Page 1

Professional Workstation AP500

Maintenance and Serv ice Guide

Second Edition (March 1999)

Part Number 338534-002

Spares Part Number 338561- 001

Compaq Computer Corporation

Page 2

Notice

The information in this publ ication is subject to change without notice.

COMPAQ COMPUTER CORPORATION SHALL NOT BE LIABLE FOR TECHNICAL OR

EDITORIAL ERRORS OR OMISSIONS CONTAINED HEREIN, NOR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE, OR

USE OF THIS MATERIAL. THIS INFORMATION IS PROVIDED “AS IS” AND COMPAQ

COMPUTER CORPORATION DISCLAIMS ANY WARRANTIES, EXPRESS, IMPLIED OR

STATUTORY AND EXPRESSLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, GOOD TITLE AND AGAINST

INFRINGEMENT.

This publication contains i nf ormation protected by copyright. No par t of this publication may be

photocopied or reproduced in any form without prior written consent from Compaq Computer

Corporation.

1999 Compaq Computer Corporation.

All rights reserved. Printed in the U.S.A.

The software described in this guide is f ur nished under a license agreement or nondisclosure agreement.

The software may be used or copied only in accordance with the terms of the agreement.

Compaq, Compaq Insight Manager, ROMPaq, QVision, SmartStar t, NetFlex, QuickFind, PaqFax,

registered United States Patent and Trademark Office.

Netelligent, SoftPaq, QuickBlank, QuickLock, and PowerStorm are trademarks and/or service marks of

Compaq Computer Corporation.

Microsoft, MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

Other product names mentioned herein may be trademarks and/or registered trademarks of their respect ive

companies.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Second Edition (March 1999)

Part Number 338534-002

Spare Part Number 338561-001

Page 3

Contents

About This Guide

Text Conventions.......................................................................................................................vii

Symbols in Text........................................................................................................................viii

Symbols on Equipment.............................................................................................................viii

Where to Go for Additional Help...............................................................................................ix

Other Information Sources..................................................................................................ix

Telephone Numbers.............................................................................................................ix

Chapter 1

Illustrated Parts Catalog

Mechanical Parts ......................................................................................................................1-1

System Components .................................................................................................................1-2

Spares Parts List.......................................................................................................................1-3

Chapter 2

Service Preliminaries

Compaq Technician Notes........................................................................................................2-1

Preliminary Warnings and Cautions.........................................................................................2-2

Electrostatic Discharge Information.........................................................................................2-3

Equipment Symbols..................................................................................................................2-3

Tools and Software Requirements............................................................................................2-4

Warranty Information...............................................................................................................2-4

iii

Chapter 3

Removal and Replacement Procedures

Serial Number...........................................................................................................................3-1

Service Preparations.................................................................................................................3-2

Cable Lock ...............................................................................................................................3-3

Workstation Feet.......................................................................................................................3-4

Side Access Panel.....................................................................................................................3-5

Front Bezel...............................................................................................................................3-6

Blank Drive Bezel....................................................................................................................3-7

EMI/Cooling Shield..................................................................................................................3-8

Speaker.....................................................................................................................................3-9

I/O Bracket Assembly ............................................................................................................3-10

Replacing the I/O Bracket Assembly...............................................................................3-11

Expansion Boards...................................................................................................................3-12

Identifying the PCI and ISA Expansion Slots..................................................................3-12

Removing a PCI or ISA Expansion Board......................................................................3-14

Removing a Symbios Wide Ultra2 PCI SCSI Controller ................................................3-15

Removing the Accelerated Graphics Port (AGP) Graphics Controller............................3-16

Removing the Card Guide...............................................................................................3-17

Removing the Backplane Board......................................................................................3-18

System Fan.............................................................................................................................3-19

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 4

iv

Removal and Replacement Procedures continued

Mass Storage Devices.............................................................................................................3-21

Drive Positions................................................................................................................3-21

Hardware Screws............................................................................................................. 3-23

CD-ROM Drive or DVD-ROM Drive.............................................................................3-24

Diskette Drive .................................................................................................................3-26

Removing a 7200 rpm Hard Drive from Bays 5 or 6.......................................................3-28

Removing a 10,000-rpm Hard Drive from Bays 5 or 6...................................................3-31

Removing the Fan from a Hard Drive Installed in Bays 5 or 6 ......................................3-35

Removing a Hard Drive from the Removable Hard Drive Cage.....................................3-37

Installing a Hard Drive in the Removable Hard Drive Cage...........................................3-39

SCSI Cables and Guidelines...................................................................................................3-41

SCSI Cables.....................................................................................................................3-41

SCSI Guidelines for Installing SCSI Devices..................................................................3-42

SCSI Guidelines for Optimizing Performance ................................................................3-42

System Board Assembly.........................................................................................................3-43

System Board with Tray and Cage..................................................................................3-43

System Board Components..............................................................................................3-45

Dual Inline Memory Modules (DIMMs).........................................................................3-46

Important Guidelines for DIMM Installation ..................................................................3-46

Removing a DIMM.........................................................................................................3-47

Processor and Heatsink Assembly..........................................................................................3-48

Processor Power Module.................................................................................................3-49

Primary Processor Power Module Cable Insulator..........................................................3-50

External Battery......................................................................................................................3-51

Running Computer Setup ................................................................................................3-51

Installing the Battery.......................................................................................................3-52

Power Switch Cable Assembly...............................................................................................3-54

Power Supply..........................................................................................................................3-55

Chapter 4

Diagnostic Tools

Power-On Self-Test (POST).....................................................................................................4-2

POST Messages........................................................................................................................4-3

Troubleshooting Minor Problems.............................................................................................4-7

Power Problems.................................................................................................................4-8

Diskette Drive Problems....................................................................................................4-9

Display Problems ............................................................................................................4-10

Printer Problems..............................................................................................................4-11

Hard Drive Problems.......................................................................................................4-12

Hardware Installation Problems ......................................................................................4-13

CD-ROM Drive and DVD-ROM Drive Problems ..........................................................4-14

Memory Problems...........................................................................................................4-15

SCSI Problems................................................................................................................4-15

Network Problems...........................................................................................................4-16

Audio Hardware Conflicts...............................................................................................4-18

Page 5

Diagnostic Tools continued

Compaq Setup and Diagnostics Utilities.................................................................................4-19

Accessing the Compaq Utilities Menu............................................................................4-19

Creating a Diagnostics Diskette.......................................................................................4-20

Computer Setup...............................................................................................................4-21

Computer Checkup (TEST).............................................................................................4-23

View System Information (INSPECT)............................................................................4-24

Managing a Diagnostics Partition....................................................................................4-25

Diagnostic Error Codes...........................................................................................................4-25

Microprocessor................................................................................................................4-26

Memory...........................................................................................................................4-27

Keyboard.........................................................................................................................4-27

Printer.............................................................................................................................. 4-28

Diskette Drive .................................................................................................................4-28

Serial Port........................................................................................................................4-29

Modem ............................................................................................................................4-29

Pointing Device...............................................................................................................4-29

CD-ROM Drive (IDE).....................................................................................................4-30

Tape Drive.......................................................................................................................4-30

Video...............................................................................................................................4-31

Audio...............................................................................................................................4-33

Network Interface............................................................................................................4-33

SCSI Error Codes...................................................................................................................4-34

Upgrading the ROM...............................................................................................................4-37

Local ROM Upgrade.......................................................................................................4-37

Remote ROM Flash.........................................................................................................4-38

FailSafe Boot Block ROM......................................................................................................4-39

Compaq Insight Manager .......................................................................................................4-41

Compaq Workstation SSD for Windows NT ..........................................................................4- 42

Remote Capability...........................................................................................................4-42

Silent Setup Command Line Interface.............................................................................4-42

Compaq Diagnostics for Windows NT...................................................................................4-43

v

Chapter 5

System Security

Security Features......................................................................................................................5-1

Password Security.............................................................................................................5-2

Windows NT Workstation Password.................................................................................5-6

National Keyboard Delimiter Characters ..........................................................................5-6

Advanced Security Management..............................................................................................5-7

Re-enabling Diskette Boot or Diskette Write....................................................................5-7

Re-enabling a Serial Port or Parallel Port..........................................................................5-8

QuickLock/QuickBlank.....................................................................................................5-8

Cable Lock Provision........................................................................................................5-9

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 6

vi

Chapter 6

Jumper and Switch Information

Battery Jumpers........................................................................................................................6-2

Switch Settings.........................................................................................................................6-3

Hard Drives..............................................................................................................................6-4

32X Max CD-ROM Drive (IDE)..............................................................................................6-4

PowerStorm 300/AGP Graphics Controller..............................................................................6-5

Chapter 7

Physical and Operating Specifications

System Unit..............................................................................................................................7-2

325W Power Supply.................................................................................................................7-7

Diskette Drive...........................................................................................................................7-8

Zip Drive..................................................................................................................................7-9

CD-ROM Drive......................................................................................................................7-10

DVD-ROM Drive...................................................................................................................7-12

Hard Drives............................................................................................................................7-14

Audio System.........................................................................................................................7-19

Keyboard................................................................................................................................7-19

Mouse.....................................................................................................................................7-20

Graphics Controllers...............................................................................................................7-21

Network Controller.................................................................................................................7-25

RJ-45 Network Cable Specifications......................................................................................7-25

Chapter 8

External Connectors

Physical Location.....................................................................................................................8-1

Pin Assignments.......................................................................................................................8-3

Index

Page 7

About This Guide

This guide is designed to be used as step-by-step instructions for installation, and as a reference for

operation, troubleshooting, and future upgrades.

IMPORTANT: The installation of options and servicing of this product should be performed

by individuals that are knowledgeable of the procedures, precautions, and hazards

associated with equipment containing hazar dous energy circuits.

vii

WARNING: Only authorized technicians trained by Compaq should attempt to

repair this equi pment. All troubleshooting and repair pr ocedures are detailed to

allow only subassembly/module level repair. Because of the complexity of the

individual boards and subassemblies, no one should attempt to make repairs at

the component level or make modifications to any printed wiring board. Improper

repairs can create a safety hazard. Any indications of component replacement or

printed wiring boa rd modifications may void any warranty.

WARNING: To reduce the risk of personal injury from electrical shock and

hazardous energy levels, only authorized service technicians should attempt to

repair this equi pment. Improper repairs could create conditions that are

hazardous.

Text Conventions

This document uses the following conventions to distinguish e l ements of text:

Keys Keys appear in boldface. A plus sign (+) between two

keys indicates that they should be presse d simultaneously.

USER INPUT User input appears in a different typeface and in

uppercase.

FILENAMES File names appear in upperca se italics.

Menu Options,

Command Names,

Dialog Box Names

COMMANDS,

DIRECTORY NAMES,

and DRIVE NAMES

Type When you are instructed to type information, type the

Enter When you are instructed to enter information, type the

These appear in initial capital letters.

These always appea r in uppercase.

information without pressing the Enter key.

information and then press the Ent e r key.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 8

viii

Symbols in Text

These symbols may be found in the te xt of this guide. They have the following meanings.

!

IMPORTANT: Presents clarifying information or specific instructions.

NOTE: Presents commentary, sidelights, or interesting points of information.

WARNING: Indicates that failure to follow directions in the warning could result in

bodily harm or loss of life.

CAUTION: Indicates that failure to follow directions could result in damage to

equipment or loss of information.

Symbols on Equipment

These icons may be located on equipment in areas where hazardous conditions may exist.

Any surface or area of the equipment marked with these symbols

indicates the presence of electrical shock hazards. Enclosed area

contains no operator serviceable parts.

WARNING: To reduce risk of injury from electrical shock hazards, do

not open this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a Network

Interface Connection.

WARNING: To reduce risk of electrical shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors

into this receptacle.

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists.

WARNING: To reduce the risk of injury from a hot component, allow

the surface to cool before touching.

Page 9

Where to Go for Additional Help

Major sources of additional information are listed below.

Other Information Sources

In addition to this guide, the following information sources are available:

■ User Documentation

■ Compaq Service Quick Refere nce Guide

■ Service Training Guides

■ Compaq Service Advisories and Bulletins

■ Compaq QuickFind

■ Compaq Insight Manager

■ Compaq Download Facility: Call 1-281-518-1418.

Telephone Numbers

ix

For the name of your nearest Compaq Authorized Reseller:

In the United States, call 1-800-345-1518.

In Canada, call 1-800- 263-5868.

For Compaq technical support:

In the United States and Canada, call 1-800-OK-COMPAQ (For continuous qua lity improvement,

calls may be recor ded or monitored.)

For Compaq technical support phone num bers outside the United States and Canada, visit the

Compaq website at:

www.compaq.com

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 10

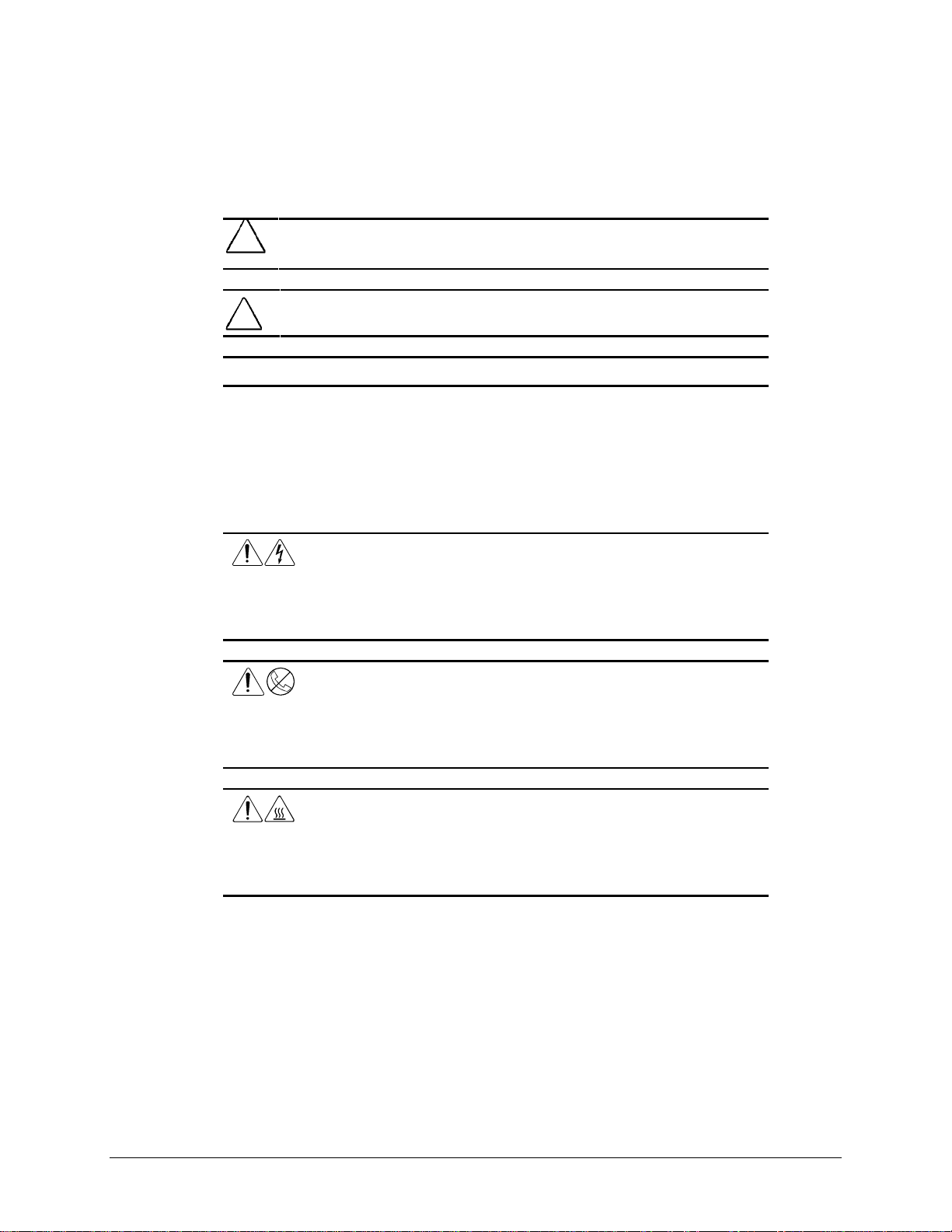

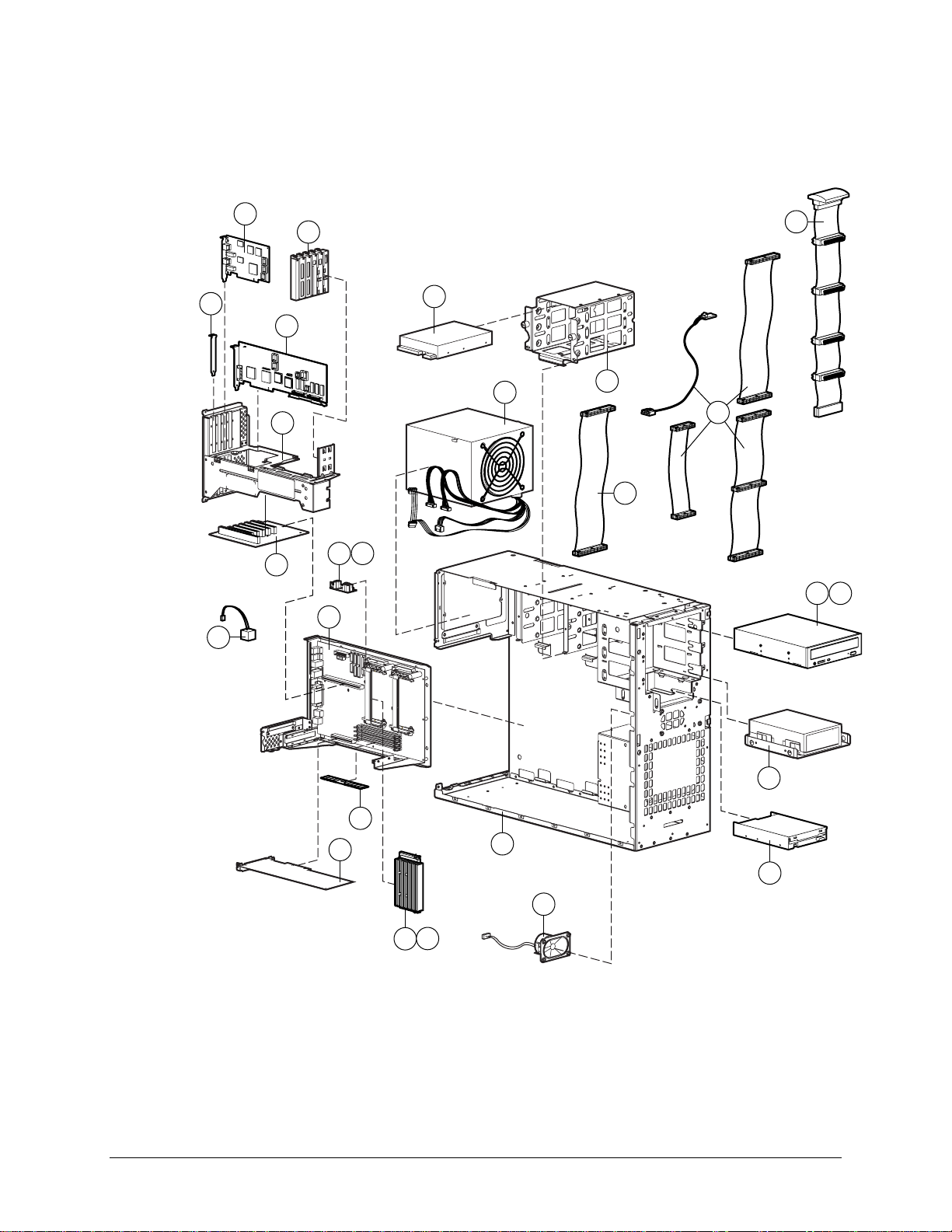

Chapter 1

Illustrated Parts Catalog

This chapter provides an illustrated parts breakdo wn and a reference for spare parts for the

Compaq Professional Workstation AP500.

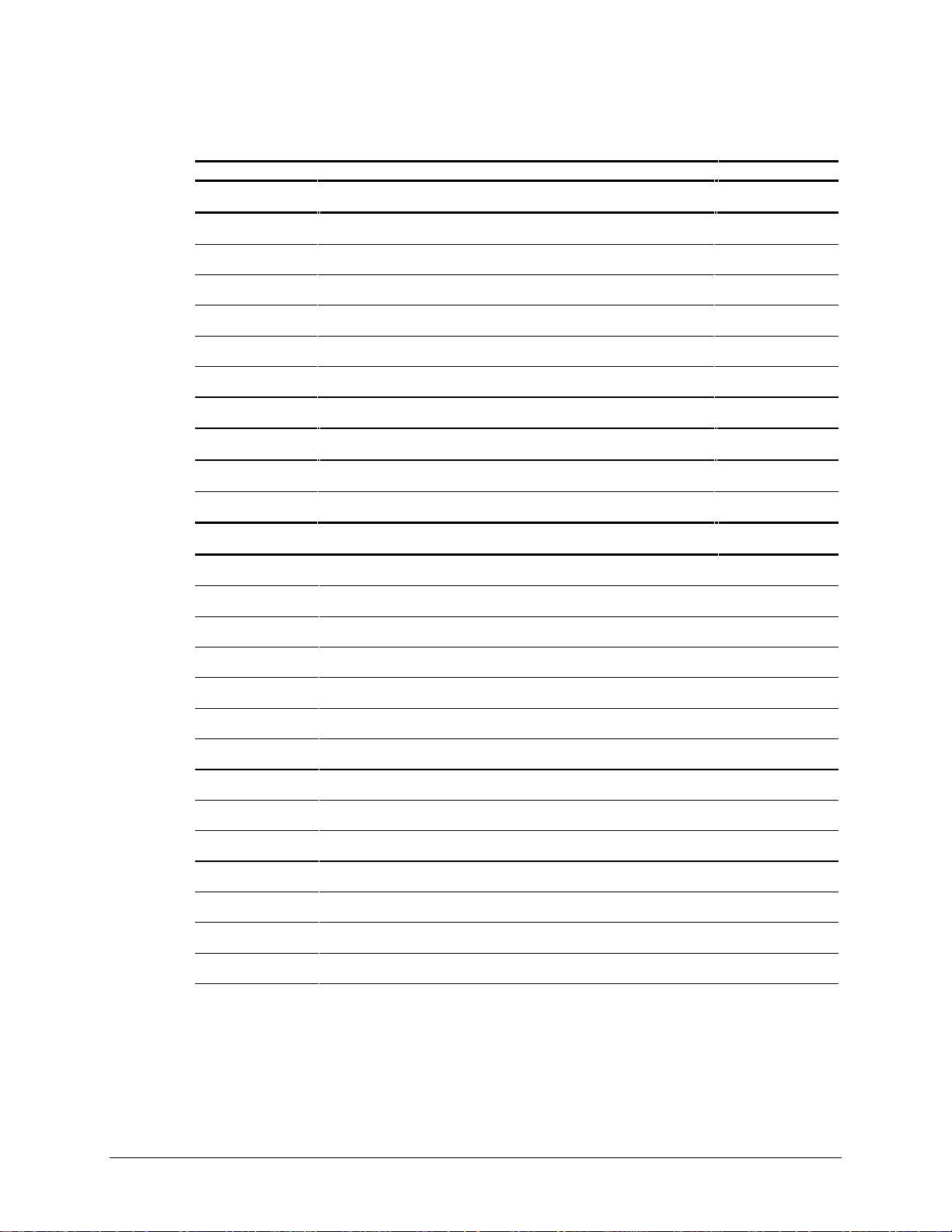

Mechanical Parts

1-1

100

11

12

10

49

24

100

9

4 98

6

2

1

Figure 1-1. Exploded view of the Compaq Professional Workstation AP500 mechanical parts

