Page 1

SERVICE MANUAL

P75

P75

US Model

Canadian Model

UK Model

AEP Model

N. Hemisphere Model

S. Hemisphere Model

Australian Model

Chassis No. SCC-L07E-A

Picture tube

Video image area

Max. resolution

Standard image area

Input signal

Video

Sync

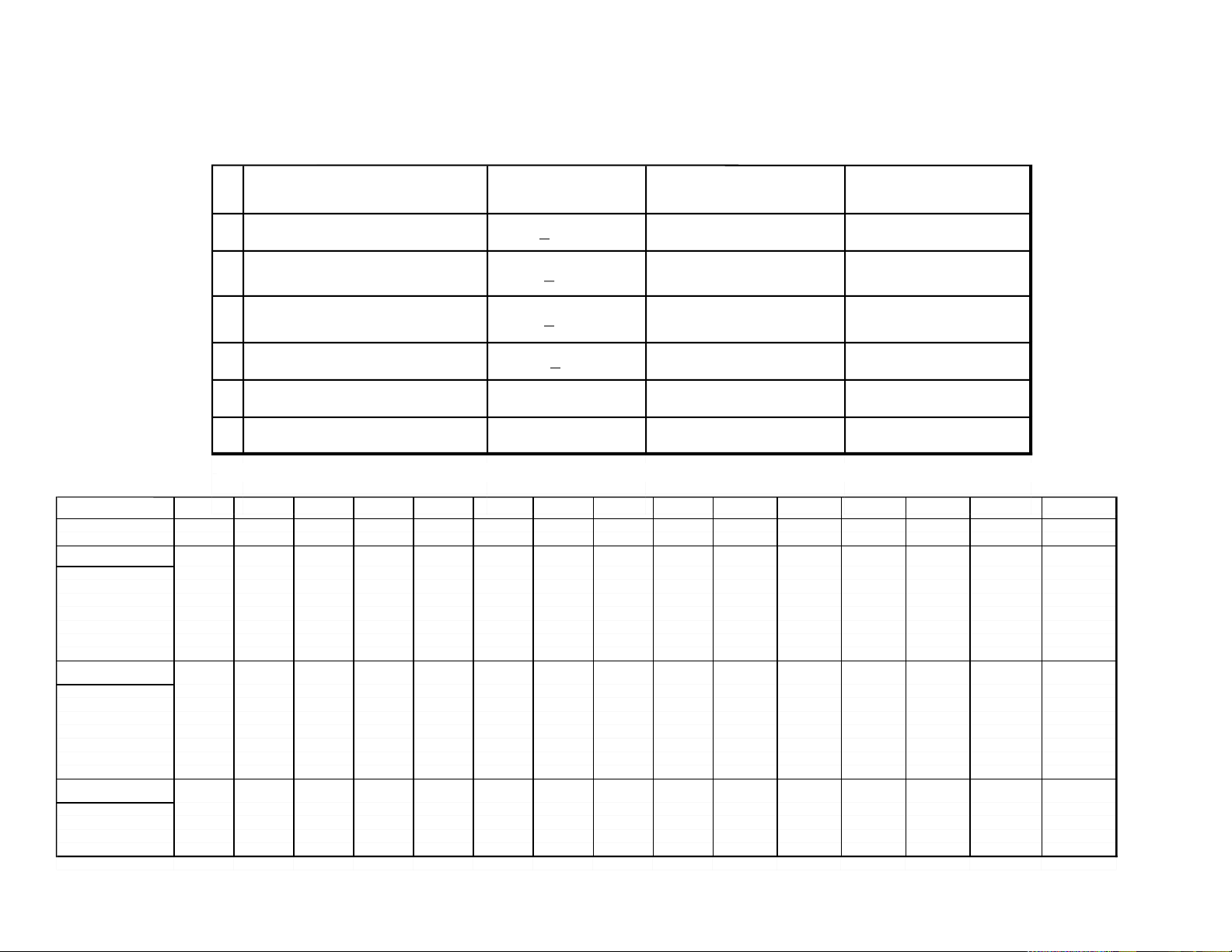

SPECIFICATIONS

0.25 mm aperture grill pitch

17 inches measured diagonally

90-degree deflection

(16" maximum viewing image)

Approx. 329.5 x 243 mm (w/h)

5/8

(13 x 9

Horizontal: Max. 1280 dots

Vertical: Max. 1024 lines

(at 75 Hz Refresh Rates)

Approx. 306 x 230 mm (w/h)(Mode 1-13)

Approx. 294 x 231 mm (w/h)(Mode 14-15)

Analog RGB (75 ohms typical)

0.7 Vp-p, Positive

External HD/VD, Composite

Polarity Free TTL

Video Composite (Sync on Green)

0.286 Vp-p, Negative

inches)

D-1H

Power Consumption

Maximum

Nominal

Deflection frequency

AC input voltage / current

Dimensions

Mass

Design and specifications are subject to change without notice.

CHASSIS

115W

100W, 341 BTU/h

Horizontal: 30 to 85 KHz

Vertical: 50 to150 Hz

100 to 120 V, 50/60 Hz, 1.8 A

220 to 240V, 50/60Hz, 1A

424 x 422 x 428 (w/h/d)

(16.7 x 16.6 x 16.9 inches)

Approx. 18.48 kg (40.8 lb.)

COLOR MONITOR

Page 2

POWER SAVING FUNCTION

MODE 1234567891011121314 15

Resolution (H x V) 640x350 640X480 640x480 640x480 720x400 800x600 800x600 800x600 832x624 1024x768 1024x768 1024x768 1152x870 1280x1024 1280x1024

Dot Clock (MHz) 25.175 25.175 31.500 36.000 28.321 40.000 49.500 56.250 57.283 65.000 78.750 94.500 100.000 108.000 135.000

HORIZONTAL

Hor. Freq. (kHz) 31.469 31.469 37.500 43.269 31.468 37.879 46.875 53.674 49.725 48.363 60.023 68.677 68.681 63.981 79.976

H-Total 31.778 31.778 26.667 23.111 31.779 26.400 21.333 18.631 20.111 20.677 16.660 14.561 14.560 15.630 12.504

H-Blanking 6.356 6.356 6.349 5.333 6.356 6.400 5.172 4.409 5.586 4.923 3.657 3.725 3.040 3.778 3.022

H-Front Porch 0.636 0.636 0.508 1.556 0.636 1.000 0.323 0.569 0.559 0.369 0.203 0.508 0.320 0.444 0.119

H-Sync. 3.813 3.813 2.032 1.556 3.813 3.200 1.616 1.138 1.117 2.092 1.219 1.016 1.280 1.037 1.067

H-Back Porch 1.907 1.907 3.810 2.222 1.907 2.200 3.232 2.702 3.910 2.462 2.235 2.201 1.440 2.296 1.837

H-Active (msec) 25.422 25.422 20.317 17.778 25.423 20.000 16.162 14.222 14.524 15.754 13.003 10.836 11.520 11.852 9.481

VERTICAL

Ver. Freq. (Hz) 70.086 59.940 75.000 85.008 70.084 60.317 75.000 85.061 74.550 60.004 75.029 84.997 75.062 60.020 75.025

V-Total 449 52 5 500 50 9 449 6 2 8 6 2 5 631 6 6 7 806 80 0 808 91 5 1066 1066

V- Blanking 9 9 4 5 2 0 2 9 4 9 2 8 2 5 3 1 4 3 38 3 2 40 4 5 42 4 2

V-Front Porch 38 1 0 1 1 12 11113113 1 1

V-Sync. 2233243336333 3 3

V- Back Porch 5 9 3 3 1 6 2 5 3 5 2 3 2 1 2 7 3 9 2 9 2 8 3 6 3 9 3 8 3 8

V-Active (lines) 3 50 480 4 80 480 4 00 600 6 00 600 6 24 7 68 7 68 7 68 870 1024 1024

SYNC.

Int(G)

NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO

Ext(H/V)/Polarity

YES +/- YES -/- YES -/- YES -/- YES -/+ YES +/+ YES +/+ YES +/+ YES -/- YES -/- YES +/+ YES +/+ YES -/- YES +/+ YES +/+

Ext (CS)/Polarity

NO NO NO NO NO NO NO NO NO NO NO NO NO NO NO

Int/Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int Non Int

State

Power

Consumption

Required Recovery

Time

uu

uu

Power Indicator

1 Normal Operation

<110W

Green on

2 Standby (1st mode)

<1 5W approx. 3 sec. Yellow

3 Suspend (2nd mode)

<1 5W approx. 3 sec. Yellow

4 Active-off (3rd mode)

<8W approx. 10 sec. Amber

5 Power-off 0W

Off

6 Failure mode

Orange flashing

This monitor has three Power Saving modes.

By sensing the absence of a video signal from the

computer, it reduces power consumption as follows:

— 2 —

TIMING SPECIFICATION

NOTE:

P75

If no video signal is input to the monitor, the "NO INPUT SIGNAL" message appears.

After about 30 seconds, the Power Saving function automatically puts the monitor into

active-off mode and the indicator lights up orange. Once the monitor detects horizontal and vertical sync signals, the monitor automatically resumes normal operation mode.

Page 3

SAFETY CHECK-OUT

(US Model only)

P75

After correcting the original service problem, perform

the following safety checks before releasing the set to the

customer:

1. Check the area of your repair for unsoldered or

poorly-soldered connections. Check the entire board

surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires

are “pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground

straps, and mounting hardware have been replaced.

Be absolutely certain that you have replaced all the

insulators.

4. Look for unauthorized replacement parts,

particularly transistors, that were installed during

a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show

obvious signs of deterioration. Point them out to

the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord

to the customer.

7. Check the B+ and HV to see if they are specified

values. Make sure your instruments are accurate;

be suspicious of your HV meter if sets always have

low HV.

8. Check the antenna terminals, metal trim,

“metallized" knobs, screws, and all other exposed

metal parts for AC Leakage. Check leakage as

described below.

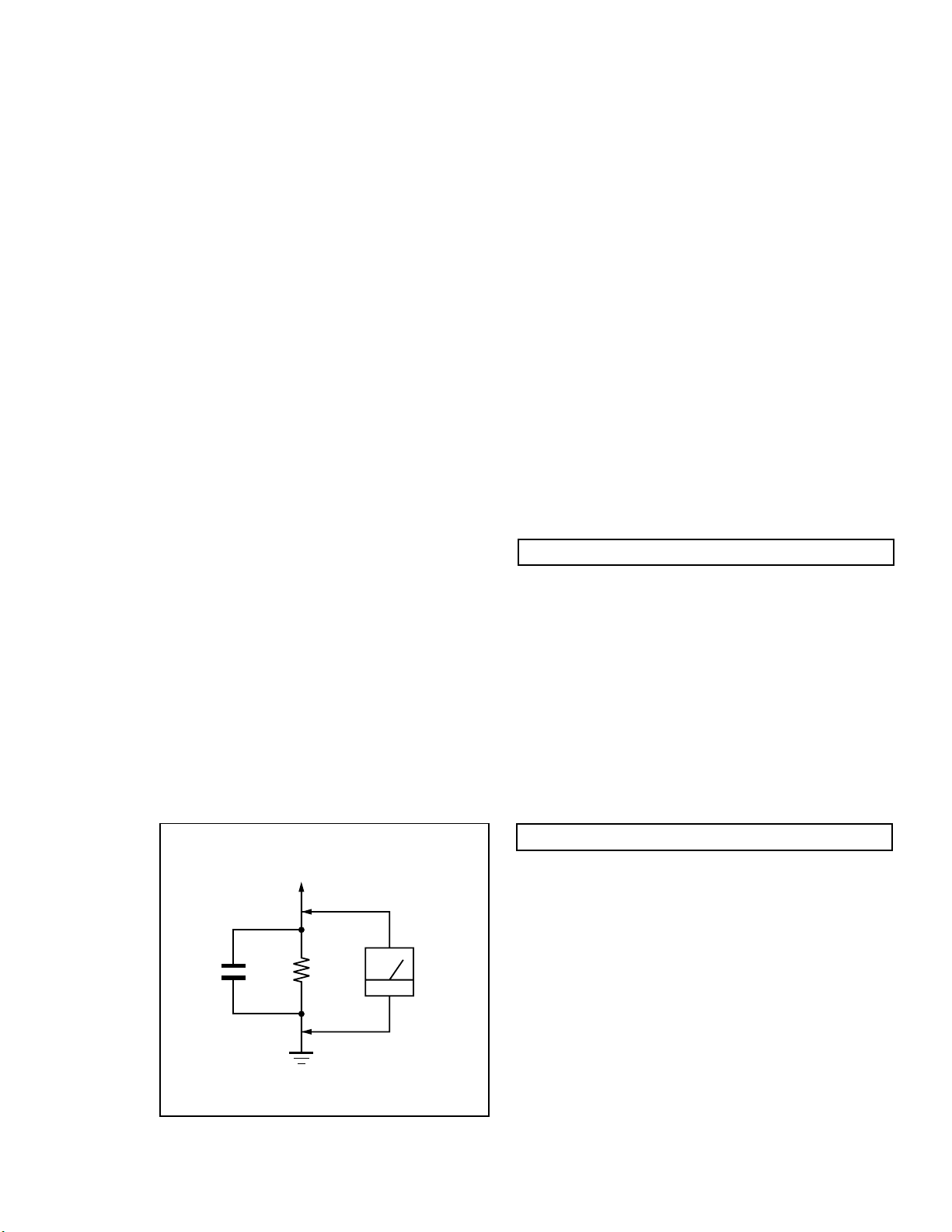

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microampere).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers' instructions to

use these instructions.

