Page 1

Page 2

Page 3

Welcome to I+ME ACTIA !

Before acquainting you with your new I+ME Hardware

we would first like to thank you for purchasing our

product. We are extremely pleased that you have

chosen to place your trust in I+ME ACTIA and will do

our best to satisfy whatever needs you may have. The

following is a brief explanation highlighting our

background, areas of expertise and general product

lines. This products and the list of our world-wide

branch offices show that you have found a competent

partner in I+ME ACTIA.

Since its foundation in 1986, I+ME ACTIA has made

quite a name for itself. Our employees are dedicated to

producing high-quality solutions in the field bus and

multiplexed systems sectors. The knowledge of our

experts allows to develop a spectrum of products which

have been used in the automotive fie ld as well as in

general industrial environments. Our products can be

used in all phases of system development: system

definition, prototyping, evaluation and field application.

Informatik und MikroElektronik

Page 4

Whether your professional background is into industryprocess-control or development and test tools, we offer

six product groups to fulfill your sophisticated needs.

Tried and tested under the most severe conditions the

automotive industry has to offer, our products have

proved themselves again and again.

Our six products groups are:

1 CAN System Test & Design Tools

Support of various user application phases: Learning, prototyping, testing and evaluation of

networked systems. Comfortable

Real-Time simulation of message

transfer characteristics in CAN

networks. Tools for mobile

diagnosis and tests.

2 CAN PC Interfaces

Easy interfacing betwe en PCs,

Laptops, notebooks and networks

with automotive fieldbus – protocols. Available for all PC standard

interfaces such as ISA-slot, PCI,

backplane, RS232, Centronics

and PCMCIA. Development of

applications under DOS/Windows according to RealTime requirements is supported

3 CAN Industrial I/O

NiPC is an intelligent hardware

concept for sensor / actuator inter-

facing. A modular architecture al-

lows the flexible change target

micro controllers for process

control.

Page 5

4 CAN System Application Software

Enabling Real-Time system

modeling, testing of networked

systems as well as application

support. Offering basic services

for network communication which

is applicable for various

processors and programming

languages. Facilitating the application interface for

distributed industrial process control according to the

CAL standard by CiA. Support of Windows 3.1,

Windows 95 & NT.

5 CAN System Know How

Promoting the understanding of

various network protocols in

practice. Understanding of CAN

networks with CAL in practice.

Developing HW/SW solutions for

customer specific problems. We

offer CAN / CAL workshops and

in-house seminars to enable CAN

users to benefit from I+ME

ACTIA’s extensive knowledge.

6 Automotive Diagnostics

Assistance during the development

phases. Diagnostic tools for quality

control in production lines as well as

after sales diagnostic, control and

servicing tools are provided to

manufacturers, suppliers and dealers

of the car industry by I+ME ACTIA.

If you have any questions concerning our products or

you look for specific solutions within our product groups,

Page 6

don’t hesitate to call us and benefit from I+ME’s

extensive knowledge - your need is our desire.

Our merger with the french corporation ACTIA in 1995

allowed us to become a powerful supplier for the

European automotive industry. ACTIA products include

diagnostic systems for automotive service and

maintenance as well as development and production of

high-quality on-board electronics. joining forces with

ACTIA has enabled I+ME to better service it’s

international customers not only in Europe, but

throughout the world.

Headquarter: Office Stuttgart:

I+ME ACTIA GmbH I+ME ACTIA GmbH

Rebenring 33 Zettachring 4, 1.OG

38106 Braunschweig 70567 Stuttgart

Germany Germany

T: +49 531 38701 0 T: +49 711 72874 45

F::+49 531 38701 88 F: +49 711 72874 46

WORLDWIDE REPRESENTATIVES

ACTIA INC.

SI-KWADRAAT

NOHAU UK LTD.

AiXIA SA

NOHAU ELEK. AB

ACTIA SA

I+ME

INDUSTRADE AG

DAIWA SANKO

Page 7

I+ME ACTIA Representatives

SI-KWADRAAT ACTIA SA

Nuenen, Netherlands Toulouse, France

T: +31 40 2631185 T: +33 05 61176161

F: +31 40 2838092 F: +33 05 61554231

NOHAU ELEK. AB ACTIA INC.

Malmö, Sweden Bedford, Texas USA

T: +46 40 592200 T: +1 817 5710435

F: +46 40 592229 F: +1 817 3559513

If needed, please contact our associates below.

