Page 1

MAN10xxx-01

User Manual

Page 2

Page 3

User Manual 6214

CONTENTS

Page

1 Barcode Printer 1

1.1

1.2

2 Printer Setup 6

2.1

2.2

2.3

2.4

2.5

3 Printer Setting and Control 19

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

4 Accessories 39

4.1

4.2

4.3

5 Maintenance and Adjustment 51

5.1

5.2

Appendix 53

Product Specifications

Box Content

Getting to Know Your Printer

Open the Printer

Loading the Ribbon

Loading the Label Roll Module

Connecting the Printer to the Host Computer

Installing Printer Driver directly from CD folder

Operation Panel

LCD Interface Introduction

LAN Setting

LCD Password

LCD Interface Function

Label Calibration and Self Test

Error Alerts

USB Port

Preparation Steps

Installing the Label Dispenser

Installing the Cutter

Cleaning the Print Head

Troubleshooting

Interface

File handling using USB stick

Bluetooth Module

1

2

6

7

12

14

16

19

20

25

27

29

33

35

37

39

41

47

51

52

53

55

56

57

MAN10xxx-01 i

Page 4

User Manual 6214

FCC COMPLIANCE STATEMENT FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a CLASS A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at own

expense.

EMS AND EMI COMPLIANCE STATEMENT FOR EUROPEAN

USERS

This equipment has been tested and passed with the requirements relating to electromagnetic compatibility

based on the standards EN 55022:1998+A1:2000+A2:2003, CISPR 22, Class A EN

55024:1998+A1:2001+A2:2003, IEC 61000- 4 Series EN 61000-3-2 / 2000 & EN 61000-3-3 / 1995. The

equipment also tested and passed in accordance with the European Standard EN55022 for the both

Radiated and Conducted emissions limits.

6214 Thermal Label Printer

TO WHICH THIS DECLARATION RELATES

IS IN CONFORMITY WITH THE FOLLOWING STANDARDS

EN55022 : 1998, CLSPR 22, Class A / EN55024 : 1998 / IEC 61000-4 Serial / EN61000-3-2 : 2000 / EN

6100-3-3 : 1995 / CFR 47, Part 15/CISPR 22 3rd Edition : 1997, Class A / ANSI C63.4 : 2001 / CNS 13438 /

IEC60950-1 : 2005 (EN 60950-1 : 2006+A11 : 2009) / GB4943 : 2001 / GB9254 : 1998 / GB17625.1 : 2003 /

EN60950-1 : 2001

Caution

Danger of explosion if battery is incorrectly replaced. Replace only with the equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Only use with designated power supply adapter model.

Changes or modifications not expressly approved by the party responsible for compliance could void

the user's authority to operate the equipment.

MAN10xxx-01 ii

Page 5

User Manual 6214

SAFETY INSTRUCTIONS

Please read the following instructions carefully.

1. Keep the equipment away from humidity.

2. Before you connect the equipment to the power outlet, please check the voltage of the power

source.

3. Make sure the printer is off before plugging the power connector into the power jack.

4. It is recommended that you connect the printer to a surge protector to prevent possible transient

overvoltage damage.

5. Be careful not to get liquid on the equipment to avoid electrical shock.

6. For safety and warranty reasons, ONLY qualified service personnel should open the equipment.

7. Do not repair or adjust energized equipment under any circumstances.

MAN10xxx-01 iii

Page 6

User Manual 6214

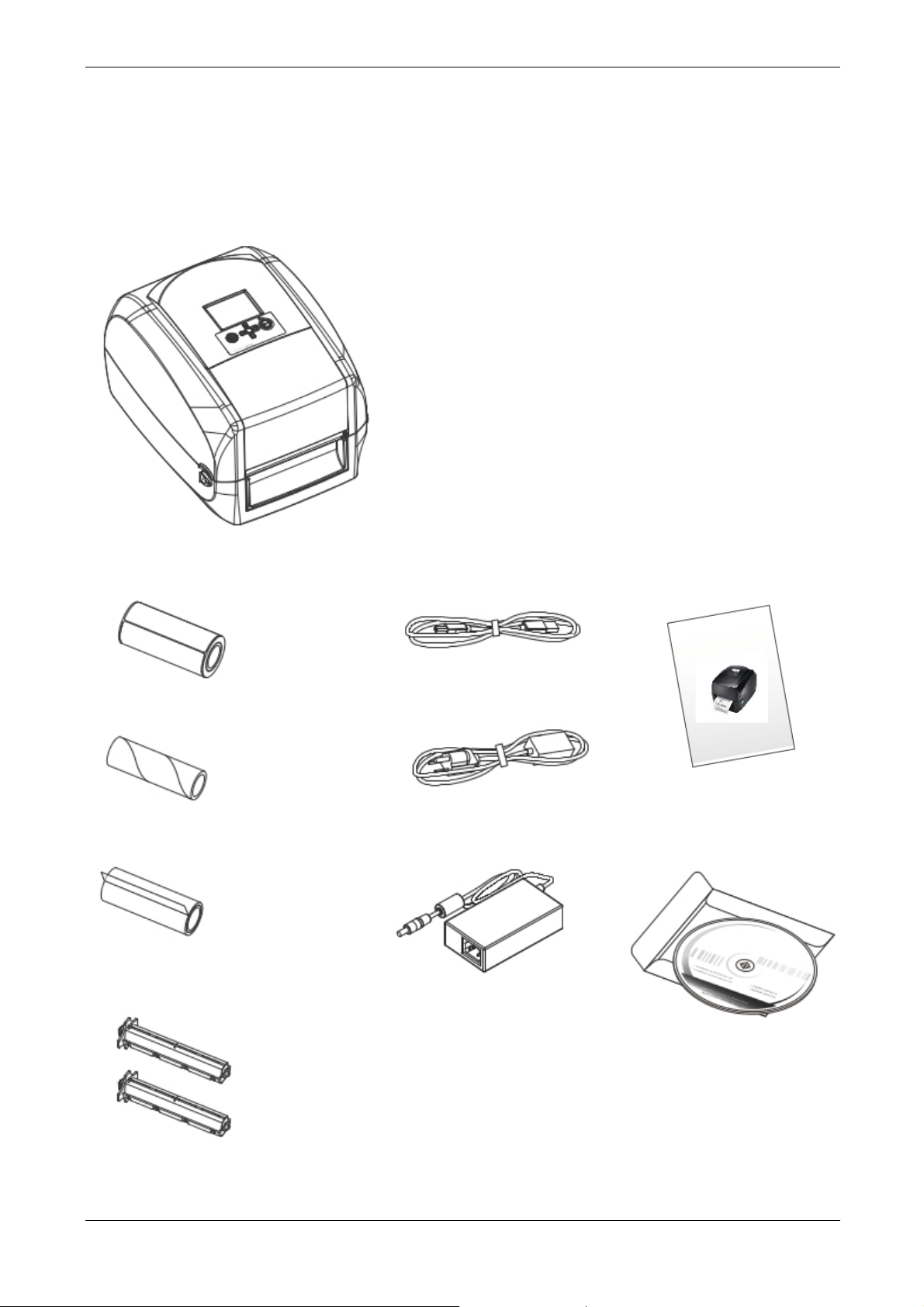

1 Barcode Printer

1.1 Box Content

Please check that all of the following items are included with your printer:

