ComAp InteliGen NT, InteliGen NTC, InteliGen NT BaseBox, InteliGen NTC BaseBox, InteliSys NT Communications Manual

...Page 1

ComAp a.s.

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +266 31 66 47

E-mail: info@comap.cz, www.comap.cz

Communication Guide for ComAp Controllers

InteliGen NT

InteliGen NTC

InteliGen NT BaseBox

InteliGen NTC BaseBox

InteliSys NT

InteliSys NTC BaseBox

Inteli Mains NT

Inteli Mains NT BaseBox

Inteli Mains NTC BaseBox

IGS-NT SW version 3.0

COMMUNICATION GUIDE

Page 2

Table of contents

Table of contents ..................................................................................................................................... 2

Scope of the document ............................................................................................................................ 5

Definition of terms .................................................................................................................................... 6

Controllers communication capabilities ................................................................................................... 7

IG/IS/IM-NTC-BB - Communications .................................................................................... 7

IG/IS/IM-NTC-BB - Terminals ............................................................................................... 8

IG/IS/IM-NTC-BB - Peripheral modules ................................................................................ 9

IG/IS/IM-NTC-BB - Jumpers settings .................................................................................. 10

IG/IM-NT-BB - Communication ........................................................................................... 11

IG/IM-NT-BB - Terminals .................................................................................................... 12

IG/IM-NT-BB - Peripheral modules ..................................................................................... 13

IG/IM-NT-BB - Jumpers settings ......................................................................................... 14

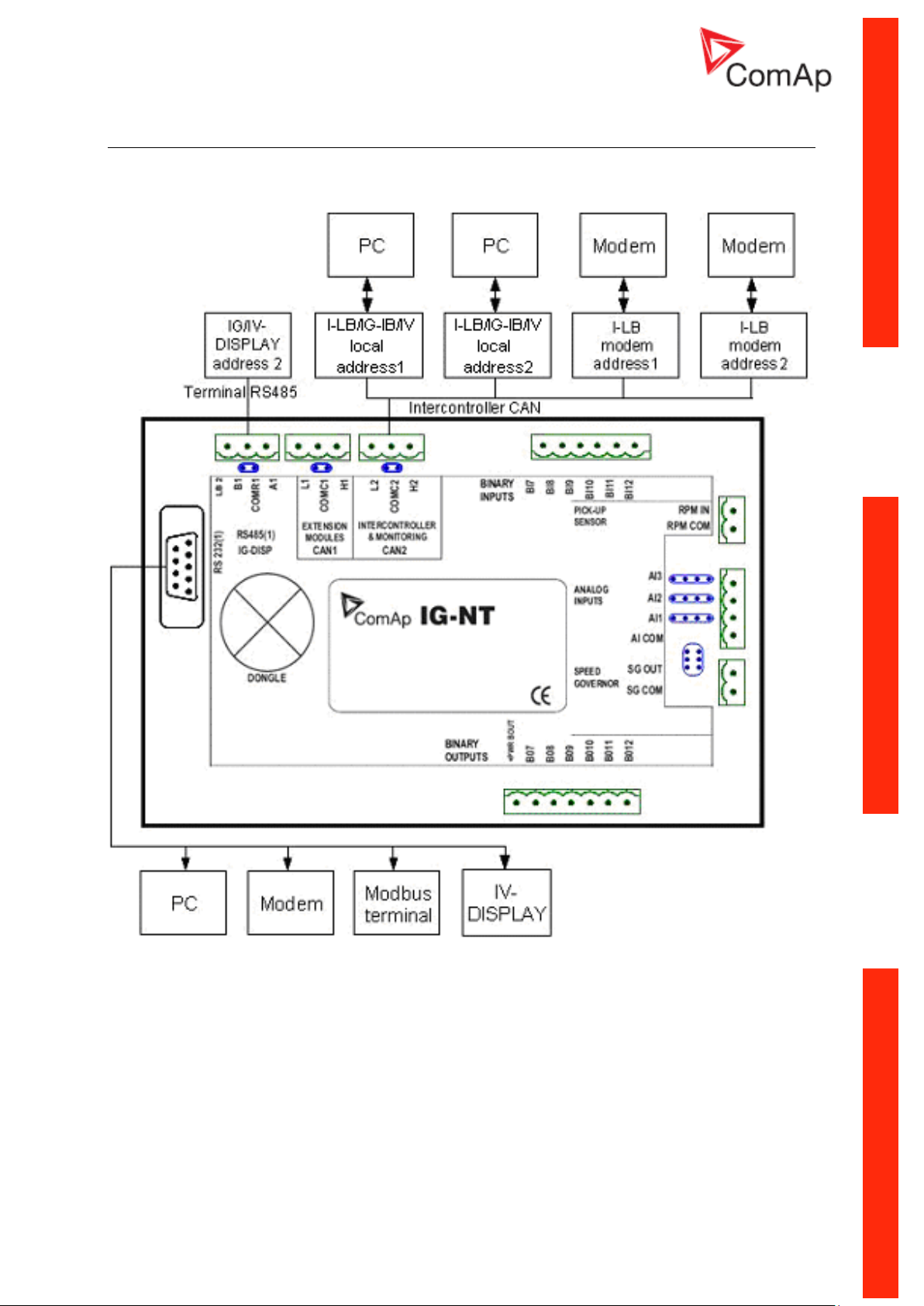

IG-NT - Communications, Terminals .................................................................................. 15

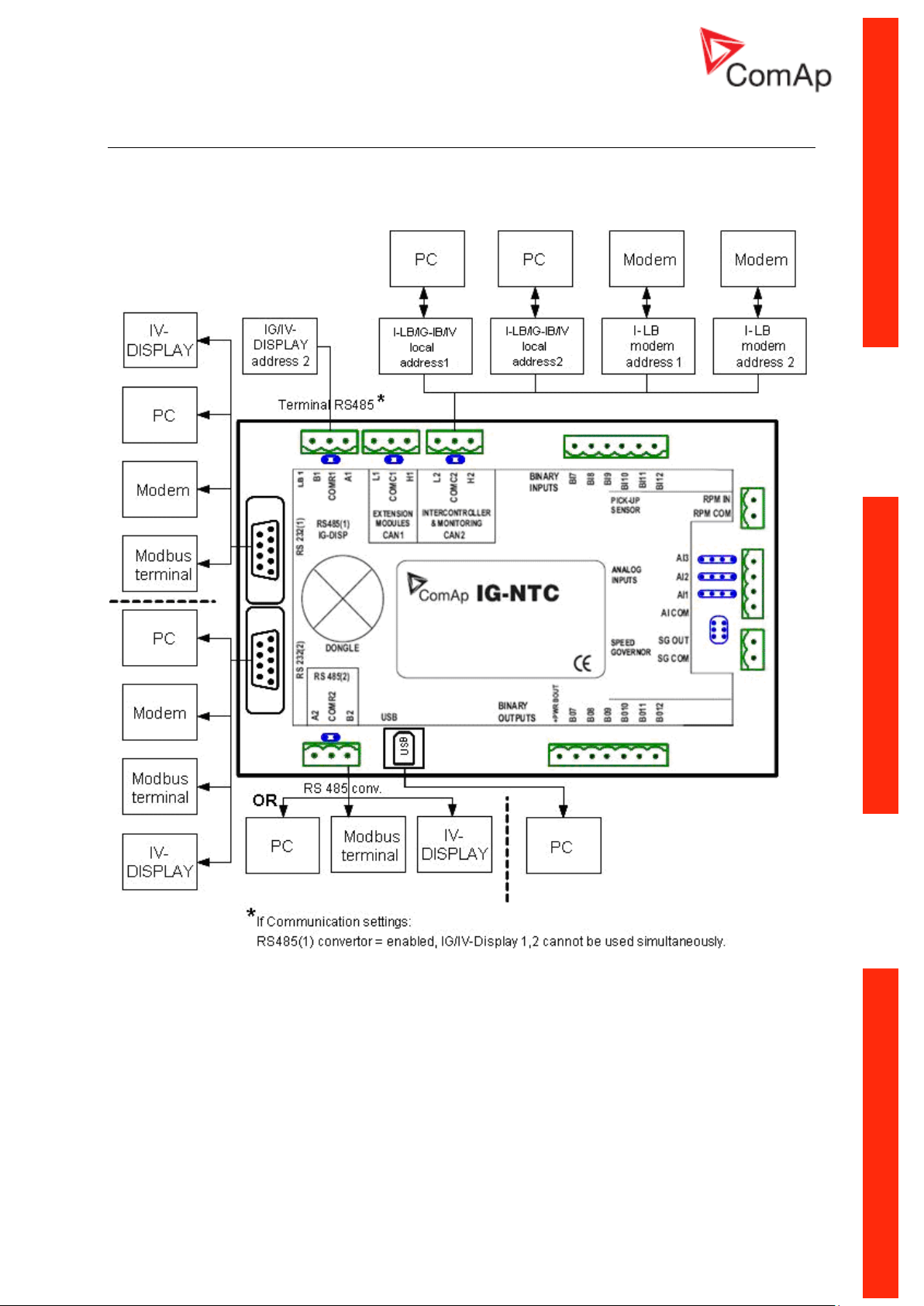

IG-NTC - Communications, Terminals ................................................................................ 16

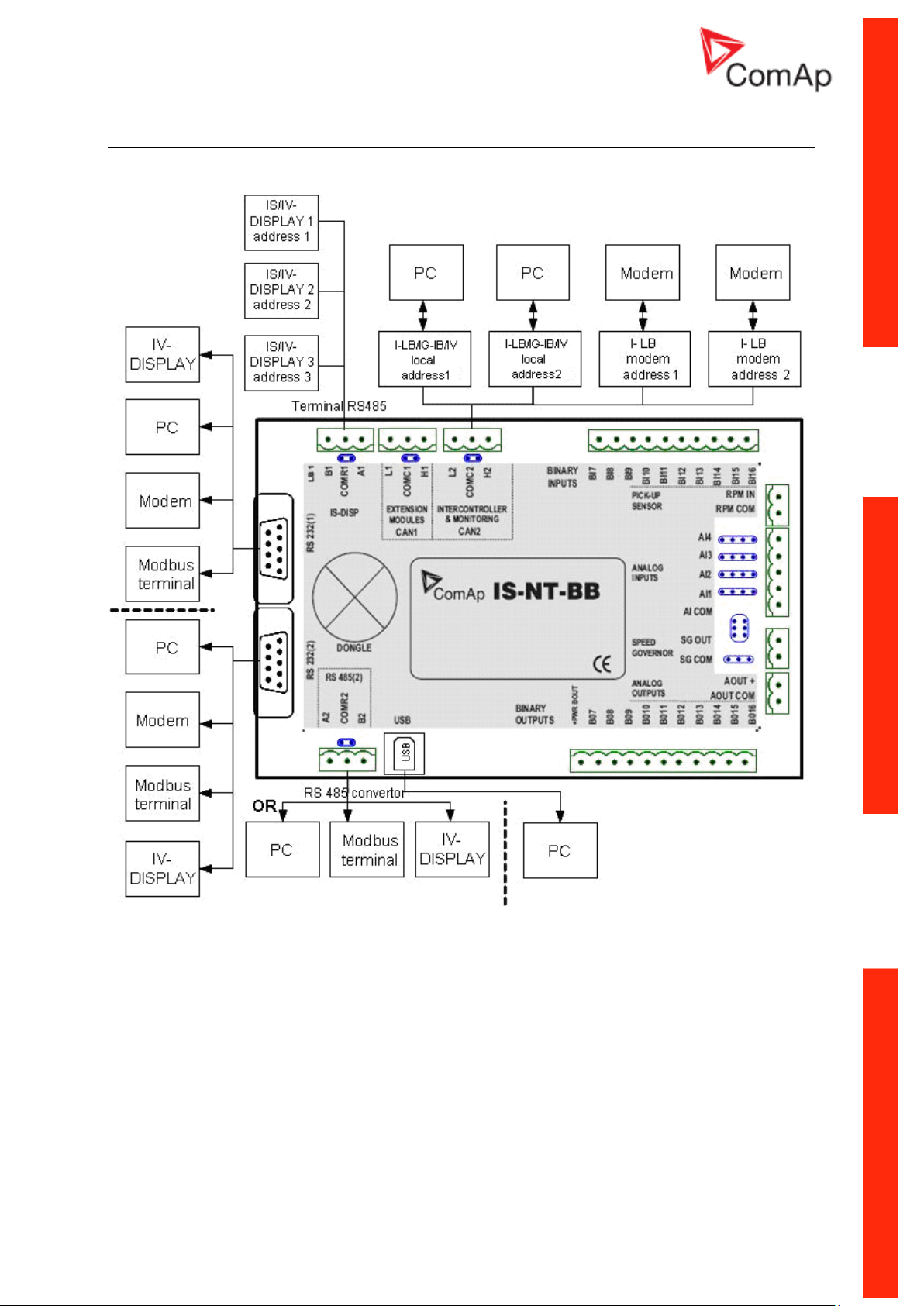

IS-NT-BB - Communications, Terminals............................................................................. 17

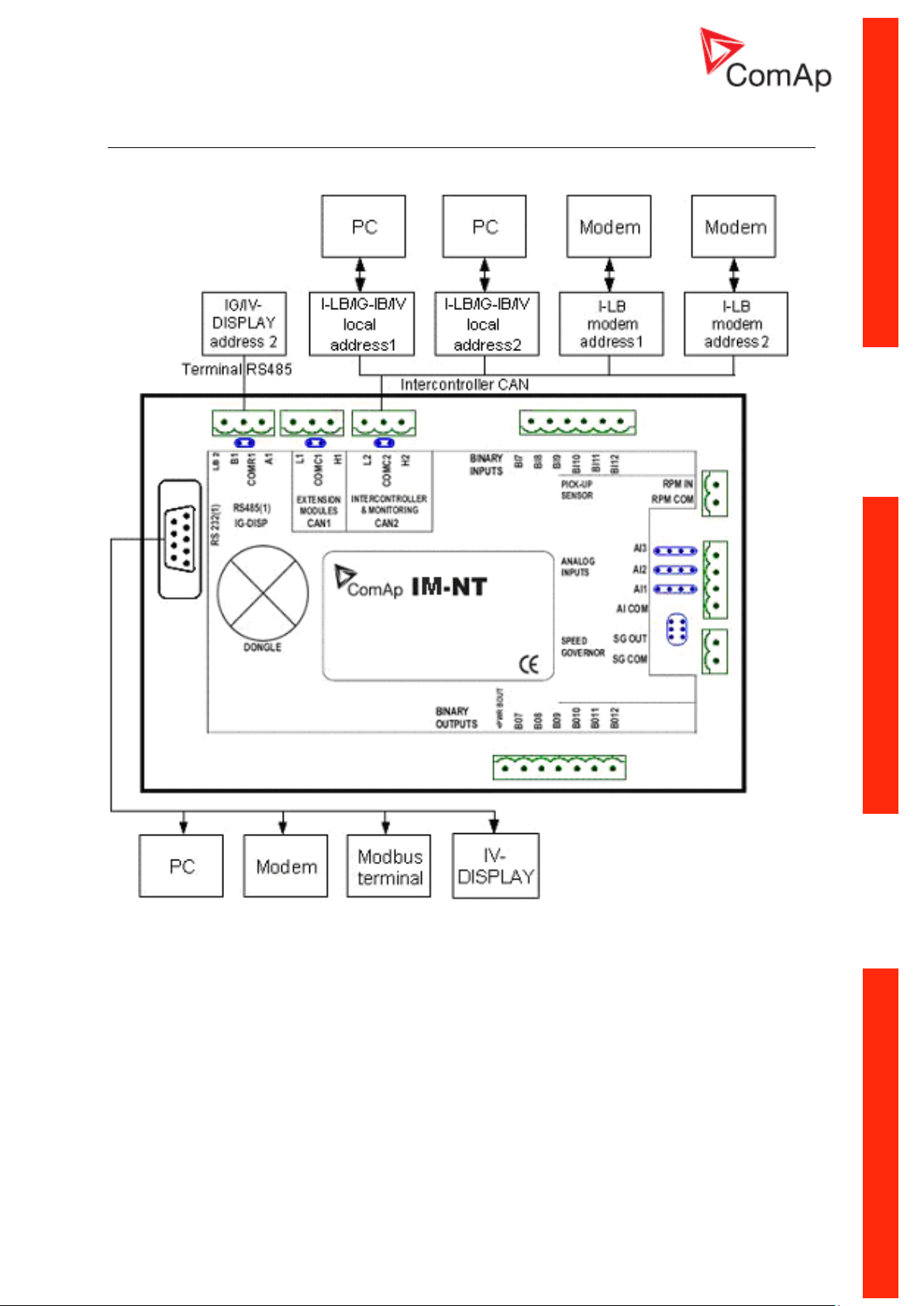

IM-NT - Communications, Terminals .................................................................................. 18

Monitoring Local on site - Comap SW ................................................................................................... 19

Direct PC connection to Single gen-set ................................................................................ 19