2. A battery-operated AC milliammeter. The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of

a VOM or battery-operated AC voltmeter. The "limit"

indication is 0.75 V, so analog meters must have an accurate

low voltage scale. The Simpson's 250 and Sanwa

SH-63Trd are examples of passive VOMs that are suitable.

Nearly all battery operated digital multimeters that have a

2V AC range are suitable. (See Fig. A)

WARNING!!WARNING!!

WARNING!!

WARNING!!WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN WHICH THE

DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ¡ ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY . CIRCUIT ADJUSTMENTS

THAT ARE CRITICAL FOR SAFE OPERATION ARE IDENTIFIED

IN THIS MANUAL. FOLLOW THESE PROCEDURES WHENEVER

CRITICAL COMPONENTS ARE REPLACED OR IMPROPER

OPERATION IS SUSPECTED.

0.15 µF

To Exposed Metal

Parts on Set

1.5 k

Earth Ground

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA BOBINE DE

DEMAGNETISATION EST ENLEVEE.

ATTENTION AUX COMPOSANTS RELATIFS A LA

W

AC

Voltmeter

(0.75 V)

LES COMPOSANTS IDENTIFIES P AR UNE TRAME ET PAR UNE

MARQUE ¡ SUR LES SCHEMAS DE PRINCIPE, LES VUES

EXPLOSEES ET LES LISTES DE PIECES SONT D'UNE

IMPORTANCE CRITIQUE POUR LA SECURITE DU

FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMERO DE PIECE EST

INDIQUE DANS LE PRESENT MANUEL OU D ANS DES SUPPLEMENTS PUBLIES PAR SONY. LES REGLAGES DE CIRCUIT

DONT L'IMPORTANCE EST CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT SONT IDENTIFIES DANS

LE PRESENT MANUEL. SUIVRE CES PR OCEDURES LORS DE

CHAQUE REMPLA CEMENT DE COMPOSANTS CRITIQUES, OU

LORSQU'UN MAUVAIS FONTIONNEMENT SUSPECTE

SECURITE!!

.

— 3 —

Page 4

TABLE OF CONTENTS

Section Title Page

1. GENERAL ................................................................................... 5

2. DISASSEMBLY

2-1. Cabinet Removal ............................................................8

2-2. Service Position .............................................................. 8

2-3. A, D, H, S Board Removal............................................. 8

2-4. Picture Tube Removal ................................................... 9

3. SAFETY RELA TED ADJUSTMENT.................................10

4. ADJUSTMENTS ........................................................................ 11

5. DIAGRAMS

5-1. Block Diagram ................................................................15

5-2. Circuit Boards Location .................................................18

5-3. Schematic Diagrams and Printed Wiring Boards ...... 18

1. D Board - Schematic Diagram .................................19

2. A Board - Schematic Diagram ................................. 23

3. H, S, U

5-4. Semiconductors ..............................................................27

, U2 - Schematic Diagram...............................26

1

6. EXPLODED VIEWS

6-1. Chassis (US/CANADIAN, AEP, NH, SH, AUS

models made in US) ...................................................... 29

6-2. Chassis (AEP, UK models made in UK) ..................... 30

6-3. Packing Materials .......................................................... 31

7. ELECTRICAL PARTS LIST ................................................ 32

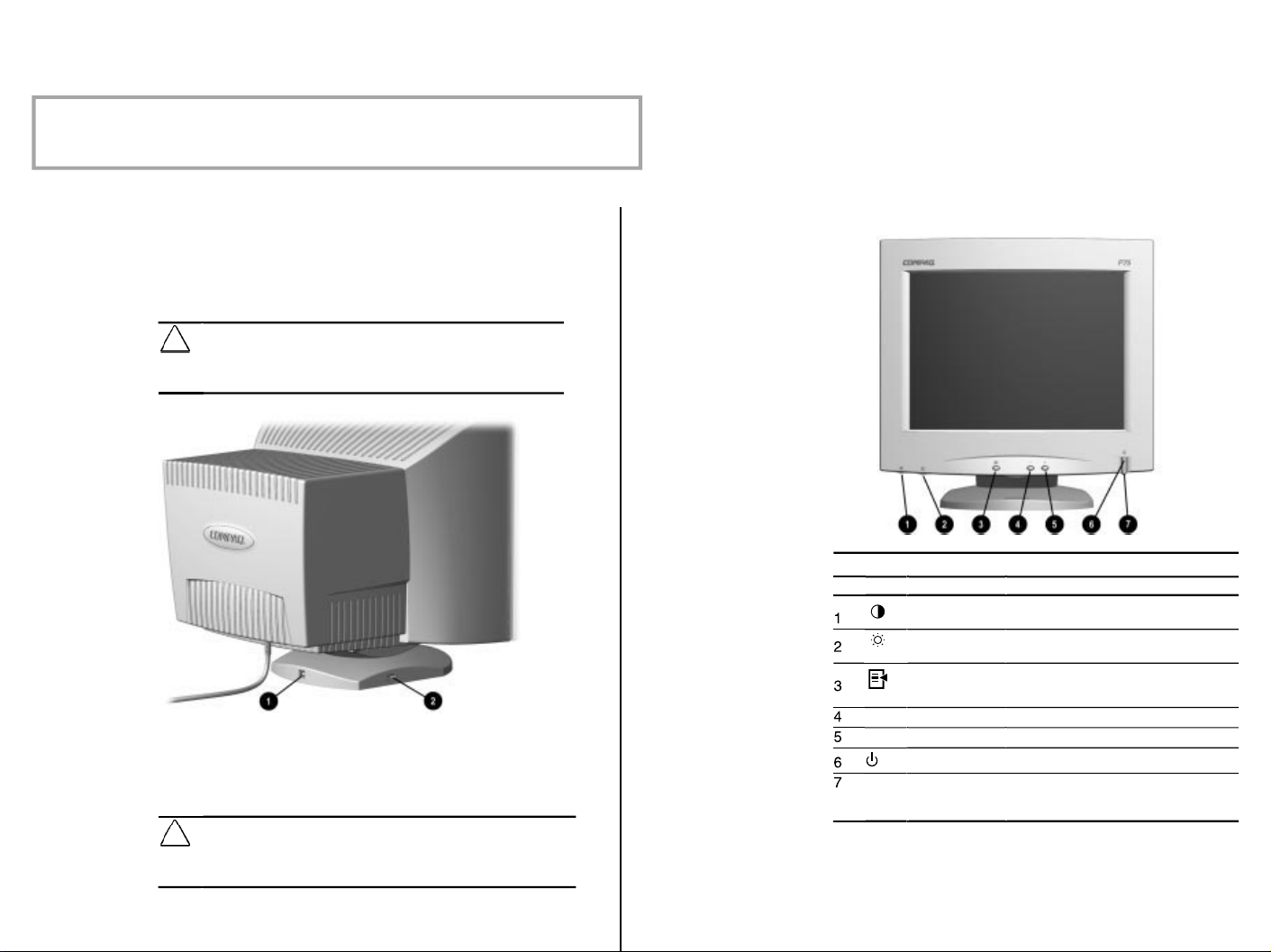

Page 5

The instructions given here are partial abstracts from the Operating Instruction

USB Connectors

The base of the monitor has two Universal Serial Bus (USB)

connectors. Use USB connector ❶ to connect the USB signal

cable

∗

to the computer. Use USB Connector ❷ to connect USB

compatible plug and play devices such as a keyboard, mouse, or

joystick if supported by your computer. This feature provides

USB pass-through and does not support USB host requirements.

CAUTION:

This USB connector is not designed for use with high

speed USB devices such as a video camera, scanner, etc.

Compaq recommends connecting high speed devices directly to

the computer

.

✎

These USB connectors operate as a pass-through system. Your

computer must have a USB host controller installed for any

USB-connected devices to operate.

CAUTION:

To prevent deterioration of signal transfer or

malfunction of USB devices, USB cables should not exceed the

combined length of 9.75 feet (3 meters). This length includes both

the USB signal cable and the USB peripheral cable.

∗

A USB signal cable is not supplied with this monitor.

Operating the

Monitor

Front Control Panel

No./ Icon Control Function

Contrast Adjusts contrast by turning control to left or

right.

Brightness Adjusts brightness by turning control to left or

right.

Select button

1. Launches on-screen display.

2. Selects function adjustments.

3. Exits menus and on-screen display.

−

Minus button Selects and adjusts the functions.

+

Plus button Selects and adjusts the functions.

Power switch Turns the monitor on and off.

Power LED 1. Green indicates monitor is turned on.

2. Yellow indicates suspend mode.

3. Amber indicates sleep mode.

Manual. The page numbers shown reflect those of the Operating Instruction Manual.

