + ESC

Compuprint 6314/6414 - User Manual

(power off mode)

ENTER + POWER ON

File

Menu

Load

Configuration

Save

Configuration

Print

Configuration

Print File

Contents

Factory

Reset

Delete Flash

Contents

Enabling and

Modes

Emulation

Selection

Set Printer

Mode

Paper Sensor

Mode

Print Method

Mode

Password

Selection

Power Up

Configuration

Closing

Head Action

Configuration

Menu

Printer

Settings

Vertical Offset

Adjustment

Backfeed

Adjustment

Form Length

Selection

Maximum Label

Length Selection

Maximum Label

Width Selection

Print Speed

Selection

Slew Speed

Selection

Backfeed Speed

Selection

Printhead Heat

Selection

Emulation

Parameters

Depending on

choice about

Emulation

Selection

menu

Diagnostic

Menu

Paper Sensor

Menu

Run Automatic

Pres. Sens. Cal.

Printhead Type

Detect

Counters

Menu

Communication

Parameters

Interface

Type

Serial

Interface

Nic

Interface

Factory

Reset

Cut Cycle

Selection

Paper Rewinder

Torque

Ribbon Rewinder

Torque

Horizontal Offset

Adjustment

Set Time

and Date

Override Print

Parameters

Fig. 29 – Menu Map

39

Page 40

Compuprint 6314/6414 - User Manual

3.2.2 Menu Navigation

This section explains how to use the control panel to change individual settings and save them as a

customized configuration. For details on the control panel keys and how they work, see “Function

Keys And LEDs” on page 37.

Pressing Scroll and Esc together enters the printer CONFIGURATION MENU (offline mode only)

and permits value selection.

Press Enter and hold it while Power On the printer. Enters the COMMUNICATION MENU and

permits value selection.

3.2.3 Setting Printer Configuration Parameters

Configuration parameters are set from the control panel or are retrieved from the printer’s memory.

The parameters define how the printer will respond to command and interface signals from the host

computer.

The configuration menu structure consists of top-level menus and various parameter selections

under each top-level menu.

IMPORTANT NOTES:

Many of the selectable configurations refer to printer options or features that may or may not

1)

be present in your printer. Selecting an option or feature that is not present will result in no

action being performed by the printer.

In many settings it is necessary to set some numbers. About this operation to use the following

2)

instructions:

- Use the Enter function key to move to the number you want to modify.

- Scroll through the numerals with the Scroll function key.

- Confirm with the Enter function key

For example: the display shows a number “0230 i” and we must change it in 1230. The

selected number or character blinks; press the Enter function key and the 0 numeral blinks;

press Scroll function key and the “1230” appears on the display; press the Enter function key

and the “2” numeral blinks; press the Enter function key and the numeral “3” blinks; press the

Enter function key and the “0” numeral blinks; press the Enter function key to confirm the

change; the previously selected menu appears on the display. During the operation don’t press

Esc function key otherwise the changes will be looses.

At the power on, the printer display shows ON LINE or OFF LINE at the first line and the

3)

series of 11 characters at the second line.

Each of this characters defines a characteristic of the printer:

- The first = the print density in dots per inch.

- The second = the maxim width of the print head (inch).

- The third and the fourth = the maximum print speed in inch per second.

- The fifth = the type of printer emulation.

- The sixth and the seventh = media type

- The eighth = the active interface

- The ninth, tenth and eleventh = the printhead temperature

up to the last cursor position.

40

Page 41

Compuprint 6314/6414 - User Manual

Example: 2410Z DT P 30º

2 = print density (2 DPI).

4 = print head width (4 inch).

10 = max. print speed (10 IPS).

Z = type of printer emulation (CZL emulation).

DT = direct thermal (also may be TT = thermal transfer).

P = the active interface is Parallel Port (also may be S = Serial, U = USB, L = LAN).

30º = current print head temperature (when the temperature exceeds 60ºC the character “>”

is show on the left of the temperature number …… eg. “>60º”)

3.2.4 Moving Within The Configuration Menu

Movement within the configuration menu is controlled by using the appropriate navigation keys.

