Page 1

PRESSURE

TEST PUMP

OPERATOR MANUAL

Page 2

CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Pressure Test Pump Kits . . . . . . . . . . . . . . . 4

1.2 Release Valve . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Volume Control. . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Over Pressure Protection . . . . . . . . . . . . . . . 5

1.5 Pressure/Vacuum Selection . . . . . . . . . . . . . 5

2. GUIDELINES FOR USE . . . . . . . . . . . . . . . . . . . 6

2.1 Calibration/Comparison against

Comark Digital Pressure Meter. . . . . . . . . . 6

2.2 Use with High Resolution Pressure

Ranges (1mBar) . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Fault Investigation . . . . . . . . . . . . . . . . . . . . 8

3. PERFORMING HYSTERESIS TESTS . . . . . . . 10

3.1 Increasing Pressure. . . . . . . . . . . . . . . . . . . . 10

3.2 Decreasing Pressure to Measure

Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . 13

1

Page 3

1. INTRODUCTION

The pressure test pump is a dual portable source of

either vacuum or pressure supply. Each pump

incorporates a vacuum/pressure selector and a volume

control feature for fine adjustment.

WARNING

THE HAND PUMP IS CAPABLE OF GENERATING

PRESSURES IN EXCESS OF 200 PSI. TO

PREVENT DAMAGE IT IS ESSENTIAL NOT TO

OVER PRESSURE ANY GAUGE CONNECTED TO

THE PUMP.