ATAL SPOL SRO ACTIA DO BRASIL

Tabor, Czech Rep. Porte Alegre, Brazil

T: +420 361 251791 T: +55 51 9699802

F: +420 361 23043 F: +55 51 3411989

ATON SYSTEMS SA ACVIBUS SA

France Mexico

T: +33 01 42071800 T: +525 368 6169

F: +33 01 42078555 F: +525 368 5646

VIDEOBUS SA

Madrid, Spain

T: +34 1 5001950

F: +34 1 5000607

Page 8

Manual

NetPorty II

Contents

1 Introduction......................................... 1-1

1.1 Your I+ME NetPorty II ......................................1-2

1.2 System Requirements ......................................1-4

1.3 Delivery Contents .............................................1-5

1.3.1 Standard................................................1-5

1.3.2 Supplementary Support ........................1-5

1.4 Technical Specifications...................................1-6

2 Installation........................................... 2-1

2.1 Overview...........................................................2-2

2.2 Installing the Hardware.....................................2-2

2.3 Installing the Software ......................................2-4

2.3.1 If you start at serial port ........................2-4

2.3.2 If you start at parallel port .....................2-5

3 Hardware.............................................3-1

3.1 Micro controller.................................................3-2

3.2 Memory.............................................................3-3

3.2.1 NetPorty II internal buffers:...................3-3

3.3 Protocol Interface .............................................3-4

3.4 Physical Interface .............................................3-5

3.5 Optical interface................................................3-5

3.6 Connector.........................................................3-6

3.6.1 9pol sub-min-D male.............................3-6

3.6.1.1 1 CAN Channel..................................3-6

3.6.1.2 More than 1 CAN Channel ................3-8

3.6.2 25pol sub-min-D male.........................3-10

3.6.3 Cable set for serial connection............3-11

3.6.4 Power Supply......................................3-12

4 Troubleshooting & Techn. Support... 4-1

4.1 What to do if you have problems......................4-2

4.1.1 Solutions for all parts ... ........................4-3

4.1.2 Solutions for PCMCIA...........................4-4

1.1.1 Non-Supported PCMCIA Drives ...........4-5

4.1.3 Solutions for NetPorty II........................4-6

Page 9

5 Glossary.............................................. 5-1

6 Literature............................................. 6-1

A LevelX API

B LevelX Demos

C PcCANControl

Administration of Document

Document version: 1.05

Page 10

Page 11

Your I+ME NetPorty II. Overview,

Systemrequirements, Delivery contents and s.o.

1 Introduction

Page 12

Introduction

Your I+ME NetPorty II

1.1 Your I+ME NetPorty II

The NetPorty II is an improved portable network

adapter. It is designed to connect devices with RS232

or Centronics interfac e to t he C AN bus . With its features

it is an ideal general purpose har dware for industrial and

automotive analyzes and diagnostics.

With NetPorty II you can visualize bus-traffic and

configure components with in a CAN network. It en ables

you to transfer sof tware from or to control com ponents.

The data can be exporte d to readable by standard PC

programs like Excel. In t his way the user can generate

statistic diagrams, etc. to analyze the CAN

communication.

In the I+ME standard s oftware you can s et bus spec ific

values. For transmitted or rec eived data it is possible to

assign fix display to one CAN message.

In addition to the above mentioned features you can

transfer your own progr ams to NetPorty II b y the use of

the RS232 link. The download utilities are included as

well as sample programs.

The NetPorty II can optionally be equipped with an

UART for automotive diagnosis. In this case it is a

converter RS 232 or Centronics to ISO 9141 (K-Line).

Working with the parallel port is 2 ..5 times fas ter as the

serial port access. The speed depends on the PC

speed.

Version 1.03

1-2

Page 13

Your I+ME NetPorty II

Introduction

I+ME ACTIA is always eager to full fill the needs of our

customers. If problems should occur, please refer to

Troubleshooting. If the problem persists, then feel free

to contact our after-sales support hotline using the

following number:

After-sales service

* I+ME ACTIA GmbH

Rebenring 33

D-38106 Braunschweig

Germany.

Tel: ++ 49 (531) 38 701 38

Fax: ++ 49 (531) 38 701 88

e-mail : info@ime-actia.de

Version 1.03

1-3

Page 14

Introduction

System Requirements

1.2 System Requirements

PC requirements:

• standard PC with RS232 or Centronics (EPP 1.7 or

1.9) interface

• other device with standard RS232 interface (used

signals described in chapter Hardware)

Version 1.03

1-4

Page 15

Delivery Contents

1.3 Delivery Contents

1.3.1 Standard

Your NetPorty II delivery package

(Order code: IME 1602401) includes:

• 1 NetPorty II

• 1 System user manual (hardware/software)

• Transfer tools to NetPorty II

Introduction

• LevelX software driver for design of 32 bit Windows

applications (Windows '95 and Windows NT),

including sample programs running on standard

firmware

• PCCANControl for Windows, Windows '95 and

Windows NT version

• RS232 adapter cable set

1.3.2 Supplementary Support

• Power supply

• Different cables for protocol interfacing (on request)

