Page 1

RF500A GATEWAY

SYSTEM MANUAL

Page 2

1

RF500A Gateway System Manual

Contents

Check Packed Items.........................................................................................................................................................5

RF500A Gateway.................................................................................................................................................5

RF500 Transmitters.............................................................................................................................................5

RF500 Product Range......................................................................................................................................................6

RF500 Gateway...................................................................................................................................................6

RF500 Transmitters are available as follows:.......................................................................................................6

RF512 Temperature Transmitter............................................................................................................ 6

RF512M Temperature Transmitter Backbone Option..............................................................................6

RF513 Temperature and Humidity Transmitter.......................................................................................6

RF513M Temperature and Humidity Transmitter Backbone Option........................................................6

RF515 Analog Input Transmitter and RF515A Connection Box.............................................................7

RF516 Precision Temperature Transmitter..............................................................................................7

RF542 Temperature Transmitter ............................................................................................................7

Optional Accessories...........................................................................................................................................7

Safety Information.............................................................................................................................................................8

Warning................................................................................................................................................................8

WEEE..................................................................................................................................................................9

Powering On and Off......................................................................................................................................................10

Switch On..........................................................................................................................................................10

Gateway Switch OFF.........................................................................................................................................11

Gateway Reset .................................................................................................................................................11

Transmitter Activation........................................................................................................................................12

RF500A-CONFIG - RF500A Conguration Utility............................................................................................................13

Requirements for RF500A-CONFIG...................................................................................................................13

Installation of USB Drivers.................................................................................................................................13

Page 3

2

Obtain Comark USB Drivers..................................................................................................................13

USB Driver Installation Instructions.......................................................................................................14

Installation of RF500A-CONFIG..........................................................................................................................15

Obtain RF500A-CONFIG Utility.............................................................................................................15

RF500A-CONFIG Installation Instructions.............................................................................................15

Running RF500A-CONFIG for the First Time.......................................................................................16

Gateway Commissioning................................................................................................................................................17

Requirements for Commissioning.......................................................................................................................17

Setting of Gateway IP Address using RF500A-CONFIG....................................................................................17

Viewing the Gateway Login Page......................................................................................................................19

Setup of First Administrator.................................................................................................................................20

Gateway Language............................................................................................................................................20

Gateway Name..................................................................................................................................................21

Gateway Clock Setup..........................................................................................................................................21

Network Setup...................................................................................................................................................22

Network Details ....................................................................................................................................22

Gateway Programming and Use ....................................................................................................................................23

RF500 System Components...........................................................................................................................................24

Know your Gateway...........................................................................................................................................24

RF500A Front Panel Indicators..............................................................................................................24

Bottom Connections...............................................................................................................................25

Alarm Outputs........................................................................................................................................26

Side Switches and Indicators.................................................................................................................26

Know your Transmitter.......................................................................................................................................27

Transmitter Display.................................................................................................................................29

RF542 Network Transmitter - Detailed Operation .............................................................................................30

Connections to Network .......................................................................................................................30

RF542 Setup Procedure .......................................................................................................................31

Equipment Installation.....................................................................................................................................................33

Page 4

3

Gateway Fixing..................................................................................................................................................33

Transmitter Fixing..............................................................................................................................................33

Mains Wiring......................................................................................................................................................33

Ventilation..........................................................................................................................................................33

RF500 Wireless Monitoring System Overview................................................................................................................34

Gateway – Introduction......................................................................................................................................34

Overview of RF500 Mesh Networking................................................................................................................35

Meshing Transmitters and Backbone Transmitters.............................................................................................37

Automatic Data Retrieval (ADR)........................................................................................................................37

Gateway Specication – RF500A....................................................................................................................................38

Transmitters Specication...............................................................................................................................................39

RF542 Network Specication..............................................................................................................................42

Changing Lithium Battery on RF500 Series Transmitters...............................................................................................43

Battery Reordering.............................................................................................................................................43

Battery Change Procedure..................................................................................................................................44

Check for Transmitter Errors...............................................................................................................................45

Gateway Indication of Low Battery......................................................................................................................45

Pinout and Wiring............................................................................................................................................................46

Door Connector .................................................................................................................................................46

Power Connector...............................................................................................................................................46

Lumberg Connector...........................................................................................................................................47

Gateway Relay Outputs ....................................................................................................................................48

FCC Approvals................................................................................................................................................................49

Equipment Ratings..........................................................................................................................................................50

Supply Voltage...................................................................................................................................................50

Environmental Conditions...................................................................................................................................50

Gateway Storage/Operating Conditions................................................................................................50

RF51X Transmitter Operating Conditions..............................................................................................50

RF542 Transmitter Operating Conditions .............................................................................................51

Page 5

4

RF5XX Transmitter Storage Conditions.................................................................................................51

RF515 Maximum Input Conditions......................................................................................................................51

Maintenance and Cleaning.............................................................................................................................................52

Service and Repair..........................................................................................................................................................52

EC-Declaration of Conformity.........................................................................................................................................53

Transmitter Fault Codes..................................................................................................................................................54

Gateway Fault Conditions...............................................................................................................................................55

Appendix A – Gateway Connection via RJ45 Cross-Over Ethernet Cable......................................................................56

Appendix B - Setting a Fixed IP Address.........................................................................................................................57

Denitions of Gateway Terminology.................................................................................................................................59

Glossary..........................................................................................................................................................................62

Page 6

5

Check Packed Items

Please conrm that the kit contents are all present and correct. If you believe any parts are missing or damaged

please contact Comark or your local Distributor to arrange replacements.

Software and USB drivers are no longer provided on CD and can be downloaded free of charge from our website.

See “RF500A-CONFIG - RF500A Conguration Utility” {Page 13} for instructions on how to download and install the

software and drivers.

RF500A Gateway

The RF500A Gateway is available in two variants:

• RF500A Standard

• RF500AP Power over Ethernet enabled

The actual Gateway model is indicated on the side label by a check

mark adjacent to the model code.

The RF500A and RF500AP Gateway Kits consist of the following items:

• RF500A Gateway Part No. RF500A or RF500AP

• Transmitter Activator Part No. RF525

• High Gain Antenna Part No. RF504

• AC Adaptor with Mains Lead with either UK, EU or US plug

• Ethernet Cable

• USB Cable (Required for conguration only)

RF500 Transmitters

RF512, RF513, RF515 & RF516 transmitters are packed with a mounting bracket and 2-tie-wraps.

RF542 transmitters are additionally packed with:

1x RF520 AC Adaptor including regional mains plug attachment

1x Cat5e Ethernet Cable

1x RF525 Transmitter Activator

1x RF542 Quick Reference Guide

ON / OFF

AUX

STAT US

1 2 3 4

RF500A

SERIAL

No.

Comark Instruments, 52 Hurricane way,

Norwich, Norfolk, NR6 6JB. UK

Tel: 01603 (+44 1603) 256647

Email: service@comarkltd.com

www.comarkltd.com

Comark Instruments, PO Box 9090,

Everett, WA 98206, USA

Tel: (503) 643 5204

Email: service@comarkUSA.com

www.comarkUSA.com

RF500AP

MADE IN UK

FOR INDOOR USE ONLY

DO NOT MOVE WHEN

IN OPERATION

Page 7

6

RF500 Product Range

RF500 Gateway

The RF500 Gateway is available in two variants:

• RF500A Standard

• RF500AP Power over Ethernet enabled

RF500 Transmitters are available as follows:

RF512 Temperature Transmitter

• Integral temperature sensor plus connectors for two external temperature sensors and an external door

sensor

• External temperature range: –40°C to +125°C

RF512M Temperature Transmitter Backbone Option

• Integral temperature sensor plus connectors for two external temperature sensors and an external door

sensor

• External temperature range: –40°C to +125°C

• Includes High Gain Antenna and RF520 AC adaptor

RF513 Temperature and Humidity Transmitter

• Integral temperature sensor, one integral humidity sensor and connector for an external door sensor

• Integral temperature range: –30°C to +70°C

• Humidity range: 10-90% RH

RF513M Temperature and Humidity Transmitter Backbone Option

• Integral temperature sensor, one integral humidity sensor and connector for an external door sensor

• Integral temperature range: –30°C to +70°C

• Humidity range: 10-90% RH

• Includes High Gain Antenna and RF520 AC adaptor

Page 8

7

RF515 Analog Input Transmitter and RF515A Connection Box

• Two analog input channels, each capable of conguration as 0-1V, 0-10V or 4-20mA using RF515A

connection box

RF516 Precision Temperature Transmitter

• Integral temperature sensor, and connector for one external temperature Pt100 sensor and an external door

sensor

• External temperature range: –200°C to +400°C

RF542 Temperature Transmitter

• Connectors for two external temperature sensors and an external door sensor

• External temperature range: –40°C to +125°C

• Includes RF520 AC adaptor

Optional Accessories

RF520 AC adaptor for RF512, RF513, RF516 and RF542

RF502 RF Bridge - 0.5m lead to enable transmission through RF resistant barriers

RF503 RF Bridge - 1.0m lead to enable transmission through RF resistant barriers

RF515A 2-Channel Terminal Box with 0.25m lead terminated with 6-Pin Lumberg Plug

Includes two sets of 10R, 2K and 18K2 precision resistors

RF521 Door Sensor for hinged doors

RF522 Door Sensor for roller shutter type doors

RF525 Transmitter Activator

RFJACK Alarm Output jack (2.5mm)

RFALARM Alarm Output lead - 2m g-8 wire terminated with 2.5mm jack

Page 9

8

Safety Information

Under no circumstances may a user make any changes to the RF500A Gateway that would alter its performance. Any

modication would void the CE compliance of the Gateway and may invalidate the warranty.