2

Page 4

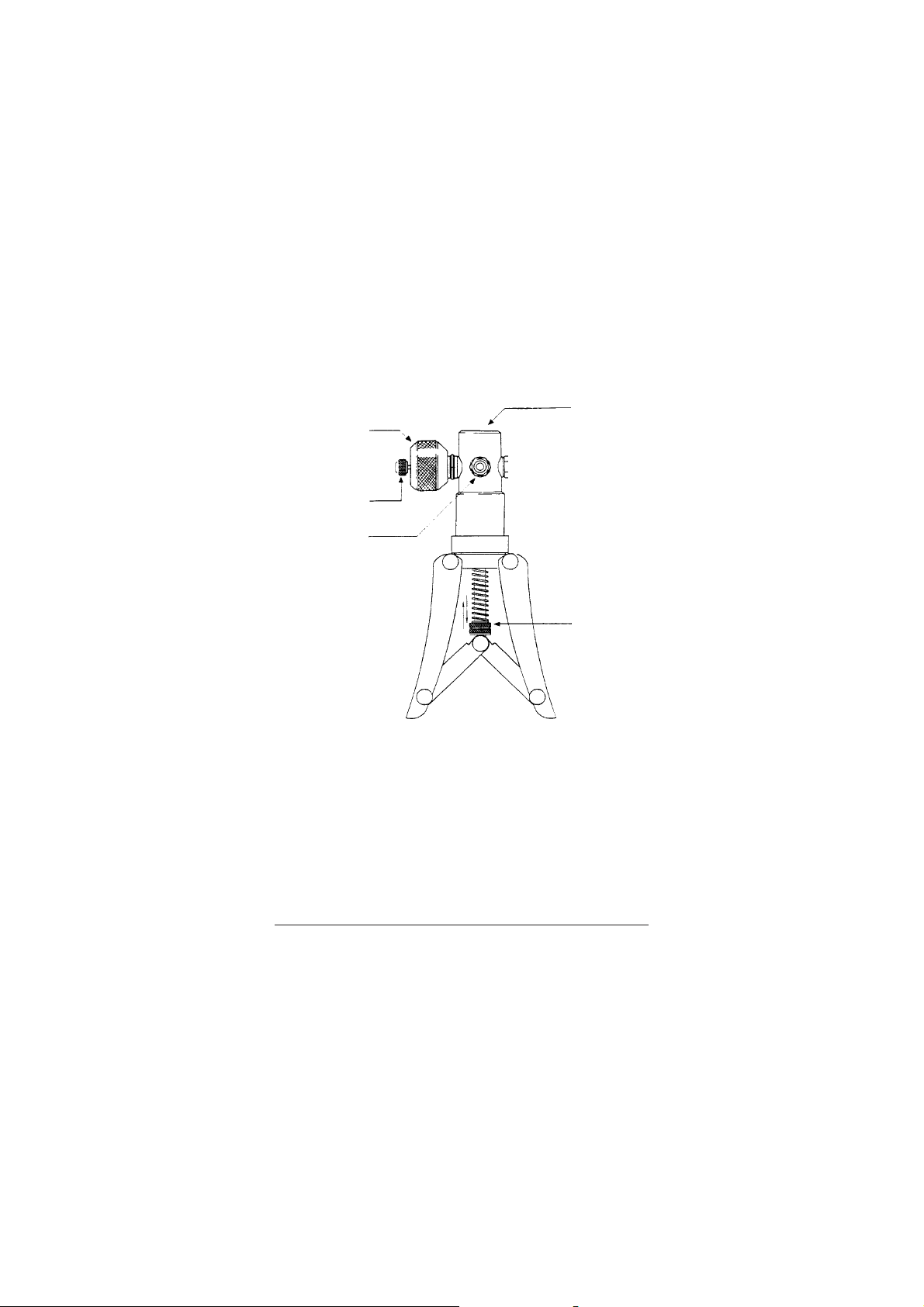

n

o

p

q

r

n Pressure port — 3/8" BSP Parallel female connection

o Fine adjustment valve

p Pressure release valve

q Pressure/vacuum selector

r Adjustable stroke for varying maximum pressure

output (over pressure protection)

3

Page 5

1.1 Pressure Test Pump Kits

The TK1 kit can be used with the Kane-May

KM5000 series and the TK2 kit with the C9500

series pressure meters and provides the capability

to set up and check the calibration of pressure

gauges, switches, pressure to current convertors

and other pneumatic instruments.

Note: Do not overtighten the hexagonal nut when

connecting the pressure meter tubing to the hand

pump or the pressure pump could be damaged.

1.2 Release Valve

This can be used to reduce or release the pressure

in the system. The rate of pressure reduction is

dependent upon the degree of rotation when

opening the valve. Minimal force is required to seal

the system. Excessive force may damage the

internal seals.

1.3 Volume Control

The pressure generated can be finely adjusted by

turning the volume control valve either clockwise

or anti-clockwise to increase or decrease pressure

accordingly.

IMPORTANT: Under no circumstances

should the volume control valve o be wound

back beyond the red line indicator on the

body. Should this occur, then the pressure

must be released from the system before

attempting to re-engage the volume control

valve.