Version 1.03

1-5

Page 16

Introduction

Technical Specifications

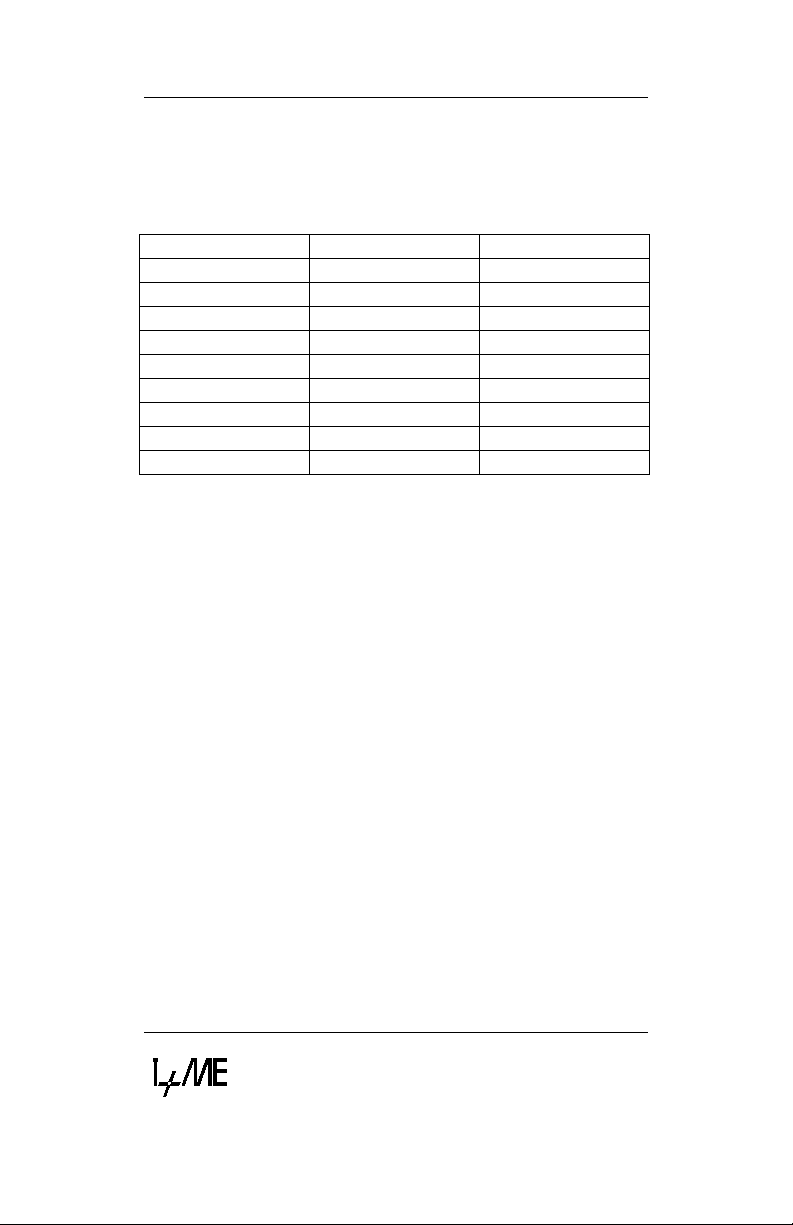

1.4 Technical Specifications

General Characteristics of NetPorty II

Processor 80C165, @36,84MHz

Protocol Interface 1 x SJA1000, @ 16 MHz

1 x 82527, @16MHz

1 x UART

Physical Interface CAN: according to ISO 11898

(PCA 82C251)

Memory 512 x 16 KByte RAM,

128 x 8 KByte Flash

Temperature Range 0° .. .+ 55 °C

Connector 9pin sub-min-D

CAN according to CiA/DS 102

Housing plastic, protection class IP30

Display 3 DUO-LED

Dimensions 95.5 mm x 41 mm x 20 mm

Power Supply 7 - 32 V DC external power

supply jack or via CAN bus

connector,

typically max.500 mA at 7 V

DC with physical interface

PCA 82C251

Version 1.03

1-6

Page 17

Technical Specifications

Introduction

Options

Memory 64 KB EPROM instead of flash

Physical interface: ISO Low Speed (ISO 11519)

Diagnosis Channel ISO 9141 physical interface

CAN CAN optional galvanic

disconnect

Cable 1 m Cable for adaptation

Power supply 230 V/AC to regulated 8 V/DC

110 V/AC to regulated 8 V/DC

Firmware Individual firmware on request

Version 1.03

1-7

Page 18

Page 19

Installing your NetPorty II. Step by step installation

procedures for hardware and software.

2 Installation

Page 20

Installation

Overview

2.1 Overview

This chapter gives detailed information about installing

the NetPorty II hardware and about the necessary

software drivers which make NetPorty II access

possible.