RS232 connection .......................................................................................................................... 19

USB connection .............................................................................................................................. 20

RS485 connection .......................................................................................................................... 21

Ethernet connection (Direct) .......................................................................................................... 22

Direct PC connection to Multiple gen-sets ............................................................................ 23

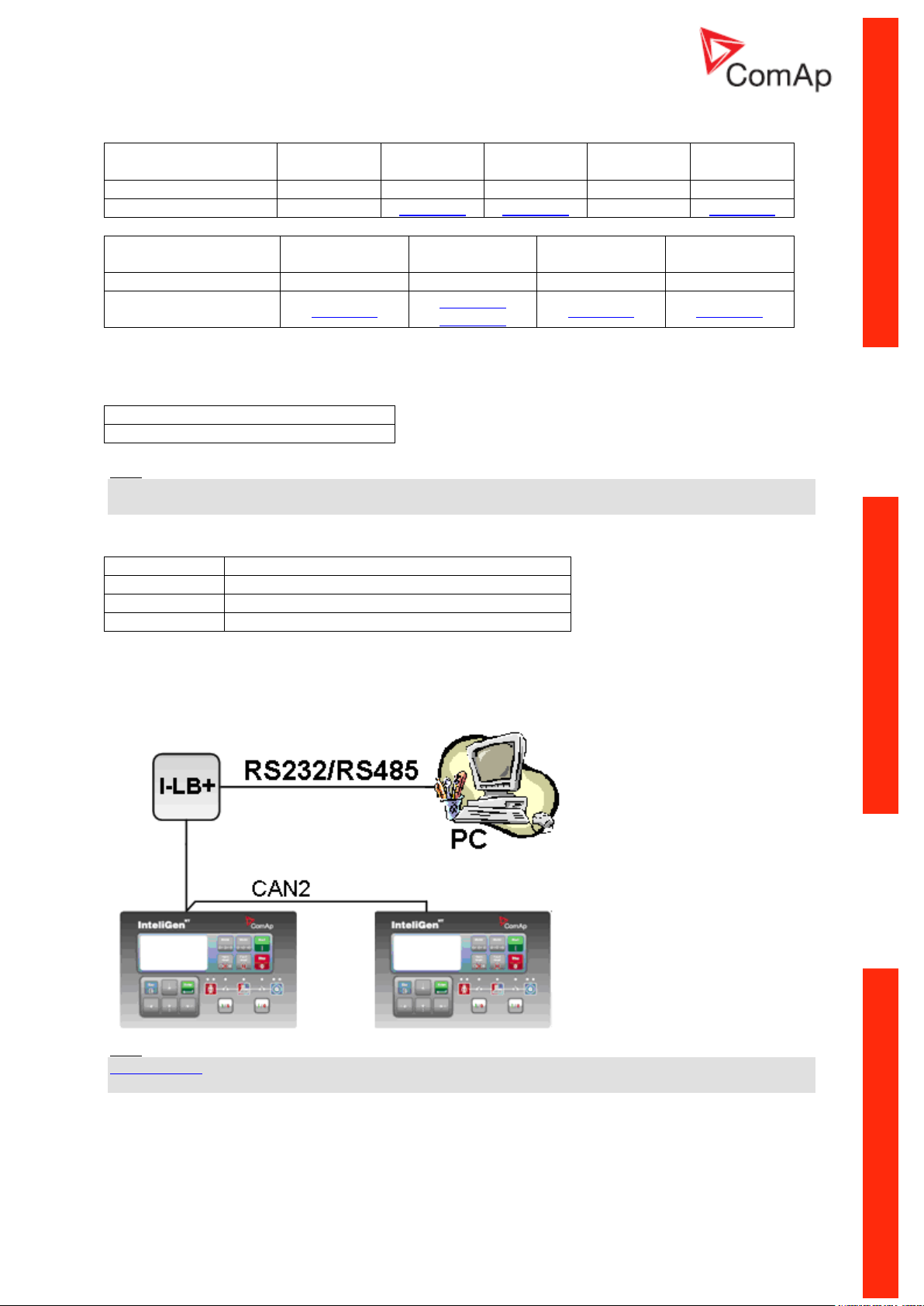

RS485 connection .......................................................................................................................... 23

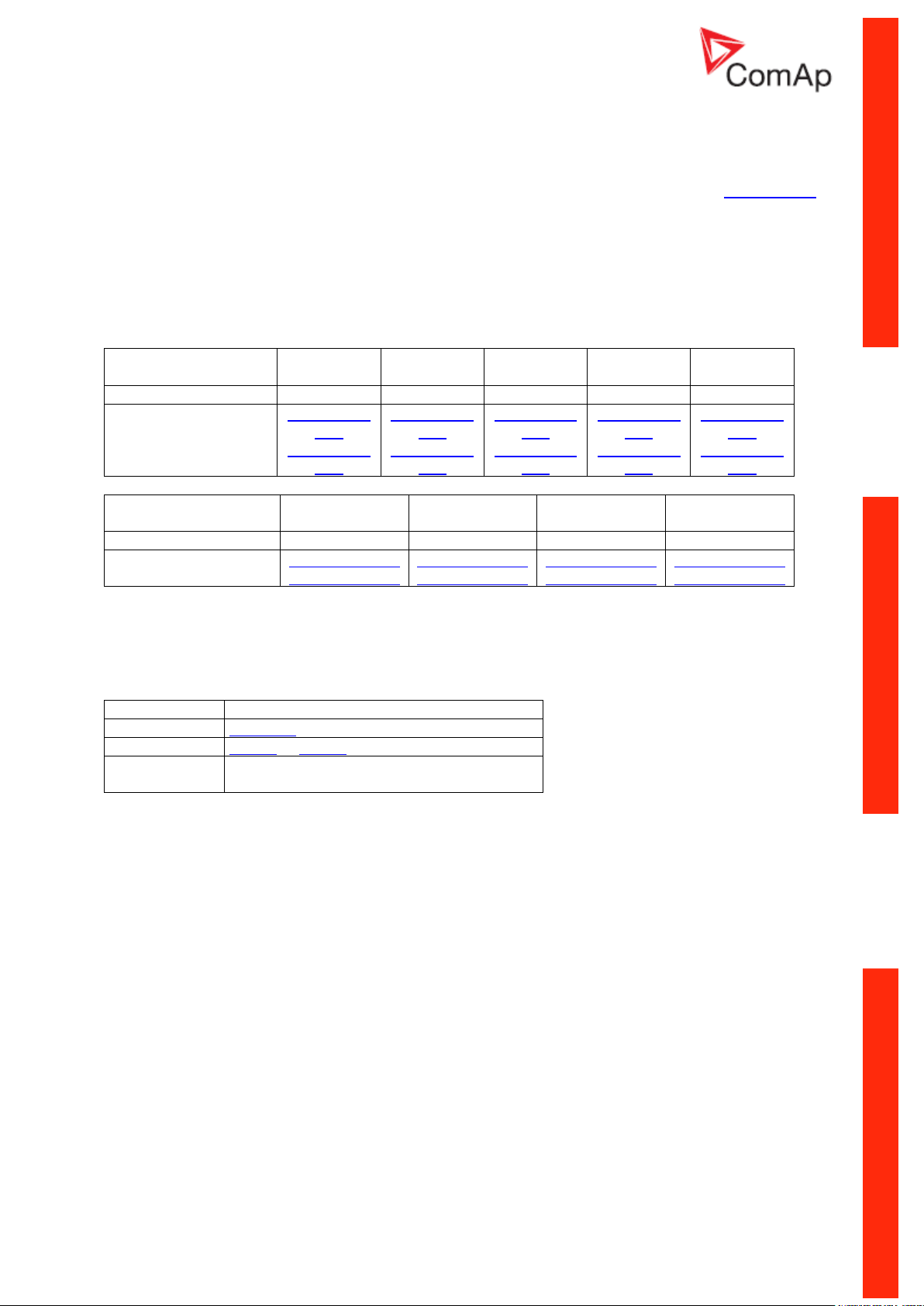

RS232/485 connection (I-LB+) ....................................................................................................... 24

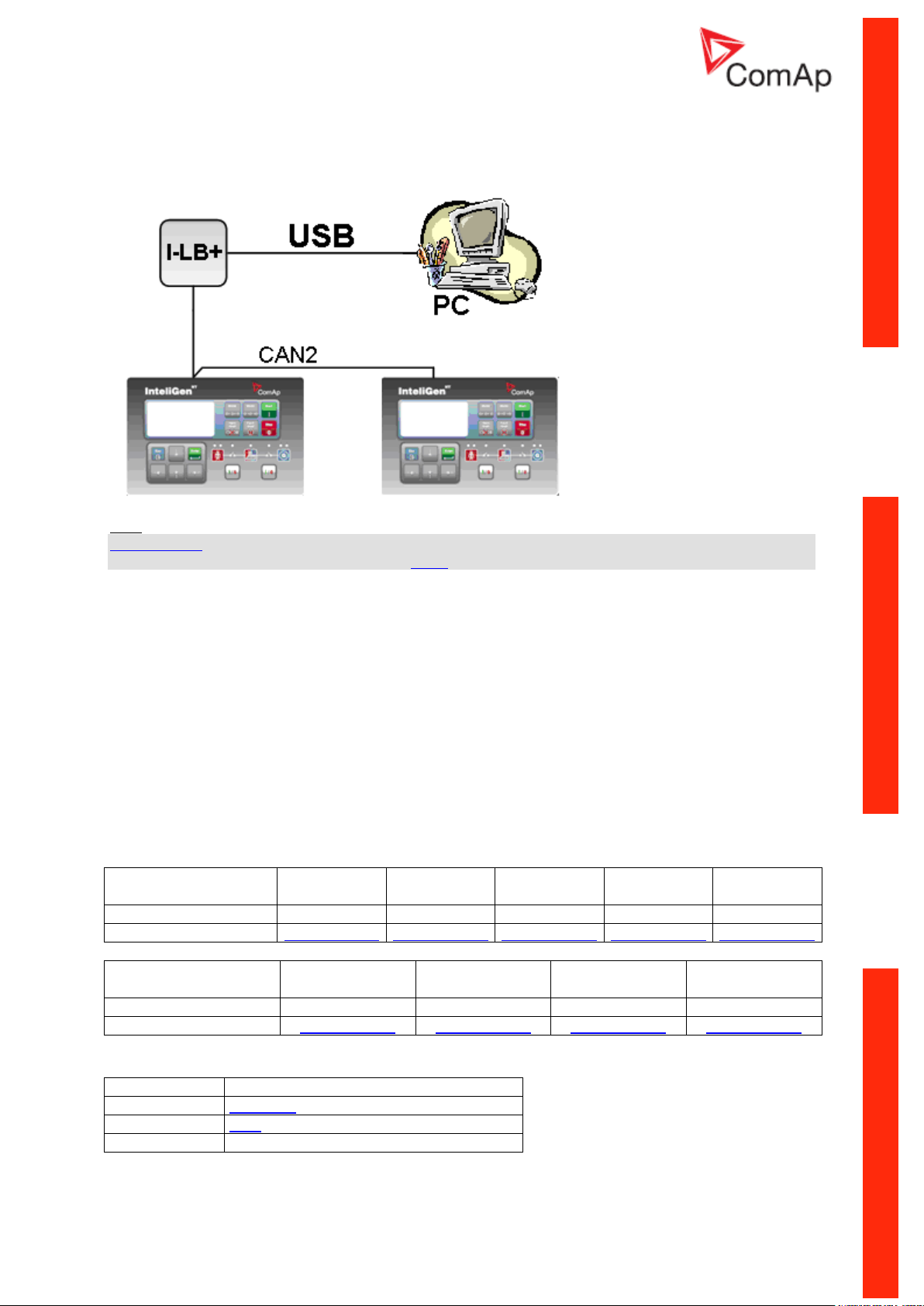

USB connection via I-LB+ module ................................................................................................. 26

Ethernet connection via IB-NT (IG-IB) ........................................................................................... 27

Ethernet connection (Direct) .......................................................................................................... 28

Monitoring Local on site - MODBUS ..................................................................................................... 30

ModBus - Single gen-set ...................................................................................................... 30

RS232 ModBus .............................................................................................................................. 30

RS485 ModBus .............................................................................................................................. 31

Ethernet - MODBUS/TCP (Direct) .................................................................................................. 32

ModBus - Multiple gen-sets .................................................................................................. 33

RS485 – MODBUS ......................................................................................................................... 33

RS232/RS485 – MODBUS (I-LB+) ................................................................................................ 34

Ethernet - MODBUS (IB-NT) .......................................................................................................... 35

Ethernet - MODBUS/TCP (Direct) .................................................................................................. 36

Remote monitoring ................................................................................................................................ 37

Connection to Internet (Direct) .............................................................................................. 37

Internet connection via AirGate ............................................................................................ 39

WebSupervisor ..................................................................................................................... 41

Web interface ........................................................................................................................ 44

Internet connection via cellular network................................................................................ 48

Connection via Internet bridge IB-NT ............................................................................................. 48

Modem connection ................................................................................................................ 49

Modem connection to Single gen-set ............................................................................................. 49

Modem connection to Multiple gen-sets......................................................................................... 50

Active Call ............................................................................................................................. 51

Active SMS ........................................................................................................................... 52

Active E-mail (SMS E-mail) ............................................................................................................ 53

Peripheral modules ................................................................................................................................ 54

Displays ................................................................................................................................ 54

InteliVision 8 display ....................................................................................................................... 54

Communication Guide, ©ComAp – March 2014 2

IGS-NT Communication Guide 03-2014.pdf

Page 3

InteliVision 5 display ....................................................................................................................... 54

Comms extension - I-LB+ Local bridge ................................................................................ 55

Comms extension - IG-IB Internet Bridge ............................................................................. 57

I-CR Module for CAN Bus Extension .................................................................................... 69

I-LB ................................................................................................................................................. 70

I-CR-R Module for CAN Bus Redundancy............................................................................ 71

Appendix ................................................................................................................................................ 75

Communication cables.......................................................................................................... 75

RS232 cable ................................................................................................................................... 75

USB cable ...................................................................................................................................... 76

Ethernet cable ................................................................................................................................ 77

Recommended CAN/RS485 connection .............................................................................. 78

CAN bus connection....................................................................................................................... 78

CAN bus extension options ............................................................................................................ 79

RS485 connection .......................................................................................................................... 82

Modem Recommendations ................................................................................................... 84

Analog Modem with DC Supply ..................................................................................................... 84

Recommended ISDN Modem ........................................................................................................ 84

Recommended CDMA Modem ...................................................................................................... 84

Recommended GSM Modems ....................................................................................................... 84

3G Modems .................................................................................................................................... 87

Recommended Satellite Modems .................................................................................................. 87

Converters ............................................................................................................................ 87

Converter RS232 RS485 ........................................................................................................... 87

RS232 Bluetooth adapter ............................................................................................................... 88

Converter 230V AC TCP/IP ....................................................................................................... 88

Converter USB RS232 .............................................................................................................. 88

Converter USB RS485 .............................................................................................................. 89

Converter Modbus RTU TCP .................................................................................................... 90

Isolator RS232 ................................................................................................................................ 90

Radio Link ...................................................................................................................................... 91

Converter Modbus RTU SNMP ................................................................................................. 92

Converter Modbus RTU Profibus .............................................................................................. 94

Ethernet converter from twisted pair (UTP/STP) to optic ............................................................. 101

SMS message commands .................................................................................................. 102

Modbus Connection ............................................................................................................................. 107

Modbus Step by Step.......................................................................................................... 107

Important setpoints in the controller .................................................................................... 107

Modbus communication via RS232 – single controller ................................................................ 107

Modbus communication via RS485 .............................................................................................. 108

Modbus communication via RS485 – multiple controllers ........................................................... 108

Modbus communication via I-LB .................................................................................................. 109

Modbus Communication ...................................................................................................................... 110

Data reading ....................................................................................................................... 110

Data writing ......................................................................................................................... 110

Modbus Protocol Description............................................................................................................... 112

Read Multiple Registers ............................................................................................................... 113

Write Single Register.................................................................................................................... 113

Alarm list reading ................................................................................................................ 115

Alarm list reading via Modbus ...................................................................................................... 115

History reading .................................................................................................................... 117

Check field calculation ........................................................................................................ 118

How get numbers of ModBus communication objects ........................................................ 118

Reserved communication objects ....................................................................................... 120

Access to password protected objects ............................................................................... 121

Commands for IGS-NT ....................................................................................................... 122

Commands for IM-NT ......................................................................................................... 123

User Modbus ....................................................................................................................................... 125

Modbus Appendix ................................................................................................................................ 126

Communication Guide, ©ComAp – March 2014 3

IGS-NT Communication Guide 03-2014.pdf

Page 4

Error list ............................................................................................................................... 126

Data types ........................................................................................................................... 127

Communication status ........................................................................................................ 129

Examples of Modbus Communication ................................................................................................. 131

Battery voltage – reading (read multiple registers) ...................................................................... 131

Values (Oil press, Water temp, Fuel level) – reading .................................................................. 132

Binary input - reading .................................................................................................................. 132

Password decode - reading ........................................................................................................ 132

Gen-set name - reading .............................................................................................................. 133

Engine state - reading .................................................................................................................. 133

Gear teeth – writing ...................................................................................................................... 134

Nominal Power – writing .............................................................................................................. 134

Mode – writing .............................................................................................................................. 134

Reset / Confirm Alarm .................................................................................................................. 135

Remote Switch 1 – Set (Remote Control 1) ................................................................................. 136

External Value1 – writing ............................................................................................................. 136

User & Password – in two steps .................................................................................................. 137

User & Password – in one step .................................................................................................... 138

Start the engine – in one step ...................................................................................................... 138

Start the engine – in two steps ..................................................................................................... 139

History – reading .......................................................................................................................... 139

AlarmList reading ......................................................................................................................... 140

Communication Guide, ©ComAp – March 2014 4

IGS-NT Communication Guide 03-2014.pdf

Page 5

Scope of the document

There are following types of communication between controller(s) and superior system in the

controller.

