Page 1

MainsPro

Mains Decoupling Protection

SW version 1.6.1

1 Document information 6

2 Introduction of Installation and Operation Guide 9

3 Installation data 11

Relay

4 User interface 19

5 Introduction of Application Guide 28

6 Important Steps of MainsPro utilization 30

7 TRIP and Fault Reset 31

8 Protective features 33

9 Application tips 40

10 Introduction of Reference Guide 44

11 Technical data 45

12 Appendix 50

Copyright © 2019 ComAp a.s.

Written byPetra Piclová

Prague, Czech Republic

ComAp a.s., U Uranie 1612/14a,

170 00 Prague 7, Czech Republic

Tel: +420 246 012 111

E-mail: info@comap-control.com, www.comap-control.com

Global Guide

Page 2

Table of contents

1 Document information 6

1.1 Clarification of notation 6

1.2 About this guide 6

1.2.1 Installation and Operation Guide 6

1.2.2 Application Guide 6

1.2.3 Reference Guide 6

1.3 Legal notice 6

1.4 Document history 8

2 Introduction of Installation and Operation Guide 9

2.1 Purpose of this manual 9

2.2 Confornity declaration 9

2.3 Warnings 10

2.3.1 Dangerous voltage 10

2.3.2 Adjust the setpoints 10

3 Installation data 11

3.1 Dimensions 11

3.2 List of terminals 12

3.3 MainsPro Frame 12

3.4 Wiring 12

3.4.1 “Star” connection 13

3.4.2 “Delta” connection 13

3.4.3 Connection with voltage transformers 14

3.4.4 Single-phase connection 14

3.4.5 Power supply 15

3.4.6 Relay outputs connection 16

3.4.7 Binary switches connection 16

3.5 Measurement range 16

3.6 Wiring examples 17

4 User interface 19

4.1 Front panel elements 19

4.1.1 Pushbuttons 20

4.1.2 Setpoints change 20

4.1.3 Reset operation time 21

4.1.4 Reset trip counters 21

4.1.5 TEST mode activation 21

Mains pro 1.6.1 Global Guide

2

Page 3

4.1.6 Factory default 22

4.2 Mechanical sealing 22

4.3 Signalization LEDs 22

4.4 Measurement screens 24

4.5 Alarm messages 26

5 Introduction of Application Guide 28

5.1 Purpose of this manual 28

5.2 MainsPro typical usage 28

5.3 Typical applications of MainsPro protection relay 28

6 Important Steps of MainsPro utilization 30

7 TRIP and Fault Reset 31

7.1 TRIP 31

7.1.1 TRIP event 31

7.1.2 TRIP status 31

7.2 Fault reset 32

8 Protective features 33

8.1 ANSI 59 Overvoltage, ANSI 27 Undervoltage 33

8.2 Floating 10 minutes average overvoltage 34

8.3 ANSI 81H Overfrequency, 81L Underfrequency 34

8.4 ANSI 47 Voltage unbalance and angle asymmetry 36

8.4.1 Voltage unbalance 36

8.4.2 Positive sequence undervoltage, Negative sequence overvoltage 36

8.5 ANSI 78 Vector shift 37

8.5.1 Measuring principle 38

8.6 81R Rate Of Change Of Frequency (ROCOF) 39

8.7 Phase rotation, incorrect phase polarity 39

9 Application tips 40

9.1 Automatic return to mains 40

9.2 Binary switches 40

9.2.1 External trip 41

9.2.2 Fault reset 41

9.2.3 Alternative settings 41

9.2.4 Disable 41

9.2.5 CB Feedback 41

9.3 Counters 41

9.4 Timer 42

Mains pro 1.6.1 Global Guide

3

Page 4

9.5 Start trip 42

9.6 TEST mode 42

10 Introduction of Reference Guide 44

10.1 Purpose of this manual 44

11 Technical data 45

11.1 Accuracies and reaction times 45

11.1.1 Operating area 45

11.1.2 Voltage measurement 46

11.1.3 Frequency measurement 46

11.1.4 Time delays accuracy 46

11.1.5 Loss of Mains reaction times 46

11.2 Technical parameters 46

11.2.1 Endurance to the power supply voltage fails 47

11.3 Factory default setting of MainsPro unit 47

12 Appendix 50

12.1 Library of Setpoints 51

12.1.1 Group: Basic 52

12.1.2 Group: V <>, A.V <> 55

12.1.3 Group: dU, A.dU 56

12.1.4 Group: f <>, A.f <> 57

12.1.5 Group: LOM, A.LOM 58

12.1.6 Group: f(BI) 59

12.1.7 Group: f(RE) 60

12.2 Library of Binary switches 61

12.2.1 Ext Trip 61

12.2.2 Fault Reset 61

12.2.3 Alt Settings 61

12.2.4 Disable 61

12.2.5 CB Feedback 61

12.3 Relay outputs 62

12.3.1 CommTrpPer 63

12.3.2 !CommTrpPer 63

12.3.3 CommTrpImp 63

12.3.4 !CommTrpImp 63

12.3.5 CommSigImp 63

12.3.6 !CommSigImp 64

12.3.7 CommSigDel 64

Mains pro 1.6.1 Global Guide

4

Page 5

12.3.8 !CommSigDel 64

12.3.9 U Sig 64

12.3.10 !U Sig 64

12.3.11 f Sig 65

12.3.12 !f Sig 65

12.3.13 LOM Sig 65

12.3.14 !LOM Sig 65

12.3.15 dU Sig 65

12.3.16 !dU Sig 66

12.3.17 Other Sig 66

12.3.18 !Other Sig 66

12.3.19 Alt Sig 66

12.3.20 TrpEndImp 66

12.3.21 !TrpEndImp 67

12.3.22 InternFail 67

12.3.23 !InternFail 67

12.3.24 BakTrpPer 67

12.3.25 !BakTrpPer 67

12.3.26 BakTrpImp 68

12.3.27 !BakTrpImp 68

Mains pro 1.6.1 Global Guide

5

Page 6

1 Document information

1.1 Clarification of notation 6

1.2 About this guide 6

1.3 Legal notice 6

1.4 Document history 8

1.1 Clarification of notation

Note: This type of paragraph calls readers attention to a notice or related theme.

IMPORTANT: This type of paragraph highlights a procedure, adjustment etc., which can cause a

damage or improper function of the equipment if not performed correctly and may not be clear at

first sight.

Example: This type of paragraph contains information that is used to illustrate how a specific function

works.

1.2 About this guide

1.2.1 Installation and Operation Guide

The Installation and Operation Guide serves for the personnel providing installation of the MainsPro unit. It

contains wiring and setting instructions needed for service and commissioning of the unit. It also contains

introduction of the user interface and necessary procedures for setting and operation of the unit. Though

MainsPro is very simple and intuitive for the operating personnel, we recommend keeping one copy of this

manual available permanently at the site where MainsPro unit is installed, to facilitate the necessary service

and operation tasks.

1.2.2 Application Guide

The Application Guide serves for the designers and engineers, who process the necessary documentation and

implementation procedures on the site, where MainsPro is installed. It contains detailed description of MainsPro

functionalities and their practical application.

1.2.3 Reference Guide

The Reference Guide contains library of setpoints, inputs and outputs functionalities and detailed technical

information. This information is referenced in the Installation and Operation Guide and Application Guide.

1.3 Legal notice

This End User's Guide/Manual as part of the Documentation is an inseparable part of ComAp’s Product and

may be used exclusively according to the conditions defined in the “END USER or Distributor LICENSE

AGREEMENT CONDITIONS – COMAP CONTROL SYSTEMS SOFTWARE” (License Agreement) and/or in

the “ComAp a.s. Global terms and conditions for sale of Products and provision of Services” (Terms) and/or in

Mains pro 1.6.1 Global Guide

6

Page 7

the “Standardní podmínky projektů komplexního řešení ke smlouvě o dílo, Standard Conditions for Supply of

Complete Solutions” (Conditions) as applicable.

ComAp’s License Agreement is governed by the Czech Civil Code 89/2012 Col., by the Authorship Act

121/2000 Col., by international treaties and by other relevant legal documents regulating protection of the

intellectual properties (TRIPS).

The End User and/or ComAp’s Distributor shall only be permitted to use this End User's Guide/Manual with

ComAp Control System Registered Products. The Documentation is not intended and applicable for any other

purpose.

Official version of the ComAp’s End User's Guide/Manual is the version published in English. ComAp reserves

the right to update this End User's Guide/Manual at any time. ComAp does not assume any responsibility for its

use outside of the scope of the Terms or the Conditions and the License Agreement.

Licensed End User is entitled to make only necessary number of copies of the End User's Guide/Manual. Any

translation of this End User's Guide/Manual without the prior written consent of ComAp is expressly prohibited!

Even if the prior written consent from ComAp is acquired, ComAp does not take any responsibility for the

content, trustworthiness and quality of any such translation. ComAp will deem a translation equal to this End

User's Guide/Manual only if it agrees to verify such translation. The terms and conditions of such verification

must be agreed in the written form and in advance.

For more details relating to the Ownership, Extent of Permitted Reproductions Term of Use of the

Documentation and to the Confidentiality rules please review and comply with the ComAp’s License

Agreement, Terms and Conditions available on www.comap-control.com.

Security Risk Disclaimer

Pay attention to the following recommendations and measures to increase the level of security of ComAp

products and services.

Please note that possible cyber-attacks cannot be fully avoided by the below mentioned recommendations and

set of measures already performed by ComAp, but by following them the cyber-attacks can be considerably

reduced and thereby to reduce the risk of damage. ComAp does not take any responsibility for the actions of

persons responsible for cyber-attacks, nor for any damage caused by the cyber-attack. However, ComAp is

prepared to provide technical support to resolve problems arising from such actions, including but not limited to

restoring settings prior to the cyber-attacks, backing up data, recommending other preventive measures against

any further attacks.

Warning: Some forms of technical support may be provided against payment. There is no legal or factual

entitlement for technical services provided in connection to resolving problems arising from cyber-attack or

other unauthorized accesses to ComAp's Products or Services.

General security recommendations and set of measures

1. AccessCode

• Change the AccessCode BEFORE the device is connected to a network.

• Use a secure AccessCode – ideally a random string of 8 characters containing lowercase, uppercase letters

and digits.

• For each device use a different AccessCode.

2. Password

• Change the password BEFORE the device enters a regular operation.

• Do not leave displays or PC tools unattended if an user, especially administrator, is logged in.

3. Controller Web interface

Mains pro 1.6.1 Global Guide

7

Page 8

• The controller web interface at port TCP/80 is based on http, not https, and thus it is intended to be used only

in closed private network infrastructures.

• Avoid exposing the port TCP/80 to the public Internet.

4. MODBUS/TCP

• The MODBUS/TCP protocol (port TCP/502) is an instrumentation protocol designed to exchange data

between locally connected devices like sensors, I/O modules, controllers etc. From it’s nature it does not

contain any kind of security – neither encryption nor authentication. Thus it is intended to be used only in closed

private network infrastructures.

• Avoid exposing the port TCP/502 to the public Internet.

5. SNMP

• The SNMP protocol (port UDP/161) version 1,2 is not encrypted. Thus it is intended to be used only in closed

private network infrastructures.

• Avoid exposing the port UDP/161 to the public Internet.

1.4 Document history

Revision number Related SW Date of issue Author

9 1.6.1 26.4.2019 Petra Piclová

8 1.6.0 13.3.2018 Petra Piclová

7 1.5.0 16.1.2015 Petra Piclová

6 1.4.1 15.11.2013 Petra Piclová

5 1.4.0 30.10.2013 Petra Piclová

4 1.3.0 30.8.2012 Tomáš Jelen

3 1.2.0 20.4.2012 Tomáš Jelen

2 1.1.0 2.11.2011 Tomáš Jelen

1 1.0.0 18.6.2010 Tomáš Jelen

6 back to Document information

Mains pro 1.6.1 Global Guide

8

Page 9

2 Introduction of Installation and Operation Guide

2.1 Purpose of this manual 9

2.2 Confornity declaration 9

2.3 Warnings 10

6 back to Table of contents

Congratulations to your purchase of ComAp MainsPro unit! MainsPro is a microprocessor-based protective

relay, providing a comprehensive set of protective and supplementary functionalities. The basic protective

functions are:

Voltage

Frequency

Loss of mains

This covers the basic requirements for mains-decoupling (inter-tie, „G59/2“) protection, but allows also usage in

many applications where benefits of the unit’s unique functionality is needed.