Compuprint 6214 Barcode Printer

Label Stock USB Cable Compuprint 6214 Quick

Guide

Ribbon Module Empty Ribbon

Core

Power Adapter & Power

Cord

Ribbon AC Adapter CD

Including QLabel software and

Compuprint 6214 user manual

Ribbon Hubs Set of 2

MAN10xxx-01 1

Page 7

User Manual 6214

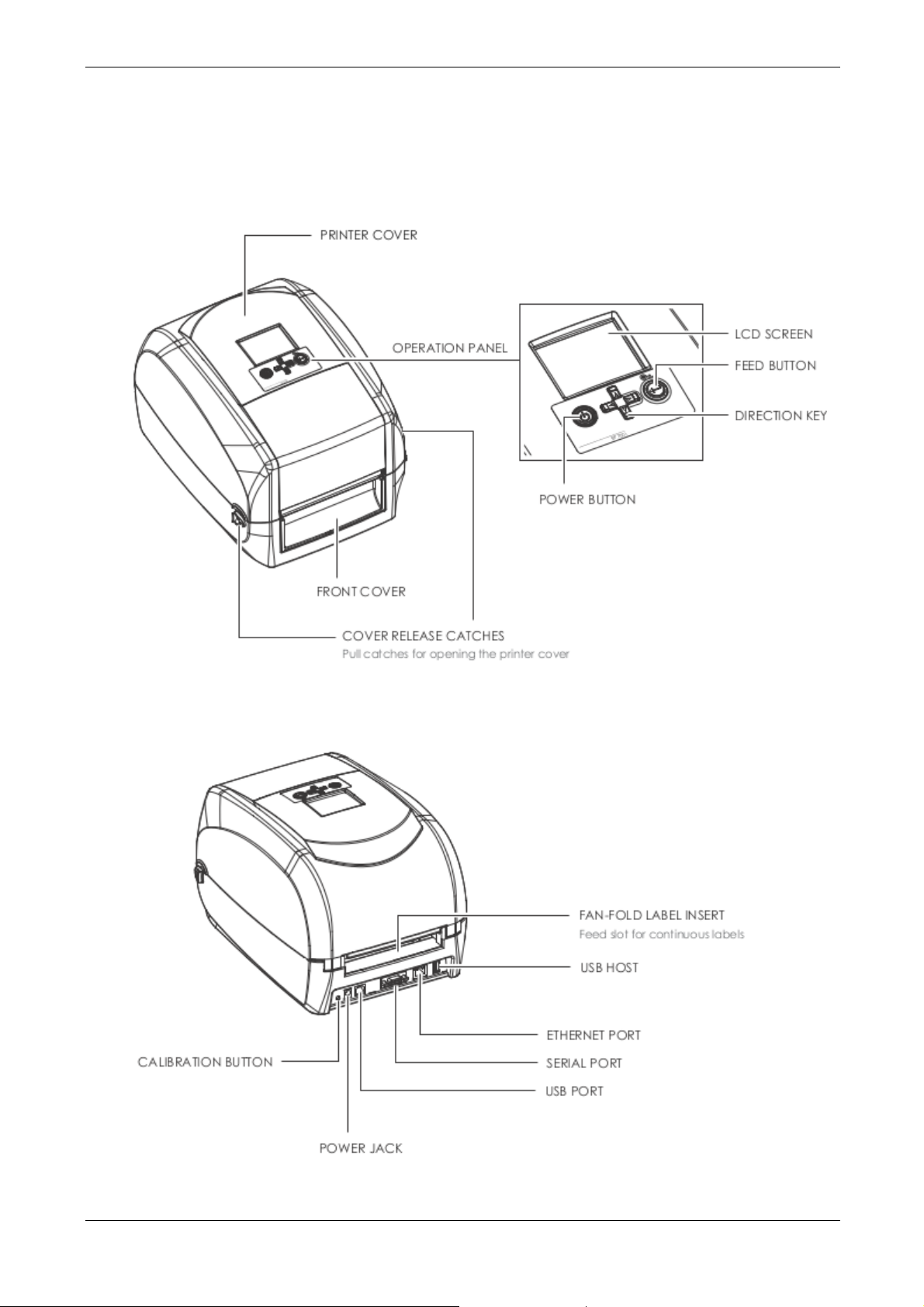

1.2 Getting To Know Your Printer

Device Overview

Front View

Rear View

MAN10xxx-01 2

Page 8

User Manual 6214

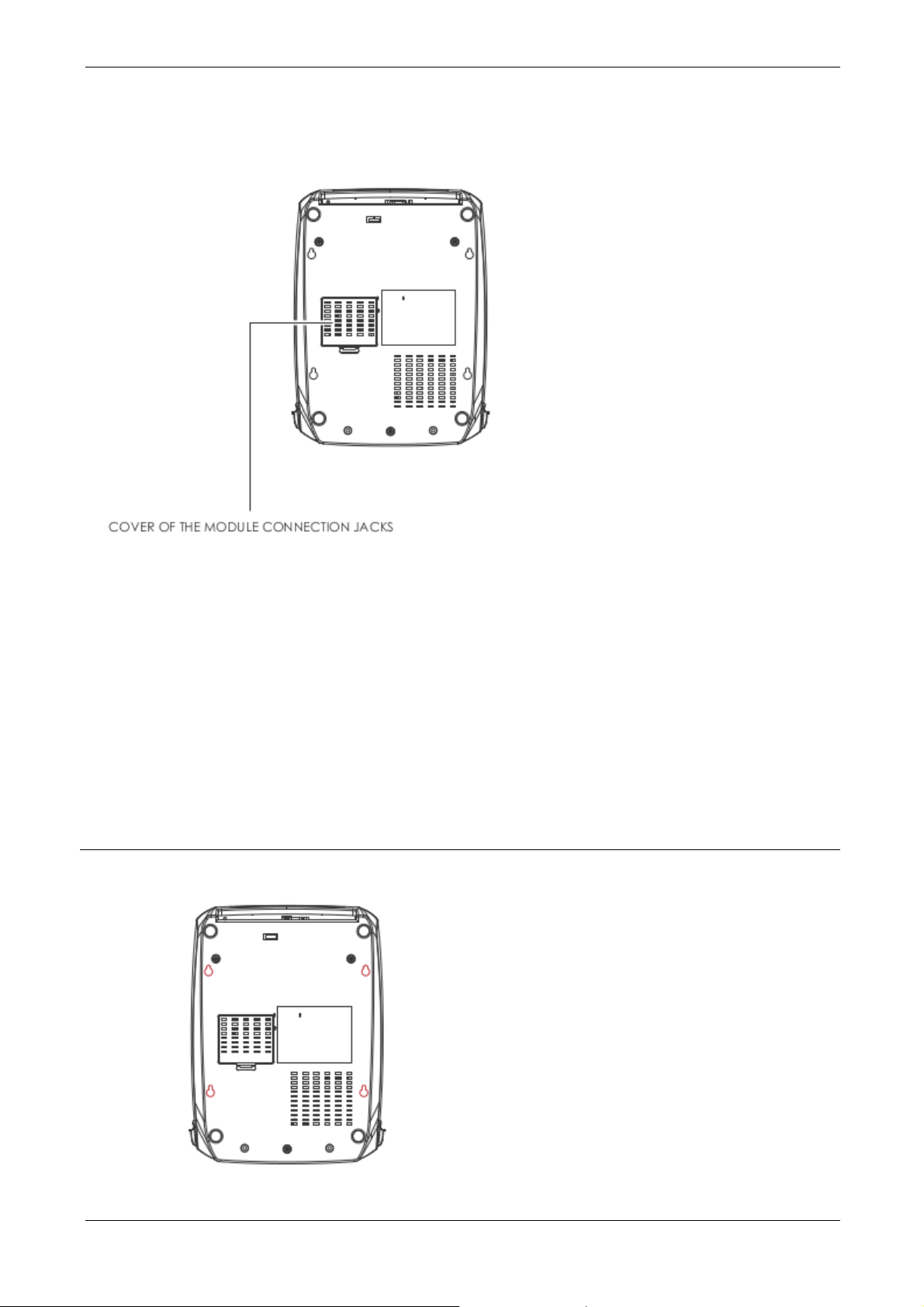

Bottom View

Notice

**** Cut-outs are not intended for wall-mount use.

.