1. Local (on site) communication

via ComAp software

via MOUDBUS (MODBUS RTU or MODBUS TCP)

2. Remote communication

via Ethernet

via Internet (AirGate)

via MODEM

These types of connections are available via RS232, RS485, USB, ETHERNET

communication ports.

Communication Guide, ©ComAp – March 2014 5

IGS-NT Communication Guide 03-2014.pdf

Page 6

Definition of terms

InteliSys NTC Basebox

IS-NTC-BB

InteliSys NT

IS-NT-BB

InteliGen NTC Basebox

IG-NTS-BB

InteliGen NT Basebox

IG-NT-BB

InteliGen NTC

IG-NTC

InteliGen NT

IG-NT

InteliMains NTC Basebox

IM-NTC-BB

InteliMains NT Basebox

IM-NT-BB

InteliMains NT

IM-NT

Local connection

Type of connection using direct connection on site via protocol of ports on the controller. Length of

connection is given by protocol specification.

Remote connection

Type of connection using standard communication lines such as Internet, modem connection and

GSM connection for communication between controller and other superior device.

Comap Protocol

Communication between PC with ComAp software (InteliMonitor, GenConfig) and controller is running

on this protocol.

3rd party software

Software using standardized protocol for sharing of data between particular systems (for example

ModBus RTU, ModBus TCP etc.).

Single gen-set communication

This type of connection allows communication only with one controller. Communication with other

controllers on site via this type of connection is not possible.

Multiple gen-set communication

This type of connection allows communication with more than one controller on site via single

communication link.

Monitoring

Type of communication used for continuous displaying of process data and process control of the

system.

Configuration

Type of communication used for writing of configuration file into the controller.

Note:

There are used some abbreviations for resolution of all hardware variations of IGS-NT controllers in

this document. These abbreviations correspond with order codes of each HW variation.