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 11

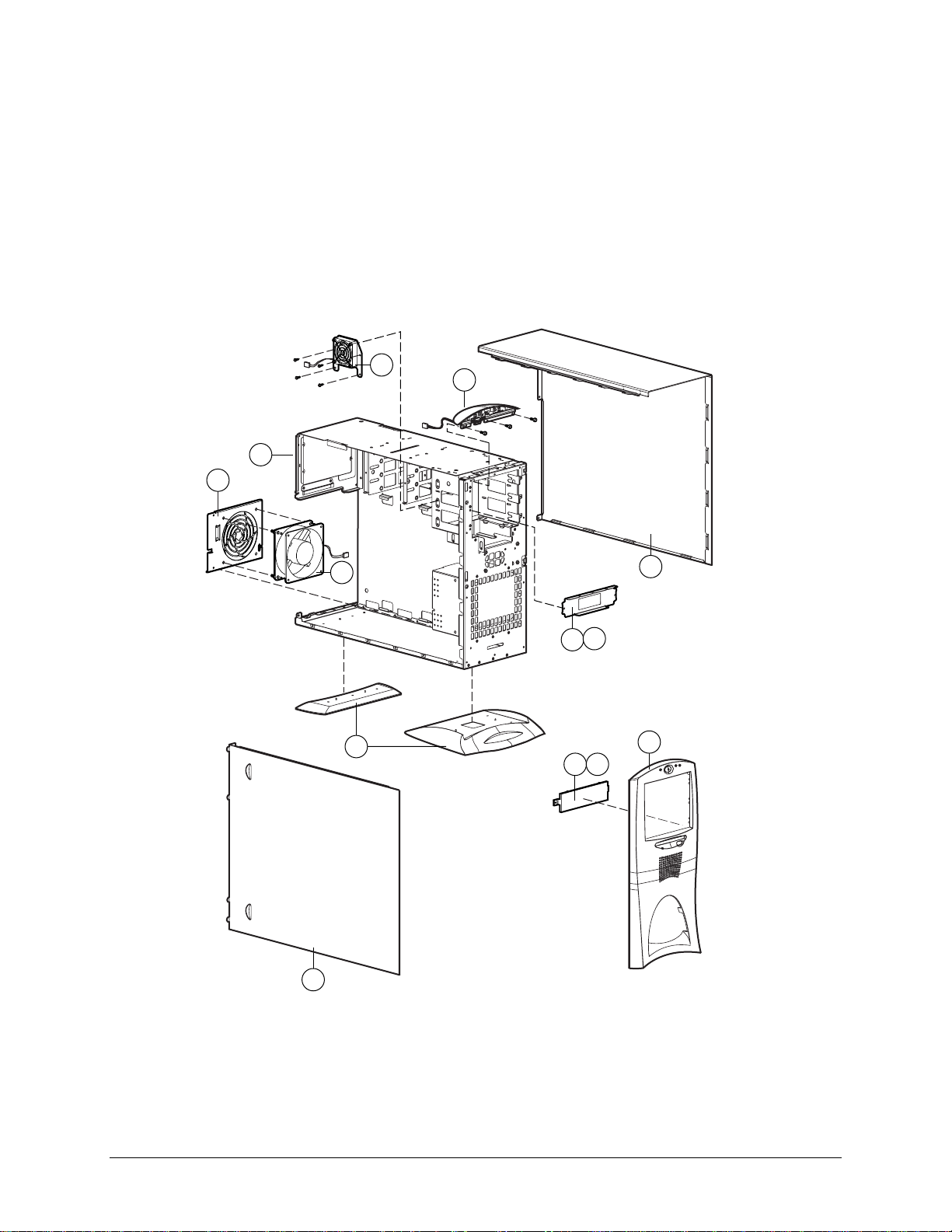

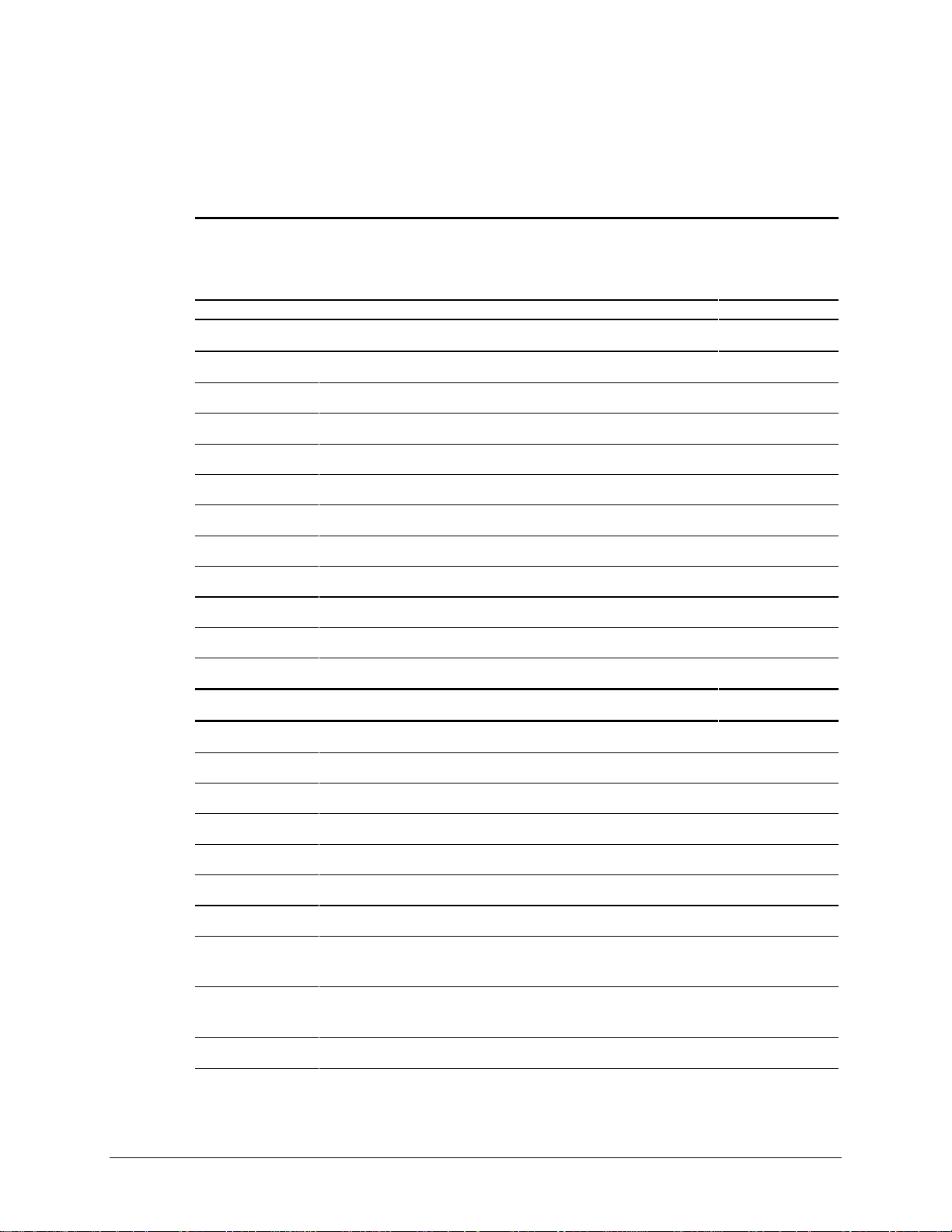

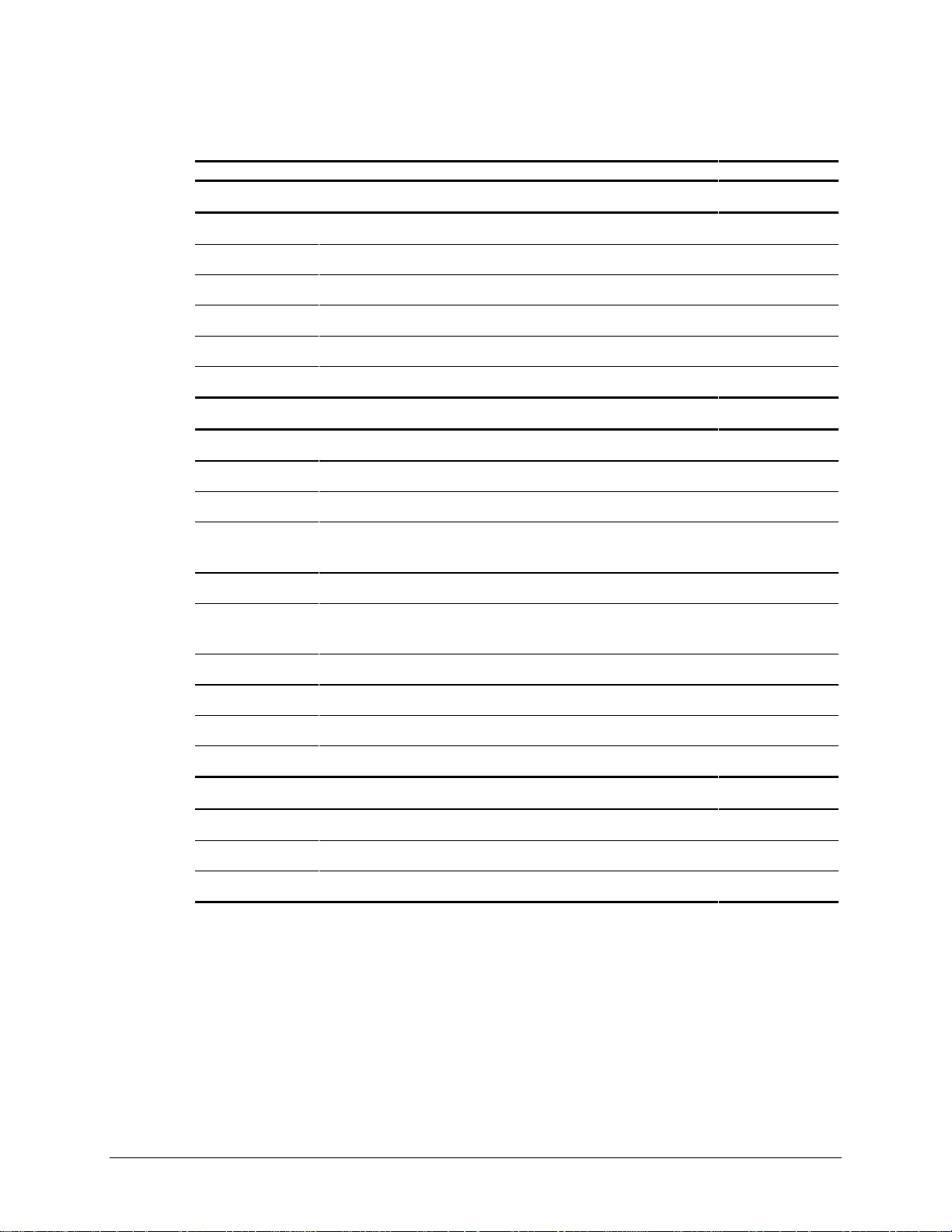

1-2 Illustrated Parts Catalog

13

66

16

17

14

19 20

8

11

26

42

33

7

32

98

23

3

50

52

22

51

74

5

44 45

87

System Components

Figure 1-2. Exploded view of the Compaq Professional Workstation AP500 system components

Page 12

Spares Parts List

Parts or components marked with an asterisk (*) are not illustrated.

Reference Description Spares Part #

MECHANICAL

1 Side Access Panel 329263-001

2 Front Bezel 338549-001

3 I/O Bracket (Expansion Board Assembly) 338563-001

4 Blank Drive Bezel (part of the Miscellaneous Plastic Kit) 329265-001

5 Backplane Board 338513-001

6 Hood 338565-001

7 Removable Hard Drive Cage 338557-001

1-3

Table 1-1

Compaq Professional Workstation AP500

Spares Parts List

SYSTEM

8 Speaker 328730-001

9 EMI/Cooling Shield (part of the Miscellaneous Hardware Kit) 338559-001

10 Workstation Feet 329264-001

11 Chassis 338547-001

12 System Fan (fan bracket included in Miscellaneous Hardware Kit) 338558-001

13 Power Supply, 325W 328563-001

14 System Board with Tray 400-, 450-, 500-MHz 402124-001

15 System Board with Tray 400-, 450-MHz 338548-001*

16 Intel Pentium II Processor, 400/100 MHz, 512K with heatsink 327648-001

17 Intel Pentium II Processor, 450/100 MHz, 512K with heatsink 328785-001

18 Intel Pentium III Processor, 500/100 Mhz, 512K with heatsink 116402-001*

19 Processor Power Module (Voltage Regulator Module)

For 350/400/450/500 MHz CPU

20 Processor Power Module (Voltage Regulator Module)

For 350/400/450 MHz CPU

329267-001

327660-001

21 Lock Security Bracket 199109-001*

Compaq Professional Workstation AP500 Maintenance and Service Guide

Continued

Page 13

1-4 Illustrated Parts Catalog

Compaq Professional Workstation AP500 Spares Parts List

Reference Description Spares Part #

22 External Battery 160274-001

23 Expansion Board Slot Cover 141081-001

24 Power Switch and LEDs with Cable 329270-001

MEMORY

25 32-MB Memory Module (Registered 100-MHz SDRAM) 317747-001*

26 64-MB Memory Module (Registered 100-MHz SDRAM) 317745-001

27 128-MB Memory Module (Registered 100-MHz SDRAM) 317756-001*

28 256-MB Memory Module (Registered 100-MHz SDRAM) 317749-001*

MASS STORAGE

29 4.3-GB Wide Ultra2 SCSI Hard Drive 7200 rpm 349533-001*

30 4.3-GB Wide Ultra2 SCSI Hard Drive 10,000 rpm 386538-001*

31 9.1-GB Wide Ultra2 SCSI Hard Drive 7200 rpm 349534-001*

32 9.1-GB Wide Ultra2 SCSI Hard Drive 10,000 rpm 386539-001

Continued

33 18-GB Wide Ultra2 SCSI Hard Drive 10,000 rpm 386540-001

34 4.3-GB Wide-Ultra SCSI Hard Drive, 7200 rpm 339514-001*

35 4.3-GB Wide-Ultra SCSI Hard Drive, 10,000 rpm 336383-001*

386539-001*

36 9.1-GB Wide-Ultra SCSI Hard Drive 7200 rpm 339515-001*

37 9.1-GB Wide-Ultra SCSI Hard Drive 10,000 rpm 336384-001*

38 18-GB Wide-Ultra SCSI Hard Drive 10,000 rpm 336385-001*

39 6.4-GB Ultra ATA Hard Drive 166973-001*

40 10-GB Ultra ATA Hard Drive, 7200 rpm 330520-001*

41 Symbios Wide Ultra2 PCI SCSI Controller 114009-001*

42 1.44-MB Diskette Drive 179161-001

43 100-MB Zip Drive 401624-001*

44 32X Max CD-ROM Drive (IDE) 327659-001

45 DVD-ROM Drive 105771-001

46 12/24-GB DAT Drive 340593-001*

Continued

Page 14

1-5

Compaq Professional Workstation AP500 Spares Parts List

Reference Description Spares Part #

47 4/8-GB SLR Drive 340591-001*

48 Hard Drive Mounting Bracket (Bays 5 and 6) 243231-001*

49 Fan and Cable for >7200 rpm Hard Drives Installed in Bay 5 or 6 329266-001

CABLE KITS

50 Miscellaneous Signal Cable Kit (CD-ROM Drive, HD, Diskette, Audio) 327649-001

51 SCSI cable, wide 338546-001

52 Wide Ultra2 SCSI cable 402222-001

53 SCSI adapter, 50- to 68-Pin (internal) 189638-001*

KEYBOARD AND MOUSE

54 Keyboard 269513-001*

55 3-Button Mouse 327716-001*

MONITOR

56 P75 Monitor 307815-xxx*

Continued

57 V75 Monitor 307713-xxx*

58 V90 Color Monitor 305602-xxx*

59 P900 Color Monitor 303502-xxx*

60 P1610 Monitor 305710-xxx*

61 P110 Monitor 284959-xxx*

62 TFT 5000:

Opal, TS, NA, TC099

Carbon, TS, NA, TC099

63 TFT 8000:

Opal, no protective panel, TC095, WW

Opal, with protective panel, TC095, WW

Carbon, no protective panel, TC095, WW

Carbon, with protective panel, TC095, WW

64 TFT 450:

Order TFT 450 spare part from the TFT 450 guide

115714-001*

115712-001*

307911-001*

102358-B24*

102359-B24*

102356-B24*

(PN 170431-001)*

65 TFT 500:

Order TFT 500 spare part from the TFT 500 guide

(PN 285012-001)*

Continued

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 15

1-6 Illustrated Parts Catalog

Compaq Professional Workstation AP500 Spares Parts List

Reference Description Spares Part #

GRAPHICS

66 GLoria Synergy+ Graphics Controller 4-MB (AGP) 327599-001

67 GLoria Synergy+ 4-MB Memory Upgrade 327600-001*

68 GLoria Synergy+ 8 MB (PCI) Graphics Controller 298796-001*

69 PowerStorm 300 Graphics Controller (AGP) 338539-001*

70 Matrox Millennium G200 Graphics Controller 294409-001*

71 Matrox Millennium G200 8-MB Memory Upgrade 386047-001*

72 Matrox Productiva G100 Multi-Monitor Series Graphics Controller 101239-001*

CONTROLLERS

73 Compaq SMART-2SL Array Controller 242777-001*

74 Dual-Channel SCSI Controller 295626-001*

COMMUNICATIONS

75 Netelligent 16/4 TR PCI IBM UTP/STP Controller 301210-001*

Continued

76 Netelligent 16/4 TR PCI UTP/STP Controller 268010-001*

77 Netelligent 10 T/2 PCI UTP/Coax Controller 292857-001*

78 Netelligent 10 T/2 ISA UTP/Coax Controller 265618-001*

79 Netelligent 100 FDDI PCI SAS Fiber-SC 242506-002*

80 Netelligent 100 FDDI PCI DAS Fiber-UTP 242506-003*

81 Netelligent 100 FDDI PCI SAS Fiber-UTP 242506-004*

82 Netelligent 100 FDDI PCI SAS Fiber-MIC 242506-005*

83 Netelligent 56K PCI Fax Modem 321510-B21*

84 Netelligent 56K ISA Fax Modem 294912-001*

85 Compaq Fast Ethernet NIC NC3122 317453-001*

86 Compaq Fast Ethernet NIC NC3120 317606-001*

87 Compaq Ethernet NIC NC1120 317358-001

88 Compaq Fast Ethernet NIC NC3161 323556-001*

Continued

Page 16

1-7

Compaq Professional Workstation AP500 Spares Parts List

Reference Description Spares Part #

SOFTWARE

89 Magellan Driver CD 297863-001*

90 Spaceball Driver CD 298033-001*

91 Microsoft Windows NT Workstation 4.0 CD 275573-xxx*

92 Compaq SmartStart for Workstations CD 275574-xx3/xx2(SP)*

93 Systems ROMPaq 275595-001*

94 Compaq Setup and Compaq Diagnostics for Workstations Diskette 275575-xxx*

MISCELLANEOUS

95 Magellan 3D Pointing Device (spacemouse) 297645-001*

96 Spaceball 3D Pointing Device 297644-001*

97 Compaq Multimedia Sound System (US) 294122-xxx*

98 Miscellaneous Plastic Kit (includes baffles*, card guide and

blank drive bezel)

99 Heatsink Bridge 327658-001*

Continued

329265-001

100 Miscellaneous Hardware Kit (includes EMI/Cooling Shield and System Fan

101 Rack Mounting Kit 338556-001*

102 Shipping Box with Buns (US) 329268-001*

103 Shipping Box with Buns (INTL) 329268-002*

104 SCSI Adapter, 68- to 50-Pin (external) 270229-001*

DOCUMENTATION

105 Maintenance and Service Guide 338561-001*

106 Illustrated Parts Map 338560-001*

107 Service Quick Reference Guide (revision -038 or later) 162212-001*

338559-001

Bracket)

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 17

Chapter 2

Service Preliminaries

This chapter identifies the following service considerations:

■ Preliminary warnings and cautions

■ Electrostatic discharge information

■ Equipment symbols

■ Tools and software requirements

■ Warranty information

IMPORTANT: Adherence to the procedures and precautions described in this chapter is

essential for proper service.

Compaq Technician Notes

WARNING: To reduce the risk of personal injury from electrical shock and

hazardous energy levels, do not exceed the level of repair specified in these

procedures. Because of the complexity of the individual boards and

subassemblies, do not attempt to make repairs at the component level or make

modifications to a ny printed wiring board. Improper repairs could create conditions

that are hazardous.

2-1

WARNING: To reduce the risk of electric shock or damage to the equipment:

Disconnect power from the computer by unplugging the power cord from either

the electrical outlet or the computer.

Do not disable the power cord grounding plug. The grounding plug is an important

safety feature.

Plug the AC adapter or power cord into a grounded (earthed) elec trical outlet that

is easily accessible at all times.

CAUTION: To properly ventilate the system, you must provide at least 6 inches

(15 cm) of clearance at the front of the workstation and 3 inches (7.6 cm) at the

back.

IMPORTANT: Any indication of repair at the component level or modification of a printed

wiring board ma y void any warranty.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 18

2-2 Service Preliminaries

Preliminary Warnings and Cautions

The following should be noted when operating or servicing the Compaq Professional

Workstation AP500:

WARNING: To reduce the risk of electric shock or damage to the equipment:

■ Disconnect power from the system by unplugging all power cords

from either the electrical outlet or the Compaq Professional

Workstation AP500.

■ Do not disable the power cord grounding plug. The ground plug is

an important safety feature.

■ Plug the power cord into a grounded (earthed) electrical outlet that

is easily accessible at all times.

WARNING: To reduce the risk of personal injury from hazardous energy levels,

only authorized service technicians should attempt to repair this equipment.

Because of the complexity of the individua l boards and subassemblies, no one

should attempt to make repairs at the component level or to make modifications to

any printed wiring board. Improper repairs can create a safety hazard.

CAUTION: The power supply in the Compaq Professional Workstation AP500 has

an auxiliary power section. This section is always active as long as the unit is

plugged into a live AC outlet. Be sure to turn off the switch and unplug the power

cord before performing any service work.

CAUTION: To properly ventilate the system, you must provide at least 6 inches

(15 cm) of clearance at the front of the workstation and 3 inches (7.6 cm) at the

back.

IMPORTANT: Any indications of component replacement or printed wiring board

modifications may void any warranty.

Page 19

Electrostatic Discharge Information

A discharge of static electricity can damage static-sensitive devices or micro-circuitry. Proper

packaging and grounding techniques are necessary precautions to prevent damage. To prevent

electrostatic damage, observe the following precautions:

■ Transport products in static-sa fe containers (conductive tube s, bags, or boxes).

■ Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

■ Cover workstations with approved static-dissipating material. Provide a wrist strap

connected to the work surface and properly grounded tools and equipment.

■ Keep work area free of non-conductive mater i als such as ordinary plastic assem bly a i ds

and foam packing.

■ Be sure you are always prope rly grounded when touching a static-sensitive component or

assembly.