2.1 Purpose of this manual

The Installation and Operation Guide serves for the personnel, providing installation of the MainsPro unit. It

contains wiring and setting instructions, needed for service and commissioning of the unit. It also contains

introduction of the user interface and necessary procedures to perform setting and operating of the unit. Though

MainsPro is very simple and intuitive for the operating personnel, we recommend keeping one copy of this

manual available permanently at the installation site, where MainsPro unit is installed, to facilitate the

necessary service and operation tasks.

2.2 Confornity declaration

Following described machine complies with the appropriate basic safety and health requirement of

the EC Low Voltage Directive No: 73/23 / EEC and EC Electromagnetic Compatibility Directive

89/336 / EEC based on its design and type, as brought into circulation by us.

The unit is certified to comply to the appropriate requirements of the standard DIN V

VDE V 0126-1-1 (certificate ref. 44 207 11 398020, available upon request), with the

following conditions:

The conformity with the Standard DIN V VDE V 0126-1-1, chapter 4.1/ 6.1,

VDE O126-1-1

which is declared in the certificate 44 207 11 398020, requires the tolerance

against one fault. In order to fulfill this functional safety requirement, a

redundant architecture has to be built by the usage of two certified units.

CEI 0-21

Mains pro 1.6.1 Global Guide

It has to be ensured that each of both units is connected to an output (relay)

which is capable to induce opening of the operated contactor.

The unit is certified to comply with the requirements of the standard CEI 0-21. The

9

Page 10

product MainsPro CEI 0-21 is set by default to cover the functionalities and default

limits requested by this certification. In line with this certification, the output

!CommTrpPer, set by default on the RE1 output of the unit, is to be used for opening

the circuit breaker in the connection point between generator and the mains.

2.3 Warnings

IMPORTANT: Be aware that the relay outputs can change state during and after the unit setting

(before the unit is used again ensure that the proper setting is done)!!!

IMPORTANT: Be aware that the devices connected to binary outputs of the unit may operate upon

disconnection of power supply, measurement inputs and/or binary inputs!!!

2.3.1 Dangerous voltage

In no case touch the terminals for voltage and current measurement!

Always connect grounding terminals!

In any case do not disconnect controller CT terminals!

2.3.2 Adjust the setpoints

All parameters are adjusted to their typical values. However the setpoints has to be checked and adjusted to

their real values before the first starting of the gen-set.

The following instructions are for qualified personnel only. To avoid personal injury do not perform any action not

specified in related guides for product.

Note: ComAp believes that all information provided herein is correct and reliable and reserves the right to

update at any time. ComAp does not assume any responsibility for its use unless otherwise expressly

undertaken.

6 back to Introduction of Installation and Operation Guide

Mains pro 1.6.1 Global Guide

10

Page 11

3 Installation data

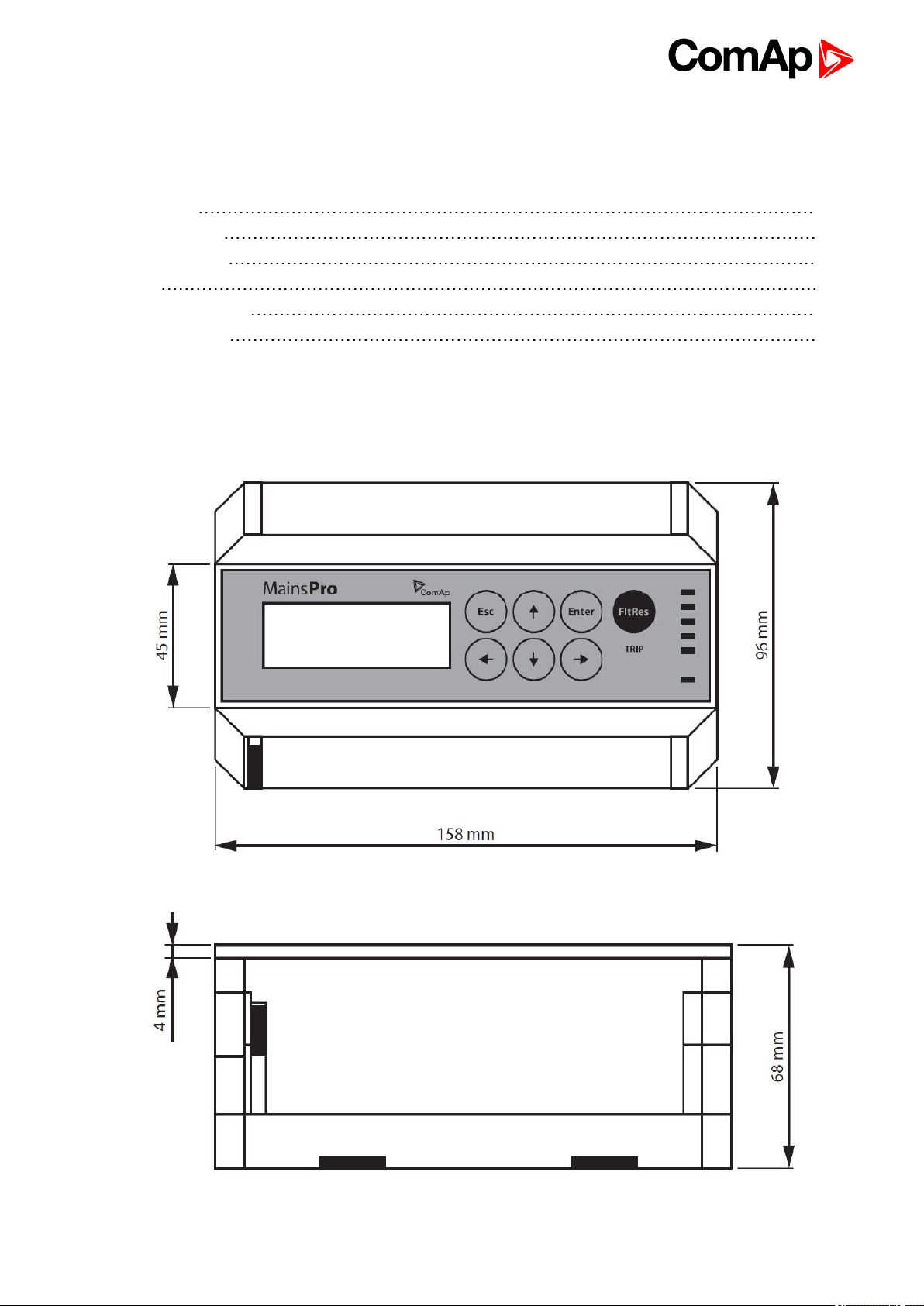

3.1 Dimensions 11

3.2 List of terminals 12

3.3 MainsPro Frame 12

3.4 Wiring 12

3.5 Measurement range 16

3.6 Wiring examples 17

6 back to Table of contents

3.1 Dimensions

Mains pro 1.6.1 Global Guide

11

Page 12

3.2 List of terminals

BIC Binary inputs – COM terminal

BI1 – BI4 Configurable binary inputs

UA1 to 3

UB1 to 3

UC1 to 3

11, 21, 31, 41, 51 RE1-5 relay contact – common

12, 22, 32, 42, 52

14, 24, 34, 44, 54

L/+ Power supply – high range 85-265 VAC / 110 – 370 VDC

+ Power supply – low range 8 – 40 VDC. Connect “+” pole to this terminal

N/-

First set of voltage measurement terminals (UA).

Terminals UA1 and UA2 are internally interconnected

Second set of voltage measurement terminals (UB).

Terminals UB1 and UB2 are internally interconnected

Third set of voltage measurement terminals (UC).

Terminals UC1 and UC2 are internally interconnected

RE1-5 relay contact – normally closed

(during fault-free conditions maintained in open position)

RE1-5 relay contact – normally open

(during fault-free conditions maintained in closed position)

Common terminal for power supply.

In case of DC supply, connect “–“ pole to this terminal

3.3 MainsPro Frame

MainsPro Frame is a MainsPro accessory product, allowing door-mounting of the unit, direct access to the

keyboard and the screen without opening the switchboard, and additional shielding (IP 55) for the front panel.

The frame size is 230x180x34 mm.

3.4 Wiring

3.4.1 “Star” connection 13

3.4.2 “Delta” connection 13

3.4.3 Connection with voltage transformers 14

3.4.4 Single-phase connection 14

3.4.5 Power supply 15

3.4.6 Relay outputs connection 16

3.4.7 Binary switches connection 16

Mains pro 1.6.1 Global Guide

12

Page 13

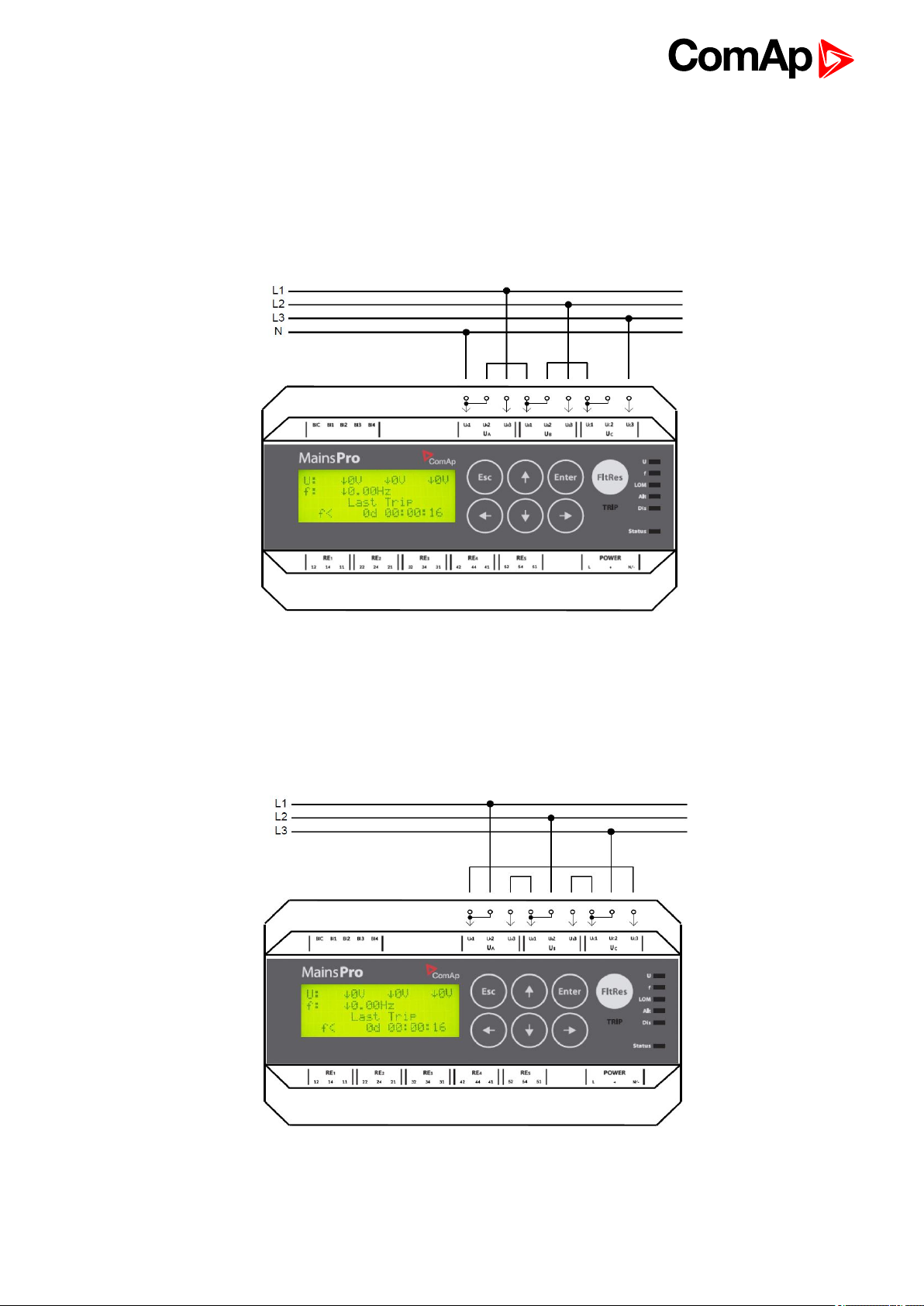

3.4.1 “Star” connection

If used for rated voltage 230 VAC ph-ground, set the setpoint Uin (page 52) to 230 V, for systems with rated

voltage 120VAC ph-ground, set the setpoint Uin (page 52) is to 120V. No additional setting is necessary for

indication of “Star” connection - MainsPro provides automatic detection of phase-ground voltage measurement.