MAN10xxx-01 3

Page 9

User Manual 6214

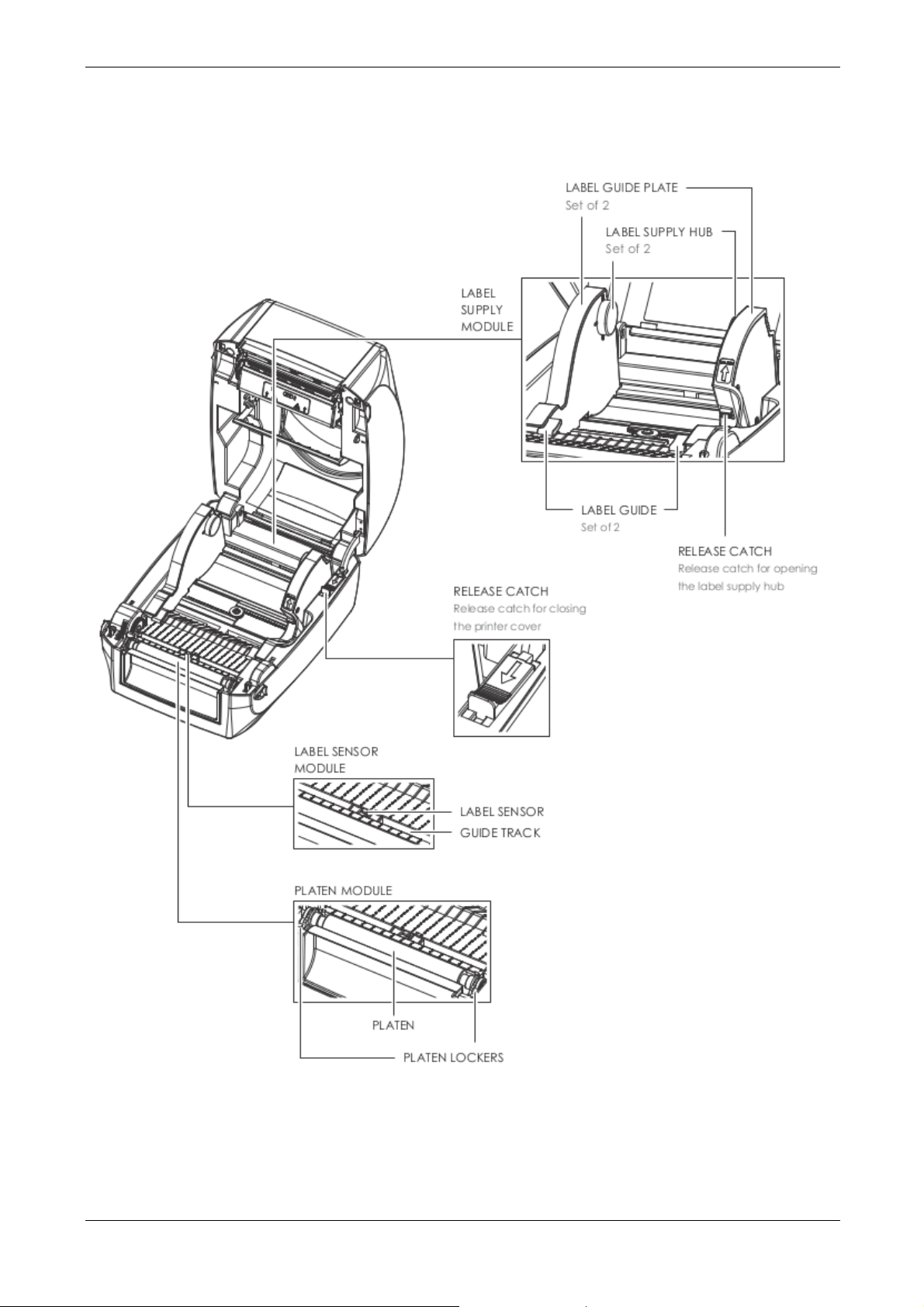

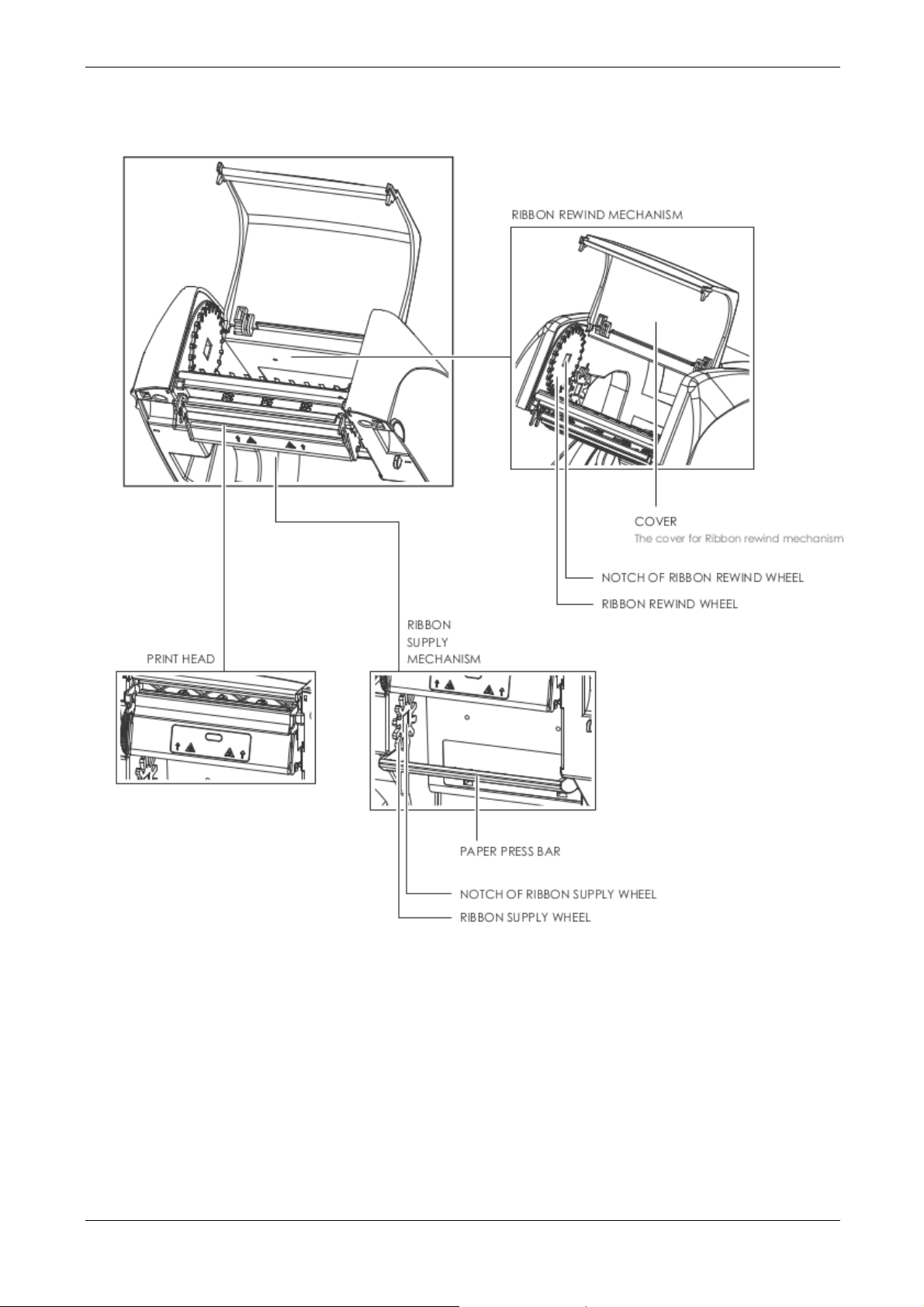

The Internal View of Printer

MAN10xxx-01 4

Page 10

User Manual 6214

The Printing Mechanism

MAN10xxx-01 5

Page 11

User Manual 6214

2 Printer Setup

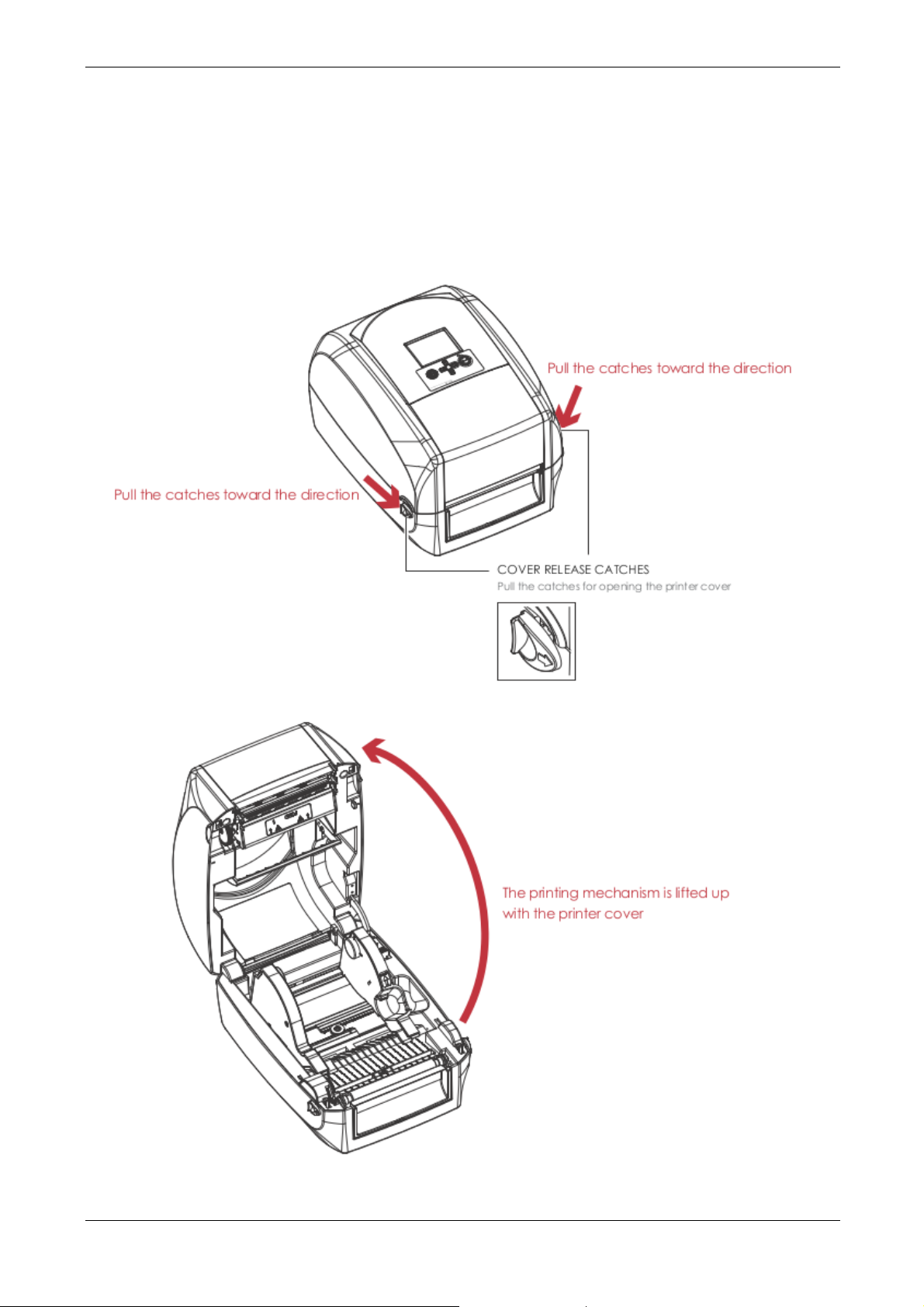

2.1 Open the Printer

Open the Printer Cover and the Printing Mechanism

Place the printer on a flat surface. Open the printer cover by pulling the release catches on both sides of the

printer and lift the printer cover.