■ Avoid touching pins, leads, or circuitry.

■ Always place drives PCB assembly-side down.

■ Use conductive field servic e tools.

2-3

Equipment Symbols

The following symbols are locat ed on applicable components of the worksta tion and should be

observed when servicing the workstation to avoid personal injury or damage to the components:

WARNING: Any surface or area of the equipment marked with these

symbols indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists. To reduce risk of

injury from a hot component, allow the surface to cool before touching.

WARNING: Any surface or area of the equipment marked with these

symbols indicates the presence of electrical shock hazards. Enclosed

area contains no operator serviceable parts. To reduce risk of injury from

electrical shock hazards, do not open this enclosure.

WARNING: Any RJ-45 receptacle marked with these symbols

indicates a Network Interface Connection. To reduce risk of electrical

shock, fire, or damage to the equipment, do not plug telephone or

telecommunications connectors into this receptacle.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 20

2-4 Service Preliminaries

Tools and Software Requirements

To service the workstation, you mi ght need:

■ Torx T-10 screwdriver

■ Torx T-15 screwdriver

■ Flat-blade screwdriver

■ Compaq Setup and Diagnostics Utility

IMPORTANT: Prior to servicing the workstation, be sure the drivers from the latest Compaq

Workstation SSD for Windows NT are installed. See Chapter 4 for installation procedures.

Warranty Information

The following warranties come standard with the workstation:

■ Standard Warranty—a three-year limited warranty that cover s three years on parts, one

year on labor carry-in, and one year of onsite service

■ Pre-Failure Warranty—a special warranty that extends the Compaq three-year limited

warranty by applying it to critical system components before they fail. This warranty

ensures that when you receive notification of a pre-failure condition through Compaq

Insight Manager or the Windows NT Event Log, the component is replaced under

warranty.

NOTE: For more information about Compaq Insight Manager, see Chapter 4.

The Pre-Failure War ranty covers the following workstation c omponents:

❏ SCSI hard drives

❏ Error Correcting Code (ECC) memory

❏ Pentium II processor

❏ Pentium III Processor

In addition to the above warrantie s, an optional Extended Warranty is available. If purchased,

this warranty extends the Standar d Warranty’s one year coverage for labor and onsite ser vic e for

two additional years.

IMPORTANT: Observe all warnings and cautions provided herein. Failure to do so may

void warranty for damaged components.

Page 21

Chapter 3

Removal and Replacement Procedures

This chapter provides subassembly/module-level removal and replacement pr ocedures for the

Compaq Professional Workstation AP500.

After completing all necessary removal and replacement procedures, run the Compaq Setup and

Diagnostics program to veri fy that all components are oper ating properly.

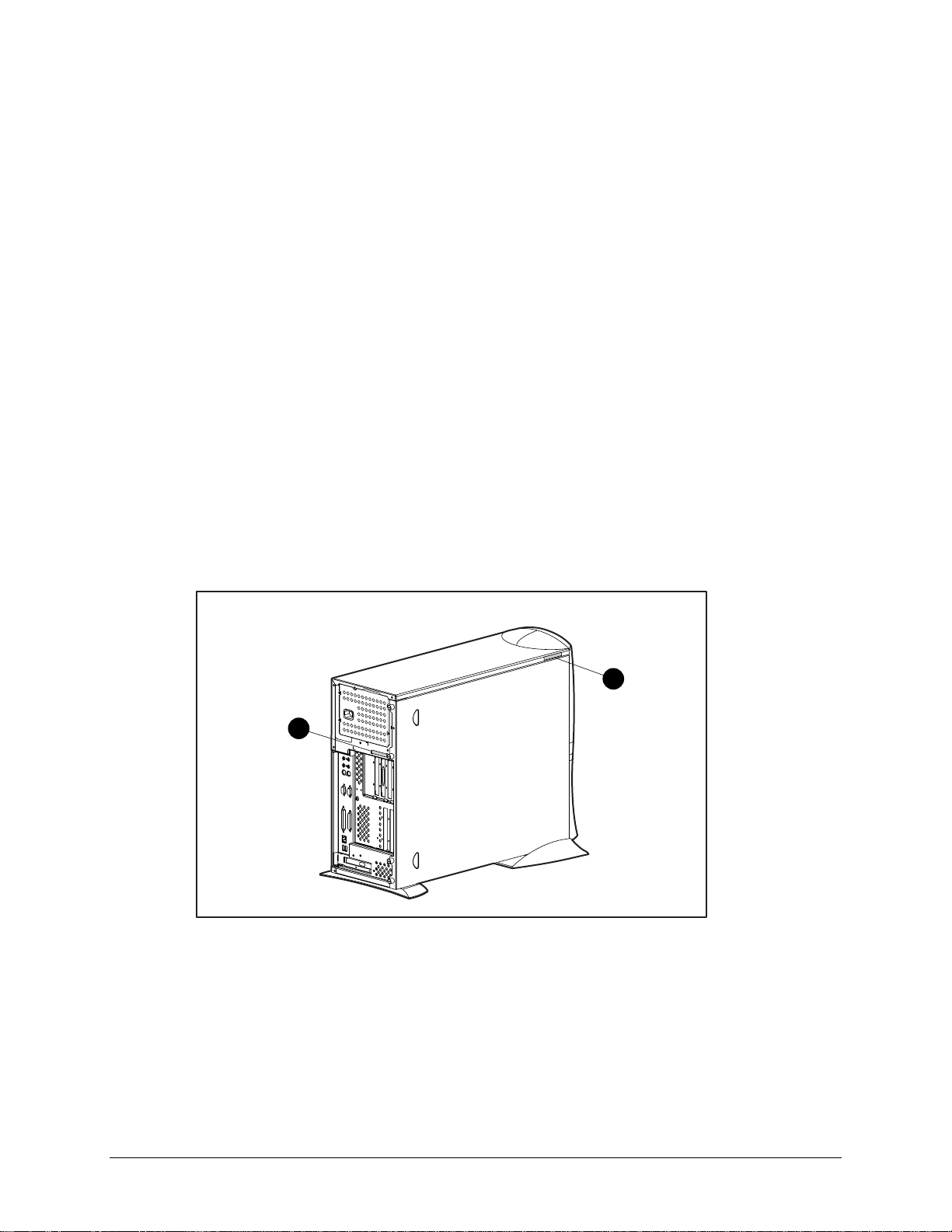

Serial Number

Provide the computer serial number to Compaq whe never you request information or order spare

parts. The serial number is located on the top right side of the workstation 1 and also on the rear

of the chassis 2.

For asset control, the seria l number is also embedded in the EP RO M on the system board. If the

system board is replaced with a spare part from Compaq, an invalid serial number condition will

be reported during POST. T o c l ear the condition, use Compaq Softpa q SP8410. It is located at:

http://www.compaq.com/support/files/workstations/us/software/674.html.

3-1

NOTE: If a system board from another workstation is installed, POST recognizes the serial

number as a val id number.

1

2

Figure 3-1. Identifying serial number locations

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 22

3-2 Removal and Replacement Procedures

Service Preparations

CAUTION: The power supply in the Compaq Professional Workstation AP500 has

an auxiliary power section. This section is always active as long as the unit is

plugged into a live AC outlet. Be sure to turn off the switch and unplug the power

cord before performing any service work.

CAUTION: Electrostatic discharge can damage electronic components. Be sure

you are properly grounded before beginning any install ation procedure. See

“Electrostatic Discharge Information” in Chapter 2 for more information.

Before beginning any of the removal and replacement procedures, complete the following steps:

1. Turn off the workstation.

2. Disconnect the power cord from the grounded AC outlet and then from the workstation.

3. Turn off all peripheral devices and disconnect cables f rom the rear of the wor ksta tion.

4. Remove the cable lock in order to access internal components. See the following section

for instructions on how to remove the cable lock.

Page 23

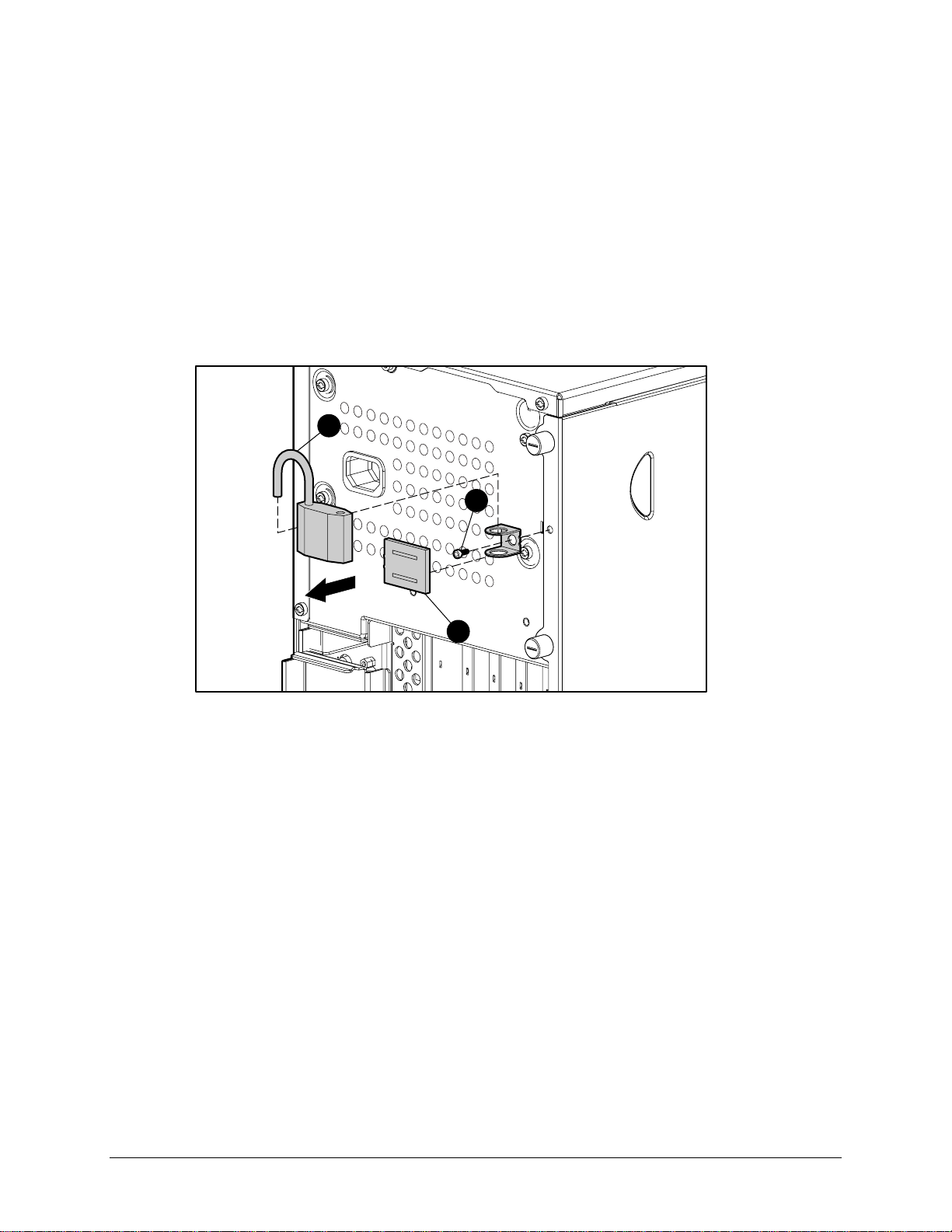

Cable Lock

The workstation comes standard w ith a cable lock provision for attaching a pa dlock and/or cable

lock. If installed, the locks must be removed before accessing internal components.

To remove the lock:

1. Unlock and remove the cable lock and/or the padlock 1.

2. Remove the security bracket (plate) seated over the cable lock bracket 2.

3. Unfasten the retaining screw to release the cable lock bracket 3.

3-3

1

3

2

Figure 3-2. Removing the padlock

NOTE: In some of the removal procedures in this chapter, you will be asked to remove the

workstation feet and lay the workstation on its side when servicing some of the internal

components.

NOTE: For more information on preparing the workstation for service, see Chapter 2.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 24

3-4 Removal and Replacement Procedures

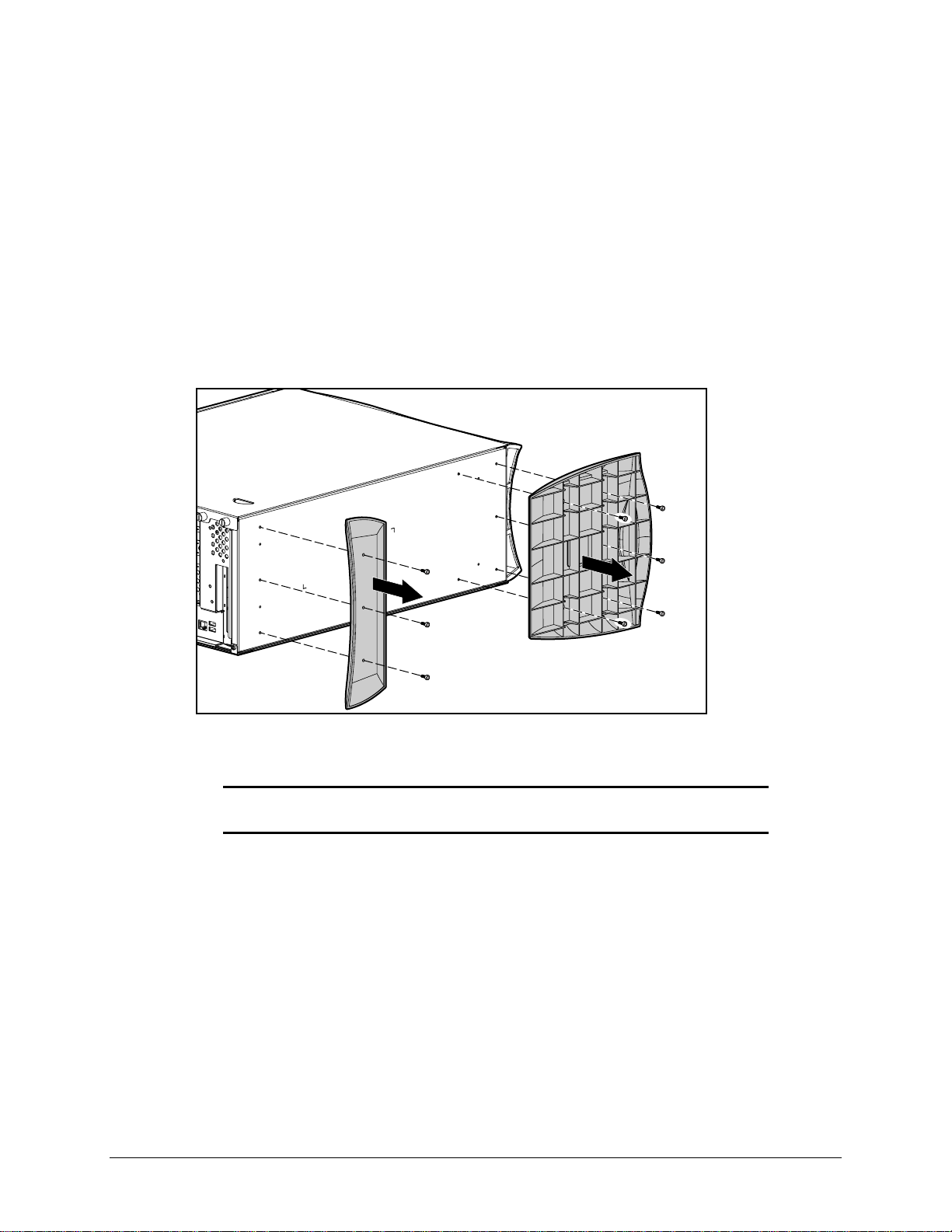

Workstation Feet

NOTE: Not all procedures in this chapter require the removal of the workstation feet. Be sure to

thoroughly read each removal and replacement procedure before attempting to access the

workstation’s internal components.