Table 3 shows how to move through the menu system. See “Function Keys And LEDs” on page 37,

for more details on the function of the operator panel keys. This example configures the printer for

Direct Thermal operation.

Use these basic guidelines to move throughout all the configuration menus.

You can select different options and save them as the power on default.

To configure the printer, it must be offline. If the Ready indicator is lit, press and release the Enter

key to place the printer offline. When the printer is offline, OFFLINE appears on the top line of the

LCD. Pressing the Scroll & Esc keys together causes the printer to enter the printer configuration

menu system and Configuration Menu appears in the LCD.

Step Press LCD Notes

1 Enter OFFLINE

2 Scroll & Esc CONFIGURATION MENU

3 Enter FILE MENU

4 Scroll Until ENABLING AND MODES

5 Enter SET PRINTER MODE

6 Scroll Until PRINT METHOD SELECTION

7 Enter PRINT MODE DIRECT THERMAL*

Allows you to make configuration

changes.

Indicates that Direct Thermal print is

currently selected.

8 Scroll PRINT MODE THERMAL TRANSFER Cycles through the choices.

9 Enter PRINT MODE THERMAL TRANSFER*

10 Esc Until SAVE CHANGES?

11 Enter Saves Changes that you have made.

Table 3 – How to configure the printer to Direct Thermal operation

Indicates that Thermal Transfer print is

now selected.

41

Page 42

Compuprint 6314/6414 - User Manual

Changing printer settings, such as print speed or emulation, is referred to as configuration. You can

configure the printer through the control panel via the following menus:

- File Menu

- Enabling And Modes

- Printer Settings

- Emulation Parameters

- Diagnostics

Under each of the above menu headings are subsequent menus that allow you to configure

individual items such as print speed, label size and print mode.

CESTINA

SCROLL

CONFIGURATION

MENU

SCROLL

ENGLISH

LANGUAGE

ENTER

FILE

MENU

SCROLL

ENABLING

AND MODES

SCROLL

PRINTER

SETTINGS

SCROLL

EMULATION

PARAMETERS

SCROLL

DIAGNOSTICS

MENU

ENTER

ENTER

ENTER

ENTER

ENTER

LOAD

CONFIGURATION

SET PRINTER

MODE

VERTICAL OFFSET

ADJUSTEMENT

Depending on choice about

EMULATION SE LE CTION

menu

PAPER SENSOR

MENU

Fig. 30 – Structure of Configuration Menu

42

Page 43

Compuprint 6314/6414 - User Manual

3.3 File Menu

This menu contains all the commands for saving and/or loading the configuration in/from the nonvolatile memory of the printer.

CONFIGURATION

MENU

ENTER

FILE

MENU

SCROLL

ENTER

LOAD

CONFIGURATION

SCROLL

ENABLING AND

MODES

SAVE

CONFIGURATION

SCROLL

PRINT

CONFIGURATION

SCROLL

PRINT FILE

CONTENTS

SCROLL

FACTORY

RESET

SCROLL

DELETE FLASH

CONTENTS

ENTER

Fig. 31 – Structure of File Menu

DELETE FILES

ALL

SCROLL

DELETE FILES

INDIVIDUAL

ENTER

DELETE FILE

xxxxx

SCROLL

DELETE FILE

OTHER

LOAD CONFIGURATION

SAVE CONFIGURATION

PRINT CONFIGURATION

PRINT FILE CONTENTS

FACTORY RESET

DELETE FLASH CONTENTS

This item loads the last configuration saved, which becomes the

current one.

This item saves the current configuration in EEPROM nonvolatile memory.

This item prints the current configuration of the printer.

This item prints the current contents of the flash memory.

This item resets the printer to factory parameters, which become

the current ones and are automatically saved.

This item allows you to delete, all or individually, the files

presents in the flash contents that have previously been stored on

the printer, such as label designs, and fonts or graphics.