The NetPorty II is delivered with access driver and

applications for Windows 95 and Windows NT. To get

your NetPorty II operational follow the installation guide

lines.

2.2 Installing the Hardware

To install the hardware you should connect the

NetPorty II to the serial or to the parallel port of your PC.

If the NetPorty II operates at the serial port of the PC

the adapter cable will be used to get the right signals.

Plug in the 25 pin D-Sub connector of the adapter cable

to the NetPorty II and the 9 pin D-Sub connector to the

serial interface of the PC.

The NetPorty II can operate at the parallel port which

must be configured as EPP

2

ECP

.mode is not supported.

1

(V1.7 or V1.9) mode.

Make sure that the right interrupts are used in the

systems configuration and the BIOS settings.

1

EPP: Enhanced Parallel Port

2

ECP: Extended Capabilities Port

Version 1.03

2-2

Page 21

Installing the Hardware

pply

S23

Installation

It is also necessary to connect the NetPorty II with a

power supply. Therefore an external power unit can be

used to supply the NetPorty II via the power connector

or via the 9 Pin D-Sub CAN-connector.

CAN

Power

su

Serial

R

Centronics

2

If all connections are done NetPorty II is operational and

the next step is the software installation.

Version 1.03

2-3

Page 22

Installation

Installing the Software

2.3 Installing the Software

2.3.1 If you start at serial port

Driver installation:

1 Insert the CD. The setup programm will start

automatic, if not please start the program

“START.EXE” in root path.

2 Go to "Software Installation"

3 Choose your operating system, is important.

4 Choose your hardware component at the selection

box then press "Start Installation". If the file is started

(*.com file), follow the steps on the screen. If

necessay type in the password.

5 If password is correct software will be installed

successful.

Application installation:

1 Insert the CD. The setup programm will start

automatic, if not please start the program

“START.EXE” in root path.

2 Go to "Software Installation"

3 Choose your operating system, is important.

4 Choose PcCANControl component at the selection

box then press "Star t Ins ta lla ti on ". If the file is s tarted

(*.com file), follow the steps on the screen. If

necessay type in the password.

5 Start PcCANControl, select “create a new project”

and the NetPorty II hardware, at this case “Porty2COM1” or “Porty2-COM2”. After the selection the

necessary NetPorty II software is activated on your

PC. For further information see also chapter about

PcCANControl.

It is not necessary to install a driv er. The software works

with the standard Win32 serial communication services

with 115200bps, 8 bits, no parity, 1 stop bit.

Version 1.03

2-4

Page 23

Installing the Software

Installation

Problems:

It is possible you chose an incorrect COM port. Start

PcCANControl again and choose an other COM port.

2.3.2 If you start at parallel port

1 Make sure that your PC parallel por t uses the EPP-

mode. You have to control it under BIOS setup. In

this version the NetPorty II supported the EPP

versions 1.7 and 1. 9. If neces sary conf igure your PC

and re-start it.

2 Follow steps 1-5 under chapter 2.3.1.

3 Configure the right driver. Change to directory

“.. / I+ME ACTIA / CANctrl-PTY / ParDrv95

(.. / ParDrvNT) and start the batch-file Drvinst.bat

4 At this point you ha ve to reboot your PC to start t he

right driver.

5 Install PcC ANContro l, follow steps 1-5 under chapter

2.3.1 Application installation.

Problems: (see also chapter troubleshootings)

You start PcCANControl but the connection doesn’t

work:

For parallel port usage it is necessary to have the EPPloader-firmware (BOOTLOAD.H86) in the NetPorty II Flash-EPROM.

All Porty's are delivered with this loader but it is possible

that you have overwritten it by your own firmware.

In this case it is possible to download the EPP-firmware

again into the NetPorty II -Flash.

Version 1.03

2-5

Page 24

Installation

Installing the Software

This software is a Win32-Console-Application and runs

under Win95 and WinNT.

Usage:

- Connect your NetPorty II with one serial port.

- If you do not use COM1 please change it into the file

L.BAT.

-Start L.BAT.

- If you get error messages like

"BSL: no response from the target hardware"

it is possible that you have used the wrong COM

port.

- If you get the message below

"-- COMx Loading bootload.h86..Ready"

without any error message in the next line, all

activities are correct finished

- Leave the software with pressing the ESC key,

sometimes Alt X does not work.

Info:

The program LDFSER.EXE is a loader that burns

firmware in the Porty-Flash and also it is a serial monitor

to display firmware print-outs.

The serial parameter are 115200,8,n,1.

I+ME also can deliver a loader to start firmware in the

RAM and a little firmware demo (Keil-C).

Please contact us if you want to develop your own

firmware.