SECTION 1

GENERAL

Page 6

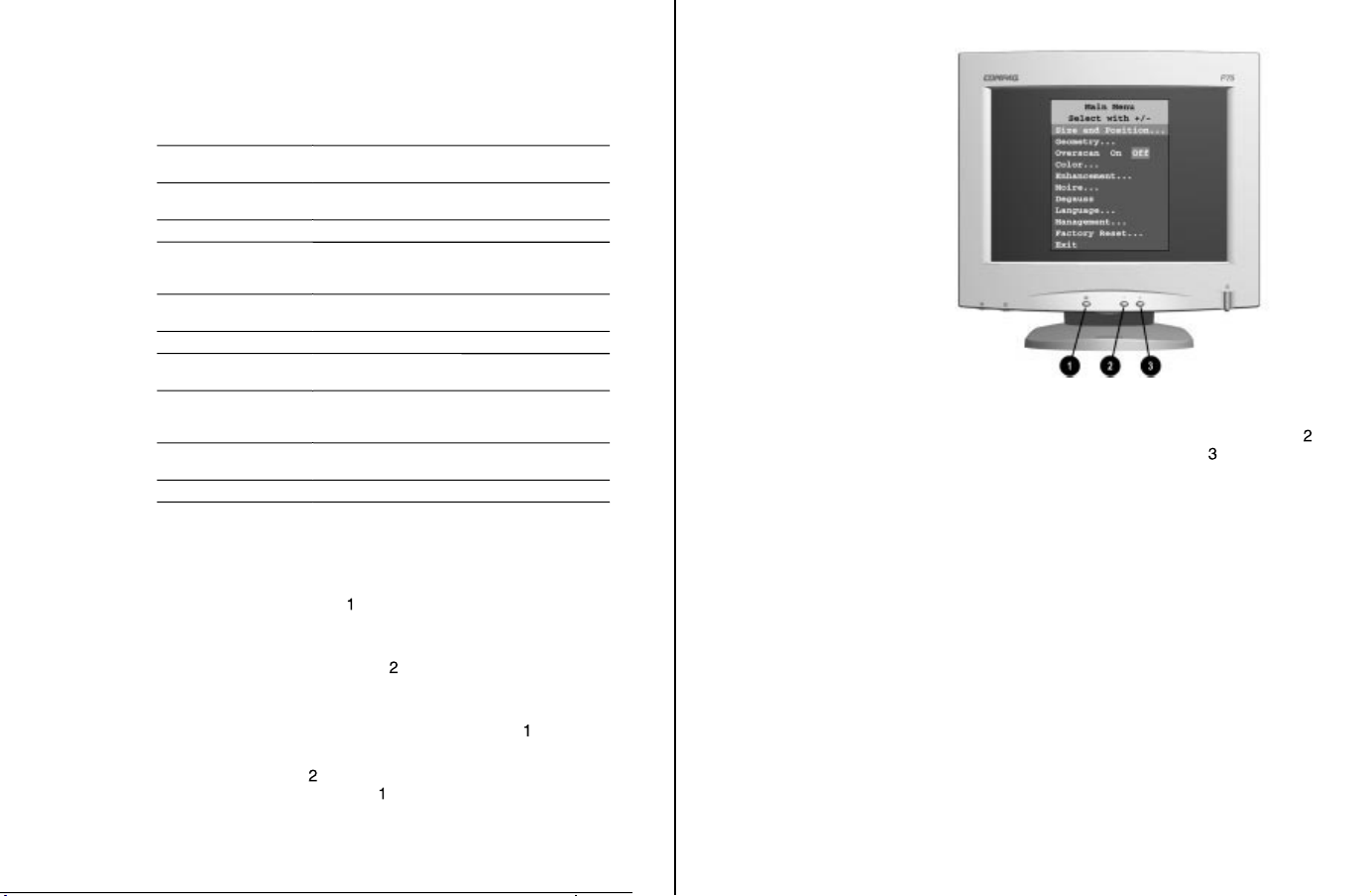

On-Screen Display Settings

The adjustments for screen settings are located in the on-screen

display and can be viewed in one of five available languages.

The on-screen Main Menu displays the following ten functions:

Size and Position Adjusts width, height, and horizontal and vertical

positions of the screen.

Geometry Adjusts pincushion, pincushion balance, trapezoid,

parallelogram, and tilt.

Overscan Zooms in and enlarges a selected portion of the screen.

Color Displays the following selections for screen color

temperature: 9300° K; 6500° K; Custom

Color/Enhancement Color; and Convergence.

Enhancement Enhances screen for screen presentations or viewing

motion video applications.

Moiré Minimizes irregular or wavy lines on the screen raster.

Degauss Corrects image distortion or color impurity caused by

external magnetic fields.

Language Lists the following five language selections for on-

screen display: English, Dutch, French, German, and

Spanish.

Management Adjusts power saver and display modes and displays

monitor serial number.

Factory Reset Resets the screen to its factory settings.

How to Adjust Settings

To launch the on-screen display Main Menu:

1. Press the Select button

on the monitor front panel to

display the Main Menu on the monitor screen.

2. To make a selection from the Main Menu, scroll down by

pressing the Minus (-) button

and reverse or back up by

pressing the Plus (+) button ❸ located on the monitor front

panel.

3. Highlight your choice and press the

Select

button

again.

For example, if your selection is

Size and Position

, press

the Minus button

until

Size and Position

is highlighted,

then press the Select button

to choose it.

Monitor with On-Screen Display

4. A second level menu displays with expanded menu items.

Again, to make a selection, press the Minus (-) button

to

scroll down or press the Plus (+) button

to reverse or

back up.

IMPORTANT: The Overscan and Degauss selections do not

display menus. When you select Overscan, the choices are to

turn it on or off. When you select Degauss, the monitor corrects

color impurities on the screen. The monitor screen

automatically degausses when the monitor is turned on.

5. Highlight your choice and select

Save and Return,

or to

advance to the third level menu, highlight your choice and

press the Select button. To void any changes made, select

Cancel

instead of

Save and Return.

6. The third level displays a sizing window for adjusting the

selected function. To adjust, press the Minus button to

decrease the degree of adjustment, or press the Plus button

to increase the degree of adjustment.

7. Press the Select button after the adjustment is made.

IMPORTANT: Selections under the Management Menu, Power

Saver and Mode Display, turn on and off at the third level. The

Serial No. selection displays the monitor serial number at the

third level.

Page 7

Display Resolutions

The display resolutions listed below are the most commonly

used modes and are set as factory defaults. The monitor

automatically recognizes these preset modes when they are

requested by a software program and will provide the user with

a properly sized and centered display.

Display Resolutions

Preset Modes Resolutions

1. VGA Compatible 640 X 350 at 31.5 kHz/70 Hz

2. VGA Compatible 640 X 480 at 31.5 kHz/60 Hz

3. VESA Standard 640 X 480 at 37.5 kHz/75 Hz

4. VESA Standard 640 X 480 at 43.3 kHz/85 Hz

5. VGA Compatible 720 X 400 at 31.5 kHz/70 Hz

6. VESA Standard 800 X 600 at 37.8 kHz/60 Hz

7. VESA Standard 800 X 600 at 46.9 kHz/75 Hz

8. VESA Standard 800 X 600 at 53.7 kHz/85 Hz

9. Macintosh Compatible 832 X 624 at 49.72 kHz/74.5 Hz

10. VESA Standard 1024 X 768 at 48.4 kHz/60 Hz

11. VESA Standard 1024 X 768 at 60.0 kHz/75 Hz

12. VESA Standard 1024 X 768 at 68.7 kHz/85 Hz

13. Macintosh Compatible 1152 X 870 at 68.7 kHz/75 Hz

14. VESA Standard 1280 X 1024 at 63.9 kHz/60 Hz

15. VESA Standard 1280 X 1024 at 80.0 kHz/75 Hz

✎

Memory channels 9 and 13 are Macintosh-compatible display

modes for use with a Macintosh-compatible computer. If your

computer has this requirement, you will need to purchase a

special adapter connector to attach to the monitor signal cable.

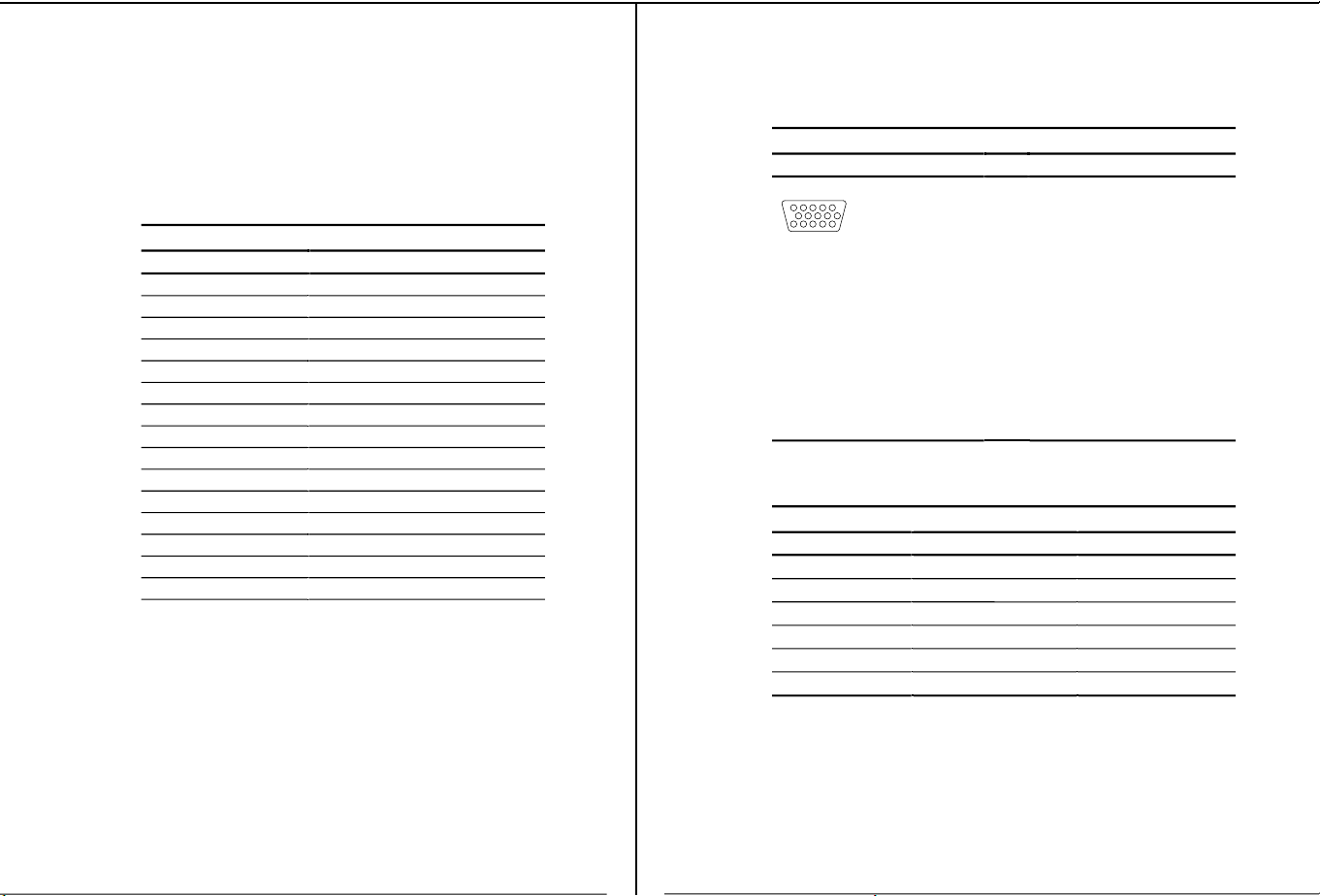

Connector Pin Assignments

Signal Cable

Connector Pin Signal

KEY

10

45

15 14

78

123

13 12 11

6

1

2

3

4

5

6

7

8

9

10

11

12

*

13

14

15

*

Red Video

Green Video

Blue Video

Open

Return

Red Gnd

Green Gnd

Blue Gnd

Reserved (No Pin)

Sync Return

Open

Bidirectional Data (SDA)

H-Sync/Composite Sync

V-Sync

Data Clock (SCL)

*

DDC Signals

Color Display Values

CIE* Chromaticity Coordinates

xy

Red

0.625 0.340

Green

0.285 0.605

Blue

0.150 0.065

White Point (9300 K)

0.281 (+/- .015) 0.311 (+/- .015)

White Point (6500 K)

0.313 (+/- .015) 0.329 (+/- .015)

Gamma: 2.25

*

Commission International d’Eclairage, 1931 Standard.