Communication Guide, ©ComAp – March 2014 6

IGS-NT Communication Guide 03-2014.pdf

Page 7

Controllers communication capabilities

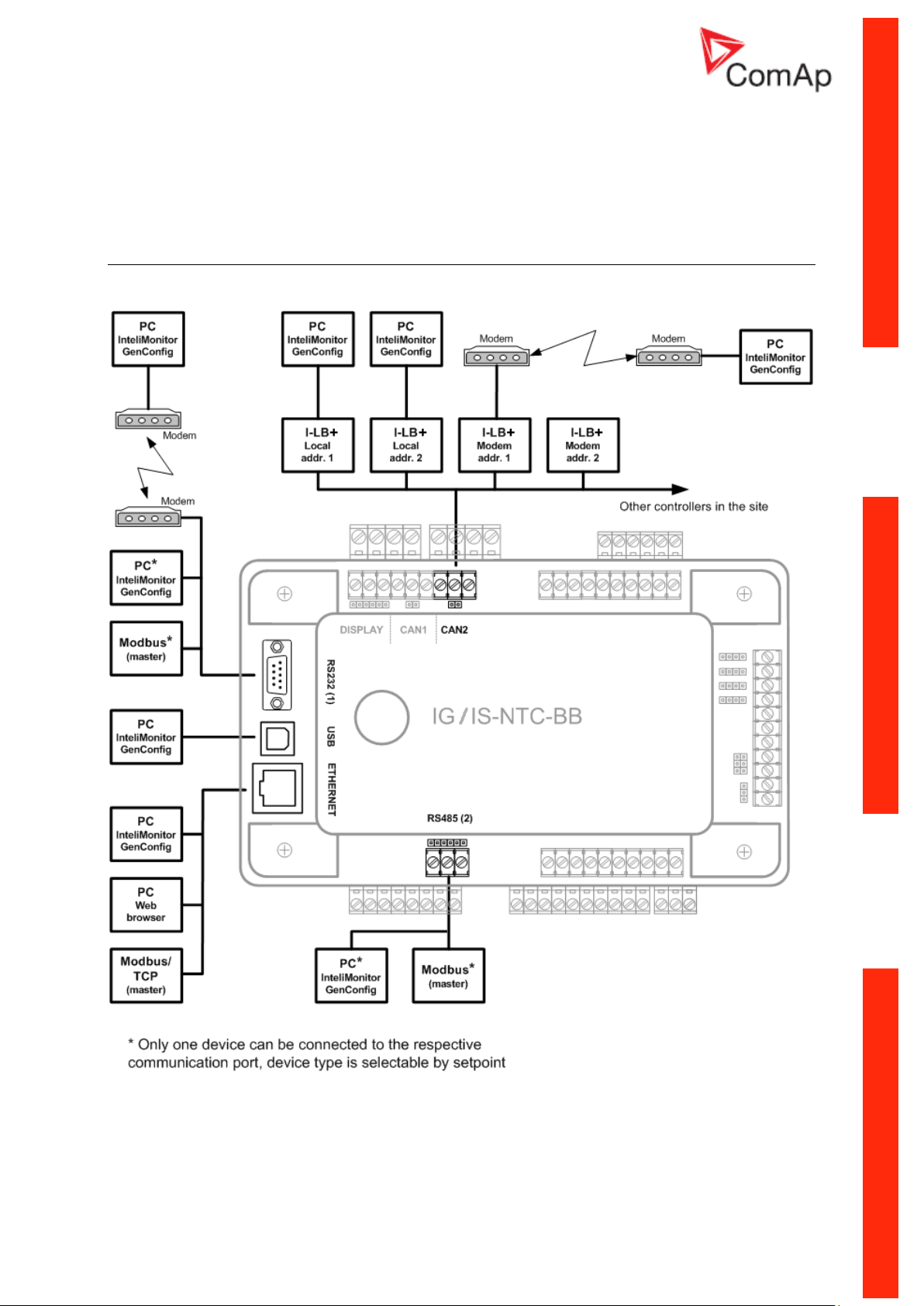

IG/IS/IM-NTC-BB - Communications

Communication Guide, ©ComAp – March 2014 7

IGS-NT Communication Guide 03-2014.pdf

Page 8

IG/IS/IM-NTC-BB - Terminals

Communication Guide, ©ComAp – March 2014 8

IGS-NT Communication Guide 03-2014.pdf

Page 9

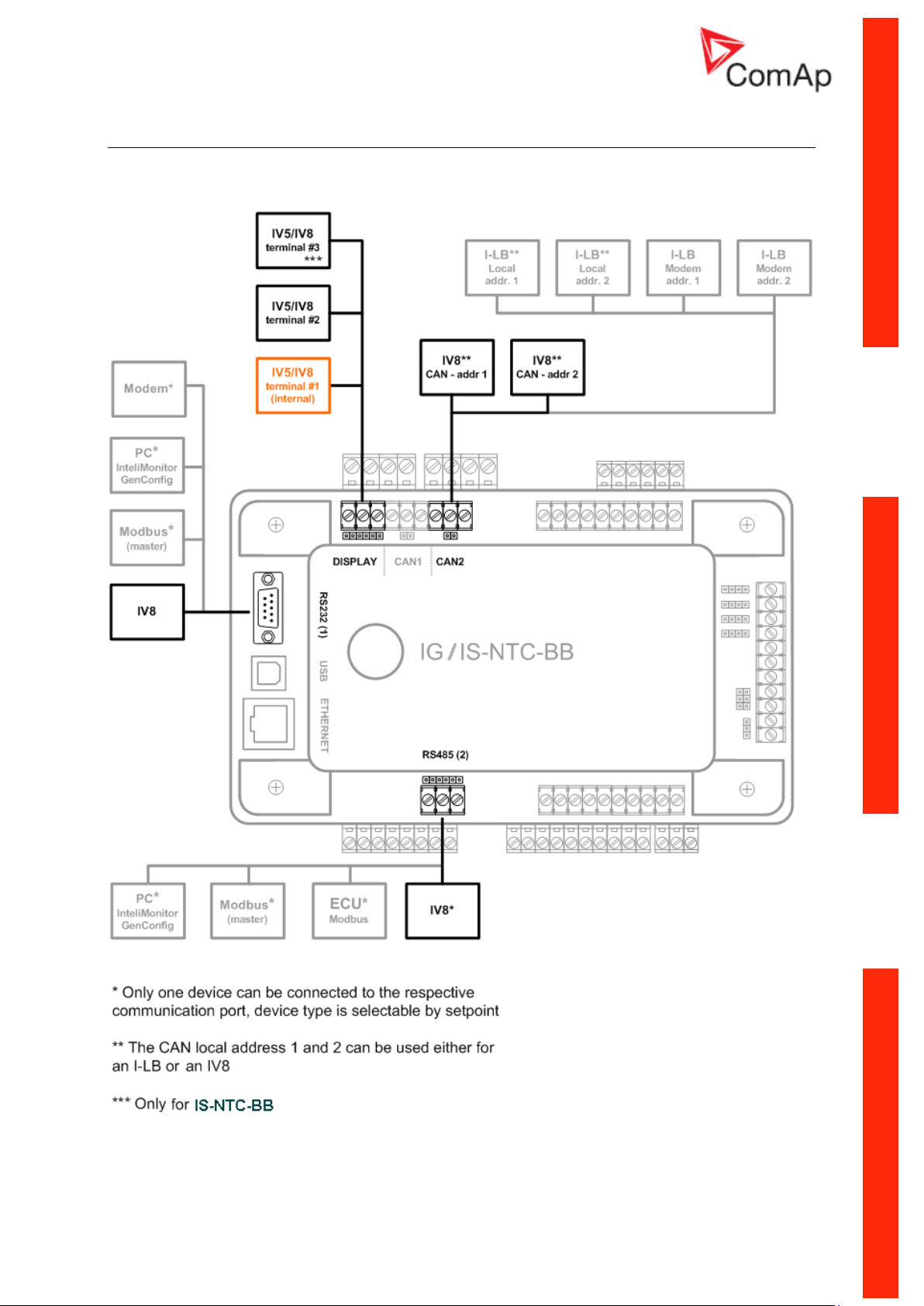

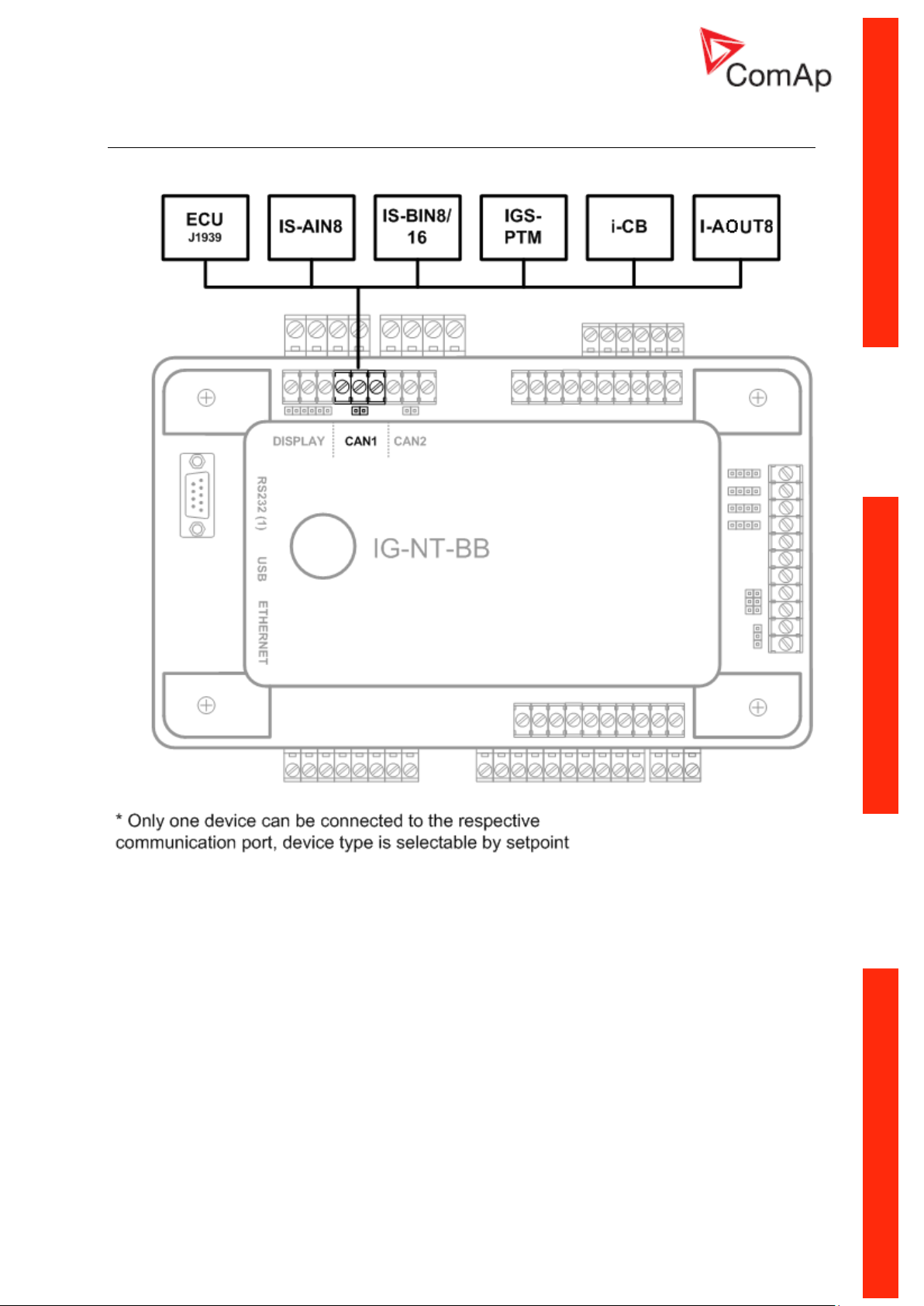

IG/IS/IM-NTC-BB - Peripheral modules

Communication Guide, ©ComAp – March 2014 9

IGS-NT Communication Guide 03-2014.pdf

Page 10

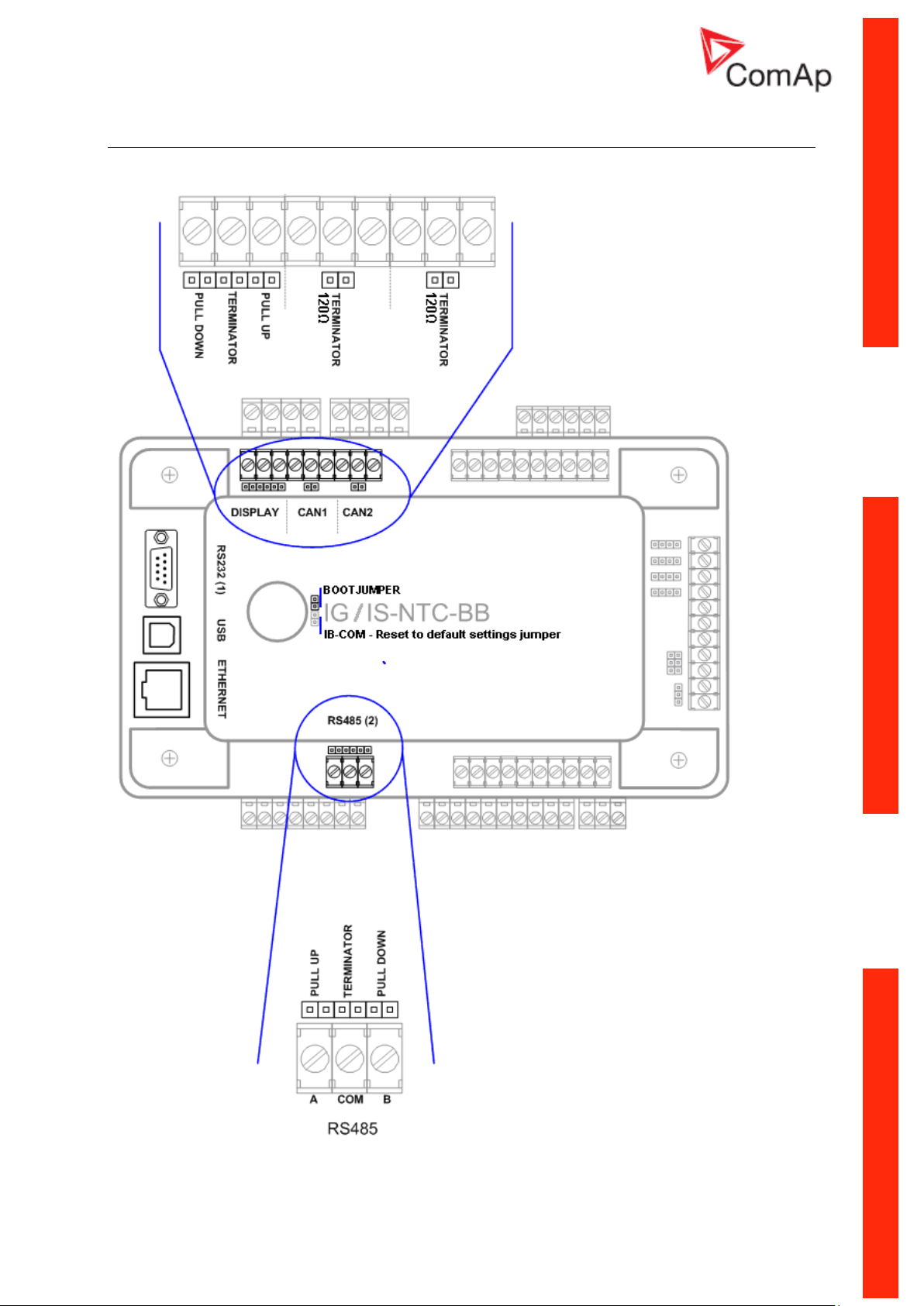

IG/IS/IM-NTC-BB - Jumpers settings

Communication Guide, ©ComAp – March 2014 10

IGS-NT Communication Guide 03-2014.pdf

Page 11

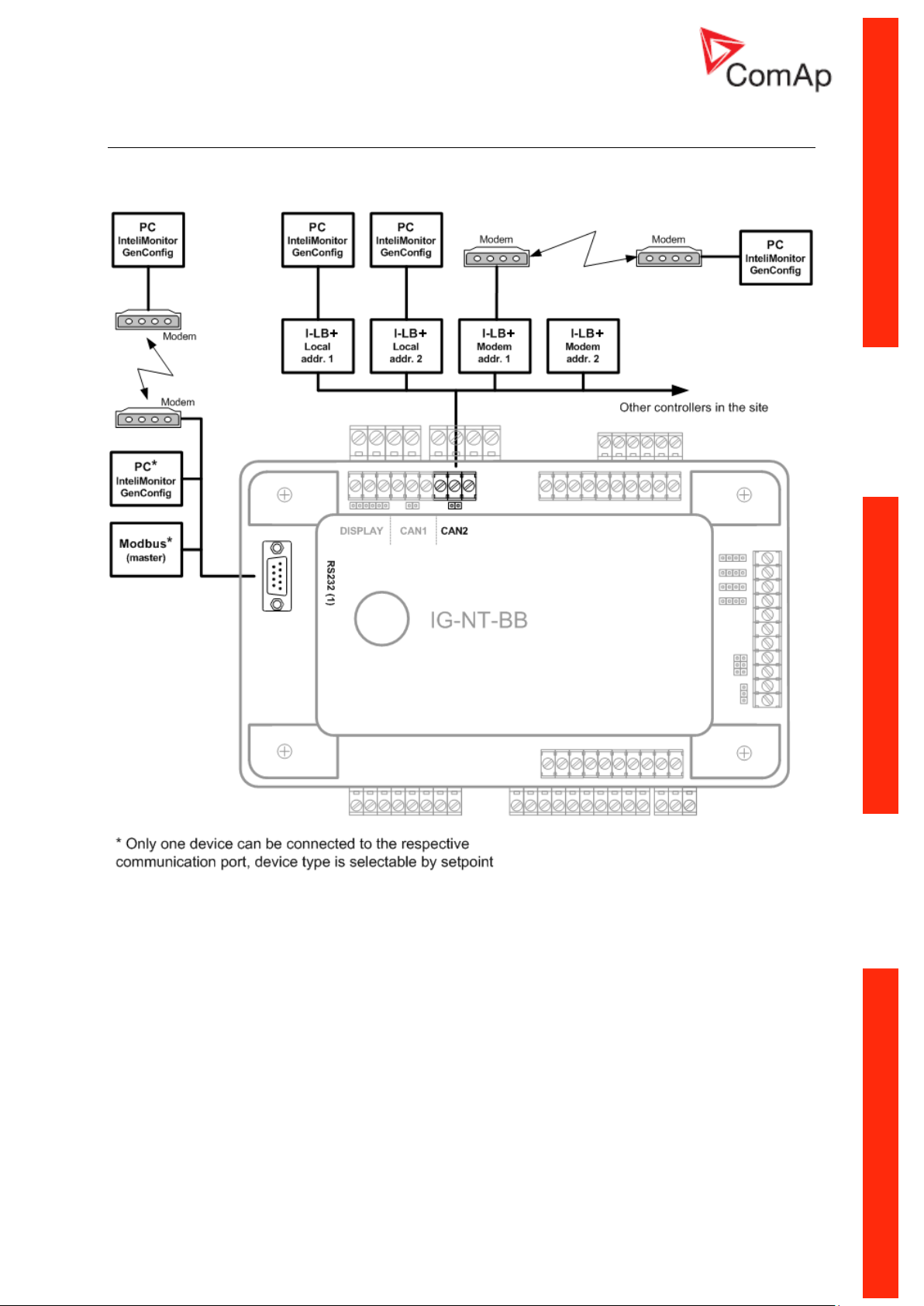

IG/IM-NT-BB - Communication

Communication Guide, ©ComAp – March 2014 11

IGS-NT Communication Guide 03-2014.pdf

Page 12

IG/IM-NT-BB - Terminals

Communication Guide, ©ComAp – March 2014 12

IGS-NT Communication Guide 03-2014.pdf

Page 13

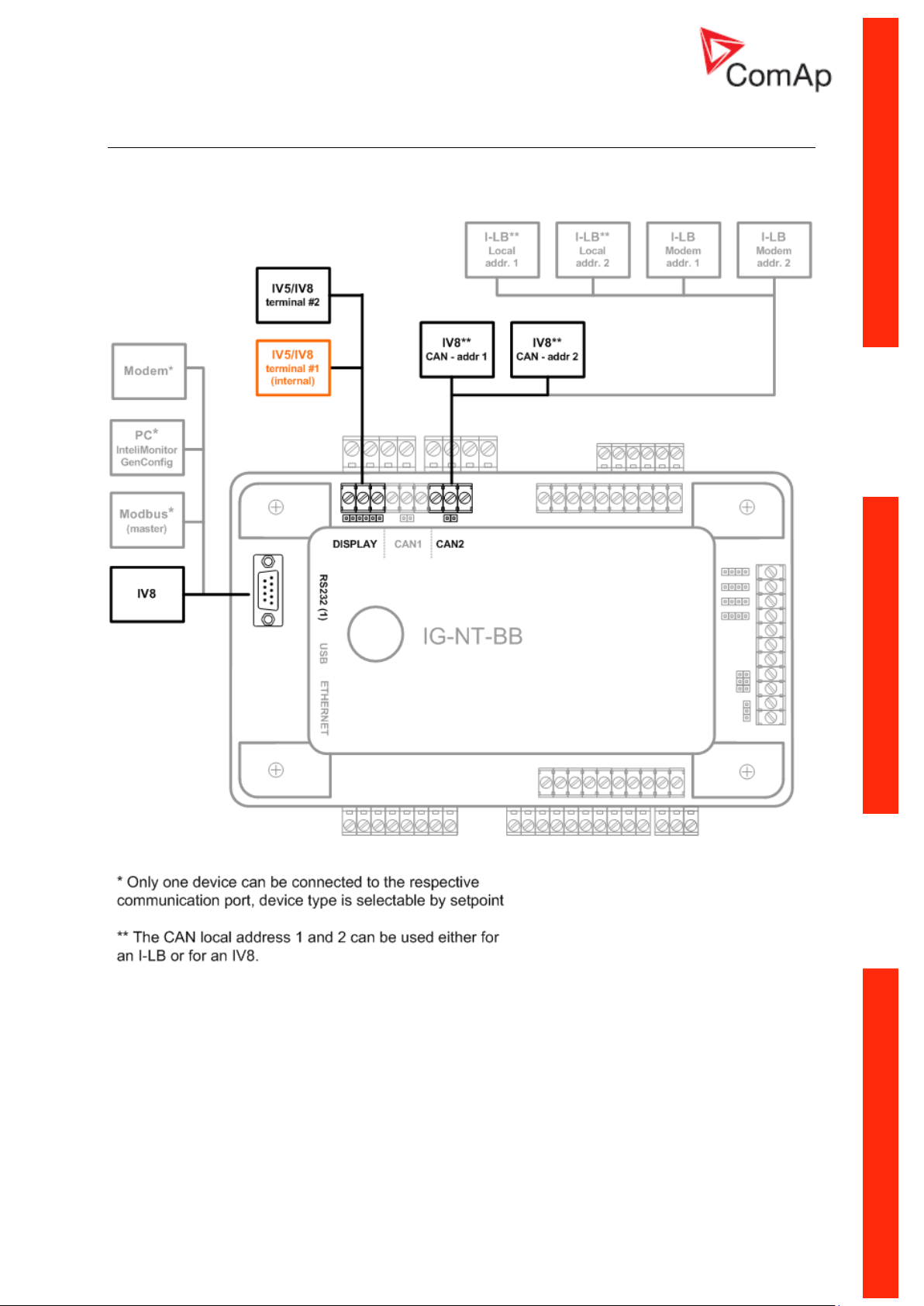

IG/IM-NT-BB - Peripheral modules

Communication Guide, ©ComAp – March 2014 13

IGS-NT Communication Guide 03-2014.pdf

Page 14

IG/IM-NT-BB - Jumpers settings

Communication Guide, ©ComAp – March 2014 14

IGS-NT Communication Guide 03-2014.pdf

Page 15

IG-NT - Communications, Terminals

Communication Guide, ©ComAp – March 2014 15

IGS-NT Communication Guide 03-2014.pdf

Page 16

IG-NTC - Communications, Terminals

Communication Guide, ©ComAp – March 2014 16

IGS-NT Communication Guide 03-2014.pdf

Page 17

IS-NT-BB - Communications, Terminals

Communication Guide, ©ComAp – March 2014 17

IGS-NT Communication Guide 03-2014.pdf

Page 18

IM-NT - Communications, Terminals

Communication Guide, ©ComAp – March 2014 18

IGS-NT Communication Guide 03-2014.pdf

Page 19

Monitoring Local on site - Comap SW

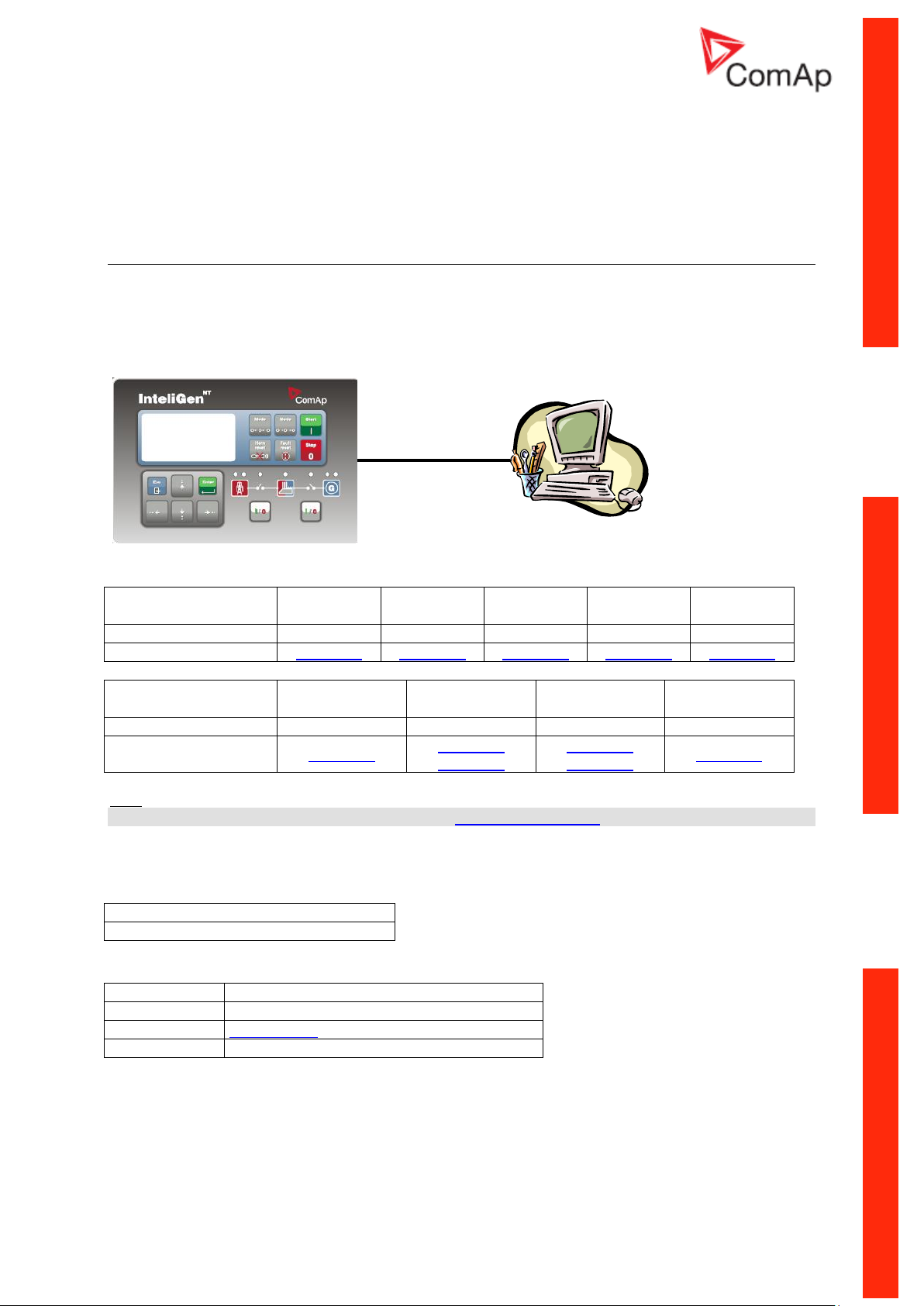

RS232

PC

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports

RS232(1)

RS232(1)

RS232(1)

RS232(1)

RS232(1)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS232(1)

RS232(1)

RS232(2)

RS232(1)

RS232(2)

RS232(1)

RS232(1) mode = DIRECT

RS485(1) conv. = DISABLED

Equipment needed

Controller side

-

Connection

RS232 cable up to 10m

PC side

RS232 connection or RS232/USB converter

Direct PC connection to Single gen-set

RS232 connection

Controllers

Hint:

Other way how to realize RS232 connection is via external bridge I-LB+.

Controller setup

(Setpoints/Comms settings group)

Equipment

Communication Guide, ©ComAp – March 2014 19

IGS-NT Communication Guide 03-2014.pdf

Page 20

USB connection

USB

PC

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

external

bridge

USB

USB

external

bridge

USB

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

YES

YES

NO

Available ports

external bridge

USB

USB

external bridge

No special settings are required

Equipment needed

Controller side

-

Connection

USB cable A-B

PC side

USB connection

Controllers

Hint:

Direct USB connection is not possible for some controllers, however USB connection is available for

all mentioned controllers via external bridge I-LB+.