If the equipment is used in a manner not specied by Comark Instruments, then the protection provided by the

equipment may be impaired.

No user serviceable parts are provided in RF500 Comark Wireless Monitoring Equipment. Contact Comark

Instruments or your local distributor for all service requirements.

Warning

• Before connecting or disconnecting the antenna, ensure anti-static precautions are observed.

• Use only the FRIWO 12V AC adaptor; Type FW74010/12 as supplied with the RF500A Gateway.

• Do not modify the RF500A Gateway AC adaptor in any way.

• Use only the PHIHONG, PSM11R-050 5V AC adaptor or FRIWO type FW7662/05 with RF500 transmitters.

It is supplied by Comark Instruments as three variants:

RF520 Transmitter AC adaptor with UK mains plug

RF520/EU Transmitter AC adaptor with European mains plug

RF520/US Transmitter AC adaptor with North American mains plug

RF520/AUS Transmitter AC adaptor with Australian mains plug

• Do not modify the AC adaptor in any way.

• RF500 transmitters contain a C-size lithium cell (AA-size for RF542). This cell must not be incinerated or

subjected to temperatures in excess of 100°C. Do not deform, mutilate, crush, pierce, disassemble, recharge

or short circuit. Such abuse can result in loss of seal, and/or cell explosion. Also exposure to humid conditions

for long periods should be avoided.

• Do not insert metal objects into connectors.

Page 10

9

• Ensure the antenna is securely connected before powering the equipment. Internal damage may result

otherwise.

• The Gateway and Transmitters have been designed to operate with the antenna supplied by Comark, and

having a maximum gain of 7dBi. Antennas not supplied by Comark Instruments or having a gain of greater

than 7dBi are strictly prohibited for use with this device.

WEEE

RF512, RF513, RF515, RF516 and RF542 transmitters contain a non rechargeable lithium

battery. This battery must be disposed of in accordance with local regulations.

Page 11

10

Powering On and Off

Switch On

BEFORE SWITCHING ON, ENSURE THE ANTENNA HAS BEEN FITTED - IT IS ESSENTIAL TO AVOID DAMAGE.

1. Plug the Gateway AC adaptor into the socket on

the underside of the Gateway, or for the PoE

model (RF500AP) plug the Ethernet cable into a

PoE enabled network socket. The Power/Battery

indicator should show steady green.

2. Using a paper clip or similar object, press in and

hold the ON / OFF switch on the side of the Gateway

for 4 seconds. The Gateway will beep once and the

blue ON* indicator will ash at a half-second interval.

Gateway bootup will begin. On successful boot, the

ON indicator will show solid blue.

* The ON indicator is shown in “Figure 6 - Front Panel Indicators” {Page 24}

Figure 1 - Switch On using Paper Clip

Page 12

11

The Gateway contains an internal backup battery, if this battery is not sufciently charged; the

Gateway will not switch on. Once external power is connected the internal battery will begin

recharging. Whenever the charge state becomes sufcient the Gateway will automatically start as requested.

Whilst in this mode Status LEDs 1, 2, 3 and 4 will ash in sequence. See “Figure 8 – Left Hand Side View of

Gateway” {Page 26} for location of these LEDs.

It takes a few minutes for the Gateway to initialise; a sequence of 2 beeps followed by 4 beeps indicates

successful initialisation.

Gateway Switch OFF

To turn the Gateway OFF navigate to the hardware page of the Gateway Web-View and use the Shutdown Gateway

button, this will initiate the Gateway shut-down procedure.

If for some reason it is not possible to use the Gateway Web-View, then using a paper clip or similar object, press in

and hold the ON / OFF switch on the side of the Gateway for 4 seconds. The Gateway will beep once and the ON

indicator will ash at a 3 second interval to indicate shut-down. Once the shut-down sequence begins, the Gateway

will beep 10 times in quick succession. The shut-down procedure could take up to 5 minutes to complete. After

shut-down is complete the ON indicator extinguishes.

Gateway Reset

There are several circumstances under which the Gateway will perform a software reset, (for example performing

Gateway Clock Setup). At start of the sequence the Gateway will beep 10 times in quick succession. The reset

could take up to 5 minutes to complete which is indicated by a sequence of 2 beeps followed by 4 beeps to indicate

successful initialisation. Unlike the shut-down described above, the ON indicator will remain steady during the reset

sequence.

Page 13

12

Transmitter Activation

RF500 transmitters are despatched in a disabled state to preserve the battery. To activate these, insert the RF525

Activator into the 3-pin socket marked B in “Figure 10 - Connector view of RF512, RF515, RF516 & RF542

Transmitter” {Page 28} until the display is enabled then remove the RF525.

On rare occasions RF542 Transmitters may show low battery on activation. This is due to a chemical process within

the AA lithium cell called passivation, this is normal and the AA cell is not necessarily dead. Simply remove and

replace the same battery by following the instructions in “Changing Lithium Battery on RF500 Series Transmitters”

{Page 43}. The low battery indication should not re-appear.

Once activated, transmitters can only be de-activated by removing the battery.

Page 14

13

RF500A-CONFIG - RF500A Conguration Utility

Each Gateway is shipped with a default IP address of 192.168.25.220. The Gateway IP address must be changed to

the Static IP address provided by your IT department before connecting to the LAN.

Comark Instruments provides a Windows utility: RF500A-CONFIG to allow changing or viewing the Gateway IP

address via the USB port.

Requirements for RF500A-CONFIG

• Windows XP, Windows XP 64-bit or Windows 7, Windows 7 64-bit

• Comark USB Drivers (The USB drivers must be installed prior to installing RF500A-CONFIG)

• Oracle (previously Sun) Java Runtime Environment 1.6.0 or later

Installation of USB Drivers

Obtain Comark USB Drivers

Comark USB Drivers can be downloaded from the following websites:

• http://www.comarkinstruments.com/software.tpl – UK and International

• http://www.comarkusa.com/software.tpl – USA, Canada and South America

Click the Comark USB Driver.exe link shown on web page above. Fill in the form and tick the box to conrm you

have read the Software License Agreement. Proceed to download the le and choose the save option to start the

download.