Version 1.03

2-6

Page 25

The technical components, there specifications and the

way they work together.

3 Hardware

Page 26

Hardware

Micro controller

3.1 Micro controller

The I+ME NetPorty II includes the 16-bit Siemens

80C165 micro controller on a piggy back. The

controller’s clock frequency is 36,84MHz.

The following recourses are used:

Port 2.14 [EX6IN] SJA1000

Port 2.15 [EX7IN] 82527 / 16CS550

CS0-CS1 Memory

CS2-CS3 Protocol interface

CS4 LED latch

Version 1.03

3-2

Page 27

Hardware

Memory

3.2 Memory

The I+ME NetPorty II is equipped with

Flash (CS0) 128 KByte (x 8 bit)

SRAM (CS1) 512 KByte (x 16 bit)

Optional it can be equipped with

Flash 512 KByte (x 8 bit) and

RAM 128 Kbyte (x 16 bit)

3.2.1 NetPorty II internal buffers:

To avoid lost data (CAN is faster than the

communication chan nels to the PC) the transfer- objects

are buffered in the NetPorty II. The biggest buffer is

between CAN reception and the communication

channel to the PC (448k Byte). If you have man y traffic

on the CAN-bus and the buff er is full it takes a time of

several minutes to transfer the data to t he PC. You can

control this with the 2nd NetPorty II LED that blinks

faster while the data transfer.

Version 1.03

3-3

Page 28

Hardware

Protocol Interface

3.3 Protocol Interface

The product has two CAN protocol chips at a frequency

of 16 MHz. The SJA1000 chip is connected to the 9 pin

D-SUB connector with the CiA pinning. The optional

82527 is also connected to the 9 pin D-Sub connector

without physical line driver .

The C165 uses the CS2 signal to select the SJA1000.

The NetPorty II can be equipped with a second CAN

channel. Therefore a 82527 will be mounted on the

PCB. The C165 uses the CS3 signal to select the

82527.

If 2 CAN channels are used there is no standard pinning

at the D-Sub connector. The physical line driver for the

second CAN channel is available via the connecting

cable (not included in standard delivery contents) and

can be used optional by your special app lic a tion.

In stade of the second CAN channel a diagnosis

channel can be used. Therefor an UART 16CS550 can

be mounted on the PCB instead of the 82527. The

C165 uses the CS3 signal to select the UART.

The physical line driver for the ISO 9141 interfacing can

be ordered separately

Version 1.03

3-4

Page 29

Hardware

Physical Interface

3.4 Physical Interface

NetPorty II has the transceiver chip 82C251 (according

to ISO 11898) as physical interf ac e. It is not galvanic

disconnect. The standard physical interface is linked to

the SJA1000, the Output Control Register must be set

to 0xFA.

To connect the second CAN channel or the ISO 9141

channel an optional physical line driver have to be

ordered.

3.5 Optical interface

State of LED during download firmware:

At serial download: no fixed state.

At parallel download LED 1 green

LED 2 green (flashing)

State of LED during work:

Color LED 1 LED 2 LED 3

Red - - Bus off

green Life cycle flash Flashing during

RS232/Parallel

data transfer

2. Data transfer 3. BUS on/off1.Life cycle flash

Bus on

Version 1.03

3-5

Page 30

Hardware

Connector

3.6 Connector

3.6.1 9pol sub-min-D male

3.6.1.1 1 CAN Channel

The CAN connector is based on the CiA standard if only

one CAN channel is used. It is a 9pol sub-min-D male

connector.

Figure 3-1 Standard CAN Connector

Pins 1, 4 and 8 are not used by NetPorty II

Version 1.03

3-6

Page 31

Hardware

Connector

Pin Signal Description

1 nc not connected

2 CAN_L CAN_L bus line (dominant low)

3 CAN_GND CAN ground

(connected on the cable shield)

4 nc not connected

5 CAN_SHIELD CAN ground

(connected on the cable shield)

6 POWER_GND power supply input ground

7 CAN_H CAN_H bus line (dominant

high)

8 nc not connected

9 POWER_V+ power supply input +7..32V

The power input and the CAN lines are galvanic

disconnect with a limit to ± 50V. There is an internal

transzorb diode to limit the disconnect voltage.

If you don't need a galvanic disconnect, the pin 6 can be

connected to pin 3 or 5.

The POWER_GND pin 6 is not connected with the CiA

standard bus in every system. If the tool does not work,

pin 6 could have to get connected to the power supply

ground!

Version 1.03

3-7

Page 32

Hardware

Connector

3.6.1.2 More than 1 CAN Channel

The pinning is different if more than one CAN channel is

used.