Controller setup

(Setpoints/Comms settings group)

Equipment

Communication Guide, ©ComAp – March 2014 20

IGS-NT Communication Guide 03-2014.pdf

Page 21

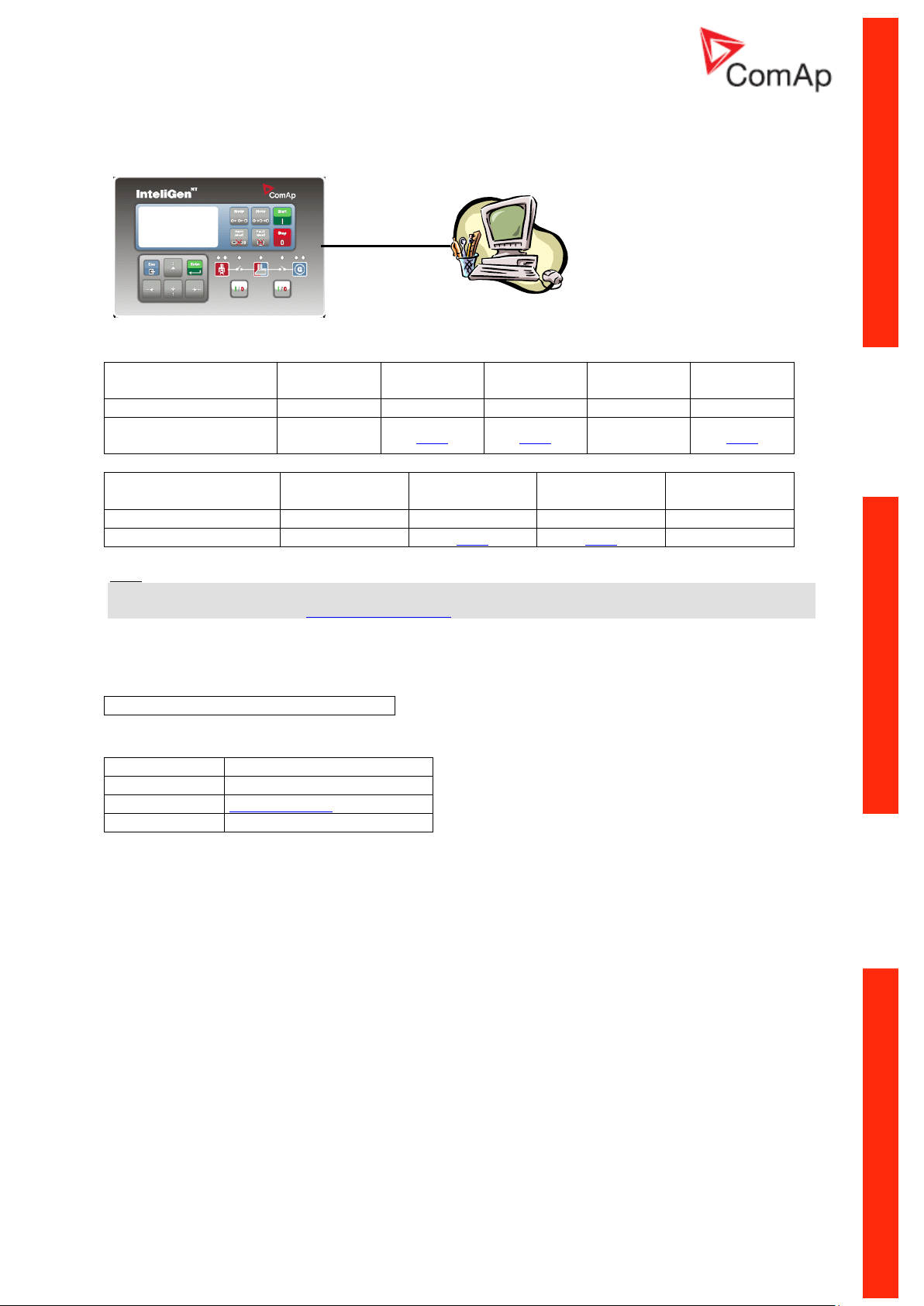

RS485 connection

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

external

bridge

RS485(2)

RS485(2)

external

bridge

RS485(2)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS485(1)

RS485(1)

RS485(2)

RS485(2)

RS485(1)

RS232(2) mode = DIRECT

RS485(2) conv. = ENABLED

Equipment needed

Controller side

-

Connection

RS485 cable - Twisted pair, length up to 1 km

PC side

Converter RS485/RS232 or USB

Controllers

Hint:

Direct RS485 connection is not possible for some controllers, however RS485 connection is available

for all mentioned controllers via external bridge I-LB+.

Controller setup

(Setpoints/Comms settings group)

Equipment

Hint:

RS485 connection can be used for gen-set control for longer distance. IG-NT-BB has no possibility of

direct connection to RS485 bus. This controller provides RS232 port only. External converter from

RS232 to RS485 is needed.

Communication Guide, ©ComAp – March 2014 21

IGS-NT Communication Guide 03-2014.pdf

Page 22

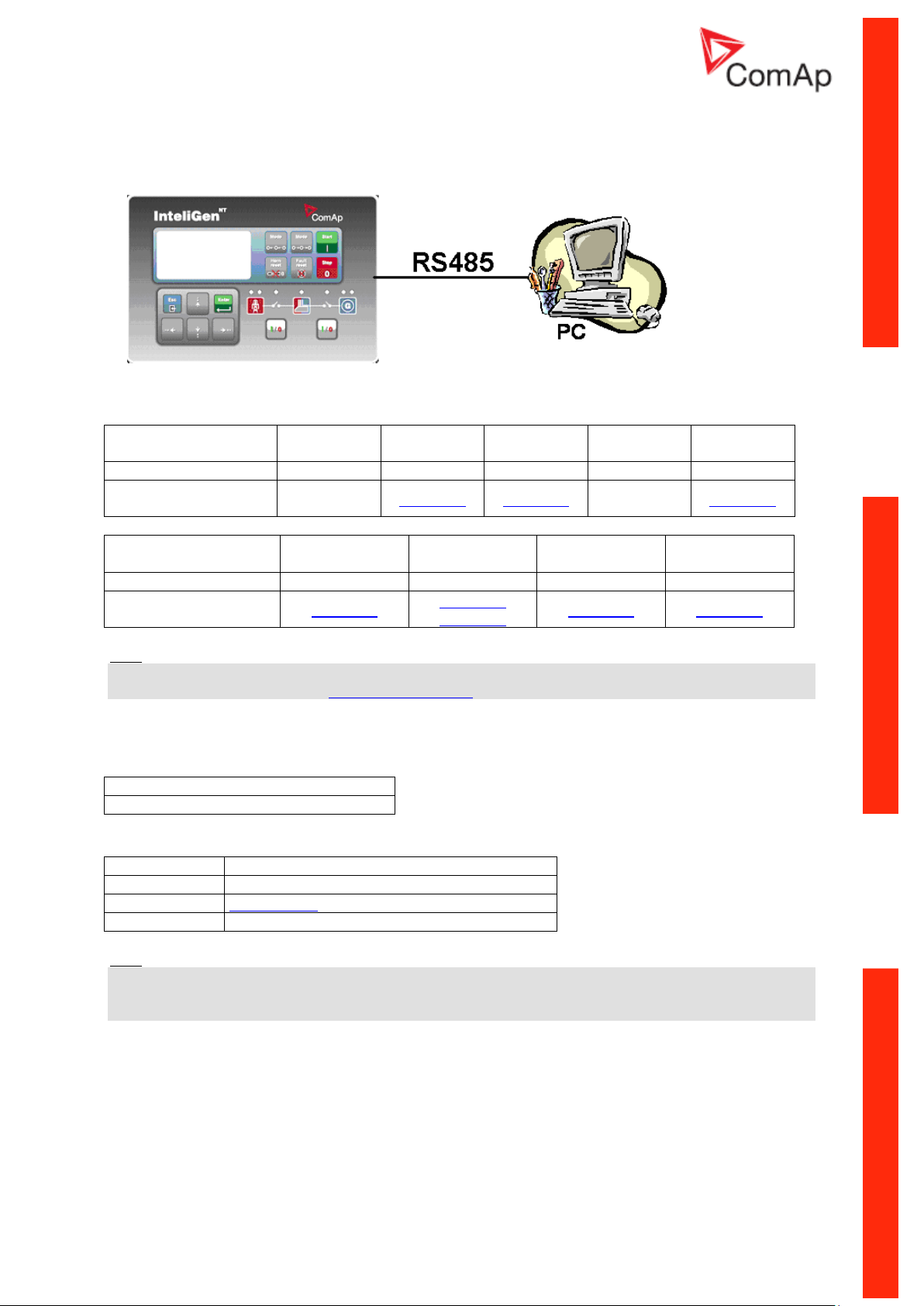

Ethernet connection (Direct)

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports or modules

-

ETHERNET

ETHERNET

-

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

NO

NO

NO

Available ports or modules

- - -

-

The Internet (Ethernet) connection is a point-to-point connection between a PC and a controller or site

via an TCP/IP protocol-based network. The physical configuration of such network can be a small

local area ethernet network as well as the Internet.

Controllers

Hint:

Ethernet connection is available for all mentioned controllers via external bridge IG-IB or IB-NT (see

the chapter Ethernet connection via IG-IB/IB-NT).

Number of clients connected simultaneously

2 clients with InteliMonitor or WebSupervisor (Comap/TCP protocol)

2 clients with web interface

Using a web browser

Ethernet connection to controller makes possible using any web browser for basic monitoring and

adjustment of the controller. Simply put the IP address of the module into the address line in your web

browser like http://192.168.1.254 and then enter access code. In case of connection from web

browser there is 5 minutes timeout after closing the browser window. After that the client is

automatically logged out.

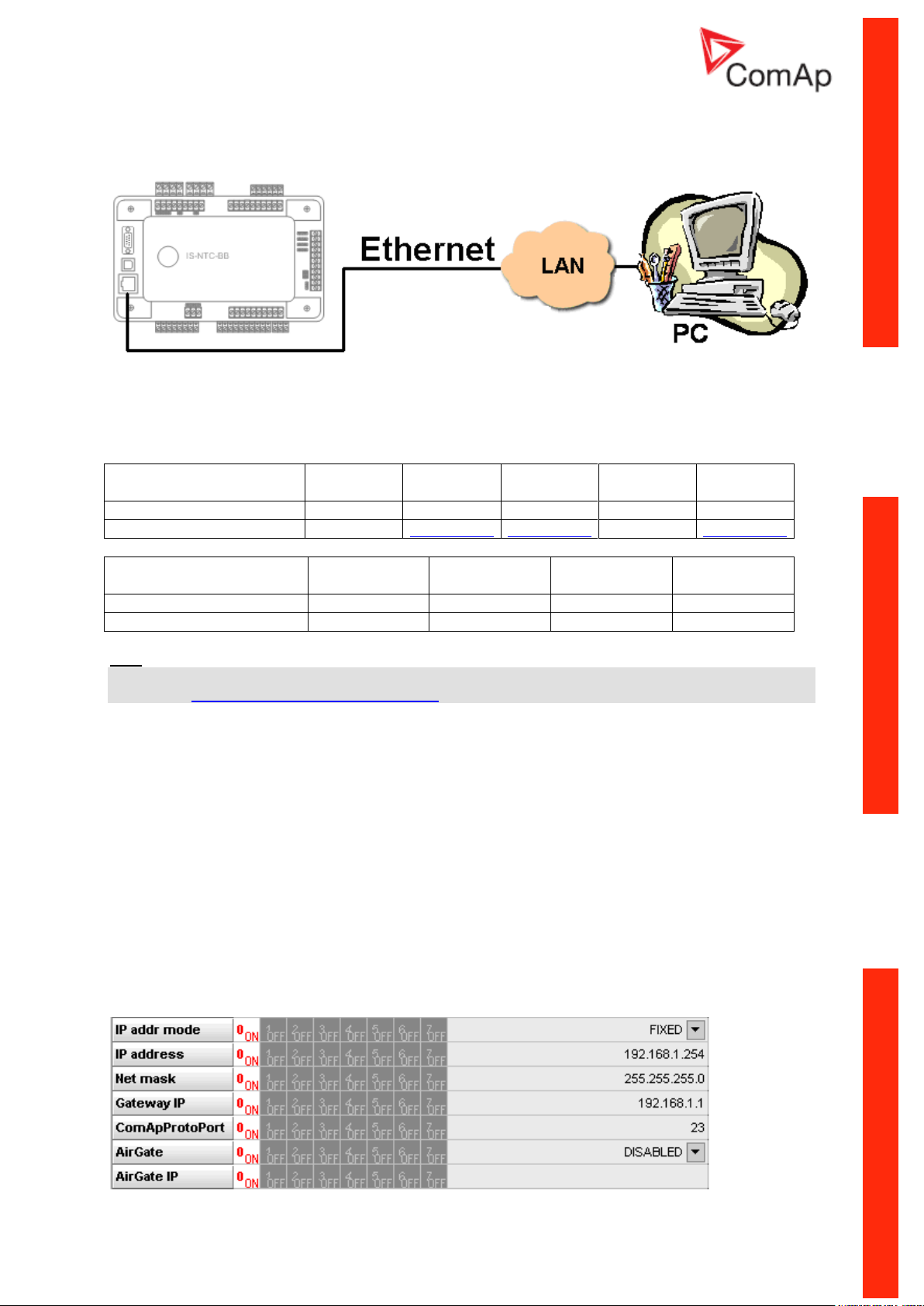

Ethernet connection settings

Parameters can be set via any type of connection (USB, RS232, Ethernet). Setup is provided via

InteliMonitor. For Ethernet connection set these parameters in Comms Settings group:

Communication Guide, ©ComAp – March 2014 22

IGS-NT Communication Guide 03-2014.pdf

Page 23

NOTE:

Equipment needed

Controller side

-

Connection

Ethernet cable to LAN, for point to point connection

between PC and controller use cross-wired cable

PC side

ETHERNET connection

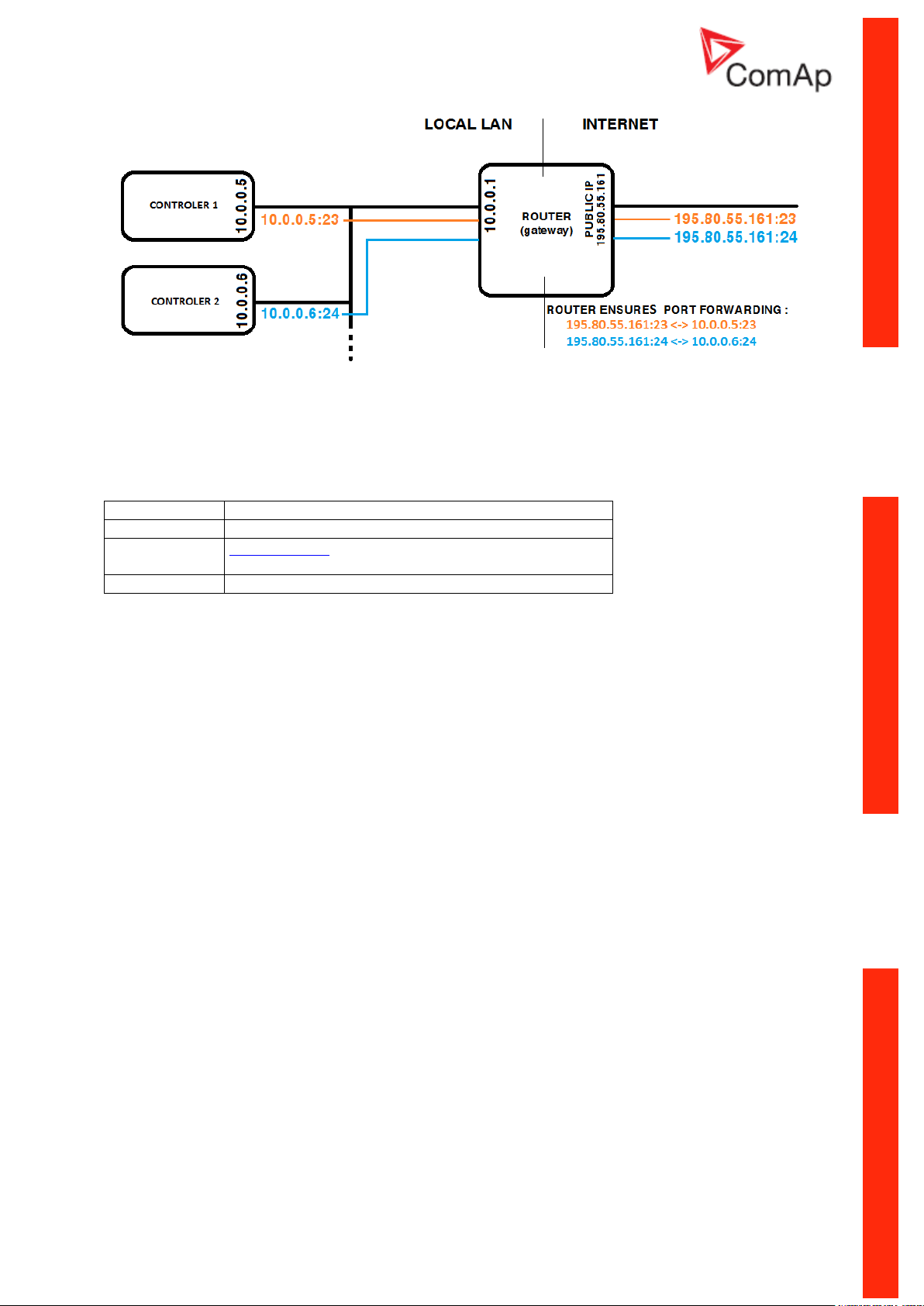

The IP addresses of the controllers must be accessible from the remote computer. If the remote

computer is connected into another LAN segment than the gen-sets are, there must be a gateway(s)

that enable direct traffic between the segments. If the remote computer is connected via Internet, then

the internet gateway of the LAN where gen-sets are connected must have public IP address, must

allow incoming traffic and must provide port forwarding from the external public IP to the different

internal gen-set IPs according to the port used.

