Page 1

Compuprint 4247 Serial Matrix Printers

Compuprint 4247 Model X03 Printer:

User’s Guide

MAN10296.00.00

Page 2

Before using this information and the product it supports, read the information in “Notices” on page 181.

First edition (October 2011)

This edition applies to the Compuprint 4247 X03 printer and to all subsequent releases and modifications

until otherwise indicated in new edition.

Internet

Visit our home page: http://www.compuprint.com

You can send comments by e-mail to : support@compuprint.com

Compuprint s.r.l.

Via Lombardore 282

10040 Leinì (Turin)

ITALY

ii User’s Guide

or by mail to:

Page 3

Contents

Figures ..............vii

Tables ...............ix

Safety and environmental notices . . . xi

Safety notices ..............xi

Danger hazard level ..........xi

Caution hazard level ..........xi

Attention notices.............xi

Safety precautions ............xii

Electrical safety ............xii

Approved power cord and receptacle ....xii

Electrical safety and portable power strip

receptacles .............xii

Connecting or disconnecting a communication

port, a teleport, or an attachment connector . . xiii

Servicing during an electrical storm .....xiii

Preface ..............xv

How to use this guide...........xv

Chapter 1. Getting started .......1

Printer parts ..............2

Unpacking the printer ...........3

Choosing a suitable location ........4

Performing a power-receptacle safety-check . . . 5

Installing the Controller Board ........5

Handling the Controller Board .......5

Inserting the Controller Board .......6

Installing the operator panel overlay ......8

Installing the ribbon cartridge ........9

Removing the ribbon cartridge .......12

Power connection ............13

Changing the display language (from English). . . 15

Loading forms in the Front Push Tractors ....16

Printing your first documents ........19

Installing the optional second tractor ......20

Removing the optional second tractor .....24

Attaching the 4247 Printer to your computer . . . 25

Completing printer setup ..........25

Software driver selection ..........26

Chapter 2. Understanding the operator

panel ...............27

Status indicators.............27

READY...............27

PROCESSING ............28

ATTENTION .............28

Display panel..............28

Audible alarm .............29

Custom Set In-Use Indicator .........29

Function Keys .............29

MENU ...............30

SCROLL/MICRO↑ or SCROLL/MICRO↓ ...30

ENTER ...............31

RETURN ..............32

PARK/PATH .............32

LINE FEED .............33

LOAD/EJECT ............33

FORM FEED .............34

SET TOP OF FORM ..........35

START...............35

STOP...............35

CANCEL PRINT ...........36

TEST ...............36

Chapter 3. Checking and changing

configuration parameter values ....37

Printing configuration defaults ........37

Checking and changing parameter values ....38

Exiting the Configuration Menu .......39

Exiting using START ..........39

Exiting using RETURN .........39

Locking the Printer Configuration Menu.....40

Configuration categories ..........40

Configuration storage ..........41

Attachment .............41

IPDS Configuration...........41

ASCII Configuration ..........42

Printer setup .............45

Printer adjustment ...........46

Power On Reset ............46

Display language ...........47

Vital Product Data ...........47

Quiet Print .............47

Hex Print ..............48

Quit From Menu ...........48

Chapter 4. Configuration storage . . . 49

Custom sets ..............49

Non-custom set .............49

Save Current Values in Custom Sets ......50

Recall Custom Set values ..........51

Power-On Custom Set ...........51

Power-On Paper Source ..........52

Recall factory defaults ...........53

Printing custom sets ...........54

Chapter 5. Attachment options ....55

Chapter 6. IPDS Configuration ....57

Characters Per Inch (CPI)..........57

Lines Per Inch (LPI) ...........58

Maximum Print Position (MPP)........58

Maximum Page Length (MPL) ........59

Print Quality ..............60

Print language .............61

Emulation mode.............62

iii

Page 4

Media Size Priority ............63

Bar Code Mode .............64

Graphics Mode .............65

Alarm control .............66

Chapter 7. ASCII Configuration ....67

Characters Per Inch (CPI)..........67

Lines Per Inch (LPI) ...........68

Maximum Print Position (MPP)........69

Maximum Page Length (MPL) ........70

Perforation skipping ...........71

Emulation Mode.............71

Print language .............72

Print quality ..............74

NLQ typeface .............75

Character set ..............75

Printer Compatibility 3 (automatic line feed on

carriage return) .............76

Printer Compatibility 4 (automatic carriage return

on line feed) ..............76

Printer Compatibility 5 (form feed suppression) . . 77

Printer Compatibility 6 (Init) ........78

Printer Compatibility 7 (condensed print) ....79

Printer Compatibility 8 (slashed zero) .....79

Printer Compatibility 9 (20 CPI) .......80

Alarm control .............81

Override Host parameters .........82

Paper source .............82

Characters Per Inch (CPI).........83

Lines Per Inch (LPI) ..........84

Maximum Page Length .........85

Parallel interface.............86

Interface type.............86

Input Buffer Size ...........86

Select-In ..............87

AutoFeed-XT .............88

Serial interface .............88

Interface type.............88

Input Buffer Size ...........89

Data Bits ..............90

Baud Rate ..............90

Parity ...............91

Pacing Control ............92

Connection Type............92

LAN Interface .............93

IP Address Assignment .........93

IP Address .............93

Subnet Mask .............94

Default Gateway ...........95

Host Name .............95

Workgroup Name ...........96

SMTP Service .............97

Mail Server Address ..........97

E-Mail Address (Receiver) ........98

E-Mail Address (Sender) .........99

Chapter 8. Printer setup .......101

Paper Source .............101

Front Forms Backup ...........102

Rear Forms Backup ...........103

Continuous Forms Linking .........104

Form Feed Mode ............105

Controlling tear off operations........106

Using automatic eject to control forms eject . . 106

Using automatic restore to control restoring of

forms ...............106

Automatic Eject ...........107

Automatic Restore...........108

Continuous Forms Eject Mode........109

Bar Code Print Direction .........110

Graphics Print Direction ..........111

Perforation Safety ............112

Jam Sensors ..............113

Chapter 9. Printer adjustments ....115

Paper-Load-Position to Tear-Position relationship 115

Front Automatic Forms Thickness Adjustment

(AFTA) ...............116

Front Tear Position ...........116

Front Left Margin Alignment ........117

Front Paper Load Position .........117

Rear Automatic Forms Thickness Adjustment

(AFTA) ...............118

Rear Tear Position ............118

Rear Left Margin Alignment ........119

Rear Paper Load Position .........120

Bidirectional Adjustment .........120

Sensor Tune ..............121

Quit From Menu ............121

Chapter 10. Power-On Reset (POR) 123

Chapter 11. Display Language ....125

Chapter 12. Vital Product Data ....127

Serial Number .............127

Device Specific Information ........128

