Cominox SteriClave 18-24, SterilClave 18-24 User and maintenance manual

USE and MAINTENANCE MANUAL

-Steam sterilizer-

FOREWORD

This manual must be considered an integral part of the sterilizer, and must always be

available to users. The manual must always accompany the sterilizer, even if it is sold to

another user.

All operators are responsible for reading this manual and for strictly complying with the

instructions and information it provides. COMINOX is not liable for any damage to people,

things, or the sterilizer itself in the event that the operator fails to comply with the

conditions described in the manual.

These instructions are confidential and the customer may not disclose any information to

third parties. Further, this documentation and its attachments may not be tampered with

or modified, copied, or ceded to third parties without authorization from COMINOX.

2

Table of contents

TABLE OF CONTENTS

TABLE OF CONTENTS........................................................................................................................ 3

Reference index .............................................................................................................................. 6

Graphic representation of references Mod. 18 ......................................................................... 7

Graphic representation of references Mod. 24 ......................................................................... 8

INTRODUCTION................................................................................................................................ 9

GENERAL SUPPLY CONDITIONS.......................................................................................................... 9

PURPOSE OF THE DOCUMENT .......................................................................................................... 10

EQUIPMENT.......................................................................................................................................... 10

OPERATING USE .................................................................................................................................. 11

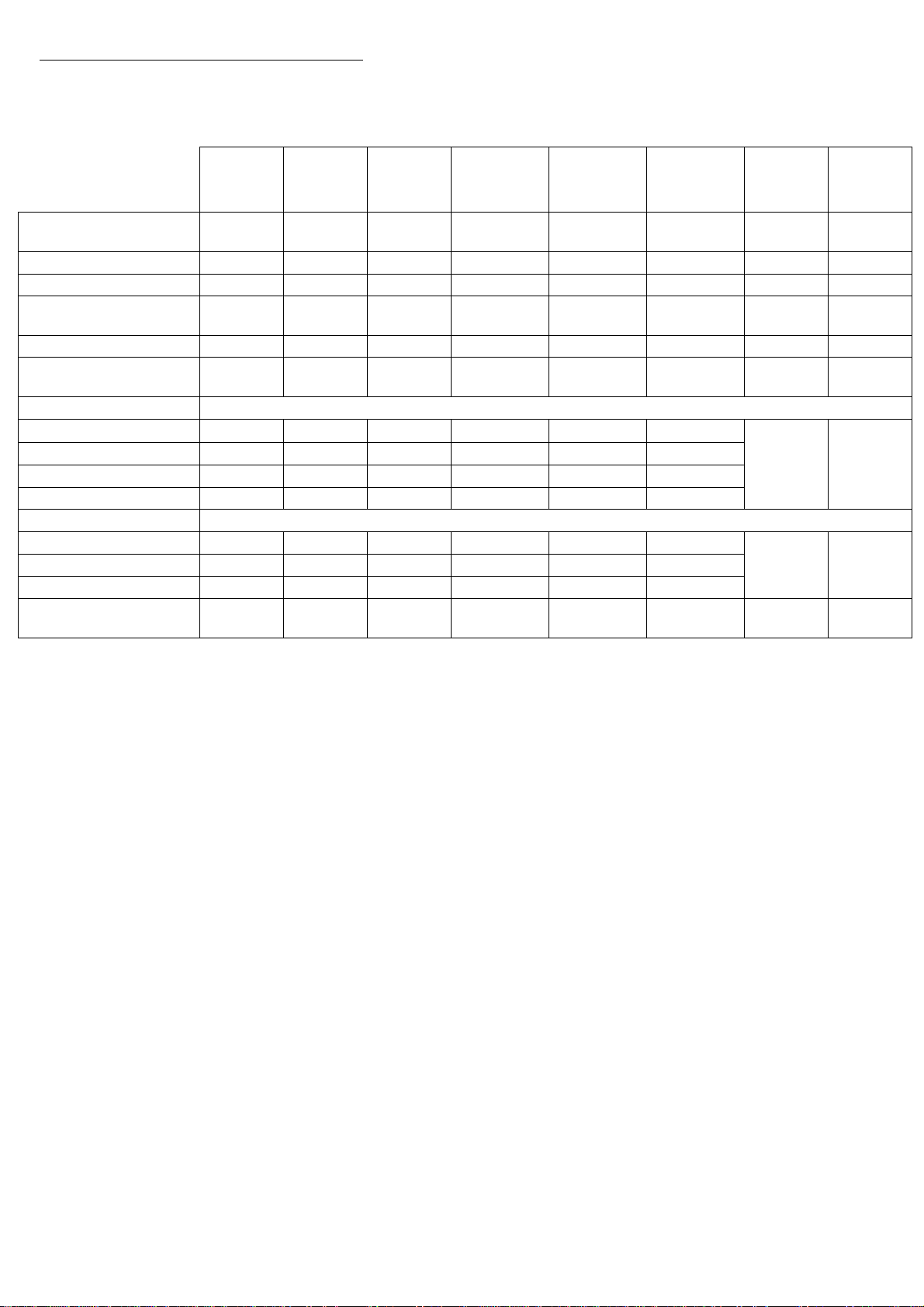

Table of cycles/sterilizable material 18B - 18BHD ..................................................................... 12

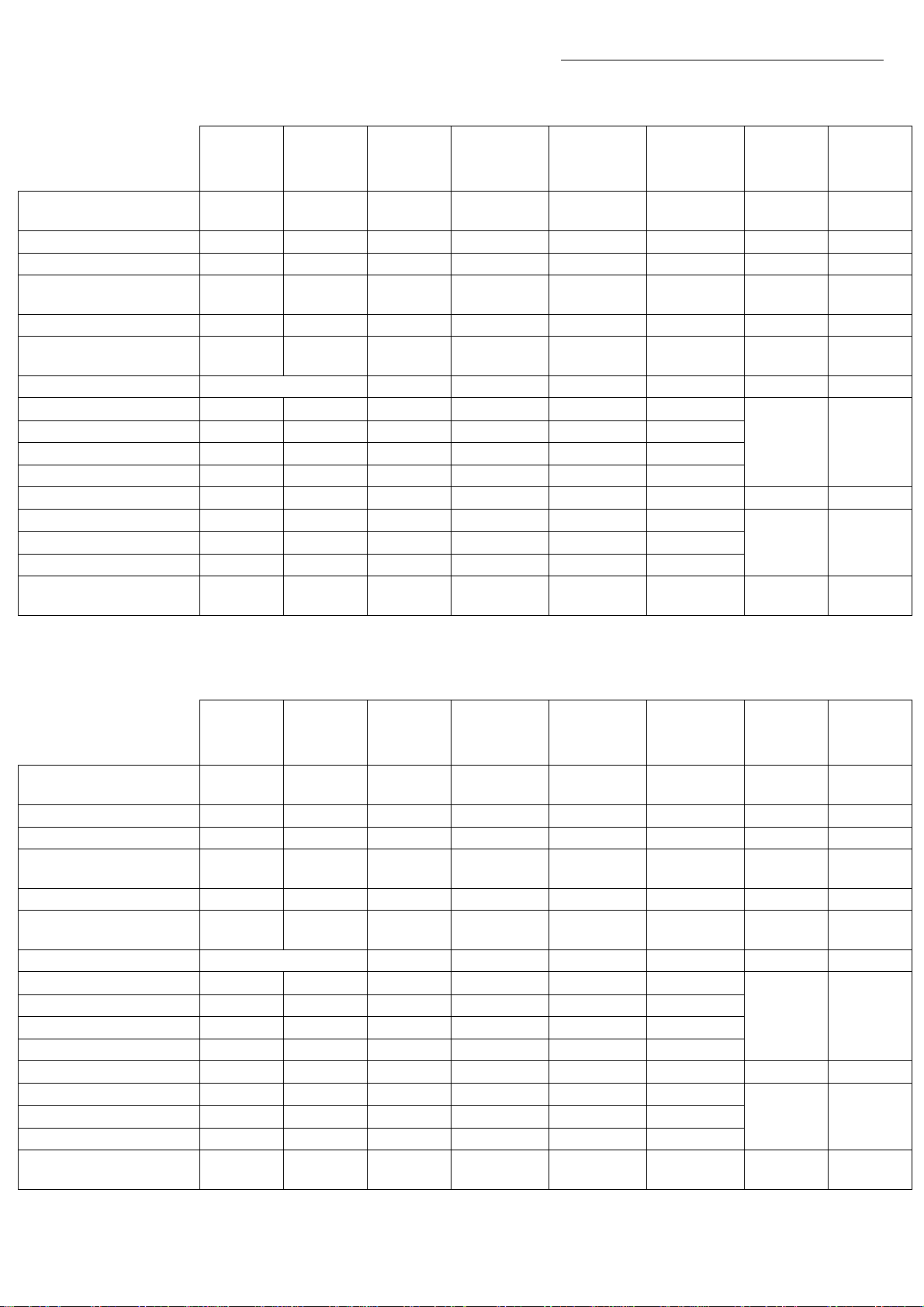

Table of cycles/sterilizable material 18S .................................................................................... 13

