Page 1

24987-A

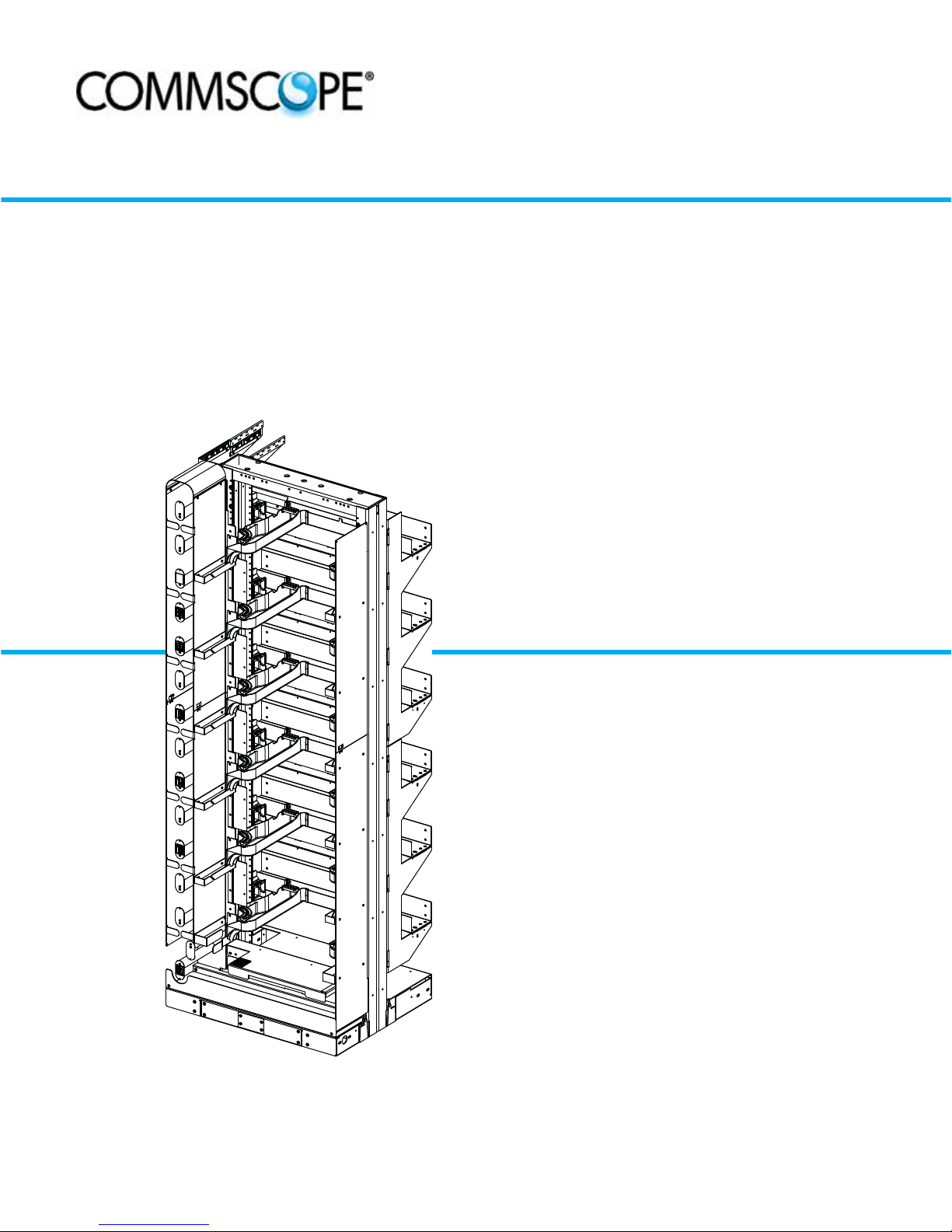

NG4access® Frame

Installation Manual (Raised Floor)

TECP-90-708

Issue 5, April 2017

300001764826 Rev B

www.commscope.com

Page 2

TECP-90-708 • Issue 5 • April 2017 • Preface

COPYRIGHT

© 2016, CommScope Inc.

All Rights Reserved

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 9/2012 Original.

2 12/2012 Added instructions for installing Raised Floor Cable Clamp Bracket Kit.

3 7/2013 Added instructions for installing the Fiber Optic Storage Panel (FOTSP) and the Auxiliary Cable Spool

4 July 2016 Reformatted for CommScope.

5 April 2017 Corrected Material ID on cover.

TRADEMARK INFORMATION

CommScope and CommScope (logo), and NG4access are trademarks.

Telcordia is a registered trademark of Telcordia Technologies, Inc.

GORE is a registered trademark of W. L. Gore & Associates, Inc.

Bracket Kit.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. CommScope reserves the right to change the contents without prior notice.

In no event shall CommScope be liable for any damages resulting from loss of data, loss of use, or loss of profits and

CommScope further disclaims any and all liability for indirect, incidental, special, consequential or other similar damages.

This disclaimer of liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting CommScope’s Technical Assistance Center at:

http://www.commscope.com/SupportCenter

Page ii

Page 3

TABLE OF CONTENTS

Content Page

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Admonishments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

List of Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

1 TOOLS AND MATERIALS REQUIRED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 FOOTPRINT OF FRAME AND FIBER OPTIC STORAGE PANEL (FOTSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 MOUNTING THE FRAME ON A RAISED FLOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 INSTALLING A FIBER OPTIC STORAGE PANEL (FOTSP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 INSTALLING A RAISED FLOOR CABLE BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 INSTALLING A SPOOL BRACKET ASSEMBLY (FOR FRAME WITH SPLICE CHASSIS). . . . . . . . . . . . . . . . . . . . . . . . . . 44

7 INSTALLING AUXILIARY CABLE SPOOLS (FOR FRAMES WITHOUT SPLICE CHASSIS) . . . . . . . . . . . . . . . . . . . . . . . . 46

8 GROUNDING THE FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9 SECURING TWO FRAMES TOGETHER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

TECP-90-708 • Issue 5 • April 2017 • Preface

© 2017, CommScope, Inc.

Page iii

Page 4

TECP-90-708 • Issue 5 • April 2017 • Preface

TABLE OF CONTENTS

Content Page

Blank

Page iv

© 2017, CommScope, Inc.

Page 5

ABOUT THIS MANUAL

This manual provides complete instructions for installing a NG4access frame on a raised floor.

Included are instructions for grounding the frame and joining two frames in a lineup.

RELATED PUBLICATIONS

Listed below are related manuals and their publication numbers. Copies of these publications

can be ordered by contacting the CommScope Technical Assistance Center at:

http://www.commscope.com/SupportCenter

Title/Description Publication Number

NG4access ODF Platform Application and Planning Manual 90-701

Contains an NG4access overview and information for planning a NG4access

application.

TECP-90-708 • Issue 5 • April 2017 • Preface

NG4access Frame Installation Manual: Concrete Floor 90-702

Provides pictorial instructions for installing an NG4access frame on a concrete

floor and grounding the frame.

NG4access ODF Platform Standard Chassis Installation Manual 90-703

Provides installation instructions for the NG4access standard chassis.

NG4access ODF Platform Splice Chassis and Splice Tray

Installation Manual 90-704

Provides installation instructions for the NG4access standard chassis.

NG4access ODF Platform Patch Cord Routing Guide 90-705

Provides pictorial guidelines for routing patch cords on a lineup consisting of

one or more NG4access frames. This manual consists of laminated cards that

hang on the front of the frame.

NG4access ODF Platform Rear Side Routing Guide 90-706

Provides pictorial guidelines for routing cables and installing cabled modules

on the rear side of a lineup consisting of one or more NG4access frames. This

manual consists of laminated cards that hang on the rear of the frame.

© 2017, CommScope, Inc.

Page v

Page 6

TECP-90-708 • Issue 5 • April 2017 • Preface

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optical adapters of the

adapter packs. Exposure to invisible laser radiation may result. An optical power meter should

be used to verify active fibers. A protective cap or hood MUST be immediately placed over any

radiating adapter or optical fiber connector to avoid the potential of dangerous amounts of

radiation exposure. This practice also prevents dirt particles from entering the adapter or

connector.

LIST OF ACRONYMS AND ABBREVIATIONS

The following acronyms are used in this manual:

FOT Fiber Optic Terminal

IFC Intra Facility Cable

OSP Outside Plant

Page vi

© 2017, CommScope, Inc.

Page 7

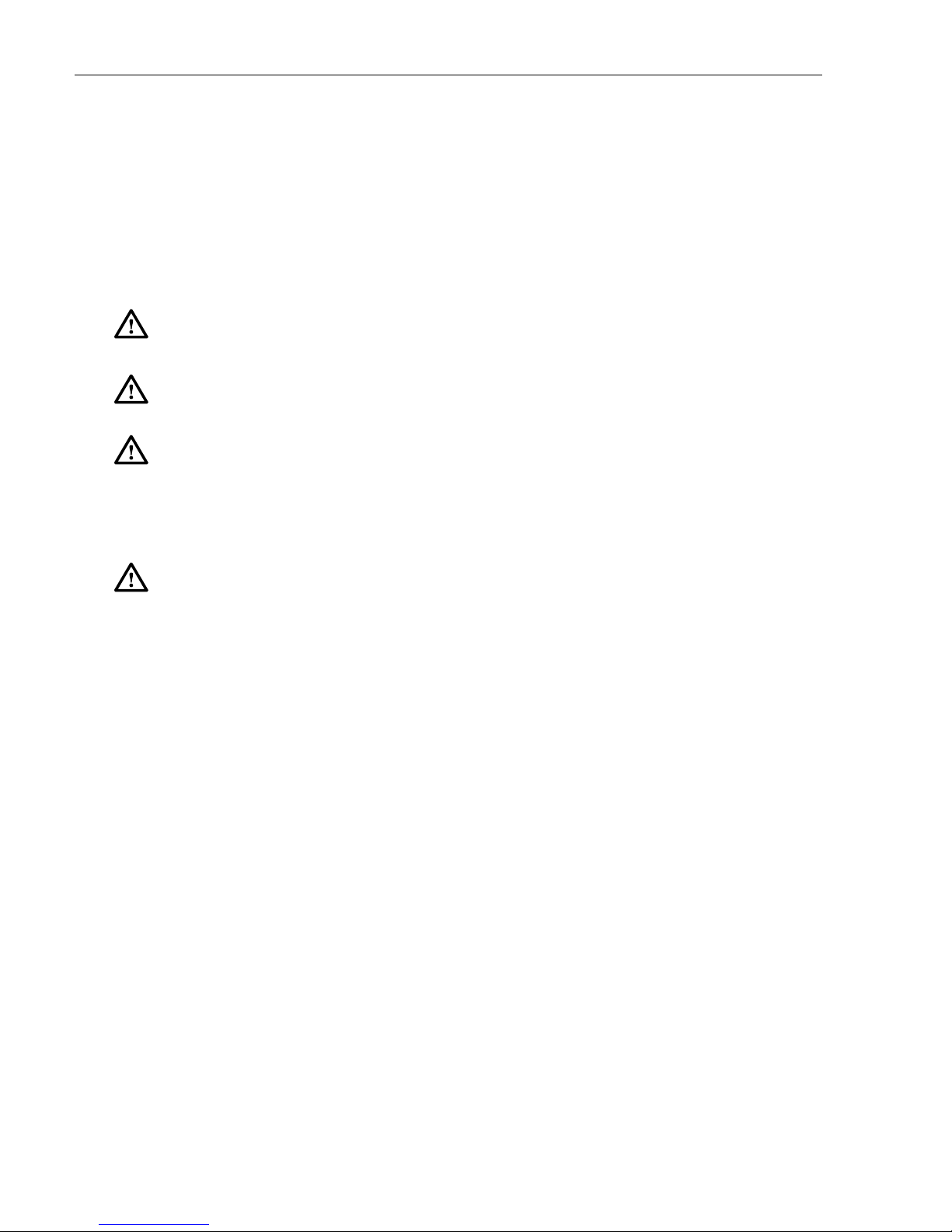

1 TOOLS AND MATERIALS REQUIRED

12494-B

12495-B

12496-B

cm

1

31

12825-a

12497-B

17721-A

18406-A

The tools and materials required for mounting the NG4access frame on a raised floor are

specified in Table 1 and Table 2.