Page 8

P75

SECTION 2

DISASSEMBLY

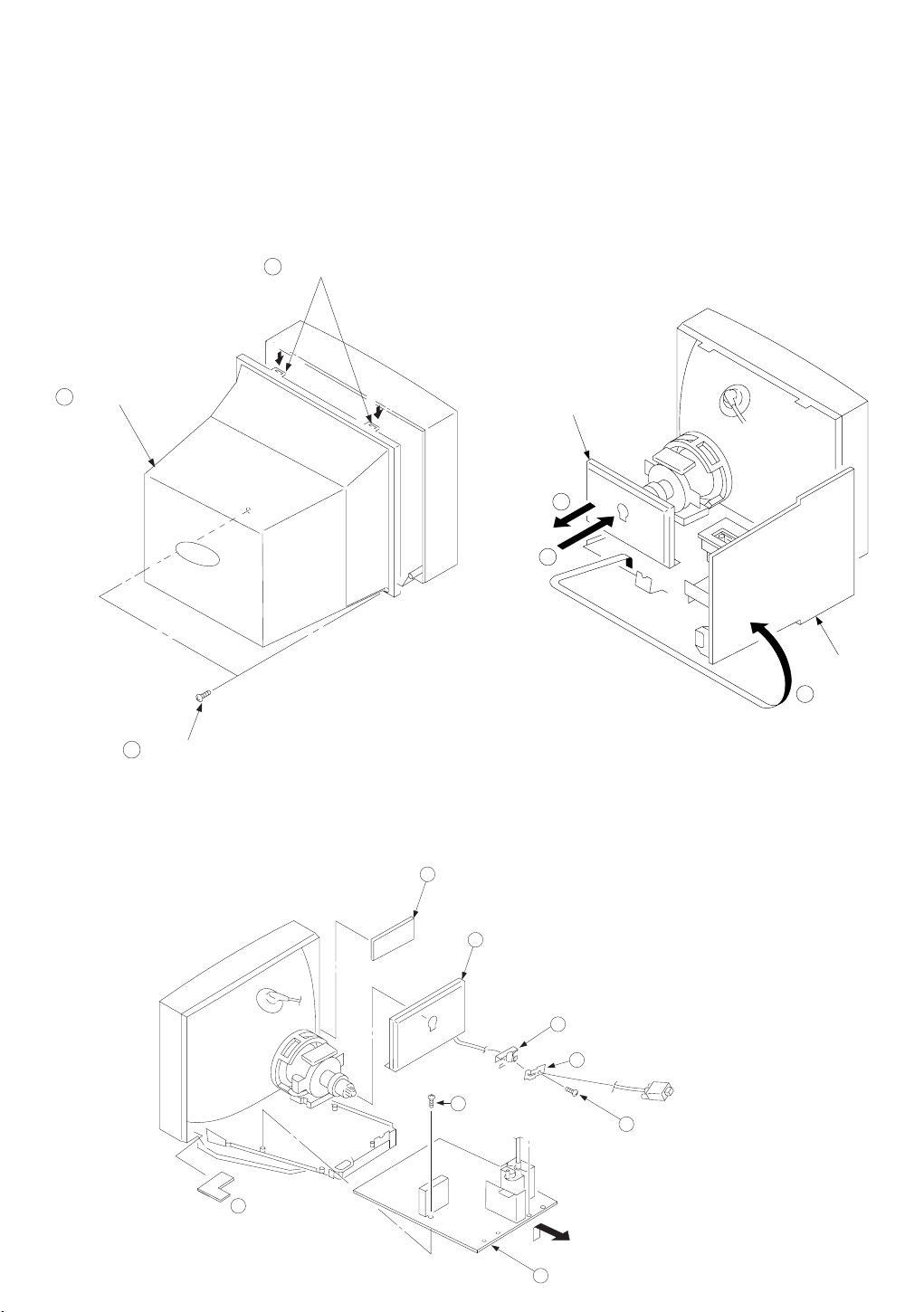

2-1. CABINET REMOVAL

2

Two claws

PUSH

3

Cabinet

2-2. SERVICE POSITION

PUSH

A board

1

3

D board

2

1

Two screws

(BVTP 4 x 16)

2-3. A, D, H, S BOARD REMOVAL

1

S board

H board

2

A board

3

Five screws

7

(BVTP 3 x 12)

Cable stopper

4

5

Cable bracket

6

One screw

(BVTT 4 x 8)

8

D board

Page 9

2-4. PICTURE TUBE REMOVAL

3

Four screws

Picture tube shield

2

8

Demagnetization coil

7

Tension spring

6

A board

5

Neck assy

4

Deflection yoke

(Tapping screw 5)

9

Two screws

10

Stand assy

(D board)

P75

(BVTP 4 x 16)

1

Anode cap

Cushion

REMOVAL OF THE ANODE-CAP

NOTE: Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon painted on the CRT, after

removing the anode.

REMOVAL PROCEDURES

Turn up one side of the rubber cap in

the direction indicated by arrow .

Use your thumb to pull the rubber cap

firmly in the direction indicated by

arrow .

HOW TO HANDLE AN ANODE-CAP

Do not use sharp objects which may cause damage to the surface

of the anode-cap.

Do not squeeze the rubber covering too hard to avoid damaging

the anode-cap. A material fitting called a shatter-hook terminal is

built into the rubber.

Do not force turn the foot of the rubber cover. This may cause the

shatter-hook terminal to protrude and damage the rubber.

When one side of the rubber cap sepa-

rates from the anode button, the anodecap can be removed by turning the rubber cap and pulling it in the direction of

arrow .

Page 10

P75

SECTION 3

SAFETY RELATED ADJUSTMENT

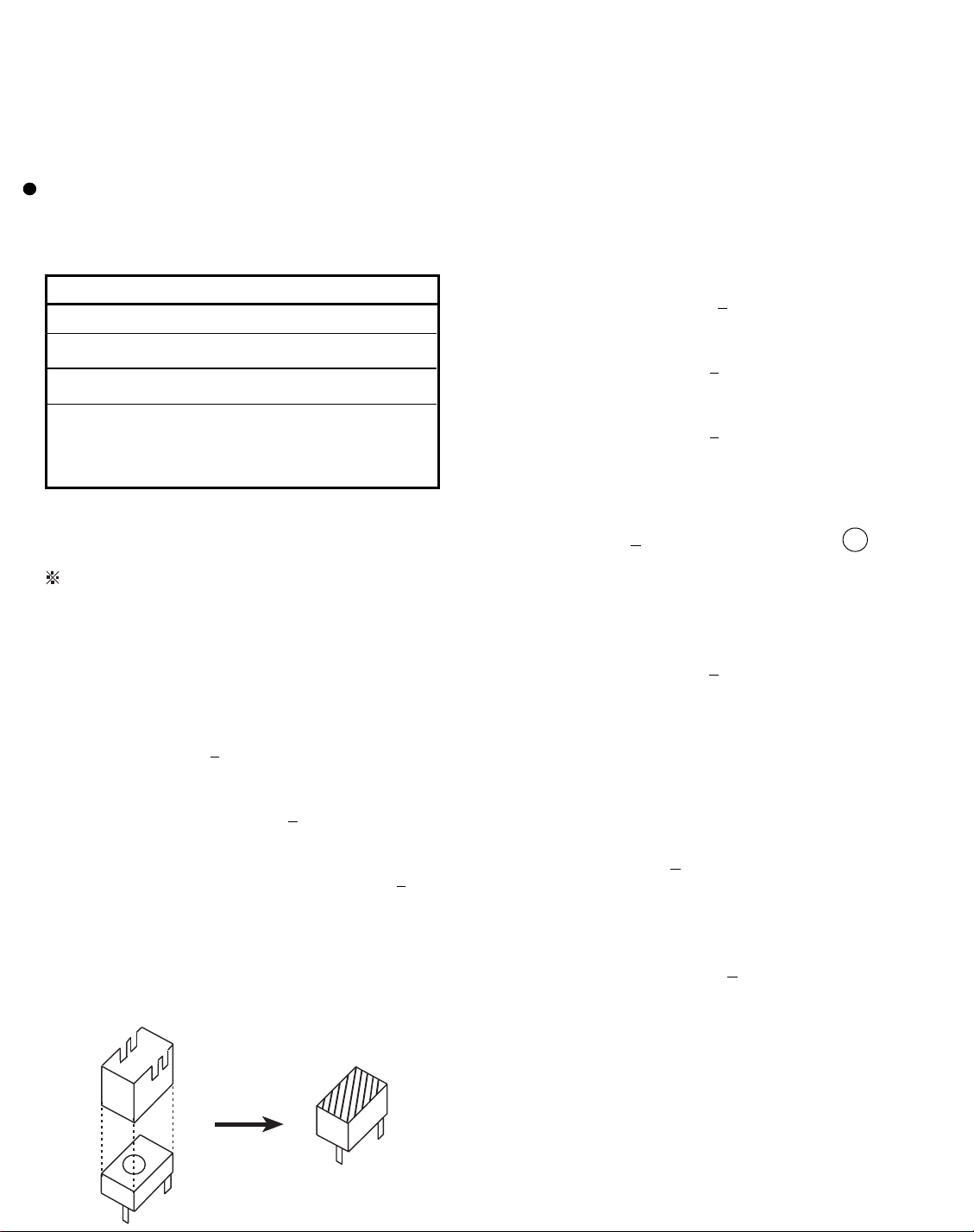

When replacing parts shown in the table below, the

following operational checks must be performed as a

safety precaution against X-ray emissions from the unit.

D - BOARD

Part Replaced ([)

Part Replaced (])

RV501, T501, R545, R546, R548, R550, R547, R549, R552,

D517, IC605, IC901, C540, C542, C544, C541, C535,

IC501, C558, R567, R564, C555, C553, C554, C561

Allow the unit to warm up for one minute prior to

checking the following conditions:

RV501

a) HV Regulator Check

1) Input white cross hatch signal. (fH = 64 kHz)

2) Minimum CONT and BRT controls.

3) Cut off Screen VR (G2).

4) Input voltage: 120

5) Confirm that the voltage is within the voltage range

shown below.

Standard voltage: 25.0KV

6) When replacing components identified by ], make

sure to recheck the High Voltage.

7) Verify the High Voltage as shown above (25.0KV

is within specification. If not, set H. SIZE data at

minimum (-127) and then adjust RV501 on "D" Board.

8) After adjusting the High Voltage within specification,

put the RV cover on RV501 as shown below and apply

sufficient amount of RTV around RV501.

+ 2 VAC

+ 0.5KV

+ 0.5KV)

b) HV Hold-Down Check

1) Using an external DC Power supply, apply the

voltage shown below between cathode of D517

on "D" Board and GND, and confirm that the

HV Hold-Down circuit works. (Raster disappears)

Apply DC Voltage: 31.4

Check Condition

• Input voltage : 120

• Input signal : (fH = 64 kHz), White Cross Hatch

• Controls : CONT (max) & BRT (center)

• B+ Voltage : 185 + 3.0 VDC

c) Beam Protector Check (Software logic)

1) Using an external DC power supply, apply the

voltage 8.8

(T501) and GND, and confirm that the voltage

across C541 is 3.7 VDC or less.

Check Condition

• Input voltage : 120

• Input signal : (fH = 64 kHz), White Cross Hatch

• Controls : CONT (max) & BRT (center)

d) B+ MAX. Check

1) Input white cross hatch (fH = 64 kHz) signal.

2) CONT (max) & BRT (center)

3) Input voltage: 120

Note: Use NF power supply or make sure that

distortion factor is 3% or less.

4) Confirm that the voltage is within the voltage

range shown below.