43

Page 44

Compuprint 6314/6414 - User Manual

3.3.1 Factory Reset Functions

The factory reset function influences the following parameters:

PARAMETERS DEFAUL VALUE

ENABLING AND MODES MENU

SET PRINTER MODE TEAR OFF MODE

PAPER SENSOR MODE TRANSMISSIVE

PRINT METHOD MODE DIRECT THERMAL

POWER UP STATUS ON LINE

POWER UP ACTION NONE

CLOSING HEAD ACTION NONE

PRINTER SETTINGS MENU

VERTICAL OFFSET ADJUSTMENT 0 i

BACKFEED ADJUSTMENT 0 i

FORM LENGTH SELECTION 394 i

MAXIMUM LABEL LENGTHSELECTION 3000 i

MAXIMUM LABEL WIDTH SELECTION 409 i

PRINT SPEED SELECTION 4 inch/sec

SLEW SPEED SELECTION 4 inch/sec

BACKFEED SPEED SELECTION 4 inch/sec

PRINTHEAD HEAT SELECTION 12

CUT CYCLE SELECTION 1

PAPER REWINDER TORQUE 4

RIBBON REWINDER TORQUE 4

HORIZ. OFFSET ADJUSTMENT 0 i

OVERRIDE HEAT PARAM DISABLED

OVERRIDE PRINT SPEED DISABLED

OVERRIDE SLEW SPEED DISABLED

OVERRIDE BACKFEED SPEED DISABLED

OVERRIDE OTHERS PARAM DISABLED

DATAMAX PARAMETERS

VERTICAL OFFSET 210 i

BACKFEED OFFSET 210 i

REFERENCE OFFSET 210 i

ROW OFFSET 0 i

COLUMN OFFSET 0 i

SELECT FINAL CHAR 0D

CONTROL CODES STANDARD CODES

ZEBRA PARAMETERS

SET FORMAT PREFIX 5E

SET CONTROL PREFIX 7E

RESOLUTION MODE NOMINAL RESOLUTION

44

Table 4 – Parameters influenced by factory reset function

Page 45

Compuprint 6314/6414 - User Manual

3.3.2 Others Parameters

The following parameters are automatically saved in NVM memory and are not influenced by the

factory reset function:

SELECT LANGUAGE

EMULATION SELECTION

PASSWORD SELECTION

LABEL LENGTH (in CZL emulation)

RESET USER COUNTER

45

Page 46

Compuprint 6314/6414 - User Manual

3.4 Enabling and Modes

This menu contains all the items necessary for activating the sensors and optional features,

including the operating modes of the printer itself. Its structure is illustrated in the following figure.

FILE

MENU

SCROLL

ENABLING

AND MODES

SCROLL

PRINTER

SETTINGS

ENTER

EMULATION SELECTION

SCROLL

SET

PRINTER MODE

SCROLL

PAPER SENSOR

MODE

SCROLL

PRINT MET HO D

MODE

SCROLL

PASSWORD

SELECTION

SCROLL

POWER UP

CONFIGURATION

SCROLL

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

EMULATION

CDL*

CZL

CPL

PRINTER MODE

TEAR OFF MODE*

CUTTING MODE

PEEL OFF MODE

REWINDER MODE

APPLICATOR MODE

SENSOR MODE

TRANSMISSIVE*

REFLECTIVE

CONTINUOUS

PRINT MODE

DIRECT THERMAL*

THERMAL TRANSFER

NEW PASSWORD

nnnn

POWER UP

STATUS

SCROLL

POWER UP

ACTION

SCROLL

SCROLL

SCROLL

SCROLL

ENTER

ENTER

POWER UP STATUS

ON LINE*

OFF LINE

POWER UP ACTION

NONE*

PAPER FEED

PAPER SENS CALIB

SCROLL

SCROLL

CLOSING HE AD ACT

CLOSING

HEAD ACTION

ENTER

NONE*

PAPER FEED

PAPER SENS CALIB

SCROLL

Fig. 32 – Structure of Enabling And Modes Menu

3.4.1 Emulation Selection

This function sets the emulation protocol of the printer. Press Enter function key to enter the