MAN10xxx-01 6

Page 12

User Manual 6214

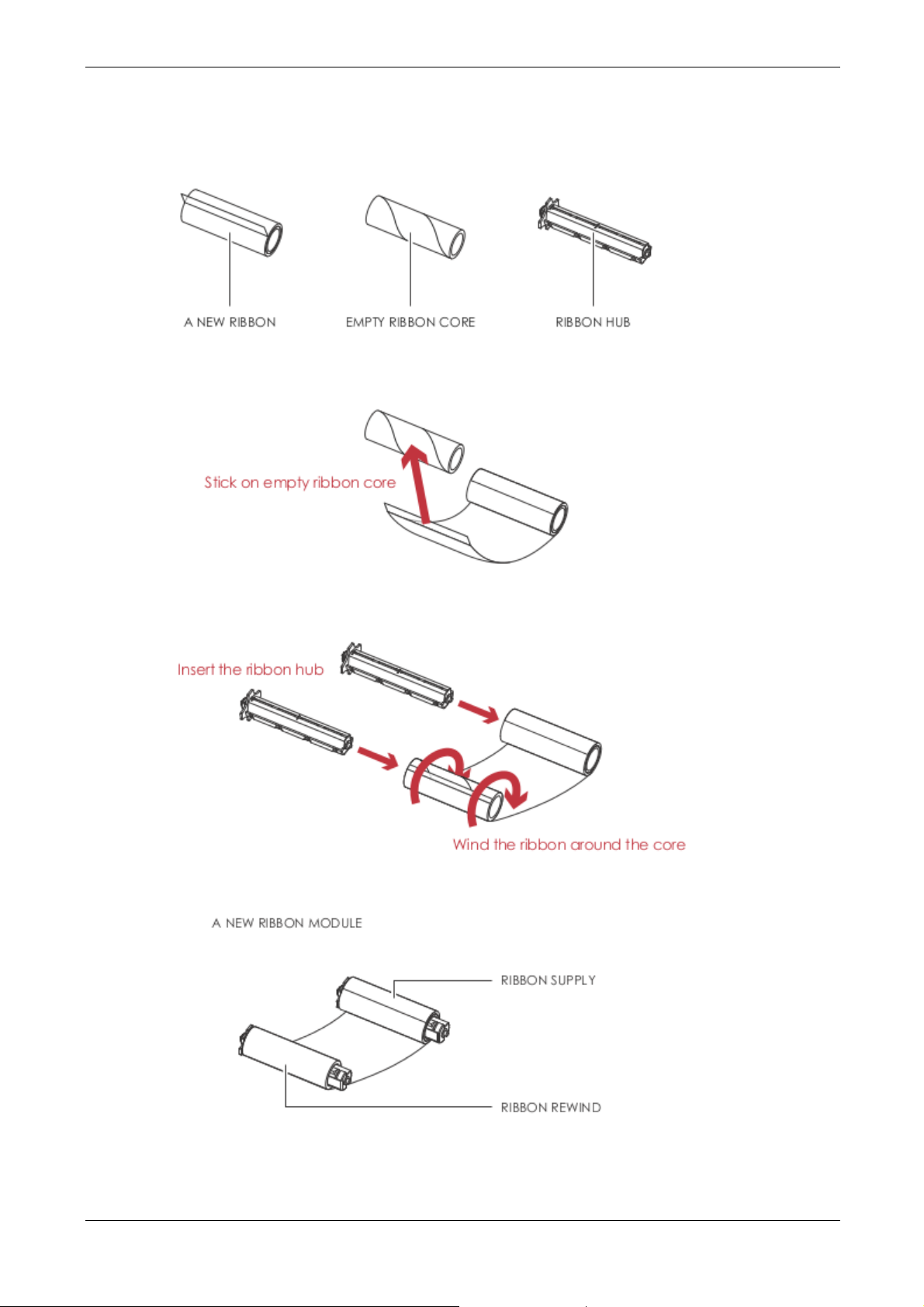

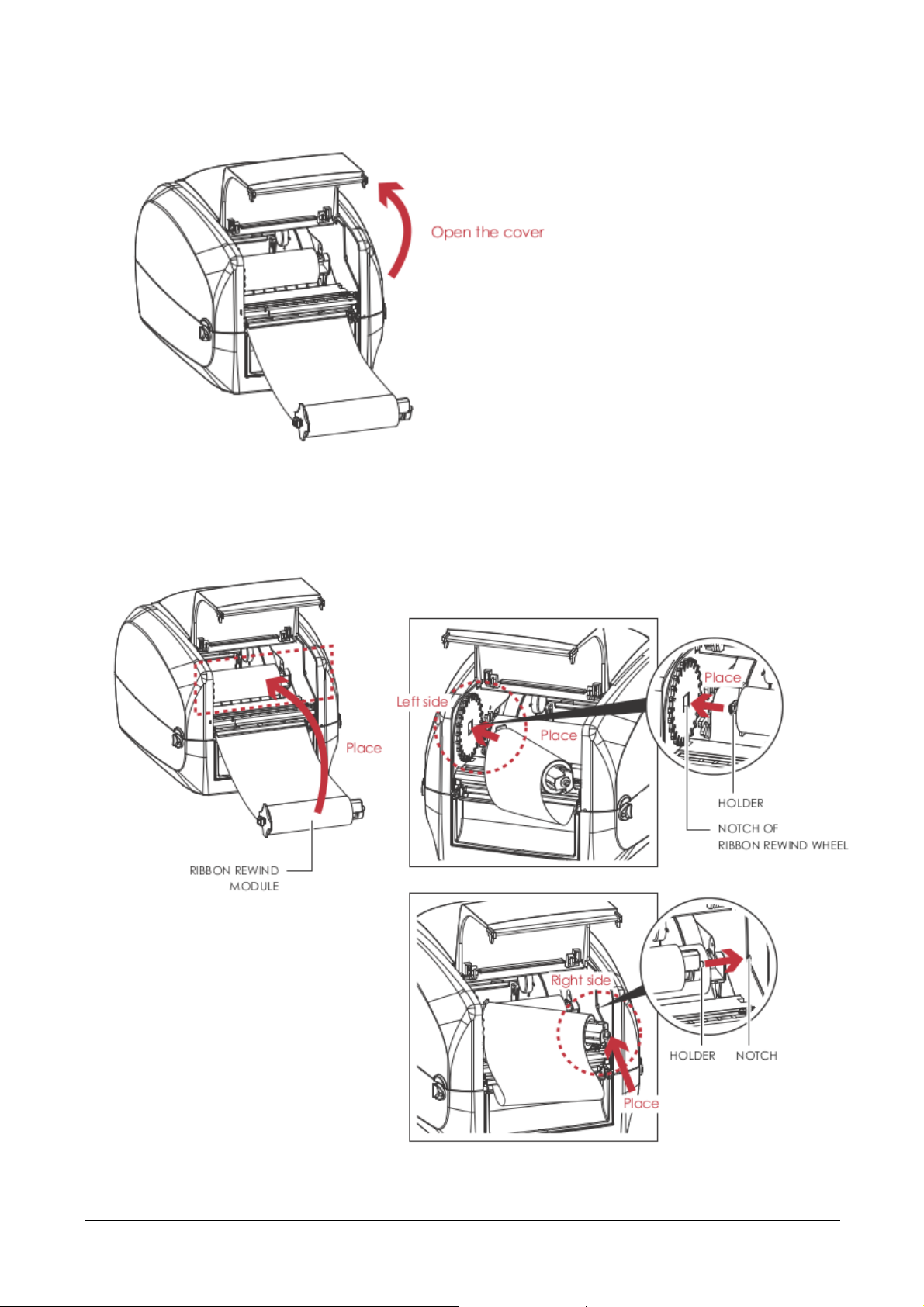

2.2 Loading the Ribbon

A New Ribbon Module Installation

1. Attach the ribbon to the empty ribbon core with the adhesive strip at the end of the ribbon.

2. Insert the ribbon hub into empty ribbon core and new ribbon. Wind the ribbon around the empty ribbon

core for 2 to 3 circles.

3. A ribbon module is assembled as below.

MAN10xxx-01 7

Page 13

User Manual 6214

Load the Ribbon on the Printer For Ribbon Supply Module

1. Place the ribbon supply module into the printing mechanism. Please the left-hand side of ribbon hub first.

Make sure the holder of ribbon hub is inserted into the notch. Then place the right-hand side of ribbon hub.

MAN10xxx-01 8

Page 14

User Manual 6214

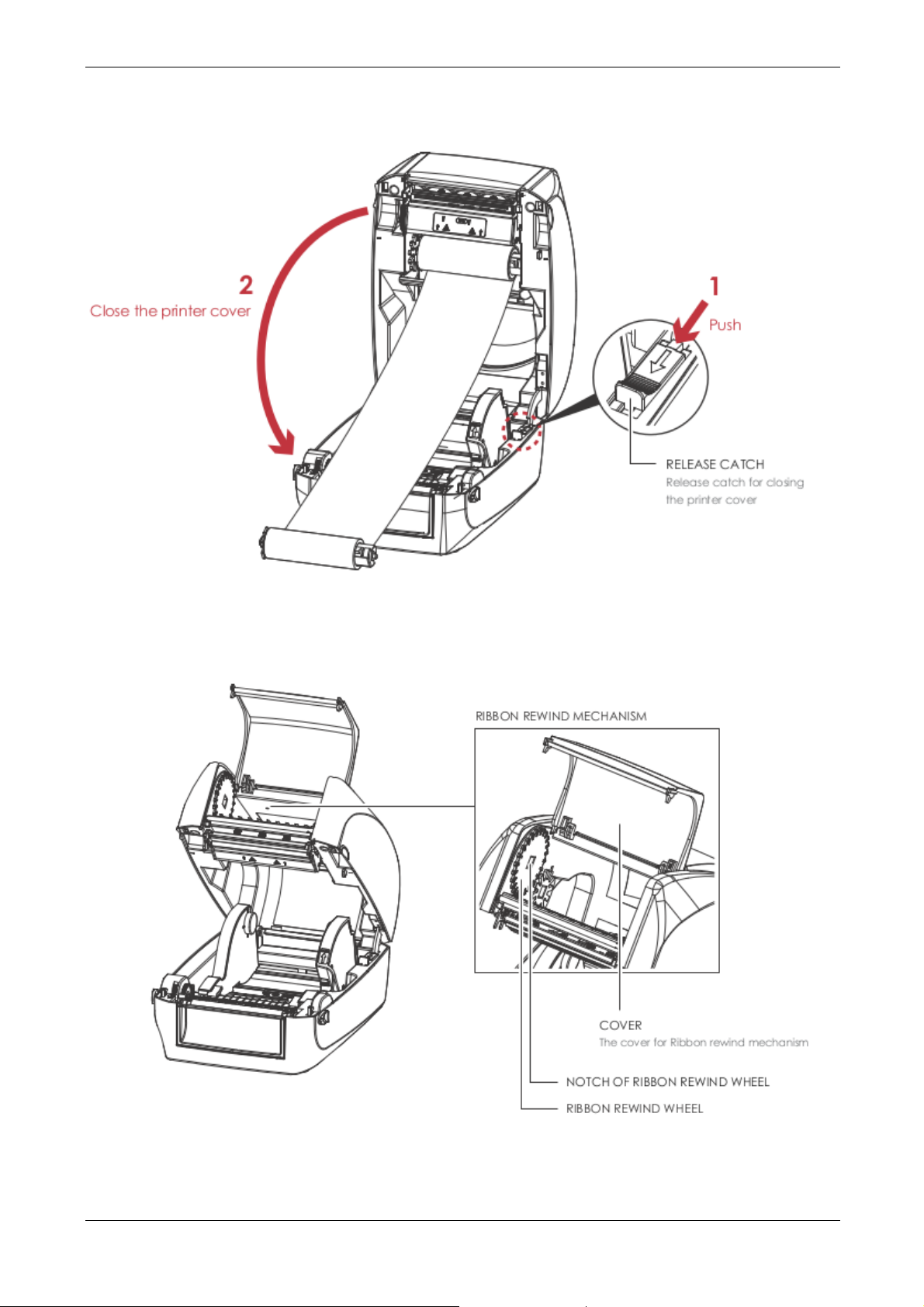

2. Unlock the release catch to close the printer cover. Push the release catch forward to unlock it.

The ribbon supply module loading is completed.

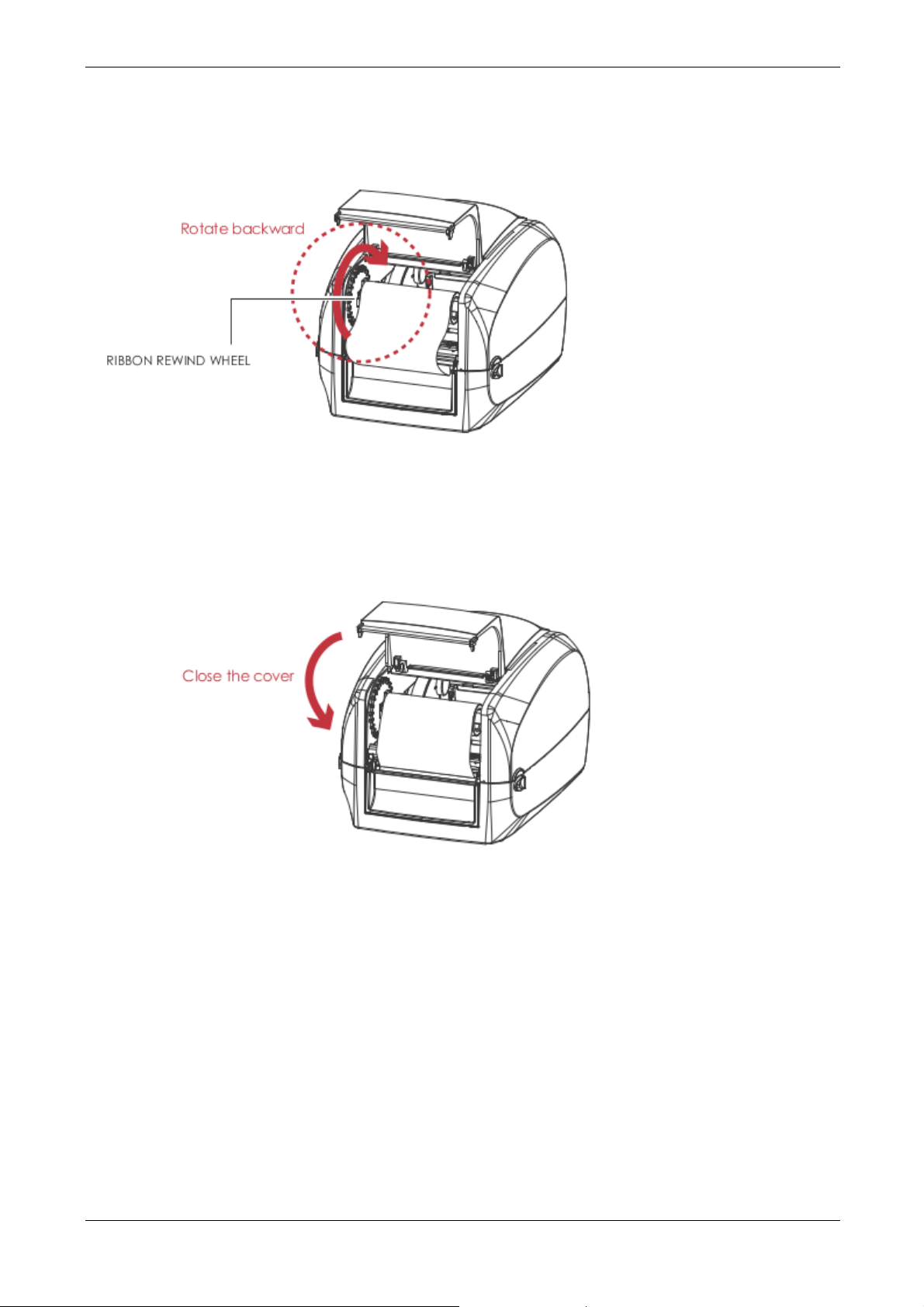

Load the Ribbon on the Printer For Ribbon Rewind Module

MAN10xxx-01 9

Page 15

User Manual 6214

1. Open the cover of ribbon rewind mechanism.

2. Place the ribbon rewind module into the ribbon rewind mechanism.

Please the left-hand side of ribbon hub first. Make sure the holder of ribbon hub is inserted into the notch.

Then place the right-hand side of ribbon hub.

MAN10xxx-01 10

Page 16

User Manual 6214

3. Turn the ribbon rewind wheel to tighten the ribbon until it has no wrinkles.

4. Close the cover of ribbon rewind mechanism.

The ribbon loading is completed once the ribbon supply module and ribbon rewind module are assembled

correctly.