Page 15

14

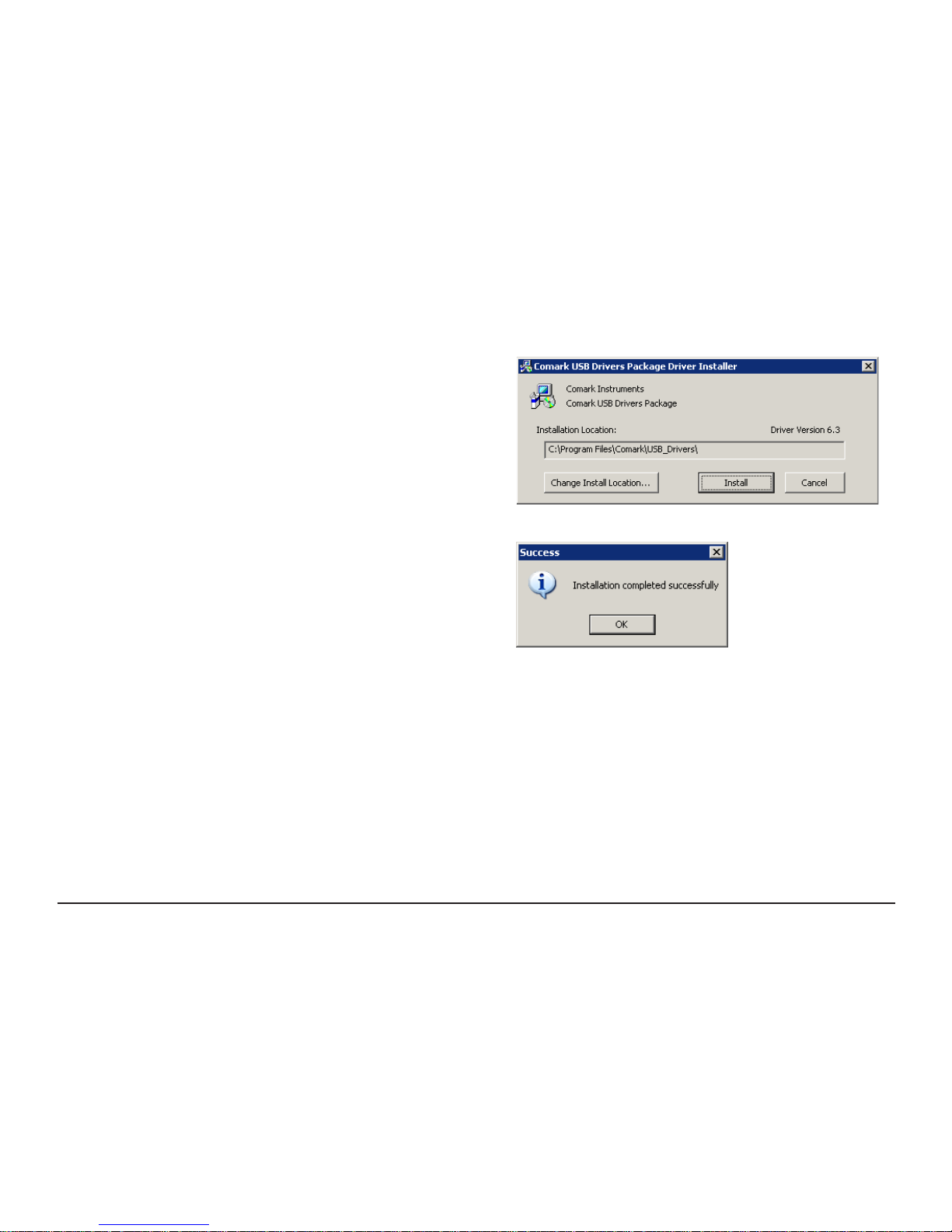

USB Driver Installation Instructions

When the download is complete; click the run button.

NOTE: Windows will ask if the user wants to allow this program

wto run, select yes.

Conrm you wish to install.

The screen opposite should be displayed - Click Install.

Once installation is complete you will see the screen opposite.

Please note your computer may request a restart after installation completes.

Page 16

15

Installation of RF500A-CONFIG

Obtain RF500A-CONFIG Utility

Comark RF500A-CONFIG can be downloaded from the following websites:

• http://www.comarkinstruments.com/software.tpl – UK and International

• http://www.comarkusa.com/software.tpl – USA, Canada and South America

Click the RF500A Cong Util-1.00-Setup.exe link shown on the web page above. Fill in the form and tick the box to

conrm you have read the Software License Agreement. Proceed to download the le and choose the save option to

start the download.

RF500A-CONFIG Installation Instructions

• When the download is complete, click the run button.

• NOTE: Windows may ask if the user wants to allow this program to run, select yes.

• Conrm “English” as the install language (there is no other choice available).

• In response to the question: This will install RF500A-Cong Util on your computer. Continue ? Click YES.

• The following screen states: It is recommended that you close all that all other applications before continuing

After closing these applications click the Next > button.

• When prompted to Choose Destination Folder accept the default of:

C:\Program Files\Comark\RF500A Cong Util by clicking the Next > button.

• When prompted to Start Copying Files click the Next > button.

• The installer will copy the les and conrm that it has successfully installed RF500A Cong Util. Click the

boxes to install your choice of short-cuts and click the Finish button.

Page 17

16

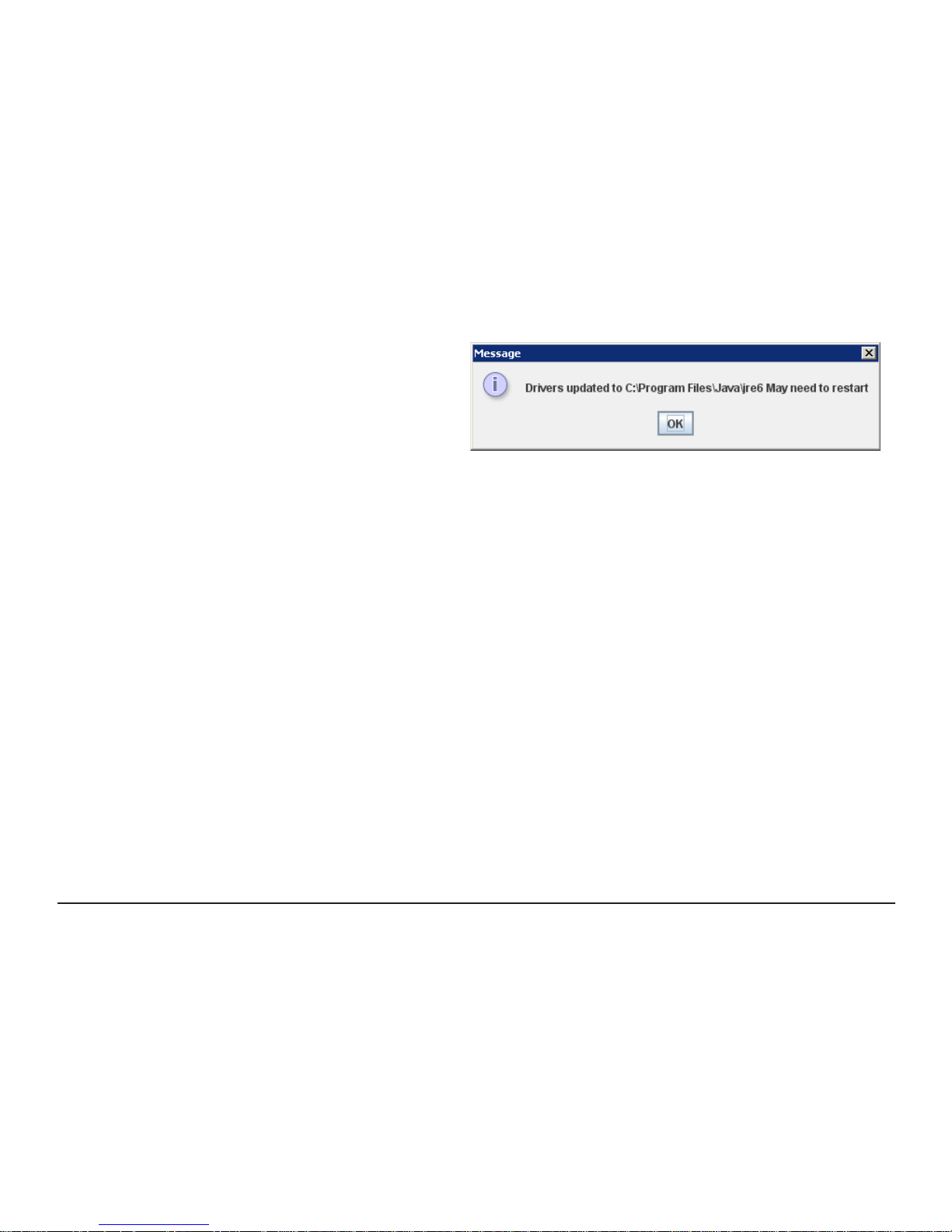

Running RF500A-CONFIG for the First Time

RF500A-CONFIG will examine the Java environment and

update it if necessary. Successful update is conrmed

by the message opposite.

After clicking OK, RF500A-CONFIG will attempt to restart

automatically but on some systems this may not occur.

In this instance simply restart RF500A-CONFIG using the

Start Menu or other installed short-cut.

RF500A-CONFIG is now properly installed and ready for use during Gateway Commissioning as follows:

Figure 2 - Java Environment Update Successful

Page 18

17

Gateway Commissioning

This section covers:

• Network conguration

• Setup of rst Administrator

• Setting Gateway language

• Setting Gateway name

• Setting date and time

Requirements for Commissioning

• Computer with USB port and RJ45 Ethernet jack

• Comark RF500A-CONFIG Utility and USB cable

• Static IP address, Subnet mask and Default gateway (Usually allocated by IT Department)

• Email server name or IP address

• DNS server IP address (required if email server is named)

Setting of Gateway IP Address using RF500A-CONFIG

Each Gateway is shipped with a default IP address of 192.168.25.220. The rst stage of commissioning is to complete

basic network conguration. Comark provides a Windows utility: RF500A-CONFIG to perform this conguration.