Figure 3-2 Pinning for more than 1 CAN channel

Version 1.03

3-8

Page 33

Hardware

Connector

Pin Signal Description

1 Uni_Out2 Connected to Port 6.7

2 CAN_L CAN_L bus line (dominant low)

3 CAN_GND CAN ground

(connected on the cable shield)

4 Uni_Out0 Connected to Port 6.5 or UART

Rx or CAN2 RX

0

5 CAN_SHIELD CAN ground

(connected on the cable shield)

6 POWER_GND power supply input ground

7 CAN_H CAN_H bus line (dominant

high)

8 Uni_Out1 Connected to Port 6.6 or UART

Tx or CAN2 TX

0

9 POWER_V+ power supply input +7..32V

Pin 1, 4 and 8 are used to provide the additional signals

for the second CAN channel or the UART. In standard

version the inputs are protected.

Port 6.5, Port 6.6 and Port 6.7 are used as additional

signal line. In case of standard version the ports are

protected.

Version 1.03

3-9

Page 34

Hardware

Connector

3.6.2 25pol sub-min-D male

To connect the NetPorty II with the PC it is possible to use the

Centronics (LPT) port directly or to use the adapter cable to

use the RS232 (COM) port. In both cases the pinning of the

25pol sub-min-D male is the same.

Connector definition:

Pin I/O Usage Description

1 Input Parallel Strobe

2 Input Parallel D0

3 Input Parallel D1

4 Input Parallel D2

5 Input Parallel D3

6 Input Parallel D4

7 Input Parallel D5

8 Input Parallel D6

9 Input Parallel D7

10 Output Parallel /acknlg

11 Output Parallel Busy

12 Output Parallel Paper em pty

13 Output Parallel Slct

14 Input Parallel /autofd

15 Output Parallel /error

16 Input Both

17 Input Parallel / slct in

18 X Both Ground

19 Input Serial TX (PC -> Porty)

20 Output Serial RX (Porty -> PC)

21 Input Serial RTS

22 Output Serial CTS

23 Input Serial Free input (DTR)

24 Output Serial DSR

25 Input Serial Free input (as serial master it can be used as

high -> RESET; low -> Operational

/init DTR (Porty RESET in): switch level 2.5V

input range -40..+40V, low speed 10ms

A weak pull-up and pull-down is necessary to

define with special mounting whether the

reset line is active or not if this line is not

connected.

CD or RI)