MainsPro provides over-range to 130% of the rated voltage, i.e. 300 VAC for 230 V system and 156 V for 120 V

system with no change of measurement accuracy.

3.4.2 “Delta” connection

In this arrangement, MainsPro is rated for 400 VAC ph-ph with over-range to 130% = 520 VAC with no change of

measurement accuracy. Setpoint Uin (page 52) is to be set to 400 V, no additional setting is necessary for

indication of “Delta” connection. MainsPro provides automatic detection of phase-phase voltage measurement.

Mains pro 1.6.1 Global Guide

13

Page 14

3.4.3 Connection with voltage transformers

MainsPro allows connecting HV or other measurement transformers with secondary rated voltage 100V.

Provide the "Star" or "Delta" arrangement on the primary windings of the transformers and connect the

secondary 100 V to the MainsPro measurement inputs. Setpoint Uin (page 52) is to be set to 120V. This setting

provides the guaranteed measurement accuracy for the 100V inputs with overrange to 120V * 130% = 156 VAC.

Note: It is recommended to use “Delta” arrangement on the HV side to avoid nuisance tripping caused by phase

voltage unbalance.

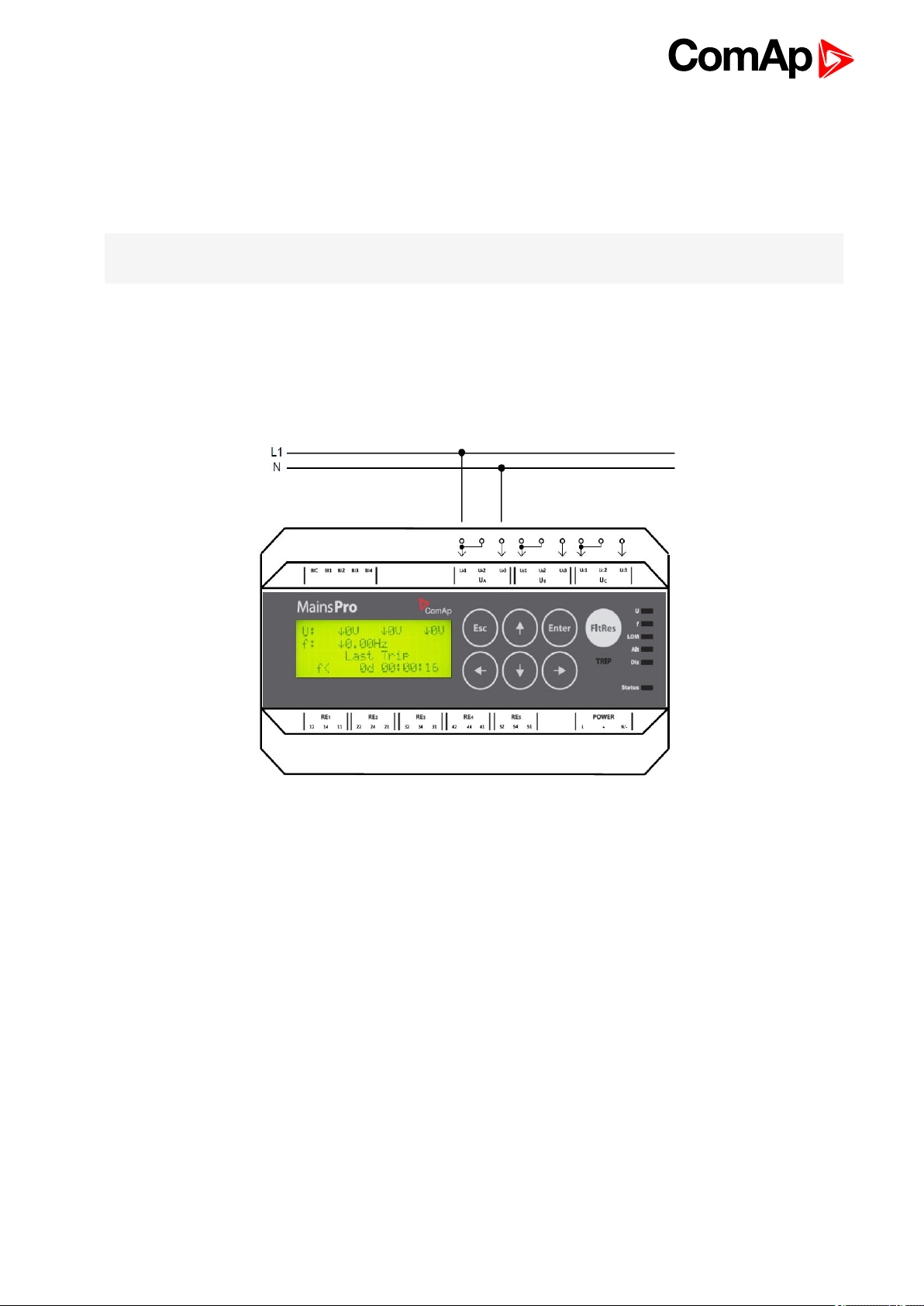

3.4.4 Single-phase connection

MainsPro provides support for single-phase applications. Use the UA terminals to connect the measured

voltage to the unit and set the setpoint System (page 52) to 1ph. Use the same setting of rated voltage

selection as mentioned above.

Mains pro 1.6.1 Global Guide

14

Page 15

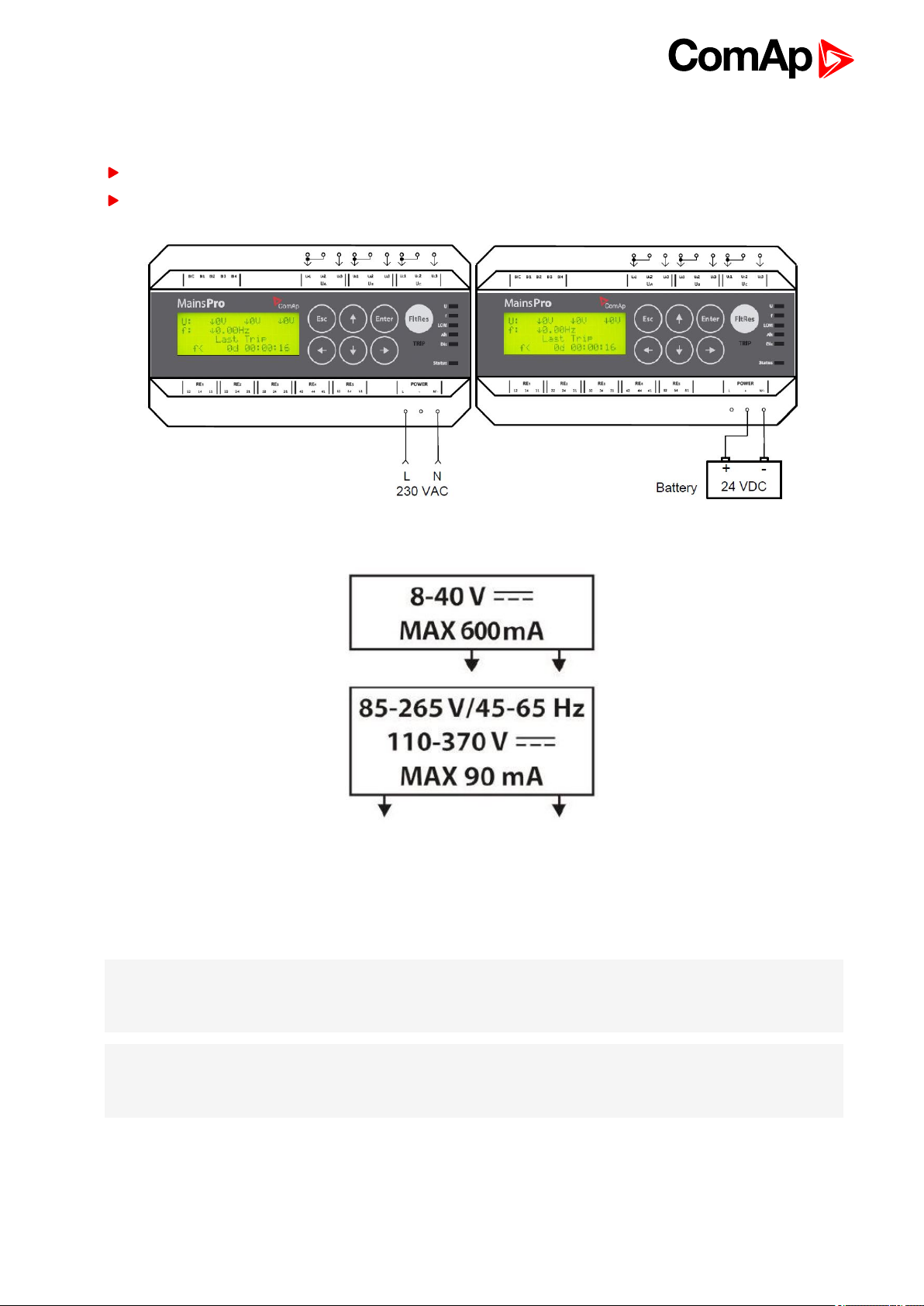

3.4.5 Power supply

MainsPro provides set of 3 terminals for the purpose of dual power supply range:

8 - 40 VDC: use the terminals + and N/-

85 - 265 VAC / 110-370 VDC: use the terminals L/+and N/-

For proper connection of the power supply, see also the printed sign on the MainsPro unit:

Requirements for power supply connections

The unit is suitable for permanent connection to the power supply. The power supply circuits must have

sufficient current withstand, corresponding to the appropriate power supply range and comply with the

standards relevant for the installation.

Note: External power supply is recommended in order to avoid excess of allowed supply voltage (256Vrms,

respectively 370V of peak value including dc offset).

Please be aware that not all power meters can detect the supply voltage including the dc component!

Note: The difference between power supply voltage and measured voltage must not exceed 1kV (peak-to-

peak), otherwise external power supply with appropriate voltage withstand is recommended to use. For

isolated, ungrounded systems external, galvanically isolated power supply is recommended in all cases.

Mains pro 1.6.1 Global Guide

15

Page 16

Requirements for power supply disconnecting device:

In case of power supply from AC voltage, the unit must be equipped by circuit breaker or contactor, marked as

disconnecting device in accordance with the EN 61010-1 standard.

Note: The power supply circuit 8-40 VDC is internally interconnected with the supply circuit 85-265 VAC. In

case of operation with both power supply terminals connected, keep in mind, that a failure of insulation in the

AC power supply may cause propagation of AC voltage into the circuits of low safe DC voltage, due to galvanic

interconnection of both circuits!

3.4.6 Relay outputs connection

For safety purposes, it is recommended to set all MainsPro relay outputs to inverse logic for failure trips and

signaling. This means that under fault-free conditions all contacts are kept in energized position. In trip or out-of-

range signaling state, the contacts de-energize. In case of power-supply fail, the unit automatically moves to

fault-signaling by de-energizing the output relays, assuring safety disconnection of the controlled devices.

These outputs are marked with exclamation mark (i.e.!CommTrpPer).

However, the outputs can be set to normal logic which means, that in fault-free state all contacts are kept in de-

energized position. In trip or out-of-range signaling state, the contacts energize. These outputs are without

exclamation mark (i.e.CommTrpPer).

Relay outputs in MainsPro are freely assignable by the setpoints f(RE).