4

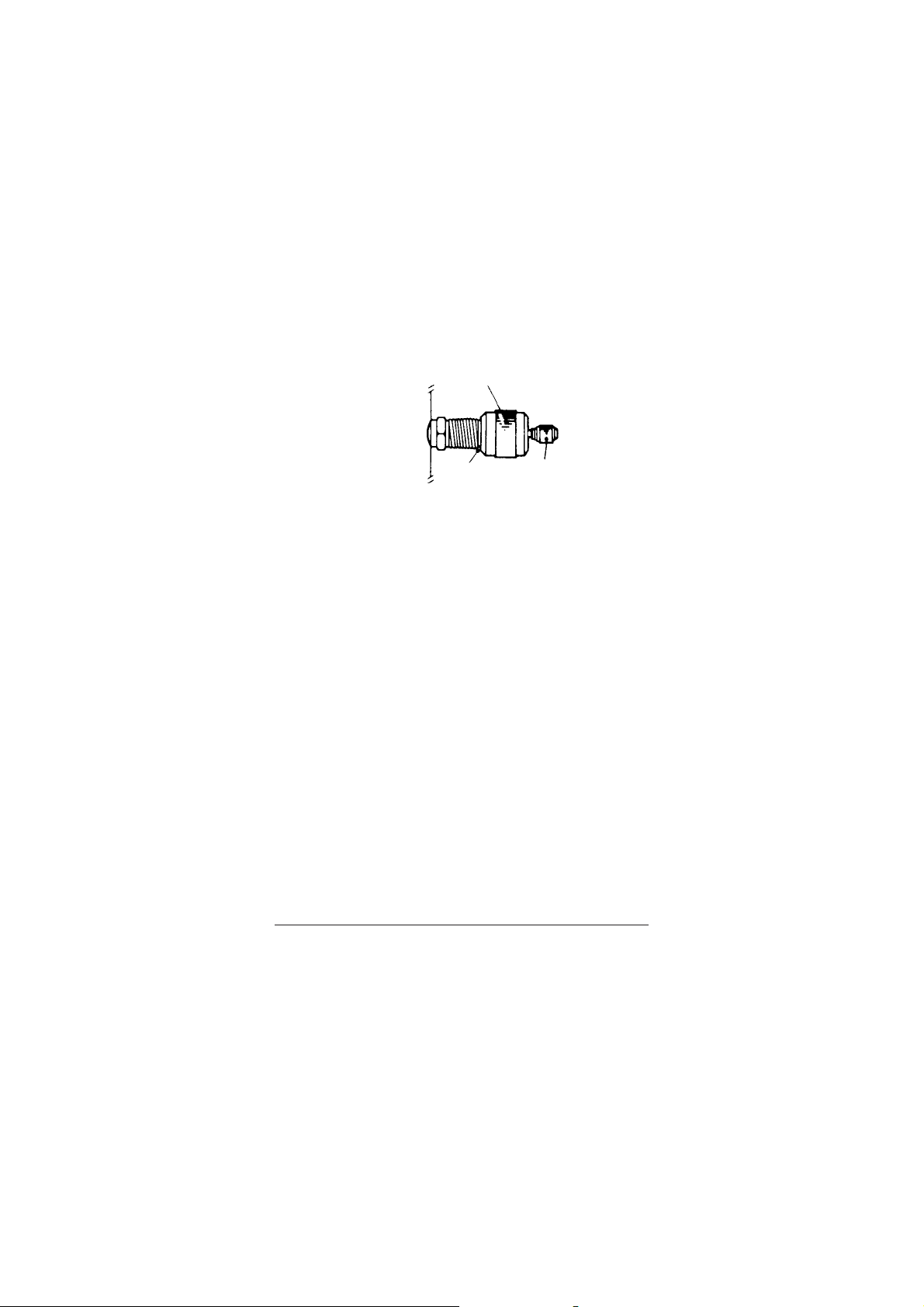

pp

p

pp

oo

o

oo

Page 6

VOLUME CONTROL VAL VE

RED LINE

INDICATOR

RELEASE

VALVE

1.4 Over Pressure Protection

To adjust the maximum output pressure of the

system turn the nuts r to increase or decrease the

stroke length.

1.5 Pressure/Vacuum Selection

qq

q

qq

Press the selector q as indicated on the label to

engage the desired mode. Ensure that the release

valve p is fully closed (clockwise motion) prior to

pumping.

Notes:

1. The pump should only be used for pressurising

small volumes due to its small displacement.

2. If the pump has not been used for a period of

time, it could be difficult to operate on the

first stroke. This is due to the piston seal

drying slightly.

3. The cylinder has been lightly greased on

assembly but, if additional lubrication should

ever be required, then apply a minimal

amount to the inside of the cylinder. Access is

via the three retaining screws located under

the black collar.

For release valve seal replacement, please contact

Comark Service Department or your Distributor.

5

Page 7

2. GUIDELINES FOR USE

2.1 Calibration/Comparison against

Comark Digital Pressure Meter

(a) Fit KM5000 or C9500 instrument to test

pump.

(b) Connect gauge under test to pump choosing

correct adaptors and seals from the set

provided.

Note: Ensure both seals are fitted and

adaptors are tightened. (See paragraph 1.1).

(c) Screw volume control knob fully clockwise.

(d) Screw pressure release valve fully clockwise,

tightening to ensure good seal.

(e) Screw volume control knob 4–6 full turns

anti-clockwise.

(f) Operate handles until the pressure is close to

that finally required.

WARNING

ONE FULL SQUEEZE OF THE

HANDLES IS SUFFICIENT TO OVER

RANGE A COMARK 2 PSI METER. IF

THIS SHOULD OCCUR REDUCE THE

PRESSURE UNTIL A READING SHOWS

ON THE DISPLAY.

6

Page 8

(g) Wind volume control knob clockwise to

increase pressure or anti-clockwise to

decrease pressure until required pressure is

reached.

Note: The pressure may settle for up to

30 seconds after increasing pressure with

pump due to thermodynamic effects, settling

of seals and expansion of the flexible pipe.

CAUTION: NEVER screw volume

control knob anti-clockwise when red

band is showing.

(h) Reductions in pressure can be achieved by

careful use of the pressure release valve,

however this valve is not guaranteed to seal

fully unless the volume control knob is

screwed fully clockwise.

(i) Vacuum is achieved using procedure

identified above and having the changeover

valve pushed completely towards the vacuum

position.

Note: The changeover valve should never be

operated with the unit pressurised, only

when the pressure release valve is open.

Operation of this valve when unit is

pressurised causes an instantaneous release

of pressure which can damage the seals

within the pump.

7

Page 9

2.2 Use with High Resolution Pressure

Ranges (1mBar)

The higher resolution available will amplify the

visibility of the thermodynamic effects as

mentioned in paragraph 2.1(g). These should

however still settle to useable values within one

minute of pressurisation.

Note: On very high resolutions such as 1mBar or

0.1 inches of water, small movements of the pipe

may result in noticeable pressure changes.

2.3 Fault Investigation

In the event that the system appears to lose

pressure then the procedure above should be

repeated ensuring new seals are used, adaptors are

tightened sufficiently and the pressure release

valve is tightened firmly with the volume control

knob screwed fully clockwise.