Table of cycles/sterilizable material 24B - 24BHD ..................................................................... 13

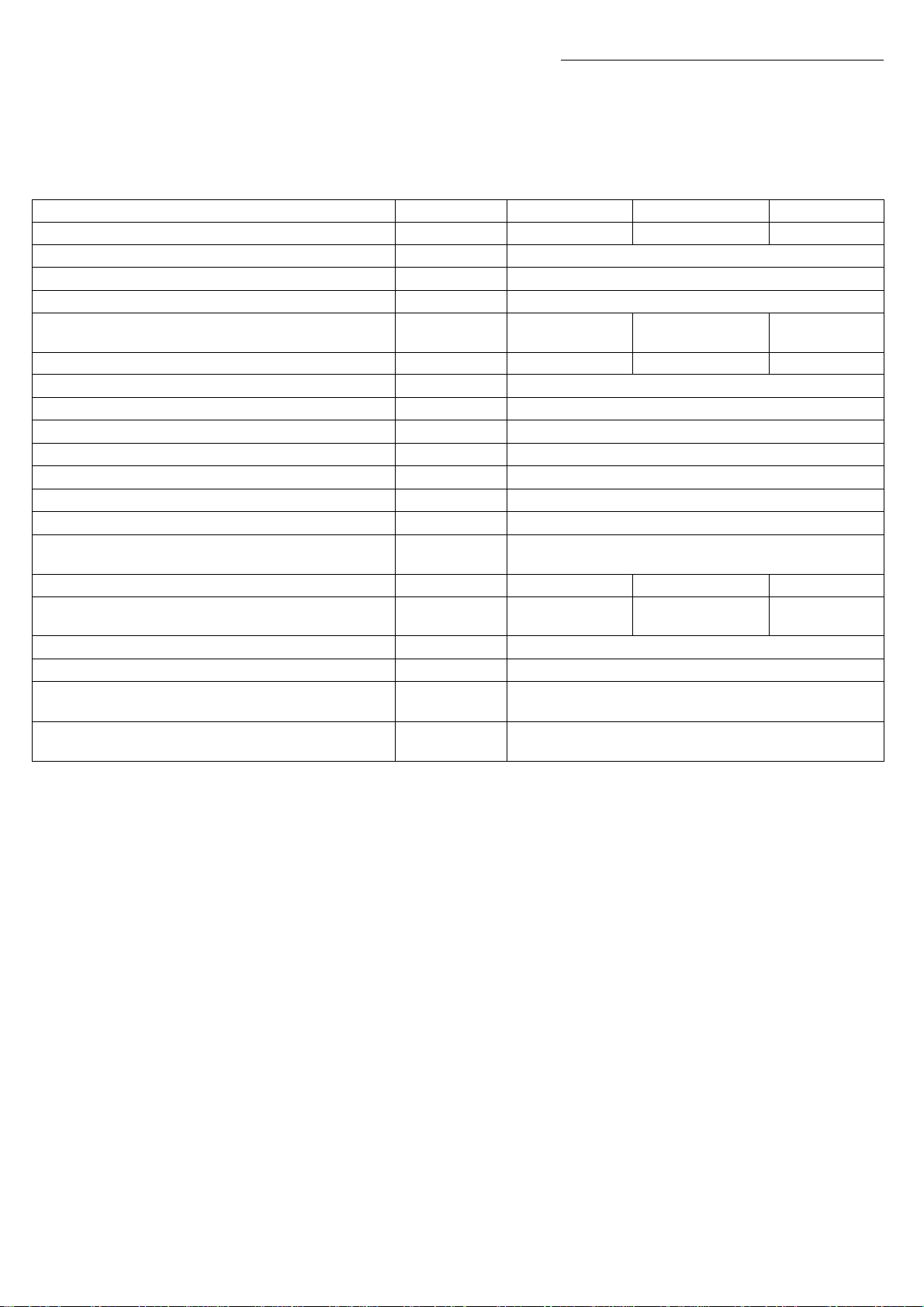

TECHNICAL SPECIFICATIONS........................................................................................................15

Technical specifications table 18 ...............................................................................................15

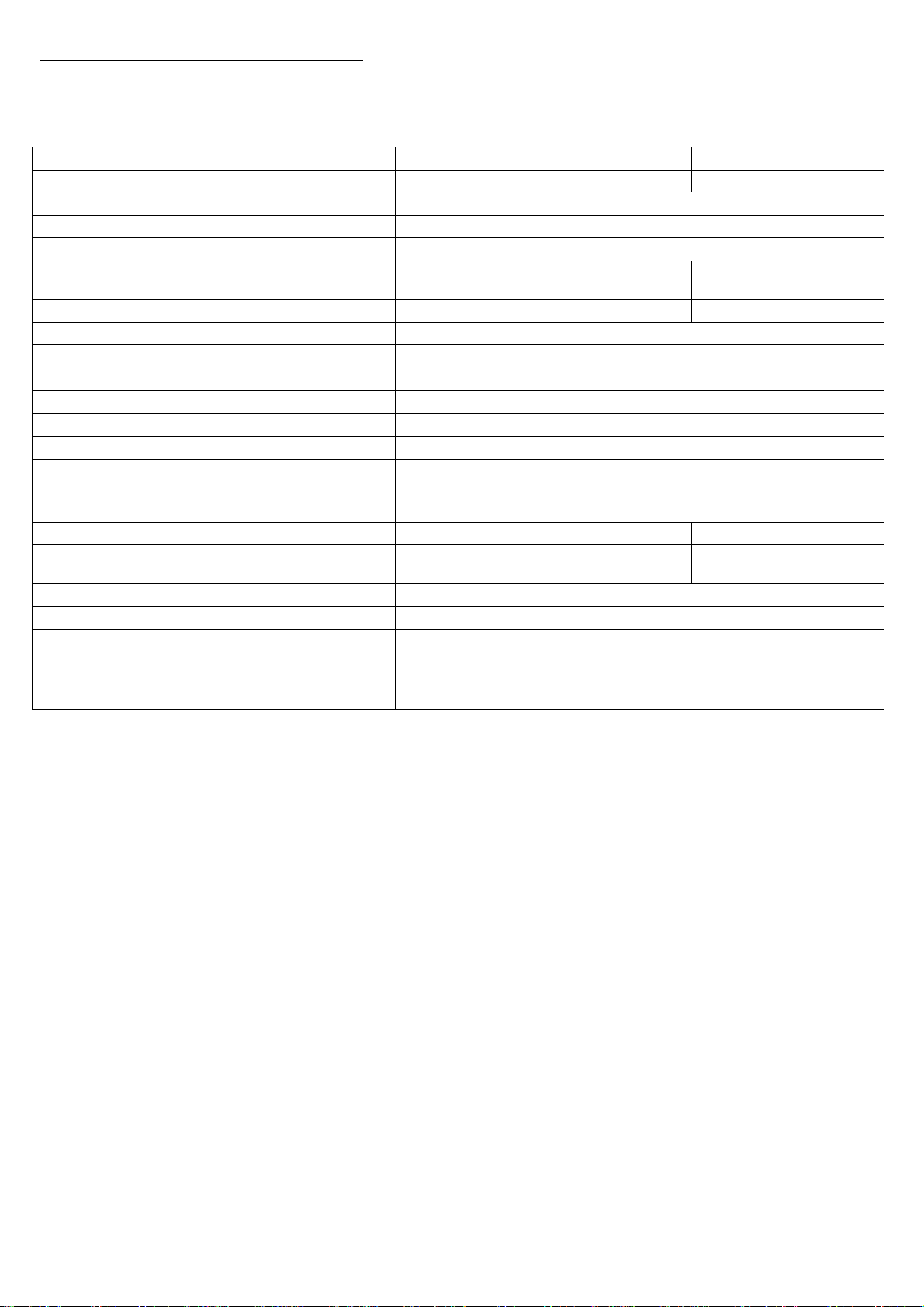

Technical specifications table 24 ..............................................................................................16