In default configuration, RE1 serves as the permanently energized common trip output contact

(!CommTrpPer (page 63)). Use this contact to operate the connector devices with permanently energized

inputs.

In default configuration, RE2 serves as an impulse common trip contact (CommTrpImp (page 63)). Use

this contact to operate e.g. opening or UV coil of circuit breakers.

Remaining 3 relay outputs serve for signaling of any sensed failure.

The arrangement of RE1 to 4 outputs in default configuration corresponds to the functionality of the previous

NPU-FUV unit outputs.

3.4.7 Binary switches connection

MainsPro provides 4 galvanically isolated binary switches with configurable functionality. These inputs allow

connection of any voltage free contact between the common terminal BIC and the appropriate functional contact

(BI2 – BI4).

Particular functions (External Trip, Fault Reset, Alternative settings, Disable, CB Feedback) are freely

assignable by setpoint in Group: f(BI) (page 59).

For full description see Library of Binary switches on page 61.

3.5 Measurement range

MainsPro allows using multiple voltage ranges on the measurement inputs with unchanged measurement

accuracy. The following ranges are applicable:

230 V - this range applies in case of "star" connection of the 3-phase system using nominal 230V phase to

neutral. It may be also used for single-phase applications 230V phase to neutral. Overshoot by 30% up to

290V is possible for this measurement range. For this case, set the setpoint Uin (page 52) to 230/400V.

MainsPro will adjust automatically the measurement method, to assure the defined accuracy for the

measured voltage 230 V.

Mains pro 1.6.1 Global Guide

16

Page 17

400 V - this range applies in case of "delta" connection of the 3-phase system using nominal 400V phase to

phase. Overshoot by 30% up to 520V is possible for this measurement range. For this case, set the setpoint

Uin (page 52) to 230/400V. MainsPro will adjust automatically the measurement method, to assure the

defined accuracy for the measured voltage 400 V.

120 V - this range is applicable in countries using 120 V nominal voltage phase to neutral. Another

application is for the high-voltage and other applications, using voltage transformers from rated voltage to

100 V. The guaranteed accuracy applies to both ranges 100 and 120 V. Overshoot by 30% up to 156V is

possible for this measurement range. For this case, set the setpoint Uin (page 52) to 120V.

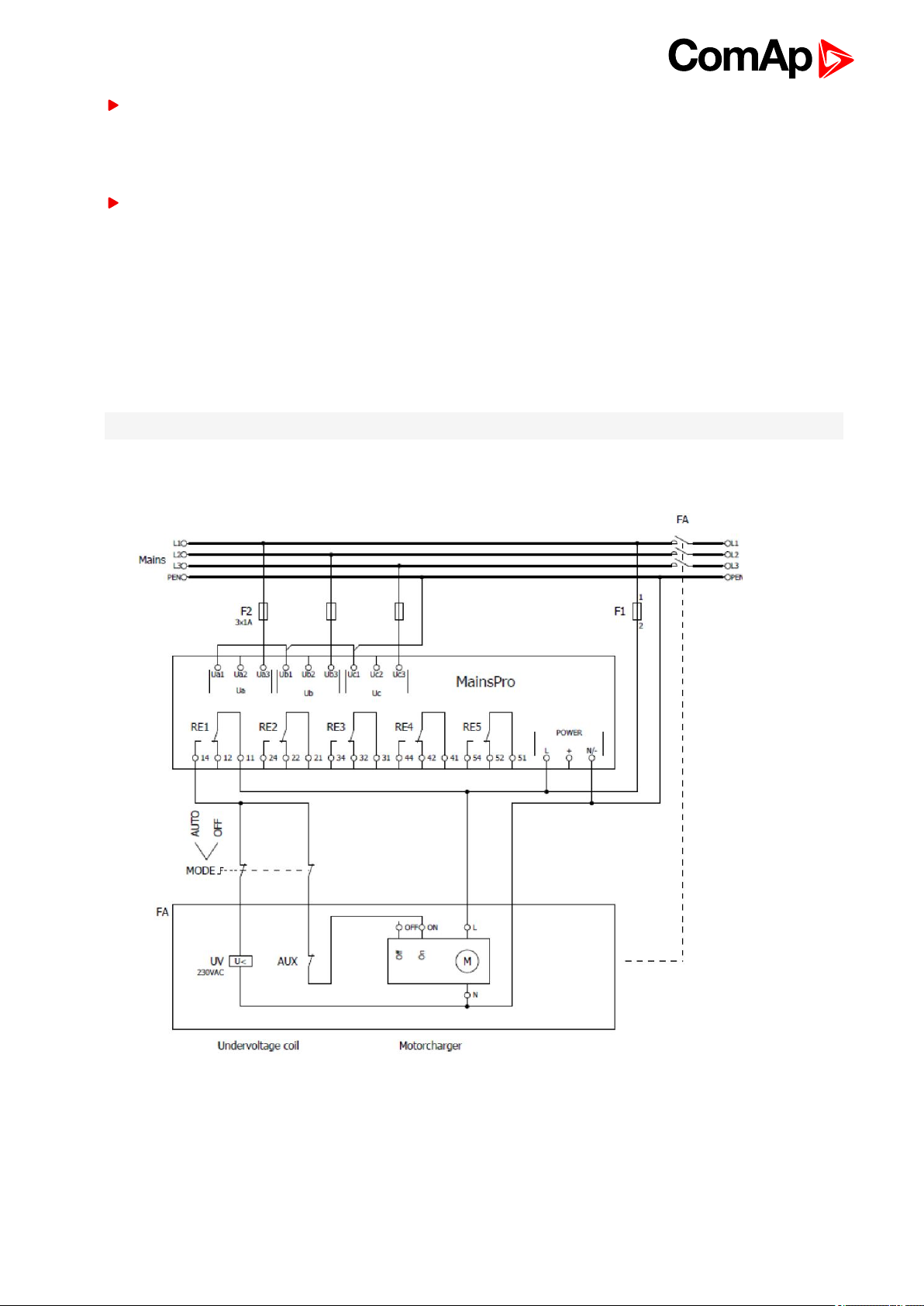

3.6 Wiring examples

This chapter provides examples of possible wiring of MainsPro which can be used as a preparation concept of

wiring scheme.

Note: ComAp bears no responsibility of functionality of the solution where these concepts are applied.

1. Under normal conditions the undervoltage coil is powered. In case of fault, the voltage is lost and the breaker

undervoltage coil opens.

2. Under normal conditions the Off coil is not powered and contacts are open. In case of failure, the contacts

(12) close and the voltage is applied on the Off coil, therefore auxiliary power supply (e.g.UPS) is necessary

to provide voltage for the Off coil.

Mains pro 1.6.1 Global Guide

17

Page 18

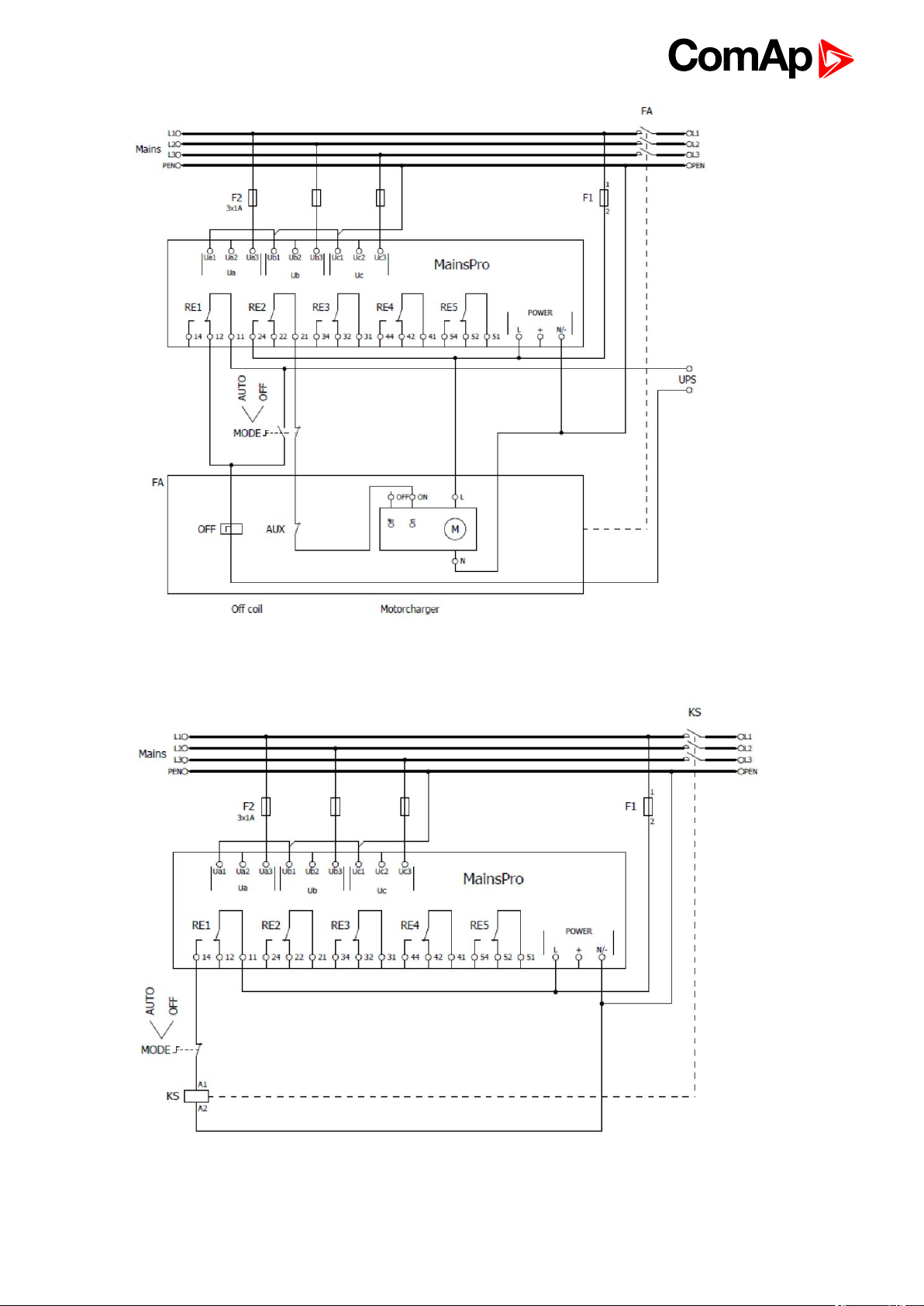

3. Under normal conditions the contacts are closed, in case of failure the contacts open. This wiring is typically

used for coil driven contactors.