Chapter 13. Quiet Print .......129

Chapter 14. Hex Print ........131

Chapter 15. Quit From Menu .....133

Chapter 16. Dual push tractor forms

paths ...............135

Introduction ..............135

Forms selection............135

Using different forms on two paths ......136

Setting up printer ...........136

Using path switching ..........136

Using same forms on both paths (linking) ....137

Setting up printer ...........137

How forms linking works ........138

Parking one continuous form and loading another 138

Parking a continuous form ........138

Changing the forms path ........138

iv User’s Guide

Page 5

Chapter 17. Using the Operator Print

Tests ...............139

General test instructions ..........139

Quick Reference ............140

Printer Demonstration ..........140

Printer Configuration...........141

Print Custom Sets ............141

Firmware Information ..........142

Printer Adjustments ...........142

Chapter 18. Supplies, optional

features, and maintenance......145

Continuous forms specifications .......145

Proper forms loading ...........146

Forms Handling Paper Paths .......147

Forms stacking recommendations .....147

Forms stack input and output locations . . . 147

Supplies ...............148

Optional features ............148

Maintenance..............149

Removing the ribbon cartridge ......149

Cleaning the printer ..........149

Appendix A. Printer specifications 165

General information ...........165

Operating and service clearance ......166

Weight ..............166

Power consumption ..........166

Heat output .............166

Airflow ..............167

Declaration of product noise emission values 167

The Parallel Interface ...........167

Parallel connector pin assignments .....167

The Serial Interface ...........168

RS-232C connector pin assignments .....168

The LAN Interface ...........169

LED indicators ............169

Environmental requirements ........169

Operating environment .........169

Shipping environment .........169

Storage environment ..........170

Electrical requirements ..........170

Power cord .............170

Safety ...............171

Branch circuits and grounding.......171

Chapter 19. Problem solving .....151

Using status code and problem listings .....151

Status code and messages displays .....151

No status code displays .........151

Status codes and recovery actions .....152

Problem list index ............156

Forms problems ...........159

Print quality and ribbon problems .....160

Configuration problems .........162

Miscellaneous problems .........162

Clearing forms jams ...........163

Appendix B. 4247 Model X03 -

Configuration Menu.........173

Appendix C. Printer driver support 175

IBM pSeries AIX colon files.........175

IBM System i workstation customization objects 175

Index ...............177

Notices . . . . . . . . . . . . . 181

Contents v

Page 6

vi User’s Guide

Page 7

Figures

1. Printer Parts: Front and Rear View .....2

2. Contents of Shipping Container ......3

3. Removing the shipping locks from the printer. 4

4. Printer clearances. ...........4

5. Removing the two screws on the metal plate. 6

6. Sliding the board in the slot. .......7

7. Attaching the Controller Board. ......7

8. Operator panel ............8

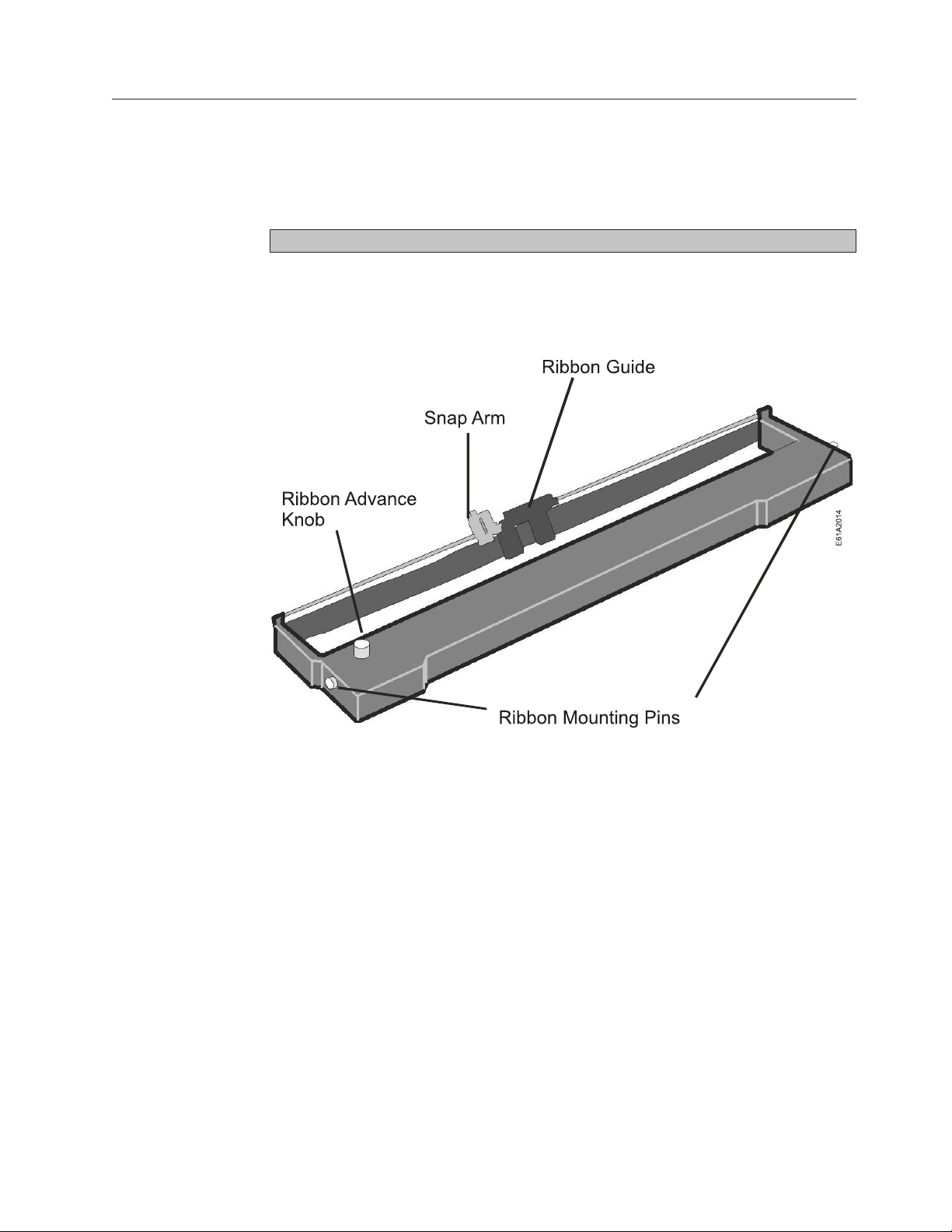

9. Ribbon Cartridge ...........9

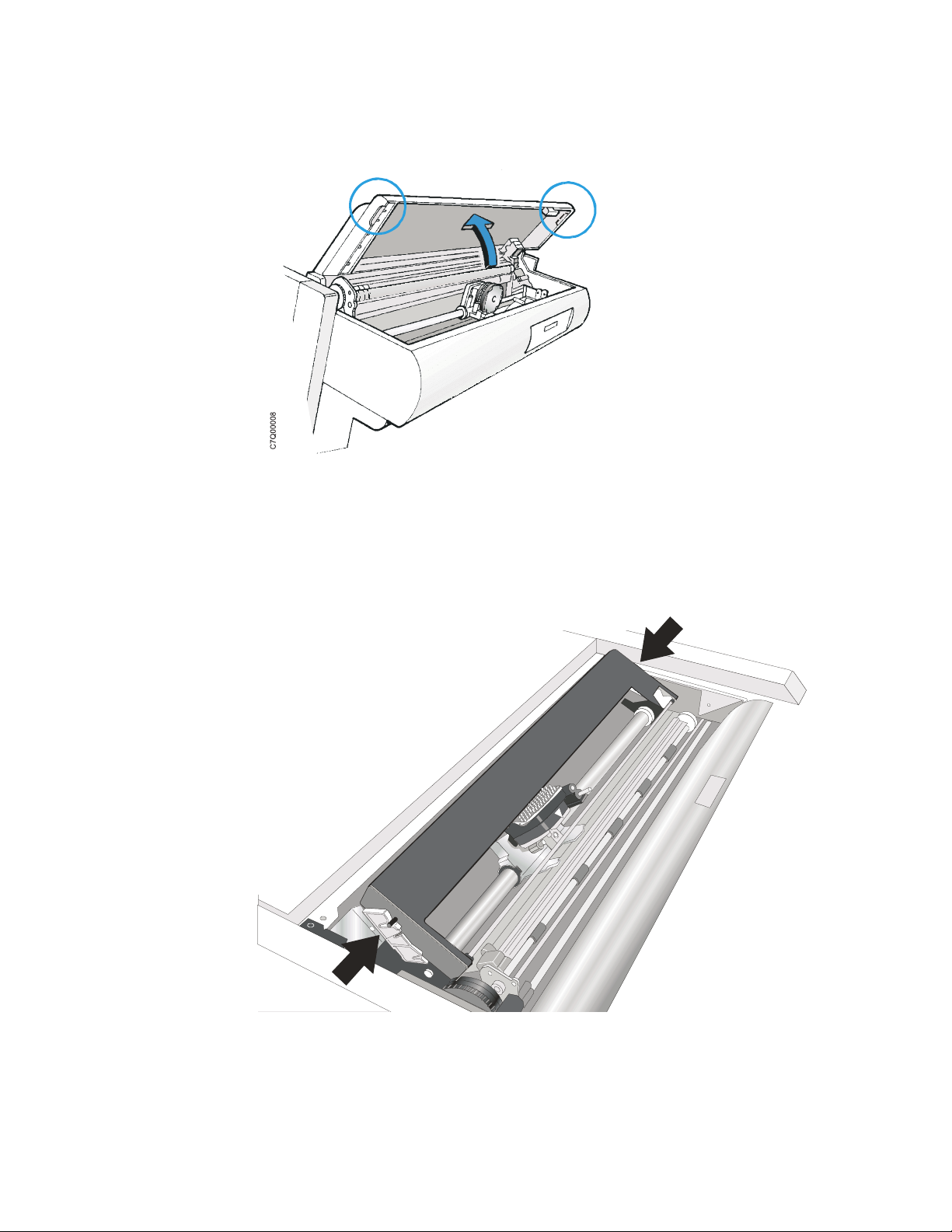

10. Opening the top cover .........10

11. Aligning the cartridge pins. .......10

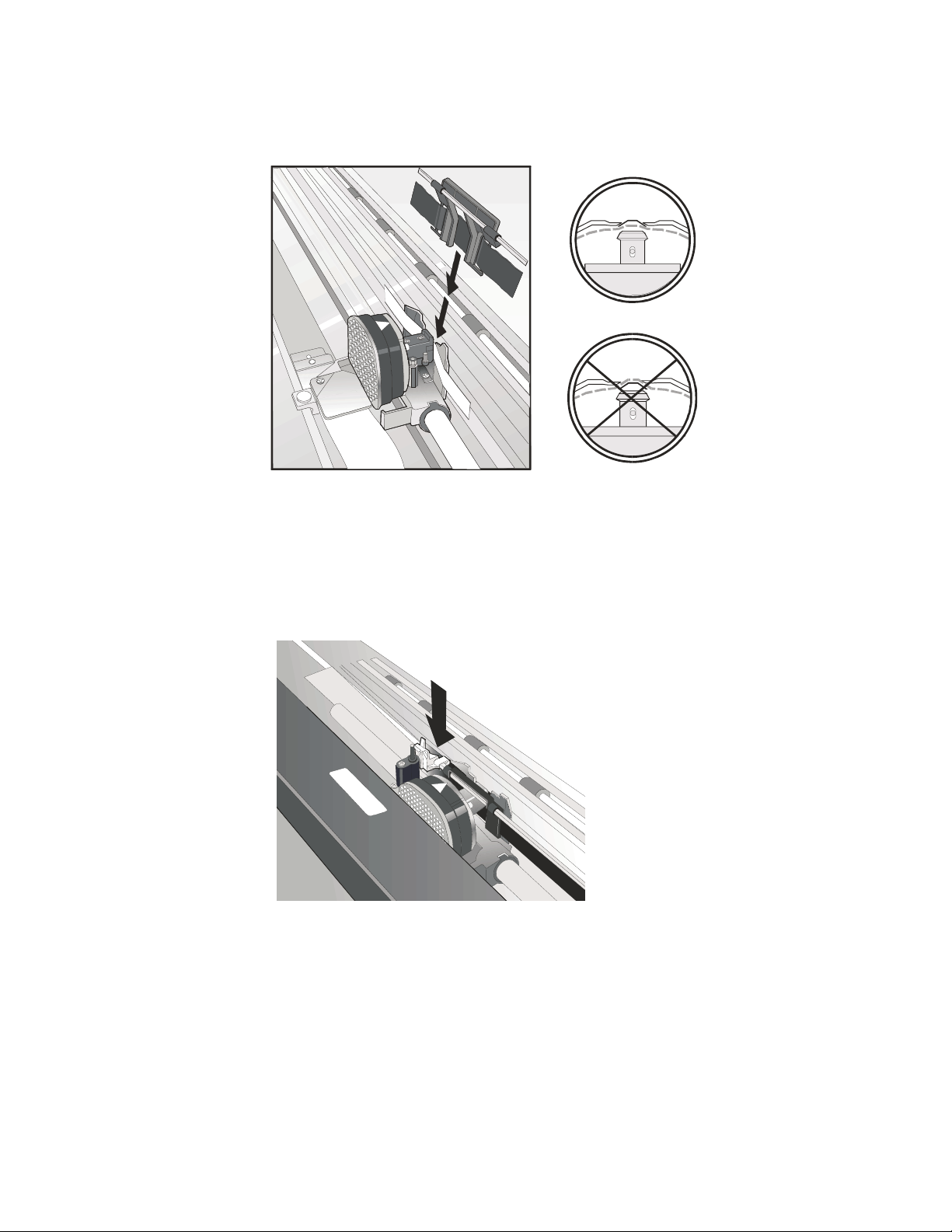

12. Print head and ribbon guide mask showing

correct positioning of the ribbon. .....11

13. Positioning the snap arm. ........11

14. Aligning the ribbon mounting pins. ....12

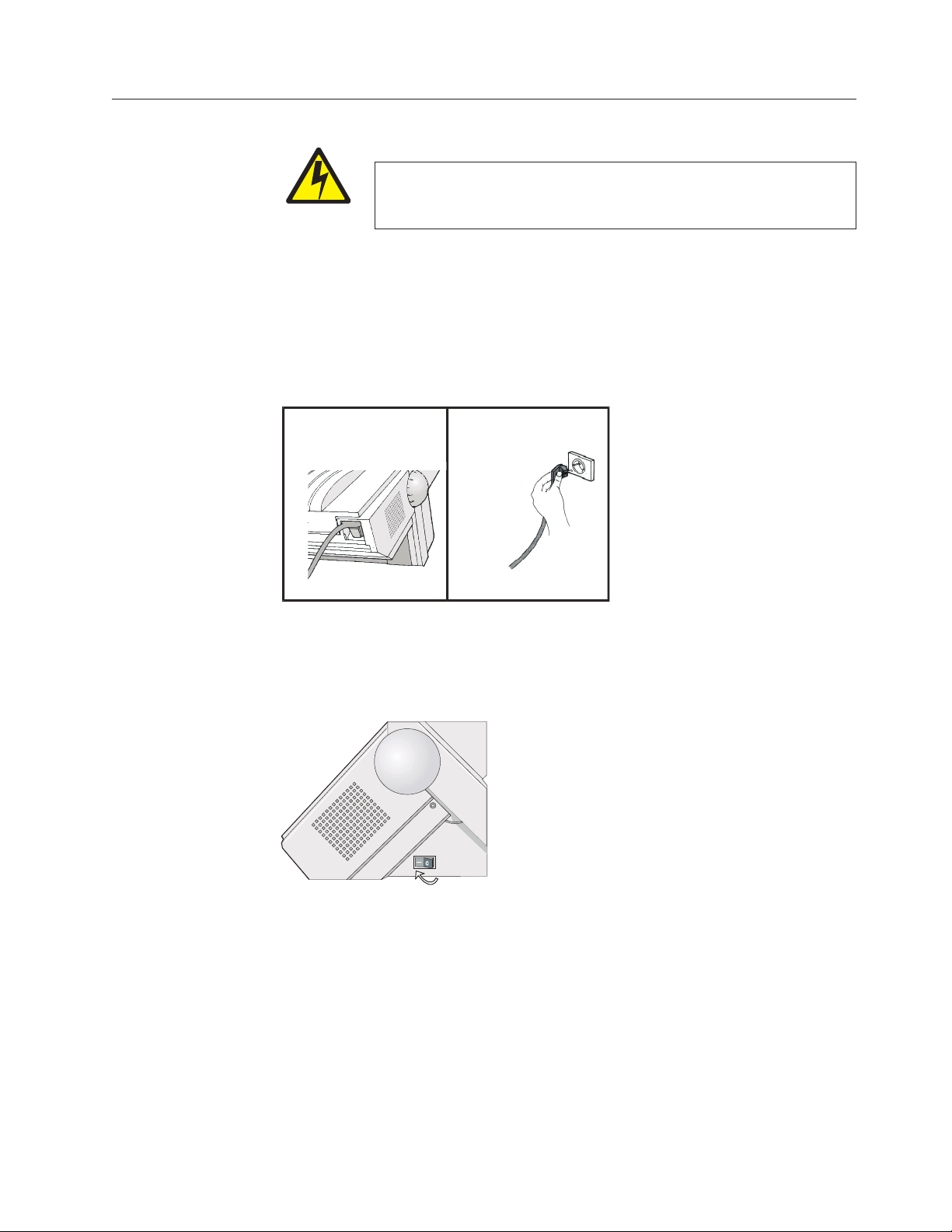

15. Inserting the power cable plug ......13

16. Power switch in the I position (ON). ....13

17. Opening the Push tractors cover .....16

18. Unlocking the sprockets of the Front1 push

tractor ..............16

19. Opening the left and right sprocket covers. 17

20. Closing the left sprocket cover. ......17

21. Inserting the paper on the right sprocket pins. 18

22. Matching the left sprocket for the first printing

position. .............18

23. Adjusting the right sprocket .......19

24. Closing the Push tractors cover. ......19

25. Opening the tractor area cover. ......20

26. Second tractor............21

27. Aligning the second tractor hooks. .....21

28. Connecting the second tractor ......22

29. Rotating the tractor gear protection cover. 22

30. Second tractor in the closed position. ....23

31. Paper path direction .........23

32. Disconnecting the second tractor. .....24

33. Closing the protection cover. .......24

34. 4247 Printer Operator Panel .......27

35. Correctly Loaded Paper ........146

36. Forms Handling Paper Paths ......147

37. Forms stacking recommendations .....147

38. Forms stacking recommendations .....148

39. Freeing the shifter holder .......149

40. Rotating the bail assembly .......163

41. Gripping the bail assembly .......163

42. Inserting the left and right paper bail end cap

pivots into the side frames .......164

43. Printer clearances. ..........166

vii

Page 8

viii User’s Guide

Page 9

Tables

1. Configuration Storage Category ......41

2. Attachment Category .........41

3. IPDS Configuration Category ......41

4. ASCII Configuration .........42

5. Printer Setup ............45

6. Printer Adjustment ..........46

7. Power On Reset ...........46

8. Display Language ..........47

9. Vital Product Data Category .......47

10. Quiet Print Category .........47

11. Hex Print Category ..........48

12. Quit From Menu Category .......48

13. Supported Print Languages .......61

14. Single Path Usage recommendations ....107

15. Dual Path Usage recommendations ....107

16. Display Languages ..........125

17. Forms buckle, twist, jam, or tractor holes tear 156

18. Forms do not feed past printhead .....156

19. Forms do not stack correctly ......156

20. Characters off registration .......157

21. Unreadable characters.........157

22. Missing dots or irregular characters ....157

23. Ribbon smudging forms ........157

24. Printing is too light or partial characters print 157

25. Ribbon snagging, tearing, or not moving 157

26. Line-to-line horizontal misregistration 158

27. Printer doesn't print or prints wrong

characters .............158

28. Printer has no power .........158

29. Throughput of printer at half speed ....158

30. Sound Emission Levels - with Standard

Covers ..............167

31. RS232/C serial interface signals .....168

ix

Page 10

x User’s Guide

Page 11

Safety and environmental notices

Safety notices

There are two levels of safety notices: Danger and Cautions.

Danger hazard level

The word Danger indicates the presence of a hazard that has the potential of

causing death or serious personal injury.

Most DANGER notices are numbered <1-1>, <1-2>, and so forth where they

appear in the text of this manual.

Example of a Danger notice:

DANGER

<1-10> Hazardous voltages are present. Do not touch the pins or sockets of

the power receptacle.

Caution hazard level

The word Caution indicates the presence of a hazard that has the potential of

causing moderate or minor personal injury.

Most CAUTION notices are numbered <2-1>, <2-2>, and so forth where they

appear in the text of this manual.

Example of a Caution notice:

Attention notices

