Comfort-aire Bhd-252 Owner's Manual

HEAT CONTROLLER, INC.

Dehumidifier

MODELS: BHD-252

BHD-652

Service Manual

CAUTION

-Before servicing the unit, read the "safety precautions" in this manual. -Only for authorized service personnel.

CONTENTS |

|

1. PREFACE |

|

1.1 SAFETY PRECAUTIONS........................................................................................................................... |

3 |

1.2 FEATURES AND DIMENSIONS ................................................................................................................ |

3 |

1.2.1 FEATURES........................................................................................................................................ |

3 |

1.2.2 DIMENSIONS.................................................................................................................................... |

3 |

1.3 SPECIFICATIONS...................................................................................................................................... |

4 |

1.4 CONTROL TYPE........................................................................................................................................ |

5 |

1.4.1 MECHANICAL TYPE......................................................................................................................... |

5 |

1.4.2 ELECTRONIC TYPE ......................................................................................................................... |

5 |

1.5 HOW TO OPERATE DEHUMIDIFIER........................................................................................................ |

6 |

1.5.1 HOW DOES THE DEHUMIDIFIER WORK? ..................................................................................... |

6 |

1.5.2 LOCATION FOR THE DEHUMIDIFIER............................................................................................. |

6 |

1.5.3 MICRO SWITCH................................................................................................................................ |

6 |

1.5.4 AUTO DEFROST............................................................................................................................... |

6 |

1.5.5 HUMIDITY CONTROLLER................................................................................................................ |

7 |

2. CIRCUIT DIAGRAM............................................................................................................................ |

8 |

3. DISASSEMBLY INSTRUCTIONS |

|

3.1 MECHANICAL PARTS ............................................................................................................................. |

10 |

3.1.1 BUCKET AND AIR FILTER ............................................................................................................. |

10 |

3.1.2 FRONT CASE AND TOP COVER................................................................................................... |

10 |

3.1.3 CABINET AND CONTROL BOX ..................................................................................................... |

10 |

3.2 CONTROL PARTS .................................................................................................................................. |

11 |

3.2.1 POWER CORD ASSEMBLY ........................................................................................................... |

11 |

3.2.2 SENSOR ASSEMBLY ..................................................................................................................... |

11 |

3.2.3 PWB(PCB) ASSEMBLY, MAIN ....................................................................................................... |

11 |

3.2.4 CAPACITOR.................................................................................................................................... |

11 |

3.2.5 MICRO SWITCH ASSEMBLY ......................................................................................................... |

11 |

3.2.6 COIL ASSEMBLY, SOLENOID ....................................................................................................... |

12 |

3.2.7 CONTROL PANEL .......................................................................................................................... |

12 |

3.2.8 FAN AND MOTOR........................................................................................................................... |

13 |

3.2.9 DRAIN PAN ..................................................................................................................................... |

13 |

3.3 REFRIGERATING CYCLE ....................................................................................................................... |

14 |

3.3.1 CONDENSER, EVAPORATOR AND CAPILLARY TUBE............................................................... |

14 |

3.3.2 ROTARY COMPRESSOR .............................................................................................................. |

14 |

3.4 HOW TO REPLACE REFRIGERATION SYSTEM................................................................................... |

15 |

4. TROUBLESHOOTING GUIDE................................................................................................... |

17 |

5. EXPLODED VIEWS.......................................................................................................................... |

19 |

6. REPLACEMENT PARTS LIST................................................................................................... |

22 |

—2—

1. PREFACE

This Service Manual provides various service information, including the mechanical and electrical parts. This dehumidifier was manufactured and assembled under the strict quality control procedures.

The refrigerant is charged at the factory. Be sure to read the safety precaution prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

•Disconnect the power supply before servicing or replacing any component.

•Do not cut off the grounding prong or alter the plug in any manner.

1.2 FEATURES AND DIMENSIONS

1.2.1 FEATURES

•Quiet operation

•High efficiency

•Adjustable humidistat

•Automatic defrost

•Automatic shut-off

•Bucket-full indicator light

•Easy roll casters

•Removable & large capacity bucket.

•Washable air filter

•Two-speed fan

•Drain hose connection.