TOOL PICTURE

Adjustable wrenches (2)

0.25 to 1 inch (8 to 25.4 mm)

Crow bar

Drill with metal and concrete drill bits

TECP-90-708 • Issue 5 • April 2017

Table 1. Tools Required

Ruler or tape measure

File

Torque wrench

Note: Capable of 60 ft.-lbs. (81 Nm)

Allen wrench (5/16-inch)

Note: Used for leveling frame

© 2017, CommScope, Inc.

Page 1

Page 8

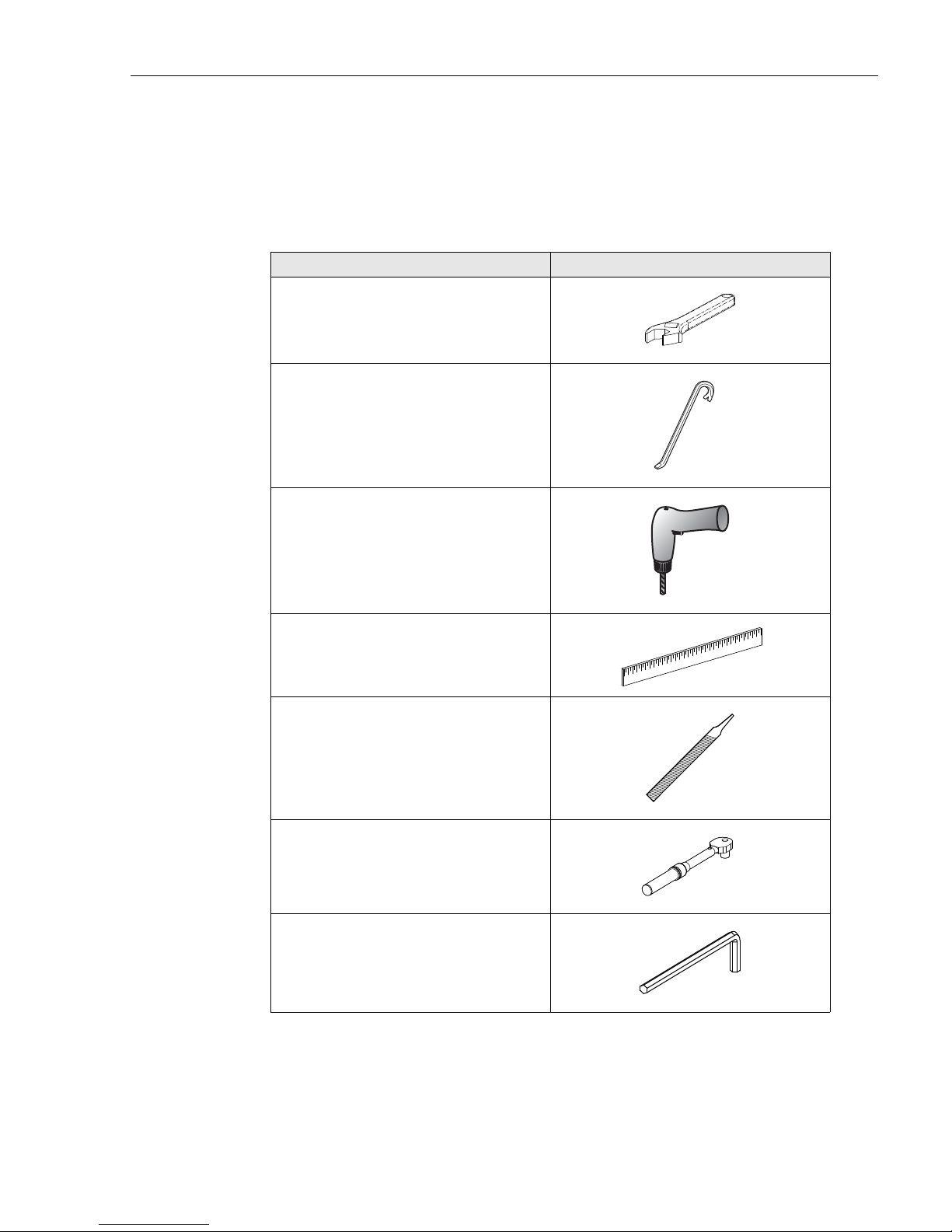

TECP-90-708 • Issue 5 • April 2017

12499-B

12500-B

12501-B

12502-B

12506-B

12504-B

12824-A

TOOL PICTURE

Hacksaw

Hammer

Jigsaw: with blades for cutting floor tile

and metal

Table 1. Tools Required, continued

Level

Set of combination open end/box wrenches

0.25 to 1 inch (8 to 25.4 mm)

Set of sockets

0.25 to 1 inch (8 to 25.4 mm)

Crimping tool

0.25 to 0.3 inches (6.35 to 7.62 mm)

Note: Used for grounding frame

Page 2

© 2017, CommScope, Inc.

Page 9

Table 1. Tools Required, continued

12503-B

12505-B

18413-A

18414-A

12498-B

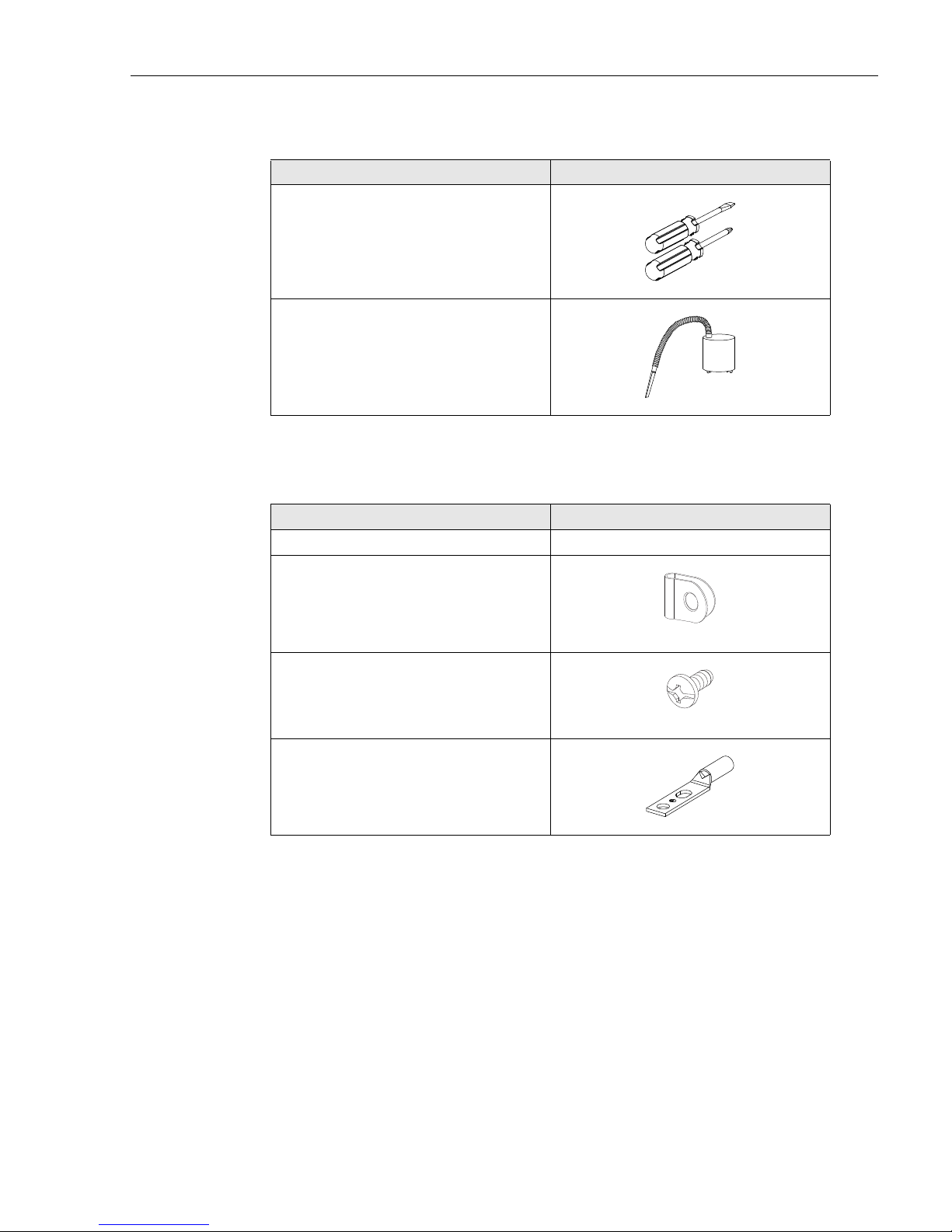

TOOL PICTURE

Flat tip and Phillip screwdrivers

(#1, #2, and #3)

Vacuum

Table 2. Ground Wire Kit Components (Accessory)

TECP-90-708 • Issue 5 • April 2017

ITEM DESCRIPTION/PICTURE

Ground cable (13 ft.) #6 AWG (4.1 mm) solid copper wire

Nylon cable clamps (8)

12-24 x 0.5 inch screws

2-hole copper compression lug (1) with

0.75-inch hole spacing.

Note: Accommodates #6 AWG wire

© 2017, CommScope, Inc.

Page 3

Page 10

TECP-90-708 • Issue 5 • April 2017

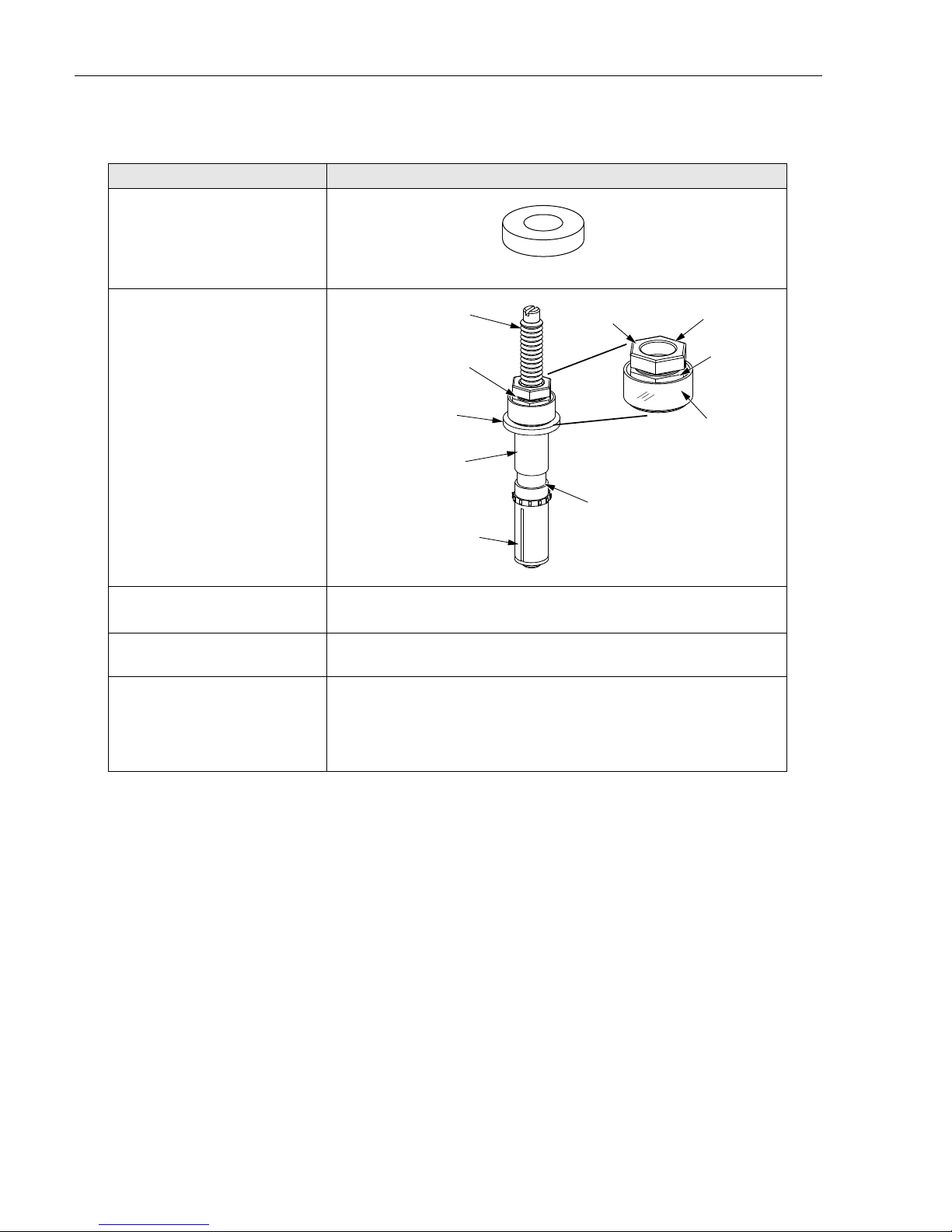

STUD

TORQUE LIMITING HEX NUT

METAL SLEEVE

NYLON SPACER

EXPANDABLE CONE

FLAT W ASHER

TOP FLANGE

(SHEARS OFF)