The word Attention calls attention to the possibility of damage to a program,

device, system, or data.

Attention notices are not numbered.

Examples of an Attention notices:

Attention: This printer has nominal AC input power requirements (see

Appendix A, “Printer specifications,” on page 165).

!

CAUTION:

<2-22> Carefully follow all cleaning instructions, using only the materials and

solutions recommended.

xi

Page 12

Safety precautions

Electrical safety

This printer is inspected and listed by recognized national testing laboratories,

such as Underwriters Laboratories, Inc. (UL) in the U.S.A. and Canadian Standards

Association (CSA) in Canada. Listing of a product by a national testing laboratory

indicates that the product is designed and manufactured in accordance with

national requirements intended to minimize safety hazards. This equipment meets

a very high standard of safety in design and manufacture. Remember, however,

that this product operates under conditions of high electrical potentials and heat

generation, both of which are functionally necessary.

Because the paper used in the printer can burn, you should take normal

precautions to prevent fire. These precautions include common-sense measures,

such as keeping potentially combustible materials (for example, curtains and

chemicals) away from the printer, providing adequate ventilation and cooling,

limiting unattended operation, and having trained personnel available and

assigned to the printer.

Approved power cord and receptacle

DANGER

<1-11> Your country may require an approved power cord and plug.

Ensure that you have the correct power cord and plug. Use this cord and

plug only with an approved, correctly-installed power receptacle.

Electrical safety and portable power strip receptacles

Extension cords

DANGER

DANGER<1-1> Do not use an extension power-cord.

The customer must supply the correct electrical outlet which must meet the

requirements stated under Appendix A, “Printer specifications,” on page 165.

Portable power strip receptacles (temporary power taps)

Portable power strip receptacles (referred to as “temporary power taps” by the

National Electrical Code) may be used if they are fully approved in the customer's

geographic location. It is the customer's responsibility to supply a fully approved

“temporary power tap”, if one is to be used.

xii User’s Guide

Page 13

Connecting or disconnecting a communication port, a teleport, or an attachment connector

DANGER

<1-14> Switch off printer power and unplug the printer power cord before

connecting or disconnecting a communication port, a teleport, or other

attachment connector.

Servicing during an electrical storm

DANGER

<1-13> Do not connect or disconnect a communication port, a teleport, or

any other connector during an electrical storm.

Safety and environmental notices xiii

Page 14

xiv User’s Guide

Page 15

Preface

This guide describes the basic operating procedures for the 4247 Model X03

printer. This information is useful to those who install or operate the printer, or for

those who supervise printer operations.

You need only basic operating experience to use this printer. This experience

includes an understanding of how printers work, how to connect cables, and how

to select items from an operator panel menu.

How to use this guide

The following list describes the contents of each chapter and the appendixes in this

book.

v Chapter 1, “Getting started,” provides information on setting up the printer and

connecting it to the host computer.

v Chapter 2, “Understanding the operator panel,” describes the operator panel and

how to use it.

v Chapter 3, “Checking and changing configuration parameter values,” describes

the configuration parameters and values and gives you a brief description and

procedure for changing them.

v Chapter 4, “Configuration storage,” provides information on saving

configuration parameters into a custom set for your printer. The configuration

storage category has eight available custom sets.

v Chapter 5, “Attachment options,” provides the procedure for setting the

configuration for printer attachment.

v Chapter 6, “IPDS Configuration,” describes how to check and change IPDS

configuration parameters for your 4247 printer.

v Chapter 7, “ASCII Configuration,” describes the procedures for checking and

changing parameter values for parallel and serial attachments.

v Chapter 8, “Printer setup,” describes the procedures for checking and changing

the parameter values in the configuration menu for the printer setup category.

v Chapter 9, “Printer adjustments,” describes the parameters for checking and

changing the parameter values in the configuration menu for the printer

adjustment category.

v Chapter 10, “Power-On Reset (POR),” describes the procedure to perform a

power-on reset for your printer.

v Chapter 11, “Display Language,” provides information on the display languages

shipped with your printer.

v Chapter 12, “Vital Product Data,” provides information to check and change

some of the vital product data for the printer.

v Chapter 13, “Quiet Print,” describes the procedure to set the Quiet Print mode

for your printer.

v Chapter 14, “Hex Print,” describes the procedure to set the Hex Print mode for

your printer.

v Chapter 15, “Quit From Menu,” describes the procedure to quit from the

configuration menu and restore the previous configuration menu values.

v Chapter 16, “Dual push tractor forms paths,” describes forms and paper loading,

and running a print job through the six different paper paths.

™

xv

Page 16

v Chapter 17, “Using the Operator Print Tests,” describes procedures for testing

and adjusting the printer.

v Chapter 18, “Supplies, optional features, and maintenance,” provides the

information you need for ordering new supplies, replacing damaged or worn

ribbons, and available printer options.

v Chapter 19, “Problem solving,” describes how to diagnose and solve printer

problems. Always start your problem determination procedure with this chapter.

v Appendix A, “Printer specifications,” contains general printer information and

planning requirements. It also contains information on the electrical and

environmental requirements, cabling information, and forms specifications.

v Appendix B, “4247 Model X03 - Configuration Menu,” contains a hierarchical

representation of the Configuration Menu.

v Appendix C, “Printer driver support,” on page 175 contains information about

downloading drivers for your printer.

xvi User’s Guide

Page 17

Chapter 1. Getting started

Printer parts ..............2

Unpacking the printer ...........3

Choosing a suitable location ........4

Performing a power-receptacle safety-check . . . 5

4247 Model X03 nominal AC input power

requirements ............5

Installing the Controller Board ........5

Handling the Controller Board .......5

Inserting the Controller Board .......6

Installing the operator panel overlay ......8

Installing the ribbon cartridge ........9

This chapter guides you through setting up your 4247 Model X03 printer. The

partial table of contents at the beginning of the chapter shows the procedures

involved in this setup process. Refer to this list for specific procedures and page

locations.

Perform Each Step in Order

Complete each step before you start the next one. If you cannot

successfully complete all of the following steps, call your place of

purchase.