REFERENCE STANDARDS.................................................................................................................... 16

DIMENSIONS........................................................................................................................................ 17

General dimensions ...................................................................................................................... 17

Dimensions required when the unit is to be built-in ................................................................. 17

GENERAL SAFETY CONDITIONS .................................................................................................... 18

Thermal danger ................................................................................................................................. 18

Noise .................................................................................................................................................... 18

Environmental conditions and risks................................................................................................. 19

Residual risks table......................................................................................................................... 19

TRANSPORTATION AND PACKAGING.......................................................................................... 20

Unpacking and cleaning the components .................................................................................. 20

Storage ................................................................................................................................................ 21

INSTALLATION ................................................................................................................................ 22

GENERAL CONDITIONS ..................................................................................................................... 22

Arrangement ...................................................................................................................................... 22

3

Table of contents

CONNECTIONS ................................................................................................................................... 23

Electrical connections .................................................................................................................. 23

Water connection ......................................................................................................................... 23

Water supply table ........................................................................................................................ 24

MANUALLY FILL CLEAN WATER TANK .............................................................................................. 25

MANUALLY DRAIN TANKS.................................................................................................................. 25

PREPARING FOR BUILT-IN INSTALLATION ......................................................................................... 25

OPERATION.................................................................................................................................... 26

SWITCH-ON ......................................................................................................................................... 26

STAND BY ............................................................................................................................................. 28

MENU.................................................................................................................................................... 29

1. Cycle Menu............................................................................................................................ 30

2. Main Settings Menu............................................................................................................... 30

2.1 Language ....................................................................................................................... 31

2.2 Date and Time ............................................................................................................... 31

2.3 Button Sound.................................................................................................................. 31

2.4 Self-stop........................................................................................................................... 31

2.5 Self-filling ......................................................................................................................... 32

2.6 Printer............................................................................................................................... 32

2.7 Cycle Recording ........................................................................................................... 32

2.8 Data Logging ................................................................................................................. 32

3. Advanced Menu Functions ................................................................................................. 33

3.1 Prog. SPECIAL ................................................................................................................. 33

3.2 Programmed start ......................................................................................................... 34

3.3 Hollow Loads .................................................................................................................. 35

3.4a Change sec. Code ....................................................................................................... 36

3.4b SterilCard Option........................................................................................................... 37

3.4b.1 Create User ............................................................................................................ 37

3.4b.2 Delete User ............................................................................................................. 40

3.4b.3 Enable User............................................................................................................. 41

4. Cycle Records Menu ............................................................................................................ 42

5. Maintenance Menu.............................................................................................................. 43

5.1 Items ................................................................................................................................ 43

5.2 Save Maintenance ....................................................................................................... 44

INFORMATION in STAND BY .............................................................................................................. 45

STARTING the CYCLE ......................................................................................................................... 45

STOP the CYCLE ............................................................................................................................. 46

EVENTS in the CYCLE ..................................................................................................................... 47

INFORMATION about the CYCLE ................................................................................................ 48

PLOT of the CYCLE......................................................................................................................... 48

CONTROL TESTS .................................................................................................................................. 49

Bowie & Dick test ........................................................................................................................... 49

Vacuum test ................................................................................................................................... 49

Helix test .......................................................................................................................................... 51

4

Table of contents

Printer ................................................................................................................................................... 51

Cycle Recording on SterilCard ....................................................................................................... 52

INDICATORS................................................................................................................................... 54

ALARMS.......................................................................................................................................... 56

List of alarm codes ............................................................................................................................ 61

MAINTENANCE .............................................................................................................................. 62

GENERAL CONDITIONS .................................................................................................................... 62

Cleaning.......................................................................................................................................... 62

Filters................................................................................................................................................. 63

Checks............................................................................................................................................. 63

Fuses................................................................................................................................................. 63

To calibrate the fuses 32, refer to the label plate inside the door 18....................................... 63

STORAGE AND DISPOSAL.................................................................................................................. 64

Machine storage or long-term disuse ....................................................................................... 64

Disposal and Scrapping .............................................................................................................. 64

Scheduled service table .................................................................................................................. 65

APPENDIX 1: GRAPHICS 18 B – 18 BHD / 24B – 24 BHD............................................................. 66

APPENDIX 2: GRAPHICS 18 S......................................................................................................67

5

Table of contents

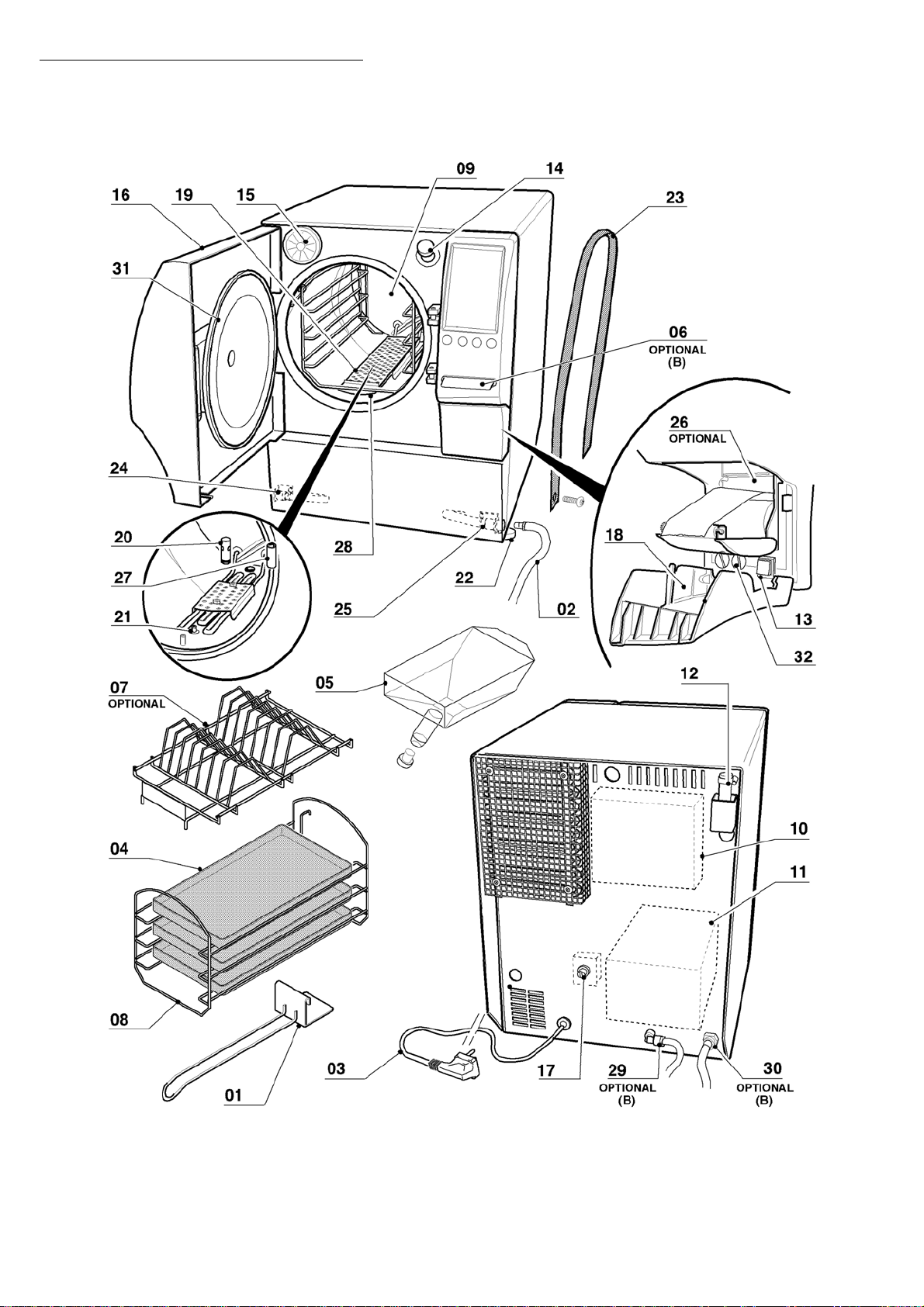

Reference index

01: tray handle

02: waste pipe

03: power cable

04: tray

05: metering funnel

06: SterilCard

07: pouch holders

08: support for 5 trays or 3 cassettes

09: chamber

10: clean water tank

11: waste water recovery tank

12: safety valve

13: main switch

14: filler

15: air sterilization filter

16: door

17: safety thermostat

18: print door

19: coil covering grid

20: waste filter

21: chamber probe

22: adjustable feet

23: lifting st raps

24: clean water tap

25: waste water tap

26: printer

27: level testing pipe

28: grid seal

29: auto water fill

30: direct drain

31: chamber seal

32: fuses

6

Graphic representation of references Mod. 18

Table of contents

7

Table of contents

Graphic representation of references Mod. 24

8

Introduction

INTRODUCTION

GENERAL SUPPLY CONDITIONS

COMINOX declares that the sterilizer complies with the standards and regulations in force