Standard voltage: 185

+ 0.01 VDC between pin 11 of FBT

+ 0.01 VDC

+ 2 VAC

+ 2 VAC

+ 2 VAC

+ 3.0 VDC

104

RV501

Page 11

SECTION 4

NECK Assy

6-pole Mg

P.S Mg

XBV

DY CRT

4-pole Mg

ADJUSTMENTS

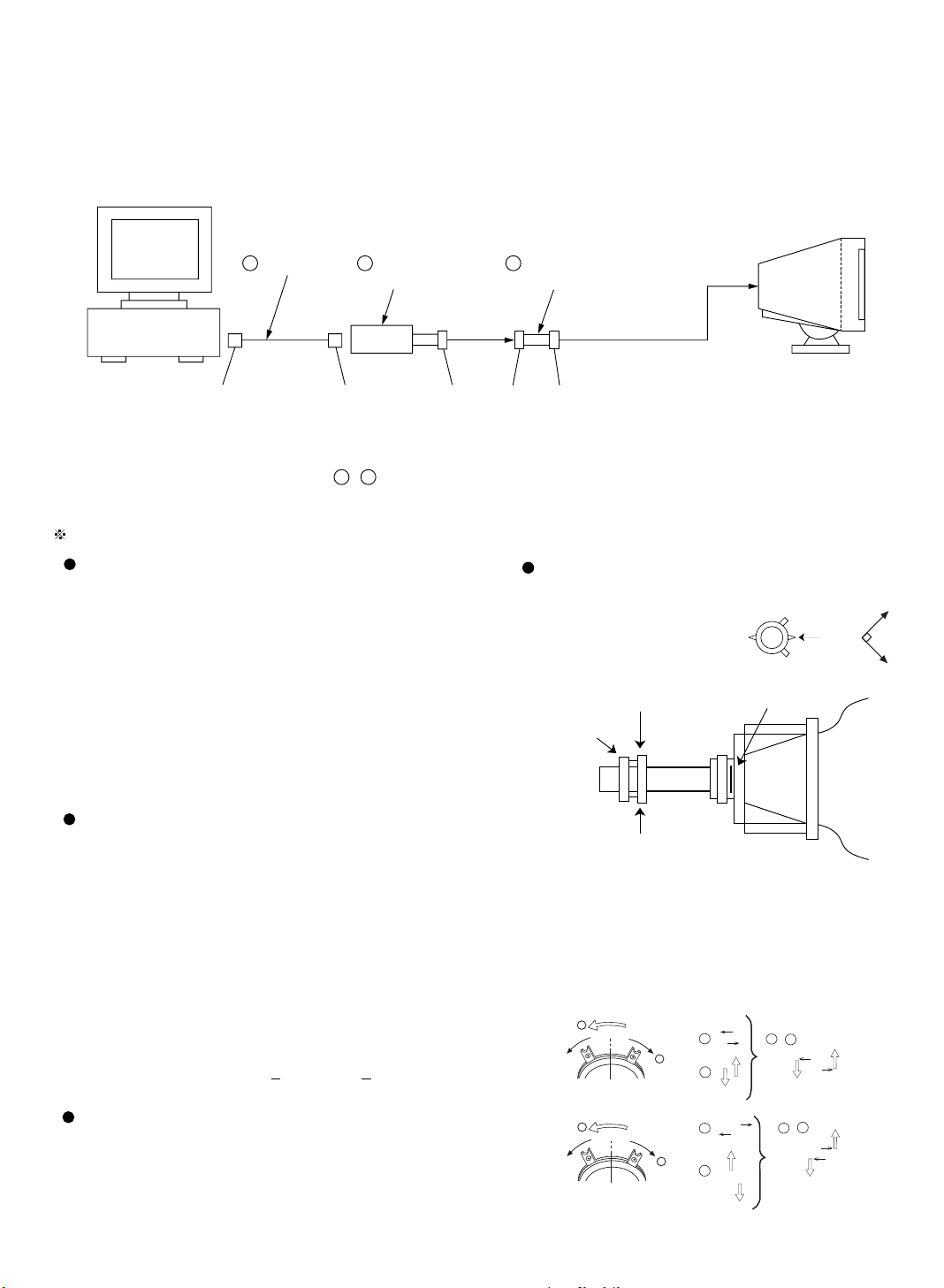

Connect the communication cable of the connector located on the D board on the monitor. Run the service software and

then follow the instructions.

IBM AT Computer

as a Jig

1-690-391-21

1

D-sub

(9 Pin [female])

*The parts above ( ~ ) are necessary for DAS adjustment.

mini Din

(8Pin)

1

A-1500-819-A

2

Interface Unit

3

4 Pin

3-702-691-01

3

Connector Attachment

To BUS CONNECTOR

4 Pin 4 Pin

Allow a 30 minute warm-up period prior to making the following adjustments:

Landing Rough Adjustment

1. Enter the full white signal.

2. Adjust the contrast to the maximum.

3. Input full green signal.

Convergence Fine Adjustment

Set DY four-pole magnet to mechanical center

before adjustment.

This should be prime mode.

4. Moving the DY backward, and adjust coarsely the purity

magnet sothat a green raster positions in the center of

screen.

5. Moving the DY forward, adjust so that an entire screen

becomes pure green.

6. Adjust the tilt of DY, and tighten lightly with a clamp.

P.S Mg

Set the

finger

Mechanical

Center

• Landing Fine Adjustment

1. Place the set in the Helmholtz coil.

2. Enter a green signal only.

3. Degauss the entire screen with hand-degausser. Then auto-

degauss it.

4. Attach a wobbling coil to the specified position of CRT

neck.

5. Attach a landing adjuster sensor on the CRT.

6. Using a landing checker, adjust the DY position, purity,

tilt of DY.

7. Clamp the DY screw.

Clamping torque: 22

• Convergence Rough Adjustment

1. All digital convergence data should be zero by MCP.

2. Enter the white crosshatch signal.

+ 2 kgcm (2.2+ 0.2 N.m)

3. Adjust roughly the horizontal and vertical

convergence at four-pole magnet.

4. Adjust roughly HMC and VMC at six-pole

magnet.

1. Receive R.B. cross-hatch.

2 Adjust H.STAT and V.STAT at four-pole magnet.

4 Pole Magnet

2

1

2

1

R

1

B

R

2

1

2

+

1

2

R

B

R

B

R

B

B

2

+

1

R

B

Page 12

P75

3. Receive White cross-hatch.

4. Adjust HMC and VMC at six-pole magnet.

< 6 Pole Magnet>

2

G

1

2

G

1

5. Receive R.B. cross-hatch.

6. Adjust H.TILT by swinging the DY neck right and left.

7. Adjust XCV with XCV core.

XCV movement

B

R

8. Adjust V.TILT with TLV VR.

TLV movement

B

R

R

B

B

R

R

B

9. Adjust Y.CROSS with YCH VR.

YCH movement

10. Paint lock the four-pole and six-pole Mg.

RB

VR Adjustment on DY

XCV

Convergence Specification

Horizontal and Vertical

0.30mm

B

A 0.24mm

B 0.30mm

0.30mm

A

Focus adjustment

Adjust focus (V) and focus (H) for optimum focus.

Focus (V)

Focus (H)

FBT

11. Digital Convergence Adjustment

A. Horizontal Convergence

YBH-T

CBH-LT

MBH-LT

APH-L

MBH-LB

0

12

4

8

2

H STAT

CBH-RT

9

MBH-RT

11

APH-R

3

MBH-RB

7

YCH

TLV

Zero Position NECK Ass'y

Purity 4-Pole Mg 6-Pole Mg

Vertical and Horizontal Position and Size

Specification

a

a < 2.5 mm

b < 2.5 mm

a

A

A B

B

bb

202 270

615

Adjust each misconvergence point in sequence.

YBH-B

CBH-RBCBH-LB

B. Vertical Convergence

V STAT-T

CCV-LT

0

MCV-LT

XBV-L

4

MCV-LB

8

12

2

V STAT

615

V STAT-B

Adjust each misconvergence point in sequence.

CCV-RT

9

MCV-RT

11

XBV-R

3

MCV-RB

7

CCV-RBCCV-LB

C. Repeat the procedure of A and B so that the

convergence of the whole screen is within the

specification.

Page 13

5-2. CIRCUIT BOARDS LOCATION

H

A

S

D

U2

D1

U1

5-3. SCHEMATIC DIAGRAMS AND PRINTED WIRING BOARDS

Note:

•

All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytic.

•

Indication of resistance, which does not have one for rating

electrical power, is as follows.

Pitch: 5 mm

Rating electrical power 1/4 W (CHIP: 1/10 W)

•

All resistors are in ohms.

• f : nonflammable resistor.

• F : fusible resistor.

• ∆ : internal component.

• p : panel designation and adjustment for repair.

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

• e : earth-ground.

• E : earth-chassis.

• The components identified by [ in this basic schematic

diagram have been carefully factory-selected for each set

in order to satisfy regulations regarding X-ray radiation.

Should replacement be required, replace only with the

value originally used.

•

When replacing components identified by ], make the necessary

adjustments by using RV501 ([) as indicated. (See page 10Z)

Note: The components identified by shading and

mark ¡

with part number specified.

Note: Les composants identifies per un trame et une

marque ¡ sont critiques pour la securite. Ne les

remplacer que par une piece portant le numero specifie.

are critical for safety. Replace only

• When replacing parts shown in the table below,

be sure to perform the safety related adjustment.

Part Replaced ([)

Part Replaced (])

RV501, T501, R545, R546, R548,

R550, R547, R549, R552, D517,

IC605, IC901, C540, C542, C544,

C541, C535, IC501, C558, R567,

R564, C555, C553, C554, C561

• All voltages are in volts.

• Readings are taken with a 10 ΜΩ digital multimeter

• Readings are taken with a color-bar signal input.

• Voltage variations may be noted due to normal

production tolerances.

• * : Cannot be measured.

• Circled numbers are waveform references.

• : B +bus.

• : B - bus.

D - BOARD

RV501

Page 14

CONNECTOR

15PIN D-SUB

CN305

8P

STBY +5V

8

CN307

9P

WHT

1

BGND

2

SIGNAL IN

BLUE

3

GGND

4

GREEN

5

RGND

6

RED

7

GND

8

VD

9

HD

CN309

7P

HSYNC

7

GND

6

VSOUT

5

4

CSYNC

BPCLP

3

SHRP1

2

CBLK

1

CN306

6P

1

VRTRC

2

HRTRC

3

GND

IICSCL

4

GND

5

IICSDA

6

CN310

4P

HOSTGND

4

3

DDCSDA

2

DDCSCL

NC

1

CN311

3P

3

DDCSCL

2

DDCSDA

1

CPUGND

5

1

11

6

IC006

SHARPNESS

21

5

BIN

R-OUT

3

19

G-OUT

GIN

17

1

B-OUT

RIN

14

SYN-OUT

13

CLAMP

12

T-SW & LEVEL

BUFFER

Q005

SWITCH

Q004

15

R-OSD

OSD

14

IC003

G-OSD

13

12

OSD-BLK

10

7

SDA

VFLB

5

8

SCL

HFLB

25

8

R-OUT

6

R-IN

8

G-IN

10

B-IN

11

CLAMP

IC001

RGB PRE-AMP

16

BLK

12

R-OSD

13

G-OSD

14

B-OSDB-OSD

15

OSD-BLK

SCL21SDA

R-IN

22

9

G-OUT

G-IN

18

11

B-OUT

B-IN

3

1

R-BKG

R-IN

4

2

G-BKG

G-IN

5

3

B-BKG

B-IN

G2

28

CRT DRIVER

CUTOFF AMP

5

R-OUT

3

G-OUT

IC002

1

B-OUT

9

R-OUT

8

G-OUT

IC004

7

VIP

B-OUT

5

+12V

SPOT KILLER

Q001

(VIDEO)

+5V

7

GND

6

+12V

+12V

5

H1

4

4

CONTROL

IC005

3

+80V

2

+185V +185V

1

1

1

1

GND

+80V

NC

CN301

1P

1.2KV

TO JOO1

PICTURE TUBE

A BOARD

HV

CN302

1P

GND

CN303

1P

GND

(TO FBT)

J001

H

7

KR

8

KG

9

KB

G2

10

G2-CUT OFF

D9202

(PWR SWITCH AND LED)