To remove the workstation fe et:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the screws that secure the feet.

3. Remove the feet.

Figure 3-3. Removing the workstation feet

4. To replace the feet, reverse the above procedure.

IMPORTANT: Compaq recommends that you perform certain removal and replacement

procedures with the workstation laying on its side. Re fer to each procedure for instructions.

Page 25

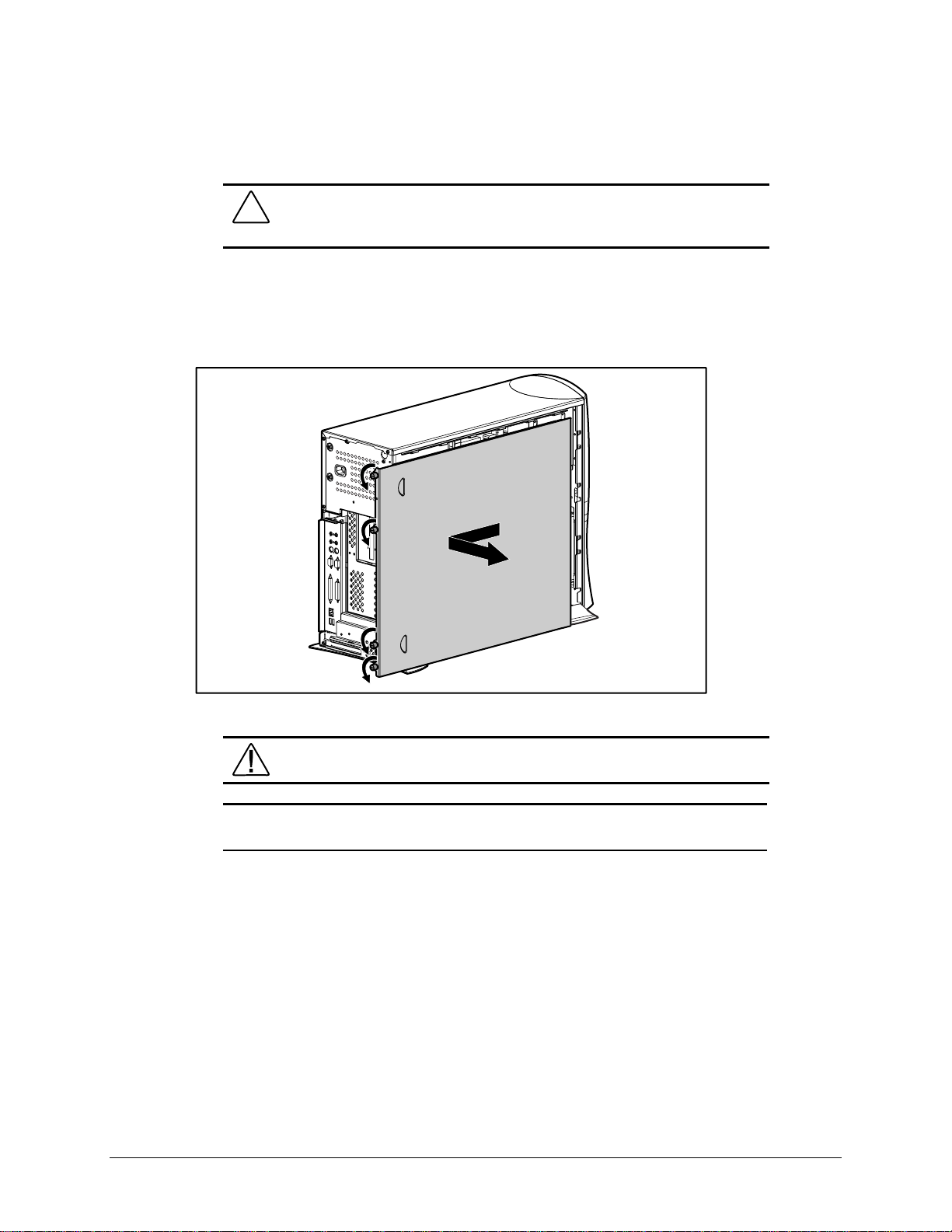

Side Access Panel

To remove the side access panel:

1. Perform the service preparations shown on page 3-2.

2. Loosen the four rear panel thumbscrews, then slide the side access off.

3-5

CAUTION: Do not operate the workstation with the side access panel removed.

The panel is an integral part of the cooling system; removing it while the system is

operating may adversely affect data integrity.

Figure 3-4. Loosening the thumbscrews and removing the side access panel

WARNING: To reduce the risk of personal injury from hot surfaces, allow the

internal system components to cool before touching.

IMPORTANT: When replacing the side access panel, be sure to tighten all four

thumbscrews.

NOTE: The hood label attached to the inside of the side access panel provides system

configurations and the installation of additional components.

To replace the side access panel:

1. Be sure all grounding clips and EMI gaskets (shielding strips) are in place.

2. Slide the side access panel in at an angle on one side, drop it into place, then slide it into

the unit completely.

3. Tighten the rear panel thumbscrews.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 26

3-6 Removal and Replacement Procedures

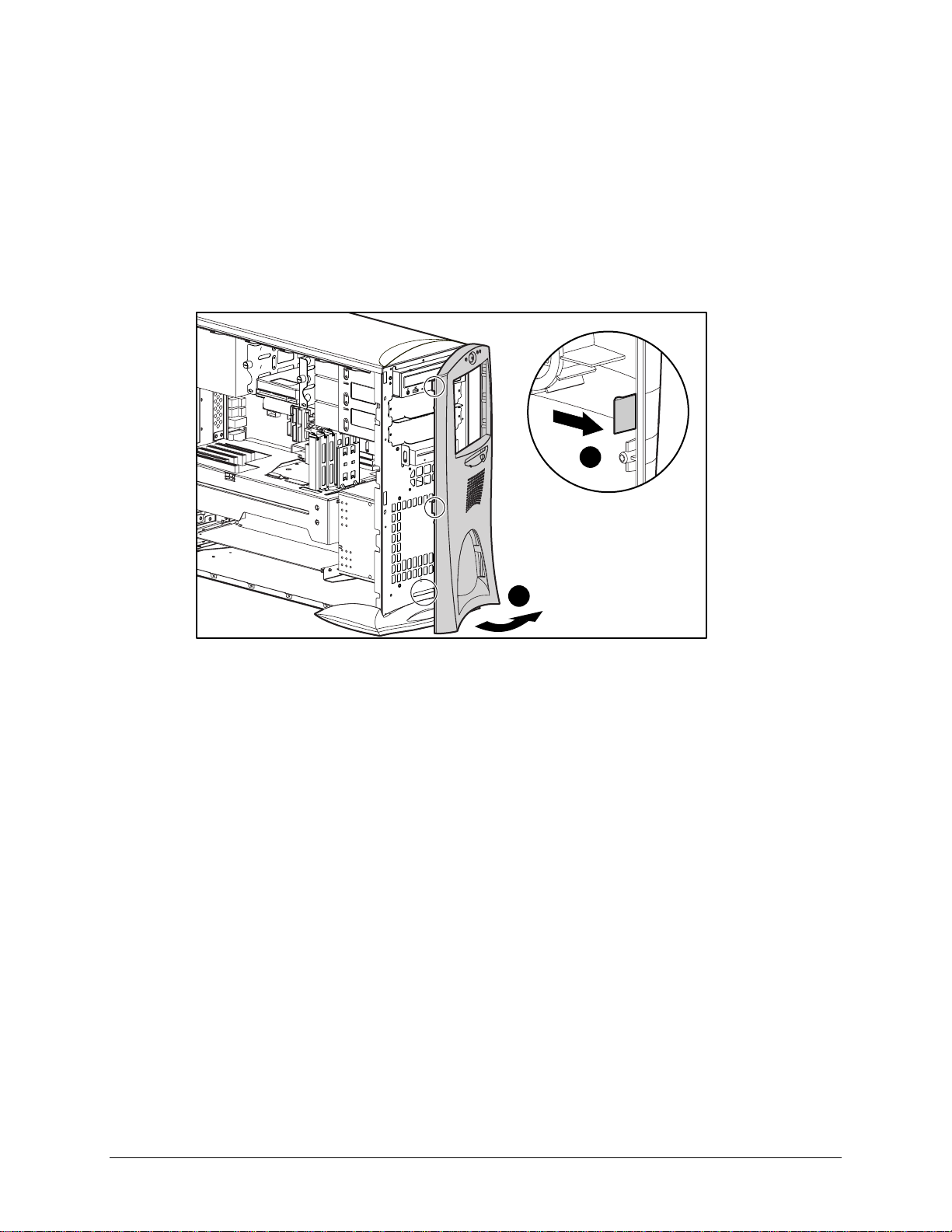

Front Bezel

To remove the front bezel:

1. Perform the service preparations shown on page 3-2.

2. Remove the side access panel.

3. Push the front bezel release latches 1 and remove the bezel 2.

COMPACT

1

2

Figure 3-5. Removing the front bezel

To replace the front bezel:

1. Line up the hinges and release latches with the appropriate slots on the f ront of the

chassis.

2. Press the bezel in to secure the release latches.

Page 27

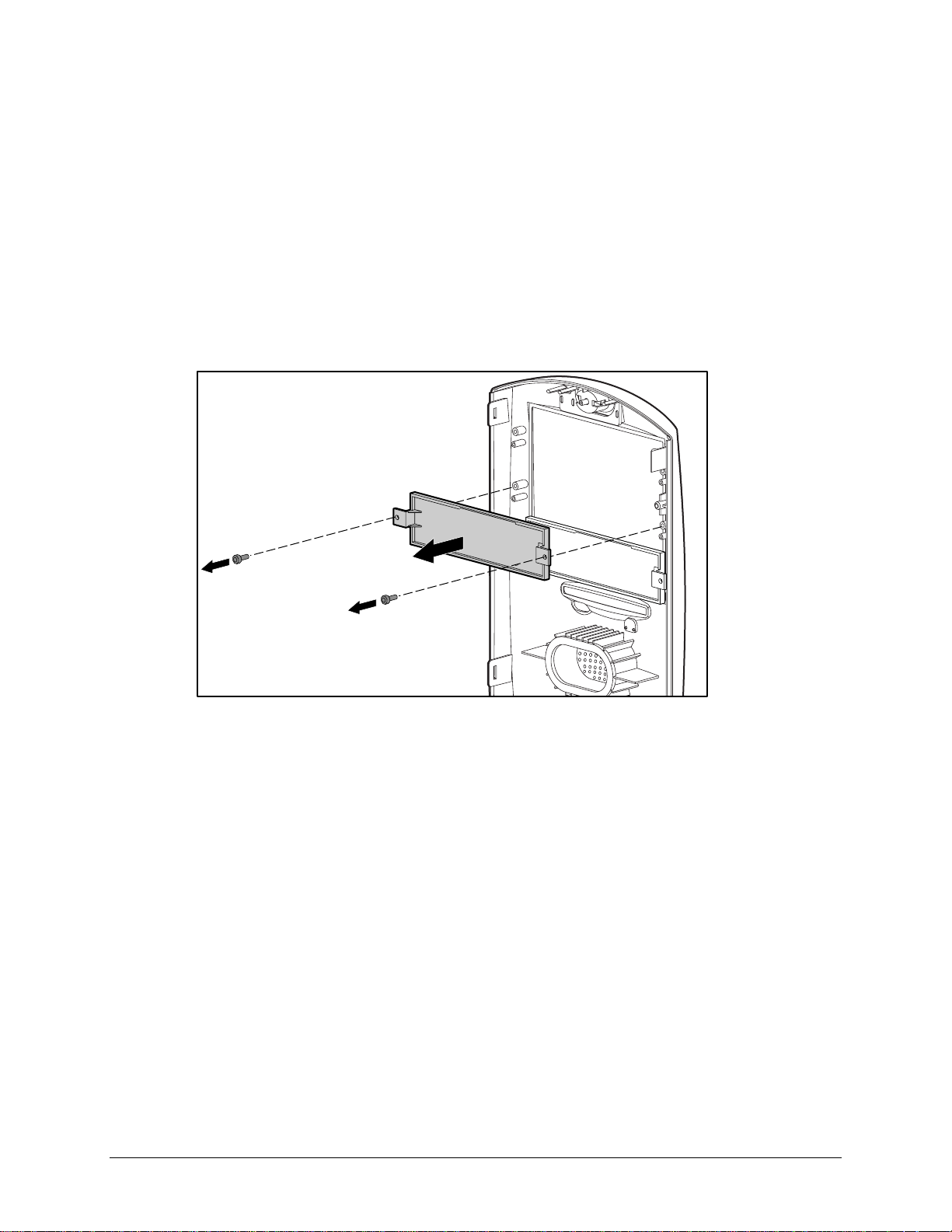

Blank Drive Bezel

To remove a blank drive bezel:

1. Perform the service preparations shown on page 3-2.

2. Remove the following components:

❏ Side access panel

❏ Front bezel

3. Remove the screws that secure the blank drive bezel to the front bezel.

3-7

Figure 3-6. Removing a blank drive bezel

To replace a blank drive bezel, reverse the above procedure.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 28

3-8 Removal and Replacement Procedures

EMI/Cooling Shield

An EMI/cooling shield cover s bays 5 and 6 to provide proper cooling and EMI protection.

To remove an EMI/cooling shield:

1. Perform the service preparations shown on page 3-2.

2. Remove the following components:

❏ Side access panel

❏ Front bezel

3. Remove the two screws that connect the EMI/cooling shield to the drive cage.

4. Remove the EMI/cooling shield from the drive slot.

COMPACT

Figure 3-7. Removing the EMI/cooling shield

To replace the EMI/cooling shield, reverse the above procedure.

IMPORTANT: You must replace the shield after a hard drive is installed in the bay.

Page 29

Speaker

3-9

To remove the speaker:

1. Perform the service preparations shown on page 3-2.

2. Remove the side access panel.

3. Unplug the speaker connector from the system board 1, and remove the cable from the

clip.

4. Remove the four T-15 screws securing the front of the speaker to the chassis 2.

5. Remove the speaker fr om the workstation by sliding it back, then lifting it up and out of

the chassis 3.

1

2

1

Figure 3-8. Removing the speaker

To replace the speaker, reverse the above procedure.

3

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 30

3-10 Removal and Replacement Procedures

I/O Bracket Assembly

The I/O bracket assembly (expansion board assembly) contains a backplane board (also ca lled a

riser card), card guide, and any expansion boa rds. To remove the I/ O bracket assembly:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

CAUTION: The power supply in the Compaq Professional Workstation AP500

contains an auxiliary power section. Be sure the power switch is off and the unit is

unplugged before rem oving the I/O bracket assembly in the next step.

3. Grasp the I/O bracket assembly and pull it out of the chassis.

Figure 3-9. Removing the I/O bracket assembly

IMPORTANT: After reconnecting the power cord to the grounded AC outlet and to the

workstation, DO NOT turn the power button on if the Power LED is a steady amber color. A

steady amber color indicates that the I/O bracket assembly is not seated properly.

Disconnect the power cord and reseat the I/O bracket assembly.

Page 31

Replacing the I/O Bracket Assembly

To replace the I/O bracket assembly (expansion board assembly), follow these steps:

1. Grasp the assembly and insert it into the chassis and connector on the system board. Press

firmly on the I/O bracket assembly, where the backplane is connected to the system

board.

2. Connect the power cord to the grounded AC outlet and to the workstation. DO NOT turn

on the power switch.

3. Check if the power LED is a steady amber color. A steady amber color indicates the I/O

bracket assembly, proc essor(s), or termina t or board (if installed) is not seated properly.