To complete this section, you will need the following pieces of information from your IT department:

• Static IP address for the Gateway

• Subnet mask

• Default Gateway

• DNS Server Not a requirement for this stage but may be needed for later conguration

1. Connect the RF500A Gateway to the computer using the USB lead.

2. Switch on the RF500A. See “Powering On and Off” {Page 10} for instructions.

Page 19

18

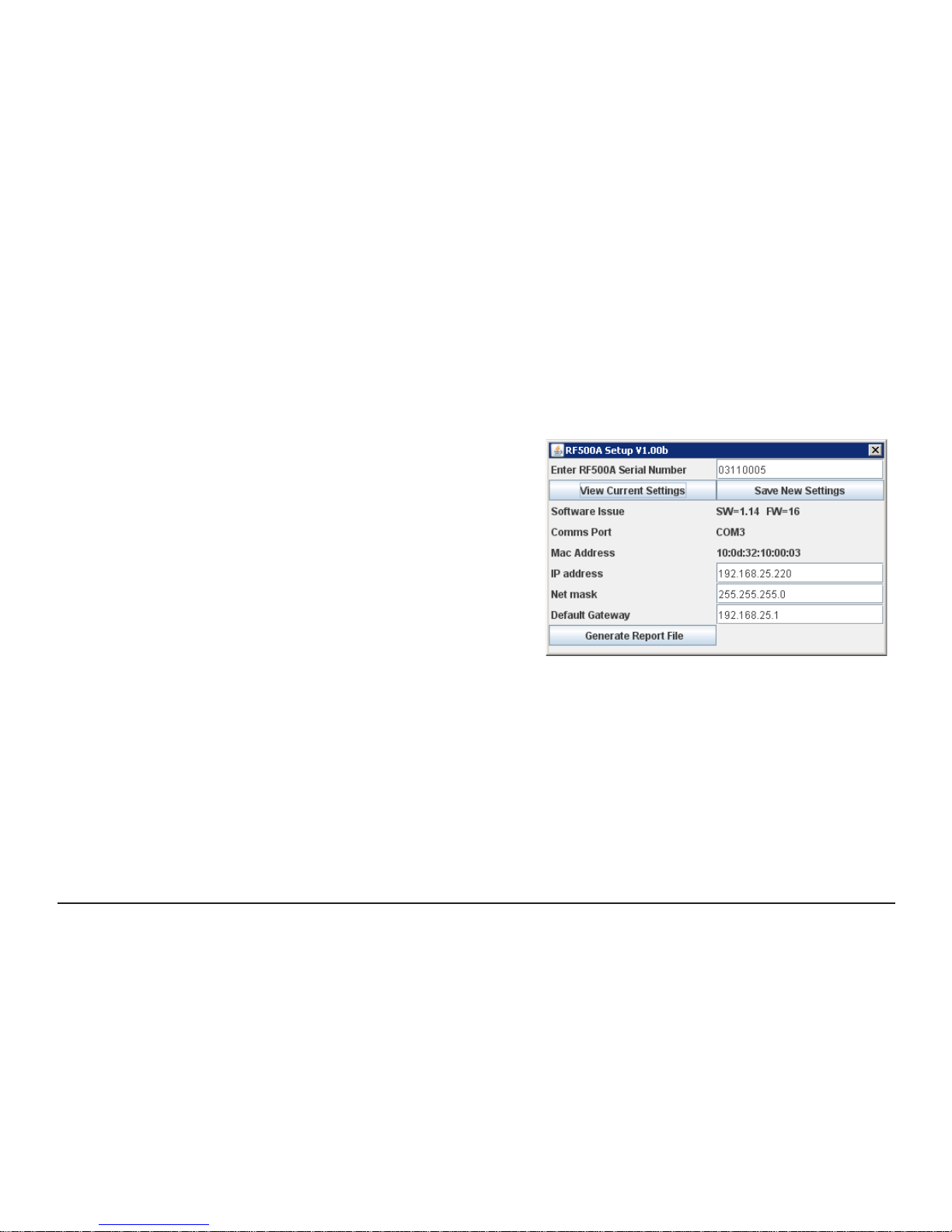

3. Start the RF500A-CONFIG Utility using the Windows Start

Menu – The screen as shown in “Figure 3 - RF500A-CONFIG

Screenshot” opposite, will be displayed:

4. Enter the Serial Number of the Gateway connected

then click the View Current Settings button - Wait until

the various elds are populated.

5. Enter the IP address, subnet mask and Default Gateway

using dotted decimal notation into their respective elds.

Software Issue For Comark Instruments use only

Comms Port For Comark Instruments use only

Mac Address Hardware address of the Ethernet interface

IP Address The IP address allocated to the Gateway

Net mask The subnet mask associated with the

IP address

Default Gateway The IP address of the network gateway to

allow access from a different subnet

6. Click the Save New Settings button - After successful transfer, RF500A-CONFIG will Reset the RF500A.

The Generate Report File button is only for use under instruction from Comark Technical Support.

Figure 3 - RF500A-CONFIG Screenshot

Page 20

19

Viewing the Gateway Login Page

Ensure both the computer and Gateway each have an Ethernet cable connection to the LAN or are connected

together via Ethernet cross-over cable.

Recall the IP address that was congured in

“Setting of Gateway IP Address using RF500A-CONFIG” above.

1. Start the Web Browser on the computer.

2. Enter the IP address into the Address Bar as displayed opposite.

3. Press “Enter” key or click “Go”.

4. The Gateway login screen as in Figure 5 below will be displayed.

Figure 4 - Browser Address Bar

Figure 5 - Gateway Login Screen

Page 21

20

Setup of First Administrator

As shipped, the Gateway has no users congured except for a special “one-time-use” installation user which enables

an installer to add the main Administrator to the Gateway. Thereafter this Administrator’s username is used to perform

all subsequent commissioning.

1. At the Gateway user login screen, type the username “comark” and click Enter.

2. At the password screen enter “42” and click Enter.

3. You will be logged into the Gateway as the installation user.

4. The Gateway will inform you that “You are about to commission a new system”.

5. Click on the Enter Administrator Details button.

6. When the Add 1st Administrator screen appears, ll in the elds with the username and password of your

choice.

7. In the top left box, marked “Password Required”, enter the installation password: ”42” and then click the

Submit button.

8. If successful the Gateway will return the message “New user added”.

9. Click the OK button to return to the Gateway user login screen.

10. Login as the new Administrator you just created.

Gateway Language

The language the Gateway uses in web pages and in emails can be changed as follows:

1. Click the Administration button then the Language button.

2. Click the radio button below the ag corresponding with your choice of language. Enter your password and

click the Submit button.

The language selected is used immediately for all web pages and emails generated for all users.

Page 22

21

Gateway Name

A Gateway name is required for email operation.

The Gateway Name is any name you choose, subject to the limit of up to 16 alphanumeric characters only. It will be

used in the “From:” eld in email and SMS notications. This is important if you have more than one Gateway in your

wireless system and all should be unique.

1. Click the Administration button then the Gateway Name button.

2. Enter the new Gateway Name into the entry eld.

3. Enter your password then click the Submit button.

Gateway Clock Setup

1. Click the Administration button then the Set Clock button.

2. Enter the current date and time using a 4-digit year.

3. Enter your password and click the Submit button.

The Gateway will automatically reset after this step.

Page 23

22

Network Setup

The Network Settings page has many elds but at this stage for a basic LAN connectivity test, only the Network

Details section is required.

This section assumes a network connection via LAN and the IP address congured using RF500A-CONFIG as

opposed to using a cross-over cable and the RF500A default IP address of 192.168.25.220.

Click the Administration button then the Setup Network button to show the Network Details page.

Network Details

Your IT Department usually provides the following information in order to set up your Gateway for Network Access:

• Static IP Address

• Subnet Mask

• Default Gateway

• DNS Server

Enter these using dotted decimal notation into their respective elds. If access from different subnets is required also

enter the Network gateway IP address. Users who implement MAC address access security will nd the MAC address

of the LAN interface displayed in this screen.

Static IP Address The IP address which has been allocated to the Gateway. E.g. 192.168.25.217

Net mask The subnet mask associated with the above IP address. E.g. 255.255.255.0

Default Gateway The IP address of the network gateway to allow access by users on a different subnet

DNS No The IP address of your LAN Name Server

1. Double-check the Static IP Address entered because any entry mistake here can cause problems connecting

after settings are saved.

2. To save changes, enter your password and click the Save button. The Gateway may automatically reset after

this step.

3. Wait until the Gateway has successfully reset. See “Gateway Reset” {Page 11} for details.

4. Verify that a connection can be made to the Gateway by following the steps in “Viewing the Gateway Login

Page” {Page 19}.