CN9901

CN9101

3P

1

2

3

1

2

RELAY

DRIVE

Q601

AC-RECT

15

PB4

46

CBLANK

5

DA4

22

BPCLAMP

28

C-SYNC

20

V-SYNC

30

H-SYNC

54

RESET

34

DDCSCL

}

35

DDCSDA

33

PCI

37

DATA

36

CLK

26

V-DRIVE

39

TXD

38

RXD

48

PA5

47

PA6

DEGAUSS

D601

6

7

8

9

16

17

CPU

IC901

7 49-53

1

Vcc

SW-REG CONT

5

FLDBK

CONV-CONTROL

H-CONVOUT

V-CONVOUT

H-STATICOUT

V-STATICOUT

SDL

SCL

S0-S4

IC601

13

REMOTE ON/OFF

EA

IC701

13V.REF

IN

2

V-SIN

3

VPOSIN

14

HD.IN

V.REF OUT

5

5V

EPROM

12

PB7

IC905

13

PB6

23

LOCK

26

V-OUT

27

H-OUT

32

HFB

4

BUFFER

DA3

Q506

9

DA8

18

PB1

6

24

HTR STDBY

15

ABL

ROTATION

TO S-CAP

CHANGE

3

OUT

CIS

7

IC603

5

4

T601

3

SRT

SW-REG

OUT

Q602

1

15V

ERROR AMP

3

2

IC604

CN701

CY

8P

CY4-

8

15

CY4+

7

CY3-

6

CY3+

5

CY2-

4

CY2+

3

CY1-

2

CY1+

1

FUNCTION

SWITCH

CN903

7P

CBLANK

1

SHRP1

2

BPCLAMP

3

CSYNC

4

VSYNC

5

GND

6

HSYNC

7

CN902

10P

WHT

1

DDCSCL

2

DDCSDA

HOST GND

3

NC

4

5

IICDATA

6

GND

7

IICCLK

GND

8

9

HRTRC

10

VRTRC

TXD

4

CN901

3

RXD

4P

WHT

2

+5V

1

NC

NC

EMI LINE FILTER

1

2

3

4 1

DGC

DGND

RED

3

2

GREEN

1

GND

CN603

4P

4

SWITCH OUT

3

2

SWITCH IN

CN601

3P

DGC1

3

NC

2

DGC2

1

CN604

4P

4

L

3

2

1

N

CN602

2P

2

THP601

1

THP601A

CN9201 CN904

3P 3P

RED

3

2

D9201

GREEN

1

GND

1

AC LIVE IN

CN6601

S901

1P

1

AC LIVE OUT

CN6602

1P

TO AC LINE

2

5

10

11

CONV AMP

14

IC702

6

1

3 412 13

IC900

SYN BUFF

41

RESET

IC904

}

+5V

DRIVERS

Q901,Q902

+12V

LF602

LFT

5V

GND

BRIGHT

CONT

H. CENT CNTL

9

8

7

6

5

4

3

2

1

5V

CONT

NC

BRIGHT

GND

CN9902

2P

27 10

3

V.DIV V.SIN

SDA

4

SCL

23

V-REF

DEF. CONTROL

IC902

2

LOCK

28

V-IN

26

H-IN

SYNC LOCK

Q522,Q523

Q518

H. CENT SW

Q517

10

11

12

13

14

15

16

17

18

CONTROL

STBY.

1

Q604

TO H.CENTER

TO H.CENTER

1

2

3

4

V.SAW

H.OUT

V. DEF

H.FLY

185V

80V

15V

-15V

IC503

IC503

1

VR9101

2

(CONT/BRITE CNTL)

8

17

12

14

+15V

5V

1

VR9102

3

2

V-OUT

4

+IN

IC401

5

-IN

4

H-CENTER

2

IC503

35

HEATER SW

Q605,Q606

1,2

DISABLE

5V,12V REG

IN1,2

IC605

CN1301 CN1304

5V

1

TO USB PNP

DMO

2

DEVICES

DPO

3

GND

4

POWER

)

DEFLECTION

(

2

OUT

H-REG

20

B1O

Q520

H.DRIVE

Q903,Q501,Q502

6

OUT

+12V

Q505

7

+5V

OUT

3

(USB1)

B-#SV9055<COMPAQ-D1H>-U1..

3

B4+

PWM-CONT

IC501

H-DRIVE REF

8

1

2

3

4

5

BUFFER

Q521

PH2

13

4

H.DRIVE OUT

DF-AMPBUFF

Q504

CN1303

CN1302

5V

DMO

DPO

DP GND

GND

12

B3O

OP2+

B2O

Q511

DFT

T503

1

5

1

5V

2

DM1

3

DPO

DP GND

4

GND

5

HST

T505

5

1

2

3

HV-REG

18

Q503

19

HV-OUT

Q510

HDT

T504

H.OUT

4

Q507

6

8

1

BUFFER

Q508

SWITCH

Q519

RY500

12

11

10

9

S-CAP CHANGE

8

Q512,Q513,Q514,Q515,Q516

7

(USB2)

B-#SV9055<COMPAQ-D1H>-U2..

2HV

1

12

ROTATION

DRIVE

IC502

1

5V

2

DM1

TO COMPUTER

USB PORT

3

DP1

4

GND

CN512

1P

GND

1

CN510

1P

1.2 KV

1

FBT

T501

TO CRT

14

RV501

13

FOCUS

17

16

ABL

11

6

5

4

8

9

B-#SV9055<COMPAQ-D1H>-BLK..

CN501

6P

DY

1

H DY+

2

H DY+

3

H DY-

4

H DY-

5

V DY-

V DY+

6

CN502

9P

WHT

1

+185V

+185V

NC

2

+80V

3

+80V

4

NC

5

GND

6

H1

7

+12V

+12V

GND

8

9

+5V

+5V

CN503

2P

1

ROT+

2

ROT-

Page 15

12

11

G3

J001

IC002

R304

68

:CHIP

0.1

25V

+12V

LM2405T

RGB OUTPUT

S

N

A

N

I

I

I

_

B

_

G

V

B

R204

68

C015

:CHIP

0.1

25V

B:CHIP

C011

0.1

100V

:PT

N

I

_

R

1 2 3 4 5 6 7 8 9

R107

5.6k

:CHIP

R207

5.6k

:CHIP

R307

5.6k

:CHIP

FB011

CN307

(VIDEO)

9P

WHT

:S-MICRO

FB302

1

BGND

0

2

BLUE

R301

75

FB202

3

GGND

:RN-CP

0

4

GREEN

:S-MICRO

CN306

NC

CN309

7P

WHT

HSYNC

VSOUT

CSYNC

BPCLP

SHRP1

6P

WHT

IICSDA

IICSCL

HRTRC

VRTRC

CN310

:S-MICRO

RGND

RED

GND

VD

HD

GND

CBLK

GND

GND

4P

WHT

R201

FB102

75

5

0

:RN-CP

6

R101

75

7

:RN-CP

8

9

D001 D003

RD5.6ESB2 RD5.6ESB2

R016 R026

10k

:CHIP

R056

2.2k

:CHIP

FB007

JW(5)

7

6

5

4

3

2

1

FB010

6

5

4

3

FB009

2

1

4

3

2

1

SIGNAL

IN

TO D.BOARD

CN903

:S-MICRO

TO D.BOARD

CN902

HOSTGND

SIGNAL

DDCSDA

IN

DDCSCL

D301

C301

1SS226

0.1

25V

B:CHIP

FB303

B:CHIP

FB203

FB103

C101

0.1

25V

B:CHIP

10k

:CHIP

R007

100

R011

220

Q005

MPS3646

R018

100

:CHIP

R017

100

:CHIP

R021

100 :CHIP

R020

100 :CHIP

D201

C201

1SS226

0.1

25V

R112

D101

47

1SS226

:CHIP

R212

47

:CHIP

R312

47

:CHIP

C048

0.01

C019

B:CHIP

0.1

STBY+5V

R006

100

:CHIP

CN311

3P

WHT

:S-MICRO

STBY+5V

IC006

CXA2093S

RGB PRE-AMP

R1_IN

2

1

GND

C112

15p

:CH

GND

2

R_OUT

1

G1_IN

3

GND

C212

10p

:CH

GND

4

G_OUT

2

B1_IN

VCC

5

C312

15p

:CH

VCC

6

B_OUT

3

R2_IN

VCC2

7

GND

8

DEFF.

G2_IN

9

SIGNAL_SW

GND

0

CLAMP

1

B2_IN

1

1

T_SW&LEVEL

R052

10k

:CHIP

C005

0.001

B:CHIP

3

2

1

D

A

L

N

D

C

TO D.BOARD

G

S

S

CN902

T

C

C

S

D

D

O

D

D

H

C102

2

0.1

25V

B:CHIP

1

2

0

C202

2

0.1

25V

B:CHIP

9

1

C302

8

1

0.1

25V

B:CHIP

7

1

6

1

C049 C051

0.01

B:CHIP4725V

5

1

4

1

R043

0

3

1

R054

2.2k

:CHIP

2

1

C050

0.1

25V

B:CHIP

:CHIP

C009

47

25V

V

5

+

Y

B

T

S

R002

1.5k

R024

4.7k

:CHIP

R025

4.7k

:CHIP

R004

1.8k

:CHIP

L002

2SC2412K

IC001

CXA2055P

PRE-AMP

8

G2

SDA

1

2

7

C_SYNC

SCL

2

2

C104

6

S/H_R

R_BKG

3

2

0.1

25V

4

B:CHIP

5

4

R_OUT

G_BKG

2

4

R_GND

B_BKG

5

2

C204

3

S/H_G

R_IN

6

+5V

7

G_IN

8

C004

SYNC_CAP

9

0.01

B:CHIP

0

B_IN

1

1

CLAMP

1

2

R_OSD

1

3

G_OSD

1

4

B_OSD

1

C042

0.1

25V

B:CHIP

1

2

C044

0.068

R003

25V

5.6k

B:CHIP

:CHIP

3

R005

C046

470k

0.01

:CHIP

B:CHIP

4

C047

47

25V

5

6

7

8

STBY+5V

R051

1k

:CHIP

Q004

SWITCH

VSSA

VCO

RP

VDDA

HFLB

SS

SDA

SCL

CXD8758P

0.1

2

25V

5

B:CHIP

2

G_OUT

2

1

G_GND

2

0

VCC

2

C013

47

+12V

16V

C304

9

S/H_B

1

0.1

25V

6

B:CHIP

8

B_OUT

1

7

B_GND

1

6

BLK

1

5

OSD.BLK

1

IC003

OSD

6

1

VSS

5

1

R_OSD

4

1

G_OSD

3

1

B_OSD

2

1

OSD_BLK

1

1

INT

0

1

VFLB

R014

100

:CHIP

9

C022

C092

VDD

0.1

47

25V

25V

B:CHIP

STBY+5V

FL002

EMI

C090

0.01

B:CHIP

FB012

STBY+5V

R106

10k

:CHIP

R206

10k

:CHIP

R306

10k

:CHIP

C205

0.1

25V

B:CHIP

C305

C105

0.1

25V

B:CHIP

B:CHIP

N

I

_

R

R104

68

:CHIP

N

I

_

G

C018

10

250V

3

D

N

G

:CHIP

C055

0.1

100V

C014

100V

47

N

I

_

B

7

C

C

V

D104

HSS82

PROT

TDA6103Q

CUT OFF AMP

D

N

G

R032

3.9k

:RN

IC004

8

9

T

T

U

1

U

2

O

D

O

D

_

N

_

N

G

G

R

G

R111

R211

47 :FPRD 47 :FPRD

FB101 FB201 FB301

000

D304

D204

HSS82

HSS82

PROT

PROT

D305

HSS82

PROT

D205

HSS82

PROT

D105

HSS82

PROT

T

T

U

U

P

C

O

O

I

C

_

_

V

G

B

V

C054

0.1

250V

:MPS

C053

0.1

R210

25V

220k

B:CHIP

R310

220k

R308

R208

6.8k

6.8k

:CHIP

:CHIP

T

U

O

_

B

1234567891011

R311

47 :FPRD

C035

470p

2kV

B

+80V

C306

0.1

250V

:MPS

C206

0.1

250V

:MPS

C106

0.1

250V

:MPS

D206

HSS82

PROT

D106

HSS82

PROT

T

U

O

_

R

R033

15k

:RN

R110

220k

R108

6.8k

:CHIP

STBY+5V

+12V

D306

HSS82

PROT

FB310

FB210

FB110

1SS119-25TD

C017

L301

L201

L101

R309

1M

:CHIP

R209

1M

:CHIP

R109

1M

:CHIP

+185V

R029

120k

:CHIP

D014

R053

PROT

22M

:RN

R045

2.2k

:CHIP

2SC5022

SPOT KILLER

C028

R031

47

1k

25V

:CHIP

0.1

10

1

RCV

9

G2

G2

8

KB

10

SG001

R064

10k

1/2W

:RC

R333

1k

R351

100

R233

1/2W

:RC

1k

R251

100

R133

1/2W

1k

:RC

R151

100

1/2W

:RC

1

13

G1

3

2

H

4

11

5

10

H

3

6789

KR

4

7

KRKG

56

R048

11

12

2.2M

1W

:RN

SG101SG201SG301

+80V

CN301

1P

1

1.2KV

TO D.BOARD

CN510

L005

C031

SG

CN302

CN303

IC005

NJM4558M

C029

CUT-OFF-CTRL

0.1

25V

B:CHIP

+

5

-

6

7

OUT

8

Q001

VCC

R049

82k

:CHIP

C027

0.01

B:CHIP

C016

470

16V

R046

100k

:CHIP

R047

10k

+12V

:CHIP

V

V

0

V

5

8

2

8

+

1

1

+

+

GND

4

3

2

1

5

0

0

B

F

+12V

CN308

4

1

0

0

0

0

B

B

F

F

CN305

8P

WHT

:S-MICRO

STBY+5V

8

GND

7

FB006

+12V

6

H1

5

C001

0.001

GND

4

500V

3

+80V

C002

0.1

2

NC

100V

1

+185V

TO D.BOARD

CN502

B-#SV9055<COMPAQ-D1H>-A..