in the European Economic Community and issues the attached DECLARATION OF

CONFORMITY.

COMINOX will repair any manufacturing defects that arise within 24 months from the time

the sterilizer is installed (refer to the Guarantee). The chamber 09 is guaranteed for 10

years.

The customer must use original spare parts only and fit them according to their intended

use.

Responsibility for commercial components lies with their manufacturers.

COMINOX is not liable for defects or malfunctions deriving from improper use of the

sterilizer, changes that occur during transportation, or those caused by specific

environmental conditions, lack of maintenance or maintenance conducted improperly,

or problems due to tampering or incorrect repairs.

COMINOX declines all responsibility if the sterilizer is not installed properly or if it is not

installed by duly trained and qualified personnel.

COMINOX IS NOT responsible for the disposal of the products required for the transport or

operation of the sterilizer or for production materials: packaging, waste water, lubricants,

etc. The customer is individually responsible, under the specific regulations and standards

in force in each installation country, for disposing of any substances that are potentially

harmful to the environment.

The same precautions apply to scrapping the sterilizer.

9

Introduction

PURPOSE OF THE DOCUMENT

This Use and Maintenance Manual aims to provide the operator with a useful guide for:

• understanding the correct procedures for installing the sterilizer;

• explaining the various SterilClave functions;

• ensuring optimal use of the sterilizer;

• operating in complete safety;

• conducting the maintenance required for proper upkeep of the sterilizer.

EQUIPMENT

In addition to this Use and Maintenance Manual, each sterilizer is supplied with a

Guarantee Certificate and the EC Declaration of Conformity.

The Cominox SterilClave sterilizer also includes the following accessories:

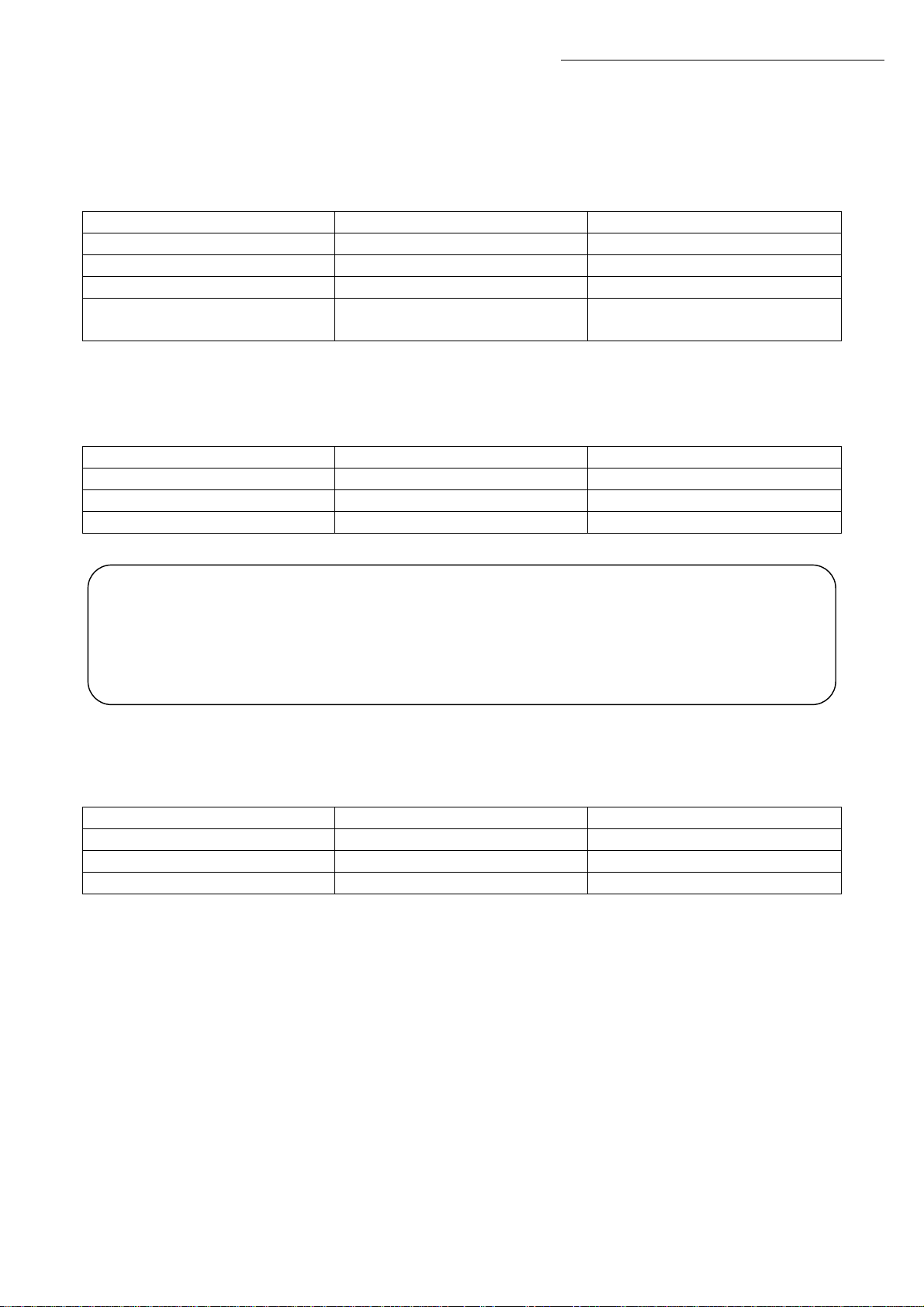

# 18S 18B - 24B 18BHD - 24BHD

Tray handle 01 1

Waste pipe 02 1

Level testing pipe27 1

Grid seal 28 1

Power cable 03 1

Trays 04 3

Pouch holders 07 1 optional optional optional

Support for 5 trays or 3 cassettes 08 1

Metering funnel 05 with cap 1

Administrator and User SterilCards 06 2 optional optional

Printer 26 1 optional optional optional

Auto wate r fill 29 1 optional optional

Direct drain 30 1 optional optional

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

•

Supplied as standard

•

•

•

10

!

r

)

y

r

Introduction

OPERATING USE

Under no circumstances should the sterilizer or its parts be used for any purpose other than

those described below.

The sterilizer was designed to:

STERILIZE

AUTOCLAVABLE SURGICAL, DIAGNOSTIC OR MEDICAL INSTRUMENTS

for example: SCISSORS, SCALPEL, GAUZE, FABRICS

Various types of materials can be sterilized, such as: stainless steel, glass, rubber, plastic,

cotton, fabrics in general.

Check that that the product to be sterilized can withstand a temperature highe

than the temperature of the programmed cycle.

Observe the normal usage conditions described. COMINOX guarantees that

the maximum measurable temperature in chamber 09 will be: PROGRAMMED

STERILIZATION TEMPERATURE +3°C (standard EN 13060: minimum temperature =

sterilization temperature -0°C; maximum temperature = sterilization temperature

+4 °C

.