MAN10xxx-01 11

Page 17

User Manual 6214

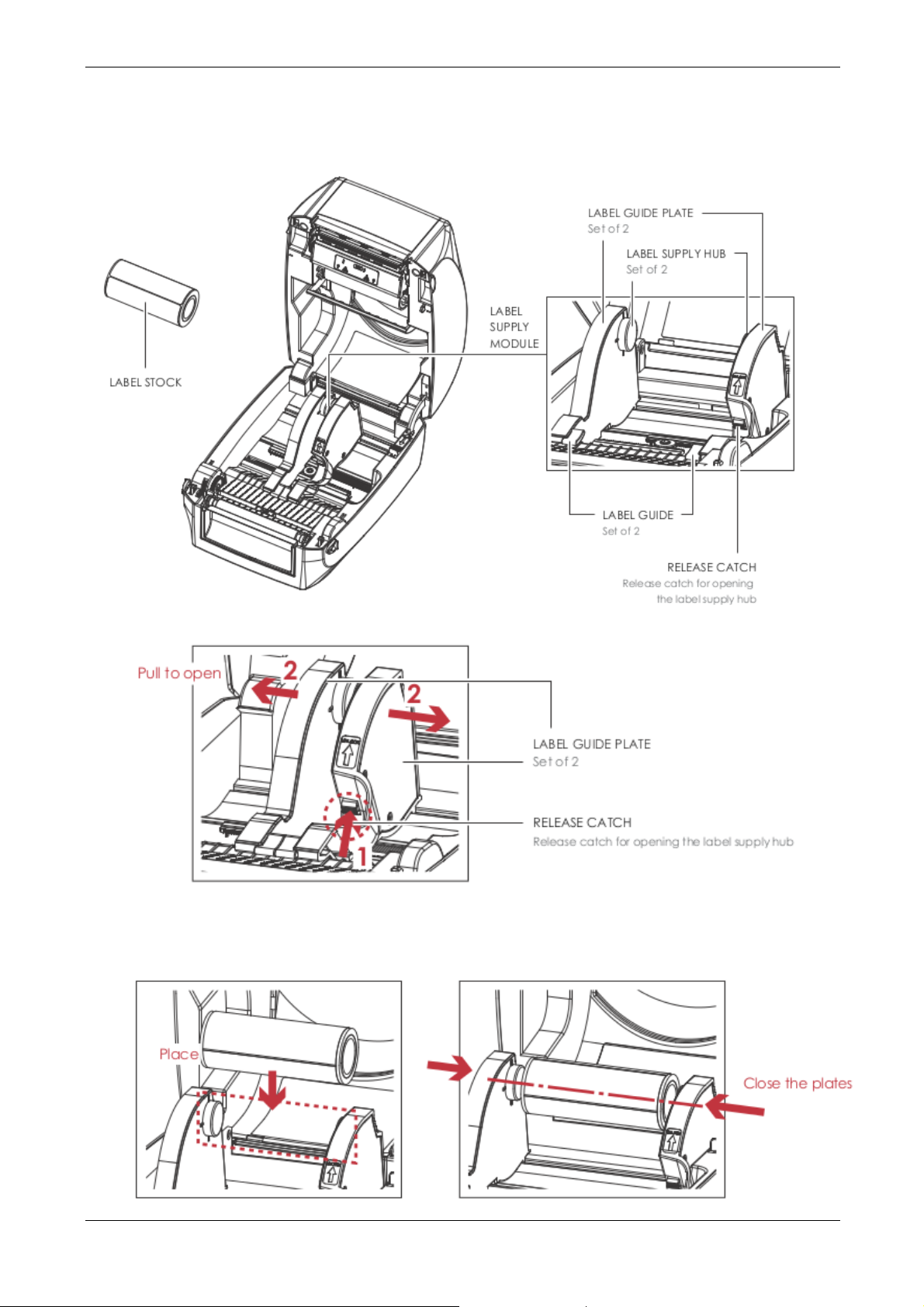

2.3 Loading the Label Roll Module

Load the Label Stock on the Printer

1. Unlock the ribbon catch and pull to open the label guide plate.

2. Place the label stock on label supply hubs.

Make sure the label stock is aligned to both hubs.

Adjust the label guide plates to fix the label width.

Remember to push the release catch when moving the label guide plates.

MAN10xxx-01 12

Page 18

User Manual 6214

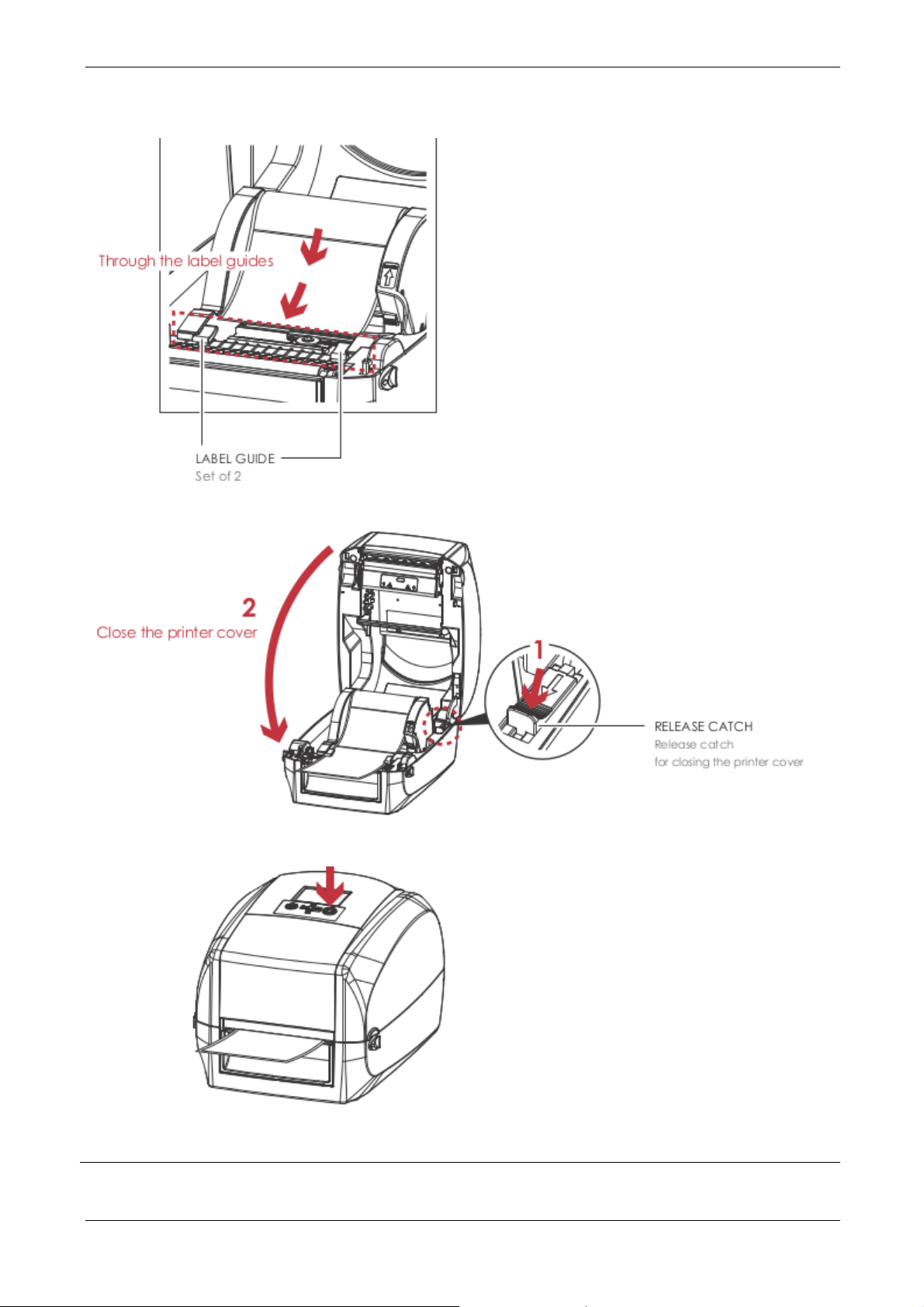

3. Feed the Label through the label guides. The label guides will help to prevent the label swaying.

4. Unlock the release catch to close the printer cover.

5. Press the FEED key and make sure the label is fed smoothly. The label loading is completed now.

Notice

* Please keeps the rack gear clean to ensure the smoothness of label holder.

MAN10xxx-01 13

Page 19

User Manual 6214

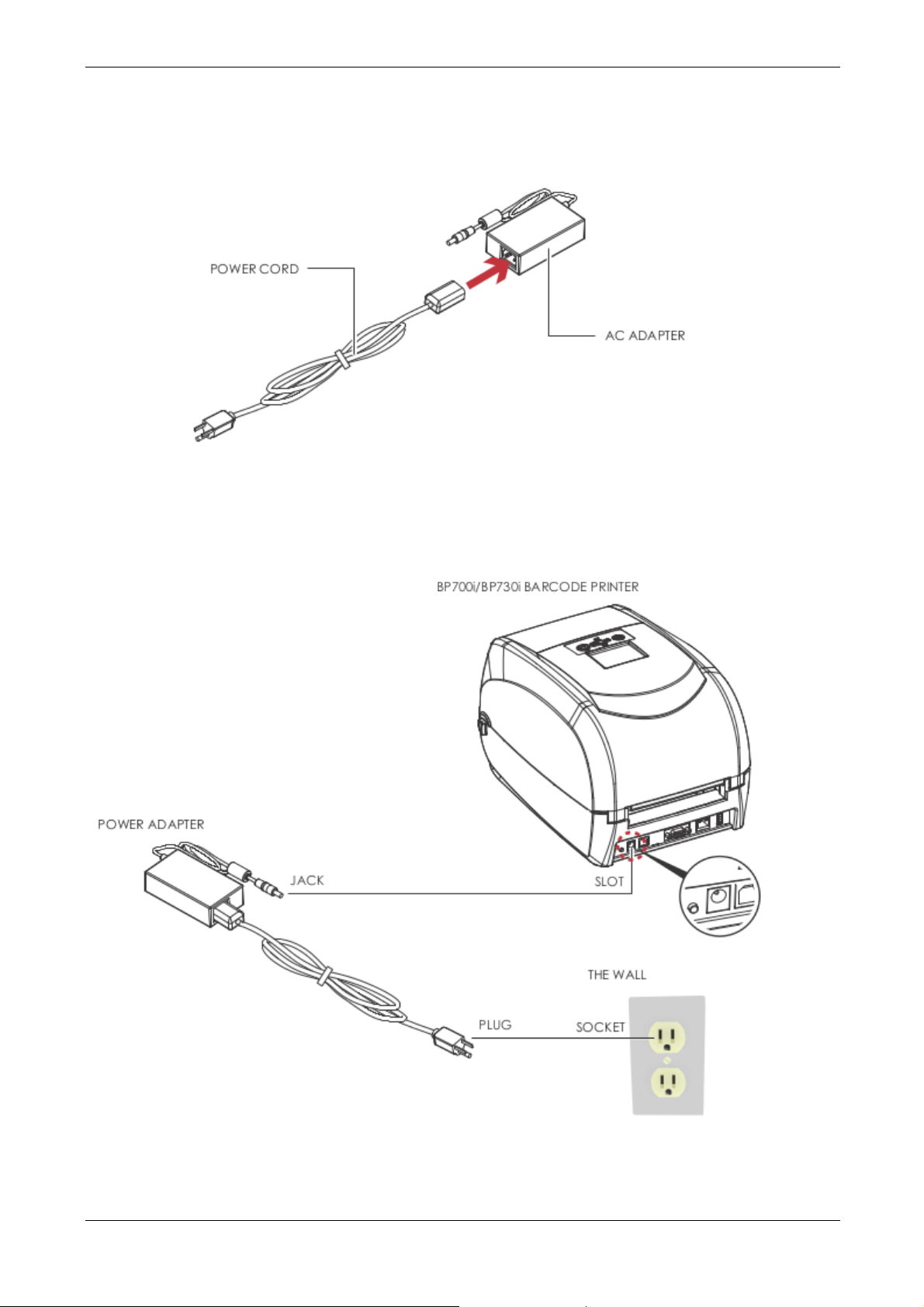

2.4 Connecting the Printer to the Host Computer

1. Please make sure that the printer is switched off.

2. Connect the power cord to the AC adapter.

Connect the jack of the power adapter to the printer and connect the plug of the power adapter to the socket

of the wall.