6 back to Installation data

Mains pro 1.6.1 Global Guide

18

Page 19

4 User interface

4.1 Front panel elements 19

4.2 Mechanical sealing 22

4.3 Signalization LEDs 22

4.4 Measurement screens 24

4.5 Alarm messages 26

6 back to Table of contents

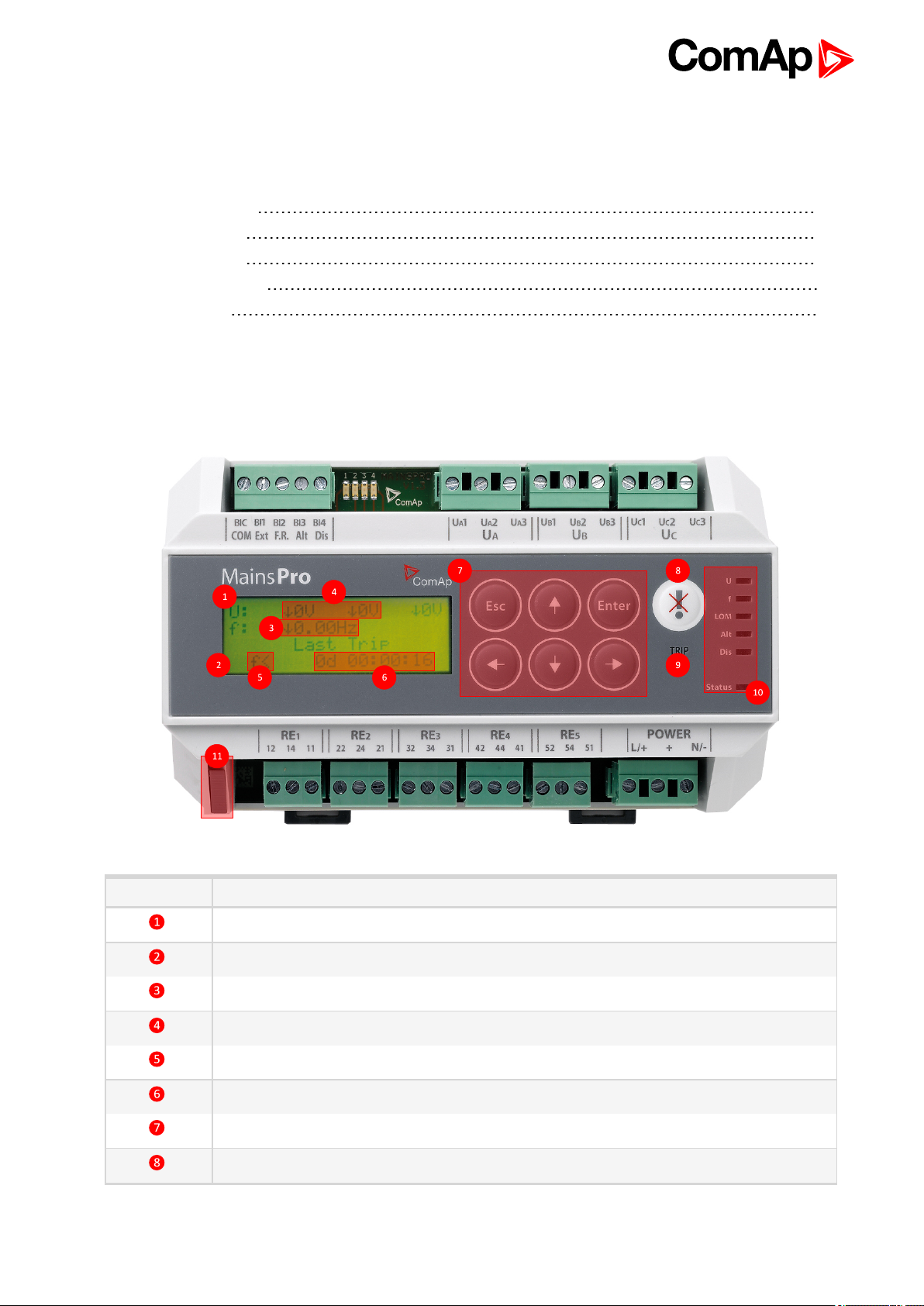

4.1 Front panel elements

Number Description

4 x 20 Alpha-numerical display

Mechanical sealing indication

Frequency measurement

3-phase voltage measurement

Last trip indication

Last trip timer

Control and navigation pushbuttons

Fault Reset button

Mains pro 1.6.1 Global Guide

19

Page 20

Number Description

TRIP LED

Singalization LEDs

Mechanical seal

4.1.1 Pushbuttons

In the measurement screens, use the ↑ and ↓ arrow buttons to browse through the measured values as

displayed on the 4x20 alphanumerical display. See the chapter Measurement screens (page 24) to get the

basic orientation.

To enter the setpoints menu, push the → button. For setpoints change, see Setpoints change on page 20.

To enter the init screen, to reset operation time, perform factory default reset, reset statistics or enter the

Test mode, push the ENTER and ESC at the same time. Together with the init screen display, the unit

performs lamp test by simultaneous cycling of all LEDs through all indication colors.

For confirmation of any value change or query, use the ENTERbutton.

For leaving any value change or query screen without change, use ESC button.

From any screen, press and hold the ESC button for 2 seconds to return back to the main measurement

screen (homepage).

4.1.2 Setpoints change

1. Push the → button to open the setpoints menu.

2. By buttons ↑ and ↓ browse through the menu. The setpoint groups are displayed in the cycling order, i.e.

from the last setpoint group by button ↓, the cursor moves to the first group and vice versa.

3. By button → or ENTER, enter the setpoint group, by button ←, move one level up in the setpoint tree. The

setpoints are displayed in the cycling order, i.e. from the last setpoint by button ↓, the cursor moves to the

first one and vice versa.

4. If standing on a setpoint, the setpoint change screen opens by pressing ENTER or →. In the screen, see the

setpoint limits at the lowest row of the screen.

5. The change is done by orders, starting from the least important digit. Use the buttons ← and → to move

between the digits. Use the buttons ↑ and ↓ to edit the digit. Please note, that the value is not limited by the

parameters limits during editing, but if an out-of-limits value is set-up, it will not be allowed to store in the unit

memory (the change may not be confirmed).

6. After the setpoint change is done, press ENTER to confirm the set value, or ESC to leave the setpoint

change screen without saving the changes.

Note: The unit allows mechanical sealing of the setpoints by the black switch in left-bottom corner of the unit. If

locked, the icon of closed padlock will appear on the position of setpoint change and the setpoints may not be

changed. Also, the padlock icon will be seen on the “homepage” measurement screen. Once the setpoint

change screen is entered and afterwards the sealing position is changed, the padlock indication is not changed,

but the internal lock is applied immediately.

Mains pro 1.6.1 Global Guide

20

Page 21

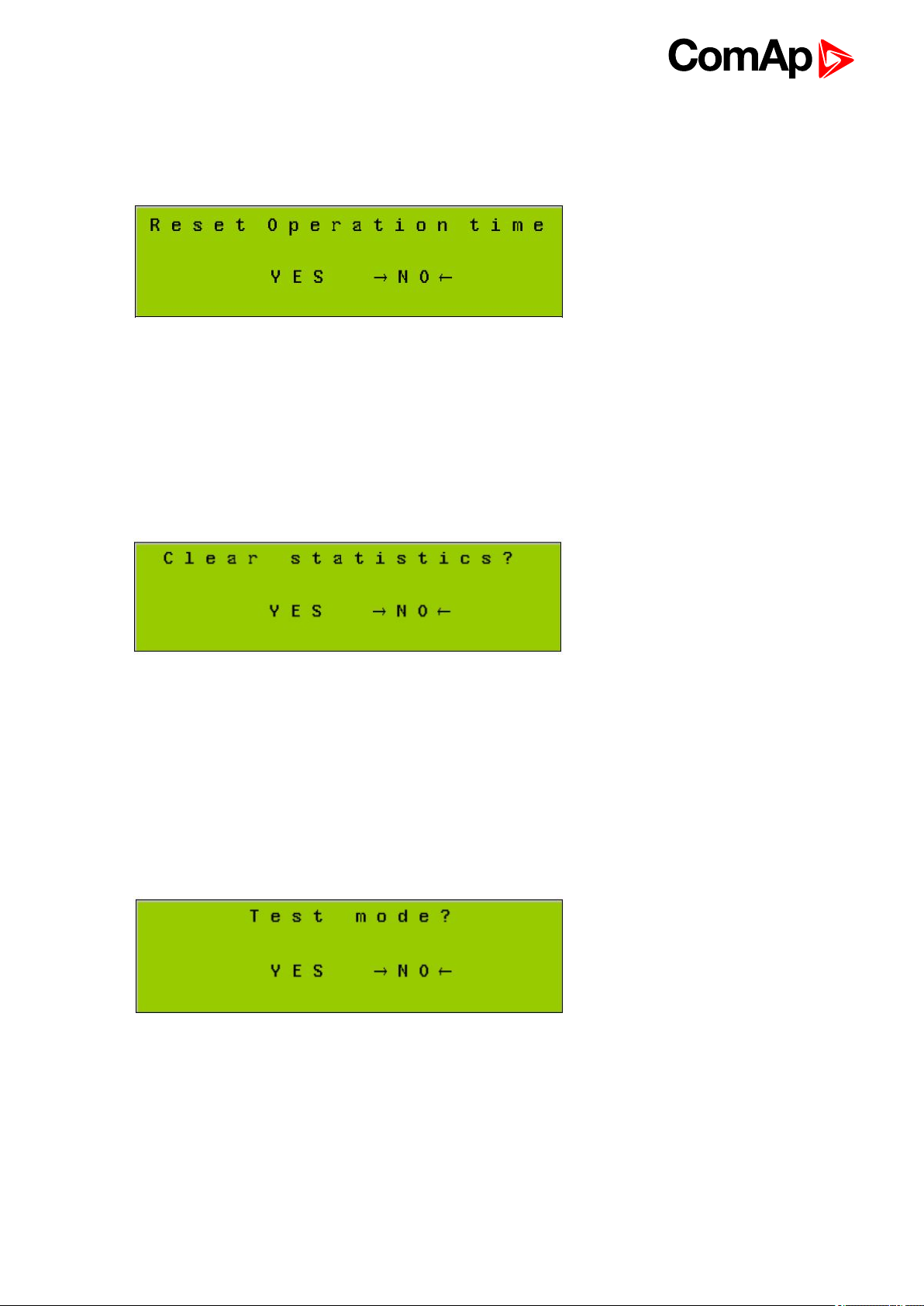

4.1.3 Reset operation time

1. Enter the init screen, by pushing the ENTER and ESC at the same time.

2. Press ← to enter the Reset Oper.Time? screen:

3. Using ← and → do your selection. By selecting YES, “Operation Time" timer will be reset, and the last five

events will be deleted. Press ENTER to confirm your selection.

4. By selecting NO and pressing ESC or by pressing ESC, return to the measurement screens with no change.

4.1.4 Reset trip counters

1. Enter the init screen, by pushing the ENTER and ESC at the same time.

2. Press ← to enter the Clear Statistics dialog screen:

3. Using ← and → do your selection. By selecting YES, all trip counters will be reset. Press ENTER to confirm

your selection.

4. By selecting NO and pressing ENTER or by pressing ESC, return to the measurement screens with no

change.

4.1.5 TEST mode activation

1. Enter the init screen, by pushing the ENTER and ESC at the same time.

2. Press ← and → to enter the Test mode activation screen:

3. Using ← and → do your selection. By selecting YES, you will activate the TEST mode - see the chapter

TEST mode (page 42) in Application Guide. Press ENTER to confirm your selection.

4. By selecting NO and pressing ENTER or by pressing ESC, return to the measurement screens with no

change.

Mains pro 1.6.1 Global Guide

21

Page 22

4.1.6 Factory default

MainsPro contains a default set of all setpoints, which corresponds to the typical requirement of distribution

network operator in some countries.

1. Enter the init screen, by pushing the ENTER and ESC at the same time.

2. Press ← and → to enter the Factory default activation screen:

3. Using ← and → do your selection. By selecting YES, you will return all previously done setting to the default

values. Please note that by this selection, you will lose all setting done prior to this operation!

Press ENTER to confirm your selection.

4. By selecting NO and pressing ENTER or by pressing ESC, return to the measurement screens with no

change.

4.2 Mechanical sealing

MainsPro allows to mechanically prevent the setting changes by securing the mechanical seal in locked

position by sealing wire. The locked position is indicated at the MainsPro side-print and on the alphanumerical

display.

4.3 Signalization LEDs

There are 7 LEDs for indication of MainsPro status with the meaning indicated in the table below

In case of signaling different statuses by one LED, the following priorities apply, i.e. the higher priority signal

is provided by the LED:

Red flashing

Red

Orange flashing

Orange

Green

Note: The U and f signalization is immediate at detection of fault conditions, regardless of the set delay for the

unit trip. After the conditions get back to the fault-free state, the LEDs may move back to green colour,

regardless of whether the unit is currently in TRIP status.

Indication of LED LOM is immediate at detection of the particular protection stage (Vector shift or ROCOF)

and fault indication remains active for the period of time, set by the setpoint Basic: Imp Len Del.

TRIP signalization is delayed according to the particular delay of the appropriate protective stage.

Mains pro 1.6.1 Global Guide

22

Page 23

Meaning of signaling LEDs

LED Color Meaning

TRIP

U

Red

Red

flashing

Nothing The unit has no output in TRIP position

Red

flashing

Red

Orange

flashing

Orange

Green All voltages are in fault-free state

Green

flashing

The unit has the appropriate outputs in TRIP position and the unit is

sensing a fault situation

The unit has the appropriate outputs in TRIP position, but the unit is

sensing fault-free situation. Fault reset is possible.