4. If the power LED is a steady amber color, disconnect the power cor d from the grounded

AC outlet, reseat the I/O bracket assembly, processor(s), or terminator board (if installed),

then reconnect the power cord.

5. Once the power LED is a steady green color, disconnect the power cord once again before

continuing with additional service.

WARNING: DO NOT turn on the power switch unless the I/O bracket assembly,

processor(s), and terminator board (if installed) are seated properly and the power

LED is a steady green color. To reduce the risk of injury, DO NOT turn on the

power until the workstation is completely reassembled.

3-11

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 32

3-12 Removal and Replacement Procedures

Expansion Boards

This section discusses removal and replacement procedures for PCI or ISA expansion boards and

the Accelerated Graphics Port (AGP) graphics controller.

NOTE: The following instructions also apply to installing and removing graphics controllers. For

information about the installed graphics controller, refer to the appropriate guide on the

SmartStart for Workstations CD under X:/DOCS/GRAPHICS, where X is the CD-ROM or DVD-ROM

drive on your machine.

Identifying the PCI and ISA Expansion Slots

The Compaq Professional Workstation A P500 contains five expansion slots on the I/O br acket

assembly: three PCI expansion slots, one shared PCI/ISA expansion slot, a nd one ISA expansion

slot. The following illustration identifies the physical locations. See the corresponding table for

component names.

1

Figure 3-10. Identifying the expansion slots

2

3

4

5

Page 33

Table 3-1

PCI/ISA Slots

Reference Description

1 PCI/ISA shared expansion slot*

2 PCI expansion slot

3 PCI expansion slot

4 PCI expansion slot

5 ISA slot

*Cannot be used simultaneously

NOTE: PCI=Peripheral Component Interconnect ISA=Industry Standard Architecture

3-13

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 34

3-14 Removal and Replacement Procedures

Removing a PCI or ISA Expansion Board

NOTE: The following instructions also apply to installing and removing graphics controllers. For

information about the installed graphics controller, refer to the appropriate guide on the

SmartStart for Workstations CD under X:\DOCS\GRAPHICS, where X is the CD-ROM or DVD-ROM

drive on your machine.

To remove a PCI or ISA expansion board:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

❏ I/O bracket assembly

3. Remove the retaining screw that holds the expansion board in place.

4. Move the tab 1 to release the board.

5. Hold the expansion board at each end and carefully rock it back and forth until the

connectors pull free from the slot. Then lift the board from the slot 2.

2

1

Figure 3-11. Removing an expansion board

To install an expansion board:

1. Remove the expansion slot cover.

2. Press firmly on the expansion board so that the whole connector seats properly in the

expansion board slot. If you are installing a full length expansion board, be sure to engage

the card guide.

3. Replace the retaining screw.

CAUTION: If you permanently remove an expansion board, install a protective

slot cover to ensure proper cooling.

Page 35

Removing a Symbios Wide Ultra2 PCI SCSI Controller

NOTE: For best performance, do not mix Wide-Ultra and Wide Ultra2 SCSI hard drives on the

same SCSI cable or the same channel.

To remove a Wide Ultra2 SCSI Controlle r:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

3. Remove the I/O bracket assembly.

4. Disconnect the SCSI cable from the controller.

5. Remove the retaining screw that holds the controller in place.

6. Remove the controller.

To replace the controller, reverse the above procedure.

3-15

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 36

3-16 Removal and Replacement Procedures

Removing the Accelerated Graphics Port (AGP) Graphics

Controller

The Compaq Professional Workstation A P500 comes equipped with an AGP expansion slot on

the system board. The following illustration identifies the physical location of the AGP graphics

controller expansion slot.

NOTE: For information about the installed graphics controller, refer to the appropriate guide on

the SmartStart for Workstations CD under X:\DOCS\GRAPHICS, where X is the CD-ROM or DVDROM drive designation.

To remove the AGP graphics controller:

1. Remove the retaining screw that holds the controller in place.

2. Hold the controller at each end, then pull up.

Figure 3-12. Removing an AGP graphics controller

To replace the controller, reverse the above procedure.

CAUTION: If you permanently remove an AGP graphics controller, install a

protective slot cover to ensure proper cooling.

IMPORTANT: When replacing the AGP graphics controller, be sure to use AGP graphics

controllers with ATX format brackets. This will ensure the controller fits properly.

IMPORTANT: When you install an AGP graphics controller, be sure to press firmly on the

controller so that the whole connector seats properly in the AGP expansion slot.

Page 37

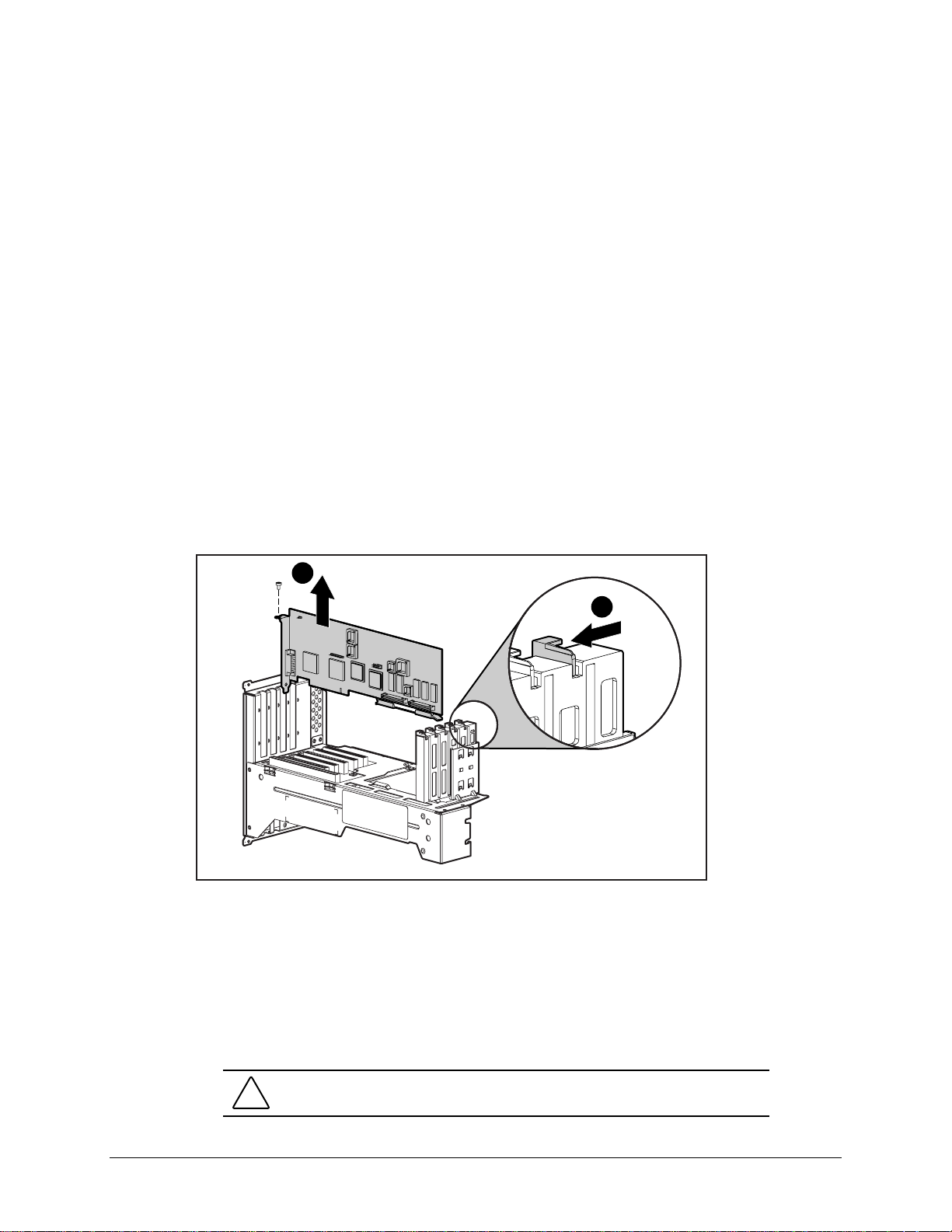

Removing the Card Guide

To remove the card guide:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

❏ I/O bracket assembly

❏ Full-length expansion boards, if installed

3. Using a blunt tool, press inward on the two c enter tabs on the card guide.

4. Gently pull the card guide out.

3-17

Figure 3-13. Removing the card guide

To replace the card guide, reverse the above procedure.

IMPORTANT: Before replacing the I/O bracket assembly, read “Important Guidelines for I/O

Bracket Assembly Replacement” earlier in this chapter.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 38

3-18 Removal and Replacement Procedures

Removing the Backplane Board

The backplane board (also called the riser card) is attached to the I/O bracket assembly. The

backplane board contains the expansion slots described and shown in the “ Expansion Boards”

section in this chapter.

To remove the backpla ne board:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

❏ I/O bracket assembly

❏ Expansion boards (if installed)

❏ Graphics controller (if installed)

3. Remove the four screws that secure the backplane board to the I/O bracket assembly.

4. Slide out then remove the backplane board from the I/O bracket assembly.

Figure 3-14. Removing the backplane board

To replace the backplane board, reverse the above procedure.

IMPORTANT: Before replacing the I/O bracket assembly, read “Important Guidelines for

I/O Bracket Assembly Replacement” earlier in this chapter.

NOTE: When replacing the backplane board, align the top edge of the board with the slots in the

I/O bracket assembly.

Page 39

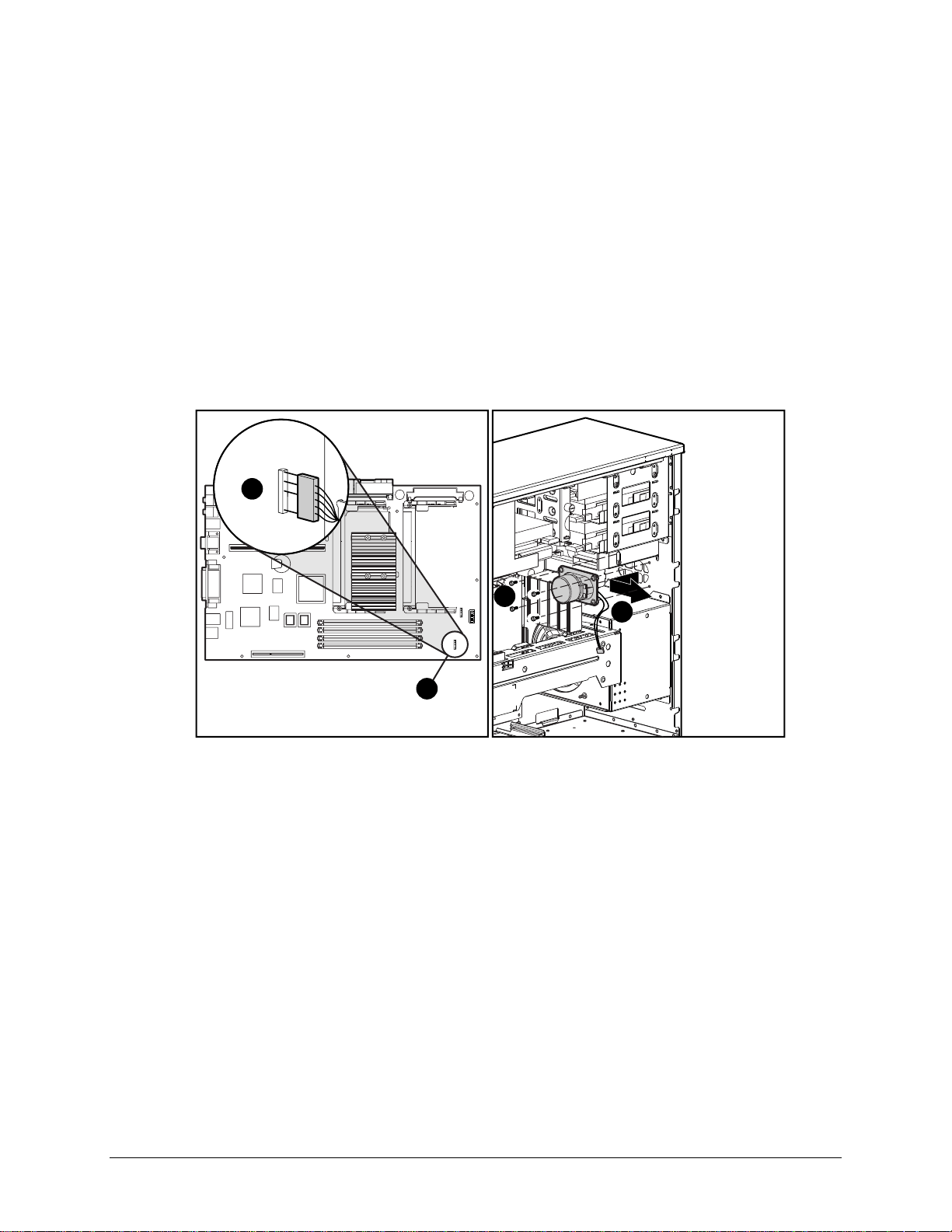

System Fan

To remove the system fan:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

3. Disconnect the fan cable from the system board 1.

4. Remove the two screws at the top of the fan 2, then pull back and slide up 3.

3-19

❏ Workstation feet

❏ Side access panel

NOTE: If the system board has not been removed, slide it out a few inches before removing the

system fan.

1

Figure 3-15. Removing the system fan

2

3

2

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 40

3-20 Removal and Replacement Procedures

5. Pull the rubber isolators through the br acket 1, then remove the fan from the bracket 2.

Figure 3-16. Removing the fan from the bracket

1

2

To replace the system fan, reverse the above procedure.

Page 41

Mass Storage Devices

This section discusses removal and replacement procedures for the mass storage devices

supported on the Compaq Professional Wor ksta tion AP500.

Drive Positions

The Compaq Professional Workstation A P500 can house up to seven mass storage devic es. All

models ship with a CD-ROM drive installed in Bay 4 and a diskette drive installed in Bay 7. The

following illustration identifies the physical drive loca tions. See the corresponding table for a

description of the drive bay components.

3-21

COMPACT

Figure 3-17. Identifying drive positions

4

5

6

7

2

3

3

2

4

1

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 42

3-22 Removal and Replacement Procedures

Reference Component Description

1 Bay 1 Part of the removable hard drive cage. A 3.5-inch, third-height bay that supports a

2 Bay 2 Part of the removable hard drive cage. A 3.5-inch, third-height bay that supports a

3 Bay 3 Part of the removable hard drive cage. A 3.5-inch, third-height bay that supports a

4 Bay 4 A CD-ROM drive is shipped in Bay 4.

5 Bay 5* 5.25-inch, half-height bay that supports 1.0-inch or 1.6-inch storage devices. An

6 Bay 6* 5.25-inch, half-height bay that supports 1.0-inch or 1.6-inch storage devices. An

Table 3-2

Drive Positions

1.0-inch hard drive or a 1.6-inch hard drive.

1.0-inch hard drive. Bay 2 is not available when a 1.6-inch hard drive is installed in

Bay 1 or Bay 3.

1.0-inch hard drive or a 1.6-inch hard drive.

optional hard drive, diskette drive, CD-ROM drive, DVD-ROM drive, or tape drive can

be installed in Bay 5.

optional hard drive, diskette drive, CD-ROM drive, DVD-ROM drive, or tape drive can

be installed in Bay 6.

7 Bay 7 3.5-inch, third-height bay that supports a 1.0-inch device. A standard 3.5-inch

diskette drive is shipped in Bay 7.

* An additional Zip drive can be installed in these bays.

CAUTION: If a hard drive is installed in Bay 5 or 6 or if the bays are empty, be

sure that EMI/cooling shields are installed to ensure proper air flow and cooling.