EMULATION SELECTION sub-menu. Press Scroll function key to scroll through the various items

of this function:

- CDL*

- CZL

- CPL

46

Page 47

Compuprint 6314/6414 - User Manual

3.4.2 Set Printer Mode

This function sets the operating modes of the printer. Press Enter function key to enter the

PRINTER MODE sub-menu. Press Scroll function key to scroll through the various items of this

function:

- TEAR OFF MODE*: this item tells the printer, that the tear-off bar is installed. The printed

labels will be torn off manually.

- CUTTING MODE: this item selects the label cut mode. It enables the optional. When the cutter

is installed, you should confirm that it has been enabled: if not, you must enable it, otherwise it

will not work. If the cutter has not been mounted but has been enabled, the machine will switch

to check; if it has been installed but not enabled, the cutter does not operate and the machine

prints without cutting.

- PEEL OFF MODE: this item selects the label peel-off mode. It enables the rewinder and the

present sensor.

- REWINDER MODE: this item enables the rewinder. The printed labels are thus rolled up.

- APPLICATOR MODE: this item provides the connection to an applicator. It enables the paper

rewinder and the present sensor (a special sensor mounted on the tear bar assembly/peel-off

system that detects the presence of a printed label).

3.4.3 Paper Sensor Mode

The printer is equipped with a paper sensor which is necessary for perfect alignment of the paper

under the head. This function enables this paper sensor and can operate in three different function

modes: in transmission mode, in reflection mode or in continuous mode.

Press Enter function key to enter the PAPER SENSOR MODE sub-menu. Press Scroll function key

to scroll through the various items of this function:

- TRANSMISSIVE*: this item enables the transmission mode and must be used when the labels

are marked off by a gap or a hole or more generally when there is an area with a net difference of

support transparency between one label and the other.

- REFLECTIVE: this item enables the reflection mode and must be used when the support is

completely opaque and there is a black tick mark on the back of the support itself.

- CONTINUOUS : this item disables the paper sensor and allows the printer to print a label of any

length.

3.4.4 Print Method Mode

Press Enter function key to enter the PRINT METHOD MODE sub-menu. Press Scroll function key

to scroll through the various items of this function:

- DIRECT THERMAL*: the direct thermal refers to printing directly on thermal paper. In this

case, the heat generated by the head alters the paper, which turns black in correspondence to the

printed characters without the need for any ribbon.

- THERMAL TRANSFER: the thermal transfer method is performed with a special ribbon, which

through the heat generated by the intelligent print head, applies the ink on the paper during

printing.

47

Page 48

Compuprint 6314/6414 - User Manual

3.4.5 Password Selection

This function allows the creation of a security password to prevent non authorized personnel to

change the printer configuration.

Press Enter function key to enter in the PASSWORD SELECTION sub-menu.

NEW PASSWORD nnnn: this item allows you to create a password using a string composed of 4

numerical characters (nnnn). Press Scroll function key to scroll the numbers to be used for the

numerical string and then confirm pressing the Enter function key.

Notes: - insert a string of four “0” character to cancel the password

- all changeable parameters of all menu are dependent on the password.

3.4.6 Power Up Configuration

With this function it is possible to set the printer state and an action that the printer performs

automatically after the power up.

Press the Enter key to select the submenu POWER UP STATE.

At this point, pressing the Scroll key, you pass over to the second submenu POWER UP ACTION.

Pressing the Enter key you select the values for the POWER UP STATE submenu.

Power Up State

This function allows the setting of the printer state after the initialization:

- ON LINE*: after initializing, the printer turns on line.

- OFF LINE: after initializing, the printer turns offline.

Power Up Action

With this function it is possible to select an action that the printer performs automatically,

when turning on the printer:

- NONE*: the printer does not perform any action.

- PAPER FEED: at power on the printer performs a paper feed.