Voltage of any phase is above threshold for 1st or 2nd stage

overvoltage

Voltage of any phase is under threshold for 1st or 2nd stage

undervoltage

Voltage unbalance (amplitude) is indicated.

If activated together with LED f and LOM, indicates incorrect phase

rotation

Negative sequence overvoltage or Positive sequence undervoltage

is indicated.

If activated together with LED f and LOM, indicates incorrect

polarity of one phase

Floating 10 minutes average overvoltage (page 34) is detected

f

LOM

Nothing

Red

flashing

Red

Orange

flashing

Orange

Green Frequency, rotation and phases polarity are in fault-free state

Nothing

Red

Orange

flashing

Orange Together with LED U and f, indicates incorrect polarity of one phase

Over/under voltage protections are not enabled by setpoint and no

other voltage failure is sensed

Frequency as sensed on terminals Ua is above threshold for 1st or

2nd stage overfrequency

Frequency as sensed on terminals Ua is under threshold for 1st or

2nd stage underfrequency

Together with LED U and LOM, indicates incorrect phase rotation

Together with LED U and LOM, indicates incorrect polarity of one

phase

Over/under frequency is protections are not enabled by setpoint and

no other indicated failure is sensed

Vector shift or ROCOF protection was indicated and Fault reset

was not yet done

Together with LED U and f, indicates incorrect phase rotation

Mains pro 1.6.1 Global Guide

Nothing

None of Vector shift or ROCOF failure is detected or neither Vector

shift nor ROCOF protections are not enabled by setpoint and no

other indicated failure is sensed

23

Page 24

LED Color Meaning

Status

Alt

Dis

Red

flashing

Orange

flahing

Orange Indication of internal failure. Contact ComAp technical support!

Green The unit is in operation with no internal problems.

Nothing The unit is not in operation

Orange

Nothing The function Alternative setting is not activated

Orange The unit is disabled by means of binary switch Disable

Nothing The unit is not disabled by means of binary switch Disable

Indication of severe internal failure. Contact ComAp technical

support!

Indication of internal failure. Contact ComAp technical support!

The function Alternative setting is activated by means of binary

switch Alt setting.

4.4 Measurement screens

Following are the examples of the measurement screens, showing values measured and evaluated by the unit:

U: measured voltages on terminal sets

Ua, Ub and Uc. If overvoltage or

undervoltage is detected on a particular

Main measurement screen (homepage), 3-phase

application:

phase, arrow symbol is displayed left of

the particular voltage value.

f: measured frequency on terminal set Ua.

If overfrequency or underfrequency is

detected, arrow symbol is displayed left of

the frequency value.

Main measurement screen (homepage), 1-phase

application (setpoint System set to 1ph):

Loss of mains (LOM) measurement screen:

Last Trip: indication of the latest event,

which caused trip by the MainsPro unit.

See the following chapter for trip

messages explanation.

U: measured voltage on terminal set Ua. If

overvoltage or undervoltage is detected,

arrow symbol is displayed left of the

voltage value.

f: measured frequency on terminal set Ua.

If overfrequency or underfrequency is

detected, arrow symbol is displayed left of

the frequency value.

Last trip: indication of the latest event, that

caused trip by the MainsPro unit

Max Vs: maximum value of measured

Vector shift since unit power-up or since

the last reset Vector shift trip.

Mains pro 1.6.1 Global Guide

24

Page 25

Act RCF: actual measured value of

ROCOF protection

Max RCF: maximum value of measured

ROCOF protection since unit power-up or

since the last reset ROCOF trip.

V asymmetry: actual value of asymmetry

of effective values measured on terminals

Ua, Ub, Uc

Voltage asymmetry measurement screen:

Binary switches status screen:

Relay outputs 1-4 status screen:

V negative: actual value of negative

sequence voltage

V positive: actual value of positive

sequence voltage

Negative sequence overvoltage and positive

sequence undervoltage are methods of

evaluation of angle asymmetry of the 3-phase

voltage system. See more in the chapter

Voltage unbalance (page 36).

List of the assigned binary switches.

Functions that are configured are displayed in

the appropriate order.

Its status is displayed in brackets.

Status of the first 4 MainsPro relay

outputs.

Name in parenthesis marks the function

assigned by the setpoints in group f(RE).

Relay output 5 status screen:

Trip counters and indication screen:

Mains pro 1.6.1 Global Guide

Status of the 5th MainsPro relay output.

Name in parenthesis marks the function

assigned by the setpoints in group f(RE).

Last Trip: indication of the latest event,

which caused trip. See the following

chapter for trip messages explanation.

TripCnt: total counter of MainsPro trips

since the MainsPro unit counters reset

U: counter of overvoltage and

undervoltage -related trips

f: counter of overfrequency and

25

Page 26

Time measurement screen:

Trip history screen

underfrequency - related trips

LOM: counter of Loss-of-Mains - related

trips (Vector shift and ROCOF)

Otr: counter of trips with other reason than

the above mentioned: External trip,

voltage asymmetry, phase sequence or

inverse phase polarity

Operation Time: time since MainsPro was

powered up*

Last Trip Time: time of the latest trip since

MainsPro was powered-up

Please note that the time information on the

MainsPro unit is not measured by a calibrated

RTC device and may serve for orientation

purposes only. Find more in Technical data

(page 45).

List of last five trips - contains reason of the

trip and time since the unit was powered up

Note:

*For case of power cut off, the time stamp is stored and after the unit is powered up again, the timer will start

from the from following second after the last stored one.

4.5 Alarm messages

One of these indications appears on the homepage screen in case of the unit trip. It indicates the first protective

stage, which issued the trip event:

f> Overfrequency, 1st stage

f>> Overfrequency, 2nd stage

f< Underfrequency, 1st stage

f<< Underfrequency, 2nd stage

U> Overvoltage, 1st stage

U>> Overvoltage, 2nd stage

U< Undervoltage, 1st stage

U<< Undervoltage, 2nd stage

Vs Vector shift

RCF ROCOF

Vunb Voltage (amplitude) unbalance

Mains pro 1.6.1 Global Guide

26

Page 27

Vneg Negative sequence overvoltage

Vpos Positive sequence undervoltage

Vavg 10 minutes floating average overvoltage

Rot Wrong phase rotation

Pol Wrong polarity of one phase

Ext External trip

STr Start Trip

6 back to User interface

Mains pro 1.6.1 Global Guide

27

Page 28

5 Introduction of Application Guide

5.1 Purpose of this manual 28

5.2 MainsPro typical usage 28

5.3 Typical applications of MainsPro protection relay 28

6 back to Table of contents

5.1 Purpose of this manual

The Application Guide serves for the designers and engineers, who process the necessary documentation and

implementation procedures on the installation site, where MainsPro is installed. It contains detailed description

of MainsPro functionalities its practical application.

5.2 MainsPro typical usage

MainsPro is a mains protective relay protecting operation of parallel-to-mains generators or other electrical

resources of distributed generation of electricity. The main purpose is to prevent unwanted interaction between

the generator and mains in case of its abnormal state (e.g. mains failure):

Specific situations may occur, causing e.g. the utility network to momentarily disconnect part of the network

and connect it back by automatic-recloser. During this fault-clearing period, the generators may move away

from synchronism and their eventual re-connection may cause severe damage to the property of the

generator operator, or to the utility equipment.

The sole operation of a generator into an unintentionally islanded part of electricity network provides

potentially dangerous situation. The load of the area may exceed the generator capacity and cause

instability of the voltage, delivered to the consumers connected in the islanded area.

Severe hazards may occur to the working personnel on the grid equipment in the area, where the mains is

presumed as failed, but there are still generators delivering power into this area without central control of

their operation.

These are some of the situations, leading the utilities to strictly require that any parallel connection to the mains

is approved and protection devices with required protective features are installed.

5.3 Typical applications of MainsPro protection relay

These are installations of any sources of electrical energy. For example:

Cogeneration

Peak-lopping power stations

Stand-by generators with soft return/short-time parallel operation with mains

Microturbines

Mains pro 1.6.1 Global Guide

28

Page 29

Small hydro power-plant

Photovoltaic power plant

Windmills

6 back to Introduction of Application Guide

Mains pro 1.6.1 Global Guide

29

Page 30

6 Important Steps of MainsPro utilization

This process describes a typical decisions and technical steps to follow in case of MainsPro utilization, if

required by the distribution network operator (DNO).

Mains pro 1.6.1 Global Guide

30

Page 31

7 TRIP and Fault Reset

7.1 TRIP 31

7.2 Fault reset 32

6 back to Table of contents

7.1 TRIP

TRIP may be considered as event or status of the unit (see chapters bellow).

7.1.1 TRIP event

Starts in the moment of terminating the count-down of any protective function with delay, or in the moment of

activation of any immediate protective function.

As a result of the trip event, are e.g. the following consequences:

Immediate deactivation of outputs !CommTrpPer and !CommTrpImp or activation of CommTrpPer and

CommTrpImp

LED TRIP goes to red

The appropriate counter in the statistics screen increments

The cause of the TRIP event is recorded among the last five history events

The Last Trip Time timer starts to count time and the last trip indication is set

7.1.2 TRIP status

Starts at the moment of TRIP event

During this status, the appropriate outputs are kept in fault position

During this status, it is not possible to perform Fault reset

TRIP status is active until a successful Fault reset. This may not be done before all measured and evaluated

values are within preset limits.

If during the TRIP status, caused by some value, another value overreached its limits for TRIP evaluation,

this second overreach is not considered as TRIP. It does not cause a second TRIP event. However, as a

consequence of this, the TRIP duration may be prolonged until the moment when both (all) values are within

limits.

If the BI Disable is set to ENABLED and the BI Disable is activated during this state, the TRIP status is

terminated and the fault is reset.

If the BI Disable is set to ENABLEDexl.TRP and the BI Disable is activated during this state, it will have no

effect on the unit.

Mains pro 1.6.1 Global Guide

31

Page 32

7.2 Fault reset

Fault reset is an event, caused by one of the following reasons:

FltRes button is pressed

Binary switch Fault reset is activated

Automatic fault reset timer set by setpoint Auto FR Del [s] (page 53), has count down. The counter is

started in the moment when all evaluated values are back within their limits. If during the count-down another

fault status appears, the timer is reset and started no sooner than after all evaluated values are back within

limits again.

The above mentioned reasons are a trigger to provide Fault reset, however, it is successfully done only in case

that the TRIP status is activated and all evaluated values have returned back into limits. If the TRIP status is

not activated, or it is activated, but any of the values is still out of limits, Fault reset is not done and any of the

mentioned triggers is forgotten. I.e., the unit may not be „provisionally“ fault-reset.

By a successful Fault reset, the TRIP status is terminated.

6 back to TRIP and Fault Reset

Mains pro 1.6.1 Global Guide

32

Page 33

8 Protective features

The following protective functionalities, referred also by their ANSI number, are available in MainsPro unit:

8.1 ANSI 59 Overvoltage, ANSI 27 Undervoltage 33

8.2 Floating 10 minutes average overvoltage 34

8.3 ANSI 81H Overfrequency, 81L Underfrequency 34

8.4 ANSI 47 Voltage unbalance and angle asymmetry 36

8.4.1 Voltage unbalance 36

8.4.2 Positive sequence undervoltage, Negative sequence overvoltage 36

8.5 ANSI 78 Vector shift 37

8.5.1 Measuring principle 38

8.6 81R Rate Of Change Of Frequency (ROCOF) 39

8.7 Phase rotation, incorrect phase polarity 39

6 back to Table of contents

8.1 ANSI 59 Overvoltage, ANSI 27 Undervoltage

The RMS value of measured voltage is compared with the preset limit of overvoltage or undervoltage. When any

of the preset limits is over/underreached, the appropriate LED signal is issued by LED U and the output U Sig

moves to fault-indicating position immediately. If voltage of in the given phase keeps out of limits for the delay of

the appropriate stage, TRIP (page 31) is issued. As the voltage returns back within limits in all measured

phases, the LED and U Sig (page 64) output stop to signal the fault state immediately, regardless of whether

TRIP (page 31) was issued or not or Fault reset (page 32) was performed or not. Both overvoltage and

undervoltage protective stages provide possibility of setting 2 levels with independent delay assigned to each

level.