MAN10xxx-01 14

Page 20

User Manual 6214

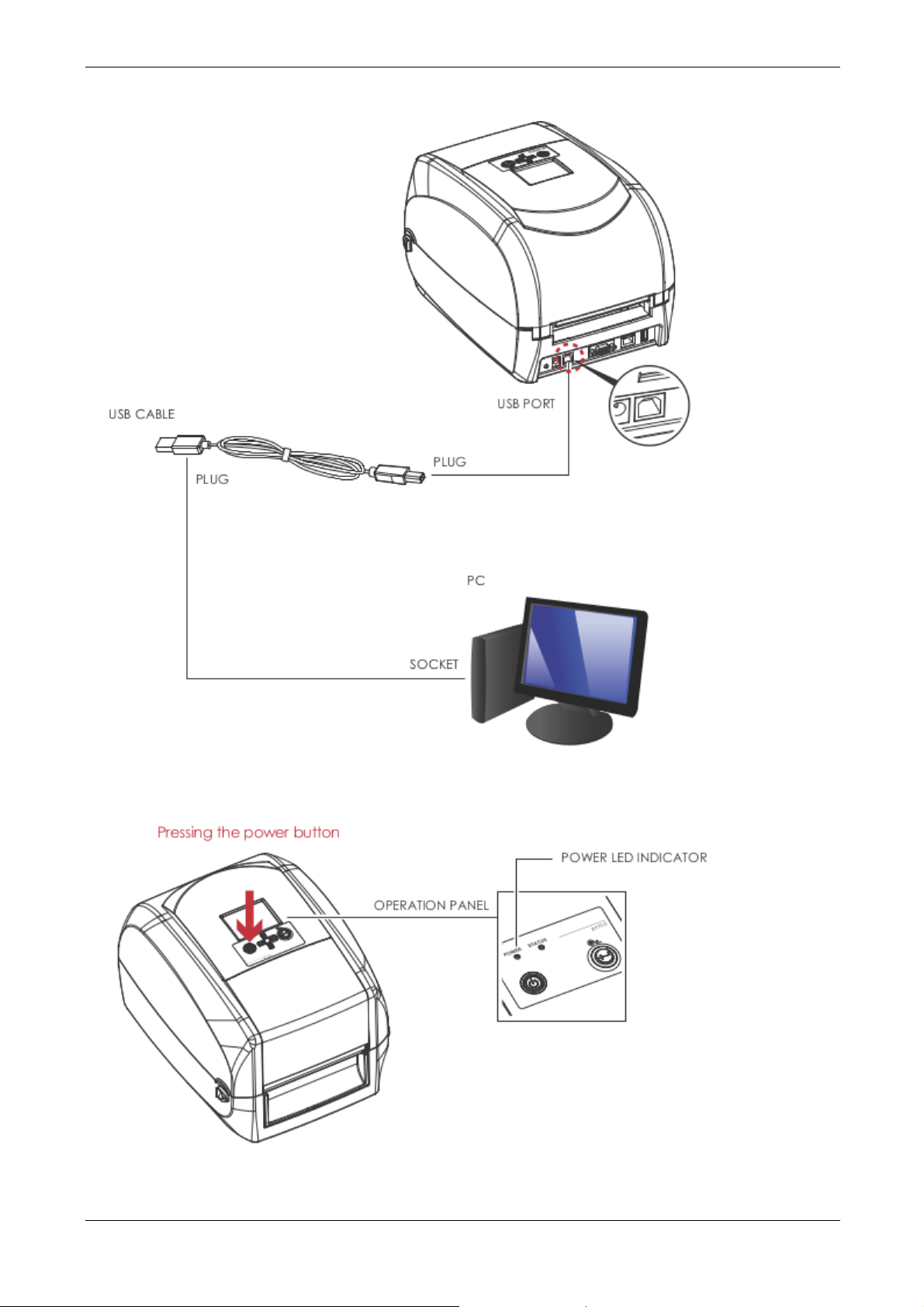

3. Connect the USB/serial cable to the printer and host computer.

4. Pressing the power button. The LED indicator should now lights up.

MAN10xxx-01 15

Page 21

User Manual 6214

2.5 Installing Printer Driver Directly from CD Folder

1. Insert the product CD in the CD/DVD drive of the host computer and open the "Seagull Drivers" folder on

the CD.

Select the icon for the driver file and click it to start the installation.

2. Follow the instructions on the screen. The Driver Wizard guides you through the installation procedure.

Select "Install printer drivers".

3. Specify your printer model.

MAN10xxx-01 16

Page 22

User Manual 6214

4. As the printer driver and QLabel are installing, a screen will display a progress bar.

5. Enter a printer name and assign the appropriate rights.

6. Once the installation is complete, a summary of the printer settings is displayed.

Check whether the printer settings are correct and click "Finish" to start copying the driver files.

Wait until copying is complete, then finish the installation.

MAN10xxx-01 17

Page 23

User Manual 6214

7. Once the driver installation is complete, the new printer should appear in the "Printers and Faxes" folder.

MAN10xxx-01 18

Page 24

User Manual 6214

3 Printer Setting and Control

3.1 Operation Panel

Operation Panel Introduction

POWER Button

Press the POWER button to turn on the printer, and the START UP SCREEN appears. The printer is on

“ready to print”

status, the LCD screen should display the message “READY“ on the screen.

When printer is turned on, keep pressing the POWER button for 3 second will turn the printer off.

FEED Button

When you press the FEED button, the printer moves the label to the defined stop position.

If you are using continuous labels, pressing the FEED button will move label stock until you release the

button again.

If you are using individual labels, pressing the FEED button will move only one label.

If the label does not stop at the correct position, you need to run the auto-detection function on the label

stock, please see Section 3.4 Label

Calibration and Self Test.

MAN10xxx-01 19

Page 25

User Manual 6214

3.2 LCD Interface Introduction

Getting Started

Press the POWER button to turn on the printer, and the START UP SCREEN appears.

Power on

If the printer is on “ready to print” status, the LCD screen should display the message “Ready“ on the screen.

Please keep pressing ►button and wait for the timer to be filled, then the LCD INTERFACE will enter into the

MENU for SETTING MODE. You can make various setting functions in SETTING MODE.

Enter Main page

MAN10xxx-01 20

Page 26

User Manual 6214

Operations on Setting Page

On MENU, press ►or ◄ button to move the cursor and select the functions.

Select a designated function and press FEED button, you will enter the SETTING PAGES for the function.

On SETTING PAGES press ►or ◄ button to select the setting items.

Select a designated function and press FEED button, you will enter the SETTING VALUE PAGES for the

setting items.

MAN10xxx-01 21

Page 27

User Manual 6214

On SETTING VALUE PAGES, press ▲or ▼ button to change the setting values.

Press FEED button will apply the setting value you just selected, and the red tick will appear to mark the

value.

Notice

* The blue arrow indicates the value you are selected.

** The red tick indicates that the selected value is applied now

.

MAN10xxx-01 22

Page 28

User Manual 6214

Exit from Current Page to Ready Status

The icon on top-left corner displays the capture of upper level screen and also guides you back to upper level

with left or up arrow.

On SETTING VALUE PAGES, press ◄ button will go back to the upper level screen.

On SETTING VALUE PAGES, press ▲ button will go back to the MAIN PAGE screen.

MAN10xxx-01 23

Page 29

User Manual 6214

On Main PAGE, select the “EXIT” icon and press the FEED button to exit from SETTING MODE and the

printer goes back to READY status.

MAN10xxx-01 24

Page 30

User Manual 6214

3.3 LAN Setting

Operations on Setting Page

On MAIN PAGE press ► or ◄ button to move the cursor and select the functions.

Select a designated function and press FEED button, you will enter the SETTING PAGES for the function.

On LAN Setting PAGE press ► or ◄ button to select the setting items.

Select DHCP and press FEED button, you will be able to setup DHCP function

MAN10xxx-01 25

Page 31

User Manual 6214

The default of DHCP is Disable. Press ▲ or ▼ button to change the setting values.

Press FEED button twice to save the setting.

MAN10xxx-01 26

Page 32

User Manual 6214

3.4 LCD Password

Operations on Setting Page

On MAIN PAGE, press ► or ◄ button to move the cursor and select the functions. Seclect a designated

function and press FEED button, you will enter the SETTING PAGE for the function.

The default of LCD Setting is Disable. Press ▲or ▼ button to change the setting values.

MAN10xxx-01 27

Page 33

User Manual 6214

Press FEED button twice to save the setting

MAN10xxx-01 28

Page 34

User Manual 6214

3.5 LCD Interface Function

Main Page

MAN10xxx-01 29

Page 35

User Manual 6214

Setting Items in Setting Mode

MAN10xxx-01 30

Page 36

User Manual 6214

MAN10xxx-01 31

Page 37

User Manual 6214

Status of LCD Interface

When printer is on standby status (ready to print), the LCD interface will display “Ready” on screen.

You can only print on this “Ready“ status.

If there is any printers error, the LCD screen will display the error screen to show the type of error.

You can fix the error according the notice.

Icon Definition

MAN10xxx-01 32

Page 38

User Manual 6214

3.6 Label Calibration and Self Test

Label Calibration

The printer can automatically detect and store label height.

That means the host computer does not need to transmit the label height to the printer.

Self Test

Self-test function lets you check whether the printer is functioning normally.

Here is how you run the label size calibration and self test.

1. Check that the label stock is loaded correctly.

2. Turn off the printer.

3. Turn the printer on again, keeping the FEED button pressed. When the LED starts to flash red, release

the FEED button. The printer will now measure the label stock and store the label height.

4. Once the printer has successfully measured the label stock, it will print a self-test label.

The contents of a self-test printout are listed below.

MAN10xxx-01 33

Page 39

User Manual 6214

Label Calibration Button

A hardware button to make a Label Calibration while printer encountering ‘’Media Error’’ during the cases

when first-time printer start up or change label or ribbon to another type, such as change using gap label to

continuous or black mark labels.

Keep pressing calibration button for 1 second, the printer can immediately run the label size calibration.

Press C-button for 2 seconds, it will make an auto-sensing to calibrate the label and ribbon’s parameters.

Notice

****Press C-button is equivalent to the auto-sensing command ‘’~S,SENSOR’’ that will cancel on-printing-job and make

the Label Calibration immediately.

.

MAN10xxx-01 34

Page 40

User Manual 6214

3.7 Error Alerts

In the event of a problem that prevents normal functioning of the printer, you will see an error message on LCD

screen and hear some beep signals. Please refer to below table for the error alerts.