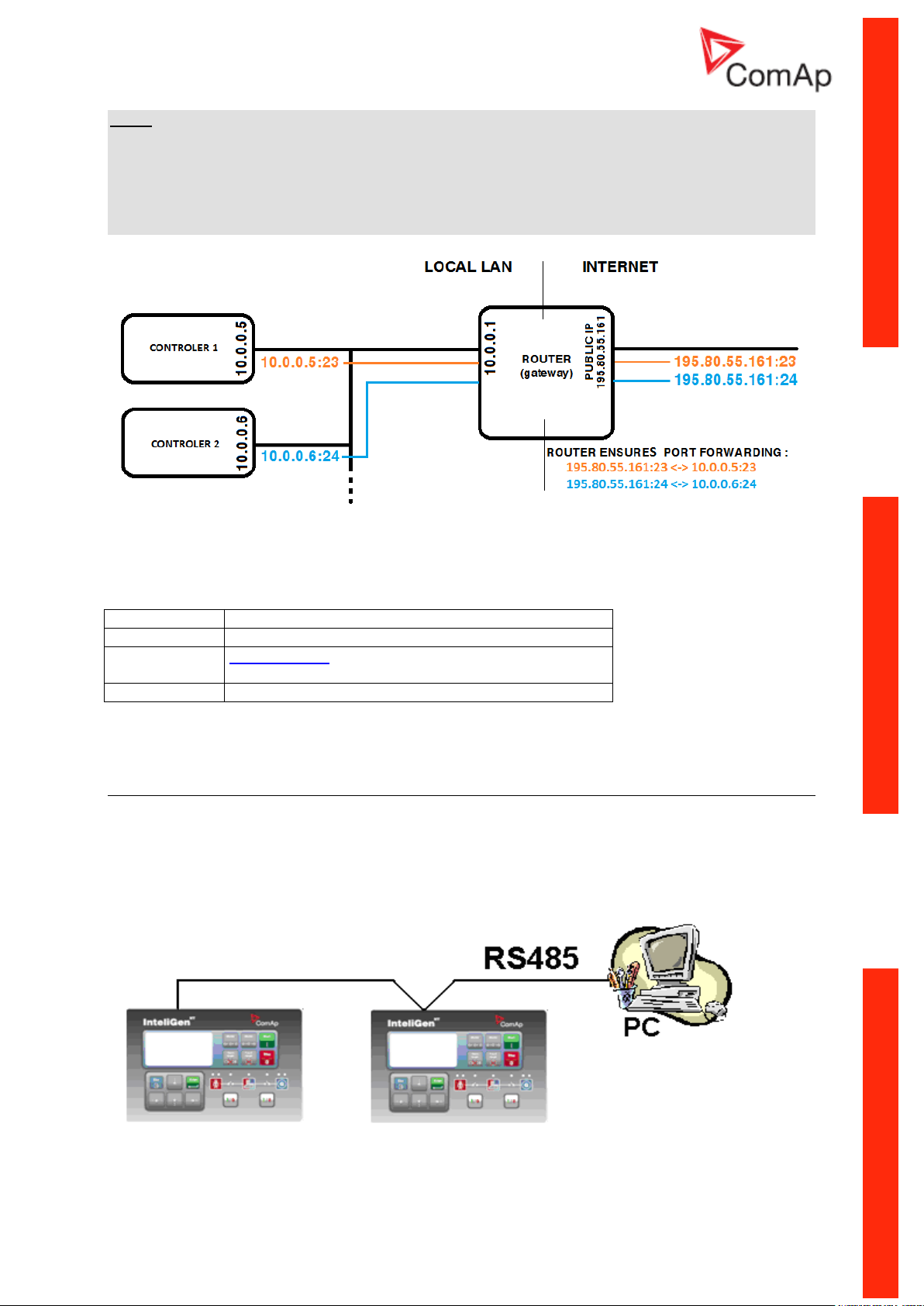

INTERNET GATEWAY CONFIGURATION EXAMPLE (PORT FORWARDING)

Equipment

Direct PC connection to Multiple gen-sets

RS485 connection

Communication Guide, ©ComAp – March 2014 23

IGS-NT Communication Guide 03-2014.pdf

Page 24

Controllers

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

-

RS485(2)

RS485(2)

-

RS485(2)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS485(1)

RS485(1)

RS485(2)

RS485(2)

RS485(1)

RS232(2) mode = DIRECT

RS485(2) conv. = ENABLED

Equipment needed

Controller side

-

Connection

RS485 cable - Twisted pair, length up to 1 km

PC side

RS232 connection, Converter RS485/RS232

HW/SW control

No matter

Controller setup

(Setpoints/Comms settings group)

Hint:

IG-NT-BB has no possibility of direct connection to RS485 bus. This controller provides RS232 port

only. External converter from RS232 to RS485 is needed.

Equipment

RS232/485 connection (I-LB+)

Hint:

I-LB+ module enables monitoring and configuration up to 32 controllers interconnected via CAN(2)

intercontroller bus. It is also possible to use I-LB+ for single controller connection.

I-LB+ hardware setup

(all jumpers in those positions)

Communication Guide, ©ComAp – March 2014 24

IGS-NT Communication Guide 03-2014.pdf

Page 25

ComAp/ModBus

Open

ADDR1/ADDR2

Selection of CAN address. Open = ADDR1, Close = ADDR2

It is possible to use up to two I-LB+ devices in direct mode on CAN(2)

bus. Let jumper open in case of using one I-LB+ module. Other I-LB

module has to have this jumper closed. (read more about I-LB+ module)

DIRECT/MODEM

Open

RS485/RS232

Selection of communication port (jumper is in RS232 or RS485 position)

Comm. speed.

No matter

RS485 120 Ohm

Open = terminator not connected, Close = terminator connected

CAN 120 Ohm

Open = terminator not connected, Close = terminator connected

USB DISABLED/ENABLED

Open

Controllers

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports

RS232 on I-

LB+

RS485 on I-

LB+

RS232 on I-

LB+

RS485 on I-

LB+

RS232 on I-

LB+

RS485 on I-

LB+

RS232 on I-

LB+

RS485 on I-

LB+

RS232 on I-

LB+

RS485 on I-

LB+

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

Equipment needed

Controller side

I-LB+ unit

Connection

RS232 or RS485 cable

PC side

RS232 connection or RS232/USB converter

RS485 connection or RS485/USB converter

Equipment

Communication Guide, ©ComAp – March 2014 25

IGS-NT Communication Guide 03-2014.pdf

Page 26

USB connection via I-LB+ module

HW/SW control

no matter (Open)

ComAp/ModBus

Open

ADDR1/ADDR2

Selection of CAN address. Open = ADDR2, Close = ADDR1

(read more about I-LB+ module)

DIRECT/MODEM

Open

RS485/RS232

No matter

Comm. speed.

No matter

RS485 120 Ohm

Open = terminator not connected, Close = terminator connected

CAN 120 Ohm

Open = terminator not connected, Close = terminator connected

USB DISABLED/ENABLED

Close = USB is enabled

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports

USB on I-LB+

USB on I-LB+

USB on I-LB+

USB on I-LB+

USB on I-LB+

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

USB on I-LB+

USB on I-LB+

USB on I-LB+

USB on I-LB+

Equipment needed

Controller side

I-LB+ unit

Connection

USB

PC side

USB connection

Hint:

I-LB+ module enables monitoring and configuration up to 32 controllers interconnected via CAN(2)

intercontroller bus. It is also possible to use I-LB+ for single controller connection.

I-LB+ hardware setup

(all jumpers in those positions)

Controllers

Equipment

Communication Guide, ©ComAp – March 2014 26

IGS-NT Communication Guide 03-2014.pdf

Page 27

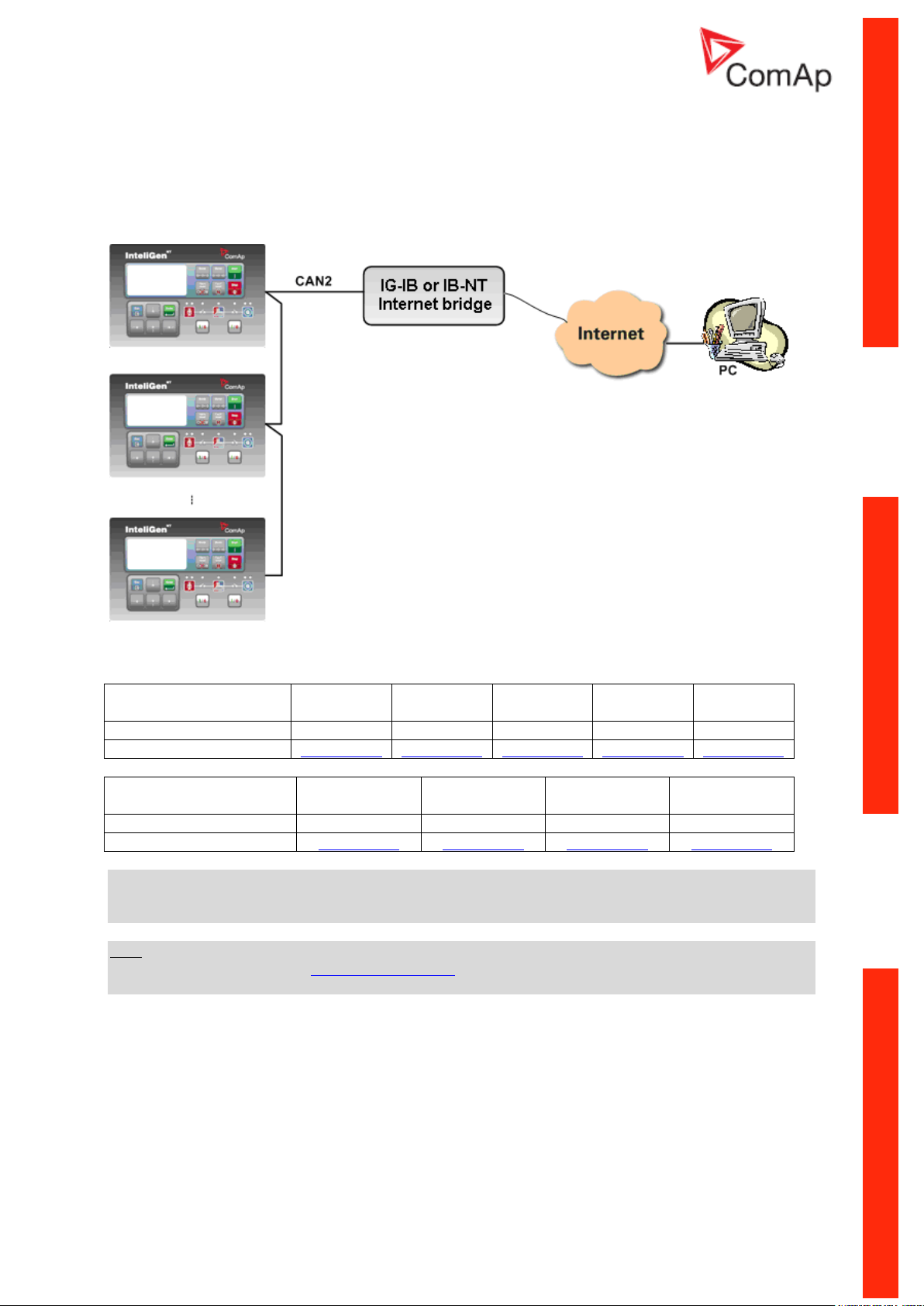

Ethernet connection via IB-NT (IG-IB)

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports / modules

IG-IB/IB-NT

IG-IB/IB-NT

IG-IB/IB-NT

IG-IB/IB-NT

IG-IB/IB-NT

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports / modules

IG-IB/IB-NT

IG-IB/IB-NT

IG-IB/IB-NT

IG-IB/IB-NT

Up to 32 controllers can be monitored via one IB-NT (IG-IB). Response time of a system with this type

of connection depends on number of controllers, higher number of controllers means slower system

response time.

Controllers

NOTE:

Max. 3 clients of ComAp type (InteliDDE server, WinScope, WebSupervisor) can be connected

simultaneously to the IB-NT (IG-IB).

Hint:

Get more information about IG-IB internet bridge. For more information about IB-NT internet bridge

read IB-NT-2.0-Reference Guide.pdf.

Communication Guide, ©ComAp – March 2014 27

IGS-NT Communication Guide 03-2014.pdf

Page 28

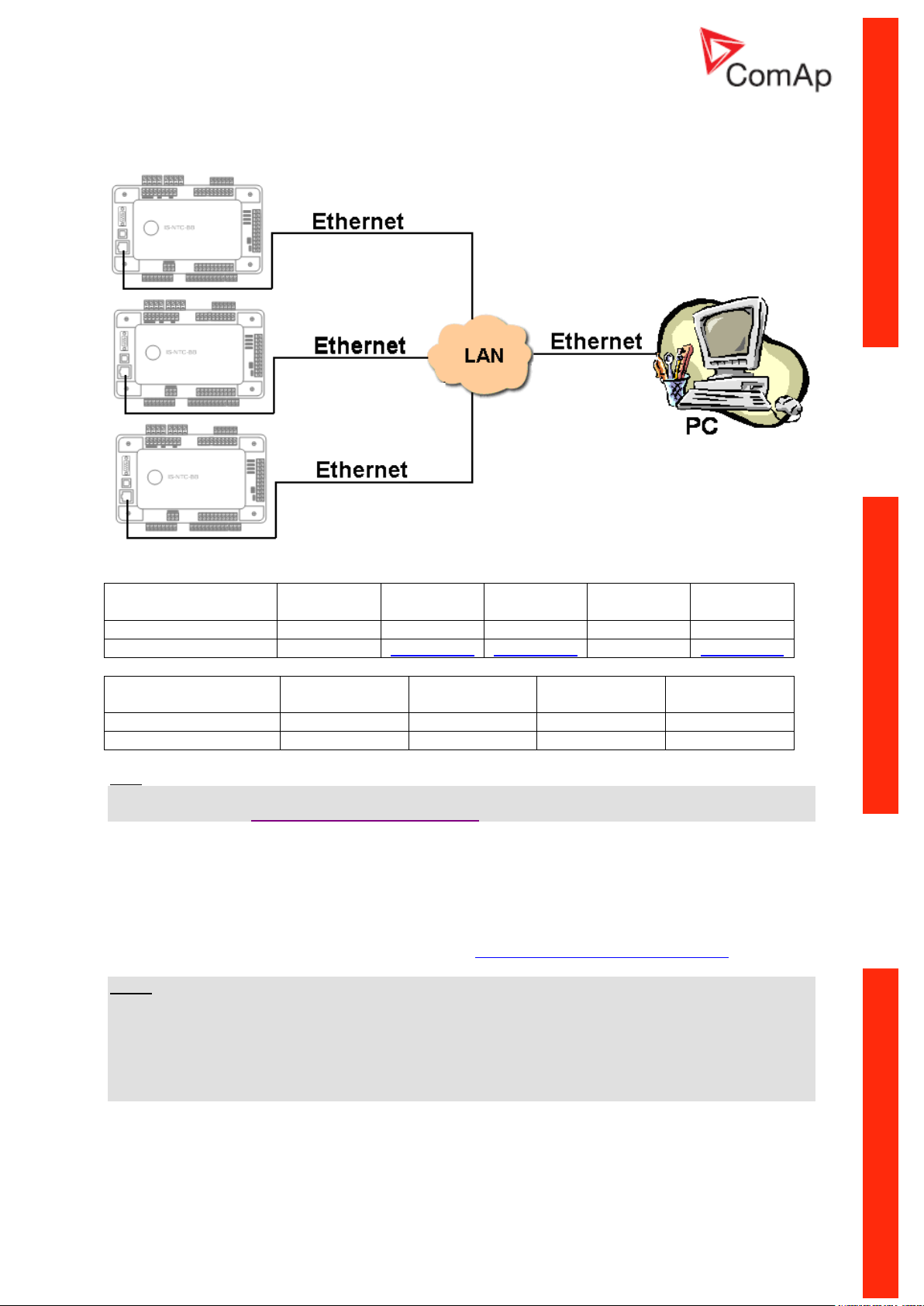

Ethernet connection (Direct)

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

-

ETHERNET

ETHERNET

-

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

NO

NO

NO

Available ports

- - -

-

Controllers

Hint:

Ethernet connection is available for all mentioned controllers via external internet bridge IG-IB or IBNT (see the chapter Ethernet connection IG-IB/IB-NT).

Number of clients connected simultaneously

2 clients with InteliMonitor or WebSupervisor (Comap/TCP protocol)

2 clients with web interface

Ethernet connection settings

Perform the connection settings the same way as for Single controller Ethernet connection.

NOTE:

The IP addresses of the controllers must be accessible from the remote computer. If the remote

computer is connected into another LAN segment than the gen-sets are, there must be a gateway(s)

that enable direct traffic between the segments. If the remote computer is connected via Internet, then

the internet gateway of the LAN where gen-sets are connected must have public IP address, must

allow incoming traffic and must provide port forwarding from the external public IP to the different

internal gen-set IPs according to the port used.