In order to prevent from unwanted voltage oscillation around the overvoltage, respective undervoltage limits,

there is a possibility to set up a voltage hysteresis. The principle is shown in the pictures below. After

overvoltage situation, voltage must decrease under the hysteresis limit to clear the fault. After undervoltage

situation, voltage must exceed the hysteresis limit to clear the fault.

Mains pro 1.6.1 Global Guide

33

Page 34

Image 8.1 Voltage hysteresis for overvoltage

Image 8.2 Voltage hysteresis for undervoltage

8.2 Floating 10 minutes average overvoltage

The unit calculates floating average of the measured voltage in each phase over 10 minutes interval. If any of

the three phase values overreaches the setpoint Avg V> [V] (page 55), TRIP (page 31) is issued, LED U

flashes and counter of voltage disturbances is incremented. As the Last Trip record, the message "Vavg" is

displayed. The protection stage is blocked for the first 10 minutes after power-up of the unit.

8.3 ANSI 81H Overfrequency, 81L Underfrequency

The frequency value measured on phase L1 is compared with the preset limit of overfrequency or

underfrequency. When any of the preset limits is over/underreached, the appropriate LED signal is issued by

Mains pro 1.6.1 Global Guide

34

Page 35

LED f and the output f Sig (page 65) moves to fault-indicating position immediately. If the frequency keeps out

of limits for the delay of the appropriate stage, TRIP (page 31) is issued. As the frequency returns back within

limits, the LED and f Sig (page 65) output stop to signal the fault state immediately, regardless of whether

TRIP (page 31) was issued or not or Fault reset (page 32) was performed or not.

Both overfrequency and underfrequency protective stages provide possibility of setting 2 levels with

independent delay assigned to each level.

Note: MainsPro measures frequency on the phase L1 only, therefore frequency measurement will be distorted

in case that a fault occurs in this phase.

In order to prevent from unwanted frequency oscillation around the overfrequency, respective underfrequency

limits, there is a possibility to set up a frequency hysteresis. The principle is shown in the pictures below. After

overfrequency situation, frequency must decrease under the hysteresis limit to clear the fault. After

underfrequency situation, frequency must exceed the hysteresis limit to clear the fault.

Image 8.3 Frequency hysteresis for overfrequency

Mains pro 1.6.1 Global Guide

35

Page 36

Image 8.4 Frequency hysteresis for underfrequency

8.4 ANSI 47 Voltage unbalance and angle asymmetry

MainsPro provides 3 independent methods for evaluation of voltage symmetry failures. All of these protections

are only active in case that 3-phase system is selected by the setpoint System (page 52).

8.4.1 Voltage unbalance

In further text, this term refers to the state, when amplitude difference between any 2 phases overreaches the

preset limit V unb, A.V unb [V] (page 56). I.e., it refers to the amplitude unbalance of the measured voltage.

8.4.2 Positive sequence undervoltage, Negative sequence overvoltage

These two methods provide very good sensitivity also to angle asymmetry of the measured voltages. The

evaluation is based on the mathematical principle of evaluation of the symmetrical components of measured

voltage. Any 3-phase system in any asymmetrical arrangement may be decomposed to 3 perfectly symmetrical

components:

Positive sequence - system of 3 phases with 120° phase-shift between the system vectors and the same

phase-order as the original system.

Negative sequence - system of 3 phases with 120° phase-shift between the system vectors and opposite

phase-order as the original system.

Zero sequence - system of 3 conphase vectors (with 0° phase-shift between the phases).

Mains pro 1.6.1 Global Guide

36

Page 37

Image 8.5 Decomposition of a generic 3-phase voltage to symmetrical components

MainsPro provides positive and negative sequence voltage evaluation and compares the measured values with

V> neg, A.V> neg [V] (page 57) and V< pos, A.V< pos [V] (page 56) thresholds. In the perfectly

symmetrical arrangement, negative sequence voltage is zero and positive sequence voltage equals to the

measured voltage. If the asymmetry situation occurs, non-zero negative sequence voltage is calculated and

positive sequence voltage drops. When any of the preset limits is over/underreached, the appropriate LED

signal is issued by LED U and the output dU Sig (page 65) moves to fault-indicating position immediately. If

the calculated values keep out of limits for the delay dU del, TRIP (page 31) is issued. As the calculated values

of voltage asymmetry return back within limits, the LED and dU Sig (page 65) output stop to signal the fault

state immediately, regardless of whether TRIP (page 31) was issued or not or Fault reset (page 32) was

performed or not. Some utilities strictly require in their regulations that symmetrical components are evaluated in

the mains-decupling relay and appropriate trip is provided. However, the method may also be used in the areas,

where no such requirement is in place, to minimize non-detection zones of detection of 1-phase mains failures.

In case that the generator, connected to the mains is operated close to equity-state, i.e. power delivered to the

mains is close to zero, it may be difficult to sense loss of one phase further in the system. The only change seen

in such situation may be movement of the failed phase by a certain angle with small or no voltage drop in the

absolute values. This may not be detected by undervoltage or unbalance protection stage. Symmetrical

components provide very good and sensitive method to detect such a situation and trip the generator in case of

this situation.

Typical setting of the V< pos vary from 0,65 to 0,85 of the rate voltage value. The exact values are delivered by

the mains operator or may be set-up during commissioning after experimental verification of the protection stage

sensitivity to the single-phase failures in equity state of the generator (e.g. by opening one fuse on the mains

transformer).

Note: If the phase L1 occurs a rapid voltage drop from 230V to e.g. 50V, tripping times might be longer and can

reach 100ms.

8.5 ANSI 78 Vector shift

The vector shift is one of the fast "Loss of Mains" protection stages. The principle is based on the fact that if a

generator works into an islanded area of the electricity network, its voltage and frequency depend strongly on

the load size, remaining in the islanded area. Decrease of the generator speed due to overload may not be fast

enough to assure e.g. trip by underfrequency stage. The mains may be equipped with auto-reclosing

mechanisms and in case that the generator is not disconnected within the auto-reclosing delay, the area may be

reconnected back to the grid by this mechanism. This reconnection may meet the generator in asynchronous

state, imposing severe risk of damage to the generator, its feeder equipment as well as equipment of the mains

operator. Vector shift provides fast protective function for this situation.

Mains pro 1.6.1 Global Guide

37

Page 38

8.5.1 Measuring principle

When synchronous alternator is loaded, the rotor displacement angle is built between the terminal voltage

(mains voltage) g and the synchronous electromotive force e. Therefore a voltage difference ΔU is built

between e and g. The rotor displacement angle between stator and rotor is depending on mechanical

moving torque of the generator shaft. The mechanical shaft power is balanced with the electrical feeder mains

power and therefore the synchronous speed keeps constant.

Image 8.6 In parallel with the mains

In case of mains failure or auto reclosing the generator suddenly feeds a very high consumer load. The rotor

displacement angle is decreased repeatedly and the voltage vector g changes its direction to g’.

Image 8.7 At mains failure

As shown in the timing diagram the voltage jumps to another value and the phase position changes. This

procedure is called phase or vector surge. MainsPro continuously measures the cycles, starting each zero up

ward slope. The time cycle is internally compared to the reference time. In case of vector surge the zero up ward

is delayed and the device trips instantaneously. The trip angle Δ and consequently the sensitivity of the vector

surge detection is adjustable by the setpoint VS lim, A.VS lim [°] (page 58).

Mains pro 1.6.1 Global Guide

38

Page 39

Proper setting of Vector shift limit has to be examined at the field tests, especially at very low setting of the

protection limit (under 3°). Vector shift is very fast method and may be sensitive to disturbances, naturally

present in the electricity grid.

Note: Due to high sensitivity, Vector shift protection is not evaluated in the transient states, e.g. when Alt

settings functionality is turned on or off, Fault reset (page 32) is performed or Vector shift limit is being set.

Functionality is blocked in the sine wave period, when such an event occurs.

8.6 81R Rate Of Change Of Frequency (ROCOF)

ROCOF is another fast "Loss of Mains" protection stages provided in MainsPro. It is based on the similar

principle as Vector shift, i.e. dependence of the generator speed and voltage on the load size. The variations of

frequency delivered by the gen-set depend on the load fluctuations and speed of the compensated fuel inlet. In

case of operation in parallel with large network, these changes are absorbed in the network and frequency is

stable. When the connected area disconnects from the mains into island operation, the frequency becomes

instable. MainsPro ROCOF stage provides fast evaluation of the frequency instability and TRIPS immediately

in case of fast frequency changes. The threshold is set by the setpoint ROCOF, A.ROCOF [Hz/s] (page 58).

As the ROCOF stage provides very sensitive protection, software filter may be set using the LOM: ROCOF filt

setpoint. By appropriate setting of those two setpoints, perfect ratio between sensitivity and speed of reaction of

ROCOF protection may be established at the field tests.

Note: ROCOF is sensitive to voltage jumps, therefore it is recommended to be disabled during tests of

overvoltage and enabled after tests are finished.

8.7 Phase rotation, incorrect phase polarity

MainsPro provides check of the phase sequence and polarity. The correct connection is indicated in the wiring

instructions e.g. on MainsPro box or in chapter Wiring (page 12), where clockwise rotation system is expected

on the mains side. It may happen, that e.g. by redesign in the mains or generator site installation, the phase

rotation changes. MainsPro ensures in such case, that this state is indicated and it prevents incorrect closing of

the circuit breaker by its standard protective functionality. To allow phase sequence or incorrect phase polarity

check, the phase angle between the 3 voltage vectors is expected in range 120° +/- 30°. If wrong phase

arrangement is detected, TRIP (page 31) is issued and the appropriate LED signalization is given. The

reconnection of measurement terminals is necessary to ensure further proper functionality of the unit.

6 back to Protective features

Mains pro 1.6.1 Global Guide

39

Page 40

9 Application tips

9.1 Automatic return to mains 40

9.2 Binary switches 40

9.3 Counters 41

9.4 Timer 42

9.5 Start trip 42

9.6 TEST mode 42

6 back to Table of contents

9.1 Automatic return to mains

Some utilities require that the protection unit provides an automatic return of the generating unit back to parallel

operation with mains. This automatic return usually does not happen immediately after the mains parameters

are within limits, but with pre-defined time delay. For such case, the unit allows setting a time delay during

which the Fault reset (page 32) can be automatically performed after the set time runs out.

Appropriate setting of automatic fault reset by setpoint Auto FR Del [s] (page 53) timer allows setting the

waiting time reserved for mains parameters to settle in their fault-free conditions after a TRIP (page 31). This

state is indicated by flashing red signal of the TRIP LED. If during this time any measured value reaches out of

the preset limits, MainsPro terminates the automatic fault reset count-down and goes back into fault indication

state. The automatic fault reset is reset and started again in the moment when all measured values are back in

limits again. After automatic fault reset is count down to zero, the unit performs automatic Fault reset (page 32)

and terminates the TRIP (page 31) status.

9.2 Binary switches

MainsPro allows basic remote operation by means of binary signals wired from an external logic to MainsPro

binary switches. The signals may be also provided remotely, e.g. through radio or GSM communicator devices.

As an example for the many similar devices on the market, see the uGATE communicator below. Ask for more

information about this product at protections@comap-control.com.

This way, MainsPro functionality may be simply controlled by a mobile telephone commands. All four binary

switches may be enabled or disabled by the appropriate setpoints in the group Basic.

Mains pro 1.6.1 Global Guide

40

Page 41

9.2.1 External trip

In case that a specific protective function is requested and this function is not supported in MainsPro, it may

be provided in an external device. Wire the output of this device to Ext Trip (page 61) to allow tripping by

this external device.

Use the External trip also for forced disconnection of the generator if such command is for example

evaluated in a superior system or transmitted through remote communication device.

External trip functionality may be also used for intertripping method of protection system topology. This

method is required by the mains operator for bigger generators.