and also optional power input source

Version 1.03

3-10

Page 35

3.6.3 Cable set for serial connection

Cable length: 30cm

25 pin female 9 pin female Signal

23 1 CD

20 2 Rx

19 3 Tx

16 4 DTR

18 5 GND

24 6 DSR

21 7 RTS

22 8 CTS

25 9 RI

Hardware

Connector

Version 1.03

3-11

Page 36

Hardware

Connector

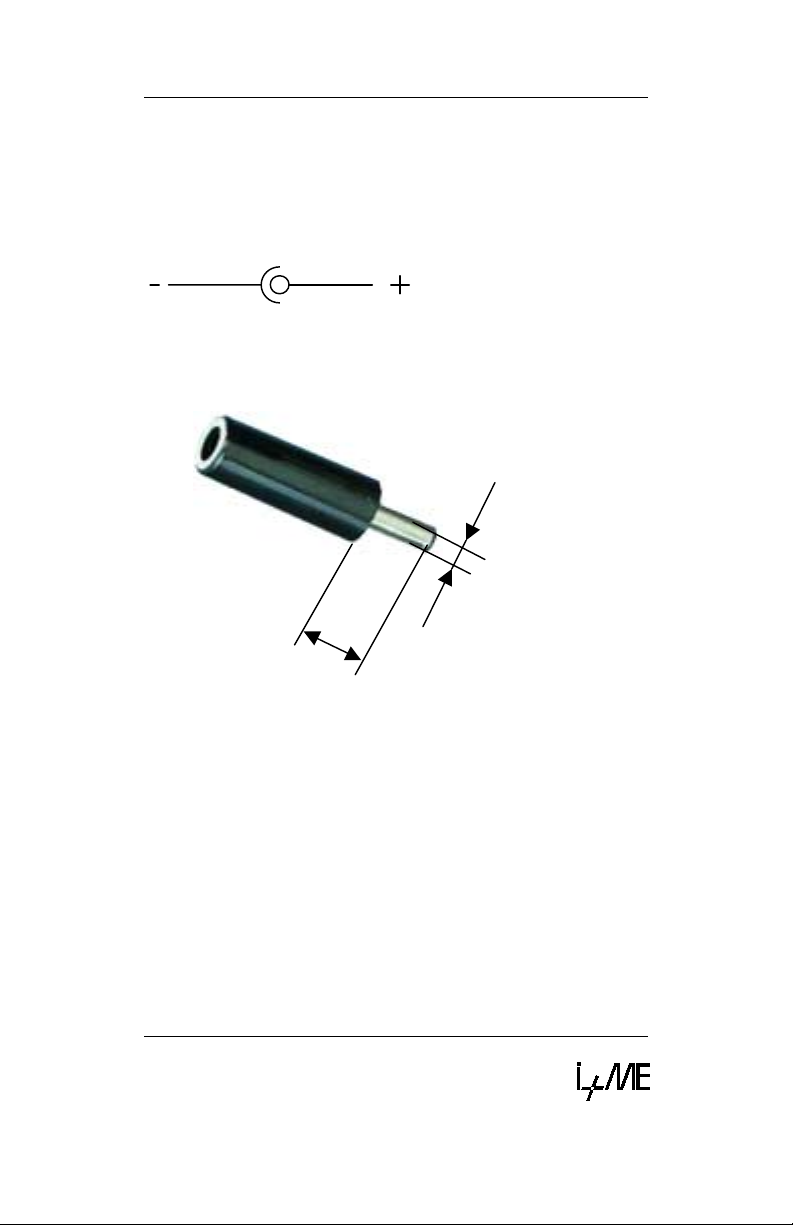

3.6.4 Power Supply

The NetPorty II can be powered by an external power

supply Therefore the connector is specified for the

power supply jack below:

The power connector is a DC3.5/1.3 mm type. That

means the internal diameter is 1.3mm.

Ø3,5mm

min. 9,0mm

Figure 3-3 Power Connector for NetPorty II

Version 1.03

3-12

Page 37

Common problems and how to solve them. How to get

in touch with our after-sales support experts if you so

desire.

4 Troubleshooting &

Techn. Support

Page 38

Troubleshooting &

Techn. Support

What to do if you have problems

4.1 What to do if you have problems

First and foremost, please read Installation very closely

and make sure that you performed your installation

exactly as described.

For developers:

The Key is often used in developing en vir onments in

combination with the API and/or DLL. If the

PcCANControl software is functioning properly, then

there is no problem with general CAN access. You

should check your usage of the API of DLL.

If the PcCANControl software is not functioning, please

consult the list of common problems below and their

possible solutions.

Version 1.03

4-2

Page 39

Troubleshooting &

What to do if you have problems

Techn. Support

4.1.1 Solutions for all parts ...

The system crashes after choose the hardware at

PcCANControl:

The selected memory area is not free, or the

selected interrupt is being used by another

application. Make sure that no conflicts exist on

your system. If you get a blue screen under Win

NT it is most likely that a memory or IRQ conflict

is occur.

PcCANControl launches correctly, but CAN access

is not possible:

Check the transceiver cable and CAN

connectors. If a connector is not correctly

plugged, connect it right. If the sub-min-D

connectors at the end of the cables are hot,

remove the Key and call I+ME.

If you use higher baudrates, remember to

protect the end of line with resistors [120Ohm]

Version 1.03

4-3

Page 40

Troubleshooting &

Techn. Support

What to do if you have problems

4.1.2 Solutions for PCMCIA

The system crashes after the installation of the Key

client:

The selected memory area is not free, or the

selected interrupt is being used by another

application. Refer to Installation.

The system crashes when the Key is inserted or

removed:

The selected memory area is not free, or the

selected interrupt is being used by another

application. Refer to Installation.

Windows will not launch after the installation of the

client and services:

Make sure that there is a memory area reserved

in the SYSTEM.INI file. The selected memory

area is not free, or the selected interrupt is being

used by another application. Refer to Installation.

The acknowledge sound after inserting or removing

the Key is sounded twice:

There are two se rvices installed on your system.

One can be found in the CONFIG.SYS and the

other in the device manager. In the device

manager, under the topic PCMCIA, you can

disable one of the services.

The Key is not inserted and PcCANControl starts

with the message: I+ME CARD not available or drive

not ready.

Insert the Key.

Version 1.03

4-4

Page 41

Troubleshooting &

What to do if you have problems

Techn. Support

The Key is inserted and PcCANControl starts with

the message: I+ME CARD not available or drive not

ready.

Some aspect of the resource allocation is wrong.

Refer to Installation for more information.

1.1.1 Non-Supported PCMCIA Drives

In the current version there are some PCMCIA drives

which are incompatible with the PCMCIA Key. Today,

as a general rule, some PCI connected drives result in

compatibility problems. The following is a list of known

incompatible drives and any laptops which are known to

use these drives.

Drive Known Laptops Using Drive

Cirrus Logic

PCIC compatible

SIEMENS NIXDORF Scenic Mobile 700

COMPAQ Armada

Version 1.03

4-5

Page 42

Troubleshooting &

Techn. Support

What to do if you have problems

4.1.3 Solutions for NetPorty II

You start PcCANControl but the connection doesn’t

work correct:

For parallel port usage it is necessary to have the

EPP-loader-firmwar e (BOO TLO AD.H86) in the

NetPorty II -Flash-EPROM. All Porty's are

delivered with this loader!