•Low temperature operation

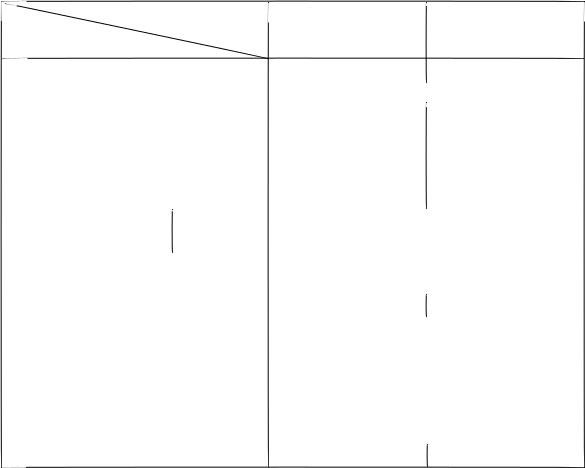

1.2.2 DIMENSIONS (mm/in)

385 (15 5/32) |

|

|

340 (13 3/8) |

|

|

||||

|

|

|

|

|

540 (21 1/4)

Figure 1

—3—

1.3 SPECIFICATIONS

MODELS |

BHD-252 |

BHD-652 |

||

ITEMS |

|

|||

|

|

|

||

CAPACITY(Liter/24hrs ) |

|

12 |

30 |

|

|

|

|

|

|

POWER SUPPLY(Phase,V,Hz) |

|

1Ø, 220V-240V,50Hz |

||

|

|

|

|

|

INPUT(W) |

|

250 |

620 |

|

RUNNING CURRENT(A) |

|

2.0 |

3.5 |

|

ENERGY FACTOR(L/kw.h) |

|

2.0 |

2.0 |

|

REFRIGERANT |

|

R134a |

R410a |

|

REFRIGERANT CHARGE, oz(g) |

|

5.82(165) |

7.76(220) |

|

|

|

|

|

|

THERMISTOR |

OPEN |

33.8˚F(1±0.5°C) |

||

|

|

|

|

|

|

|

CLOSE |

50˚F(10±0.5°C) |

|

SOLENOID VALVE |

|

Using Temp/Humid.:-4~122˚F(-20~50°C)/95%RH |

||

|

|

|

Rating:7W/90mA |

|

|

|

|

|

|

COMPRESSOR MODEL No. |

|

NR45HAEG |

GA066PAB |

|

PROTECTOR |

|

OVERLOAD PROTECTOR FOR COMPRESSOR |

||

|

|

|

|

|

|

|

|

INTERNAL PROTECTOR(FUSE)FOR MOTOR |

|

|

|

|

|

|

CAPACITOR |

|

|

25µF,370VAC |

|

MOTOR ASSEMBLY,SINGLE |

|

Shadedpolemotor,72W/1.4A,Thermalcutoff:266°FV/130°C |

Shadedpolemotor,72W/1.4A,Thermalcutoff:266°FV/130°C |

|

|

|

|

|

|

SWITCH ASSEMBLY,MICRO |

|

15A/250VAC |

||

|

|

|

||

OUTSIDED MENSIONS WxHxD,mm(in) |

385X540X340(15 5/32 x 21 1/4 x 13 3/8) |

|||

NET WEIGHT,kg |

|

18 |

21 |

|

*NOTE: Specifications are subject to minor change without notice for further improvement.

—4—

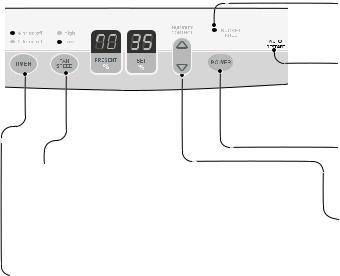

1.4 CONTROL TYPE

Figure 2

Fan Speed

•This controls the speed of the airflow.

•High: Fan speed is set to high.

•Low: Fan speed is set to low.

•When Fan Speed button is pressed, the fan speed mode is changed.

Timer

•Press this button to select type of operation.

•Select continuous On for uninterrupted operation.

•Select either 2 or 4 hr. On/Off for cycled operation: The unit will operate for 2 or 4 hours, and then shut off completely for 2 or 4 hours.

