Page 1

INSTALLATION AND OPERATION MANUAL

FDX72(M,S)1

MULTI-PROTOCOL RS232/422/485 DATA TRANSCEIVER

FEATURING LINEAR DROP-INSERT-REPEAT

The ComNet™ FDX72(M,S)1 series Transceiver unit is a fully-digital transceiver

designed for implementing full RS232, RS422 or RS485 2 or 4-wire traffic

signalization/communications data networks of the highest possible reliability.

A network of FDX72 units, used with the ComNet FDX70E(A,B)(M,S)1 series

products as end points, can support one full-duplex data channel or two halfduplex data channels. These transceivers also feature data translation to convert

between data protocols. Full data re-clocking and regeneration permit an almost

unlimited number of transceiver/controller units to be used within the network.

These environmentally hardened transceivers are ideal for use in unconditioned

out-of-plant or roadside installations.

Utilizing wave division multiplexing technology (WDM), only one optical fiber is

required between units

Bi-color (Red/Green) LED indicators are provided for rapidly ascertaining equipment

operating status. See Figure 8 on Page 5 for an explanation of LED indications.

These units are interchangeable between stand-alone or card-cage mount

configurations. See Figure A on Page 7 for mounting instructions.

See Figures 1 – 9 for complete installation details.

INS_FDX72_REV–

02/29/12

PAGE 1

Page 2

INSTALLATION AND OPERATION MANUAL FDX72(M,S)1

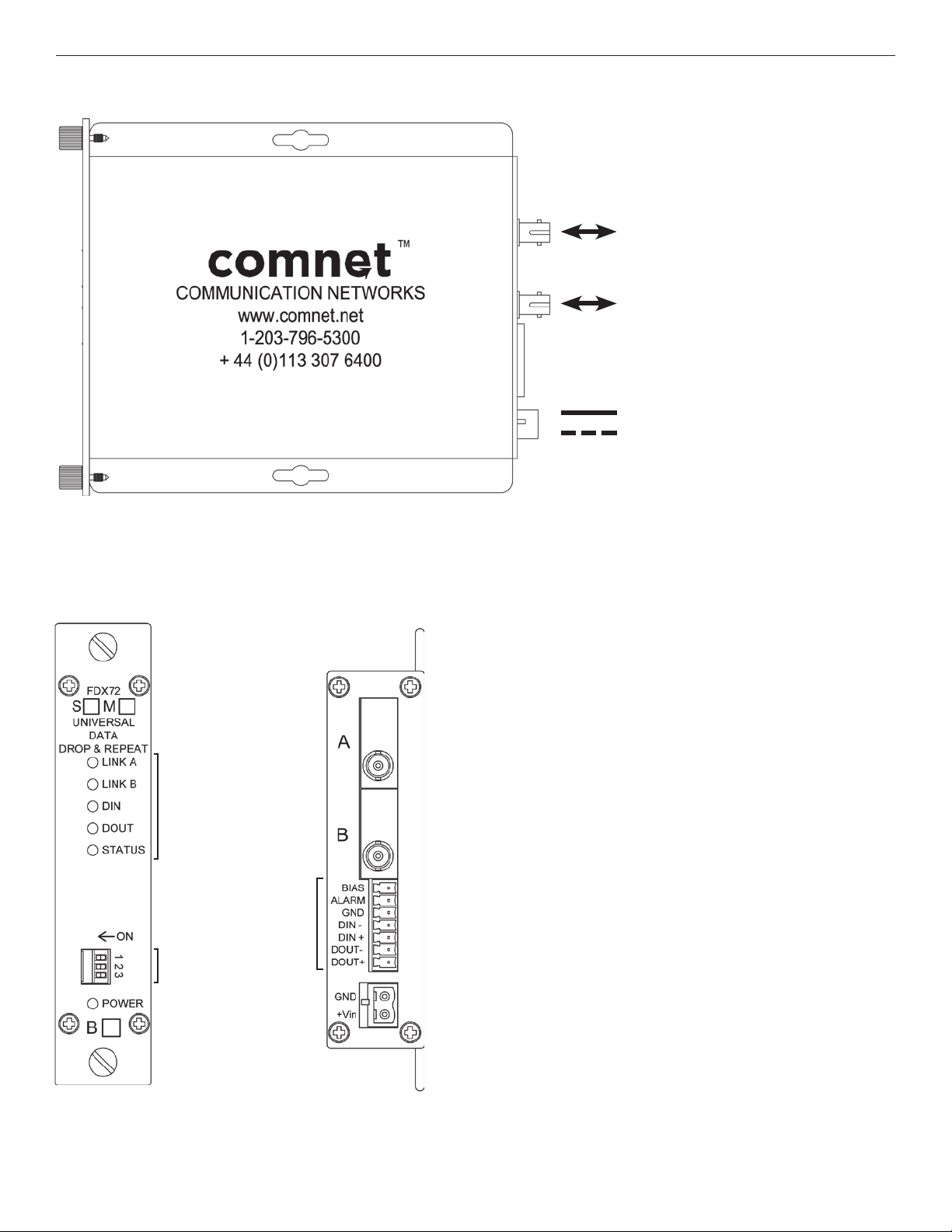

FIGURE 1 – FDX72 FIBER CONNECTIONS

MULTIMODE OR SINGLE MODE OPTICAL

FIBER (DEPENDING ON MODEL)

Optical Port A must be connected to

Optical Port B on another FDX72 unit.