Operation Panel

Status

Type Beeps Description Solution

Print Head Error 2 x 4 beeps

The printing

mechanism is not

correctly closed.

Open the print mechanism and

close it again.

Print Head Error None

Media Error 2 x 3 beeps

Media Error 2 x 2 beeps

High temperature at the

print

head.

No ribbon is installed

and the printer displays

an error

The ribbon is finished

or the label

supply hub is not

moving.

No paper is detected.

Paper is finished. Replace the label roll.

Printer feed problem.

Once the print head has cooled

down, the printer switches to

standby mode.

Make sure that the printer is set to

direct thermal printing mode.

Replace the ribbon roll.

Make sure that the label sensor is

positioned correctly. If the sensor

still does not detect the paper,

run the auto-detection function

again.

Possible reasons: the print medium

has become trapped around the

rubber roll; the sensor cannot

detect a gap or black mark

between the labels; there is no

paper. Please reset the sensor.

MAN10xxx-01 35

Page 41

User Manual 6214

Operation Panel

Status

Type Beeps Description Solution

The memory is full. The

printer

prints the message

"File System full".

Delete unnecessary data or install

additional memory.

File Error 2 x 2 beeps

Unable to find file. The

printer

prints the message

"File Name not

found"

Use the "~X4" command to print

all files. Then check whether the

files exist and whether the names

are correct.

A file of the same name

already

exists. The printer

prints the

message "Duplicate

Name".

Change the name of the file and

try storing it again..

MAN10xxx-01 36

Page 42

User Manual 6214

3.8 USB Host

Definition : USB Host port supports either deviceUSB memory stick, keyboard or scanner.

Purpose

USB memory stick : It extends the user memory space up to 32GB for Graphic, Font, Label Format, DBF

and Command files downloading. The printer’s Firmware also can be updating if copy new version of

Firmware into USB memory stick.

Connecting an USB keyboard to printer for ‘’ Standalone’’ mode operation.

Plug-in an USB scanner to operate the printer in ‘’Standalone’’ mode.

Usage of Extended Memory

USB memory stick : It supports hot-plugging function; printer will create a Folder ‘’\LABELDIR’’ and

switch ‘’User Flash’’ to ‘’ Extended Memory‘’ automatically while user plugs an USB memory stick into a

GoDEX ‘’i’’ model printer.

Connect the USB Stick plugged -in printer to PC via USB Device or Ethernet port and run ‘’GoLabel’’

software to download Graphic, Font, Label Format, DBF and Command files to the printer.

Detail download procedures, please refer to ‘’GoLabel On-line Help’’.

Usage of Firmware Update

Remove USB memory stick from printer and plug-in it to a PC’s USB port; delete Firmware ‘’*.bin’’ file

from ‘’\LABELDIR\FW’’ of USB memory stick if it existing; or create a Folder ‘’\LABELDIR\FW’’ to USB

memory stick if it doesn’t existing.

Copy a new version of Firmware ‘’xxxx.bin’’ to the Folder ‘’\LABELDIR\FW’’; and then remove USB and

plug-in back to the printer that going to update Firmware.

The printer will update the Firmware automatically when plug-it-into the printer and printer find-out the

Firmware in ‘’\LABELDIR\FW’’ is newer version.

Don’t remove the USB memory stick out while it’s under updating with ‘’Flash Writing...’’message that

displays on LCD panel.

MAN10xxx-01 37

Page 43

User Manual 6214

USB Keyboard

When plug-in an USB keyboard to the printer, LCD panel will display “Standalone Mode”, press the

“Enter” key on keyboard and “Feed” key in the printer to entering to the dialog for “Recall Label”

operation.

Only the sub-dialog “Recall Label” is able operating by keyboard as follow definition:

1. Press “ESC” key to exist from “Standalone Mode” or back to previous dialog

2. Press “F1”, it will let the printer from “Ready” mode entering into “Standalone Mode”

3. Press “Enter”, “Arrow” and “Alphabetic” keys as the usual in PC that will perform the key-in function

of “Recall Label” in “Standalone Mode”.

Scanner

When plug-in an USB scanner to the printer, LCD panel will display “Standalone Mode”, press the “Feed”

key in the printer to entering the dialog of “Recall Label” operation. User performs the “Recall Label”

function interactively through the LCD panel, 4 direction keys, Feed key and Scanner.

Scanner is using in “standalone Mode” to scanning the “Serial Number, Variable” and Print Quantity while

the printer prompts a message on LCD panel and wait for data input.

Notice

** The USB Host port on ‘’i’’ ‘’x’’ model printer is without ‘’HUB’’ function.

** The USB Memory Stick supports with ‘’FAT32’’Disk Format and up to 32GB only. The certified vendors

are Transcend, Apacer, Patriot, Consair and Kingston.

* The download function for Graphic, Font, Label Format, DBF and Command files is operated by GoLabel

of PC and must go through the a ‘’i’’ ‘’x’’ model printer itself.

* On a PC, user may copy entire folder’’\LABELDIR’’ from USB memory stick to PC or vice-versa. Copy a

sub-folder or individual file in ‘’\LABELDIR’’ to PC or vice-versa is not supported..

MAN10xxx-01 38

Page 44

User Manual 6214

4 Accessories

4.1 Preparations Steps

Before installing the optional modules, please make some preparations as follows.

1. Turn off the printer :

Remember to switch off the printer before installing any module.

2. Open the printer cover and the printing mechanism :

Open the printer cover by pulling the release catches on both sides of the printer and lift the cover.

Please see the Section 2.1 for further information about Open the Printer.

3. Remove the front cover :

Please pull upward to remove the front cover.

MAN10xxx-01 39

Page 45

User Manual 6214

4. Remove the platen :

Lift up the release clips on both sides of the platen to release and pull upward the platen.

5. Ribbon loading :

Please see the Section 2.2 for further information about Loading the Ribbon.

6. Label loading

Please see the Section 2.3 for further information about Loading the Label Roll Module.

MAN10xxx-01 40

Page 46

User Manual 6214

4.2 Installing the Label Dispenser

The Overview of the Label Dispenser

Preparation Steps

Please see the Section 5.1 Preparation Steps to complete the preparation steps before installing the label

dispenser.

Installing the Label Dispenser

1. Pass the connection cable through the slot of the printer.

Notice

**** A label liner thickness of 0.006 mm ± 10% and a weight of 65 g/m2 ± 6% are recommended.

**** The label dispenser will take labels up to a max. width of 118 mm.

MAN10xxx-01 41

Page 47

User Manual 6214

2. Place label dispenser to align both holes of screw and then tighten the screws.

3. Place the platen back to the printer and lock the clips.

4. Close the printer cover and printing mechanism.

Then to turn the printer upside down.

MAN10xxx-01 42

Page 48

User Manual 6214

5. Open the cover on the bottom of printer.

6. Plug the connector for the label dispenser to the jack.

7. Close the cover of the module connection jacks.

Notice

****The printer must be switched off when plugging the connector, or the motherboard may be destroyed!

****There are 2 jacks : the lower jack for the label dispenser, the upper jack for the cutter.

MAN10xxx-01 43

Page 49

User Manual 6214

Loading Label Roll with the Label Dispenser Module

1. Remove the first label from the label stock.

2. Feed the Label stock through the label guides.

And pull the label liner through the platen and the steel of the label dispenser.

Notice

****Labels should be at least 25 mm high.

MAN10xxx-01 44

Page 50

User Manual 6214

3. The feeding path of label and liner should be as shown in below graphic.

4.Close the label dispenser and printer cover. The installation is completed now.

MAN10xxx-01 45

Page 51

User Manual 6214

5. Press the FEED button to feed the label. The label will be peeled from the liner while it passes through the

label dispenser.

Notice

**** There is a paper sensor on the Label Dispenser module. It will stop the printing if it is covered by label.

Remove the last printed label and the printer will then continue to print next label..

MAN10xxx-01 46

Page 52

User Manual 6214

4.3 Installing the Cutter

The Overview of the Cutter

Preparation Steps

Please see the Section 5.1 Preparation Steps to complete the preparation steps before installing the cutter.

Installing the Cutter

1. Pass the connection cable through the slot of the printer.

Notice

****Labels should be at least 25 mm high.

****Remember to switch off the printer before installing the cutter.

****Do not use to cut adhesive labels! Glue residue will be left on the cutter blade and impair its functioning.

The cutter has a blade life of 400,000 cuts when using paper liner which is 250μm thick and 3 inches

wide.

****You can cut paper with a max. width of 116mm.

****With the cutter installed, set the stop position in Qlabel to 30, and the E value to 30.

MAN10xxx-01 47

Page 53

User Manual 6214

2. Place the cutter to align both holes of screw and then tighten the screws.

3. Place the platen back to the printer and lock the clips.

4. Close the printer cover and printing mechanism.

Then to turn the printer upside down.

MAN10xxx-01 48

Page 54

User Manual 6214

5. Open the cover on the bottom of printer.

6. Plug the connector for the cutter to the jack.

7. Close the cover of the module connection jacks.

Notice

****The printer must be switched off, or the motherboard may be destroyed!

****There are 2 jacks : the lower jack for the label dispenser, the upper jack for the cutter.

MAN10xxx-01 49

Page 55

User Manual 6214

Installing the Label Roll Module on the Printer

1. Pass the labels through the guides and the cutter.

2.Close the top cover and printing mechanism. To finish, press the FEED button to set the label position.

Notice

****We advise against using inside wound label stock.

****Labels should be at least 30 mm high. When using the printer with the cutter, you should set the stop position

(^E) to 30.

MAN10xxx-01 50

Page 56

User Manual 6214

5 Maintenance and Adjustment

5.1 Cleaning the Print Head

Dirt on the print head or ribbon, or glue residue from the label stock may result in inadequate print quality.

The printer cover must therefore always be closed during printing. Keeping dirt and dust away from the paper

or labels ensures a good print quality and a longer lifespan of the print head.

Cleaning Steps

Here is how you clean the print head.

1. Turn off the printer.

2. Open the printer cover.

3. Remove the ribbon.

4. To remove any label residue or other dirt from the print head (see red arrow), please use a soft lint-free

cloth dipped in alcohol.

Notice

****The print head should be cleaned once a week.

****Please make sure that there are no metal fragments or other hard particles on the soft cloth used to clean the print

head..

MAN10xxx-01 51

Page 57

User Manual 6214

5.2 Troubleshooting

Problem Solution

The printer is switched on but the LED

does not light up.

The LED lights up red and printing is

interrupted.

The label stock passes through the

printer

but no image is printed.

The label stock jams during printing. ♦ Clear the paper jam. Remove any label material left on

There is no printed image on some parts

of the label.

There is no printed image on part of the

label or the image is blurred.

The printed image is positioned

incorrectly.

A label is missed out during printing ♦ Check the label height setting.

The printed image is blurred. ♦ Check the darkness setting.

The cutter does not cut off the labels in

a straight line.

The cutter does not cut off the labels

completely.

When using the cutter, the labels are not

fed through or cut off incorrectly.

The label dispenser is not functioning

normally.

♦ Check the power supply.

Please see the Section 2.4

♦ Check the software settings (driver settings) or

command codes.

♦ Look for the error alert in the table in Section 3.5. Error

Alerts.