Removing the ribbon cartridge .......12

Power connection ............13

Changing the display language (from English). . . 15

Loading forms in the Front Push Tractors ....16

Printing your first documents ........19

Installing the optional second tractor ......20

Removing the optional second tractor .....24

Attaching the 4247 Printer to your computer . . . 25

Completing printer setup ..........25

Software driver selection ..........26

1

Page 18

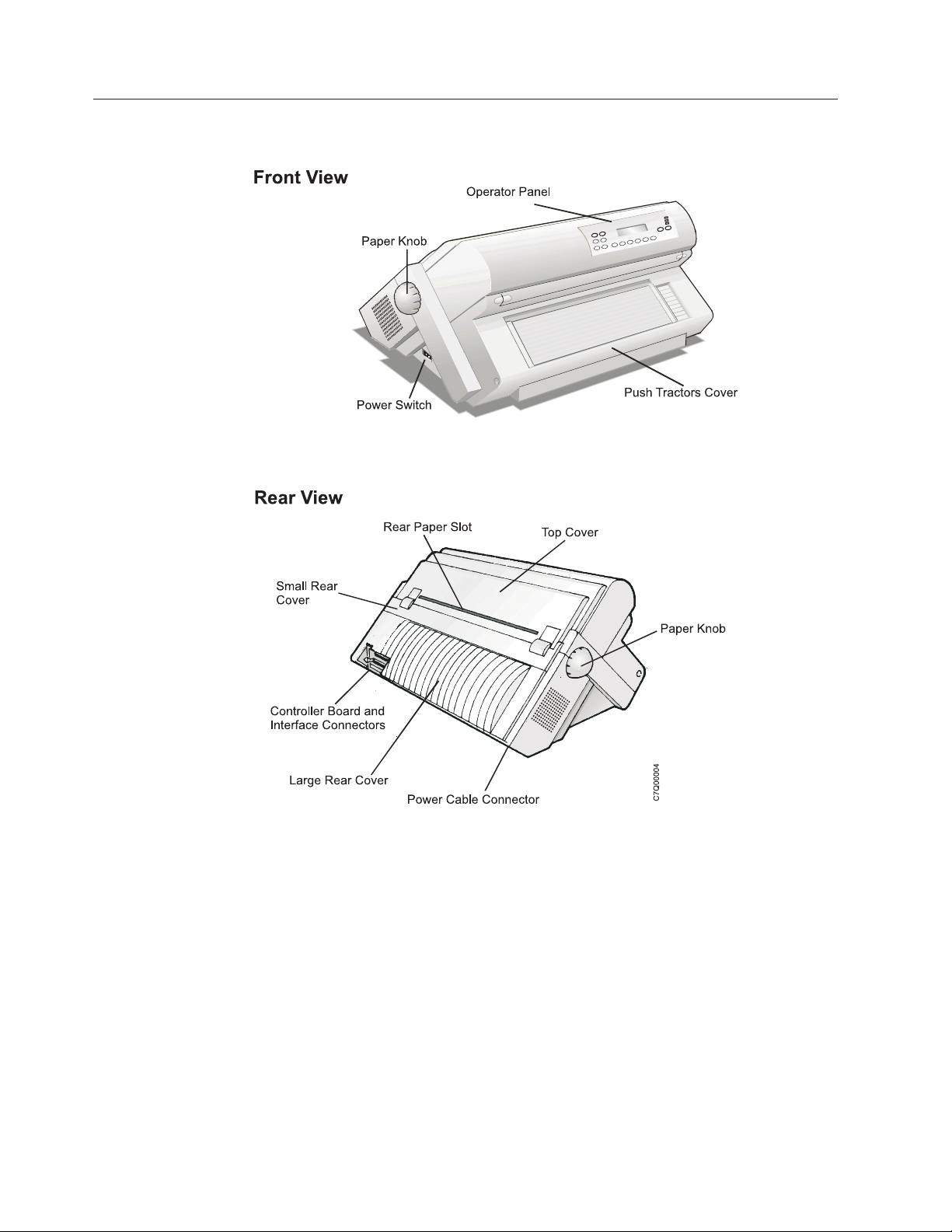

Printer parts

2 User’s Guide

Figure 1. Printer Parts: Front and Rear View

Page 19

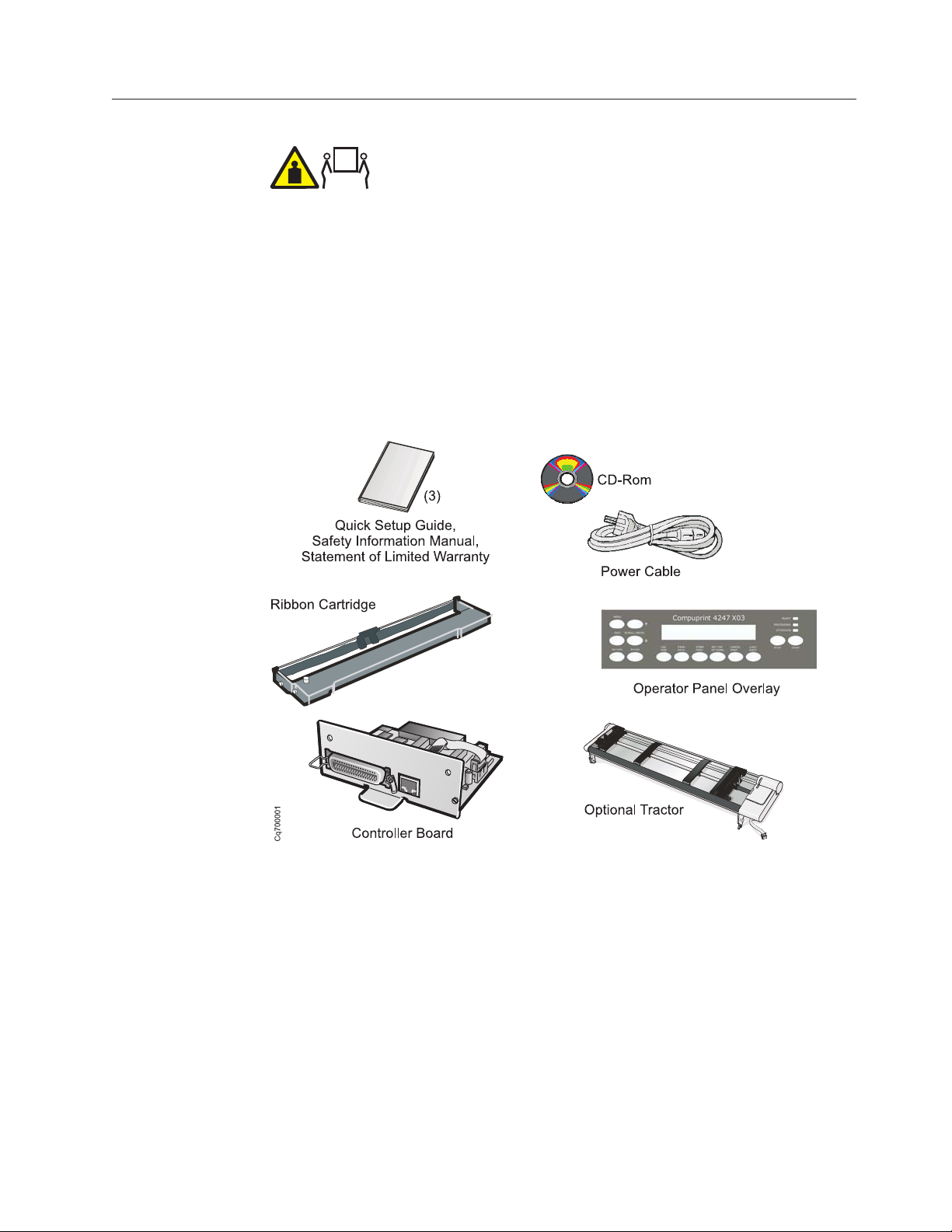

Unpacking the printer

1. Review the following list of contents as you unpack the shipping container.

Contact your point of purchase if any items are missing.

__ v Printer

__ v One forms tractor (and optional second tractor)

__ v Ribbon cartridge

__ v Documentation and CD

__ v Controller Board (do not remove from protective package)

__ v Operator panel overlay

__ v Power cable

__ v CD Rom

CAUTION:

The 4247 printer weighs 21 kg (46 lbs). Two persons are required to lift

it.

Figure 2. Contents of Shipping Container

Additionally, you can order the following option (not pictured here).

v Printer Stand - Provides adequate printer support, and especially helpful

when using the Dual Push forms path

2. After opening the shipping container, have another person help you remove the

printer and place it on a table or the optional printer stand. If you select a table

as the permanent location, ensure:

v You have access to both the front and the rear of the printer.

v The table you select is sturdy enough to support the weight of the printer,

and firm enough to contain the action of the printer movement. To meet this

criteria, We recommend the optional printer stand which is available from

your marketing representative.

Chapter 1. Getting started 3

Page 20

3. Remove the remainder of the contents from the shipping container. (See

Appendix A, “Printer specifications” for dimensions of the table or printer

stand surface and the clearances required around the printer.)