PLASTIC COVER

NOTE: ONE PIECE

TORQUE NUT

18008-B

ITEM PICTURE

Hold-down washer (4)

(provided with frame)

Concrete floor frame

installation kit

(four anchor bolts)

Table 3. Other Components Used

21899-A

Zone 2/Zone 4 Raised Floor

Mounting Kit

Raised Floor Cable Clamp

Bracket Kit (separately ordered)

Large Cable Clamp Kit

(separately ordered)

Refer to Table 4

This kit is required if cables will be routed into the frame from under the

floor. For more information, refer to Section 5 on Page 35

This kit is required, in addition to the Raised Floor Cable Clamp Bracket

Kit if large cables will be routed into the frame from under the floor.

Large cables are defined as having an Outside Diameter (OD) of 0.8 in.

(2.03 cm) up to 1.03 in. (2.61 cm). For more information, refer to

Section 5 on Page 35

Page 4

© 2017, CommScope, Inc.

Page 11

TECP-90-708 • Issue 5 • April 2017

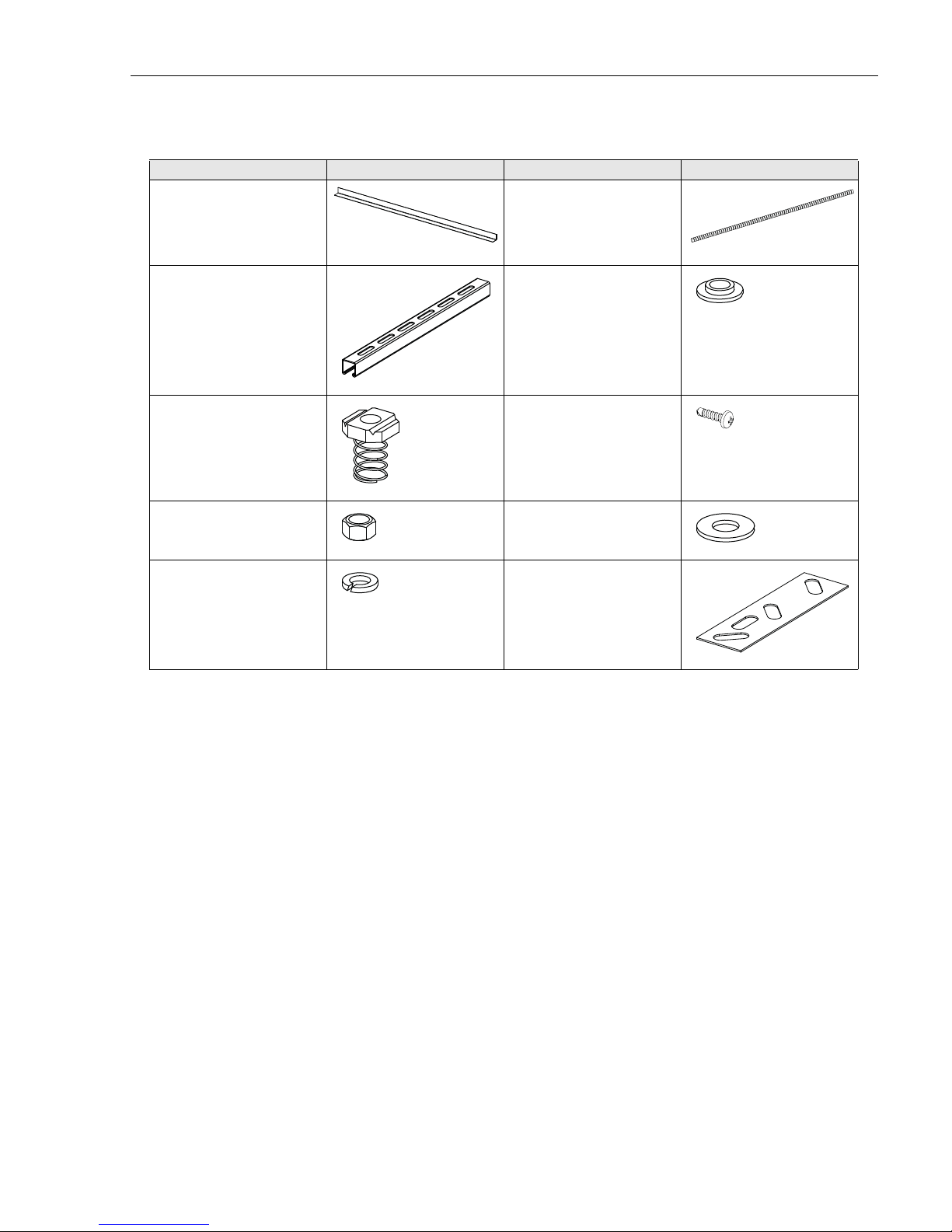

Table 4. Raised Floor Mounting Kit Components

ITEM PICTURE ITEM PICTURE

Edge protector (1) 72 in. Threaded rod (4) 5/8”-11

x 30” long

Unistrut

10 ft. long

Unistrut nut

with spring (4)

Hex nut heavy (12)

5/8” x 11

Split lock washer (12)

5/8”

Plastic shoulder washer

(4)

(Note: Not used)

Wood screw (16)

Flat washer (12) 5/8”

Hold down plate (2)

Note: Not used

© 2017, CommScope, Inc.

Page 5

Page 12

TECP-90-708 • Issue 5 • April 2017

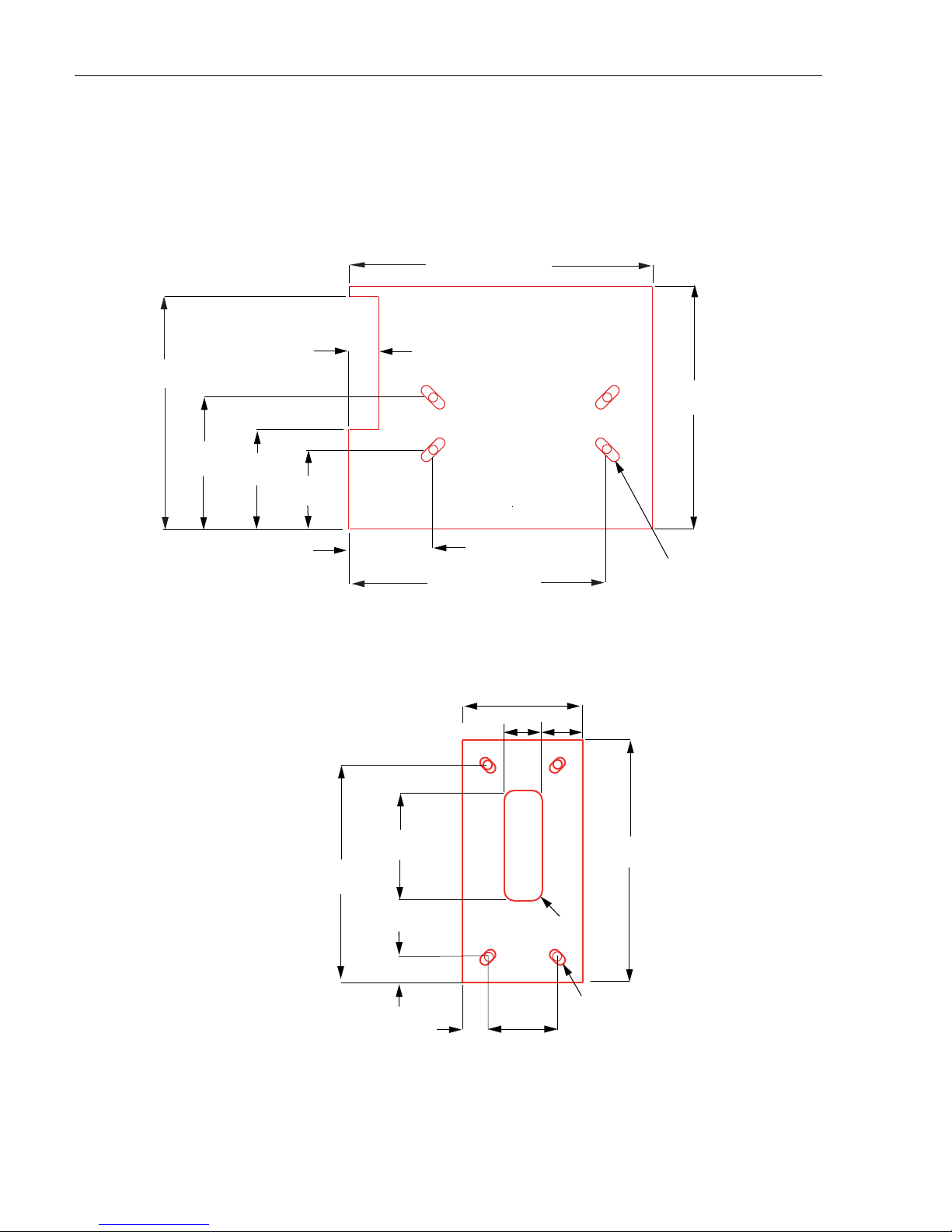

2 FOOTPRINT OF FRAME AND FIBER OPTIC STORAGE PANEL (FOTSP)

Figure 1 shows the frame footprint. Figure 2 shows the FOTSP footprint. The FOTSP is

installed adjacent to the frame on the left side of the frame looking from the front.

29.84 IN. (75.79 CM)

2-7/8 IN.

(7.30 CM)

22-

27/32 IN. (58.02 CM)

23.89 IN.

(60.68 CM)

13 IN.

(33.02 CM)

9-5/8 IN.

(23.45 CM)

13/16 IN.

7-

(19.84 CM)

FRONT

8-5/16 IN.

(21.11 CM)

25-1/2 IN. (64.77 CM)

Figure 1. Frame Footprint (Optional Template Shown)

11.88 IN. (

3.75 IN. (9.52 CM)

10.90 IN.

(27.69 CM)

18.98 IN.

(48.21 CM)

25162-A

1.0 IN. (2.54 CM) DIAMETER

(4) PLACES

30.17 CM)

4.0 IN. (10.16 CM)

23.98 IN.

(60.91 CM)

Page 6

© 2017, CommScope, Inc.

RADIUS 1.0 IN.

2.5 IN.

(6.35 CM)

FRONT

6.88 IN. (17.47 CM)

Figure 2. FOTSP Footprint

(2.54 CM)

SLOT 1.75 X 1.0 IN.