The EN 13060 standard distinguishes various types of load depending on the material to be

sterilized: solid tools (e.g. scalpels), hollow tools of type A or type B (e.g. surgical extraction

cannula) and porous loads (e.g. fabrics and gauzes). This division should guide the

operator in selecting the sterilization cycle (see Table of cycles/sterilizable material).

Strictly comply with the sterilization instructions and information specified by the

manufacturer for any material to be sterilized.

Instruments and fabrics to be sterilized MUST be carefully washed, rinsed with

!

Comply with the maximum total load weight (see Table of cycles/sterilizable material).

Use the load support system supplied by COMINOX (see Preparation of the load to be

sterilized). Use of load supports other than the standard support provided may

compromise the steam penetration and drying performance confirmed during approval

tests.

Follow instructions concerning correct packaging, and only use packaging materials

compliant with standard EN868.

additive-free water and dried. The support for the load must also be perfectl

dry.

The sterilizer may NOT be operated or installed in areas in which gas or any othe

explosive volatile substance is present.

!

11

Introduction

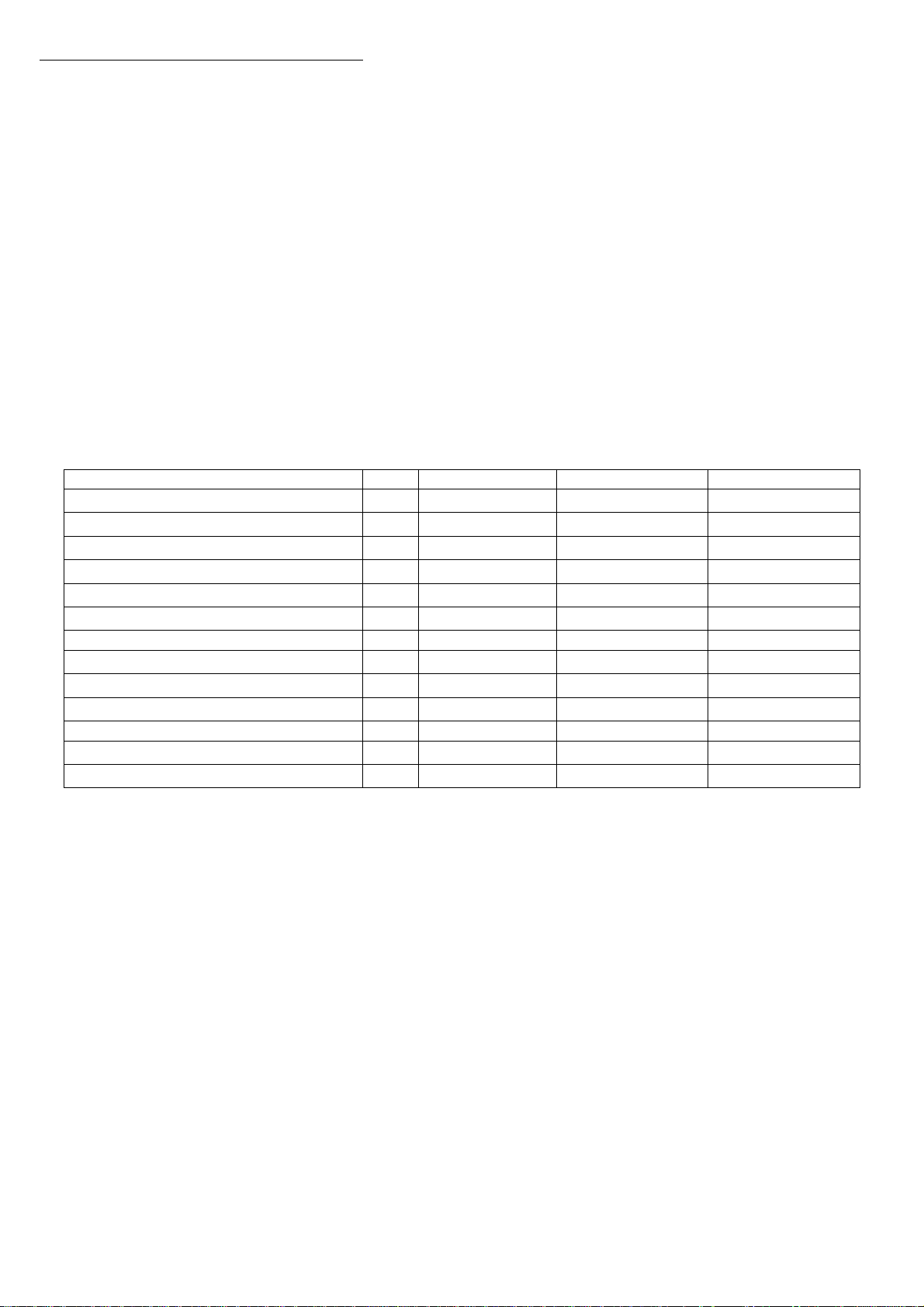

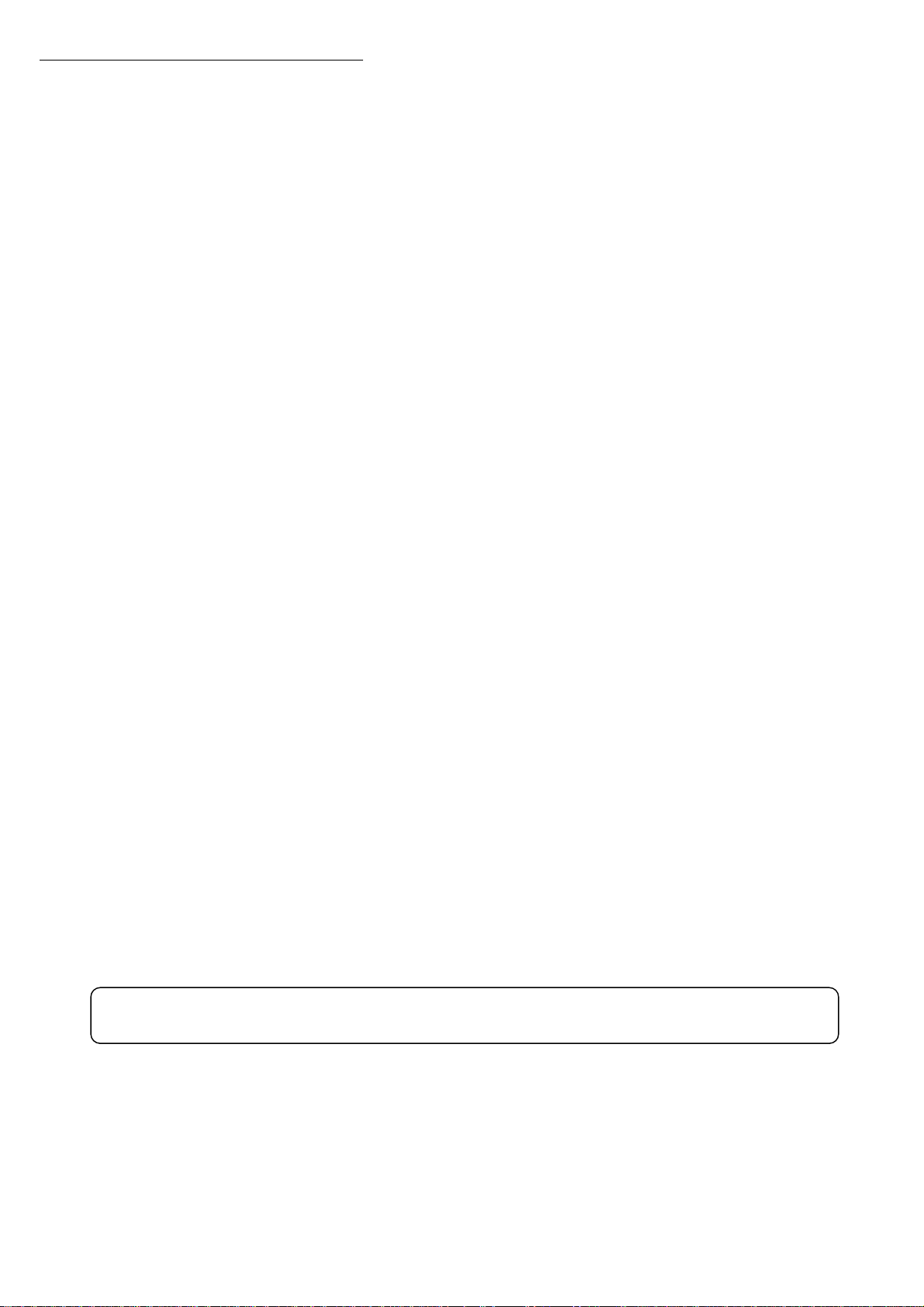

Table of cycles/sterilizable material 18B - 18BHD

Type according to

EN 13060

Temperature

Pressure

Duration of

sterilization phase

Drying

Total duration

(minimum - maximum)