Page 24

23

Gateway Programming and Use

This, the RF500A System Manual covers installation and commissioning of the RF500 Wireless Monitoring system

from a hardware point of view.

A Web-View Help Guide for the RF500 Wireless Monitoring System is available online via the Gateway itself. This is a

detailed manual incorporating help and detailed information on use of the Gateway and transmitters, including all the

available pages.

Using the Web-View manual as a guide the remainder of the RF500 Gateway conguration can be performed. This

includes:

• Email Setup

• Email Account

• Adding Transmitters

• Create a Backup

Page 25

24

RF500 System Components

Know your Gateway

RF500A Front Panel Indicators

Figure 6 - Front Panel Indicators

There are four LEDs on the front of the Gateway:

ON Steady Blue The Gateway is running

Flashing at ½s rate Gateway is starting up

Flashing at 3s rate Gateway is shutting down

POWER / BATTERY Steady Green External power is available

Flashing Green Gateway is on and running off the battery pack

Off Gateway is off and external power is not available

FAULT Flashing Yellow Contact technical support from your local distributor or Comark

Instruments. The Home Page may provide more information on

possible faults

ALARM Flashing Red An enabled alarm event has occurred

ON

POWER /

BATTERY

FAULT ALARM

Page 26

25

Bottom Connections

Figure 7 - Bottom View of RF500A Gateway

A. Cable clamps

B. 12 VDC input

C. SW1 – Jack Socket for Relay Output 1

D. SW2 – Jack Socket for Relay Output 2

E. RJ45 Ethernet LAN Socket

ED

C

B

AA

Page 27

26

Alarm Outputs

SW1 & SW2 are two switched outputs provided for connection to customer alarm indicators, via relay contacts with

24Vdc 500mA rating, congurable for either NO (Normally Open) or NC (Normally Closed). These are marked as

SW1 and SW2, and are in the form of 2.5mm Jack Sockets. Plugs to t these sockets can be ordered from Comark

Instruments using part number: RFJACK.

With the Gateway switched OFF the relays are in a Normally Open condition, this may cause any equipment

connected to the contacts to energise.

Side Switches and Indicators

Figure 8 – Left Hand Side View of Gateway

ON / OFF Gateway Startup/Powerdown switch

STATUS Diagnostic LEDs for technical support use

AUX Reserved Switch

ON / OFF

AUX

STAT US

1 2 3 4

RF500A

SERIAL

No.

Comark Instruments, 52 Hurricane way,

Norwich, Norfolk, NR6 6JB. UK

Tel: 01603 (+44 1603) 256647

Email: service@comarkltd.com

www.comarkltd.com

Comark Instruments, PO Box 9090,

Everett, WA 98206, USA

Tel: (503) 643 5204

Email: service@comarkUSA.com

www.comarkUSA.com

RF500AP

MADE IN UK

FOR INDOOR USE ONLY

DO NOT MOVE WHEN

IN OPERATION

Page 28

27

Know your Transmitter

BA C

E

D

F

Figure 9 - Front view of RF512 Series Transmitter

A. Alarm LED. Flashes red to indicate any one channel in alarm

B. Active LED. Flashes green to indicate external power detected

C. Infra-Red interface. For Comark use only

D. Antenna. (Do not remove whilst in operation)

E. Lashing eye - Four available

F. Internal temperature sensor

Page 29

28

Figure 10 - Connector view of RF512, RF515, RF516 & RF542 Transmitter

A. Lumberg Socket for Probe

B. Socket for Door & RF525 Activator (Dual function)

C. External DC adaptor socket

Figure 11 - Ethernet Link Indication Window (RF542 Only)

A. Ethernet link indication (once a link is detected the green indicator will be illuminated)

C

B

A

Page 30

29

Transmitter Display

RF500 transmitters all have a liquid crystal display as shown below. Only RF512 is capable of using all three display

areas and annunciators.

Indicates that the door channel

reads open.

Indicates that the internal lithium battery

requires replacement.

Indicates an unacknowledged alarm on any channel.

When steady, indicates that the transmitter has logged

onto the Gateway.

When ashing, indicates the transmitter is currently

attempting transmission with the Gateway.

Indicates that the sensor or probe is broken.

Indicates that the number to be displayed is too big to t

on the LCD. E.g. 2000 cannot be shown on a “1999” digit area.

INT

EXT1

EXT2

Figure 12 - Transmitter Display

Page 31

30

RF542 Network Transmitter - Detailed Operation

The RF542 Network Transmitter is a two external channel temperature monitor. Communication to the RF500

Gateway does not use RF but an Ethernet LAN connection is used instead. It allows temperature monitoring in

locations which are out of radio range of the Gateway.

The RF542 will only transmit data to its associated Gateway when connected to external power via the RF520

AC adaptor. If external power is removed, transmitter temperature monitoring and logging will continue. Once

external power is restored, data record transmission to the Gateway will resume.

Whilst external power is connected, the transmitter will become noticeably warm to the touch.

This is normal and expected behaviour.

Figure 13 - RF542 RJ45 Network Port

Connections to Network

This device supports xed speed 100Mbps, half duplex. It has a DHCP client so the IP address will be assigned by the

network; there is no facility to set a static IP address.

Page 32

31

RF542 Setup Procedure

1. Plug RF542 into network.

2. Plug the RF520 into the mains and into the RF542.

3. Plug in the RF525, the LCD will rst display the current IP address of the RF542 which needs to be noted

down for the next step. In the example in Figure 14 below the IP address would be 192.168.25.188. If the RF542 IP

address is 0.0.0.0 this means the network has not issued an IP address yet, remove the RF525 and try again. If you

missed some of the sequence, remove the RF525 and try again.

Figure 14 - Display of RF542 IP Address

4. Once the set of four numbers for the IP address has been displayed the LCD will nally show SETUP as shown

below:

Figure 15 - RF542 in Setup Mode

Page 33

32

5. Using the PC and a suitable Web Browser

(use Firefox, Chrome or Internet Explorer), enter the IP

address as noted down from step 3 into the address bar

and the page opposite will be displayed:

6. In the text box above the buttons type in the IP address or

URL of the RF500A that will store the data for this transmitter.

4. Click the Enter button and the conrmation screen opposite

will be displayed:

5. Setup is now complete. Remove the RF525, the transmitter

will now revert to normal operation ready to be added to the

Gateway for tasking.

7. Click the Enter button and the conrmation screen opposite

will be displayed:

8. Setup is now complete. Remove the RF525, the transmitter

will now revert to normal operation ready to be added to the

Gateway for tasking.

Figure 16 - RF542 Setup Page

RF542 Setup Page

Serial No: CN11070474

Mac Address: 00-07-3C-1D-0C-01

Link Speed: 100

Current Gateway Address:

192.168.25.92

Enter RF500A Gateway Address

Enter Cancel

Serial No: CN11070474

Mac Address: 00-07-3C-1D-0C-01

Link Speed: 100

Current Gateway Address: 192.168.25.92

Enter RF500A Gateway Address

Figure 17 - RF542 Setup Page Conrmation Page

Page 34

33

Equipment Installation

Comark Instruments strongly recommend that RF500 System installation is carried out by a Comark Installation

Engineer or by a Comark Authorised Distributor or Agent.

Gateway Fixing

Mounting of the Gateway is possible using the keyhole screw xings provided on the rear of the Gateway itself.

However the xings used are to be determined by the installation engineer depending on the type of material used

in the construction of the area where the Gateway is to be placed. To avoid accidental disconnection, the DC power

cable and cables connecting to the Relay Outputs should be secured using the cable clamps provided on the Gateway

case. See “Figure 7 - Bottom View of RF500A Gateway” {Page 25}.

Positioning of the Gateway should be in such a way as to limit the risk of liquid being spilt on it as damage may result.

Transmitter Fixing

Mounting of the transmitters is possible using the mounting bracket provided. The bracket is xed using 2 screws

and the transmitter then slides into the bracket from the top. With each transmitter, Comark Instruments provide

two cable ties which, once the transmitter is slid into the bracket, can be fed through the slots in both bracket and

transmitter case to retain it. The door and DC power cables should be tie-wrapped to the bracket to avoid accidental

disconnection.

Mains Wiring

Connections to mains supply for the Gateway and powered transmitters is via the AC mains adaptors supplied and

a locally installed socket. Any power requirements for the hardware will be determined during survey and should be

installed by qualied electrician and certied as safe to use before installation can be started.

Ventilation

At no time should the ventilation slots on the Gateway be covered or obstructed. At least 100mm of free space must

be provided above and below the Gateway to ensure that sufcient airow is maintained through the case to provide

adequate cooling. Failure to do this may result in damage to the Gateway due to overheating and invalidation of the

warranty.