Similarly, Optical Port B must be connected

to Optical Port A on another FDX72 unit.

Refer to Figure 9 on Page 6.

BLACK

BLACK WITH WHITE STRIPE

Power Supply:

Surface Mount: 8–15 VDC @ 4W

Rack Mount: From Rack

FIGURE 2 – FDX72

LED Indicators

See Figure 8

7-Pin Data Connector

See Figures 6 & 7

Data Format Switch

See Figure 5

NOTE: Remove Electrical Connector

for Rack Mount Units

REAR PANELFRONT PANEL

TECH SUPPORT: 1.888.678.9427

INS_FDX72_REV–

02/29/12

PAGE 2

Page 3

INSTALLATION AND OPERATION MANUAL FDX72(M,S)1

FIGURE 3 – DATA FORMAT SWITCH POSITIONS

1 2 3

Switch

Located on front panel.

The first two switches set the

data type, the third sets the

Master/Remote Mode.

RS485 2-Wire, Sensornet

1 2 3

Master Mode

1 2 3

RS232 Data

Data

RS422, Bi-Phase or

Manchester Data

1 2 3

RS485

4-Wire Data

1 2 3

Remote Mode

1 2 3

There are two virtual data channels shared between all FDX72 units in a system: a Master channel and a Remote channel.

The Master/Remote Mode switch sets the data channel used by the equipment connected to each FDX72 unit in the system.

The behavior of a Master and Remote depends on the data type (set by switches 1 and 2):

RS232, RS422, RS485 (4-wire):

Units in Master Mode transmit data to all units set to Remote Mode.

Units in Remote Mode transmit data to all units set to Master Mode.

There is no limit to the number of Masters or Remotes in a system as long as the equipment connected to the FDX72 can handle

multiple Masters and multiple Remotes. Most applications requiring Master/Remote communications would use just one Master

and multiple Remotes. Masters can communicate with all Slaves, but not with other Masters. Remotes can communicate with all

Masters, but not with other Remotes.

RS485 (2-wire):

Units in Master Mode transmit data to all units set to Master Mode.

Units in Remote Mode transmit data to all units set to Remote Mode.

The concept of Master and Remote are not used with RS485 (2-wire) mode. Rather, the Master/Remote Mode switch simply sets

which of two independent data channels each unit will use. All Masters can communicate with each other, but not with Remotes.

All Remotes can communicate with each other, but not with Masters.

INS_FDX72_REV–

TECH SUPPORT: 1.888.678.9427

02/29/12

PAGE 3

Page 4

INSTALLATION AND OPERATION MANUAL FDX72(M,S)1

FIGURE 6 – DATA CONNECTIONS

RS232

RS422

Bi-phase or

Manchester

2-Wire

RS485,

Sensornet

4-Wire

RS485

Customer

Equipment FDX72

Data Transmit

Data Receive

Signal Ground

Data Out (+)

Data Out (–)

Data In (+)

Data In (–)

Data Out (+)

Data Out (–)

Data (A)

Data (B)

Data Out (A)

Data Out (B)

Data In (A)

Data In (B)

DIN(–)

DOUT(–)

GND

DIN(+)

DIN(–)

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

DIN(+)

DIN(–)

DIN(+)

DIN(–)

DOUT(+)

DOUT(–)

DOUT(–)

DIN(–)

GND

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

Customer

EquipmentFDX72

Data Receive

Data Transmit

Signal Ground

Data In (+)

Data In (–)

Data Out (+)

Data Out (–)

Data In (+)

Data In (–)

Data (A)

Data (B)

Data In (A)

Data In (B)

Data Out (A)

Data Out (B)

FIGURE 7 – 7-PIN DATA CONNECTOR

BIAS Current limited +5V connection. This terminal can be used as a

connection for pull-up resistors, if required.

ALARM Alarm relay output. Indicates fault conditions. The relay is internally

connected to the GND terminal when no faults are detected (i.e.

a normally closed relay). The relay circuit opens when a fault is

detected anywhere in the system.

GND: Signal ground reference. This terminal can be also be used as a

connection for pull-down resistors, if required.

DIN+/DIN- Electrical data inputs. See Figure 6 for data connections.