IMPORTANT: Compaq recommends 10,000 rpm hard drives be installed first in Bays 1, 2,

or 3. Installing a 10,000 rpm hard drive in Bays 5 or 6 will require an additional cooling fan

kit.

Page 43

Hardware Screws

A total of 17 extra hardware screws are provided on the side of the air plenum. The top group of

eight screws 1 is for installing hard dr ives in the removable hard drive cage. The bottom group

of nine screws 2 is for installing removable media storage devices in the front drive bays.

3-23

1

2

Figure 3-18. Locating the hardware screws

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 44

3-24 Removal and Replacement Procedures

CD-ROM Drive or DVD-ROM Drive

To remove the CD-ROM drive or DVD-ROM drive:

1. Perform the service preparations shown on page 3-2.

2. Remove the following components:

❏ Side access panel

❏ Front bezel

3. Remove the retaining screws 1 and slide the drive 2 halfway out.

4. Disconnect the audio, data, and power cables 3 from the back of the drive.

1

COMPACT

2

3

Figure 3-19. Disconnecting the cables from the back of the CD-ROM drive or DVD-ROM drive

Page 45

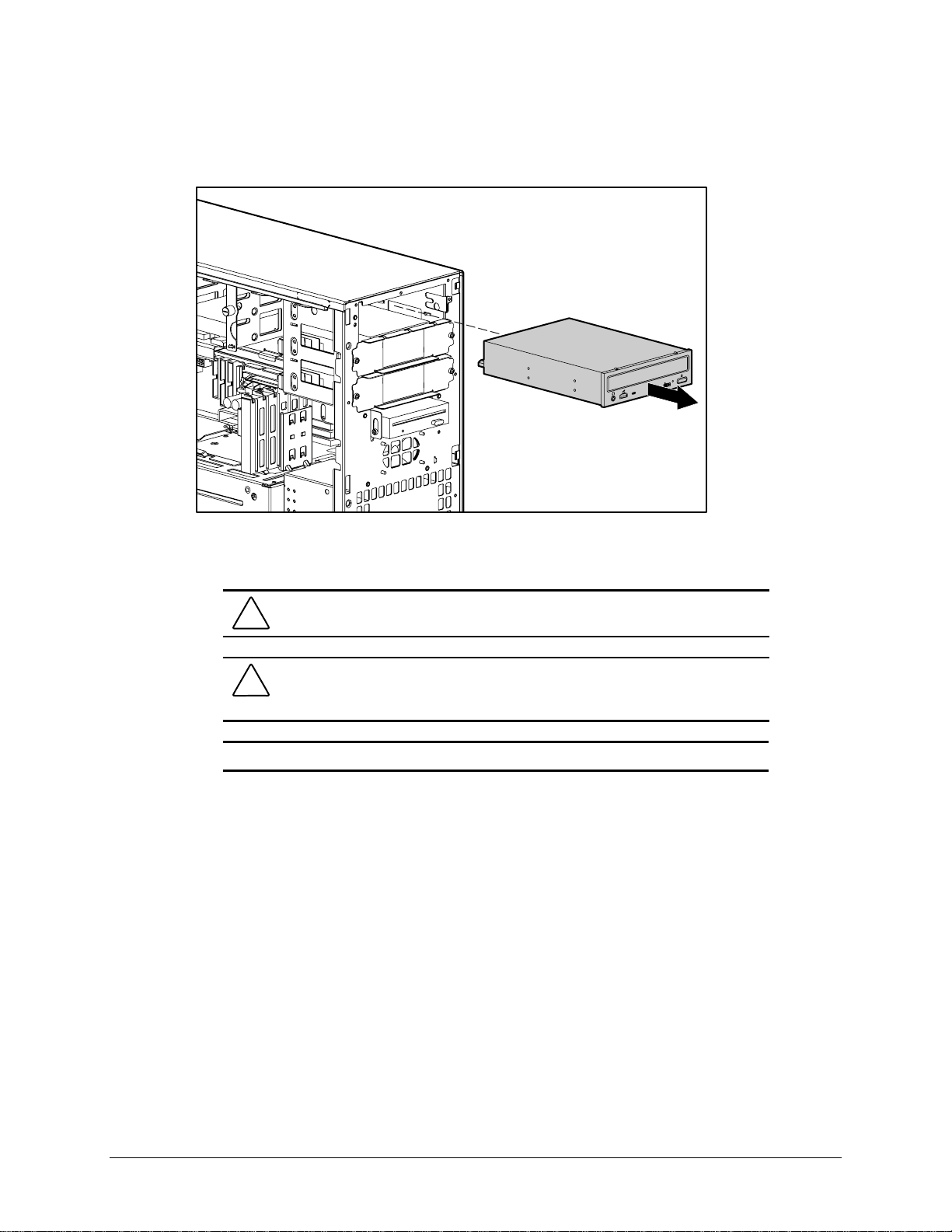

5. Pull the drive completely out of the drive cage.

Figure 3-20. Removing the CD-ROM drive or DVD-ROM drive

3-25

COMPACT

To replace the drive, reverse the above procedure.

CAUTION: Use only 3/16-inch or 5 mm long screws. Using longer screws can

damage the internal components of the drive.

CAUTION: When servicing the workstation, be sure cables are placed in their

proper locations during the reassembly process. Improper cable placement can

damage the computer.

IMPORTANT: Make sure you attach the middle connector of the data cable to the drive.

NOTE: Be sure to transfer the guide screw from the old drive to the new one. The screw is

installed on the right front side of the drive. Note that extra guide screws are provided on the side

of the air plenum.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 46

3-26 Removal and Replacement Procedures

Diskette Drive

IMPORTANT: Before removing the diskette drive, be sure there is no diskette in the drive.

To remove the diskette drive:

1. Perform the service preparations shown on page 3-2.

2. Remove the following components:

❏ Side access panel

❏ Front bezel

3. Disconnect the cables from the back of the diskette drive.

Figure 3-21. Disconnecting the cables from the back of the diskette drive

4. Remove the diskette drive retaining screws.

Page 47

5. Pull the diskette drive straight out.

COMPACT

Figure 3-22. Removing the diskette drive

3-27

To replace the diskette drive, reverse the above procedure.

CAUTION: Use only 3/16-inch or 5 mm long screws. Using longer screws can

damage the internal components of the drive.

CAUTION: When servicing the workstation, be sure cables are placed in their

proper locations during the reassembly process. Improper cable placement can

damage the computer.

NOTE: Be sure to transfer the guide screw from the old drive to the new one. The screw is

installed on the right front side of the drive. Note that extra guide screws are provided on the side

of the air plenum.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 48

3-28 Removal and Replacement Procedures

Removing a 7200 rpm Hard Drive from Bays 5 or 6

Drive bays 5 and 6 can be configured with either a 1.0- inch or a 1.6-inch, 7200 rpm hard drive.

Other than using different sc rew holes, the removal of both drives a basically the same.

To remove a 7200 rpm hard drive:

1. Perform the service preparations shown on page 3-2.

2. Remove the following components:

❏ Side access panel

❏ Front bezel

3. Disconnect the signal and power cables.

Figure 3-23. Disconnecting the cables from the hard drive

Page 49

4. Remove the EMI/cooling shield.

Figure 3-24. Removing the EMI/cooling shield

5. Pull the hard drive straight out.

3-29

COMPACT

Figure 3-25. Removing the hard drive

COMPACT

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 50

3-30 Removal and Replacement Procedures

6. Remove the retaining screws and lift the hard drive from the bracket.

Figure 3-26. Removing a hard drive from the hard drive bracket

To reinsert a hard drive in Bays 5 or 6, revers e the above procedure.

CAUTION: Use only 3/16-inch or 5 mm long screws. Using longer screws can

damage the internal components of the drive.

CAUTION: When servicing the workstation, be sure cables are placed in their

proper locations during the reassembly process. Improper cable placement can

damage the computer.

Page 51

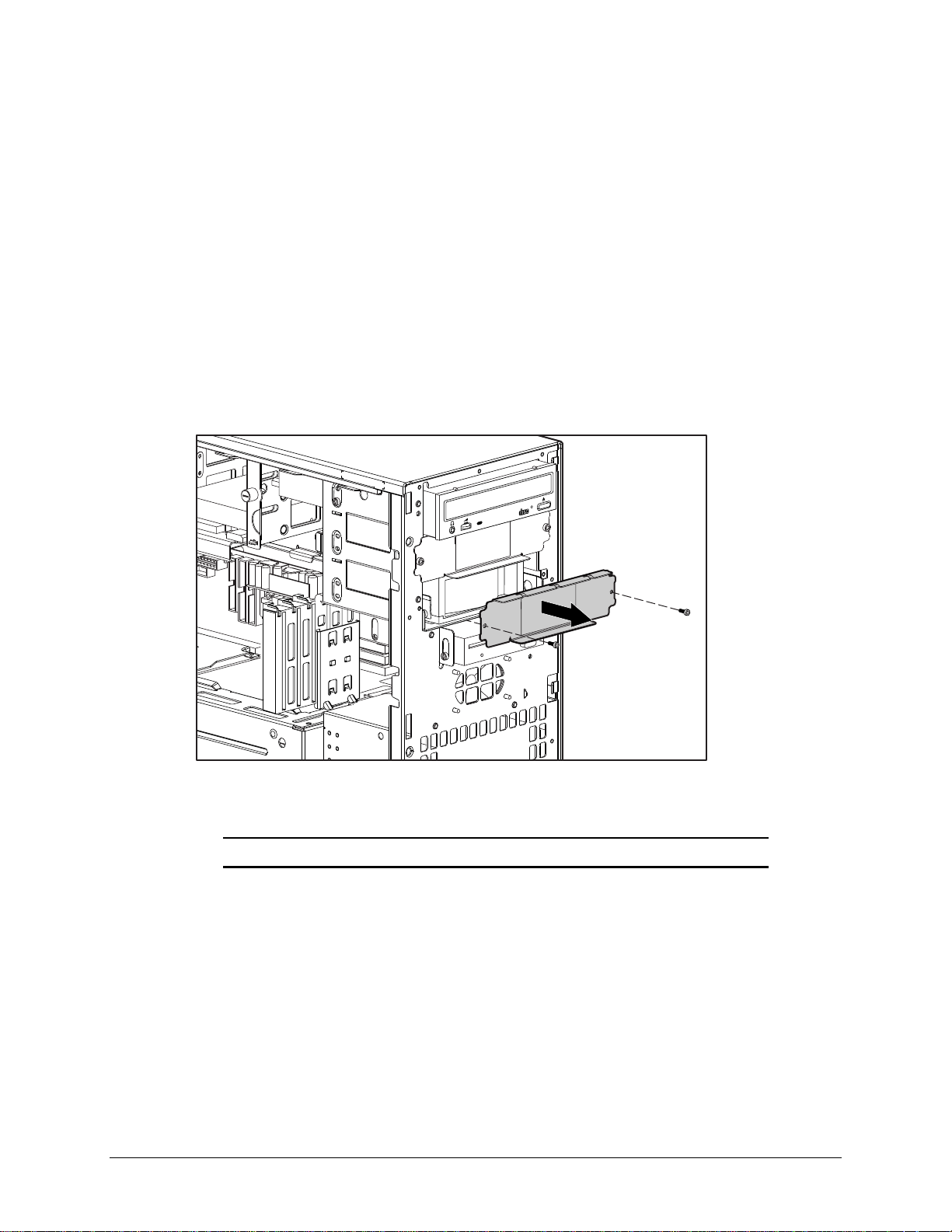

Removing a 10,000-rpm Hard Drive from Bays 5 or 6

Drive bays 5 and 6 can be configured with a 10,000 rpm hard drive. The remova l of the drive is

basically the same as removing a 7200 rpm hard drive except you will be also be removing a

cooling fan. :

To remove a 10,000-rpm hard drive:

1. Perform the service preparations shown on page 3-2.

2. Remove the following components:

❏ Side access panel

❏ Front bezel

3. Disconnect the signal and power cables.

3-31

Figure 3-27. Disconnecting the cables from the hard drive

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 52

3-32 Removal and Replacement Procedures

4. Disconnect the fan power cable.

Figure 3-28. Disconnecting the fan power cable

5. Remove the retaining scre w s securing the fan.

NOTE: The screws that secure the fan also secure the hard drive.

Figure 3-29. Removing the fan

Page 53

6. Remove the EMI/cooling shield.

Figure 3-30. Removing the EMI/cooling shield

7. Pull the hard drive straight out.

3-33

COMPACT

Figure 3-31. Removing the hard drive

COMPACT

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 54

3-34 Removal and Replacement Procedures

8. Remove the retaining screws and lift the hard drive from the bracket.

Figure 3-32. Removing a hard drive from the hard drive bracket

To reinstall a hard drive in Bays 5 or 6, reverse the above procedure.

CAUTION: Use only 3/16-inch or 5 mm long screws. Using longer screws can

damage the internal components of the drive.

CAUTION: When servicing the workstation, be sure cables are placed in their

proper locations during the reassembly process. Improper cable placement can

damage the computer.

Page 55

Removing the Fan from a Hard Drive Installed in

Bays 5 or 6

NOTE: This section only applies if there is a fan installed over Bays 5 and 6. The fan is required

only in high-altitude environments or when a hard drive faster than 7200 rpm is installed in Bay 5

or 6.

To remove the fan:

1. Perform the service preparations shown on page 3-2.

2. Remove the side access panel.

3. Disconnect the power cable.

3-35

Figure 3-33. Disconnecting the power cable

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 56

3-36 Removal and Replacement Procedures

4. Remove the screws that hold the fan in place and remove the fan.

NOTE: The screws also secure the hard drive in that bay and must be replaced. DO NOT

remove the screws from the CD-ROM drive. They are not used to install the fan.

Figure 3-34. Removing the fan

To replace the fan, reverse the above procedure.

Page 57

Removing a Hard Drive from the Removable Hard Drive

Cage

The removable hard drive cage supports up to three 1.0-inch hard drives or two 1.6-inch hard

drives. Other than using different screw holes, the removal and replacement for both drives is

basically the same.

To remove a hard drive in the removable har d drive cage:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

3. Disconnect the cables from the back of the hard drive(s).

3-37

Figure 3-35. Disconnecting the cables from the back of a hard drive

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 58

3-38 Removal and Replacement Procedures

4. Pull back the power supply air baffle 1.

5. Loosen the two thumbscrews 2 and slide the removable hard drive cage out 3.

1

2

3

Figure 3-36. Removing the removable hard drive cage

6. Remove the four screws that secure the hard drive to the removable hard drive cage and

pull the hard drive straight out.

Figure 3-37. Removing a hard drive

CAUTION: When servicing the workstation, make sure cables are placed in their

proper locations during the reassembly process. Improper cable placement can

damage the workstation.

Page 59

Installing a Hard Drive in the Removable Hard Drive Cage

To install a hard drive in the removable hard drive cage:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

❏ Removable hard drive c age

3. Remove the hard drive sc rews (top group of screws) from the side of the air plenum

located at the front of the workstation.

3-39

4

3

2

1

Figure 3-38. Locating the removable hard drive screw holes

Table 3-3

Removable Hard Drive Screw Holes

Reference Bay

4 Bay 3: 1.0-inch drive

3 Bay 3: 1.6-inch drive

2 Bay 2: 1.0-inch drive

1 Bay 1: 1.0-inch drive

4. Insert the hard drive into the removable hard drive cage, and secure the drive with the four

hard drive screws. (Se e the above illustration and table for the location of the correct screw

holes for the hard drive you ar e installing.)