Load:

solid

porous

hollow A

hollow b

Packaging:

not packaged

single pack

double pack

Maximum load weight

(solid/hollow - porous)

121

UN-

WRAPPED

134

UN-

WRAPPED

134

WRAPPED

121

POROUS /

HOLLOW

134

POROUS /

HOLLOW

134 PRION

BOWIE &

DICK TEST

VACUUM

TEST

N N S1 B B B

121°C 134°C 134°C 121°C 134°C 134°C 134°C -

2.1 bar 3.1 bar 3.1 bar 2.1 bar 3.1 bar 3.1 bar 3.1 bar -

15' 4' 4' 15' 4' 18' 3.5' -

no no 20' 20' 20' 20' no no

23' - 30' 13' - 21' 37' - 48' 57' - 77' 49' - 69' 63' – 85' 25' 20'

yes yes yes yes yes yes

no no no yes yes yes

no no no yes yes yes

no no no yes yes yes

yes yes yes yes yes yes

no no yes yes yes yes

no no no yes yes yes

5 Kg 5 Kg 3 Kg 2.5 - 1.5 Kg 2.5 - 1.5 Kg 2.5 - 1.5 Kg - -

empty

chamber

empty

chamber

empty

chamber

empty

chamber

12

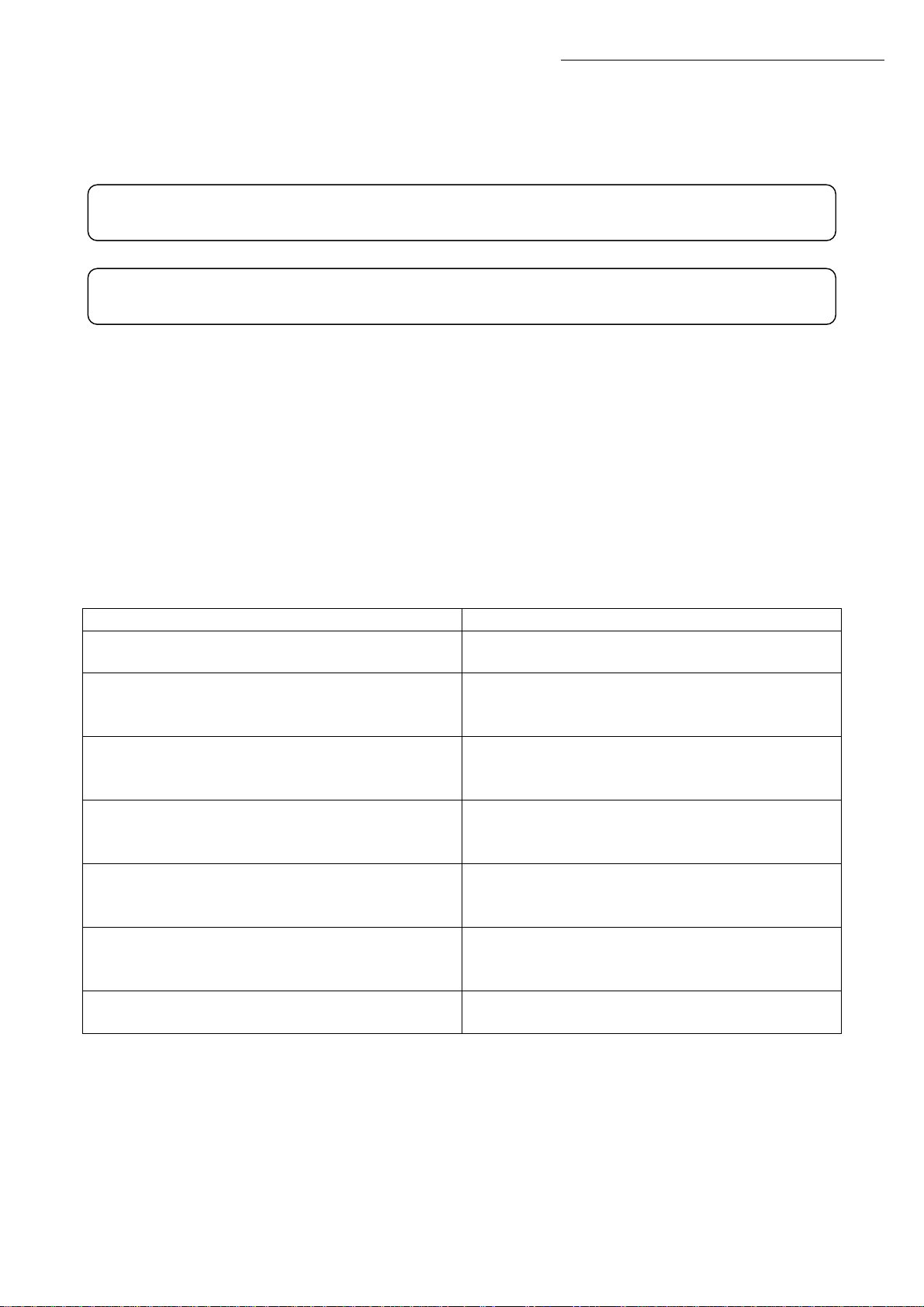

Table of cycles/sterilizable material 18S

Type according to

EN 13060

Temperature

Pressure

Duration of

sterilization phase

Drying

Total duration

(minimum - maximum)

Load:

solid

porous

hollow A

hollow b

Packaging:

not packaged

single pack

double pack

Maximum load weight

(solid/hollow - porous)

Table of cycles/sterilizable material 24B - 24BHD

Type according to

EN 13060

Temperature

Pressure

Duration of

sterilization phase

Drying

Total duration

(minimum - maximum)

Load:

solid

porous

hollow A

hollow b

Packaging:

not packaged

single pack

double pack

Maximum load weight

(solid/hollow - porous)

IntroduzioneIntroduction

121

UN-

WRAPPED

134

UN-

WRAPPED

134

WRAPPED

121

POROUS/

HOLLOW

134

POROUS/

HOLLOW

134 PRION

BOWIE &

DICK TEST

VACUUM

TEST

N N S1 S2 S2 S2

121°C 134°C 134°C 121°C 134°C 134°C 134°C -

2.1 bar 3.1 bar 3.1 bar 2.1 bar 3.1 bar 3.1 bar 3.1 bar -

15' 4' 4' 15' 4' 18' 3,5' -

no no 25' 25' 25' 25' no no

24' - 29' 14' - 19' 44' - 54' 59' - 70' 50' - 59' 64' - 74' 25' 20'

yes yes yes yes yes yes

no no no yes yes yes

no no no no no no

no no no yes yes yes

yes yes yes yes yes yes

no no yes yes yes yes

no no no no no no

5 Kg 5 Kg 3 Kg 2.5 - 1 Kg 2.5 - 1 Kg 2.5 - 1 Kg - -

121

UN-

WRAPPED

134

UN-

WRAPPED

134

WRAPPED

121

POROUS/

HOLLOW

134

POROUS/

HOLLOW

134 PRION

empty

chamber

empty

chamber

BOWIE &

DICK TEST

empty

chamber

empty

chamber

VACUUM

TEST

N N S1 B B B

121°C 134°C 134°C 121°C 134°C 134°C 134°C -

2.1 bar 3.1 bar 3.1 bar 2.1 bar 3.1 bar 3.1 bar 3.1 bar -

15' 4' 4' 15' 4' 18' 3,5' -

no no 20' 20' 20' 20' no no

21' - 28' 11' - 19' 37' - 49' 60' - 79' 49' - 73' 66' - 88' 25' 20'

yes yes yes yes yes yes

no no no yes yes yes

no no no yes yes yes

no no no yes yes yes

yes yes yes yes yes yes

no no yes yes yes yes

no no no yes yes yes

7.5 Kg 7.5 Kg 4 Kg 3.7 - 2.2 Kg 3.7 - 2.2 Kg 3.7 - 2.2 Kg - -

empty

chamber

empty

chamber

empty

chamber

empty

chamber

13

Introduction

NOTE

CYCLE N: sterilization cycle for solid instruments, unpackaged only.