Page 16

CN901

4P

WHT

:S-MICRO

1

D GND

+5V

2

R903

1k

R904

1k

R912

1k

R913

100

R914

100

R918

1k

FB902

R919

R935

R938

R936

C933

0.01

:CHIP

C934

47p

C553

0.001

B

R567

R564

C558

10k

47k

1

:CHIP

131415161718192021222324

R

REF

C554

C561

0.1

0.001

25V

B

B

C556

220p

:CHIP

R562

12k

:RN

R566

22

1W

:RS

R563

1.5

:FPRD

15V

FOR TEST

RXD

3

TXD

4

CN9902

TO H-BOARD

CONT

2

CN9101

BRIGHTNESS

1

1

DDCSCL

DDCSDA

2

3

HOST GND

4

NC

TO A-BOARD

5

IICDATA

CN306 & CN311

GND

6

IICCLK

7

FB901

GND

8

5MM

9

HRTRC

10

VRTRC

CN902

10P

WHT

:S-MICRO

TO S-BOARD

CN9201

1

GND

RED

2

GREEN

3

CN904

TO H-BOARD

5V

CN9101

1

5V

NC

2

3

GND

CN9901

TO A-BOARD

CN309

100

1

CBLANK

1k

2

SHRP1

100

3

BPCLAMP

100

CSYNC

4

100

VSYNC

5

6

GND

7

HSYNC

R937

1k

CN903

7P

WHT

:S-MICRO

R959

3.3k

N

O

I

T

A

T

O

R

9

2

1

2

1

5

S

D

S

1

9

3

1

2

1

5

S

D

S

1

N

O

I

T

A

T

O

R

R560

15k

:RN

C547

1

CN503

2P

2

ROTATION-

1

ROTATION+

1

A

C

W

CP1 CP2 CP3

R909

2.2k

:CHIP

DDC CLK

1234

0

A

CAT24C08P

C

C

V

+5V

B1 B2

RR R RR

R557

18k

:CHIP

CN513

:TUB

5V

R906

10k

:CHIP

D901

1SS119

IIC DATA

IIC CLK

D908

IC905

EPROM

Y

L

F

H

C911

0.01

:PT

12V

C555

0.1

:PT

C562

100

16V

:RN-CP

C557

22

B3

R

R

R

R

SAW GEN1 AGC TYPE

SAW GEN2 NON AGC TYPE

C576

C548

47p

CH

0.001

:PT

R583

10k

:CHIP

12V

R584

4.7k

:CHIP

R568

47k

+12V

C549

0.068

:PT

5V-2

IC502

LA6500-FA

ROTATION DRIVE

R558

12345

10k

:RN

C513

R559

10

2.7k

-15V

1P

SV9055<COMPAQ-D1H>-D..

T

A

E

T

K

D

A

L

V

D

C

5

D905

C

C

C

1SS119

I

I

D

I

I

D

R916

15k

:CHIP

R922

D909 D910

10k

RD5.6ES RD5.6ES

:CHIP

C912

100

16V

C545

0.022

B

T

Y

N

L

E

V

F

C

H

V

H

R554

150k

:RN-CP

T

N

1

O

0

C

5

-

C

M

I

W

P

1 2 3 4 5 6 7810911 12

R569

470 :RN-CP

R551

R553

C543

22k

100p

100k

:RN

:RN-CP

CH

C551

0.01

B:CP

C539

R541

1k

0.022

:RN

100V

13

R540

200k

:RN

16

RV501

100k

FOCUS

R544

1M

R542

:RN

1k

SG501

C532

:RN

0.47

100V

C535

D514

0.01

HSS82

:PT

R545

47k

:RN-CP

R546

33k

:RN

7

R543

4.7

:FPRD

6

D515

ERA34

9

R547

C542

560k

1

:RN

1012

R549

C540

82k

0.01

:RN

630V

:PP

RXD

TXD

D906

1SS119

R908

2.2k

:CHIP

D907

1SS119 1SS119

R917

15k

:CHIP

2

S

A

S

V

L

A

C

D

S

S

5 6 7 8

CBLANK

H FLY

V FLY

CSYNC

SHRP1

R556

47k

:RN-CP

C546

220p

:CH

DP1 B4

B4

C552

C563

0.01

470p

B:CP

B:CHIP

L507

C550

5mm

100

16V

L

B

A

R548

1.8k

:RN-CP

R550

1.8k

:RN

C541

4.7

D517

RD27ES

R552

C544

56k

0.01

:RN

:PT

CN512

1P

:TUB

KEY SCANKEY SCAN

5V-2

(POWER DEFLECTION)

CN702

3P

3

H-CONV OUT

2

V-CONV OUT

1

GND

CN703

3P

1

GND

2

V-CONV IN

3

H-CONV IN

CN701

8P

WHT

:S-MICRO

8

CY4-

7

CY4+

6

CY3-

5

CY3+

4

CY2-

3

CY2+

2

CY1-

1

CY1+

TO CONV

YOKE

S

S

U

A

G

E

D

R610

47k

3W

:RS

D606

RB441Q

Q601

DTC143ESA-TP

RELAY DRIVER

12V

D602

1SS119

VA600

1

DGC2

TH601

NC

2

300V

:POS

3

DGC1

RY601

CN601

3P

1

THP600

THP600A

2

CN602

2P

C642

4

SW OUT

TO

S-BOARD

CN6601/

CN6602

4700p

250V

3

:PT

2

SW IN

1

CN603

2P

F601

4A

250V

FB610FB611

100p 250V B

FB608FB609

CN605

JW601

JW(10MM)

JW602

JW(10MM)

C630

IC601

0.1

MC44603P

SW-REG CONTROL

D608

MTZJ-T-77-18

RREF

6

1

1

VCC

R611

R645

10k

STBYMNG

47k

5

2

1

VC

E/AIN

R612

4

8.2

3

1

OUTPUT

C635

0.01

R638

3.9

D648

1SS133

R603

68

R649

100k

1W

D649

RD13ES-T1B2

D601

GBU4JL

TH600

5.1

300V

C606

C602

R600

4700p

4700p

1

250V

250V

10W

E

E

C643

4700p

C605

250V

1

250V

1

4

LF602

:LFT

2 3

C604

0.47 250V

FB614

R604

560k 1/2W :RC

C601

VA601

C608

100p 250V B

FB612 FB613

1

2

3

4

CN604

4P

N

L

TO

EMI FILTER-

AC LINE

R613

50V

10k

E/AOUT

3

GND

:PT

4

1

R644

D609

3.9k

RB441Q

CLAMP E/AIN

:CHIP

2

5

1

FOLDBACK IN

C614

R634

1

15k

SFTSTRT

:MPS

1

6

1

OVP

C616

C661

27p

630V

R617

470p

1k

CT

B

0

7

1

C617

CUR SENSE IN

0.0022

:PT

8

9

STBYLSET

DEMAGIN

C618

100p

B

FB615

C929

1000p

B:CHIP

R940

2.7k

:RN

S901

SW

+

S902

SW

R941

1k

-

R943

680

S903

:RN-CP

SW

MENU

R708

10k

R709

R707

10k

10k

C706

100p

R712 R716

:CH

33

R711 R713

1W

0.56

:RS

1W

15

1 2 3 4 5 6 7 8 9

C647

470p

500V

TO Q602

E

HEATSINK

C640

4700p

250V

FB616

E

C629

470p

C610

250V

390

B

R605

400V

0.1

1/2W

:RF

FB603

1UH

T601

9

R609

8

47k

C634

3W

330

25V

7

6

Q602

IRFIBC40G

FB605

SW REG

5

D607

UF4007

FB604

G23

S

4

C611

FB607

150p

2kV

3

C613

10000p

R615

630V

180k

2

D610

R616

R618

R619

5MM

RGP10G

2.2k

390

1

R614

D611

0.22

HSS82

3W

:RS

C615

0.001

:PT

R626

220

R620

22k

1

6

2

5

C645

0.0001

43

R627

0.1

IC603

MOC8105TV

C625

PHOTO COUPLER

100K

:PT

3

IC604

1

TL431CLP

ERROR AMP

2

12V

5V-2

9

5

6

7

8

1

D

V

D

V

H

N

5

N

2

CN502

G

+

G

1

9P

+

WHT

:S-MICRO

TO A-BOARD

CN305

185V

C619

L603

R642

FB601

220

D612

220k

0.45UH

200V

FMC-26UA

1/2W

:HT

10

D613

80V

FB602

L604

EGP10G

0.45UH

11

C620

100

15V

FB606

D614

100V

0.45UH

R639

EGP30DL

12

0.1

1/2W

L605

R621

13

0.1

C622

C621

1/2W

470

2200

25V

D615

25V

EGP20D

14

R641

C632

R622

10k

1000

D616

0.12

25V

EGP20DL

1/2W

15

R623

L606

FB617

C623

0.12

1000

-15V

1/2W

25V

16

C624

R624

D617

470

0.12

EGP20D

16V

:RF

17

C633

470

16V

18

R625

D618

0.12

EGP20D

R631

:RF

220

C637

D654

0.1

RD2.7ES-TIB2

D622

MTZJ-T-77-8.2

D605

D625

1SS119

ERA82

R635

1k

R628

Q605

R636

270k

1k

2SB1375

R637

:RN

1.5

PROT

1W

:RS

R629

Q606

1SS119

15k

DTC114ESA

HEATER SW

R630

4.7k

RV601

:RN

5k

Q604

DTC114ESA

STDBY CONTROL

80V

185V

5

1

1

2

3

4

C

C

V

+

V

N

N

0

Y

5

8

D

8

+

1

H

+

IC701

CXA8070P

CONV-CONTROL

A_GND

1

V_SIN

2

VPOSIN

3

V_DF

4

VREF OUT

5

C702

10

H_CONVOUT

6

V.CONVOUT

7

H-SAW_CAP

R705

4.7k

H_STATICOUT

8

H-AGC_CAP

V_STATICOUT

9

R706

4.7k

R710

10k

V-REF

C707

100p

:CH

33

1W

0.68

:RS

1W

R718

100

R717

1W

2.2

:RS

1W

:RS

R724

-15V

27

C708

1W

0.1

:PT

C709

470

15V

25V

L701

IC702

STK392-910A

CONV AMP

15

15

R

F

E

D

T

.

A

V

E

H

R646

100k

8

1

D_GND

D935

5.1B

7

1

SCL

6

1

SDL

R703

270

1/2W

5

1

C712

D_VCC

D704

0.1

1SS119

:PT

4

1

HD.IN

R704

10k

3

1

C714

V_REFIN

C701

390p

0.1

CH:CHIP

25V

2

1

C704

220p

CH

1

1

C703

0.22

:MPS

0

1

C705

A_VCC

0.1

:PT

R719

15k

15V

L702

C710

470

25V

10 11 12 13 14 15

IC605

12V

5V

TDA8138A

5V, 12V REG

OUTPUT2

7

OUTPUT1

6

C626 C627

220

NC

25V

5

GND

4

R633

10k

DISABLE

3

INPUT2

2

INPUT1

1

C628

100

25V

+5V

C713

2200

10V

12V

C715

470

16V

R727

15k

R728

100

1W

:RS

R729

2.2

1W

:RS

C711

0.1

R730

15

:PT

33

1W

5V-2

F

L902

F

O

/

N

O

E

T

O

M

220

E

25V

R

15V

R601

JW(7.5MM)

185V

T504

:HDT

C575

1

8

100

200V

2

7

D502

SB340L

346

Q511

IRFU110

H-DRIVE OUT

D501

R508

RD12ES

100

C502

10

R509

0.01

22k

:PT

L508

152

HCL1

D505

ERB91-02TP1

C662

100

D626

ERA82

5V

D624

R643

3.9k

C644

47

25V

6

5

4

3

2

6

+

-

-

-

+

Y

Y

Y

Y

Y

D

D

D

D

D

CN501

V

V

H

H

H

4

R577

27

2W

:RS

TH502

R593

1.2k

12V

D512

1SS119

R502

R505

10k

180k

:CHIP

:RN-CP

Q505

Q504

2SA1309A

2SC3941A

AMP

BUFFER

C501

R501

10

100

R503

10k

C503

:RN-CP

0.01

13

B:CHIP

C578

1000p

2kV

:R

-15V

D520D521

7

ERA34ERA34

C577

0.01

8

2kV

F

1

V

K

2

CN510

.