- PAPER SENSOR CALIBRATION: at power on the printer calibrates the paper sensor.

3.4.7 Closing Head Action

With this function it is possible to set the printer state and an action that the printer performs

automatically after the closing head.

Press the Enter key to select the CLOSING HEAD ACT sub-menu.

Press Scroll function key to scroll through the various items of this function:

- NONE*: the printer does not perform any action.

- PAPER FEED: closing the head the printer performs a paper feed.

- PAPER SENSOR CALIBRATION: closing the head the printer calibrates the paper sensor.

48

Page 49

Compuprint 6314/6414 - User Manual

3.5 Printer Settings

The structure of this menu is illustrated in the following figure. The parameters in this menu

correspond to those printing parameters the printer uses as default, if it does not receive any other

value from software.

ENABLING AND

MODES

SCROLL

PRINTER

SETTING

SCROLL

PAPER SENSOR

MENU

Fig. 33 – Structure of Printer Settings Menu

ENTER

VERTICAL OFFSET

ADJUSTMENT

SCROLL

BACKFEED

ADJUSTMENT

SCROLL

FORM LENGTH

SELECTION

SCROLL

MAXIMUM LABEL

LENGTH SELECTION

SCROLL

MAXIMUM LABEL

WIDTH SELECTION

SCROLL

PRINT SPEED

SELECTION

SCROLL

SLEW SPEED

SELECTION

SCROLL

BACKFEED SPEED

SELECTION

SCROLL

PRINTHEAD HEAT

SELECTION

SCROLL

CUT CYCLE

SELECTION

SCROLL

PAPER REWINDER

TORQUE

SCROLL

RIBBON REWINDER

TORQUE

SCROLL

HORIZ. OFFSET

ADJUSTMENT

SCROLL

SET TIME

AND DATE

SCROLL

OVERRIDE PRINT

PARAMETERS

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER PRINT SPEED

ENTER

ENTER BACKFEED SPEED

ENTER PRINTHEAD HEAT

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

FINE OFFEST ADJ

+nn i*

+nn d

+nn m

BACKFEED ADJUST.

+nn i*

+nn d

+nn m

FORM LENGTH

nnnn i*

nnnn d

nnnn m

MAX LABEL LENGTH

nnnn i*

nnnn d

nnnn m

MAX LABEL WIDTH

nnn i*

nnn d

nnn m

4.0*

SLEW SPEED

4.0*

4.0*

12*

CUT CYCLE

nnnn

PAPER REW TORQUE

04*

RIBBON REW TORQ.

04*

HORIZONTAL OFFS

nnn i*

nnn d

nnn m

YEAR

MONTH

DATE

HOUR

MINUTE

OVERRIDE PARAM .

HEAD TEMP

PRINT SPEED

SLEW SPEED

OTHERS PARAM.

SCROLL

49

Page 50

Compuprint 6314/6414 - User Manual

3.5.1 Vertical Offset Adjustment

This function sets the label edge offset adjustment, setting a “mechanical” offset (both positive and

negative) for the paper scroll position under the print head. This can be useful when you replace a

previously installed printer or you need to center all text on a pre-printed label without altering the

software

Press Enter function key to enter in the FINE OFFSET ADJ sub-menu:

- nn i (d,m): select the unit of measurement between i (the values are indicated in hundredths of an

inch), m (the values are indicated in tenths of a millimeter) or d (the values are indicated in dots)

using the Scroll function key. After having chosen the unit of measurement, use the Enter

function key to move to the number you want to modify, scroll through the numerals with the

Scroll function key, and then confirm with the Enter function key up to the last cursor

position, when the menu item appears.

3.5.2 Backfeed Adjustment

This function sets the backfeed adjustment.

Press Enter function key to enter in the BACKFEED ADJUSTM sub-menu:

- nn i (d,m): select the unit of measurement between i the values are indicated in hundredths of an

inch), m (the values are indicated in tenths of a millimeter ) or d (the values are indicated in dots)

using the Scroll function key. After having chosen the unit of measurement, use the Enter

function key to move to the number you want to modify, scroll through the numerals with the

Scroll function key, and then confirm with the Enter function key up to the last cursor

position, when the menu item appears.