(4.44 X 2.54 CM)

25243-A

Page 13

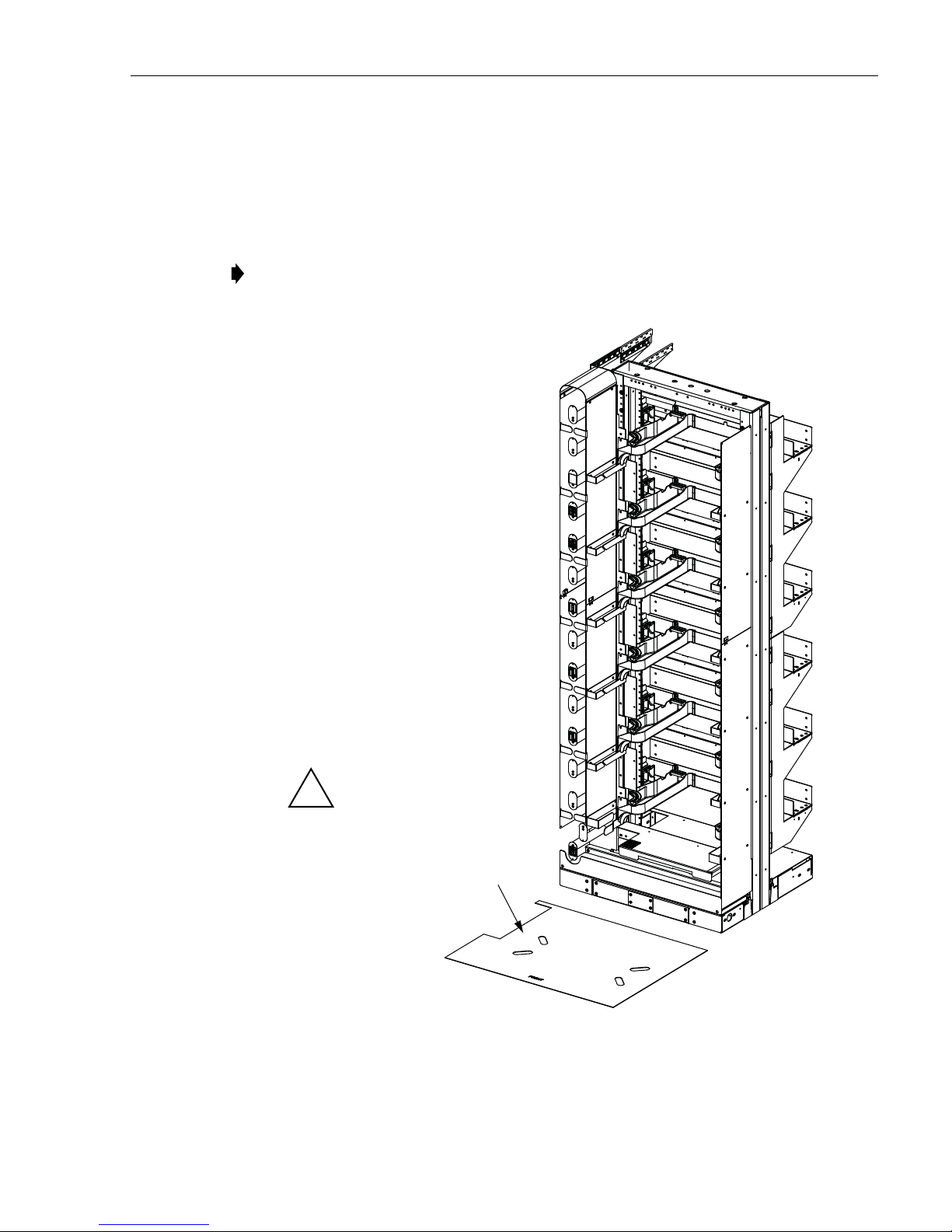

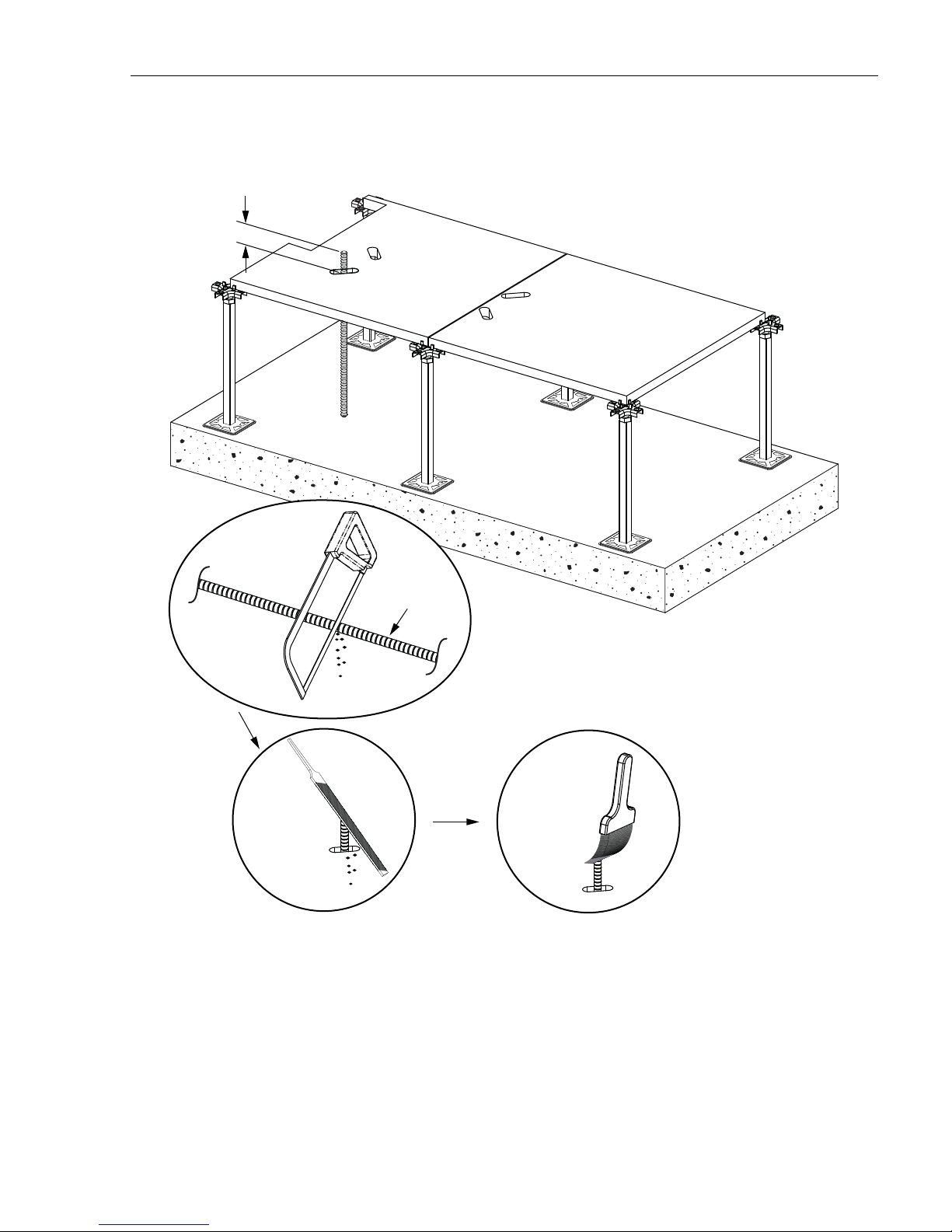

3 MOUNTING THE FRAME ON A RAISED FLOOR

To mount the frame on a raised floor, use the following procedure.

1. Unpack the frame.

2. Set out the frame and optional template/isolation pad as shown in Figure 3.

Note: Storage spools may loosen during shipment. Check storage spools for looseness.

Tighten spool cover screws if spools are loose.

TECP-90-708 • Issue 5 • April 2017

NOTE: TEMPLA TE/ISOLATION PAD

NOT REQUIRED FOR INSTALLATION

CAUTION: USE APPROPRIATE

EQUIPMENT TO LIFT RACK

!

OPTIONAL

TEMPLATE/ISOLATION PAD

(ORDERED SEPARATELY)

Figure 3. Setting Out Frame and Optional Template/Isolation Pad

25045-A

Page 7

© 2017, CommScope, Inc.

Page 14

TECP-90-708 • Issue 5 • April 2017

FRONT AISLE

(4-FEET

RECOMMENDED

MINIMUM)

REAR AISLE

(3-FEET

RECOMMENDED

MINIMUM)

25046-B

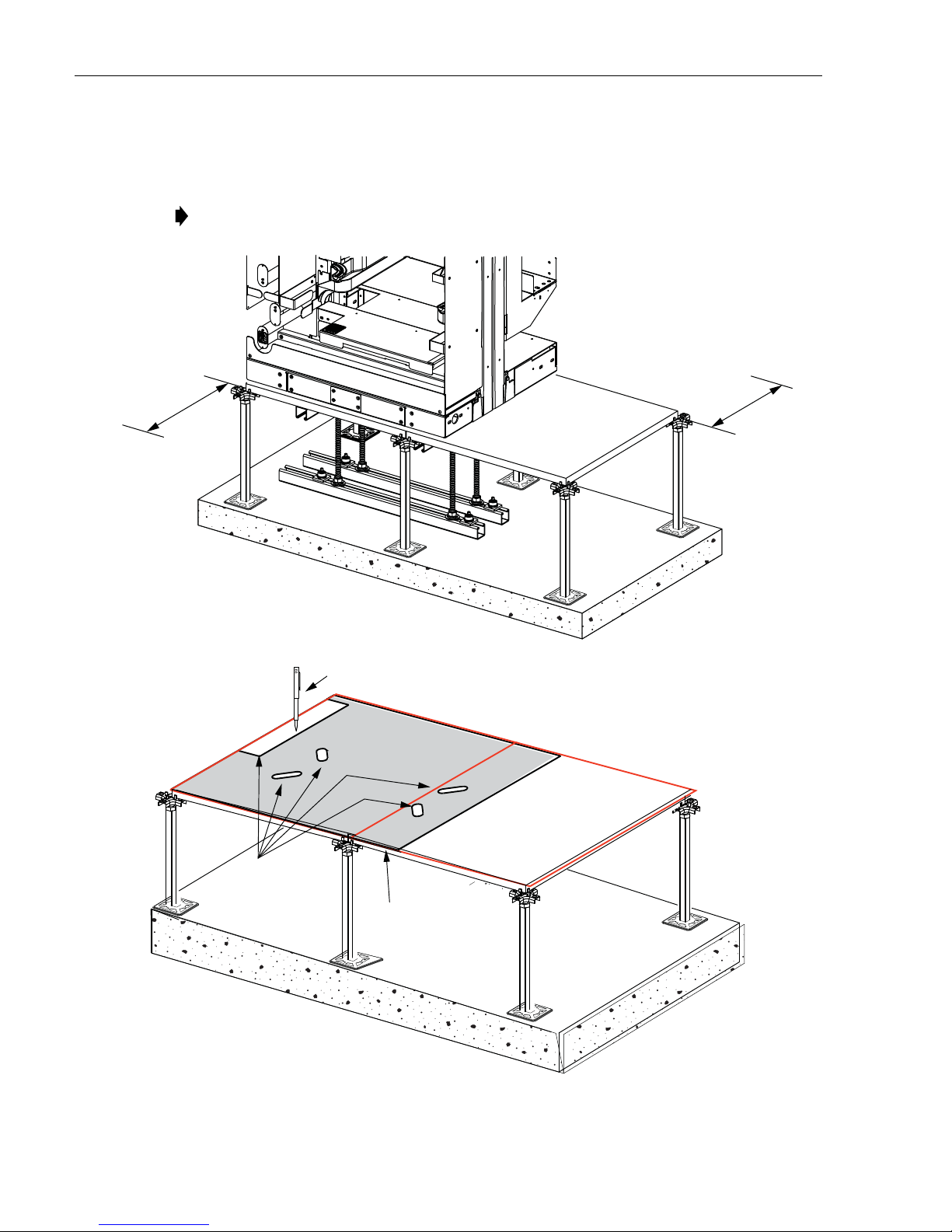

3. Determine the frame location taking note of the clearance requirements shown in Figure 4.

Place the optional template/isolation pad on the floor tiles and mark the tile as shown. If

installing without a template, refer to Section 2 on Page 6 for installation dimensions.