Page 35

34

RF500 Wireless Monitoring System Overview

Gateway – Introduction

The RF500A Gateway is an embedded microprocessor device containing a radio module for RF communications

to the monitoring transmitters. The radio module uses a licence free band in the 2.4GHz spectrum. Comark

Instruments RF500 uses proprietary protocols over a standard IEEE 802.15.4 link. These protocols achieve reliable

communication between the transmitters and the Gateway via self-healing mesh radio networks.

Data from measurements taken by the transmitters is stored on the RF500A Gateway in contrast to other systems

which store their data on a PC using special software. For operating the RF500 system the only software required

is a Web Browser such as Internet Explorer or Firefox. There is no requirement to install software on each user's

computer.

The Gateway contains sufcient data storage capacity for up to 10 years which can be automatically backed up to

external storage using the built in shared drive backup method, or by manual request to generate and download a

backup le via your web browser.

An external power adaptor provides the mains power for the Gateway. An internal Nickel-Metal-Hydride (Ni Mh)

rechargeable battery is included, this provides normal operation of the Gateway during power failure until the battery is

exhausted; the Gateway then shuts down until power is restored.

Two relay connectors are provided for external alarms, Autodiallers/Klaxons etc. All other connections to the Gateway

are disabled. See “Figure 7 - Bottom View of RF500A Gateway” {Page 25} for further details.

Emails for alarms will be instigated directly from the Gateway. It is also possible to send a text message alarm via

email using a third party provider.

The Gateway can be either desk mounted or wall mounted. Wall mount keyhole slots are provided on the case. The

external long range Antenna has variable orientation to suit vertical or horizontal mounting.

Four LEDs on the Gateway display the current status of the system – ON, Power/Battery, Alarm indication, and Fault

indication.

Page 36

35

Overview of RF500 Mesh Networking

The RF500 Wireless Monitoring System uses the IEEE 802.15.4 radio transmission standard to implement a radio

mesh network.

A mesh network is comprised of the following devices:

• Gateway

• Mesh Transmitter

• Transmitter

On installation each transmitter is associated with a particular Gateway by serial number. Messages are transferred

between transmitters and the Gateway using two-way communication with acknowledgement of successful message

reception.

Transmitters which are physically close to their associated Gateway such as transmitter A in Figure 18 below will

most likely transmit directly to it. Others such as transmitter B which are further away rely on meshing transmitters to

forward messages to and from the Gateway on their behalf.

The route taken by the message can vary depending on network load and link reliability. The ability to dynamically

recongure the network is termed self-healing. In the gure below the self-healing ability is shown.

Page 37

36

Figure 18 - A Typical Mesh Network

Mesh Transmitter

Gateway

Transmitter

!

Data transfer interrupted

transmitter continues to

store data.

Transmitter reroutes to

self-heal network and

transfers stored data.

A

B

A

B

Page 38

37

Meshing Transmitters and Backbone Transmitters

Whenever a RF512, RF513 or RF516 transmitter is powered by a RF520 AC adaptor it will become a Meshing

transmitter and will form part of the radio mesh network, intelligently forwarding messages on behalf of other

transmitters. However if external power is removed it will revert back to a regular transmitter.

In “Figure 18 - A Typical Mesh Network” above , regular Transmitter B is supported by its nearest Mesh Transmitter

(coloured blue/dark) which in turn is supported by other Mesh Transmitters. If external power failed on one on those

Mesh Transmitters; Transmitter B would not have a route back to the Gateway, effectively isolating it from the radio

network. To prevent missed alerts from transmitters such as B it is recommended to set those Mesh Transmitters it

depends on for its radio route to the Gateway as Backbone Transmitters.

RF512, RF513 and RF516 have the option to become “Network Backbone” transmitters, this option can be enabled

using a setup option in the Gateway. Backbone transmitters will form part of the mesh network continuously even

when not powered by a RF520. Due to the very large drain on the internal battery, Backbone transmitters must be

powered using a RF520 mains adaptor. The internal battery is considered only as a backup battery for Backbone

transmitters.

Automatic Data Retrieval (ADR)

The fact that transmissions between transmitters and the RF500 Gateway are acknowledged ensures that the

transmitters know exactly which data records have been successfully transferred to the Gateway and those which

must be re-transmitted. Therefore if the Gateway is temporarily unable to receive or transmit messages for whatever

reason, data will not be lost during this period. When the Gateway is again able to receive and transmit properly the

transmitters will re-transmit those records which were unable to be transmitted during the period of outage.

This re-transmission of data happens automatically without user intervention and results in seamless graphical and

tabular data with no gaps.

Page 39

38

Gateway Specication – RF500A

No of Channels Up to 256

No of Transmitters Up to 64

Storage Capacity Up to 10 years worth of data

RF Frequency 2.4GHz using IEEE 802.15.4

Operating Conditions 0°C to +40°C (+32°F to +104°F)

10-90% RH non-condensing

Power Sources AC power adaptor, rechargeable Ni-Mh battery

RF500AP only:

Power over Ethernet (PoE) capability. Compliant to

IEEE 802.3af

Power Adaptor 100-240VAC 1.5A 50/60Hz

Battery Backup 4.3Ah Ni-Mh Rechargeable Battery.

Running time approximately 1 hour

Clock Accuracy 4ppm (2 minutes per year)

Relay Outputs (SW1 & SW2) Two individual 2.5mm jack sockets.

Contacts: 24Vdc 500mA maximum

Maximum Relay Output Lead Length Not to exceed 30m

Power Consumption 12W typical

Dimensions L 225mm x W 150mm x D 40mm

Weight 1.3kg

Page 40

39

Transmitters Specication

Temperature Measurement Range

Integral Thermistor Sensor - RF512, RF516

Integral Thermistor Sensor - RF513

External Sensor - RF512, RF542

External Pt100 Sensor - RF516

-30°C to +70°C / -22°F to +158°F

-30°C to +70°C / -22°F to +158°F

-40°C to +125°C / -40°F to +257°F

-200°C to +400°C / -328°F to +752°F

Humidity Measurement Range (RF513) 10 to 90% RH

Analog Input Measurement Range (RF515) 0-1V, 0-10V, 4-20mA

System Accuracy Temperature with Standard Sensors

Internal Thermistor – 0°C to +70°C / -32°F to +158°F

External Thermistor – -20°C to +70°C / -4°F to +158°F

Thermistor – full range

Pt100 – full range between two points

±0.5°C / ±1°F

±0.5°C / ±1°F

±1°C / ±2°F

±0.1°C / ±0.2°F

Humidity

10-90% RH

±3%

System Accuracy - Analog Input (23°C) / (73°F) 0.3% of reading

Page 41

40

Resolution

Temperature

Thermistor

Pt100

Door Sensor

Humidity

10 to 90% RH

Analog Input

0-1V

0-10V

4-20mA

0.1°C / 0.1°F

0.015°C / 0.03°F

7.5 seconds

±0.1%

0.1mV

1mV

1µA

Maximum Probe Lead Length (Except RF516)

Maximum Probe Lead Length (RF516)

Not to exceed 30m

Not to exceed 3m

Pt100 Connection Type 4-Wire

Pt100 Sensor Drive Current 400µA Nominal

Operating Temperature Range (RF542) 0°C to +50°C (32°F to 122°F)

10-90%rh - Non-Condensing

Storage Temperature -40°C to +85°C (-40°F to +185°F)

RF Frequency 2.4GHz using IEEE 802.15.4

Standard Antenna

High-Gain Antenna (optional)

External, removable, Omni directional with pivot.

Length: 90mm from pivot

Length: 235mm from pivot

Radio Range* *Typically 50 metres indoors

Page 42

41

Clock Accuracy** 20ppm (1 minute/month) at 25°C (77°F)

Logging Memory 32000 records

Logging Frequency Programmable between 1 minute and 60 minutes

Monitoring Frequency 1 minute

Indicator LEDs Red – Warning

Green – External Power (Not RF515)

Green - LAN Connection (RF542 only)

Case Material Over moulded food safe clear polycarbonate with

BioCote® antimicrobial

Battery Type Replaceable Lithium ‘C’ Cell

Saft LSH14 LIGHT

Saft LS26500 (Restricted for transport)

Replaceable Lithium ‘AA’ Cell (RF542 only)

Battery Life*** Up to 3 years

Dimensions L 134mm x W 83mm x D 34mm

L107mm x W 83mm x D 40mm (RF542)

Weight 270g

215g (RF542)

Mains PSU Optional Mains PSU Part No RF520

100-240VAC 0.3A 50/60Hz

* Internal RF range cannot be guaranteed as it varies from building to building. Requirement for all hardware is

always determined on site by a physical site survey.