4. If you have not already done so, remove the plastic bag from the printer.

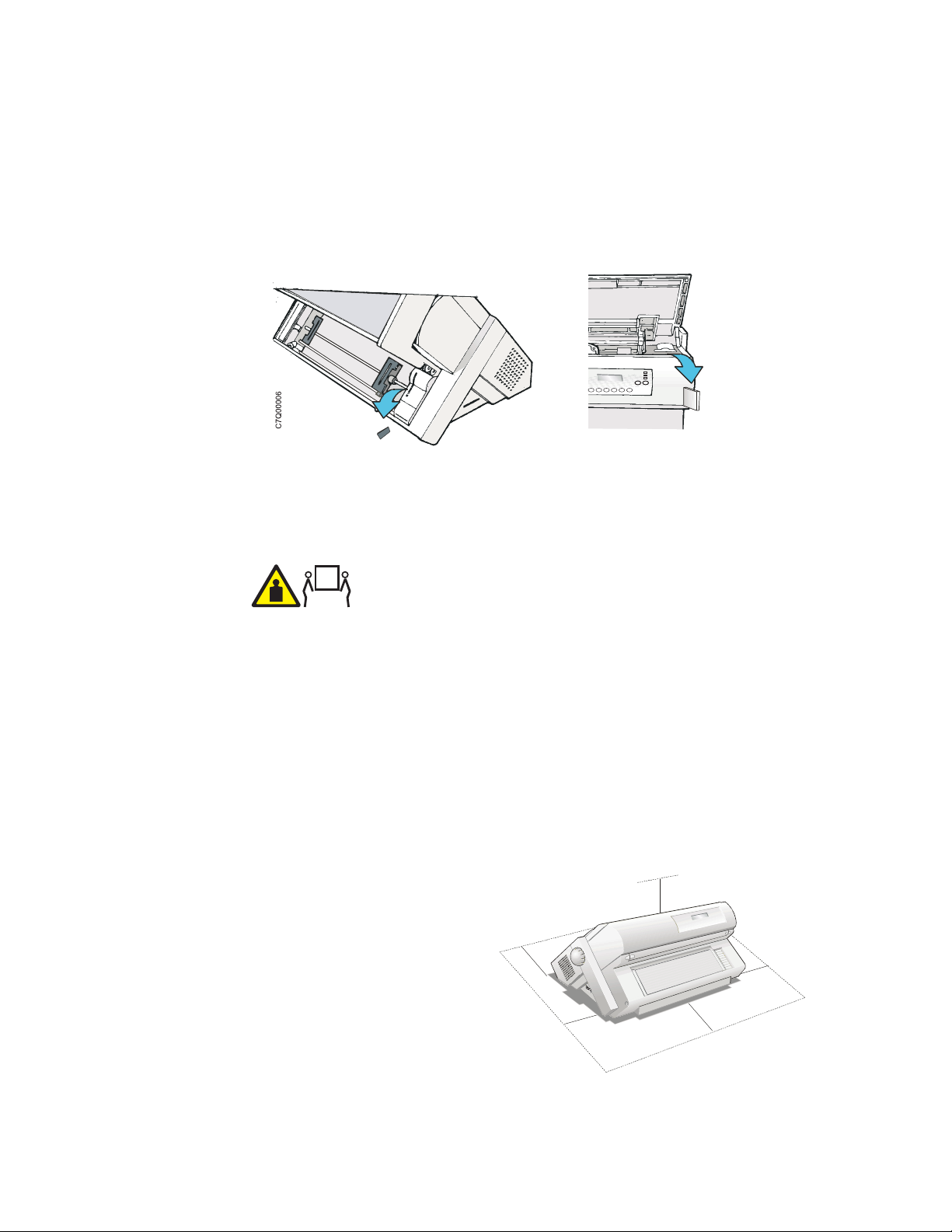

5. Lift the bottom edge of the front tractor cover into the open position.

6. Remove the shipping locks from the printer.

Figure 3. Removing the shipping locks from the printer.

Choosing a suitable location

CAUTION:

The 4247 printer weighs 21 kg (46 lbs). Two persons are required to lift

it.

Consider the following points when you choose the location for your printer:

v The distance between the printer and the host computer must not exceed the

length of the interface cable. The location must be sturdy, horizontal and stable

v Your printer must not be exposed to direct sunlight, extreme heat, cold, dust or

humidity (see Appendix A, “Printer specifications,” on page 165.

v You need a power outlet compatible with the plug of the printer's power cord.

v For best continuous forms stacking, the forms should be stacked on the floor or

on a surface below the base of the printer.

v For successful forms parking, the input forms stack must always be lower than

the base of the printer.

There must be sufficient

clearances on all sides for easy

operation. The required space is

shown in the following figure:

1

0

3

9

.

4

Hc0i0005

0

c

m

i

n

m

c

0

2

n

i

9

.

7

80 cm

31.5in.

m

c

0

2

n

i

9

.

7

1

0

3

0

9

c

.

4

m

i

n

4 User’s Guide

Figure 4. Printer clearances.

Page 21

Performing a power-receptacle safety-check

DANGER

<1-10> Hazardous voltages are present. Do not touch the pins or sockets of

the power receptacle.

For pluggable equipment, the socket-outlet shall be installed near the equipment

and shall be easily accessible.

“Portable power strip receptacles (temporary power taps)” on page xii, conforming

to all requirements, may be used.

A qualified electrician should perform all checks necessary to ensure safe

operation. These should include the following checks and any other required by

local regulations.

v Check the AC voltage at all associated power receptacles (see “4247 Model X03

nominal AC input power requirements”).

v Check the AC impedance to ground at all associated power receptacles.

Attention: If the voltages are not within the correct operating range, allow

correction before the equipment is plugged in and operated.

4247 Model X03 nominal AC input power requirements

Nominal Voltage Voltage Range Amps Phase / Hz

100–230 Vac 90–264 Vac 3.8–1.6 A Single phase /

Installing the Controller Board

The 4247 printer arrived with the Controller Board that you ordered.

You must install the Controller Board (received with the printer) into the proper

slot in the back of the printer before it can be used.

Handling the Controller Board

Attention: Do not remove the Controller Board from the protective package until

instructed to do so. Static electricity, though harmless to you, can damage sensitive

Controller Board components. Use the information in this section to avoid

damaging a Controller Board.

v Limit your movement. Your movement can create static electricity that, when

released to the Controller Board, can damage the electronic components on the

Controller Board. Sliding your foot across carpeting is an example of how you

create unwanted static electricity.

v Handle the Controller Board only by the edges and prevent others from making

direct contact with it.

v Before removing the Controller Board from the protective package, ground the

package to exposed metal at the back of the printer. This will release any static

50–60 Hz

Chapter 1. Getting started 5

Page 22

charge that may have developed on the package or on your body. Hold the

package against the metal for at least two seconds.

v When you are instructed, remove the Controller Board and install it directly into

the Controller Board slot without setting it down. If you have removed the

Controller Board from the protective package and cannot immediately insert it in

the printer, place the protective package on a flat surface, and set the Controller

Board on top of the protective package.

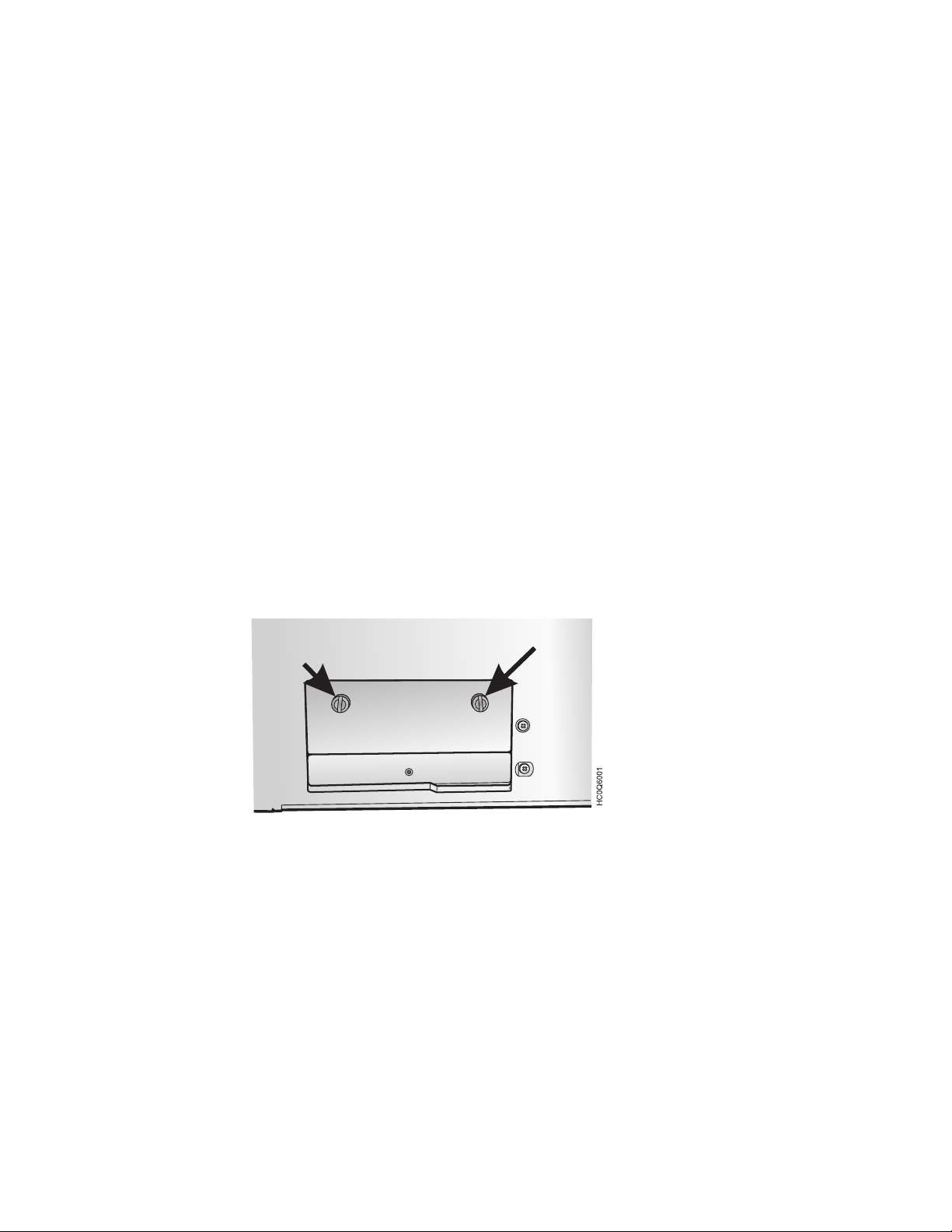

Inserting the Controller Board

Attention: Ensure that the printer is powered off before installing or removing

the Controller Board.

If the Controller Board is installed while the printer is powered on, the controller

will not synchronize with the printer mechanism board. Unpredictable printer

behavior will result.

Perform the following steps to install the Controller Board:

1. Ensure that the printer is powered off. Installing the Controller Board with the

printer power on will result in unpredictable printer behavior.

2. Use the screwdriver that came in the Controller Board box to remove the metal

plate on the back of the printer by unscrewing the two screws.

Note: Save the two screws as you need them to attach the Controller Board to

the back printer. Save the metal plate for reuse if the Controller Board is

removed.

6 User’s Guide

Figure 5. Removing the two screws on the metal plate.

3. Use the information under “Handling the Controller Board” on page 5 as you

remove the Controller Board from its shipping box and from the protective

package.

4. Align the left and right sides of the Controller Board with the guides in the

printer and slide it into the slot.

Page 23

Figure 6. Sliding the board in the slot.

5. Gently push the Controller Board into the printer until it is seated in the

connector inside the printer. The Controller Board is correctly seated in the

printer when the Controller Board metal plate is aligned with the back profile

of the slot.

6. Attach the Controller Board with the two captured screws using the

screwdriver that came in the Controller Board box.

Figure 7. Attaching the Controller Board.

Chapter 1. Getting started 7

Page 24

Installing the operator panel overlay

Figure 8. Operator panel

1. Remove the protective film from the printer operator panel display.

2. Remove the paper backing from the reverse side of the operator panel overlay.

3. Align the bottom of the overlay and align both sides. Ensure that the placement

you choose for the overlay will allow free movement of the operator panel

keys.

4. After being satisfied with the placement, press the overlay in place starting at

the bottom below the keys, and continue working upwards until the overlay is

pressed into place.

8 User’s Guide

Page 25

Installing the ribbon cartridge

It is recommended that you use an approved ribbon cartridge. To install the ribbon

cartridge, follow these steps:

1. Remove the ribbon cartridge from the package. Locate the ribbon guide, snap

arm, ribbon advance knob, and the ribbon mounting pins.

To avoid damage to the ribbon, do not turn the winding knob in the wrong direction.

2. Turn the ribbon advance knob in the direction of the arrow to take up any

slack in the ribbon. If the ribbon does not move, contact your place of ribbon

purchase to replace the ribbon cartridge.

Figure 9. Ribbon Cartridge

Chapter 1. Getting started 9

Page 26

3. Open the top cover using the small handles on either side of the top cover.

Figure 10. Opening the top cover

4. Slide the print head to the center of the printer.

5. Align the cartridge pins with the locking grooves on the left and right

cartridge supports.

10 User’s Guide

C7Q02016

Figure 11. Aligning the cartridge pins.