Note: If optional FOTSP is present, see Figure 5.

MARK THESE

LOCATIONS

PENCIL

ALIGN FRONT OF

TEMPLATE/ISOLATION PAD

WITH EDGE OF TILE

25271-A

Figure 4. Determining Frame Location

Page 8

© 2017, CommScope, Inc.

Page 15

TECP-90-708 • Issue 5 • April 2017

25270-A

MARK HOLES

AND CUTOUT

ON TEMPLATE

ALIGN FRONT OF

TEMPLATE/ISOLATION PAD

WITH EDGE OF TILE

PENCIL

FOTSP

LOCATION

FRONT

25268-A

EXAMPLE ONLY (OTHER ARRANGEMENTS ARE POSSIBLE)

FOTSP FOOTPRINT FRAME FOOTPRINT

MARK CUTOUT

FOR FOTSP

IF FLOOR ENTRY

WILL BE USED

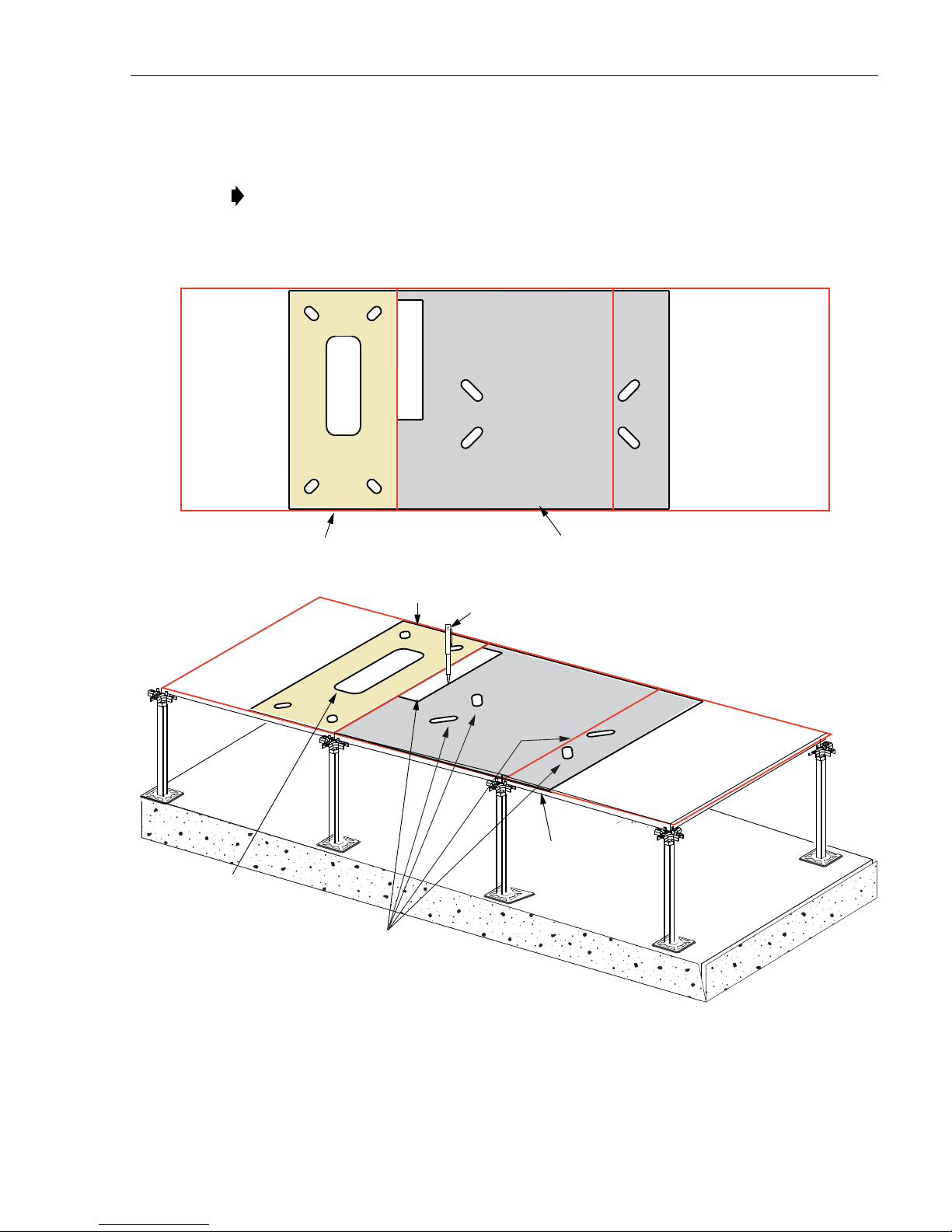

4. If FOTSP will be installed, also mark out and cut out a hole for the FOTSP to the left of

the frame template. Figure 5 shows an example.

Note: The optional FOTSP is only shown in this illustration in the frame installation

procedure. For the separate FOTSP installation procedure, refer to Section 4 on Page 30.

Figure 5. FOTSP and Frame Footprints on Floor Tiles

Page 9

© 2017, CommScope, Inc.

Page 16

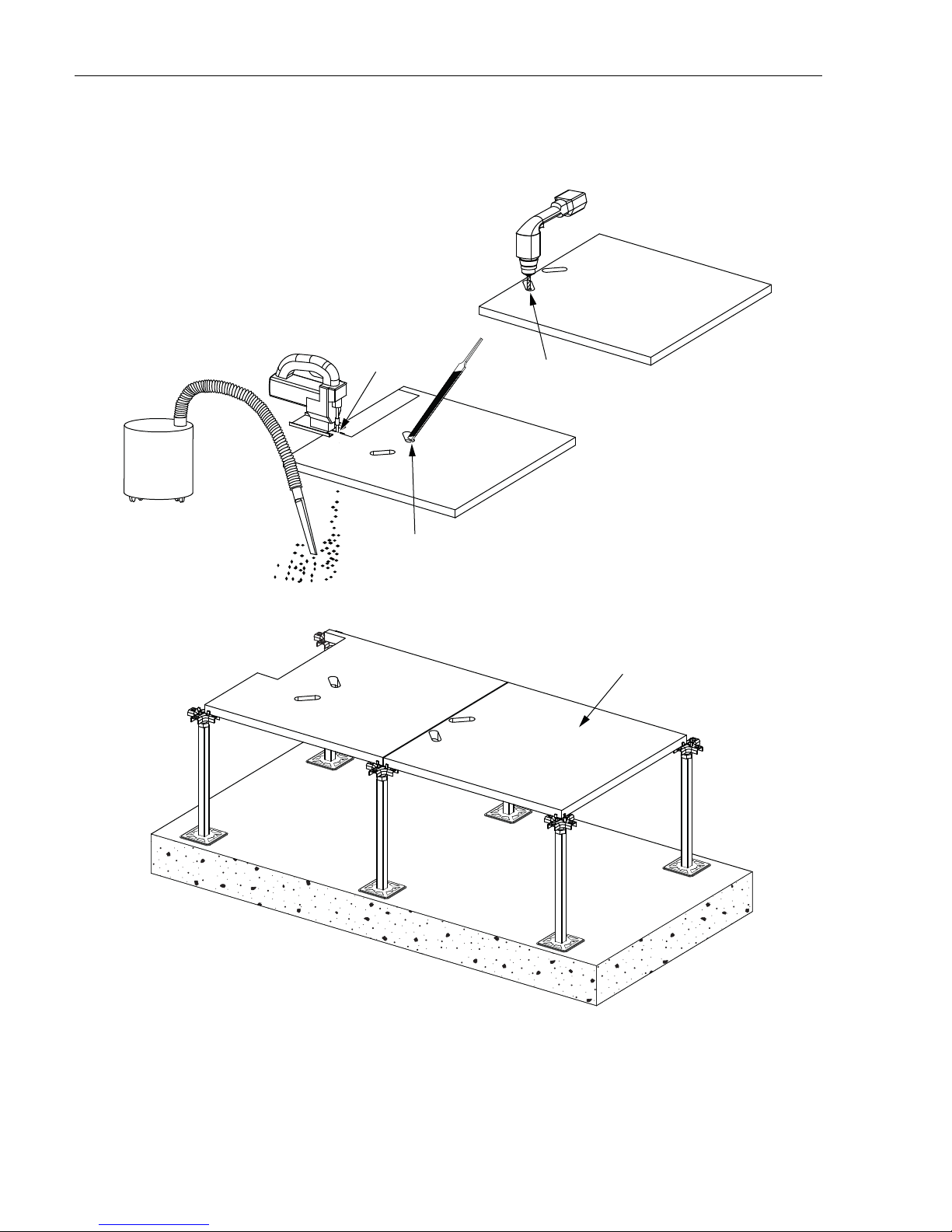

TECP-90-708 • Issue 5 • April 2017

DRILL

PILOT HOLES

VACUUM

AS REQUIRED

SET FLOOR TILES

ON PEDESTALS

25048-A

FILE

ALL EDGES

CUT

TILES

5. Remove and cut the tiles, file all edges, and set the floor tiles on the pedestals, as shown in

Figure 6.

Figure 6. Setting Floor Tiles on Pedestal

Page 10

© 2017, CommScope, Inc.

Page 17

FILE

ENDS

PAINT ENDS

(OPTIONAL)

NOTE: MEASURE FROM CONCRETE

TO 1-5/8 IN. (+/- 3/8 IN.) ABOVE FLOOR TILE

1-5/8 IN.

(+/- 3/8 IN.)

THREADED

ROD

25049-A

TECP-90-708 • Issue 5 • April 2017

6. Cut threaded rod to floor height +1-5/8in. (+/- 3/8 in.) (four places). Refer to Figure 7.

Figure 7. Cutting Threaded Rod

Page 11

© 2017, CommScope, Inc.

Page 18

TECP-90-708 • Issue 5 • April 2017

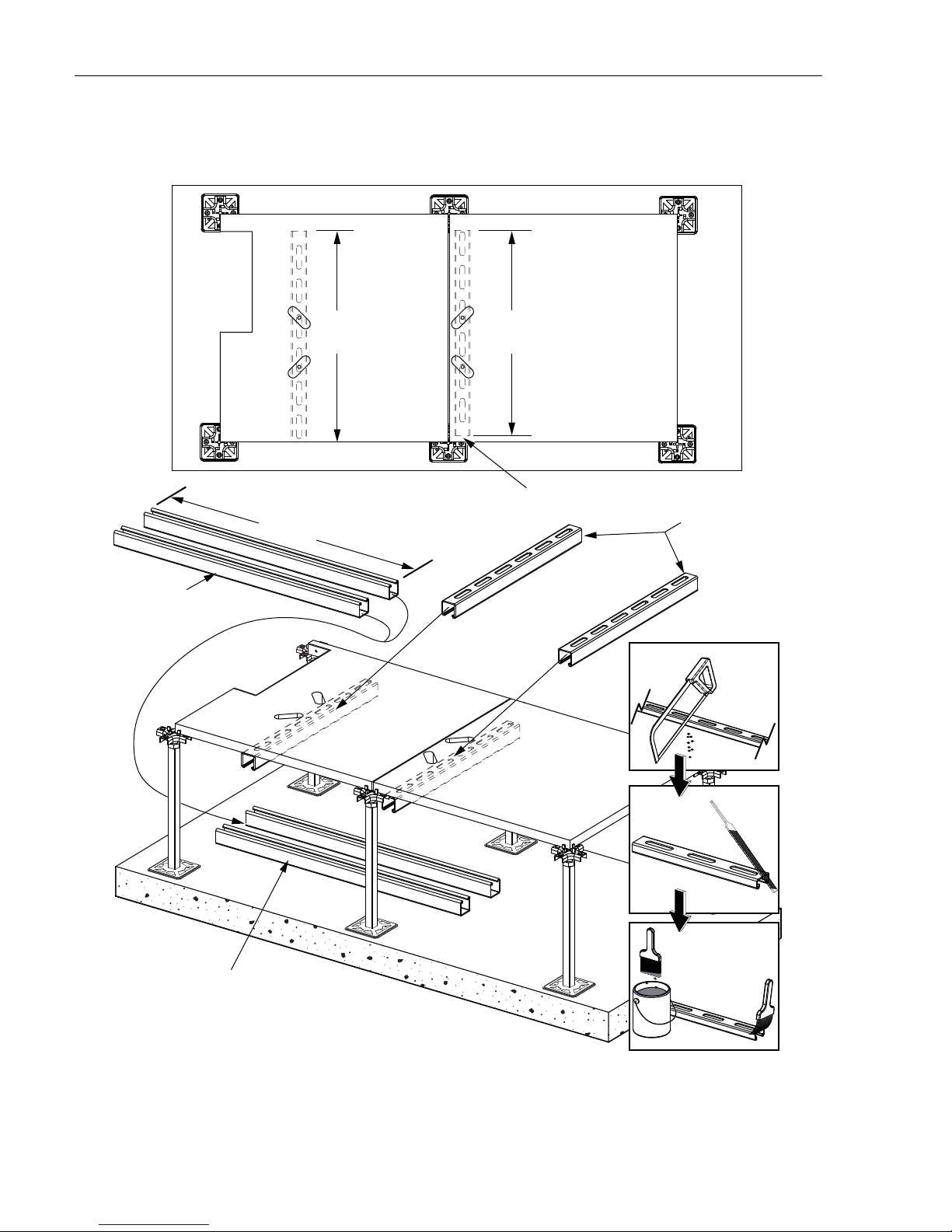

7. Cut the unistrut to the required length, as shown in Figure 8.

TOP VIEW

CUT TO REQUIRED LENGTH

29.8 IN.

(75.8 CM)