1P

1

6P

:DY

R517

2.2 3W :RS

R513

220

2W

15V

R518

C510

S

2.2 3W :RS

470p

500V

C584

R511

C508

0.1

1

100

B:CHIP

:FPRD

25V

T505

R589

4.7k

3

L509

HLC2

R591

150 1/2W

R592

150 1/2W

R516

150 1/2W

-15V

R590

C517

Q521

22k

0.01

2SA1309A

:RN

:PT

BUFFER

R506

R565

330k

330k

:RN

:RN

1

12

11

R507

3

10

2.7k

:RN

C504

1000p

500V

4

9

5

8

C505

22p

2kV

6 7

T503

:DFT

D510

ERA34

C528

R532

0.01

2.2

2kV

:FPRD

F

5V

CXA8071AP

DEF CONTROL

R907

100

1/2W

1

D VCC

C903

C902

0.01

470

B:CHIP

16V

2

LOCK

R915

4.7k

:CHIP

IIC DATA

SDA

3

IIC CLK

SCL

4

5

V.GND

C905

0.068

:PT

V.OSC

6

C906

1.0

:MPS

V.AGC

7

8

V.SAW

V SAW

E/W

9

E/W

0

V.SIN

V.SINV.SIN

1

1

H.AGC

1

C913

0.1

:PT

2

V.DF

1

3

H.DF

1

4

H.FLY

1

H.GND

151

W

K

F

A

L

W

D

S

B

/

.

E

V

V

H

1 2 3 4 5 6 7

W

A

S

C402

V

0.22

100V

-15V

:PT

C401

470

R401

25V

1.5

:FPRD

14

R581

10k

D518

FB506

RD10ES

S

Q520

IRFI9620GS

H-REG

FB505

5MM(JW)

D516

3DL41A

Q507

BU2527AX

H-OUT

R522

FB504

47

C518

0.0022

4300pF

1.8kV

D506

PG124S15

RY500

JW117

5MM

R576

47k

R578

27

C573

2W

L506

4.7

:RS

250V

R512

4.7

C511

0.3 200V :PP

R515 R521

1k

1k

:FPRD

:FPRD

R519 R524

C512 C515 C520

47k

0.01

C507

:CHIP

B:CHIP

0.3

400V

4

S

Q514

IRLI530GLF33

S-CAP CHANGE

IIC CLK

IC902

C936

220p

0

D.GND

3

X902

9

X5

2

8

V.IN

V-USYNC

2

7

V.DIV

2

6

H.IN

H-USYNC

2

5

H.PH.FI

2

4

AFC1

2

3

REF

V-REF

2

2

VCO.FI

2

1

R.F/V

2

0

DELAY CAP

2

9

9V

1

C917

C916

0.01

22

B:CHIP

12V

8

R931

AFC2

1

2.2k

7

H.OUT

1

D903

R933

1k

RB441Q

6

VCC

C925

C926

0.01

B:CHIP

C918

10

V-REF

12V

R504

0.47

:FPRD

Q501

2SC3311A

H-DRIVE

Q502

2SA1309A

BUFF

H BLK

E/W

IC401

LA7840L

V-OUT

G

C408

0

1

100p

1

0

P

4

:PT

G

D

C403

E

220

R407

2.2k

D403

1SS119

D402

RD4.7ES

R402

330

C406

0.0047

1W

:RS

:PT

R404

5.6k

:RM

C407

R411

0.022

36k

R403

R405

:PT

:RN-CP

1.5

1.5

R406

1/2W

1/2W

12k

:RN

:RN

:RN-CP

L503

R582

C574

1

0.01

C579

:FPRD

250V

22p

2

2kV

:SL

D525

D524

4

HSS82

HSS82

5 6

C521

R586

R585

100p

2.2k

1k

2kV

1/2W

:SL

1/2W

D527

C522

RD5.1ES

100V

R526

:PT

4.7k

D507

RD5.1ES

12V

D519

1SS119

2SC3311A

C572

C571

4.7

10

250V

R575

68

1/2W

:FPRD

C514

0.91

L505

200V

2.2mH

:PP

C516

0.36

250V

:PP

C530

0.12

200V

R525

1k

:FPRD

SS

47k

0.01

:CHIP

B:CHIP

3

S

Q513

IRLI540GLF33

S-CAP CHANGE

+5V

RB441QT-77

+5V-2

L901

R929

4.7k

C923

:CHIP 10k

470p

:CHIP

C922

1.0

C935

C920 C921

1

0.01

B:CHIP

Q903

2SC3311A

H-DRIVE

D922

470

MA111-TX

16V

D923

MA111-TX

D925

MA111-TX

D924

MA111-TX

R632

220

:CHIP

9

F

E

R

V

K

15V

L

B

H

F

C404

E

R

470

-

25V

V

R408

10k

:CHIP

C405

0.047

:PT

R410

12k

:RN

R409

6.8k

:RN-CP

Q508

Y

2SC3311A

L

F

BUFF

56

10

H

9

H BLK

H FLY

L510

H-CENTER AMP

12345

Q519

SW

R573

R574

10k

RD5.1ES-TIB2

C523

0.12

C531

200V

0.068

250V

:PP

R533

:FPRD

R523 R535 R537

S

47k

:CHIP

0.01

B:CHIP

2

S

Q512

IRLI520GLF33

S-CAP CHANGE

D920

470

C924

16V

12V

R587

1k

:CHIP

R539

10

3W

:RS

IC503

LA6500-FA

R572

47k220k

D511

R580

:CHIP

1k

1

S

LOCK

R951

100

:CHIP

C

C

N

N

Y

Y

S

S

U

U

-

V

H

22

L

A

M

L

R

B

E

A

H

T

L

A

M

R

E

H

T

K

L

B

H

C583

0.1

:PT

R538

10

3W

:RS

C580

0.01

:PT

R579

150k

R570

1k

R571

33k

3W

:RS

Q518

2SC3209LK

H-CENT CNTL

15k

+5V

C536 C538

0.01

B:CHIP

Q515

IRLI520GLF33

S-CAP CHANGE

C930

0.01

:PT

N

A

C

S

Y

E

SHRP1

K

R934

C928

0.01

C927

0.01

C931

470p

:CHIP

DEGAUSSDEGAUSS

HEATERHEATER

REMOTE ON/OFFREMOTE ON/OFF

12V

R529

10k

:FPRD

C509

R500

100p

0.47

500V

:FPRD

C570

100

25V

C559

0.0047

:PT

R510

22k

:CHIP

Q517

2SC2611

H-CENT SW

C525

0.082

200V

:PP

R536

1k

:FPRD

S S

47k

:CHIP

0

S

B

0.01

B:CHIP

Q516

IRLI520GLF33

S-CAP CHANGE

IIC CLK

IIC DATAIIC DATA

DDC 5VDET

5

1

TEST

DA0

6

5

2

5

IR

DA1

AUDIO

5

3

4

RESET

RESET

DA2

ROTATION

5

4

3

PA0

DA3

H.CENT

5

5

PA1

DA4

2

SHRP1

5

6

PA2

DA5

REMOTE ON/OFF

2SA1309A

W

S

T

N

E

C

H

1

5

7

0

PA3

DA6

DEGAUSS

4

8

9

PA4

DA7

4

9

PA5

DA8

8

LED RED

1

4

PA6

VSS2

0

7

LED GREEN

1

1

4

1

6

CBLK

VDD2

CBLANK

D902

5.6B

DDC 5VDET

KEY SCAN

RD5.6ES

ABL

RD5.6ES

THERMAL

V-USYNC

R924

10k

Q506

BUFF

C529

0.047

400V

:PP

:CHIP

C914

22p CH

1

4

2

5

OSCIN

PB7

2

D9911

X901

5.6B

24MHz

1

4

OSCOUT

PB6

3

4

D9913

C915

5.6B

22p CH

1

4

CLKOUT

PB5

4

3

FB904

:CHIP

1

4

5

2

NC

PB4

D918

1

4

6

1

NC

PB3

D919

1

4

NC

PB2

7

0

1

3

TDO

PB1

8

9

HV

TXD

1

3

9

8

RDI

VFB

RXD

V FLY

2

3

0

7

SDA

VSI1

IIC DATA

V-SYNC

2

3

SCL

IIC CLK

VSI2

1

6

2

3

DDCSDA

CLP

2

5

DDC DATA

2

3

3

4

DDCSCL

ITA

DDC CLKLOCK

2

3

4

3

PC1

PD4

HEATER

HOST GND

2

3

5

2

HFB

PD3

H BLK

3

2

3

VDD

VSO

6

1

4

2

3

7

0

HSI1

HSO

H-USYNC

H-SYNC

282

9

VSS

CSI

CSYNC

IC901

CDX8757S

CPU

C907

1

H CENT H CENT

ROTATION

HV

SHRP1

H FLY

H BLK

V-SYNC V-SYNC V-SYNC

D916

D914

1SS119

1SS119

C932

0.01

:B

IC900

TC7SET08F

SYNC BUFF

1 2 3

V FLY

E/W

ABL

Q523

R514

2SA1309A

22k

SYNC LOCK

:CHIP

H CENT

185V

C506

1

C560

C524

0.36

100

250V

200V

:PP

S

Q503

2SJ449(1)

HV-REG

R561

82 3W :RS

R530

82 3W :RS

R531

82 3W :RS

L

A

M

R

E

H

T

D513

MUR-160

FB502

0.45UH

Q510

STP5NA80FI

HV-OUT

R520

22

:FPRD

MTZJ-T-77-18

12V

5V

R528

22k

47k

TH501

10K

4

S

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

R527

10k

D509

RD10ES

L501

L502

D504

D934

45

D933

D932

UDZ-TE-17-5.6B

5V-2

R920

:CHIP

R961

100

:CHIP

FB503

5MM

D931

1k

+5V-2

C909 C908

1000

10V

C582

10

C526

2200p

500V

12

C519

S

0.001

2kV

:PP

CN0002

5V-2

S0

S1

S2

S3

S4

B

B

B

6

6

6

.

.

.

5

5

5

-

-

7

7

7

1

1

1

-

-

E

E

E

T

T

T

-

-

Z

Z

Z

D

D

D

U

U

U

8

9

0

2

2

3

9

9

9

D

D

D

47 :CHIP

47 :CHIP

0.01

B:CHIP

C910

0.1

:PT

3

D917

UDZ-TE17-5.6B

+5V

2SA1309A

SYNC LOCK

R534

C527

100

0.01

:FPRD

250V

11

2

2

1

1

12

k

k

0

0

1

1

4

3

Q902

5

5

9

9

3311A

R

R

DRIVER

Q901

3311A

DRIVER

R911

R910

220

390

R957

R958

R925

4.7k

R927

:CHIP

0

IC904

:CHIP

PST600D-T

2

RESET

3

12

BPCLAMP BPCLAMP

V FLY

ROTATION

HV

H-SYNC H-SYNC

+5V

Q522

T501

:FBT

HV

14

13

17

16

11

6

5

4

8

9

Page 17

1

0

VR9102

10K

3

1

VR9101