Page 27

6. Position the ribbon guide over the printhead, holding it perpendicular to the

print head.

HC0I0030

Figure 12. Print head and ribbon guide mask showing correct positioning of the ribbon.

7. Turn the ribbon advance knob to take up any slack in the ribbon.

8. Position the snap arm with the small lever up onto the ribbon lift assembly.

Push the snap arm down onto the ribbon lift assembly until it snaps into

place.

Figure 13. Positioning the snap arm.

e61a2018

Chapter 1. Getting started 11

Page 28

9. Align the ribbon mounting pins on the left and right side of the ribbon

cartridge with the slots in the cartridge supports. Snap the ribbon cartridge

down into place.

Figure 14. Aligning the ribbon mounting pins.

10. Turn the ribbon advance knob again in the direction of the arrow to take up

any slack in the ribbon, as you slide the printhead back and forth to ensure

that the ribbon guide runs freely along the ribbon.

11. If the ribbon is not running freely, or to ensure that you have installed the

ribbon cartridge correctly, ensure that:

a. The left and right ribbon mounting pins are securely snapped into the

cartridge supports.

b. There are no twists or folds in the ribbon.

c. The ribbon is not catching on the printhead.

d. The ribbon moves when you turn the ribbon advance knob in the direction

of the arrow. If the ribbon does not move, replace the ribbon cartridge.

Contact your place of ribbon cartridge purchase if you believe that the

ribbon is faulty.

12. Close the top printer cover.

Removing the ribbon cartridge

12 User’s Guide

See “Removing the ribbon cartridge” on page 149 for instructions on this

procedure.

Page 29

Power connection

1. Make sure the power outlet is near the printer location and easily accessible.

2. Make sure that the power switch is in 0 position (OFF).

3. Insert the power cable plug into the printer connector and the other power

DANGER

<1-11> Your country may require an approved power cord and plug.

Ensure that you have the correct power cord and plug. Use this cord

and plug only with an approved, correctly-installed power receptacle.

cable end into a convenient outlet.

12

HC0I0014

Figure 15. Inserting the power cable plug

4. Turn the printer on, press the power switch in the I position (ON).

HC0I0015

Figure 16. Power switch in the I position (ON).

Attention: If, for any reason, the Controller Board was not correctly installed in

the printer, the printer will not work and the following audio/visual symptoms

will occur:

v The buzzer sounds continuously

v The Operator Panel display is partially filled with solid black boxes

v The Operator Panel LEDs are all lit.

If this is the case, power off the printer, re-seat the Controller Board, and power

the printer on again.

Chapter 1. Getting started 13

Page 30

Note: If the printer does not show the correct display sequence, go to the status

code section of “Using status code and problem listings” on page 151.

Follow the instructions for the status code shown on the display panel.

14 User’s Guide

Page 31

Changing the display language (from English)

The printer is delivered with English as the default language. Follow this

procedure to change the language in which messages and menu items will appear

in the operator panel display.

1. Press MENU to enter configuration.

2. Press SCROLL/MICRO

CONFIGURATION MENU

Display Language

3. Press ENTER to display the current value.

4. Press SCROLL/MICRO

is displayed.

5. Press ENTER. An asterisk (*) will be displayed in front of the selected value.

6. Press RETURN to return to the Configuration Menu.

7. Press START. The printer displays:

Press ENTER to Save

Press START to Not Save

8. Choose between one of these options:

v If you want to use the selected display language as the printer default for

this session only (the printer will use the existing defaults the next time it is

powered on), press START. The printer will exit the menu and become

ready.

v OR

v If you want to keep the selected display language as the printer default,

press ENTER. The printer displays:

or SCROLL/MICRO until the printer displays:

or SCROLL/MICRO until the language you want

Save Current Values

Custom Set A

9. Press ENTER.

10. Press START again. The printer will exit the menu and become ready.

Chapter 1. Getting started 15

Page 32

Loading forms in the Front Push Tractors

This sequence describes how to load the fanfold paper with the push tractor

(default).

1. Turn the printer on.

2. Open the Push tractors cover turning it upwards and lay it on the top of the

printer.

Figure 17. Opening the Push tractors cover

3. Unlock the tractors by moving the sprocket levers to the up position. Slide the

left tractor to the left.

Figure 18. Unlocking the sprockets of the Front1 push tractor

16 User’s Guide

Page 33

4. Space the paper guides along the tractor bar. Open the left and right sprocket

covers.

HC0I0019

Figure 19. Opening the left and right sprocket covers.

5. Hold the fanfold paper in front of the sprockets and insert the paper

perforation on the left sprocket pins and close the left sprocket cover.

Figure 20. Closing the left sprocket cover.

Chapter 1. Getting started 17

Page 34

6. Insert the paper on the right sprocket pins.

HC0I0022

Figure 21. Inserting the paper on the right sprocket pins.

7. Match the left sprocket for the first printing position, that is the left margin

must match the 9

Note: Aligning the left-hand edge of the paper past the 22

th

mark on the printer cabinet.

nd

spacer on the

printer cabinet will cause the paper to be misaligned with the Paper

Load Sensor resulting in a '001 End of Forms' error.

9

1

345678

2

HC0I0023

18 User’s Guide

Figure 22. Matching the left sprocket for the first printing position.

Page 35

8. Adjust the right sprocket gently to remove slack from the paper. Lock the left

and right sprockets moving the sprocket levers to the up position.

HC0I0025

Figure 23. Adjusting the right sprocket

9. Close the Push tractors cover.

HC0I0026

Figure 24. Closing the Push tractors cover.

10. Press the STOP key to take the printer Not Ready.

11. Press the LOAD/EJECT key to load the paper into the printer.

12. Press the START key to put the printer READY.

Printing your first documents

The Quick Reference is a popular print test that may help familiarize you with the

operator panel keys and the configuration menu you can set. The Quick Reference

printout allows you to check print quality and printer operations.

v Each key is listed with a corresponding description to the right.

v Each parameter is shown with the corresponding values you can select printed

to the right.

1. Ensure that the printer is offline. If the printer is ready, press STOP to make the

printer not ready.

2. Press TEST.

3. Press SCROLL/MICRO

or SCROLL/MICRO until the printer displays:

Chapter 1. Getting started 19

Page 36

OPERATOR PRINT TESTS

Quick Reference

4. Press ENTER or START to print this test. The READY indicator comes on and

printing begins. Press STOP if you want stop the Print Test before it completes

printing.

5. Wait for the printer to stop printing and the READY indicator to go off.

6. Press FORM FEED until you can remove the printout. The printout should be

clear and readable.

YOU HAVE JUST COMPLETED A SETUP AND CHECKOUT OF THE PRINTER.

We recommend that you now print your printer configuration defaults. Save this

printout for future reference. You can create a printout of the printer configuration

by following these steps:

1. Press SCROLL/MICRO

OPERATOR PRINT TESTS

Print Custom Sets

or SCROLL/MICRO until the printer displays:

2. Press ENTER or START to print this test. See “Print Custom Sets” on page 141

for more information about this printout.

3. To exit Print Test, press RETURN to make the printer not ready or CANCEL

PRINT to make the printer ready.

Installing the optional second tractor

A second optional tractor is available for your printer. This tractor may be installed

on the first (standard) front tractor.

1. Open the tractor area cover.

Figure 25. Opening the tractor area cover.

20 User’s Guide

Page 37

2. Unpack the second tractor.

C7QU2023

Figure 26. Second tractor

3. Align the hooks on both sides of the second tractor with the pins on the first

tractor. Push the second tractor on the pins until it is fully engaged.

Figure 27. Aligning the second tractor hooks.

C7Q02024

Chapter 1. Getting started 21

Page 38

4. Connect the second tractor to the first using the electrical cable/connector

provided on the tractor.

C0Q02025

Figure 28. Connecting the second tractor

5. Rotate the tractor gear protection cover downwards to free the gear.

22 User’s Guide

C7Q02026

Figure 29. Rotating the tractor gear protection cover.

Page 39

6. Rotate the second tractor into the closed operating position.

C7Q02027

Figure 30. Second tractor in the closed position.

7. To load paper onto the first tractor when the second tractor is installed, rotate

the second tractor out and insert paper between the two tractors. (See “Loading

forms in the Front Push Tractors” on page 16 for paper loading procedures.)

Figure 31. Paper path direction

Chapter 1. Getting started 23

Page 40

Removing the optional second tractor

If you need to remove the second optional push tractor, turn the printer off.

1. Disconnect the connector cable and press on the push buttons on either side to

disengage the tractor. Then pull the tractor off.

Figure 32. Disconnecting the second tractor.

CAUTION:

<2-53> If the second tractor unit is not installed, make sure the gear protector

cover is closed. Do not touch inside the printer or insert any object into the

gears.

e61a2028

2. Close the tractor gear protection cover.

Figure 33. Closing the protection cover.

24 User’s Guide

Page 41

Attaching the 4247 Printer to your computer

Connect the printer to your host computer using the interface on the Controller

Board (supplied in the printer box) you installed in the printer.

There are three types of Controller Boards:

1. Controller Board with a bidirectional IEEE1284 parallel interface, Serial

RS232/C 9-pin interface and USB 2.0 interface.

2. Controller Board with a bidirectional IEEE1284 parallel interface and ASCII

Ethernet 10/100 BaseT LAN interface.

3. Controller Board with a bi-directional IEEE1284 parallel interface and

ASCII-IPDS Ethernet 10/100 BaseT LAN interface.

DANGER

<1-14> Switch off printer power and unplug the printer power cord

before connecting or disconnecting a communication port, a teleport, or

other attachment connector.

Insert the host computer cable(s) into the back of the printer as shown below:

Controller Board with parallel interface and

ASCII-IPDS Ethernet 10/100 LAN interface.

Completing printer setup

Your 4247 Printer is now ready to use with the forms tractor mounted in the Front

Push position and with the configuration parameters set to manufacturing defaults.

The exception is that you have selected new defaults for display language.

To select any of the other 4247 paper paths, or to change printer configuration

parameters, see:

v Chapter 2, “Understanding the operator panel” for information on operating the

printer.

v Chapter 3, “Checking and changing configuration parameter values” for

configuration information.

v Chapter 16, “Dual push tractor forms paths” for forms loading procedures.

Controller Board with parallel interface,

Serial interface, and USB interface.

Chapter 1. Getting started 25

Page 42

Software driver selection

See Appendix C, “Printer driver support,” on page 175 for information about

selecting printer drivers.

26 User’s Guide

Page 43

Chapter 2. Understanding the operator panel

Status indicators .............27

READY...............27

PROCESSING ............28

ATTENTION .............28

Display panel..............28

Audible alarm .............29

Custom Set In-Use Indicator .........29

Function Keys .............29

MENU ...............30

SCROLL/MICRO↑ or SCROLL/MICRO↓ ...30

Adjusting forms ...........31

Scrolling through categories, parameters,

values, and tests ...........31

ENTER ...............31

This chapter describes the function of the operator panel. The operator panel

contains 3 status indicators, a 2-line by 24-character display panel, 14 printer

function keys, and an audible alarm. Figure 34 illustrates the operator panel and

keys for the printer.