22.1 IN.

(38.4 CM)

21.4 IN.

(36.6 CM)

TOP-RIGHT UNISTRUT SHORTENED

TO ALLOW FOR TOP OF PEDESTAL

CUT TO REQUIRED

LENGTH

(SEE TOP VIEW)

CUT

NOTE: LOWER UNISTRUT CUT LENGTH

IS SHOWN FOR ONE FRAME INSTALLATON.

Page 12

© 2017, CommScope, Inc.

25050-A

Figure 8. Cutting Unistrut

FILE EDGES

PAINT FILED EDGES

(OPTIONAL)

E

N

V

O

I

N

S

-

C

O

R

O

R

P

A

T

I

N

Page 19

TECP-90-708 • Issue 5 • April 2017

8. Assemble the washer and hex nut onto the threaded rod and insert the threaded rod in the

floor tile. Plumb the threaded rods from front to back and mark concrete. Repeat these

steps using the same threaded rod for the three remaining slots. Refer to Figure 9.

PLUMB THREADED

ROD FROM FRONT

TO BACK

HEX NUT

WASHER

CENTER

THREADED

ROD IN SLOT

MAKE SURE THREADED R OD

DOES NOT TOUCH CONCRETE

SIDE VIEW

MARK CENTER

REPEAT STEPS USING SAME THREADED ROD

FOR REMAINING THREE SLOTS

25051 -A

Figure 9. Marking Concrete With Threaded Rod

Page 13

© 2017, CommScope, Inc.

Page 20

TECP-90-708 • Issue 5 • April 2017

9. Remove the threaded rod assembly and set the floor tiles aside. Use a ruler or straight edge

to draw lines on the concrete. Refer to Figure 10.

THREADED ROD

ASSEMBLY

SET FLOOR

TILES ASIDE

DRAW LINES

ON CONCRETE

Page 14

© 2017, CommScope, Inc.

25052-A

RULER OR

STRAIGHT EDGE

Figure 10. Marking Concrete

Page 21

10. Center unistruts over lines on concrete. Refer to Figure 11.

TOP VIEW

25053-A

CENTER UNISTRUT

ON LINE

TECP-90-708 • Issue 5 • April 2017

Figure 11. Centering Unistruts on Lines

© 2017, CommScope, Inc.

Page 15

Page 22

TECP-90-708 • Issue 5 • April 2017

11. Set the floor tiles on the pedestals. Install a spring nut in each unistrut. Assemble the 5/8inch hex nut, 5/8-inch lock washer, and 5/8-inch washer onto the threaded rod (12A).

Install the threaded rod assembly (12B) into the spring nut. Refer to Figure 12.

SPRING NUT INSTALLED,

SIDE VIEW

SLIDE SPRING NUT

INTO END OF UNISTRUT

THREADED ROD

5/8-INCH HEX NUT

5/8-INCH WASHER

SPRING NUT

INSTALLED

12A: ASSEMBLE 5/8-INCH HEX NUT, 5/8-INCH LOCK WASHER,

AND 5/8-INCH WASHER ONTO THREADED ROD

5/8-INCH LOCK WASHER

SPRING NUT

THREADED

ROD ASSEMBLY

UNISTRUT

LEAVE SPACE BETWEEN BOTTOM

OF THREADED ROD AND TOP, INSIDE

SURFACE OF UNISTRUT

Figure 12. Setting Floor Tiles on Pedestals

Page 16

© 2017, CommScope, Inc.

12B: INSTALL THREADED ROD ASSEMBLY

INTO SPRING NUT

25054-A

Page 23

TECP-90-708 • Issue 5 • April 2017

PLUMB THREADED R OD

FROM SIDE TO SIDE

25055-A

ANCHOR PLATE

X

X

X

X

UNISTRUT

THREADED ROD ASSEMBLY

AND SPRING NUT

MARK CONCRETE

(FOUR PLACES)

TOP VIEW

INSTALL REMAINING

THREADED ROD

ASSEMBLIES

12. Plumb the threaded rod assembly and mark anchor plate location on concrete. Install three

remaining threaded rod assemblies in the same manner. See Figure 13.

Figure 13. Installing Threaded Rod Assemblies

© 2017, CommScope, Inc.

Page 17

Page 24

TECP-90-708 • Issue 5 • April 2017

13. Set the floor tiles and unistrut assemblies aside and drill holes at the anchor bolt locations.

Refer to Figure 14.

VACUUM AS

REQUIRED

HOLE DIMENSIONS:

DIAMETER: 0.71-IN. (18MM)

DEPTH: 3-15/16-IN. (100MM)

DRILL HOLES (4)

Page 18

© 2017, CommScope, Inc.

25056-A

Figure 14. Drilling Holes

Page 25

TECP-90-708 • Issue 5 • April 2017

INSERT ANCHOR BOLT

ASSEMBLY INTO HOLE

ANCHOR BOLT ASSEMBLY

WASHER

TORQUE NUT

ANCHOR SLEEVE

THREADED ROD

25057-A

14. Thread the washer and torque nut onto the threaded rod of the an chor bolt. The washer

should touch the top of the anchor sleeve. Insert the anchor bolt assembly into the hole just

drilled. Using a hammer, tap the anchor bolt assembly into the hole until the washer

touches the concrete. Refer to Figure 15.

Figure 15. Setting Anchor Bolts

Page 19

Page 26

TECP-90-708 • Issue 5 • April 2017

15. Pre-torque the anchor bolts approximately 30 ft-lbs (41 Newton meters) (16A). Loosen the

torque nut several turns (16B). Then remove the torque nut and washer (16C). Refer to

Figure 16.

TORQUE WRENCH

16A: PRE-TORQUE ANCHOR BOLT

TO APPROXIMATELY 30 FT-LBS

(41N-m)

LOOSEN

TORQUE NUT

16-B: LOOSEN TORQUE NUT

Figure 16. Pre-torquing Anchor Bolts

25058-A-A

TORQUE NUT

WASHER

THREADED ROD

16-C: REMOVE TORQUE NUT

AND WASHER

Page 20

© 2017, CommScope, Inc.

Page 27

TECP-90-708 • Issue 5 • April 2017

25059-A

UNISTRUT ASSEMBLY CONSISTS OF A

UNISTRUT AND THREADED ROD ASSEMBLY (2)

ANCHOR BOLT THREADED ROD (4)

TORQUE NUT

FLAT W ASHER

ANCHOR PLATE

THREADED

ROD

17A: ASSEMBLE ANCHOR PLATE,

FLAT W ASHER, AND TORQUE NUT

ONTO THREADED ROD

TOP FLANGE

TORQUE NUT

TORQUE WRENCH

17B: TIGHTEN TORQUE NUT

UNTIL TOP FLANGE SHEARS OFF

66

70

68

60

62

64

0

FT-LB

17C: THE TORQUE NUT WILL BE

CORRECTLY SET AT 60 FT-LBS (81N-m)

16. Position the unistrut assemblies over the anchor bolt threaded rods. Assemble the anchor

plate, flat washer, and torque nut onto the threaded rod (17A). Tighten torque nut until top

flange shears off (four places) (17B). The torque nut will be correctly set at 60 ft-lbs (81

Newton meters) (17C). Refer to Figure 17.

Figure 17. Positioning Unistrut Assemblies

© 2017, CommScope, Inc.

Page 21

Page 28

TECP-90-708 • Issue 5 • April 2017

UNISTRUT

FLAT W ASHER 5/8-11-INCH

SPLIT LOCK

WASHER 5/8-INCH

HEX NUT 5/8-INCH

NOTE: ALLOW SPACE BETWEEN

UNISRUT AND FLOOR TILE TO MAKE SURE

FLOOR TILE IS NOT RAISED OFF PEDESTALS.

25060-A

FLOOR TILE

UNISTRUT

SPACE

SIDE VIEW

17. Assemble hex nuts, split lock washers, flat washers, unistruts, and floor tiles onto threaded

rods. Refer to Figure 18.

Figure 18. Placing Floor Tiles on Threaded Rods

Page 22

© 2017, CommScope, Inc.

Page 29

TECP-90-708 • Issue 5 • April 2017

18. Cut out edge protectors to the required length for the slots in the floor tile. Secure the edge

protectors to the floor tiles using self-drilling screws (provided). Refer to Figure 19.

SELF-DRILLING

SCREWS (PROVIDED)

CUT TO REQUIRED

LENGTH

DRILL PILOT HOLES

NOTE: EDGE PROTECTOR MAY

BE CUT TO FIT AROUND PEDESTAL

NOTE: INSTALL EDGE PROTECTOR ON ALL SIDES

OF CABLE ENTRANCES (RECOMMENDED)

25061-A

Figure 19. Installing Edge Protectors

Page 23

© 2017, CommScope, Inc.

Page 30

TECP-90-708 • Issue 5 • April 2017

19. Plumb threaded rod assemblies (4) and tighten hex nuts (4). Refer to Figure 20.

PLUMB THREADED

ROD ASSEMBLIES

FROM SIDE TO SIDE

TIGHTEN

HEX NUTS (4)

25062-A

Figure 20. Plumbing Threaded Rods

Page 24

© 2017, CommScope, Inc.

Page 31

TECP-90-708 • Issue 5 • April 2017

20. Hand tighten the hex nuts to raise unistruts to floor tile. Refer to Figure 21.

MAKE SURE FLOOR TILES ARE

!

NOT RAISED OFF PEDESTALS

25063-A

FLOOR TILE

UNISTRUT

(SHADED FOR CLARITY)

HAND TIGHTEN

HEX NUTS TO

RAISE UNISTRUTS

TO FLOOR TILE

Figure 21. Raising Unistruts to Floor Tile

Page 25

© 2017, CommScope, Inc.

Page 32

TECP-90-708 • Issue 5 • April 2017

FRONT

VIEW

MOUNTING SLOTS

(PARTIALLY SHOWN)

LOWER

TROUGH

BACK

LOWER

TROUGH

BASE

GUARD BOX

COVER

24995-A

REAR VIEW

MOUNTING SLOTS

(PARTIALLY SHOWN)

REAR COVER

25065-A

21. Remove the frame front and rear troughs to access mounting slots. Refer to Figure 22.

(Caution: Do not attempt to lift or move the frame without appropriate equipment.)

Page 26

© 2017, CommScope, Inc.

Figure 22. Removing Troughs

Page 33

22. Position the frame on the optional template/isolation pad and floor tile. Install hardware

SET SCREW

(FOUR PLACES)

SEE 23B, BELOW

TECP-90-708 • Issue 5 • April 2017

(four places). Do not fully tighten (23A). Use 5/16-inch allen wrench and adjust set screws

(4) to level rack. Refer to Figure 23.