** Transmitters will synchronise their clocks with the Gateway at midnight.

*** When used at 23°C (73°F) room temperature and Radio Rate of 15 minutes.

Page 43

42

RF542 Network Specication

Ethernet Connectivity Fixed 100Mbps - Half Duplex - RF45 Jack

IP Address Conguration DHCP Only

Link Status Indication Green LED for Link Established

Page 44

43

Changing Lithium Battery on RF500 Series Transmitters

Battery Reordering

RF512, RF513, RF515 & RF516 transmitters are tted as standard with a high power 3.6V Primary lithium-thionyl

chloride C-size cell. Manufacturers part number Saft LSH14 LIGHT or Saft LS26500.

The Saft LS26500 battery can only be used in transmitters manufactured after April-2009. The date-of-manufacture is

encoded in the serial number. The serial number has the format MMYYxxxx where MM represents the 2-digit month

and YY represents the 2-digit year in which the transmitter was manufactured.

Comark recommend that only the Saft LSH14 LIGHT be used in powered transmitters. The Saft LS26500 battery can

suffer from short lifetime when installed in powered transmitters.

Only use Saft LSH14 LIGHT or Saft LS26500 as replacements. Use Comark part number: ‘RFBATT’ to order a

replacement battery.

RF542 transmitters use a 3.6V AA lithium thionyl chloride battery; this can be replaced by any brand of 3.6V AA lithium

battery.

Page 45

44

Battery Change Procedure

The transmitter latches any low battery condition and must be powered off fully for it to clear. Waiting for the display to

go blank ensures that the low battery status is cleared.

1. Disconnect all plugs from the transmitter and remove it from its mounting bracket by sliding it upwards.

2. Using a Philips No 0 or at-blade screwdriver undo the two retaining screws and remove the battery cover.

3. Remove the exhausted battery and wait a few seconds for the display to blank.

4. Replace with a fresh one ensuring the polarity is correct and taking care to snap the new battery in cleanly

without making and breaking the contacts repeatedly.

5. Replace the battery cover and do up the two screws taking care not to overtighten them.

6. Observe any local restrictions on disposal of the used cell.

tfa

S

BATTERY

COVER

s

t

f

a

Figure 19 - Battery Cover Figure 20 - C-Size Cell Fitment Figure 21 - AA-Size Cell Fitment

Page 46

45

Check for Transmitter Errors

The removal of the battery will cause the internal clock on the transmitter to reset and so generate a Code-100

condition. This will be cleared automatically by the Gateway, see “Transmitter Fault Codes” {Page 54} for details.

Verify that the transmitter display shows either “No Code”, “No Fault” or “Code-100” only.

Should a “Code-400” or “Code-500” occur after battery change on a previously working transmitter try removing

and reinserting the battery, taking care to snap the new battery in cleanly without making and breaking the contacts

repeatedly.

Gateway Indication of Low Battery

Once a transmitter shows “low battery” the radio is disabled, monitoring and data logging however will continue until

the battery becomes completely exhausted. If a transmitter is left in a state of low battery for a long period, there may

be many logged records awaiting transmission to the Gateway.

On changing the battery the transmitter logs a “battery good” record but due to Automatic Data Retrieval (ADR)

{Page 37} this record is only transmitted to the Gateway after any previously logged temperature records have been

transmitted. Therefore it may take several hours before the “battery good” record is received by the Gateway which in

turn clears the indication of Low Battery for the transmitter.

Page 47

46

Pinout and Wiring

These connectors are drawn from the point of view of looking into the socket from outside the transmitter

Door Connector

A Door Positive

B RF525 Activator Positive

C Common Ground for Door and RF525

Power Connector

A Positive +5 VDC

B Negative Ground

A

C

B

A

B

Page 48

47

Lumberg Connector

Pin No RF512 Pinout RF515 Pinout RF516 Pinout

1 Thermistor External 2 External 2 Positive Pt100 Positive Voltage Input

2 Thermistor External 1 External 1 Positive Pt100 Positive Current Drive

3 Thermistor External 4

(Reserved for future use)

Reserved for future use

Do Not Connect

No Connection

4 Thermistor Common External Common Pt100 Negative Current Drive

5 Thermistor External 3

(Reserved for future use)

Reserved for future use

Do Not Connect

Pt100 Negative Voltage Input

6 No Connection No Connection No Connection

1

2

3

4

5

6

Page 49

48

Gateway Relay Outputs

The two relay outputs each accept a 2.5mm jack plug. These are individually controlled SPST relay contacts. Comark

can supply jack plugs for wiring external equipment to be activated by the Gateway.

The maximum lead length for the relay outputs is 30m.

Ensure that any external equipment presents only a low voltage on the jack so as to prevent any

chance of personal injury due to electric shock should the jack plug become disconnected.

Page 50

49

FCC Approvals

The RF500 Gateway and transmitters comply with Part 15 of the FCC Rules. Operation is subject to the following four

conditions:

• This device may not cause harmful interference, and

• This device must accept any interference received, including interference that may cause undesired operation.

• To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that

the equivalent isotropic radiated power (e.i.r.p.) is not more than that permitted for successful communication.

• Changes or modications not expressly approved by the party responsible for compliance could void the

user's authority to operate the equipment.

Transmitters must be placed greater than 20cm from the body.

Page 51

50

Equipment Ratings

Supply Voltage

Comark will provide mains adaptors with plugs to suit your country, if the correct socket adaptor has not been provided

please contact Comark for a replacement.

AC adaptors supplied for use with RF500A Gateway and transmitters have been designed for worldwide use over the

following voltage and frequency ranges.

Voltage 100-240 VAC

Frequency 50/60Hz

Only use adaptors as supplied by Comark and do not attempt to use others as damage to the equipment and voiding

of the CE approval may occur.

Environmental Conditions

All RF500 equipment is designed for indoor use only.

(Some outdoor installation of RF500 transmitters is permitted. Contact Comark for details)

Gateway Storage/Operating Conditions

Temperature 0°C to 40°C (32°F to 104°F)

Humidity 10-90% RH (Non-condensing)

RF51X Transmitter Operating Conditions

Temperature –30 to +70°C (-22°F to 158°F)

Humidity 10-90% (Non-condensing)

Page 52

51

RF542 Transmitter Operating Conditions

Temperature 0 to 50°C (32°F to 122°F)

Humidity 10-90% (Non-condensing)

RF5XX Transmitter Storage Conditions

Temperature –40 to +85°C (-40°F to 185°F)

Humidity 10 to 90% RH (Non-condensing)

RF515 Maximum Input Conditions

0-1V Range 0 - 3V

0-10V Range 0 - 30V

4-20mA Range 0 - 100mA

Page 53

52

Maintenance and Cleaning

No specic maintenance is required for the Gateway. Transmitters however will require periodic battery replacement

which can be performed by the user by following the instructions on {Page 43} “Changing Lithium Battery on RF500

Series Transmitters”.

Cleaning of the Gateway should be limited to a dry lint free cloth to remove dust and debris from the airow grills. A

damp cloth may be used in the event that a more stubborn mark needs to be removed. At no time should a wet cloth

or any detergent agent be used to clean the Gateway.

Service and Repair

Should service of the Gateway, transmitters or probes be required; then a “return to base” service is provided by

Comark. Please contact Comark Instruments or your local distributor to make arrangements for return of any items for

repair.

Page 54

53

EC-Declaration of Conformity

Comark Instruments

52 Hurricane Way

Norwich

Norfolk.

NR6 6JB

Declare that the products:

Comark Wireless Monitoring System Comprising Part Numbers:

RF500A, RF500AP, RF512, RF513, RF515, RF516, RF520 & RF542

Is in conformity with the requirements of the following documents (Directives):

Radio & Telecommunications Terminal Equipment Directive (R&TTE) 1999/5/EC

Electromagnetic Compatibility Directive 2004/108/EC.

The Low Voltage Directive (2006/95/EC) Annex-1

Standards:

EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control and laboratory

ETSI EN 301 489-17 V2.1.1 (2009-05) Specic conditions for 2.4 GHz wideband transmission systems and 5 GHz

high performance RLAN equipment

David Goulden

Development Manager

Comark Instruments

Page 55

54

Transmitter Fault Codes

Under certain conditions the transmitter display can show a status code or fault code. These codes can help in

diagnosing the reason a transmitter may fail to transmit data to the Gateway. Status codes indicate problems that can

be resolved by the user. Fault codes indicate more serious problems that generally require that the transmitter be

returned for service.

This is not an exhaustive list of fault codes; only the most common will be described here.