Note: The connections to the hand held test pump

are sealed with nylon washers and should not leak.

The pipe to body connection can be checked but

tightened no more than 2Nm.

DO NOT attempt to tighten the other fitments to

the test pump as this could lead to breaking of

sealed joints.

When testing for leaks it may be noticed that air is

drawn in or expelled from around the changeover

valve. This is normal and should cause no concern.

8

Page 10

Some instruments include pressure relief valves to

protect the instrument. Before suspecting a leak in

the pump check the relief valve pressure is not

being exceeded and the relief valve is seated

properly. This can be achieved by substitution with

another gauge and retest for leaks.

9

Page 11

3. PERFORMING HYSTERESIS TESTS

The hand held test pump can be used with a high

resolution instrument to check accuracy and hysteresis

of a pressure measuring instrument.

3.1 Increasing Pressure

(a) Fit KM5000 or C9500 instrument to test

pump.

(b) Connect the gauge under test to pump

choosing correct adaptors and seals from the

set provided.

Note: Ensure both seals are fitted and

adaptors are tightened. (See paragraph 1.1).

(c) Screw the volume control knob fully

clockwise.

(d) Screw the pressure release valve fully

clockwise, tightening to ensure good seal.

(e) Screw the volume control knob 8–9 full turns

anti-clockwise.

(f) Operate the handles until the pressure is

slightly less than that finally required.

10

Page 12

WARNING

ONE FULL SQUEEZE OF THE

HANDLES IS SUFFICIENT TO OVER

RANGE A COMARK 2 PSI METER. IF

THIS SHOULD OCCUR REDUCE THE

PRESSURE UNTIL A READING SHOWS

ON THE DISPLAY.

(g) Wind the volume control knob clockwise to

increase pressure to the calibration point

and record readings.

Note: The pressure may settle for up to

1 minute after increasing pressure with

pump due to thermodynamic effects, settling

of seals and expansion of the flexible pipe. If

this is significant, operate the volume control

knob again to retain calibration pressure.

CAUTION: NEVER screw the volume

control knob anti-clockwise when red

band is showing.

(h) Repeat steps 3.1(f) and (g) for other

calibration points. If the volume control knob

does not have sufficient travel remaining,

screw it fully clockwise and return to

paragraph 3.1(e).

(i) When maximum calibration pressure has

been achieved and the results noted, proceed

to paragraph 3.2 — Decreasing Pressure.

11

Page 13

3.2 Decreasing Pressure to Measure Hysteresis

To correctly measure hysteresis it is important

that the pressure in the system never falls lower

than the calibration point next required.

(a) Carefully unscrew the release valve slightly

to allow the pressure to drop gently, but not

to fall below the next calibration point. Fully

tighten the release valve (clockwise).

(b) Screw the volume control knob fully

clockwise, repeating paragraph 3.2(a) if

maximum pressure is reached before volume

control knob is fully screwed in.

(c) Carefully unscrew the release valve slightly

to allow the pressure to drop close to the

next lowest calibration point ensuring that

the pressure does not fall below the

calibration point. Fully tighten the release

valve (clockwise).

(d) Wind the volume control knob anti-clockwise

until calibration pressure is reached and

record readings.

(e) Wind the volume control knob fully clockwise

(to ensure that the pressure release valve

can be tightened satisfactorily).

(f) Repeat paragraphs 3.2(c) to 3.2(e) for

remaining calibration positions.

(g) When test completed unscrew the pressure

release valve before removing either

instrument to ensure the system is not

pressurised.

12

Page 14

4. SPECIFICATION

Output Pressure 0 to 25bar (adjustable)

Output Vacuum 0 to –0.8bar/0 to –24inHg

Materials Bright nickel plated brass, clear

anodised aluminium

Adjustment Fine volumetric pressure/vacuum

adjuster

Dimensions 220mm (L) x 105mm (W) x 63mm (D)

Weight 650 grams

13

Page 15

141516

Page 16

Page 17

Page 18

Comark

52 Hurricane Way

Norwich, Norfolk, NR6 6JB England

Tel: 01603 (+44 1603) 256647

Fax: 01603 (+44 1603) 256644

E-mail: service@comarkltd.com

Website: www.comarkltd.com

Comark Instruments

PO Box 9090, Everett

WA 98206, USA

Tel: (503) 643 5204

Fax: (503) 644 5859

Email: sales@comarkUSA.com

Website: www.comarkUSA.com

© Comark Stock No. 16683 Issue 3

Loading...

Loading...