ALIGN SLOTS IN RACK AND

TEMPLATE/ISOLATION PAD

WITH THREADED R ODS

OPTIONAL

TEMPLATE/ISOLATION PAD

(SHADED FOR CLARITY)

HEX NUT

5/8-11-INCH

SPLIT LOCK

WASHER 5/8-INCH

HOLDDOWN W ASHER

(PROVIDED WITH RACK)

THREADED ROD

23A: INSTALL HOLDDOWN WASHER,

SPLIT WASHER 5/8-INCH AND HEX NUT 5/8-11 INCH

Figure 23. Positioning Frame on Optional Template/Isolation Pad and Floor Tile

(DO NOT FULLY TIGHTEN)

25066-A

23B: USE 5/16-INCH ALLEN WRENCH

AND ADJUST SET SCREW TO

LEVEL RACK

Page 27

© 2017, CommScope, Inc.

Page 34

TECP-90-708 • Issue 5 • April 2017

TIGHTEN HEX NUTS UNTIL

SPLIT LOCK WASHER IS FLATTENED

DO NOT FULLY TIGHTEN

OR RAISE FLOOR TILES

SIDE VIEW

25067-A

NOTE: MAKE SURE RACK REMAINS LEVEL

!

23. Use wrench to tighten hex nuts under floor tile. Do not fully tighten. Refer to Figure 24.

Page 28

© 2017, CommScope, Inc.

Figure 24. Tightening Hex Nuts 1

Page 35

25068-A

TIGHTEN HEX NUTS (4)

UNDER FLOOR TILE

TIGHTEN HEX NUTS (4)

ABOVE FLOOR TILE

NOTE: MAKE SURE RACK REMAINS LEVEL

!

TECP-90-708 • Issue 5 • April 2017

24. Use wrench (5/8-inch) to tighten hex nuts above floor tile (four places). Then fully tighten

hex nuts under floor tile. Refer to Figure 25.

25. If cables will be routed into the frame from under the floor:

Figure 25. Tightening Hex Nuts 2

© 2017, CommScope, Inc.

Page 29

Page 36

TECP-90-708 • Issue 5 • April 2017

a. Install the Raised Floor Cable Clamp Bracket Kit (separately ordered). For

instructions on how to install the kit, refer to Section 5 on Page 35 .

b. If the cables from under the floor will be routed into a splice chassis, install a spool

bracket assembly. For instructions, refer to Section on Page 46.

26. Re-install front and rear trough as shown in Figure 26.

27. Ground the frame. Refer to Section 9 on Page 49.

FRONT

VIEW

LOWER

TROUGH

BACK

REAR

GUARD BOX

LOWER

TROUGH

GUARD BOX

COVER

BASE

25069-A

Figure 26. Re-installing Troughs

4 INSTALLING A FIBER OPTIC STORAGE PANEL (FOTSP)

A Fiber Optic Storage Panel (FOTSP), installed onto the left side of the NG4access frame as

looking from the front, provides storage space on the rear for Fiber Optic Terminal Equipment

patch cords. The FOTSP is 12 inches wide. For a view of the frame and FOTSP footprints, refer

to Section 2 on Page 6. Use the following procedure to install a FOTSP.

1. If the front trough covers, front guard box, and the rear guard box, are present on the

frame, remove them. Figure 26 above shows the same components, but being installed.

2. If cables will enter the FOTSP from under the floor, saw out a cable entry hole, referring to

Figure 2 on Page 6 for hole location and dimensions.

3. Unpack the FOTSP and set it up next to the frame, with the cross-frame troughs on the rear

side corresponding to the location of the cross-frame troughs on the frame.

Page 30

© 2017, CommScope, Inc.

Page 37

4. Remove the FOTSP front cover, referring to Figure 27.

25258-A

FOTSP

FRONT

COVER

25260-A

FOTSP

BACK

COVER

FOTSP

COVER

PLATE

TECP-90-708 • Issue 5 • April 2017

Figure 27. Removing FOTSP Front Cover

5. Remove the FOTSP back cover and cover plate (Figure 28).

Figure 28. Removing FOTSP Back Cover and Cover Plate

Page 31

© 2017, CommScope, Inc.

Page 38

TECP-90-708 • Issue 5 • April 2017

25257-A

TIE BRACKET

(2 PLACES)

TROUGH

TIE

(6 PLACES)

HOLE

COVER

EDGE

PROTECTOR

6. Secure the FOTSP to the NG4access frame by installing tie brackets in two places and

trough ties in six places as shown in Figure 29.

Note: Refer also to the detailed views in Figure 30 and Figure 31.

Figure 29. Installing Brackets

Page 32

© 2017, CommScope, Inc.

Page 39

TECP-90-708 • Issue 5 • April 2017

TOP CROSS-FRAME TROUGH

REAR VIEW

3RD-DOWN CROSS-FRAME TROUGH

TOP TIE

BRACKET

MID-FRAME

TIE BRACKET

25262-A

PLACE ONE

TROUGH TIE

ON BOTTOM

SIDE OF

EACH

JUNCTION

OF TROUGHS

3RD DOWN CROSS-FRAME TROUGH

REAR VIEW

Figure 31. Rear View With Frame Tilted to Show Bracke ts Under Trough

Figure 30. Rear View of Bracket Locations

25263-A

MID-FRAME TIE BRA CKET

© 2017, CommScope, Inc.

Page 33

Page 40

TECP-90-708 • Issue 5 • April 2017

25261-A

1/4-20 HEX BOLTS (2)

1/4 FLAT WASHER (2)

1/4 LOCK WASHER (2)

1/4-20 HEX NUT (2)

EDGE

PROTECTOR

REAR VIEW

(REAR TROUGH NO T

SHOWN FOR CLARITY)

NOTE: INSTALL SAME HARDWARE

IN ANALOGOUS LOCATION

ON FRONT OF FRAME AND FOTSP

7. To secure the bases of the frame and FOTSP together, install two hex bolts on the rear of

the frame as shown in Figure 32, then, as noted, install two hex bolts in the analogous

location on the front of the frame.

Page 34

© 2017, CommScope, Inc.

Figure 32. Bolting Together Frame and FOTSP Bases

Page 41

8. Install the edge protector on the FOTSP in the location shown in Figure 32.

9. Install the hole cover in the location shown in Figure 29 on Page 32.

10. Re-install the front and rear troughs, as shown in Figure 26 on Page 30.

11. Re-install FOTSP front and rear guard boxes (reverse of steps 3 and 4, and reverse of what

is shown in Figure 27 on Page 31 and Figure 28 on Page 31).

5 INSTALLING A RAISED FLOOR CABLE BRACKET

If cables will be brought into the frame from under the raised floor, a Raised Floor Standard

Cable Clamp Bracket (available from CommScope) must be installed on the rear side of the

frame in the bottom right corner.

The kit is designed for standard size cables, with an Outside Dia meter (OD) of up to 0.8 in.

(2.03 mm). If large cables are to be installed, with an OD in the range from 0.8 to 1.03 in. (2.03

to 26.16 mm), a large cable kit (NG4-ACCRFCLMP3) is also required.

This procedure covers both standard and large cables, and assumes that the installer has the kit

or kits required.

TECP-90-708 • Issue 5 • April 2017

Use the following procedure to install a raised floor cable clamp bracket.

1. Determine whether the cables to be installed are standard or large as defined above. Set

out the bracket plate (largest piece in the kit) and identify the hole pattern to be used for

mounting cables, referring to Figure 33 on Page 36. There are separate hole patterns for

large and standard cables.

© 2017, CommScope, Inc.

Page 35

Page 42

TECP-90-708 • Issue 5 • April 2017

25125-A

LARGE CABLE GROMMET PLACEMENT

STANDARD CABLE GROMMET PLACEMENT

ROW A

ROW B

ROW E

18-32 x 5/16 IN.

SCREWS

18-32 x 5/16 IN.

SCREWS

18-32 x 5/16 IN.

SCREW

18-32 x 5/16 IN.

SCREW

NOTE: DO NOT DRIVE THE SCREW HEADS TIGHT AGAINST THE BRACKET. ALLOW SUFFICIENT SPACE

BETWEEN THE SCREW HEADS AND BRACKET FOR THE CABLE CLAMPS TO BE HUNG ON THE SCREWS.

ROW F

Figure 33. Grommet Placement on Bracket

Page 36

© 2017, CommScope, Inc.

Page 43

TECP-90-708 • Issue 5 • April 2017

18-32 x 5/16 IN.

PANHEAD SCREW

(24 PLACES,

EACH SIDE; 48 TOTAL)

25127-A

NOTE: DO NOT DRIVE THE SCREW

HEADS TIGHT A GAINST THE

BRACKET. ALLOW SUFFICIENT SPACE

BETWEEN THE SCREW HEADS AND

BRACKET FOR THE CABLE CLAMPS

TO BE HUNG ON THE SCREWS.

18-32 x 5/16 IN.

PANHEAD SCREW

(12 PLACES, EACH SIDE;

24 TOT AL)

25128-A

NOTE: DO NOT DRIVE THE SCREW

HEADS TIGHT A GAINST THE

BRACKET. ALLOW SUFFICIENT SPACE

BETWEEN THE SCREW HEADS AND

BRACKET FOR THE CABLE CLAMPS

TO BE HUNG ON THE SCREWS.

2. Install 8-32 x 5/16 inch pan head screws as shown in Figure 33, Figure 34, and Figure 35.

Leave enough space between the screw heads and bracket for the cable clamps to be hung

on the screws in a later step.

Figure 34. Standard Cable Screw Placement

Figure 35. Large Cable Screw Placement

© 2017, CommScope, Inc.

Page 37

Page 44

TECP-90-708 • Issue 5 • April 2017

25168-A

REAR VIEW

OF FRAME

3. If the frame has a splice chassis:

a. Remove the splice chassis cover (if present) from the bottom rear of the NG4access

frame, as shown in Figure 36. To do this, remove the two #8 pan head screws and two

star washers securing the cover to the frame. Set aside these items for re-installing the

cover later.

REAR VIEW

OF FRAME

25137-A

Figure 36. Removing Front Plate from Frame

b. Fully slide out the splice chassis (if present), as shown in Figure 37.

Page 38

© 2017, CommScope, Inc.

Figure 37. Sliding Out the Splice Chassis

Page 45

TECP-90-708 • Issue 5 • April 2017

4. If the frame does not have a splice chassis, remove the cover shown in Figure 38.

REAR VIEW

OF FRAME

25161-A

Figure 38. Removing Rear Cover on a Non-Splice Frame

5. Place the cable bracket into the cable entry hole, and position the holes in the bracket on

the threaded studs, as shown in Figure 39. Install a #10 washer and #10 nut on each

threaded stud. Tighten to 16 inch lbs. (1.8 Newton meters).

Note: This illustration shows a frame without a splice chassis.

© 2017, CommScope, Inc.

Page 39

Page 46

TECP-90-708 • Issue 5 • April 2017

POSITION BRACKET ON

THREADED STUD.

INSTALL #10 WASHER

AND #10 NUT

(TWO PLACES).

TIGHTEN TO 16 INCH-LBS.

(1.8 NEWTON METERS)

25171-A

6. Route the cables to be installed through the entry hole, taking care to position each cable

on the correct side of the raised floor cable breakout per the cable clamp locations shown

in Figure 33 on Page 36.

Note: The Row locations shown in this same figure (Figure 33 on Page 36) will also be

used to figure out the DIM ‘A” values when breaking out the cables in the next step.

7. Prepare each cable as follows, referring to Figure 40:

a. Pull the cable up through the hole.

b. If the cable being installed is an NG4access cable terminated with one or more cabled

module(s), obtain the appropriate DIM ‘A’ length from Table 5 based on where the

cable clamp will be installed on the bracket, measure out this length from the factory

breakout on the cable, and mark the cable at this location as shown in Figure 40. This

is where the cable clamp should be placed on the cable.