You have overwrite the delivered EPP-Loader by

your own firmware.

In this case it is possible to download the EPPfirmware again into the NetPorty II -Flash. This

software is a Win32-Console-Application and

runs under Win95 and WinNT.

How to use:

- Connect your NetPorty II with one serial port.

- If you do not use COM1 please change it into

the file L.BAT.

-Start L.BAT.

If you get an error messages like

"BSL: no response from the target hardware"

it is possible that you have used the wrong

COM port.

- If you get the message below

"-- COMx Loading bootload.h86..Ready"

without any error message in the next line, all

activities are correct finished

- Leave the software with pressing the ESC key,

sometimes Alt X does not work.

Info:

The program LDFSER.EXE is a loader that burns

firmware in the Porty-Flash and also it is a serial monitor

The serial parameter are 115200,8,n,1. I+ME also can

deliver a loader to start firmware in the RAM and a little

firmware demo (Keil-C). Please contact us if you want to

develop your own firmware.

Version 1.03

4-6

Page 43

Troubleshooting &

What to do if you have problems

Techn. Support

The NetPorty II doesn’t work under parallel port:

Use the right EPP mode on BIOS. It can be only

one of the EPP modes work with one Win-System

together. In past we find out that EPP 1.7 is

necessary for Win9x and EPP 1.9 is necessary

for Win NT. Please try out the right mode.

Using a printer and NetPorty II under Win NT:

If you use NetPorty II under NT note that you are

not able to print!

Using a printer and NetPorty II under Win 9x:

If you use NetPorty II under Win9x the normal

printer driver is active but it can make prob le ms

while printing with the active driver.! One way to

solve this problem is to load the firmware into the

flash of the NetPorty II.

Version 1.03

4-7

Page 44

Troubleshooting &

Techn. Support

What to do if you have problems

If you encounter difficulties which are not discussed in

the manual, or if you need more help than is offered in

Installation and Troubleshooting, please call our

after-sales service. Our experts will do their best to

solve whatever problem you might have.

Version 1.03

4-8

Page 45

For better understanding...

5 Glossary

Page 46

Glossary

Glossary

Adapter

A piece of hardware which

contains one or more PCMCIA

sockets.The Adapter contains

the interface between the

Socket Controller and the Host

System.

AUTOEXEC.BAT

A set of commands in the form

of a batch file program that are

automatically executed by DOS

to help configure your system

when you Boot-Up your

computer.

BIOS

An abbreviation for Basic

Input/Output System. A set of

instructions/routines stored in

ROM. These routines work

closely with hardware devices

(memory chips, disk drives and

monitor) to input and output

interrupt requests indicating

when a device is ready to

accept or send data.

CONFIG.SYS

A system configuration command file that contains installable device drivers, memory

management commands and

control files that DOS accesses

and uses when your system

starts up.

I/O

An abbreviation for lnput

Output. Refers to the sending

(input) and receiving (output) of

data through an 110 channel in

the CPU. Example: The

keyboard inputs data to the 110

channel in the CPU that in turn

is output to the monitor.

IRQ

An abbreviation for Interrupt

Request. A signal sent by a

device and routed through the

BIOS indicating when a device

is ready to accept or send data.

PCMCIA

Personal Computer Memory

Card International Association,

a trade association of leading

hardware and software

vendors, established to adopt a

set of standards pertaining to

adapter slots and PC cards for

portable PC accessories.

Slot

A receptacle on a micro,

portable, laptop or palmtop

computer that is used to insert

and operate PCMCIA PC

Cards. Also referred to as a

Socket.

Socket

Same as Slot (see above).

DPRAM

Dual Ported Random Access

Memory. The data for

communication between PC

and CANcard are exchange via

a DPRAM.

5-2

Page 47

Socket-Controller

A PC system hardware

component that manages the

operation of PCMCIA sockets in

conjunction with system

software.

SYSTEM.INI

A Windows initialization file

(similar to the CONFIG.SYS file

for DOS) that contains Windows

device drivers, commands and

settings you can use to

customize Windows for your

system's hardware.

Upper-Memory

Memory area within the PC

address space between 640 KB

and 1 MB. This area is used by

hardware devices like graphics

controller. The DPRAM of the

CANcard is located in the

Upper Memory.

Glossary

V 1.00

5-3

Page 48

Page 49

For more informations ...

6 Literature

Page 50

Literature

Literature

[1] SAB 80C167CR User Manual

Siemens AG.

[2] SAB C167CR Description of the

On-chip CAN-Module

Siemens AG.

[3] CiA DS 102-1CAN in Automation e.V

6-2

Loading...

Loading...