The cycle repeats until you change the setting.

•When Timer button is pressed, the Timer indicator lights shift as follow from 2hr.On/Off to 4hr.On/Off.

Bucket Full Indicator

•This light glows when the water bucket is full and needs to be emptied.

Auto Restart

•Once power is restored after a power outage, the unit returns to its previous operation setting after a 2 minute delay.

The fan runs immediately when the power is restored.

Power

•Operation starts when this button is pressed and stops when the button is pressed again.

Humidity Control

•This button controls the humidity in the room.

•Press  button to raise the humidity setting.

button to raise the humidity setting.

•Press  button to lower the humidity setting.

button to lower the humidity setting.

•The humidity setting can be set to a permanent "On" setting or to a specific humidity setting between 35% and 70% in 5% increments.

•"On" setting: Dehumidifier runs continuously regardless of humidity condition.

•35% - 70% setting: Dehumidifier runs on and off according to surrounding humidity conditions.

— 5—

1.5HOW TO OPERATE DEHUMIDIFIER

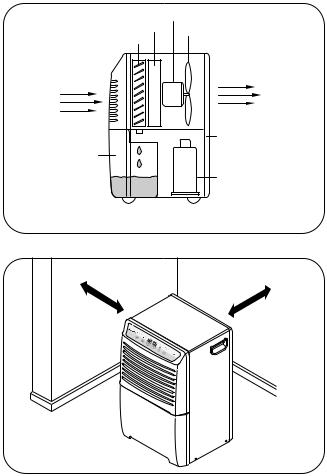

1.5.1HOW DOES THE DEHUMIDIFIER WORK?

Moist, humid air is drawn over a cold refrigerated dehumidifying coil. Moisture in the air condenses on this coil and drains into a bucket (or through the bucket into a hose and drain).

Dry, clean air is drawn over the condenser where it is actually heated several degrees and discharged out the rear grill into the room. (See Figure 3)

■ It is normal for the surrounding air to become slightly warmer as the dehumidifier operates.

This warming effect further reduces the relative humidity of the surrounding air.

1.5.2 LOCATION FOR THE DEHUMIDIFIER

Allow at least 30 cm of space on all sides of the unit for good air circulation. (See Figure 4)

■The dehumidifier must be operated in an enclosed area to be most effective.

■Close all doors, windows and other outside

openings to the room.

Place the dehumidifier in a location that does not restrict air flow into the front grille or out the rear grille.

The operation of dehumidifier in a basement will have little or no effect in drying an adjacent enclosed storage area, such as a closet, unless there is adequate circulation of air in and out of the area.

Motor

Condenser |

Fan |

|

Evaporator |

|

|

|

|

|

Humid |

|

Dry |

|

Air Out |

|

Air In |

|

|

|

|

|

|

|

Rear Grille |

Bucket |

|

|

|

|

Compressor |

Side View |

Figure 3 |

|

|

||

30 cm |

|

30 cm |

Figure 4

1.5.3 MICRO SWITCH

The micro switch assembly, which is located on the drain pan of inside unit, automatically shuts off the dehumidifier when the bucket is full (note, the Auto Shut Off lights, to indicate bucket must be emptied). The bucket replaces in its place, the unit again turns itself on.

1.5.4 AUTO DEFROST

When frost builds up on the cooling coils, the unit will automatically cycle off until the frost disappears. The fan continues to run.

NOTE: The unit will not operate satisfactorily if the room temperature is below 18˚C. If the dehumidifier is operated in low temperature conditions frost can form in the evaporator coil and the unit will cycle ON/OFF repeatedly. In this case, please check your room temperature conditions and stop the unit.

NOTE: The low temperature operation feature in the BHD-252 and BHD-652 models will continuously cycle up to a temperature of 6°C.

— 6—

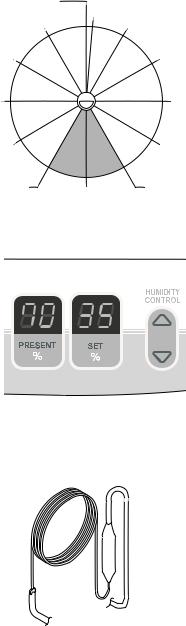

1.5.5 HUMIDITY CONTROLLER

1.5.5.1 Mechanical Type

The humidity control can be set anywhere between Off and Max for normal operation.