CYCLE S1: sterilization cycle for solid instruments, packaged or unpackaged.

CYCLE S2: sterilization cycle for solid instruments, porous loads, and hollow loads type B,

packaged or unpackaged.

CYCLE B: sterilization cycle for solid instruments, porous loads, and hollow loads type A or B,

packaged or unpackaged; double packaging is also permitted.

TYPE A HOLLOW LOADS: Instruments with an open cavity on one side only, where the

length to cavity diameter ratio is greater than or equal to 1 and less than or equal to 750

(1

≤ L/D ≤ 750), and where the length of the cavity is no longer than 1500 mm (L ≤ 1500

mm). Alternatively, instruments with an open cavity on both sides, whose length to cavity

diameter ratio is greater than or equal to 2 and less than or equal to 1500 (2

and where the length of the cavity is no longer than 3000 mm (L

TYPE B HOLLOW LOADS: Instruments with an open cavity on one side only, where the

length to cavity diameter ratio is greater than or equal to 1 and less than or equal to 5 (1

L/D

≤ 5), and where the diameter of the cavity is greater than or equal to 5 mm (D ≥ 5

mm). Alternatively, instruments with an open cavity on both sides, whose length to cavity

diameter ratio is greater than or equal to 2 and less than or equal to 10 (2

where the diameter of the cavity is greater than or equal to 5 mm (D

MAXIMUM LOAD WEIGHT: the maximum weight permitted for each load category

described, including the load support system and its packaging.

TOTAL MAXIMUM DURATION: the total time the sterilizer requires to run a complete cycle,

calculated from cold startup (room temperature) and maximum load.

TOTAL MINIMUM DURATION: the total time the sterilizer requires to run a complete cycle,

including hot startup (one cycle after the other) and minimum load (load support only).

≤ 3000 mm).

≥ 5 mm).

≤ L/D ≤ 1500),

≤ L/D ≤ 10), and

≤

14

Technical specifications

TECHNICAL SPECIFICATIONS

Technical specifications table 18

U.M. S B BHD

Steam generation in chamber in chamber in chamber

Chamber capacity l 17,15

Clean water tank capacity l 2,1

Waste water recovery tank capacity l 2,1

Water consumption per cycle

(minimum/maximum) cm³ 180 - 500 210 - 700 210 - 700

Minimum water load cm³ 500 700 700

Maximum flow discharge rate (direct) cm³/s 30

Maximum discharge temperature (direct) °C 83

Absolute operating pressure (maximum) kPa 331

Electrical voltage and frequency V - Hz 230 – 50/60 (single-phase AC)

Maximum allowed voltage fluctuations % ±10

Absorbed maximum power W 2000

Heat emission J/h 0,3

Detected noise level in work areas under

suitable conditions (medium-peak)

Weight (mass) kg 48,7 51 51

Weight per support area with full tank and

maximum load

Room temperature allowed °C from 15 to 40

Maximum relative humidity allowed % 85

Maximum altitude allowed with standard safety

valve

Conditional connections:

maximum impedance

dB(A) - dB(C) 55.7 - 62.7

kg/cm² 1,16 1,2 1,2

m asl 1500 (2000 with replacement of the valve)

Ω 0.139+j0.087

15

Technical specifications

Technical specifications table 24

U.M. B BHD

Steam generation in chamber in chamber

Chamber capacity l 23,15

Clean water tank capacity l 3,1

Waste water recovery tank capacity l 3.1

Water consumption per cycle

(minimum/maximum) cm³ 420-1040 420-1190

Minimum water load cm³ 1040 1190

Maximum flow discharge rate (direct) cm³/s 30

Maximum discharge temperature (direct) °C 83

Absolute operating pressure (maximum) kPa 331

Electrical voltage and frequency V - Hz 230 – 50/60 (single-phase AC)

Maximum allowed voltage fluctuations % ±10

Absorbed maximum power W 2800

Heat emission J/h 0.3

Detected noise level in work areas under

suitable conditions (medium-peak)

Weight (mass)

Weight per support area with full tank and

maximum load

Room temperature allowed

Maximum relative humidity allowed

Maximum altitude allowed with standard safety

valve

Conditional connections:

maximum impedance

dB(A) - dB(C) 56 - 63

kg 63 68

kg/cm² 1.53 1.63

°C from 15 to 40

% 85

m asl 1500 (2000 with replacement of the valve)

Ω 0.153+j00.096

REFERENCE STANDARDS

SterilClave sterilizers were conceived and designed in conformity with the following

directives and standards:

Directives

97/23/CE Pressure equipment

93/42/EEC Medical devices (class II a)

89/336/CEE Electromagnetic compatibility (and subsequent updates)

73/23/CEE Low voltage (and subsequent updates)

Standards

EN 13060 Small steam sterilizers

EN 61010-1 Safety regulations for laboratory devices - Part 1: General regulations

EN 61010-2-040 Safety regulations specific to sterilizers used in the processing of medical

material.

EN 61326-1 Electromagnetic compatibility regulations for laboratory devices

16

r

Technical specifications

DIMENSIONS

General dimensions

SterilClave 18 SterilClave 24

A - Width 445 445

B - Height 390 470

C - Depth 640 700

D - Unit depth with door

open

Dimensions required when the unit is to be built-in

SterilClave 18 SterilClave 24

E - Width 450 450

F - Height 395 475

G - Depth 560 620

880 940

NEVER place the machine on soft surfaces (such as cloth or foam) and neve

!

Usable space dimensions

SterilClave 18 SterilClave 24

H - Width 185 185

I - Height 150 150

L - Depth 285 420

remove the adjustable feet.

Leave approximately 20 mm of space for rear ventilation. Built-in units require an

additional 20 mm between the unit and the wall. In this case, the unit must have

a rear opening for ventilation, as illustrated.

17

General safety conditions

r

GENERAL SAFETY CONDITIONS

• Switch off the sterilizer at the main switch 13 and disconnect the power cable 03

before conducting any operations apart from those in the normal operations cycle.

• The main power supply must be properly grounded.

• It is essential that operators are properly educated. It is therefore compulsory for

them to read and comply with the technical information provided in the manual

and attached documentation. The use of unqualified personnel is strictly

prohibited.

• Personnel who operate the sterilizer must always use the appropriate individual

protective devices: gloves for sharp or pointed objects and heated elements, and

the special tray handle for emptying the chamber.

• Avoid any temporary repairs: repairs must be performed exclusively with original

spare parts, and these must be installed by an authorized technician.

• Never remove or dismantle any part from the sterilizer. Only authorized personnel

trained in advance by COMINOX may remove the exterior protective cover and

access the interior parts.

• Labeling plates on the unit should not be removed, damaged, or dirtied. They must

be kept clean and clearly visible.

• Do not use the sterilizer if there are possible defects in its operation.

• The sterilizer should be cleaned using suitable means and detergents that will not

damage or corrode any machine components. It is strictly forbidden to clean or

wash the sterilizer with jets of water.

• Never place containers of liquids on the sterilizer or the shelves above it. Leakage or

spillage on the electric system can cause a short circuit.

• Do not place flammable or toxic materials and products for sterilization in the

chamber 09.

• Do not use the sterilizer to process containers that hold fluids, whether they are

sealed or not.

• Never lean on the door 16.

The information in this manual does not replace any safety instructions or technical data

for installation and operation on the unit itself, nor any safety standards in force in the

installation country, or the rules of common sense.

Thermal danger

Interior parts of the door 16 and of the chamber 09 can reach extremely high

temperatures.

Never touch the heated surfaces until they have cooled, and always use the appropriate

protective gloves. The same applies when a load is to be removed from the sterilization

chamber. To remove the trays 04 holding the load, always use the tray handle 01. Never

leave the tray handle inside the sterilization chamber.

When opening the door 16, steam may escape, which could cause burns. Neve

!

The temperature in the sterilization chamber is controlled by a safety thermostat 17 that

intervenes if overheating occurs. The safety thermostat must be reset manually.

stand in front of or above the door!