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 60

3-40 Removal and Replacement Procedures

Figure 3-39. Inserting a hard drive in the removable hard drive cage

4

2

1

Figure 3-40. Reinstalling a removable hard drive cage

5. Pull back the air baffle 1.

6. Slide the hard drive cage 2 into place.

7. Align the tabs 3 on the bottom of the cage with the workstation chassis.

8. Tighten the thumbscrews 4.

9. Connect the signal and power cable s to the hard drive.

10. Reassemble the workstation.

3

Page 61

SCSI Cables and Guidelines

All workstation models use three areas for connecting mass storage SCSI devices: internally

with hard drive in the removable hard drive cage, internally with storage devices in the front

panel drive bays, and externa lly w ith external storage devices. The workstation has an integrated

Wide-Ultra SCSI controller that has one internal connector on the system board and one external

connector on the rear panel.

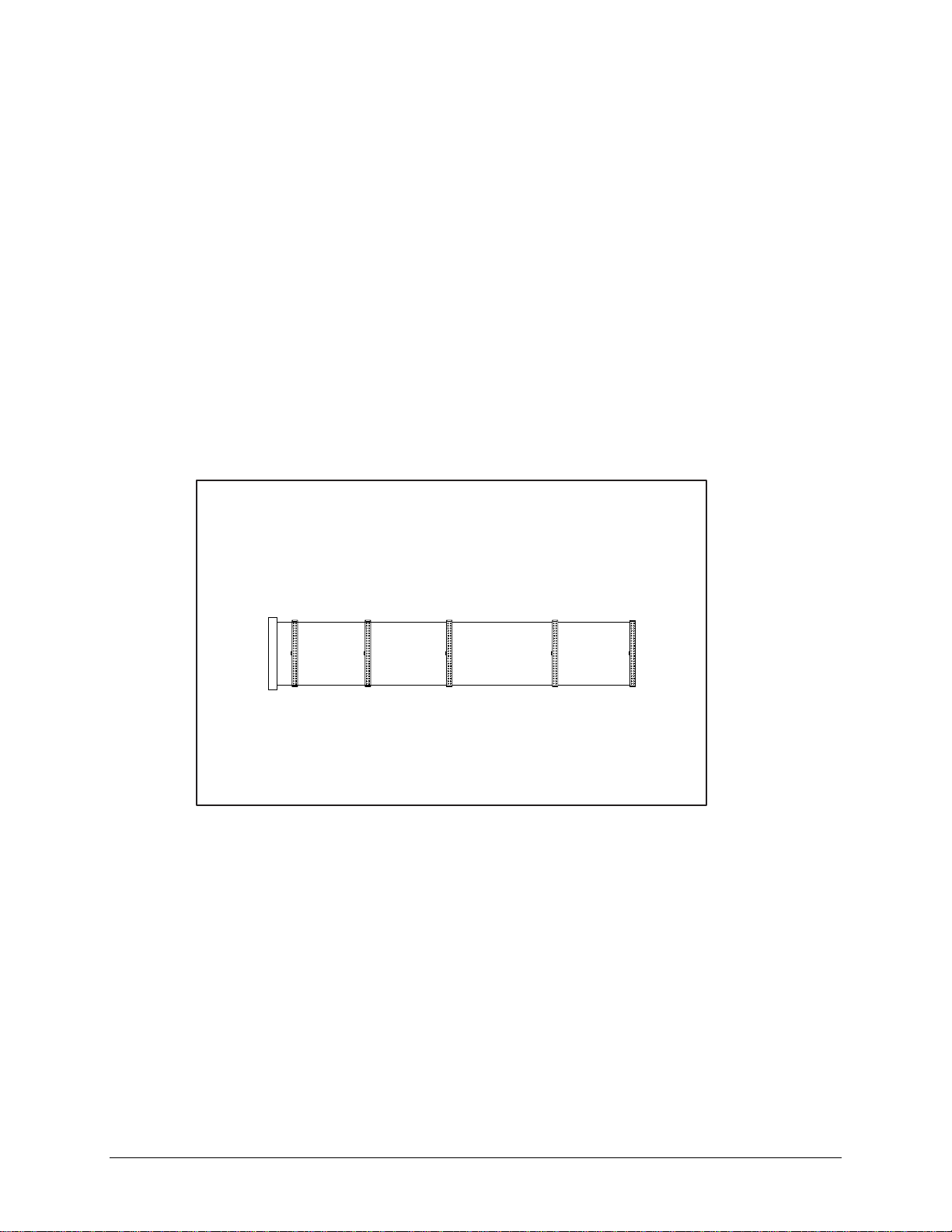

SCSI Cables

The workstation ships standard with a 5-de vice Wide-Ultra or Wide Ultra2 SCSI cable that has a

terminator on one end. The other end of this cable connects to the internal Wide-Ultra SCSI

connector on the system board. The first device connector of the cable connects to the hard drive

in the removable hard drive cage. The cable has five connectors to handle up to five SCSI

devices, a maximum of three in the rem ovable hard drive cage and two in the front drive bay

area.

3-41

Figure 3-41. 5-device Wide-Ultra SCSI cable

NOTE: The SCSI cable included with the workstation may look slightly different than the one

pictured.

When installing a Wide Ultra2 SCSI hard drive a Wide U ltra2 SCSI cable (not shown) is

required.

Compaq Professional Workstation AP500 Maintenance and Service Guide

Page 62

3-42 Removal and Replacement Procedures

SCSI Guidelines for Installing SCSI Devices

■ If you are installing a narrow SCSI device, you will need to attach a 68- to 50-pin SCSI

adapter to the narrow SCSI device.

■ A maximum of seven SCSI devices may be installed on the integrated Wide-Ultra SCSI

controller.

■ A unique SCSI ID (0-6 and 8-15) must be set for each SCSI device installed.

■ Before you install a SCSI device, verify the SCSI ID of the drive, and if necessary, set the

SCSI ID to a unique ID number.

■ The controller identifies a SCSI device by its SCSI ID (SCSI ID 1) number rather than its

bay location (Bay 2). The refore, moving a SCSI device from one bay loca tion to another

or changing the position of the device on the SCSI chain does not affect the

communication between the c ontroller and the SCSI device.

■ The reserved and available SCSI ID numbers for SCSI devices are as follows:

❏ SCSI ID 0 is reserved for the primary hard drive (boota ble drive).

❏ SCSI ID 7 is reserved for the controller.

❏ SCSI IDs 1-6 and 8-15 are available. Do not use IDs 8-15 for narrow devices on the

same SCSI bus.

■ Bay 4 is reserved for the CD-ROM drive. Do not install a SCSI device in this bay.

■ If only one SCSI hard drive is used, it should be installed on the lowest numbered bay

(Bay 1).

■ Every SCSI chain must be ter minated (closed) at both ends.

■ SCSI devices may not have ter minating jumpers on the device. Determine if the device

ought to have termination enabled or disabled. Set the termination if necessary.

Termination on these device s must be achieved with a non-terminated cable.

■ Turn on an external SCSI device before turning on power to the workstation. This enables

the system board controller to r ecognize the external SCSI devic e.

■ When an external SCSI device is connected to the external SCSI connector on the rear

panel of the workstation, that devic e becomes the end of the SCSI cha i n and must be

terminated.

■ SCSI drives on the SCSI controller must be either internal or in an external storage

system, but not both.

SCSI Guidelines for Optimizing Performance

■ To maintain Ultra speeds, do not insta ll more than four SCSI devices on a SCSI bus.

■ Do not mix Wide-Ultra and nar row SCSI devices on the same SCSI chain or the same

controller.

For additional information about optional SCSI devices, refer to the doc umentation included

with the device.

Page 63

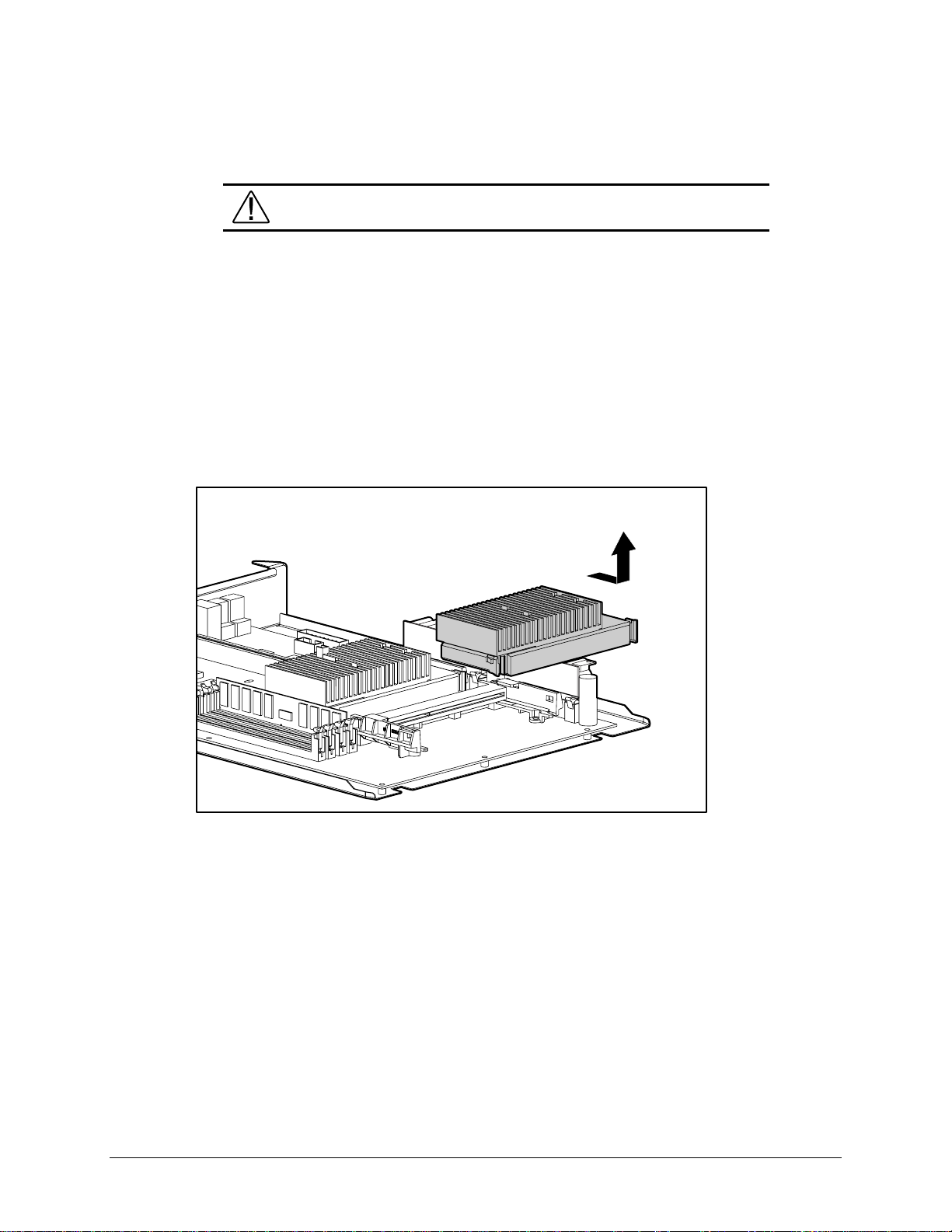

System Board Assembly

The system board assembly contains the DIMMs, Pentium II or Pentium III processor/heat sink,

Processor Power Module( s), system board with tray, the AGP Graphics Controller, and the

external battery, if installed. Each of these components is spa red separately. The com ponents on

the system board are illustra ted in Figure 3-43. See Table 3-4 for component names.

CAUTION: Static electricity can damage the electronic components of the

workstation. Before beginning these procedures, make sure you are properly

grounded. See “Electrostatic Discharge Information” in Chapter 2.

System Board with Tray and Cage

To remove the system board with tray and cage:

1. Perform the service preparations shown on page 3-2, then lay the workstation on its side.

2. Remove the following components:

❏ Workstation feet

❏ Side access panel

3-43

❏ I/O bracket assembly

3. Disconnect and remove all cables plugged into the system board.

IMPORTANT: Be sure to disconnect the system fan and speaker connectors located at the

front of the system board before removing the system board with tray and cage.

4. Grasp the back edge of the system board with tray and slide it out of the chassis.

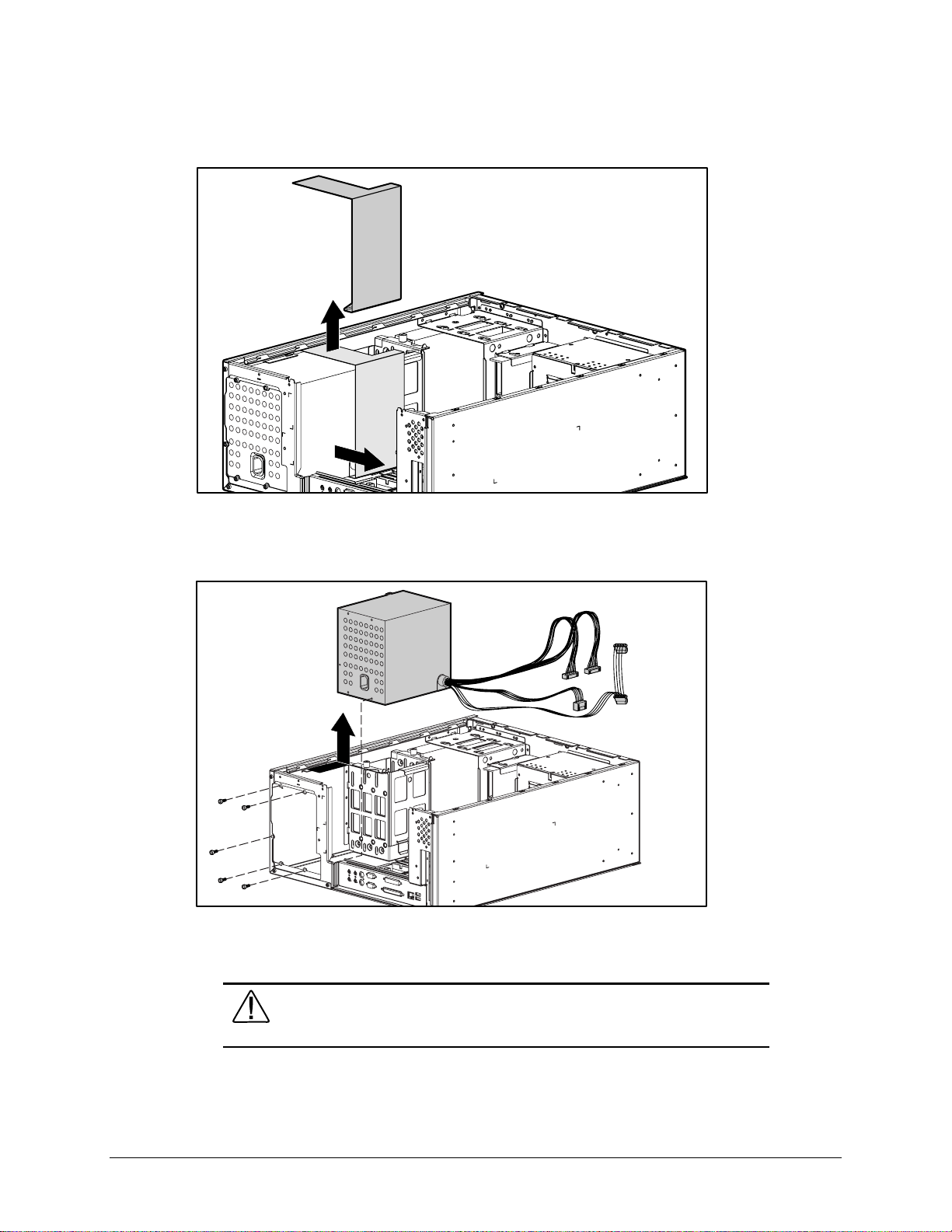

Figure 3-42. Removing the system board with tray and cage