Communication Guide, ©ComAp – March 2014 28

IGS-NT Communication Guide 03-2014.pdf

Page 29

Equipment needed

Controller side

-

Connection

Ethernet cable to LAN, for point to point connection

between PC and controller use cross-wired cable

PC side

ETHERNET connection

INTERNET GATEWAY CONFIGURATION EXAMPLE (PORT FORWARDING)

Equipment

Communication Guide, ©ComAp – March 2014 29

IGS-NT Communication Guide 03-2014.pdf

Page 30

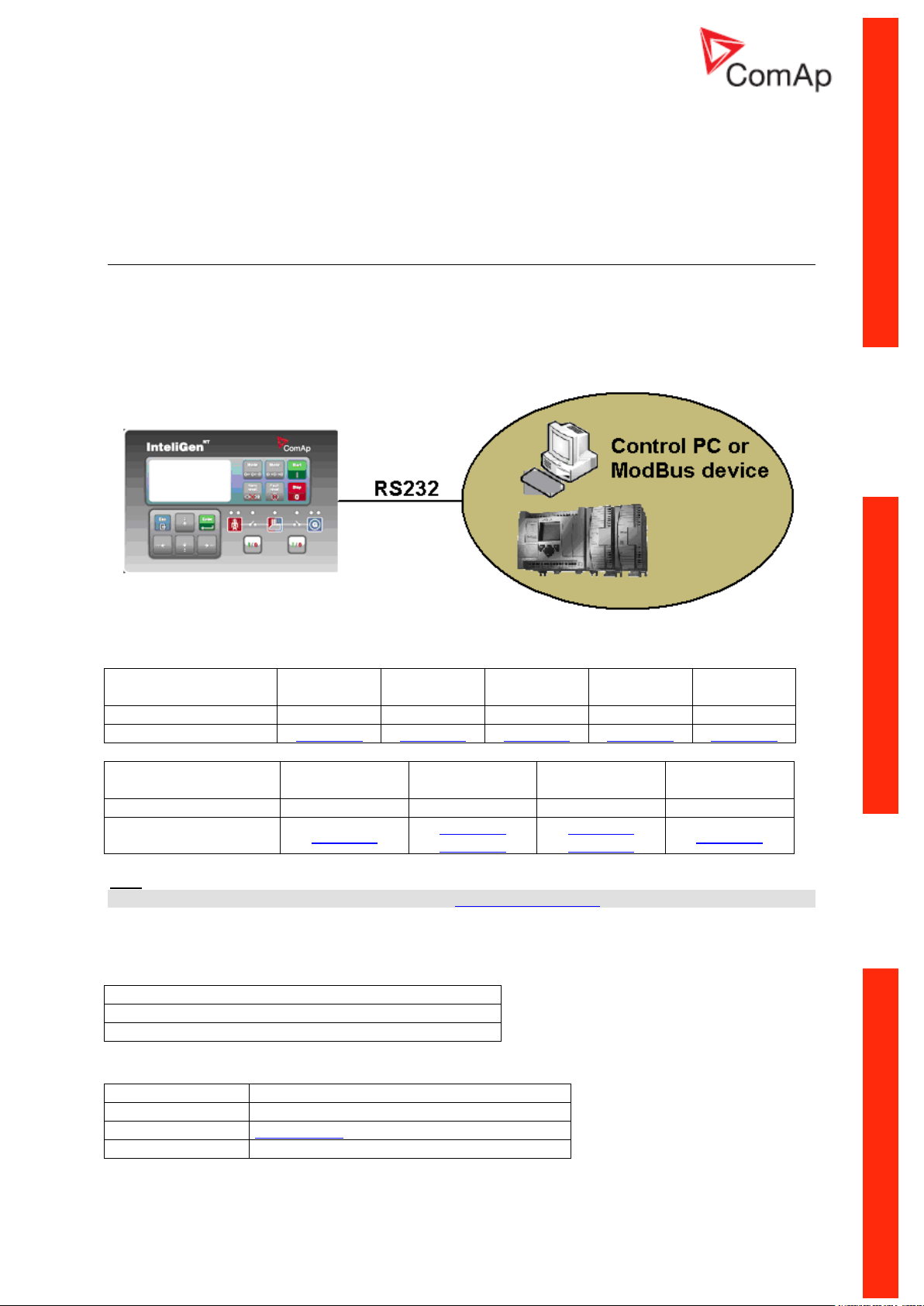

Monitoring Local on site - MODBUS

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports

RS232(1)

RS232(1)

RS232(1)

RS232(1)

RS232(1)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS232(1)

RS232(1)

RS232(2)

RS232(1)

RS232(2)

RS232(1)

RS232(1 or 2) mode = MODBUS-DIRECT

RS485(1 or 2) conv. = DISABLED

RS232(1)MBCSpd = 9600, 19200, 38400, 57600

Equipment needed

Controller side

-

Connection

RS232 cable up to 10 m

Other device side

RS232 connection or RS232/USB converter

ModBus - Single gen-set

RS232 ModBus

Controllers

Hint:

Other way how to realize RS232 connection is via external bridge I-LB+.

Controller setup

(Setpoints/Comms settings group)

Equipment

Communication Guide, ©ComAp – March 2014 30

IGS-NT Communication Guide 03-2014.pdf

Page 31

RS485 ModBus

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

-

RS485(2)

RS485(2)

-

RS485(2)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS485(1)

RS485(1)

RS485(2)

RS485(2)

RS485(1)

RS232(2) mode = MODBUS-DIRECT

RS485(2) conv. = ENABLED

RS232(2)MBCSpd = 9600, 19200, 38400, 57600

Equipment needed

Controller side

-

Connection

RS485 cable

Other device side

RS485 connection or RS485/USB converter

Controllers

Hint:

Some controllers do not allowe direct RS485 connection, however RS485 connection is available for

all mentioned controllers via external bridge I-LB+.

Controller setup

(Setpoints/Comms settings group)

Equipment

Communication Guide, ©ComAp – March 2014 31

IGS-NT Communication Guide 03-2014.pdf

Page 32

Ethernet - MODBUS/TCP (Direct)

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

-

ETHERNET

ETHERNET

-

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

NO

NO

NO

Available ports

- - -

-

Controllers

Hint:

Ethernet Modbus/TCP connection is available for all mentioned controllers via external internet bridge

IB-NT (see the chapter Ethernet – MODBUS (IB-NT)).

Number of clients connected simultaneously

1 client ModBus TCP/IP

Ethernet connection settings

Perform the connection settings the same way as for Single controller Ethernet connection.

Modbus/TCP access code

Every Modbus/TCP session has to be started with writing the access code from the modbus/tcp client

to the controller. If the session is closed and reopened again the access code must be written again.

The session can be closed by the client or the controller closes the session automatically if there is no

activity from the client side for 15s.

- There are new dedicated registers for entering the AccessCode via Modbus/TCP.

- The register numbers are 46339-46346 (register address 6338-6345).

- The previous method using register address 24535 remains working as well.

- Example of the Modbus message is following (in HEX):

01 10 18 C2 00 08 10 30 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 FE F3

01 Controller address

10 Modbus function (16dec – Write multiple registers)

18C2 Register address (18C2hex = 6338dec = register 46339)

0008 Number of registers

10 Length of the data (Number of registers x 2B)

30000000... Access code string (16 chars, null-terminated, ASCII, here “0”)

FEF3 CRC

Communication Guide, ©ComAp – March 2014 32

IGS-NT Communication Guide 03-2014.pdf

Page 33

Some devices do not support the modbus function 16. In this case can be the access code

Equipment needed

Controller side

-

Connection

Ethernet cable to LAN, for point to point connection

between PC and controller use cross-wired cable

PC side

ETHERNET connection

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

-

RS485(2)

RS485(2)

-

RS485(2)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

YES

YES

NO

Available ports

RS485(1)

RS485(1)

RS485(2)

RS485(2)

-

RS232(2) mode = MODBUS-DIRECT

RS485(2) conv. = ENABLED

RS232(2)MBCSpd = 9600, 19200, 38400, 57600

writen in controller as one register No. 46339 using the function 6. The access code has to

be the number in the range 0 to 65535.

Equipment

For more informations about ModBus implementation to ComAp controllers read the chapter ModBus

communication.

ModBus - Multiple gen-sets

RS485 – MODBUS

Controllers

Controller setup

(Setpoints/Comms settings group)

Communication Guide, ©ComAp – March 2014 33

IGS-NT Communication Guide 03-2014.pdf

Page 34

Hint:

Equipment needed

Controller side

-

Connection

RS485 cable - Twisted pair, length up to 1 km

Other device side

RS485 connection or RS485/RS232 or USB converter

HW/SW control

No matter

ComAp/ModBus

Close

ADDR1/ADDR2

Selection of CAN address. Open = ADDR1, Close = ADDR2

It is possible to use up to two I-LB+ devices in direct mode on CAN(2)

bus. Let jumper open in case of using one I-LB+ module. Other I-LB

module has to have this jumper closed. (read more about I-LB+ module)

DIRECT/MODEM

No matter

RS485/RS232

Selection of communication port (jumper is in RS232 or RS485 position)

Comm. speed.

Selection of communication speed by jumpers P13, P14 to 9600, 19200,

38400, 57600 bps

RS485 120 Ohm

Open = terminator not connected, Close = terminator connected

CAN 120 Ohm

Open = terminator not connected, Close = terminator connected

USB DISABLED/ENABLED

No matter

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection

applicable

YES

YES

YES

YES

YES

Available

ports

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

For gen-set control for longer distance can be RS485 used. IG-NT-BB has no possibility of direct

connection to RS485 bus. This controller provides RS232 port only. External converter from RS232 to

RS485 may be a good solution (for example...ADAM).

Equipment

RS232/RS485 – MODBUS (I-LB+)

Hint:

I-LB+ module enables monitoring and configuration up to 32 controllers interconnected via CAN(2)

intercontroller bus. It is also possible to use I-LB+ for single controller connection.

I-LB+ hardware setup

(all jumpers in those positions)

Controllers

Communication Guide, ©ComAp – March 2014 34

IGS-NT Communication Guide 03-2014.pdf

Page 35

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

YES

YES

NO

Available ports

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

RS232 on I-LB+

RS485 on I-LB+

Equipment

Equipment needed

Controller side

I-LB+ unit

Connection

RS232, RS485 cable

PC side

RS232 connection or RS232/USB converter

RS485 connection or RS485/USB converter

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports / modules

external

bridge IB-NT

external

bridge IB-NT

external

bridge IB-NT

external

bridge IB-NT

external

bridge IB-NT

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports / modules

external bridge

IB-NT

external bridge

IB-NT

external bridge

IB-NT

external bridge

IB-NT

Ethernet - MODBUS (IB-NT)

Up to 32 controllers can be monitored via one IG-IB. Response time of a system with this type of

connection depends on number of controllers, higher number of controllers means slower system

response time.

Controllers

Hint:

For more information about IB-NT internet bridge read IB-NT-2.0-Reference Guide.pdf.

Communication Guide, ©ComAp – March 2014 35

IGS-NT Communication Guide 03-2014.pdf

Page 36

Ethernet - MODBUS/TCP (Direct)

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

-

ETHERNET

ETHERNET

-

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

NO

NO

NO

Available ports

- - -

-

Equipment needed

Controller side

-

Connection

Ethernet cable to LAN, for point to point connection

between PC and controller use cross-wired cable

PC side

ETHERNET connection

Controllers

Hint:

Ethernet Modbus/TCP connection is available for all mentioned controllers via external internet bridge

IB-NT (see the chapter Ethernet – MODBUS (IB-NT)).

Number of clients connected simultaneously

1client ModBus TCP/IP

Ethernet connection settings

Perform the connection settings the same way as for Single controller Ethernet connection.

Equipment

For more informations about ModBus implementation to ComAp controllers read the chapter ModBus

communication.

Communication Guide, ©ComAp – March 2014 36

IGS-NT Communication Guide 03-2014.pdf

Page 37

Remote monitoring

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

-

ETHERNET

ETHERNET

-

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

NO

NO

NO

Available ports

- - -

-

Connection to Internet (Direct)

Controllers

Hint:

Internet connection is available for all mentioned controllers via external bridge IG-IB or IB-NT (see the

chapter Ethernet connection via IG-IB/IB-NT).

Number of clients connected simultaneously

2 clients with InteliMonitor or WebSupervisor (Comap/TCP protocol)

1 client Modbus/TCP

2 clients with web interface

Communication Guide, ©ComAp – March 2014 37

IGS-NT Communication Guide 03-2014.pdf

Page 38

Ethernet connection settings

Equipment needed

Controller side

-

Connection

Ethernet cable to LAN, for point to point connection

between PC and controller use cross-wired cable

PC side

ETHERNET connection

Software

GenConfig

InteliMonitor

WinScope

Applicable

YES

YES

YES

Perform the connection settings the same way as for Single controller Ethernet connection.

How to open Internet connection in InteliMonitor?

Use the same procedure as well as for Multiple gen-sets Ethernet connection.

Using a web browser

Ethernet connection to controller makes possible using any web browser for basic monitoring and

adjustment of the controller. Simply put the IP address of the module into the address line in your web

browser like http://192.168.1.254 and then enter access code. In case of connection from web

browser there is 5 minutes timeout after closing the browser window. After that the client is

automatically logged out.

NOTE:

The IP addresses of the controllers must be accessible from the remote computer. If the remote

computer is connected into another LAN segment than the gen-sets are, there must be a gateway(s)

that enable direct traffic between the segments. If the remote computer is connected via Internet, then

the internet gateway of the LAN where gen-sets are connected must have public IP address, must

allow incoming traffic and must provide port forwarding from the external public IP to the different

internal gen-set IPs according to the port used.

INTERNET GATEWAY CONFIGURATION EXAMPLE (PORT FORWARDING)

Equipment

Available software for IG/IS-NT

Communication Guide, ©ComAp – March 2014 38

IGS-NT Communication Guide 03-2014.pdf

Page 39

Internet connection via AirGate

This connection type is used for connection to controllers/sites, that are connected to the Internet,

however they do not have public and static IP address. The controllers connect by themselves to the

AirGate server and cyclically ask whether there is a connection request from a client or not. On the

other side the clients (InteliMonitor, WebSupervisor) connect to the AirGate server instead of

connecting directly to the controller. The server then creates a "tunnel" between the client and the

controller. Internet connection via AirGate server is supported by controllers IG-NTC-BB and IS-NTCBB with ethernet connection possibility. The connection to ethernet is realized the same way as

remote ethernet connection.

CAUTION!

To avoid unauthorized access to the controller change the access code and keep it secret!

PRINCIPLE OF AIRGATE CONNECTION

Airgate connection settings

Parameters can be set via any type of connection (USB, RS232, Ethernet). Setup is provided via

InteliMonitor. For ethernet connection set these parameters in Comms Settings group:

Communication Guide, ©ComAp – March 2014 39

IGS-NT Communication Guide 03-2014.pdf

Page 40

Controllers

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

NO

YES

YES

NO

YES

Available ports

external

bridge IB-NT

ETHERNET

ETHERNET

external

bridge IB-NT

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

NO

NO

NO

NO

Available ports

external bridge

IB-NT

external bridge

IB-NT

external bridge

IB-NT

external bridge

IB-NT

CAUTION!

Connection via AirGate is supported by controllers with direct connection to LAN only or via IB-NT

module. Airgate connection is not available for connection via IG-IB module.

Connection to InteliMonitor via AirGate server

1. Select the AirGate connection type.

2. Fill-in the correct AirGate ID for each controller.

3. Enter the AirGate server address.

Hint:

You will obtain the AirGate ID by the registration of the particular controller on the AirGate server. Set

all setpoints in Comms Settings group according to AirGate connecgtion settings and connect

controller to LAN. Controller AirGate ID will be viewed on the screen.

NOTE:

This function is available in InteliMonitor ver. 2.6 and higher. Please watch the ComAp web site for

detailed information.

NOTE:

Although the controllers in your site are not connected together by the CAN2 bus they must have

different controller addresses.

Communication Guide, ©ComAp – March 2014 40

IGS-NT Communication Guide 03-2014.pdf

Page 41

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports

external

bridge IB-NT

ETHERNET

ETHERNET

external

bridge IB-NT

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

external bridge

IB-NT

ETHERNET

ETHERNET

external bridge

IB-NT

AIRGATE CONNECTION SETTINGS

WebSupervisor

WebSupervisor is web based system designed for monitoring and controlling ComAp controllers via

the internet. This system offers a number of beneficial features that help optimize revenue for

machinery fleets, as each piece of equipment can be individually monitored for all important operation

values.

Controllers

Communication Guide, ©ComAp – March 2014 41

IGS-NT Communication Guide 03-2014.pdf

Page 42

WebSupervisor connection settings

Connect ComAp

Controller with

WebSupervisor support

to the Internet

Use connection via

AirGate or IG-IB

external bridge

Is connection o.k.? Try

it with InteliMonitor or

LiteEdit or DriveMonitor

Open Internet Browser

http://websupervisor.comap.cz

Login into

WebSupervisor with

your account

Do not have an account?