♦ Check whether the print mechanism is closed correctly.

Please see the Section 3.5

♦ Please make sure that the label stock is loaded the right

way up and that it is suitable material.

♦ Choose the correct printer driver.

♦ Choose the correct label stock and a suitable printing

mode.

the

thermal print head and clean the print head using a soft

lint-free cloth dipped in alcohol.

Please see the Section 6.1

♦ Check whether any label material or ribbon is stuck to

the thermal

print head.

♦ Check for errors in the application software

♦ Check whether the starting position has been set

incorrectly

♦ Check the ribbon for wrinkles.

♦ Check the thermal print head for dust or other dirt.

♦ Use the internal “~T” command to check whether the

thermal print head will carry out a complete print job.

♦ Check the quality of the print medium.

♦ Check whether there is paper or dust covering the

sensor

♦ Check whether the label stock is suitable. Contact your

supplier.

♦ Check the paper guide settings.

♦ Check whether there is dust covering the sensor

♦ Run the auto-detection function.

Please see the Section 3.4

♦ Check the thermal print head for dust or dirt.

Please see the Section 6.1

♦ Check whether the label stock is positioned straight.

♦ Check whether the label is more than 0.2 mm thick.

♦ Check whether the cutter has been correctly installed.

♦ Check whether the paper guides are functioning

correctly.

♦ Check whether there is dust on the label dispenser

♦ Check whether the label stock is positioned correctly.

MAN10xxx-01 52

Page 58

User Manual 6214

APPENDIX

Product Specifications

Model 6214 6214-H

Print Method

Resolution

Print Speed

Print Width

Print Length

Processor

Memory

Sensor Type

Media

Core diameter

Printer Language

Label design

Software

Resident

Fonts

Download

Fonts

Barcodes

Code Pages

Bitmap fonts

Scalable fonts

Bitmap fonts

Scalable fonts

1-D Bar codes

2-D Bar codes

Graphics

Flash

SDRAM

Types

Width

Thickness

Label roll

diameter

software

Driver

DLL

Asian fonts

Thermal Transfer / Direct Thermal

203 dpi (8 dots/mm) 300 dpi (12 dots/mm)

Up to 7 IPS (177 mm/s) 5 IPS (127mm/s)

4.25” (108 mm) 4.16” (105.7 mm)

Min. 0.16” (4 mm)** ;

Max. 68” (1727 mm)

32 Bit RISC CPU

8MB Flash (4MB for user storage)

16MB SDRAM

Adjustable reflective sensor (full range). Fixed transmissive sensor,

central aligned

Wax, wax/resin, resin

981’ (300 m)

1.18” Min. - 4.33” (30 mm - 110 mm) Max.

2.67“ (68 mm)

1” (25.4 mm)

CZL (Compuprint Zebra Language

CEL (Compuprint Eltron Language)

GoLabel (for EZPL only)

Windows 2000, XP, Vista, 7, Windows Server 2003 & 2008

Windows 2000, XP, Vista

6, 8, 10, 12, 14, 18, 24, 30, 16X26 and OCR A & B

Bitmap fonts 90°, 180°, 270° rotatable, single characters 90°, 180°,

270° rotatable

Bitmap fonts 8 times expandable in horizontal and vertical

directions

90°, 180°, 270° rotatable

Bitmap fonts 90°, 180°, 270° rotatable, single characters 90°, 180°,

270° rotatable

Asian fonts 90°, 180°, 270° rotatable and 8 times expandable in

horizontal and

vertical directions

Scalable fonts 90°, 180°, 270° rotatable

Code 39, Code 93, EAN 8 /13 (add on 2 & 5), UPC A/E (add on 2 &

5), I 2 of 5 & I 2 of 5 with Shipping Bearer Bars,

Codabar, Code 128 (subset A, B, C), EAN 128, RPS 128, UCC

128, UCC/EAN-128, K-Mart, Random Weight,

Post NET, ITF 14, China Postal Code, HIBC, MSI, Plessey,

Telepen, FIM, GS1, DataBar

PDF417, Datamatrix code, MaxiCode, QR code, Micro PDF417,

Micro QR code and Aztec code

CODEPAGE 437, 850, 851, 852, 855, 857, 860, 861, 862, 863,

865, 866, 869, 737

WINDOWS 1250, 1251, 1252, 1253, 1254, 1255, 1257

Unicode (UTF8, UTF16)

Resident graphic file types are BMP and PCX, other graphic

formats are downloadable from the software

Min. 0.16” (4 mm)**;

Max. 30” (762 mm)

MAN10xxx-01 53

Page 59

User Manual 6214

Model 6214 6214-H

Standard

Auto Switching 100-240VAC, 50-60Hz

41°F to 104°F(5°C to 40°C)

-4°F to 122°F (-20°C to 50°C)

30-85%, non-condensing

10-90%, non-condensing

CE(EMC), FCC Class A, CB and CCC, cUL

11.0”(280mm)

7.3”(186mm)

8.3”(210mm)

6.6 lbs (3.0Kg) ,excluding consumables

Bluetooth module

Guillotine cutter

Label dispenser

External label roll holder for 10” (250 mm) O.D. label rolls

External label rewinder

Environment

Humidity

Dimension

Real Time Clock

Power

Operation

Temperature

Storage

Temperature

Operation

Storage

Agency Approvals

Length

Height

Width

Weight

Options

Notice

****Specifications are subject to change without notice. All company and/or product names are trademarks

and/or registered trademarks of their respective owners.

****Minimum print height specification compliance can be dependent on non-standard material variables

such as label type, thickness, spacing, liner construction, etc. It is pleased to test non-standard materials

for minimum height printing capability.

MAN10xxx-01 54

Page 60

User Manual 6214

INTERFACE

Pinout Description

USB

Connector Type : Type B

Pin NO. 1 2 3 4

Function VBUS D- D+ GND

Pinout Description

Serial Port

RS232 Housing (9-pin to 9-pin)

DB9 Socket DB9 Plug

--

RXD 2_____________________________2 TXD

TXD 3_____________________________3 RXD

DTR 4_____________________________4 N/C

GND 5_____________________________5 GND

DSR 6_____________________________6 RTS

RTS 7_____________________________7 CTS

CTS 8_____________________________8 RTS

RI 9_____________________________9 N/C

Computer Printer

Default settings: Baud rate 9600, no parity, 8 data bits, 1 stop bit,

XON/XOFF protocol and RTS/CTS

Notice

****The total current to the serial port may not exceed 500mA.

1_____________________________1 +5V (*)

MAN10xxx-01 55

Page 61

User Manual 6214

File handling using USB stick

File Manipulation

The files in both devices (USB memory stick and printer internal Flash memory) are able to copy and move

by the commands ‘’~MCPY’’ and ‘’MMOV’’ that sends from GoLabel on a PC via either connection - USB or

Ethernet ports.

Copy

Syntax ~MCPY,s:o.x,d:o.x

Description Copy file from USB memory stick to Flash memory, or vise-versa

Parameter s = source device of stored object;

Example ~MCPY,F:*.F,D:*.F

Move

Syntax ~MMOV,s:o.x,d:o.x

Description Move files from USB memory stick to Flash memory or vise-versa

Parameter s = source device of stored object;

Example ~MMOV,F:*.F,D:*.F

“D” for USB memory stick; “F” for internal Flash memory

d = destination device of stored object

“D” for USB memory stick; “F” for internal Flash memory

o = object name (file name); the name “o” is substituted for “*”

x = extension (file type), the type “x” is substituted by ”*”, or following

either one: D= database, A= Asia font, C= TTF font, E= Bit-Mapped

font, F= label format, G= graphic, S= serial file, T= text, B= Unicode

Table.

(Copy entire “Label Format” files from Flash memory to USB memory

stick)

~MCPY,D:*.G,F:*.G

(Copy entire “Graphic” files from USB memory stick to Flash Memory)

~MCPY,D:*.*,F:*.*

(Copy all object files from USB memory stick to Flash Memory)

“D” for USB memory stick; “F” for internal Flash memory

d = destination device of stored object

“D” for USB memory stick; “F” for internal Flash memory

o = object name (file name); the name “o” is substituted for “*”

x = extension (file type), the type “x” is substituted by ”*”, or following

either one: D= database, A= Asia font, C= TTF font, E= Bit-Mapped

font, F= label format, G= graphic, S= serial file, T= text, B= Unicode

Table.

(Move entire “Label Format” files from Flash memory to USB memory

stick)

~MMOV,D:*.G,F:*.G

(Move entire “Graphic” files from USB memory stick to Flash Memory)

~MMOV,D:*.*,F:*.*

(Move all object files from USB memory stick to Flash Memory)

MAN10xxx-01 56

Page 62

User Manual 6214

Bluetooth Module

Install Bluetooth Module

Getting Started

Follow the indicator to insert the module. Push the module to the end of the slot.

The Installation Line on Bluetooth Module

must right along with the edge of mainboard.

Otherwise, it might cause signal error.

Notice

**** Please prevent below incorrect installation..

MAN10xxx-01 57

Page 63

User Manual 6214

Work with Bluetooth Keyboard (Logitech K810)

After install Bluetooth Module,

the Bluetooth icon will be appear on LCD display.

Connect printer and Bluetooth keyboard

Turn on the switch and push the Connect Button.

The indicators are flashing and can be detected by Bluetooth.

Notice

**** Different operation with different Bluetooth keyboard. Please refer to Bluetooth keyboard user manual.

MAN10xxx-01 58

Page 64

User Manual 6214

MAN10xxx-01 59

Page 65

User Manual 6214

MAN10xxx-01 60

Page 66

User Manual 6214

MAN10xxx-01 61

Page 67

User Manual 6214

Setting and Control for Operation Panel

Functions

Clear Bind

Bluetooth

Setting

Make Device Visible

SSP

PIN Code 0000

Search Devices

Enable

Disable

Enable

Disable

Enable

Disable

MAN10xxx-01 62

Page 68

User Manual 6214

Functions

Descriptions

The default of Clear Bind is Disable. When enable this

function, it will clear up the saved connection of

Bluetooth device then come back to Disable.

Enable: Printer can be detected by Bluetooth device.

Disable: Printer cannot be detected by Bluetooth

device.

* The default of Make Device Visible is Disable.

Printer can be detected during 120 sec.

Secure Simple Pairing. The default is Disable.

When connect successful, the setting of Make Device

Visible, SSP and PIN Code cannot be changed. They

only can be changed after Clear Bind.

Password for connect printer and Bluetooth device.

When connect successful, the PIN Code only can be

changed after Clear Bind.

The default of PIN Code is ''0000''.

Search Device only available when Bluetooth function

was enabled.

Press FEED to search Bluetooth devices.

LCD will display all of available devices.

1. Only supports SPP & HID Profile.

2. Alphanumeric only

3. Maximum 16- device can be displayed

* When connect successful, needs to disconnect before

perform this function.

MAN10xxx-01 63

Page 69

Page 70

COMPUPRINT s.r.l.

Via Lombardore, 282

10040 Leinì (TO)

ITALY

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

This manual refers to various company and products by their trade names.

In most of the cases, these designations are claimed as trademarks or

registered tramarkers by their respective companies.

Copyright 2013 COMPUPRINT s.r.l. - Printed in Italy

Loading...

Loading...