ENTER function ...........31

RETURN ..............32

RETURN function ..........32

PARK/PATH .............32

PARK function ...........32

PATH function ...........32

LINE FEED .............33

LOAD/EJECT ............33

FORM FEED .............34

SET TOP OF FORM ..........35

START...............35

STOP...............35

CANCEL PRINT ...........36

TEST ...............36

Figure 34. 4247 Printer Operator Panel

Status indicators

The following status indicators appear on the operator panel:

v READY

v PROCESSING

v ATTENTION

You can determine printer status by checking these indicators.

READY

If the READY indicator is lighted, the printer is ready to print. If READY is not

lighted, the printer is not ready to print. The printer can receive data when this

indicator is not lighted, but no data can be printed.

The Ready indicator is lighted because of one of the following conditions:

v Successful power-on sequence

v After pressing START, if the indicator was off because of one of the following

conditions:

– An error condition (if the error has been corrected)

27

Page 44

– An intervention required condition (if the error has been corrected)

– After pressing STOP

v After pressing ENTER or START to run a test in the Operator Print Tests menu

v After a successful partial reset to ready after pressing CANCEL PRINT to exit

the Operator Print Tests

The READY indicator is not lighted because of one of the following conditions:

v After pressing STOP

v After detection of an intervention required condition

v After detection of a printer error

v After pressing MENU to enter the Configuration Menu when no print job is in

progress

v After pressing LOAD/EJECT to perform an eject to tear off position when Front

Push or Rear Push is selected.

PROCESSING

If lighted, the printer is printing or processing data. If blinking, the printer buffer

contains data that cannot be printed immediately. If not lighted, there is no data to

process and no data in the print buffer.

ATTENTION

If blinking, the printer requires operator intervention (for example, to add forms or

to clear a forms jam). The type of intervention needed appears on the display

panel. If not lighted, the printer does not require immediate attention.

Display panel

The display panel is a 2-line by 24-character liquid crystal display (LCD) that

displays printer status messages, the print test menu, and the configuration menu

categories, parameters, and values. Use this display panel and the printer function

keys to scroll through and select Configuration Menu items and Operator Print

Tests. You can set this display so the messages appear in one of the following

languages:

v 000 English (default)

v 001 Deutsch

v 002 Français

v 003 Italiano

v 004 Español

v 005 Nederlands

v 006 Dansk

v 007 Português

v 008 Norsk

v 009 Svenska

v 010 Suomi

v 011 Polski

28 User’s Guide

Page 45

Audible alarm

If you do not disable the audible alarm, it beeps if any of the following conditions

occur:

v Immediate intervention is required

v A printer error condition exists

v The printer receives a command from the host to turn on the alarm

v An invalid key press is attempted

v The SET TOP OF FORM key is pressed

To turn a beeping alarm off, press STOP. You can disable the audible alarm. See

“Alarm control” on page 66 for instructions.

Note: Pressing SET TOP OF FORM and some attention conditions sound the

alarm, even if it is disabled.

Custom Set In-Use Indicator

This indicator shows the parameter custom set that is currently being used by the

printer. The indicator is located in the top right corner of the operator panel. A

custom set is a set of configuration values that have been defined at the operator

panel and saved under a letter ID. When the custom set identified by this ID is

selected from the operator panel, these configuration values are used by the

printer.

Function Keys

NOT READY <X>

The current custom set in use is displayed in parentheses <X>. Where <X> can be:

A (Custom Set A in use)

B (Custom Set B in use)

C (Custom Set C in use)

D (Custom Set D in use).

E (Custom Set E in use)

F (Custom Set F in use)

G (Custom Set G in use)

H (Custom Set H in use).

If a change was made in the configuration menu and not saved in a custom set,

then the change is temporary and a blank < > is displayed in the parentheses. For

more information on Custom Sets, see Chapter 4, “Configuration storage.”

There are 14 keys available on the operator panel for performing printer functions.

These keys perform general printer functions (for example, adjusting forms) and

are used to scroll through and select items in the Configuration Menu and

Operator Print Tests menu.

The following section describes each of the printer function keys on the operator

panel.

Chapter 2. Understanding the operator panel 29

Page 46

MENU

Use the Menu function key to enter the Configuration Menu. This function key is

valid when the printer is not ready or the printer is ready and no job is in progress.

After you enter the Configuration Menu, paper movement functions are not

available.

Press MENU to enter the Configuration Menu.

The printer displays:

CONFIGURATION MENU

Configuration Storage

Note: If a print job is in progress (the printer is printing or the PROCESSING

indicator is on), the printer displays:

009 INVALID KEY PRESS

PRESS STOP FIRST

In this case, you can press STOP first and then enter the Menu. However, it is not

recommended that you change the Configuration Parameter Values while a print

job is in progress.

The configuration menu can be locked to prevent an unauthorized user from

changing parameter values. When the configuration menu is locked, pressing the

MENU key only allows recall of Custom Set Values. The Printer Adjustments in

the Operator Print Tests Menu are disabled.

If the MENU is locked, the printer displays:

097 FUNCTION DISABLED

MENU LOCKED

For more information on the Menu Lock function, see your system programmer or

the 4247 Model X03 Printer Programmer Manual.

For more information on configuration parameters and values, see “Checking and

changing parameter values” on page 38.

SCROLL/MICRO↑ or SCROLL/MICRO↓

Use SCROLL/MICRO or SCROLL/MICRO to perform the following functions:

v Adjust forms upward or downward when the printer is not ready.

v Scroll through the Configuration Menu categories, parameters, and values.

v Scroll through the Operator Print Tests menu items.

30 User’s Guide

Page 47

Adjusting forms

Press SCROLL/MICRO or SCROLL/MICRO to move the form 0.176 mm

(1/144 in.) in the direction of the arrow each time you press the key. If you

continue to hold down the SCROLL/MICRO key, the forms move continuously

until you release the key.

When the printer is at the top of the forms and the SCROLL/MICRO keys are

used, the new forms position is now the top of forms.

Note: If you use these keys when the PROCESSING indicator is blinking, the top

of form position could become misaligned.

Scrolling through categories, parameters, values, and tests

The scrolling functions are available only when the Configuration Menu or Test

Menu is displayed.

ENTER

Pressing SCROLL/MICRO

the second line of the display to show the previous configuration category,

parameter, or value. Pressing SCROLL/MICRO

displayed changes the second line of the display to show the next configuration

category, parameter, or value.

Pressing SCROLL/MICRO

line of the display to show the previous test name. Pressing SCROLL/MICRO

when the Test Menu is displayed changes the second line of the display to show

the next test name.

The scroll keys also enable the selection of numeric values. The list of numeric

values starts with the lowest value. When a numeric value is to be entered, use

SCROLL/MICRO

SCROLL/MICRO

second line of the display panel. When the value you wish to select appears, press

ENTER.

The scrolling functions are also used during some of the Operator Print Tests. See

Chapter 17, “Using the Operator Print Tests” for more information.

to see the next lower value in the range and

to see the next higher value. The values are shown on the

when the Configuration Menu is displayed changes

when the Configuration Menu is

when the Test Menu is displayed changes the second

ENTER function

The Enter function is available when the Configuration Menu or Operator Print

Tests Menu is displayed.

Pressing ENTER selects the displayed option.

The Enter function is also used during some of the tests.

Chapter 2. Understanding the operator panel 31

Page 48

RETURN

RETURN function

Pressing RETURN in the Configuration Menu returns to the previous level of the

menu, unless the printer already displays:

CONFIGURATION MENU

Configuration Storage

If Configuration Menu is displayed, the printer exits the menu and becomes not

ready.

Note: If you have made configuration changes and have not saved them in a

PARK/PATH

Custom Set, the display will prompt you to save the changes. If you are in

the Operator Print Tests Menu and a test is not running, pressing RETURN

will exit the Test Menu and make the printer not ready.

PARK function

Pressing this key causes the printer to enter the Park function in either the ready

and not ready state. The continuous forms will back up (reverse the process

direction of) the forms in the forms path.

If continuous forms are currently in the printer and the top of the form is beyond

the print area, press PARK/PATH. The forms will be ejected for tearoff and the

printer will display:

091 FANFOLD PARK

TEAR OUTPUT PRESS PARK

If special forms are currently in the printer that cannot be moved backwards (for

example, labeled continuous forms), the printer displays:

092 FANFOLD PARK

TEAR INPUT PRESS EJECT

Perform the action requested on the operator panel display. The printer is then

ready for the paper path selection.

PATH function

When no forms are in the current path and the printer is in the not ready state,

pressing PARK/PATH allows the selection of the different forms paths available on

the printer. When the desired path is displayed, press START. The forms path

displayed becomes the active forms path and the printer becomes ready. You can

also press LOAD/EJECT or FORM FEED for continuous forms to select the active

forms path.

32 User’s Guide

Page 49

The forms path selected by PARK/PATH also becomes the current value for Paper

Source in the Printer Setup category. See “Paper Source” on page 101.

LINE FEED

This function is valid only when the printer is not ready.

Press LINE FEED to cause the printer to advance the forms one print line, based

on the current LPI setting. If you hold LINE FEED more than four seconds, the

forms move continuously until you release the key.

Similar to the forms advance knob on other printer products, the LINE FEED key

allows coarse vertical movement of forms. This key does not function as an

“Index” key, which may be found on other printer products.

Note: If you use this key when the PROCESSING indicator is blinking, the top of

form position could become misaligned.

LOAD/EJECT

The LOAD/EJECT function depends on what active form path you have selected.

This section describes the function for each of the paper paths.

The LOAD/EJECT key performs the following functions:

v Automatically loads forms

After the forms are loaded under the sensor and onto the tractors at the bottom

of the forms device press LOAD/EJECT to automatically load the forms to the

top of form position.

v Moves forms to the tear-off position

Do not press STOP first.

If a Form Feed is done, either by data stream command or by pressing FORM

FEED, prior to pressing LOAD/EJECT, the forms will be positioned for you to

tear off the forms at a perforation.

Note:

If pressing LOAD/EJECT did not align the forms perforation with the tear

bar, check the following:

1. Assure that a Form Feed has been done just prior to pressing

LOAD/EJECT.

2. Verify that the Tear Position value for the path you are using (Front or

Rear) in the Printer Adjustments section of the Configuration Menu

has been set correctly. Often this value is the negative of the Paper

Load Position value. Adjust the Tear Position to give the best

alignment of the forms perforation to the tear bar edge. Each path has

its own set of adjustment values. When you change these values,

ensure that you are setting the values for the desired path.

Chapter 2. Understanding the operator panel 33

Page 50

If you specify Immediate Eject for Continuous Forms Eject Mode parameter

(default value) in the Printer Setup category, press LOAD/EJECT to immediately

make the printer not ready. The printer displays:

003 FORMS EJECTED

PRESS LOAD

and advances the form so that you can tear off the form at the perforation and

remove it from the printer.

If you specify Delayed Eject for the Continuous Forms Eject Mode parameter in

the Printer Setup category, press LOAD/EJECT to cause the printer to display:

093 EJECT PENDING

and beep the alarm. When the end of the form is reached, the printer becomes

not ready, displays:

003 FORMS EJECTED

PRESS LOAD

and advances the form so that you can tear off the form at the perforation and

remove it from the printer.

Pressing the key a second time moves the next form to be printed back to the

previous print position and makes the printer ready.