If you need more dehumidification, turn the Humidity Control toward Max. If you need less dehumidification, turn the Humidity Control toward Off.

The relative humidity range is from 20% to 80%. (See Figure 5)

Turn the Humidity Control to Off to stop the unit manually.

1.5.5.2 Electronic Type

The humidity control can be set 'on' or 35%-70% RH(Relative Humidity) for normal operation. (See Figure 6)

If you need drier air, press the Humidity Control button.

Humidity Control button.

If you need moister air, press the  Humidity Control button.

Humidity Control button.

Press the Power button to stop the unit manually.

1.5.6 DRYER

Dryer is used to prevent capillary blockage from moisture in the refrigerant system and H/E, condenser and evaporator. Also, dryer is used to remove corrosion of the components.

NOTE: When dryer is replaced, proper injection to capillary is needed. On opening the dryer, it should be welded instantly. The oxidization of dryer inside and all tubes inside after welding can be prevented.

42% R.H |

5(42%) |

|

4(50%) |

40% |

6(35%) |

3(60%) |

|

7(30%) |

2(70%) |

|

8(25%) |

1(80%) |

|

9(20%) |

Off |

DEAD DIAL |

Max. |

|

|

Figure 5

Figure 6

Dryer

Dryer

Figure 7

—7—

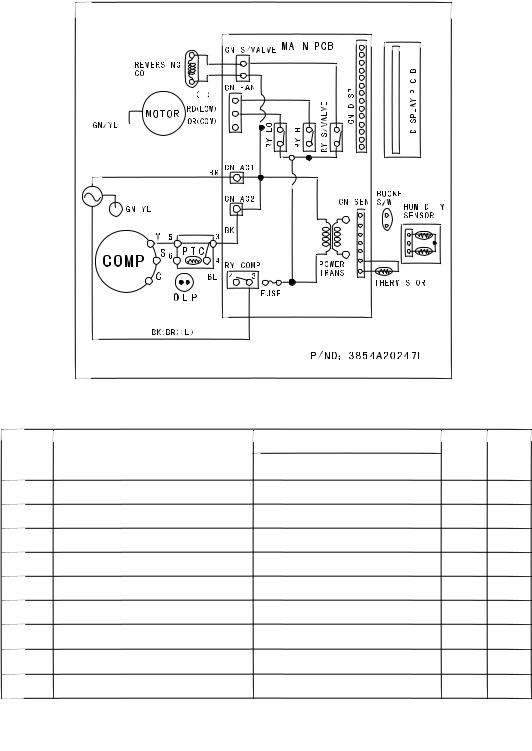

2. CIRCUIT DIAGRAM

• MODEL : BHD-252

BK HI

WH  BL

BL

N

N

NO. |

DESCRIPTION |

|

PART NO. |

Q'TY |

RE- |

|

|

BHD-252 |

PER SET MARKS |

||||

|

|

|

|

|||

1 |

POWER CORD ASSEMBLY |

6411A20044B |

1 |

S |

||

2 |

MOTOR ASSEMBLY |

4681A20040N |

1 |

S |

||

3 |

PTC ASSEMBLY |

|

6748C-0003C |

1 |

S |

|

4 |

COMPRESSOR, SET |

5416A20009A |

1 |

S |

||

5 |

OLP |

|

6750C-0005M |

1 |

S |

|

6 |

PWB(PCB) ASSEMBLY, DISPLAY |

6871A20600B |

1 |

S |

||

7 |

SENSOR ASSEMBLY |

6877A30013L |

1 |

S |

||

8 |

SWITCH ASSEMBLY, MICRO |

6600A30003C |

1 |

S |

||

9 |

PWB(PCB) ASSEMBLY, MAIN |

6871A20888E |

1 |

S |

||

S: SERVICE PARTS |

A: ALTERNATE PARTS |

N: NOT SERVICE PARTS |

|

|||

—8—

Loading...

Loading...