Noise

The sound pressure level (noise) detected in suitable work spaces must be lower than

70dB(A).

18

General safety conditions

Environmental conditions and risks

The sterilizer may not be installed in the open or be exposed to unfavourable weather

conditions (sun, rain, snow, wind).

In addition, make sure that there is no electromagnetic interference that could

!

!

COMINOX is not liable for the disposal of materials required for the operation or

production of the sterilizer (e.g.: plastic packaging or potentially contaminated waste

water...). The client must personally provide for the removal of any substances that are

potentially harmful to the environment in compliance with regulations in force in the

country of installation.

The same precautions apply to scrapping the sterilizer.

The sterilizer was designed in compliance with best practices concerning energy

conservation, preventing needless waste.

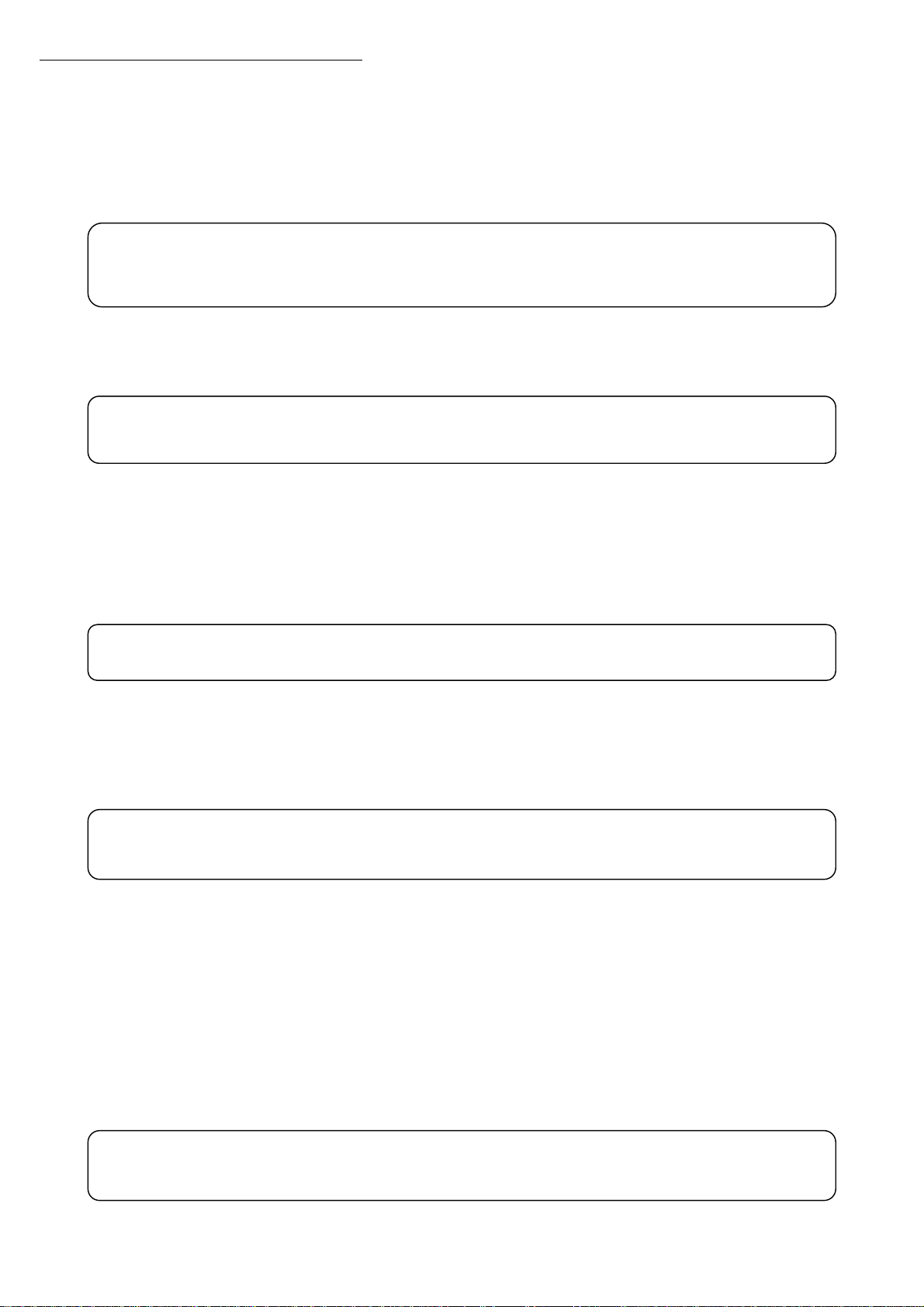

Residual risks table

Losses or leaks with risks of slipping, short

circuit or pollution.

Drainage of waste water contaminated by

viruses, bacteria, or pathogenic microorganisms.

Escaping steam and/or gas fumes when

opening the door 16.

Excessively hot surfaces, especially in the

sterilization chamber 09 and on certain

solenoid valves or internal components.

The chamber seal is hermetic even when

the unit is switched off; plants and animals

cannot survive inside the machine.

Poor cleaning or scratching of label plates

and/or instrumentation can lead to mistakes

and consequent dangers.

Poor training of personnel.

affect the data in the electronic devices.

The unit is not equipped as standard for operation in environments that present a

particular risk of fire or explosion.

RISK ANALYSIS AND DESCRIPTION SUGGESTED REMEDY

Carefully clean the workplace.

Dispose of according to the regulations in

force.

Always carefully check whether the load

complies with cycle temperatures, and

open the door with caution.

Wear protective gloves and/or never touch

any internal components unless duly

AUTHORIZED.

Do not place plants or animals inside the

chamber.

Clean instruments and label plates carefully

with the appropriate products.

Request an additional training course from

COMINOX.

19

Transportation and packaging

TRANSPORTATION AND PACKAGING

During transport, the sterilizer is protected by a cardboard box.

Lifting and transportation are to be carried out by qualified personnel only.

Weights and dimensions of occupied space are provided in the DIMENSIONS chapter and

in the Technical specifications table.

Lifting means should not damage or compromise the operation of the sterilizer.

!

Transportation of the sterilizer, particularly by road, must be conducted using means of

transportation that can adequately protect the components (especially electronic

components) against violent knocks, humidity, vibrations, and so on.

The packed sterilizer must be lifted after being fitted onto the special pallet, and

only using forklifts.

The sterilizer may be transported only after fully emptying the clean water tank 10

and the waste water recovery tank 11.

!

COMINOX does not accept sterilizers for repair if they have full tanks (see Chap.

MANUALLY DRAIN TANKS).

Very heavy items or equipment (heavier than 30 kg) must only be moved or lifted using

appropriate lifting devices.

At least two people are required for manual lifting, using the special lifting straps 23

provided and following the correct procedures as specified by current regulations.

Never lift or move the sterilizer using the door 16 or holding onto other plastic

!

Unpacking and cleaning the components

They should be removed using appropriate means and not left within reach of

unauthorized persons (especially children). The same applies to any device used to

remove packaging (scissors, hammers, tongs, knives, etc.).

Packaging components must be removed and disposed of according to the regulations

in force in each country.

You are advised to retain the packaging and the lifting straps 23 for possible moves in the

future.

When opening the package, the first thing to do is check all the pieces and parts of the

sterilizer. Check that all components required are present and in perfect condition (see

SUPPLY CONDITIONS).

Remove the supplied parts by opening the door 16 (see OPERATION).

parts.

Remember that packaging (wood, nails, paper, cellophane, metal staples,

adhesive tape, straps, ropes, etc.) can cut and/or injure if not carefully handled.

20

In the event of defects or wear and tear, immediately interrupt any operation,

contact the shipping or forwarding agent, and promptly inform COMINOX.

Transportation and packaging

The load support system and the external surface of the sterilizer are sometimes protected

by a plastic film: it must be removed before using the machine.

Storage

If the sterilizer will not be used immediately or if will be removed from the installation site, it

must be stored in a dry, protected location.

If you wish to cover the machine with plastic sheeting, you must first insert silica gel or other

desiccant systems inside the packaging.

Never place any objects on top of the machine packaging, especially with loads

!

Ideal ambient storage conditions are:

- temperature with empty systems - 25°C + 40°C.

- maximum relative humidity 90%.

concentrated on protruding feet or screws.

21

Loading...

Loading...