3.5.3 Form Length Selection

This function sets the label length. The printer can print on labels that are separated by a reference

(gap, black mark or a hole) and on a continuous form. In this case you must inform the printer of the

length of the label to be printed (in dots, millimeters or inches).

Press Enter function key to enter in the FORM LENGTH sub-menu:

- nnnn i (d,m): select the unit of measurement between i (the values are indicated in hundredths of

an inch), m (the values are indicated in tenths of a millimeter) or d (the values are indicated in

dots) using the Scroll function key. After having chosen the unit of measurement, use the Enter

function key to move to the number you want to modify, scroll through the numerals with the

Scroll function key, and then confirm with the Enter function key up to the last cursor

position, when the menu item appears. If you select 0000, you can use labels marked off by a

gap or a hole as length reference.

50

Page 51

Compuprint 6314/6414 - User Manual

3.5.4 Maximum Label Length Selection

This function sets the maximum length of the label.

Press Enter function key to enter in the MAX LABEL LENGTH sub-menu:

- nnnn i (d,m): select the unit of measurement between i (the values are indicated in hundredths of

an inch), m (the values are indicated in tenths of a millimeter) or d (the values are indicated in

dots) using the Scroll function key. After having chosen the unit of measurement, use the Enter

function key to move to the number you want to modify, scroll through the numerals with the

Scroll function key, and then confirm with the Enter function key up to the last cursor

position, when the menu item appears.

3.5.5 Maximum Label Width Selection

This function sets the maximum width of the label.

Press Enter function key to enter in the MAX LABEL WIDTH sub-menu:

- nnn i (d,m): select the unit of measurement between i (the values are indicated in hundredths of

an inch), m (the values are indicated in tenths of a millimeter) or d (the values are indicated in

dots) using the Scroll function key. After having chosen the unit of measurement, use the Enter

function key to move to the number you want to modify, scroll through the numerals with the

Scroll function key, and then confirm with the Enter function key up to the last cursor

position, when the menu item appears.

3.5.6 Print Speed Selection

This function sets the print speed.

Press Enter function key to enter in the PRINT SPEED sub-menu:

- nn: scroll through the numerals with the Scroll function key, and then confirm with the Enter

function key up to the last cursor position, when the menu item appears. The print speed is

indicated in inches per second (ips). The values range between 2 and 10, in steps of 0.5 ips

(depending on the model that you have).

3.5.7 Slew Speed Selection

This function sets the slew speed.

Press Enter function key to enter in the SLEW SPEED sub-menu:

- nn: scroll through the numerals with the Scroll function key, and then confirm with the Enter

function key up to the last cursor position, when the menu item appears. The slew speed is

indicated in inches per second (ips). The value range is between 2 and 10 in steps of 0.5 ips

(Depending on the model that you have).

51

Page 52

Compuprint 6314/6414 - User Manual

3.5.8 Backfeed Speed Selection

This function sets the backfeed speed.

Press Enter function key to enter in the BACKFEED SPEED sub-menu:

- nn: scroll through the numerals with the Scroll function key, and then confirm with the Enter

function key up to the last cursor position, when the menu item appears. The backfeed speed is

indicated in inches per second (ips). The value range is between 2 and 10 in steps of 0.5 ips

(Depending on the model that you have).

3.5.9 Print Head Heat Selection

This function selects the temperature of the print head that directly affects print quality. The optimal

temperature depends on the type of ribbon and support used.

Press Enter function key to enter in the PRINTHEAD HEAT sub-menu:

- nn: the temperature can be adjusted with this parameter and with the Hnn software commands (a

description of which is found in the Programmer Manual of the current emulation). Scroll

through the numerals with the Scroll function key, and then confirm with the Enter function key

up to the last cursor position, when the menu item appears. The value range is between 01 and 20