Code Meaning Resolution

004 Fault with Radio / Ethernet Module Try removing the battery then

replacing it. Otherwise return for

service

1000 Battery is Dead Replace the battery

100 Date and time lost Wait for the transmitter to receive

correct date and time from the

Gateway

400 Invalid Programmed Task Program a new task from the

Gateway

500 Codes 100 & 400 combined Resolve Code 100 & Code 400

individually

Page 56

55

Gateway Fault Conditions

Under certain conditions the Gateway Fault LED can ash to indicate an error. The possible faults which can cause

the Fault LED to ash are:

• Overheating

• Battery Pack fault

• Clock error

• PSU fault

• Software errors

• Radio Module fault

Page 57

56

Appendix A – Gateway Connection via RJ45 Cross-Over Ethernet Cable

1. Set up your computer temporarily with a xed IP address using the instructions given in Appendix B - Setting a

Fixed IP Address.

2. Connect the cross-over Ethernet cable between computer and RJ45 jack on the Gateway.

3. Congure the RF500A Gateway as in Gateway Commissioning. {Page 17}

4. Remove the cross-over Ethernet cable after the Gateway has reset. (See Gateway Reset {Page 11})

5. Using Appendix B - Setting a Fixed IP Address as a guide, restore the computer network settings back to as

existed previously.

6. Connect both the PC and RF500 Gateway to the LAN using regular Ethernet patch leads.

7. Verify that a connection can be made to the Gateway by following the steps in “Viewing the Gateway Login

Page” {Page 19} but using the newly congured IP Address instead of 192.168.25.220.

Page 58

57

Appendix B - Setting a Fixed IP Address

The following instructions detail the Windows 98, ME, 2000 and XP procedure for setting a computer to a xed

IP address.

1. Go to the Windows control panel and

double-click the Network icon or the

Network Connections icon.

2. Right-click on the “Local Area Connection”

and select Properties

3. In the General Tab select the “Internet Protocol

TCP/IP” item and click on the properties button.

Figure 22 - Local Area Connection Properties

Page 59

58

4. Record the original settings so that they can be

restored after RF500 conguration.

5. Select the Use the following IP address button.

6. Enter the following IP address: 192.168.25.200.

7. Enter the following subnet mask: 255.255.255.0

then click OK.

The Computer is now setup to use a xed IP address.

Page 60

59

Denitions of Gateway Terminology

Avg – This is the average reading recorded in the Period being displayed. On the Home Page this is the average

reading over the period of time from midnight to the timestamp of the latest reading received. In the summary pages

the average reading could be over a much longer period of time.

Backbone – A transmitter during setup can be designated to be part of the Wireless Network Backbone. This

requirement is identied during site surveys. A Backbone transmitter will be mains powered and constantly active. It

will therefore (almost) always be available to re-transmit messages received from nearby transmitters.

Event Logging – All transmitters have the capacity to measure from one or more sensor inputs at a number of pre-

dened logging intervals. However should an alarm event occur between log intervals then the transmitters will wake

up to record this event. As soon as the alarm is triggered, the transmitter will wake up and transmit the alarm back to

the Gateway via the mesh network. This technique allows for long intervals between logging static readings knowing

that if an alarm does occur it will be captured. This results in a robust system that will log an extra reading when there

is an event to record.

Gateway Name – A customer selectable name for each Gateway enables easy identication.

Last – This is the last known good reading from the transmitter. It does not imply that the transmitter is functional or

currently within range.

Location – A logical grouping of transmitters for the purpose of ltering and directing alerts. These Locations

may correspond to the physical siting of transmitters but more usually group transmitters monitoring equipment or

environments “owned” by an individual person or department.

Login Page – A user name and password are required in separate pages to log in to the Gateway to perform any

setup changes or maintenance.

Page 61

60

Max – This is the maximum reading recorded in the Period being displayed. On the Home Page this is the maximum

reading over the period of time from midnight to the timestamp of the latest reading received. In the summary pages

the maximum reading could be over a much longer period of time.

Min – This is the minimum reading recorded in the Period being displayed. On the Home Page this is the minimum

reading over the period of time from midnight to the timestamp of the latest reading received. In the summary pages

the minimum reading could be over a much longer period of time.

Mesh Network – The technology used in the RF500 system to increase wireless reception reliability. Transmitters

are setup to be either part of a Backbone or to be a regular transmitter. Those designated as part of the Backbone

remain in RF contact with each other. By doing this the system is able to dynamically adapt to changing conditions

automatically ensuring the integrity of the system at all times.

No Signal – The Gateway has not received any signal from a transmitter for a long time. Usually 1 hour or 5 times the

radio-rate whichever is longest.

Period – A continuous session of logged records. Any break in monitoring will result in the creation of a new logging

Period.

PST – Precision Semiconductor Technology or Thermistor, a sensor for measuring temperature.

Radio-Rate – The rate at which a transmitter enables its radio to contact the Gateway. The default is once every 15

minutes.

Restricted User – A user of RF500 who can only perform a selection of functions.

Self-Healing – As part of the Mesh technology the system is able to adapt automatically if one part of the system is

damaged, i.e. Radio Contact is lost with part of the Backbone. Only regular transmitters directly reliant on the faulty

part of the system will be affected with the rest of the transmitters simply nding alternative routes for the data.

Page 62

61

Task – The name given to the collection of logging parameters for a specic monitoring job. Tasking is the action of

entering these parameters into RF500 and sending them to the transmitter.

TextMagic™ – Internet SMS provider (www.textmagic.com). Warning emails sent from the Gateway can be converted

to SMS messages using this service. Other service providers may also work but only TextMagic has been tested.

Transmitter – A transmitter is a device connected wirelessly to the system. This device records data locally from a

number of sensors and sends the information back to the Gateway using RF. A transmitter is powered via battery or

AC adaptor.

Page 63

62

Glossary

21 CFR – The FDA (Food and Drug Administration) in the USA, issued regulations Title 21 CFR (Code of Federal

Regulations) Part 11 that provide criteria for acceptance by FDA or an approved regulatory body, for the acceptance

of electronic records, electronic signatures, and handwritten signatures executed to electronic records as equivalent

to paper records and handwritten signatures executed on paper. These regulations, which apply to all FDA program

areas, are intended to permit the widest possible use of electronic technology, compatible with the FDA’s responsibility

to promote and protect public health. Part 11 applies to any record governed by an existing FDA predicate rule that is

created, modied, maintained, archived, retrieved, or transmitted using computers and/or saved on durable storage

media. In other words any record from a data logger for instance that is at some stage stored on a PC or where a PC

is used to retrieve the data, 21 CFR Part 11 can be applied. The RF500 system is designed to aid compliance with 21

CFR Part 11.

Administrator – An Administrator is a user who has unrestricted access to all Gateway functions.

Antenna – Electrical device for collecting or disseminating RF energy. The interface between a radio transmitter or

receiver and transmission medium (air).

Autodialler – A device when triggered (by Gateway alarm for example) to dial a specic telephone number to

playback a pre-recorded alarm message.

Ethernet/Network/LAN – Terms used to describe the connection of the Gateway to various users with access to the

system. Personal Computers are connected together using a network via Ethernet ports combining to make a Local

Area Network.

FCC – Federal Communications Commission.

Firmware – The software program operating the various components of RF500 e.g. Transmitter, RF module and

RF500 Gateway.

Page 64

63

Frequency – Number of oscillation cycles-per-second of a radio signal.

IE – Microsoft Internet Explorer.

IP address – Internet Protocol address. Unique identier for each device connected to a network.

ISP – Internet Service Provider.

Licence free – Term used to describe the frequency band in which the system operates in terms of licence to

broadcast. RF500 uses the licence free Industrial, Scientic and Medical (ISM) band of 2.4GHz where operators and

users are not required to purchase any kind of licence in order to use the product.

Password – A password is a string of characters that is used for user authentication. The password is personal and

should be kept secret.

Pt100 – Platinum Resistance Device for measuring temperature.

RF – An abbreviation of the words Radio Frequency. Commonly used to describe “wireless radio communication”.

RH – Relative Humidity. The amount of water vapour present in the atmosphere expressed as a percentage of the

maximum that could be present at the same temperature.

Users – A user is anyone who is able to log onto an IT system such as RF500.

Page 65

64

Page 66

Comark Instruments

52 Hurricane Way

Norwich, Norfolk

NR6 6JB United Kingdom

Tel: +44 844 815 6599

Fax: +44 844 815 6598

Email: sales@comarkinstruments.com

Website: www.comarkinstruments.com

Comark Instruments

PO Box 500

Beaverton

OR 97077 USA

Tel: 503 643 5204

Fax: 503 644 5859

Email: sales@comarkusa.com

Website: www.comarkusa.com

© Comark Instruments

Part No. 20081/5 8/13

Loading...

Loading...