9.2.2 Fault reset

Use this switch in case that complex conditions are to be evaluated before the generator is connected back

to mains. These conditions may be processed in an external system and the result may be sent to this

switch.

External fault reset may be also provided in case that locked button is used for performing the Fault reset

(page 32) operation by authorized personnel only. In this case, MainsPro is to be secured inside of the

locked switchboard and external fault reset only made possible.

Remote fault reset via GSM communicator may also be a useful feature for the remote sites.

9.2.3 Alternative settings

Alt Settings (page 61) binary switch may be used in case that a specific setting of the protection relay is

required by the mains operator when exceptional conditions occur. After deactivation, the unit immediately

switches to the default groups of setpoints.

9.2.4 Disable

The Disable (page 61) switch may be used for blocking the MainsPro protective functions, e.g. in case that

the generator is not running in parallel operation with mains, or any other blocking conditions are fulfilled.

9.2.5 CB Feedback

The CB Feedback (page 61) switch is used to confirm that a circuit breaker opened on a command issued

by MainsPro. Any time some protective function is activated and a trip is issued, deactivation of this binary

input is expected. If the feedback does not confirm opening of the CB, additional back-up trip BakTrpPer

(page 67) and BakTrpImp (page 68) will be issued after adjustable time delay BakTrpDel.

9.3 Counters

Keeping a track of the most frequent trips may provide valuable information for the generator as well as

distribution network operator. Use the counters indication on the Measurement screens (page 24) for keeping

track of the most frequent failures detected in the point of your connection. For example, in case that the

MainsPro counters show significantly higher rate of a certain failure types (e.g. overvoltage or Vector shift), it

may be a good signal to perform a detailed evaluation of the voltage quality in the point of connection or start

discussions with the DNO to allow for wider limits of the protection setting to minimize down-times of the

generator.

Mains pro 1.6.1 Global Guide

41

Page 42

9.4 Timer

MainsPro provides two time counters: since the unit power-up and since the last TRIP (page 31). Use these

timers for investigation of failures that were detected by MainsPro unit. Please note that MainsPro does not

provide RTC clock and after each power-up of the unit, the time and date is lost. For this reason only indication

of days / hh : mm is used. The accuracy of the time measurement may also not be fully guaranteed. During

internal tests, the measurement error of 4 seconds per 24 hours was recorded.

9.5 Start trip

The unit supports start into the TRIP (page 31) state after connection of the power supply, depending on the

setpoint Start Trip (page 53). If this setpoint is set to ENABLED, the unit goes into the TRIP state immediately

after the auxiliary power supply is turned on. If there are no failures detected by the unit measurement, it is

possible to provide Fault reset (page 32) by any of the mentioned means and so to put the unit into fault-free

operation. If the setpoint is set to DISABLED, the unit goes directly into the fail-free state.

The purpose of this functionality is to allow automatic delayed return to mains in case that the mains is

completely lost and MainsPro unit is powered from the same mains voltage.

9.6 TEST mode

MainsPro provides a TEST mode, which enables phase-to-phase testing of 3-phase protective features by

single-phase power source.

The test mode may be activated by entering the init screen (entered by pressing the ENTER and ESC at the

same time). Follow by ← button and then ↑ button. This will open the Test mode activation screen.

Select Y to enter the TEST mode.

The voltage asymmetry protections are deactivated.

The following functions are fix-assigned to the appropriate relay outputs, regardless of their actual

assignment:

Comm Trp Per to RE3

f Sig to RE4

U Sig to RE5

In TEST mode, the setpoint group TEST becomes visible. This group contains only one setpoint – „Phase“.

Use this setpoint to assign to which input is the 1-phase measurement voltage source connected (UA, UBor

UC).

All relevant protections are evaluated only in that phase, which is selected:

If TEST/Phase = Ua, the following protective functions are evaluated:

Overvoltage and undervoltage on the UA terminals, with dual stage setting, including the Alt

parameters possibility

Overfrequency and underfrequency on the UA terminals, with dual stage setting, including the Alt

parameters possibility

Loss OF Mains protections on the UA terminals, with the Alt parameters possibility

Mains pro 1.6.1 Global Guide

42

Page 43

If TEST/Phase = Ub or Uc, the following protective functions are evaluated:

Overvoltage and undervoltage on the appropriate terminals, with dual stage setting, including the Alt

parameters possibility

Note: When testing on the terminals Ub and Uc, it is always necessary, that the same measurement voltage

as applied on terminals Ub or Uc is also present at the terminals Ua. It is not used for testing purposes, but

serves for the internal synchronization of the measurement process of the unit.

On the first measurement screen (homepage), the sign !!!TEST!!! is displayed in the bottom line instead of

the last trip information.

If any TRIP is performed during the TEST mode, no counters are incremented and the last trip indication and

timer is not affected.

In the TEST mode, it is possible to change setpoints, but some functionality, which is disabled in the TEST

mode (e.g. voltage asymmetry setting or assignment of f(RE)) is not active.

After return from the TEST mode, the unit goes back to its original setting including the outputs assignment

and the setpoint group TEST is hidden.

To return from the TEST mode:

Go to Test mode activation screen and select NO, or

Turn the unit off and on again, or

The unit goes back to the standard operation after 10 minutes from the last keyboard activity.

6 back to Application tips

Mains pro 1.6.1 Global Guide

43

Page 44

10 Introduction of Reference Guide

10.1 Purpose of this manual

The Reference Guide contains library of setpoints, inputs and outputs functionalities and technical data for the

purpose of detailed technical information. This information is referenced in the Installation and Operation Guide

and Application Guide.

Mains pro 1.6.1 Global Guide

44

Page 45

11 Technical data

11.1 Accuracies and reaction times 45

11.2 Technical parameters 46

11.3 Factory default setting of MainsPro unit 47

6 back to Table of contents

11.1 Accuracies and reaction times

11.1.1 Operating area

MainsPro provides the below mentioned accuracies and reaction times in case that the measured voltage on all

3 phases is within the green area on the picture below. Outside of the green area, MainsPro provides the

expected performance (i.e. trips in case of voltage overreaching the green area border), but the behaviour,

accuracies and reaction times may not be guaranteed.

Mains pro 1.6.1 Global Guide

45

Page 46

Note: Please note, that in order to fulfill the requested accuracies of the unit, it is necessary that the voltage is

always present at the terminals UA with the same frequency as on the other terminals. If this is not fulfilled,

even if the voltages on the measurement inputs UB and UC are within green area, they will not be evaluated

accurately!

11.1.2 Voltage measurement

Voltage measurement accuracy is 1% of the nominal value at frequency 50 Hz ± 10% and temperature

25°C.

The accuracy is 1,5% within the complete temperature range and in the green operational area (see

Operating area on page 45).

Maximum reaction time for voltage failures (in case of the delay set to 0,00 s) is 2 periods of measured

voltage + 15 ms. This is valid at nominal frequencies 50 Hz ± 10% and 60 Hz ± 10%.

11.1.3 Frequency measurement

Frequency measurement is 0,1 Hz in the complete green operating area.

Maximum reaction time for frequency failures (in case of the delay set to 0,00 s) is 75 ms. This is valid in

complete green operating area.

11.1.4 Time delays accuracy

The unit allows to set the time delays with step 10 ms.

The maximum tolerance of the unit timing is ≤3% ± 15ms.

11.1.5 Loss of Mains reaction times

Reaction time of Vector shift protection is 1,5 period of measured signal + 15 ms.

11.2 Technical parameters

Power supply:

8 - 40 V

85 - 265 V/45-65 Hz, 110 - 370V Maximum consumption 90 mA

Operating temperature range -20°C to +70°C

Heat radiation 13 W

Dimensions 158 x 96 x 68 mm

Protection IP20

Maximum consumption 600 mA

Not galvanically separated from power supply 85 - 265 VAC!

Rated voltage 120 V / 230 V ph-n / 400 V ph-ph

Maximal voltage range Rated + 30%

50 Hz,60 Hz

Rated frequency of measured voltage

(indicated accuracy is guaranteed on frequency range 40-70 Hz)

Measurement input impedance: 400 kΩ

Signal relay contacts:

Mains pro 1.6.1 Global Guide

46

Page 47

Max switched voltage/current 250 V / 4A

Max switched power resistive load: 1000 VA AC, 200 W DC

inductive load: 50 VA AC, 25 W DC

Rated voltage/current resistive load: 250 V / 4 A AC

200 V / 0,1 A DC, 24 V / 4A DC

inductive load: 250 V / 2 A AC

200 V / 0,1 A DC, 24 V 3A DC

Minimum load 1 W / 1VA at U

Lifetime 1 x 105cycles

Terminal tightening torque 0,4 Nm

Measurement category III (EN 61010-1)

Appliance class

Recommended fuse of the unit power

supply and measurement circuits

Intended use according to UL508

standard

The unit is intended for use on a DIN rail inside a switchboard with prevention of access of non-qualified

personnel. In case of access of non-qualified personnel, it is necessary to cover the terminals by means

corresponding to the environment of the unit operation. It is possible to make the user interface accessible to the

operation staff.

II, double insulation, the device has no protective earthing terminal

(IEC 61140)

fuse 1A

MainsPro is intended for use with switchgear and associated

equipment as per the category for Protective relays – NRGU

min

> 10 V

11.2.1 Endurance to the power supply voltage fails

MainsPro unit withstands the power supply voltages failures of 100 ms lengths in the full range of power supply

voltage on the 85 - 265 VAC / 110 - 370 VDC terminals and at the voltage .18 - 40 VDC connected to the 8 - 40

VDC terminals. The construction of the power supply allows that the unit withstands the voltage drop down to

min 40 VAC in case that the unit was started from the AC voltage within the allowed range 85 - 265 VAC. Such

a drop of the voltage for unlimited time does not influence the unit operation.

11.3 Factory default setting of MainsPro unit

Note: The following default setting is available from version 1.5. For older versions, different factory default

setting was applied.

Setting

Overvoltage limit 1*)

Overvoltage delay 1

Overvoltage limit 2

Overvoltage delay 2

Undervoltage limit 1*)

Undervoltage delay 1

Mains pro 1.6.1 Global Guide

Setpoint

group

V<>

V<>

V<>

V<>

V<>

V<>

Setpointname Value Step Unit

V>

V> Del

V>>

V>> Del

V<

V< Del

262

1.00

273

0.50

184

2.50

1

0.01

1

0.01

1

0.01

[V]

[s]

[V]

[s]

[V]

[s]

47

Page 48

Setting

Setpoint

group

Setpointname Value Step Unit

Undervoltage limit 2

Undervoltage delay 2

10 minutes floating average

overvoltage*

Overvoltage hysteresis V<> RstV>,RstV>> 100 1 [%]

Undervoltage hysteresis V<> RstV<,RstV<< 100 1 [%]

Voltage asymmetry limit

Negative sequence overvoltage limit

Positive sequence undervoltage limit

Common delay of all voltage asymmetry

protections

Overfrequency limit 1

Overfrequency delay 1

Overfrequency limit 2

Overfrequency delay 2

Underfrequency limit 1

Underfrequency delay 1

V<>

V<>

V<> Avg V> 0 (OFF) 1 [V]

dU

dU

dU

dU

f<>

f<>

f<>

f<>

f<>

f<>

V<<

V<< Del

V unb

V> neg

V< pos

dU Del

f>

f> Del

f>>

f>> Del

f<

f< Del

0

0.50

0.0 (OFF)

0.0 (OFF)

0.0 (OFF)

2.50

0

0

52.00

0.50

47.50

20.00

1

0.01

0.1

0.1

0.1

0.01

0.1

0.01

0.1

0.01

0.1

0.01

[V]

[s]

[%]

[%]

[%]

[s]

[Hz]

[s]

[Hz]

[s]

[Hz]

[s]

Underfrequency limit 2

Underfrequency delay 2

Overfrequency hysteresis f<> Rstf>,Rstf>> 100 0.1 [%]

Underfrequency hysteresis f<> Rstf<,Rstf<< 100 0.1 [%]

Vector shift limit

ROCOF limit

ROCOF filter

ROCOF delay

Vector shift and ROCOF evaluation delay

Vector shift and ROCOF signalization time

(TRIP duration)