Refer to “Continuous Forms Eject Mode” on page 109 for more information on

changing Continuous Forms Eject mode.

v Ejects forms for viewing

If a Form Feed is not done prior to pressing LOAD/EJECT, the forms will be

positioned for you to view them to examine the printing

FORM FEED

This key advances the forms so that the next form is at the top of form position.

The Form Feed function is available when the printer is not ready.

v If you interrupt a print job by pressing STOP, pressing FORM FEED, and then

pressing START (when you are ready to resume the job), the printer continues

to print on the next form at the place where printing was interrupted on the

previous form.

v If FORM FEED is pressed during Front Push or Rear Push load operation, the

FORM FEED functions as a LOAD/EJECT and performs an automatic load.

v The printer does not always have to be not ready before pressing FORM FEED.

See “Form Feed Mode” on page 105 for more information.

34 User’s Guide

Page 51

SET TOP OF FORM

This should only be used when printing occurred and no Top-of-Forms commands

have been passed to the printer (such as Form Feed or Printer initialization).

The Set Top of Form function is available only when the printer is not ready, and

the paper is loaded to the print line. This key can be used only for the continuous

forms paper sources.

Press SET TOP OF FORM to set the top of form position for continuous paper

sources only. The alarm beeps and the printer displays:

TOP OF FORM SET

while you hold down the SET TOP OF FORM key.

If preprinted forms are being used, use Paper Load Positioning (see Chapter 9,

“Printer adjustments,” on page 115) instead of Top-of-Form.

START

STOP

Press START to perform the following functions:

v Make the printer ready and cause the READY message to appear in the operator

panel display.

v Exit the Configuration Menu and make the printer ready. If a partial reset is

required, it is performed to put configuration changes into effect before the

printer becomes ready.

Note: If you have made configuration changes and have not saved them in a

Custom Set, the display will prompt you to save the changes.

v Start the printer printing if no error condition appears on the display and if the

computer is sending data to be printed.

v Begin a test from the Operator Print Tests menu.

If the printer is in a ready state, press STOP to:

v Make the printer not ready and cause the READY message to disappear from the

operator panel display

v Stop printing as soon as possible without losing print data

v Stop a test if the printer is in test mode

v Stop the printer alarm from beeping

v Allow you to use the other printer function keys

v Cause the printer to display:

Chapter 2. Understanding the operator panel 35

Page 52

NOT READY <X>

(or cause the current test menu to display if the printer is in Operator Print Tests

mode)

If an error condition appears on the operator panel display, press STOP to:

v Clear the error message from the display

v Stop the printer alarm from beeping.

CANCEL PRINT

When this key is pressed while the printer is active and online, the attachment

sends a “cancel request” to the host the printer displays:

059 CANCEL PRINT ACTIVE

For any attachment option, the CANCEL PRINT button clears all print data and

buffers. This function is valid only when the printer is not ready.

CANCEL PRINT is also active in Operator Print Tests. If CANCEL PRINT is

pressed while in the tests, the printer stops any test in process, exits the test mode,

performs a partial reset, and becomes ready.

TEST

Press TEST to enter the Operator Print Tests menu. The Test function is valid only

when the printer is not ready.

There are several tests available. After you press TEST, the printer displays:

OPERATOR PRINT TESTS

Quick Reference

Press SCROLL/MICRO or SCROLL/MICRO to display the other available tests.

Refer to Chapter 17, “Using the Operator Print Tests,” on page 139 on selecting and

running tests.

36 User’s Guide

Page 53

Chapter 3. Checking and changing configuration parameter values

Printing configuration defaults ........37

Checking and changing parameter values ....38

Exiting the Configuration Menu .......39

Exiting using START ..........39

Exiting using RETURN .........39

Locking the Printer Configuration Menu.....40

Configuration categories ..........40

Configuration storage ..........41

Attachment .............41

IPDS Configuration ...........41

This chapter gives you brief descriptions and procedures for checking or changing

the Configuration Parameter Values. Parameter values are settings the printer

recognizes and uses to process print data. These values can be set using the

operator panel. They are grouped together into categories of values and are

accessed on the operator panel by these categories. These categories are available

on the Configuration Menu:

v Configuration Storage

v Attachment

v IPDS Configuration

v ASCII Configuration

v Printer Setup

v Printer Adjustments

v Power On Reset

v Display Language

v Vital Product Data

v Quiet Print

v Hex Print

v Quit From Menu

ASCII Configuration ..........42

Printer setup .............45

Printer adjustment ...........46

Power On Reset ............46

Display language ...........47

Vital Product Data ...........47

Quiet Print .............47

Hex Print ..............48

Quit From Menu ...........48

You can use the Configuration Parameter Values set at the manufacturer, or you

can change them. Instructions for checking and changing the Parameter Values for

each of these Configuration Categories are described in this section.

Notes:

1. The computer program can override Parameter Values that you select from the

operator panel. The values that the computer program cannot override are

listed in “Configuration categories” on page 40.

2. If a category or parameter that is not valid for your printer application is

displayed, you should ignore it; it will not harm the printer or affect its

operation.

3. We recommend that you print your custom sets for reference. See “Printer

Configuration” in Chapter 17, “Using the Operator Print Tests” for information.

Printing configuration defaults

We recommend that you print your configuration values and save this printout for

future reference. See “Printer Configuration” on page 141 for information on

printing your printer configuration values.

37

Page 54

Checking and changing parameter values

Checking and changing Configuration Parameter Values is done in the

Configuration Menu, which is entered with the MENU key. The Configuration

Menu is divided into three levels:

v Category

v Parameter

v Value

Note: Do not change Parameter Values during a print job; data may be lost.

Press MENU to enter the Configuration Menu.

CONFIGURATION MENU

Configuration Storage

The first category in the Configuration Menu is listed on the second line of the

display. Use SCROLL/MICRO or SCROLL/MICRO to scroll through the

Categories until the category you want is displayed. Press ENTER to display the

first Parameter in the Category you select. Use SCROLL/MICRO

SCROLL/MICRO

to check or change is displayed. Press ENTER to display the current value for the

selected Parameter (indicated by an asterisk [*]).

to scroll through the Parameters until the parameter you want

or

Use SCROLL/MICRO

available Values until the value you want is displayed. Press ENTER to select this

new value.

When you change the values and do not save them in a custom set, the printer

retains the values until one of the following occurs:

v You power off (O) the printer

v You change the values again

Unless you save the values in a custom set, the values you changed are lost when

you power off (O) the printer. The next time you power on (|) the printer, the

values you saved previously in the Power-On Custom Set, are the values the

printer uses.

See Chapter 4, “Configuration storage” for information about saving and recalling

parameter values in custom sets.

Configuration changes do not take effect until the printer completes printing the

buffered data (data the printer has in its storage areas).

If you change a parameter (or several parameters) and then decide you do not

want to keep your changes, you can return to the previous value settings by

selecting Quit from Menu from the Configuration Menu. The printer displays

Quit from Menu

Restore Previous Values

and SCROLL/MICRO to scroll through the other

38 User’s Guide

Press ENTER to restore the previous values, exit the Configuration Menu, and

make the printer not ready. See Chapter 15, “Quit From Menu” for more

information about restoring previous values.

Page 55

Exiting the Configuration Menu

You may quickly exit the Configuration Menu and make the printer ready by

pressing START. You may also exit the menu and make the printer not ready using

the RETURN key. These two methods maintain the changes you have made to the

configuration.

Note: If you wish to cancel your changes, you may Quit from the menu; see

Chapter 15, “Quit From Menu.”

Exiting using START

If you did not make any configuration changes or you stored your changes in a

custom set, press START and the printer will exit the menu and become ready.

If you made configuration changes and did not store them in a custom set, to exit

by using START, use the following steps:

1. Press START from any level of the menu.

The printer displays

Press ENTER to Save

Press START to Not Save

2. If you do not want to store your changes (they will be lost when the printer is

turned off), press START again and the printer will exit the menu and become

ready.

3. To store your changes in a custom set, press ENTER.

4. The printer will go to the Value level of the Configuration Storage Category in

the menu and display

Save Current Values

Custom Set A

5. Press SCROLL/MICRO or SCROLL/MICRO until the desired custom set

name is displayed.

6. Press ENTER to store the current parameter values (see Chapter 4,

“Configuration storage” for more details).

7. Press START again.

The printer will exit the menu and become ready.

See “Configuration categories” on page 40 for the parameters you can change and

the manufacturing values.

Exiting using RETURN

If you did not make any configuration changes or you stored your changes in a

custom set, press RETURN and the printer will exit the menu and become not

ready.

If you made configuration changes and did not store them in a custom set, to exit

by using RETURN use the following steps:

1. If CONFIGURATION MENU is not on the first line of the display, press RETURN.

2. Press RETURN again.

The printer displays

Chapter 3. Checking and changing configuration parameter values 39

Page 56

Press ENTER to Save

Press RETURN to Not Save

3. If you do not want to store your changes (they will be lost when you power off

the printer), press RETURN again and the printer will exit the menu and

become not ready.

4. To store your changes in a custom set, press ENTER.

5. The printer will go to the Value level of the Configuration Storage Category in

the menu and display

Save Current Values

Custom Set A

6. Press SCROLL/MICRO or SCROLL/MICRO until the desired custom set

name is displayed.

7. Press ENTER to store the current parameter values (see Chapter 4,

“Configuration storage” for more details).

8. Press RETURN three times to back out of the menu.

The printer will exit the menu and become not ready.

See “Configuration categories” for the parameters you can change and the

manufacturing values.

Locking the Printer Configuration Menu

The configuration menu can be locked to prevent an unauthorized user from

changing parameter values. When the configuration menu is locked, you can recall

saved custom sets (A through H), but cannot change configuration parameter

values. The Printer Adjustments in the Operator Print Tests Menu are also

disabled.

To lock or unlock the printer configuration:

1. Press STOP.

2. Press and hold TEST, while pressing START. The printer displays

PRESS STOP-->NOT READY

Note: Do not press STOP.

3. Press SET TOP OF FORM.

Configuration categories

This section lists all the selectable values available and the manufacturing defaults

for the parameters in each configuration category.

40 User’s Guide

Page 57

Configuration storage

Table 1 lists the parameters available for the Configuration Storage Category. Refer

to Chapter 4, “Configuration storage” for detailed information on setting these

parameters.

Table 1. Configuration Storage Category

Parameters Values Default

Save Current Values Custom Set A-H N/A

Recall Custom Set Custom Set A-H N/A

Power-On Custom Set Last Used

Power-On Paper Source Front

Recall Factory Defaults Yes N/A

Note: Use Recall Factory Defaults to set all the parameters to the manufacturing default

values. See “Recall factory defaults” on page 53.

Attachment

Table 2 lists the parameters available for the Attachment Category. Refer to

Chapter 5, “Attachment options,” on page 55 for detailed information on setting

these parameters

Last Used

Custom Set A-H

Front

Rear

Last Used

Table 2. Attachment Category

Parameters Values Default

Attachment Hot Port Switch, Parallel,

IPDS Configuration

Table 3 lists the parameters available for the IPDS Configuration Category.

Parameters that can be overridden by the computer are noted with a dagger (†).

Refer to Chapter 6, “IPDS Configuration,” on page 57 for detailed information on

setting these parameters