See chapter How to

Register (Become a User

of the WebSupervisor) and

Login?

Register new Unit into

WebSupervisor. See

chapter Chyba!

Nenalezen zdroj odkazů.

Start to using

WebSupervisor in

accordance with

WebSupervisor manual

Connection of controllers with direct Ethernet port can be realized two diferent ways:

1. Internet connection via AirGate: No fixed and public IP address is needed. Connect

and set the controller the same way as for Internet connection via AirGate.

2. Internet connection without AirgGate: Controller has to have fixed and public IP

address. Connect and set the controller the same way as for Ethernet Connection

(Direct).

Connection of all controllers can be realized using IG-IB external bridge. Connect and set the

controller the same way as for Ethernet (Internet) connection via IG-IB module.

First Steps

Communication Guide, ©ComAp – March 2014 42

IGS-NT Communication Guide 03-2014.pdf

Page 43

Start to using

How to Register (Become a User of the WebSupervisor) and Login?

You can start using WebSupervisor without installation any special software on your PC.

To start and login into WebSupervisor:

1. Open http://websupervisor.comap.cz/ in your browser.

The WebSupervisor homepage appears:

2. Insert your login name and password into field LOGIN NAME and PASSWORD, see below.

If you have not created an access, please send email to

admin.websupervisor@comap.cz. Please send us Name, Login name, Email address

and Timezone. We will create free account for you to start using it.

More information about WebSupervisor you can get in WebSupervisor-2_0 Reference Guide.pdf.

Communication Guide, ©ComAp – March 2014 43

IGS-NT Communication Guide 03-2014.pdf

Page 44

Web interface

The web interface is intended to monitor the controller from a web browser. Static IP address is

required for this function as you must know the IP address to put it into the browser. Public IP address

or port forwarding is required if you want to see the web pages from the Internet.

PORT FORWARDING EXAMPLE FOR WEB CONNECTION

The web server is designed for basic monitoring and adjustment of the controller using a web browser.

Put the Controller IP address into the browser. You will be asked for the controller access code prior

to entering the controller web.

NOTE:

The web server is optimized for IE6 or higher and screen resolution 1024x768 pixels.

CAUTION!

Do not use the browser navigation buttons as "Back", "Forward" or "Reload". Use the links and the

reload button located in the toolbar instead.

Communication Guide, ©ComAp – March 2014 44

IGS-NT Communication Guide 03-2014.pdf

Page 45

Scada

Click to the SCADA link in the toolbar to display the scada page. The scada page is also the main

page which is displayed by default if you just put the controller address into the browser.

NOTE:

The scada page layout may differ according to the firmware branch, version and application. Certain

old firmware versions does not support web access at all.

Measurement

Click to the MEASUREMENT link in the toolbar to display the measurement page. Then click to the

required group name in the left box to display values of the group in the right box.

NOTE:

The measurement page is automatically refreshed every 60 seconds.

Communication Guide, ©ComAp – March 2014 45

IGS-NT Communication Guide 03-2014.pdf

Page 46

Setpoints

Click to the SETPOINTS link in the toolbar to display the setpoints page.

Click to the required group name in the left box to display setpoints of the group in the right

box.

Click to the required setpoint name or value to change the value. If the respective setpoint is

protected by password, which is indicated by a lock icon by the setpoint name, you have to

click on the "Controller password" icon located in the toolbar and then enter valid password.

NOTE:

The setpoint page is automatically refreshed every 60 seconds. If an another user changes a setpoint

from other terminal, the web page will not show this change immediately as e.g. InteliMonitor.

Communication Guide, ©ComAp – March 2014 46

IGS-NT Communication Guide 03-2014.pdf

Page 47

History

Click to the HISTORY link in the toolbar to display the history page.

Use the control buttons to move within the history file.

NOTE:

The history page is automatically refreshed every 5 minutes. If a new record appears in the controller,

the web page will not show it immediately as e.g. InteliMonitor.

Communication Guide, ©ComAp – March 2014 47

IGS-NT Communication Guide 03-2014.pdf

Page 48

Web server adjustment

Click to the "Webserver settings" icon in the toolbar to display the settings page.

Select the controller language the web pages will appear in.

Select the rate of automatic refresh of the scada page.

Internet connection via cellular network

Connection via Internet bridge IB-NT

What is InternetBridge-NT?

InternetBridge-NT is a communication module that allows connection of a single controller as well as

whole site to the Internet or Local area network. The connection to the Internet can be via built-in

cellular modem supporting 2G and 3G networks or Ethernet cable.

The module can be used for controllers from following product lines: IG-NT, IS-NT and IC-NT.

NOTE:

For proper operation it is necessary to update the controller firmware to a version which supports IBNT. For IG-NT and IS-NT standard branch the first version supporting IB-NT is 2.6.

For more information about IB-NT read IB-NT-2.0-Reference Guide.pdf.

Communication Guide, ©ComAp – March 2014 48

IGS-NT Communication Guide 03-2014.pdf

Page 49

Features

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports

RS232(1)

RS232(1)

RS232(1)

RS232(1)

RS232(1)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS232(1)

RS232(1)

RS232(2)

RS232(1)

RS232(2)

RS232(1)

RS232(1,2) mode = MODEM (HW) / MODEM (SW)

RS485(1,2) conv. = DISABLED

Direct ethernet connection to ComAp PC programs

AirGate® support

SMTP protocol for sending of active emails from the controller

HTTP protocol for web-based monitoring and adjustment

MODBUS/TCP server

SNMP protocol

Modem connection

Modem connection to Single gen-set

Controllers

Hint:

Other way how to realize modem connection is via external bridge I-LB+.

Controller setup

(Setpoints/Comms settings group)

Communication Guide, ©ComAp – March 2014 49

IGS-NT Communication Guide 03-2014.pdf

Page 50

Equipment

Equipment needed

Controller side

Analog, ISDN or GSM modem

Connection

Phone line or GSM

PC side

Analog, ISDN or GSM modem

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection

applicable

YES

YES

YES

YES

YES

Available

ports

RS232 on I-LB+

RS232 on I-LB+

RS232 on I-LB+

RS232 on I-LB+

RS232 on I-LB+

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

RS232 on I-LB+

RS232 on I-LB+

RS232 on I-LB+

RS232 on I-LB+

CANAddrSwitch 1/CANAddrSwitch 2 = MODEM

Hint:

For appropriate function is the same type of modem on both sides needed. Use of combination of

analog and GSM modem is not recommended.

Modem connection to Multiple gen-sets

Hint:

I-LB+ module enables monitoring and configuration up to 32 controllers interconnected via CAN(2)

intercontroller bus. It is also possible to use I-LB+ for single controller connection.

Controllers

Controller setup

(Setpoints/Comms settings group)

Communication Guide, ©ComAp – March 2014 50

IGS-NT Communication Guide 03-2014.pdf

Page 51

HW/SW control

According HW or SW control of modem

ComAp/ModBus

Open

ADDR1/ADDR2

Selection of CAN address. Open = ADDR1, Close = ADDR2

It is possible to use up to two I-LB+ devices in modem mode on CAN(2)

bus. Let jumper open in case of using one I-LB+ module. Other I-LB

module has to have this jumper closed. (read more about I-LB+ module)

DIRECT/MODEM

Close

RS485/RS232

Set jumper to RS232 position

Comm. speed.

No matter

RS485 120 Ohm

Open = terminator not connected, Close = terminator connected

CAN 120 Ohm

Open = terminator not connected, Close = terminator connected

USB DIASABLED/ENABLED

No matter

Equipment needed

Controller side

I-LB+ unit, Analog, ISDN or GSM modem

Connection

Phone line or GSM

PC side

Analog, ISDN or GSM modem

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Act. calls/SMS: AcallCH1(-3)-Type = DATA

Act. calls/SMS: AcallCH1(-3)-Addr = telephone number

I-LB+ hardware setup

(all jumpers in those positions)

Equipment

Active Call

Function

When active calls are activated for alarms on site (warning, shut-down…) the controller calls to the

preselected telephone number and sends the ANT archive file.

Software (e.g. InteliMonitor) on the PC side must be running and waiting for active call.

Controllers

Hint:

Active call uses for communication the modem connection.

Equipment

The same as for modem connection

Controller setup

(Setpoints/Comms settings group)

Communication Guide, ©ComAp – March 2014 51

IGS-NT Communication Guide 03-2014.pdf

Page 52

Active SMS

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Equipment needed

Controller side

GSM Modem or I-LB + GSM Modem

Connection

GSM

PC side

GSM Mobile Phone

Act. Calls/SMS: AcallCH1(-3)-Type = SMS

Act. calls/SMS: AcallCH1(-3)-Addr = mobil phone number

Act. calls/Acall+SMS lang: AcallCH1(-3)-Addr = 1, 2, 3, ...

Function

When SMS active calls are activated for alarms on site (warning, shut-down…) the controller sends

SMS message to the predefined GSM number.

Controllers

Hint:

Active SMS uses for communication the modem connection.

Equipment

Controller setup

(Setpoints/Comms settings group)

Hint:

Maximum length of SMS sent in not default language is 70 characters. Number of language

corresponds with number of language in GenConfig (card “Languages”).

Example

SMS in format

#Gen-set name:AL=(Wrn PrimWater temp, !Emergency stop)

is sent in case that the primary water temperature exceeded the warning limit and Emergency stop

input has been deactivated.

Communication Guide, ©ComAp – March 2014 52

IGS-NT Communication Guide 03-2014.pdf

Page 53

Active E-mail (SMS E-mail)

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Available ports

external

bridge IB-NT

ETHERNET

ETHERNET

external

bridge IB-NT

ETHERNET

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Available ports

external bridge

IB-NT

ETHERNET

ETHERNET

external bridge

IB-NT

Equipment needed

Controller side

Ethernet connection

Connection

Internet

PC side

Ethernet connection, e-mail message box

Act. calls/SMS: AcallCH1(-3)-Type = IB-E-MAIL

Act. calls/SMS: AcallCH1(-3)-Addr = email address (maximum

length of email address is 31 characters)

Act. calls/Acall+SMS lang: AcallCH1(-3)-Addr = 1, 2, 3, ...

Controllers

Equipment

Function

When active e-mails are activated for alarms on site (warning, shut-down…) the controller sends

e-mail message to the predefined e-mail address. The function and settings for Direct Ethernet port

connection and connection via external bridge IG-IB are the same.

Controller setup

(Setpoints/Comms settings group)

Hint:

Number of language corresponds with number of language in GenConfig (card “Languages”).

Communication Guide, ©ComAp – March 2014 53

IGS-NT Communication Guide 03-2014.pdf

Page 54

Peripheral modules

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Physical port

RS485 (1),

CAN(2)

RS485 (1),

CAN(2)

RS485 (1),

CAN(2)

RS485 (1),

CAN(2)

RS485 (1),

CAN(2)

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Physical port

RS485 (1),

CAN(2)

RS485 (1),

CAN(2)

RS485 (1),

CAN(2)

RS485 (1),

CAN(2)

RS485(1) conv. = DISABLED

Controllers

IG-NT-BB

IG-NTC-BB

IS-NTC-BB

IM-NT-BB

IM-NTC-BB

Connection applicable

YES

YES

YES

YES

YES

Physical port

RS485 (1)

RS485 (1)

RS485 (1)

RS485 (1)

RS485 (1)

Displays

InteliVision 8 display

Controllers

It is possible to connect up to 3 IV8 displays to RS485(1) terminal Link and up to 2 displays on CAN(2)

bus.

Hint:

Connection InteliVision 8 to IG/IS-NT controllers is described in InteliVision-1.2.2-Reference Guide.pdf

Attention:

In case of connection IV8 to controller via CAN(2) bus the collision can occur. IV8 is in this case

connected via 123 and 124 CAN (2) physical address, that can be used for other peripheral modules

(see the table bellow). Make sure, that real CAN(2) physical address (123 and 124) are not shared by

other devices such as I-LB+ module.

Controller setup

(Setpoints/Comms settings group)

InteliVision 5 display

Controllers

Communication Guide, ©ComAp – March 2014 54

IGS-NT Communication Guide 03-2014.pdf

Page 55

Controllers

IG-NT

IG-NTC

IS-NT-BB

IM-NT

Connection applicable

YES

YES

YES

YES

Physical port

RS485 (1)

RS485 (1)

RS485 (1)

RS485 (1)

RS485(1) conv. = DISABLED

It is possible to connect up to 3 InteliVision 5 displays to RS485(1) terminal Link.

Hint:

Connection InteliVision 5 to IG/IS-NT controllers is described in InteliVision 5 Reference Guide.pdf

Controller setup

(Setpoints/Comms settings group)

Comms extension - I-LB+ Local bridge

Description

I-LB+ is communication modules for communication with all devices connected to CAN(2) bus. I-LB+

is successors of the IG-MU unit designed to be used with IG/IS controllers. It therefore provides

additional communication port and higher communication speed. Speed for direct/modem connection

can be up to 57600 bps (IG-MU only 19200 bps). I-LB / I-LB+ can be connected with PC via USB,

RS232 or RS485. I-LB is without USB port, I-LB+ is with USB port (speed ≈ 115200 bps).

Communication Guide, ©ComAp – March 2014 55

IGS-NT Communication Guide 03-2014.pdf

Page 56

Jumper

Description

State

P1

CAN terminating resistor

Opened – not connect

P2

RS485 terminating resistor

Opened – not connect

P3

RS232 or RS485

1–2 – active RS485

P8

USB enable/disable

Opened – disabled

P13

Modbus rate

9600, 19200, 38400, 57600 bps

(according to picture: O = Open, C =

Close.

P14

Modbus rate

P15

HW or SW modem control

Opened – HW control

P16

ComAp or Modbus

Opened – ComAp protocol

P17

ADR1 or ADR2

Opened – ADR1

P18

Direct or Modem

Opened – Direct

RS232/485 DIRECT

MODEM

USB

Addr. 1

124

125

123

Addr. 2

123

122

124

Jumper setings:

According Addr.1/Addr.2 setings real CAN address is assigned to port.

It is possible to use those combinations simultaneously:

2x direct RS232/RS485 and 2x MODEM (USB communication has to be disabled, P8 is

opened)

Communication Guide, ©ComAp – March 2014 56

IGS-NT Communication Guide 03-2014.pdf

Page 57

1x USB and 1x RS232/RS485

Jumper selection tree

ComAp / ModBus – selects between ComAp PC tools (InteliMonitor, WinScope, ...) and third party

PC SW for monitoring:

- ComAp

o Direct / Modem – selects between direct connection (via RS232 or RS485) and

modem connection type

DIRECT

RS232 / RS485 – selection of serial communication type

ADR1 / ADR2 – selection between two available local communication

channels; if I-LB+ is used, the USB communication automatically

occupies the other channel

MODEM

HW / SW control – selection between modems with full interface

ADR1 / ADR2 – selection between two available modem

communication channels; IG/IS-NT controllers only, in ID the

secondary modem channel not available

Setting RS232 / RS485 jumper to RS232 position is obligatory

- ModBus (not available at USB port of I-LB+, USB port always works in ComAp mode)

o Direct / Modem – selects between direct connection (via RS232 or RS485) and

modem connection type

DIRECT

RS232 / RS485 – selection of serial communication type

ADR1 / ADR2 – selection between two available local communication

channels; if I-LB+ is used, the USB communication automatically

occupies the other channel

MODEM

ADR1 / ADR2 – selection between two available modem

communication channels; IG/IS-NT controllers only, in ID the

secondary modem channel not available

Setting HW / SW control has no influence; a modem with HW control

is always expected in this mode

o ModBus Rate (9600 / 19200 / 38400 / 57600 bps) – selects the communication

speed when ModBus protocol is selected, no matter if in Direct or Modem mode

For more information read IGS-NT accessory modules manual.

Comms extension - IG-IB Internet Bridge

How to establish connection between the IG-IB and InteliMonitor

IP address of IG-IB needs to be set in InteliMonitor in this way if default port number 23 is used:

Communication Guide, ©ComAp – March 2014 57

IGS-NT Communication Guide 03-2014.pdf

Page 58

IP address of IG-IB needs to be set in InteliMonitor in this way if port number other than 23 is used:

Internet Bridges IP’s definition consist of two parts:

195.122.194.91 : 24

IP address Port number

Several IG-IB’s connection using RS232

Use the next type of internet connection for faster communication with more than 10 controllers

Communication Guide, ©ComAp – March 2014 58

IGS-NT Communication Guide 03-2014.pdf

Page 59

One IG-IB is connected to each controller via RS232 for faster communication. It means that up to 32

Equipment needed

Controller side

InternetBridge (IG-IB) unit configured for Ethernet connection (Ethernet connection

firmware); Internet connection with “visible” IG-IB

Connection

Ethernet

PC side