DOUT+/DOUT- Electrical data outputs. See Figure 6 for data connections.

FIGURE 8 – LED INDICATORS

LINK A LINK B DIN DOUT STATUS POWER

GREEN Unit In Sync Unit In Sync Data Activity Data Activity System OK. No Alarm Unit Powered Up

RED Unit Not In Sync Unit Not In Sync – – Fault Detected. Alarm Condition. –

OFF – – No Data Activity No Data Activity – Unit Powered Down

TECH SUPPORT: 1.888.678.9427

INS_FDX72_REV–

02/29/12

PAGE 4

Page 5

INSTALLATION AND OPERATION MANUAL FDX72(M,S)1

FAULT CONDITIONS

A fault condition is when a FDX72 unit system loses power or optical link. The FDX72 provides three LED indicators to help identify

when and where fault conditions occur in a system:

1. ALARM relay output

2. STATUS LED

3. LINK A and LINK B LEDs

When a fault occurs, the ALARM relay on every FDX72 in the system goes from closed to open. In addition, the STATUS LED on

every FDX72 in the system goes from solid green to solid red. The LINK A and LINK B LEDs can then be used to identify the actual

location of the fault based on their color and pattern:

Solid Green Optical link has been established between this optical port and the adjacent FDX72 over fiber.

Furthermore, every other unit in the system is also reporting that link has been established. There are no faults in

the system.

Solid Red Optical link over this port has been lost.

This could be due to a broken fiber, a bad connection, or loss of power at the adjacent unit.

Blinking

Green/Red Optical link has been established between this optical port and the adjacent FDX72 over fiber.

However, a fault condition has been detected somewhere in the system. The LINK LED will be green for a

period of time, and then flash red some number of times. The number of red flashes indicates the location of

the fault by “hops” around the ring. If the LED flashes red three times, then the location of the fault is three hops

away (i.e. three FDX72 units away). For larger systems with faults greater than 9 hops away, the LED will use a

combination of long and short red flashes. Each long flash indicates 10 hops. Each short flash indicates 1 hop.

For example, a fault 47 hops away would be encoded as 4 long red flashes, followed immediately by 7 short

red flashes. The pattern repeats indefinitely until the fault is resolved.

Note Use of a FDX72 unit as an end point will always result in a fault condition. Use ComNet parts FDX70EA and

FDX70EB as end points in this system for accurate fault reporting.

FIGURE 9 – TYPICAL APPLICATION

FDX70EAS1

Unit 1

A

Optical Fiber Optical Fiber Optical Fiber

DIN/DOUT DIN/DOUT

B

FDX72S1

Unit 2

D

D

A

B

FDX72S1

Unit 3

A

DIN/DOUT DIN/DOUT

D

B

FDX70EBS1

Unit 4

D

TECH SUPPORT: 1.888.678.9427

INS_FDX72_REV–

02/29/12

PAGE 5

Page 6

MECHANICAL INSTALLATION INSTRUCTIONS

INSTALLATION CONSIDERATIONS

This fiber-optic link is supplied as a Standalone/Rack module. Units

should be installed in dry locations protected from extremes of

temperature and humidity.

C1-US, C1-EU, C1-AU OR C1-CH CARD CAGE RACKS

CAUTION: Although the units are hot-swappable and may be installed

without turning power off to the rack, ComNet recommends that

the power supply be turned off and that the rack power supply

is disconnected from any power source. Note: Remove electrical

connector before installing in card cage rack.

1. Make sure that the card is oriented right side up, and slide it into the

card guides in the rack until the edge connector at the back of the

card seats in the corresponding slot in the rack’s connector panel.

Seating may require thumb pressure on the top and bottom of the

card’s front panel.

CAUTION: Take care not to press on any of the LEDs.

2. Tighten the two thumb screws on the card until the front panel of the

card is seated against the front of the rack.

WARNING: Unit is to be used with a Listed Class 2 or LPS power supply.

FIGURE A

Dimensions are for a standard ComNet™ one slot module

.156 [3.96 mm]

.313 [7.95 mm]

IMPORTANT SAFEGUARDS:

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the equipment is not

compromised.

3 CORPORATE DRIVE | DANBURY, CT 06810 | USA

T: 203.796.5300 | F: 203.796.5303 | TECH SUPPORT: 1.888.678.9427 | INFO@COMNET.NET

8 TURNBERRY PARK ROAD | GILDERSOME | MORLEY | LEEDS, UK LS27 7LE

T: +44 (0)113 307 6400 | F: +44 (0)113 253 7462 | INFO-EUROPE@COMNET.NET

© 2012 Communications Ne tworks Cor poration. All Rights Reserved. “ComNet” and the “ComNet Logo” are registered trademark s of Communication Net works, LLC.

INS_FDX72_REV–

02/29/12

PAGE 6

Loading...

Loading...