Page 40

© 2017, CommScope, Inc.

Figure 39. Installing Bracket in Frame

Page 47

TECP-90-708 • Issue 5 • April 2017

25140-A

OUTER CABLE JACKET

BREAKOUT

DIM ‘A’

CABLE

CLAMP

STANDARD LENGTH

25163-A

OUTER CABLE JACKET

BREAKOUT

DIM ‘A’

CABLE

CLAMP

210 IN. (533.4 CM)

Note: There is no need for further breakout as all NG4acces s cables with cabled modules

are of one standard length.

Table 5. Row Position vs. DIM ‘A’

CABLE SIZE

ROW

POSITION* DI M ‘A’

Standard A 3-1/16 in. (80.96 mm)

Standard B 4-11/16 in. (119.06 mm)

Standard C 5-7/16 in (138.11 mm)

Standard D 7-3/32 in. (180.18 mm)

Large E 3-7/8 in. (98.42 mm)

Large F 6-5/16 (160.34 mm)

* per Figure 33 on Page 36

Figure 40. Cabled Module Assembly Cable Clamp Position and Breakout

c. If the cable being installed is designated for the splice chassis, obtain the appropriate

DIM ‘A’ length from Table 5 based on where the cable clamp will be installed on the

bracket, and measure an additional length of 210 in. (533.4 cm), as shown in

Figure 41. This is where the cable clamp should be placed on the cable. For cable

routing instructions, refer to NG4access ODF Platform Splice Chassis and Splice Tray

User Manual (TECP-90-704).

8. If the cable diameter is 0.8 in (2.0 cm) or less, assemble the “standard” cable clamp at the

cable clamp position (see Figure 42). There are different sizes of grommets, measured by

their inside diameters of 0.4, 0.5, 0.6, and 0.7 in. (1.0, 1.27, 1.52, and 1.78 cm). Select the

grommet with an inside diameter that is one size smaller than the outside diameter of the

cable. After assembling the components on the mounting screws, tighten the screws until

the yokes make contact, then tighten the screws four additional revolutions.

Figure 41. Splice Cable Clamp Position and Breakout

© 2017, CommScope, Inc.

Page 41

Page 48

TECP-90-708 • Issue 5 • April 2017

MOUNTING

SCREWS

(6-32 x 1.75 IN.)

BACK

PLATE

RUBBER

YOKE

25136-A

GROMMET

COVER

Figure 42. Standard Cable Clamp Exploded View

9. If the cable diameter is greater than 0.8 in (2.03 cm) and less than 1-1/32 inch (2.62 cm),

assemble the “large” cable clamp at the cable clamp position (see Figure 43). There are

different sizes of grommets, measured by their inside diameters of 0.8, 0.9, and 1.0 in.

(2.03, 2.29, and 2.54 cm). Select the grommet with an inside diameter that is one size

smaller than the outside diameter of the cable. After assembling the components on the

mounting screws, tighten the screws until the yokes make contact.

Page 42

© 2017, CommScope, Inc.

MOUNTING

SCREWS

(10-32 x 2.00 IN.)

BACK

PLATE

RUBBER

YOKE

25135-A

GROMMET

COVER

LARGE

Figure 43. Large Cable Clamp Exploded View

Page 49

TECP-90-708 • Issue 5 • April 2017

25139-A

CABLE BRACKET

MOUNTING

SCREWS

HANGING

SLOT

CABLE

CLAMP

NOTE: START HANGING CABLE CLAMPS AT

THE BACK OF THE BRACKET, WORK TO THE

REAR OF THE FRAME. LAST FOUR CLAMPS

MAY NEED TO BE INSTALLED BELOW THE

RAISED FLOOR.

REAR OF

FRAME

25141-A

ROW C

ROW D

ROW F

EXAMPLES OF STANDARD

CLAMP POSITIONS

EXAMPLES OF LARGE

CLAMP POSITIONS

Note: Do not continue to tighten as instructed for the standard cable clamp in Step 8.

Note: If large cables are being installed, the last four cable clamps may need to be

assembled on the cable below the raised floor.

10. Beginning at the back of the cable clamp bracket (in the middle of the frame), hang the

cable clamps by positioning the hanging slots on the mounting screws, as shown in

Figure 44. Be sure to position the clamps on th e correct mounting screws as indicated in

Figure 45. Work from the back of the bracket towards the rear of the frame. After hanging

a cable clamp on the mounting screws, tighten the mounting screws until secure.

Figure 44. Hanging Cable Clamps on Bracket

Figure 45. Correct Placement of Cable Clamps

© 2017, CommScope, Inc.

Page 43

Page 50

TECP-90-708 • Issue 5 • April 2017

25134-A

INSTALLED

CABLES

AND CLAMPS

PROTECTION

PLATE

11. If the frame does not have a splice chassis, re-install the cover for non-splice applications

(removed in Step 4 on Page 39).

Note: See TECP-90-713 for instructions on installing auxiliary cable spools for use with

NG4access cabled module assemblies routed into the frame from the raised floor bracket.

6 INSTALLING A SPOOL BRACKET ASSEMBLY (FOR FRAME WITH SPLICE CHASSIS)

If the frame on which the bracket was just installed has a splice chassis, the Spool Bracket

Assembly (provided with the Raised Floor Standard Cable Clamp Bracket Kit) must also be

installed.

Use the following procedure.

1. Install the protection plate (second largest piece in the Raised Floor Standard Cable Clamp

Bracket Kit) in the location shown in Figure 46. Secure the plate using the mounting

screws provided. Torque to 16 in.-lbs. (1.8 Newton meters).

Page 44

© 2017, CommScope, Inc.

Figure 46. Installing Bracket in Frame

Page 51

TECP-90-708 • Issue 5 • April 2017

25170-A

REAR VIEW

OF FRAME

NOTE:

FOR CLARITY

SOME SHEET METAL

REMOVED FROM FRAME

REMOVE

VERTICAL CABLE

GUIDE

REMOVE

AND

DISCARD

SCREW

AND

WASHER

2. Remove and discard #12 washer and screw securing vertical cable guide next to the

bottom chassis, as shown in Figure 47. Discard screw, washer, and cable guide.

Figure 47. Removing Vertical Cable Guide

3. Locate the spool bracket assembly that came with the Standard Cable Bracket Kit, and

install the bracket in the location from which the vertical cable guide was just removed as

shown in Figure 48. Install the two screws and washers provided using the hole from

which the standard bracket screw was just removed and the hole above it. Torque to 18

inch-pounds (2.03 Newton meters).

SPOOL

BRACKET

ASSEMBLY

NOTE:

FOR CLARITY

SOME SHEET METAL

REMOVED FROM FRAME

REAR VIEW

OF FRAME

INSTALL TW O EACH

MOUNTING SCREWS

AND LOCK WASHERS

(#12 PANHEAD).

TIGTHEN TO 18 INCH-LBS.

(2.03 NEWTON METERS)

25143-A

Figure 48. Installing Spool Bracket

Page 45

© 2017, CommScope, Inc.

Page 52

TECP-90-708 • Issue 5 • April 2017

25144-A

CABLE ROUTED INTO AREA

BELOW SPLICE CHASSIS

BACK

PLATE

REAR VIEW

(SPLICE

CHASSIS

REMOVED)

Note: When routing a cable from the cable clamp bracket to the splice chassis, bring the

cable up in front of the spool and loop the cable back and over the spool then down into

the area below the splice chassis as shown in Figure 49.

Figure 49. Routing Cables On Spool Bracket

Note: For instructions on routing the cables into the splice chassis and splice chips, refer

to NG4access ODF Platform Splice Chassis and Splice Tray User Manual (TECP-90-

704). This procedure only covers the spool bracket.

4. Slide the splice chassis back into the frame.

5. Re-install the front plate removed in Step 3 on Page 38.

7 INSTALLING AUXILIARY CABLE SPOOLS (FOR FRAMES WITHOUT SPLICE CHASSIS)

If the frame on which the bracket was just installed does not have a splice chassis (cables will be

routed to the universal chassis), auxiliary cable spool brackets (separately ordered) must also be

installed. The purpose of these spools is to provide a means for looping the cables over before

they are routed into the universal chassis. One kit is required for each universal chassis on the

right rear side only. Before the kit can be installed, the vertical cable guide in that location must

be removed.

Page 46

© 2017, CommScope, Inc.

Page 53

TECP-90-708 • Issue 5 • April 2017

25240-A

25241-A

Use the following procedure.

1. On the rear side of the frame, remove the vertical cable guide by removing one #12 screw

and washer holding the bracket in place. Set aside the screw and washer for use in

installing the new bracket. Refer to Figure 50.

Figure 50. Removing the Vertical Cable Guide

2. Install the auxiliary cable spool bracket in the location from which the vertical cable guide

was just removed. Refer to Figure 51 and Figure 52.

Note: Top chassis mounting holes are different than for other chassis in frame. Mount as

shown in Figure 52.

Figure 51. Installing the Auxiliary Cable Spool Bracket

© 2017, CommScope, Inc.

Page 47

Page 54

TECP-90-708 • Issue 5 • April 2017

25242-A

MOUNTING

HOLES

2.78 IN.

(7.06 CM)

1.81 IN.

(4.60 CM)

TOP CHASSIS

ON FRAME

ALL OTHER

CHASSIS

BOTTOM

HOLE

MOUNTING

UPPER

HOLE

MOUNTING

Figure 52. Rear View of Bracket Locations (Top Two Chassis)

8 GROUNDING THE FRAME

Standard grounding is accomplished by connecting a compression lug to a grounding point on

the top member of the frame, as shown in Figure 53.

Any 2-hole location with the correct hole spacing may be used. Use a 2-hole #10 compression

lug with 3/4 inch hole (1.905 cm) spacing.

Scrape the paint to expose bare metal and apply deoxidant in the grounding location. For a

grounding wire, use only 6 AWG or thicker copper wire.

Page 48

© 2017, CommScope, Inc.

Page 55

TECP-90-708 • Issue 5 • April 2017

TO OFFICE

GROUND

GROUND

LUG

25082-A

9 SECURING TWO FRAMES TOGETHER

When a NG4access frame is installed adjacent to an existing NG4access frame, the frames must

be secured together. This is done using the following items shipped with the frame: junction

plates (6); rear splice brackets (4); and associated hardware.

Use the following procedure:

1. Position yourself on rear side of the two frames. Locate the place where the two top

horizontal troughs interface with one another. Install a junction plate spanning the two

troughs on the bottom side (Figure 54). Secure using four 10x32 flathead screws.

Figure 53. Grounding the Frame

Page 49

© 2017, CommScope, Inc.

Page 56

TECP-90-708 • Issue 5 • April 2017

BOTTOM

VIEW

10 x 32

FLATHEAD

SCREWS

JUNCTION

PLATE

JUNCTION

PLATE

REAR

TROUGH

REAR

TROUGH

25105-A

Figure 54. Installing Junction Plates (Six Places)

2. Continue down the frames installing junction plates in a like manner for each of the

remaining five levels of rear horizontal trough.

3. Install rear splice brackets. There are two sets of two brackets installed in the two locations

shown in Figure 55.

Page 50

© 2017, CommScope, Inc.

Page 57

REAR VIEW

REAR SPLICE

BRACKETS

INSERT REAR SPLICE BRACKET INTO

CABLE TROUGH SLOT (2 PLACES)

SPLICE BRACKET LOCATIONS (2)

SHOWN IN GRAY FOR CLARITY

12-24 SCREWS (6)

25070-A

NOTE: SPLICE BRACKETS

PROVIDED WITH RACK

TECP-90-708 • Issue 5 • April 2017

Figure 55. Installing Rear Splice Brackets

Page 51

© 2017, CommScope, Inc.

Page 58

TECP-90-708 • Issue 5 • April 2017

10 CUSTOMER INFORMAT ION AND ASSISTANCE

• To find out more about CommScope® products, visit the web at www.commscope.com/

• For technical assistance, customer service, or to report any missing/damaged parts, visit

http://www.commscope.com/SupportCenter

Page 52

Loading...

Loading...