Page 1

InteliPro

Protection Relay for Parallel Applications

Comprehensive Guide - rev. 1

SW version 1.0, May 2011

Installation and Operation Guide

Communication Brochure

Application Guide

Reference Guide

Copyright © 2011 ComAp s.r.o.

Written by Tomas Jelen

Prague, Czech Republic

ComAp, spol. s r.o.

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 246 316 647

E-mail: info@comap.cz, www.comap.cz

Page 2

Purpose of the InteliPro manuals

Installation and Operation Guide

The Installation and Operation Guide serves for the personnel, providing installation of the InteliPro

unit. It contains wiring and setting instructions, needed for service and commissioning of the unit. It

also contains introduction of the user interface and necessary procedures to perform setting and

operating of the unit. Though InteliPro is very simple and intuitive for the operating personnel, we

recommend to keep one copy of this manual available permanently at the installation site, where

InteliPro unit is installed, to facilitate the necessary service and operation tasks.

Application Guide

The Application Guide serves for the designers and engineers, who process the necessary

documentation and implementation procedures on the installation site, where InteliPro is installed. It

contains detailed description of InteliPro functionalities and their practical application.

Communication Brochure

The Communication Brochure gives specific tips for wiring and set-up of communication interface of

InteliPro and preparing it for local or remote communication. For more detail about communication of

ComAp products, see the IL-NT, IA-NT, IC-NT Communication Guide as published on ComAp

download centre.

Reference Guide

The Reference Guide contains library of setpoints, inputs and outputs functionalities and technical

data for the purpose of detailed technical information. This information is referenced in the Installation

and Operation Guide and Application Guide.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Comprehensive Guide – r2

2

Page 3

InteliPro

Protection Relay for Parallel Applications

Installation and Operation Guide

SW version 1.0, May 2011

Installation and Operation Guide

Copyright © 2011 ComAp s.r.o.

Written by Tomas Jelen

Prague, Czech Republic

ComAp, spol. s r.o.

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 246 316 647

E-mail: info@comap.cz, www.comap.cz

Page 4

Table of contents

Introduction.............................................................................................................................................. 3

Conformity declaration ........................................................................................................................ 3

Warnings ............................................................................................................................................. 3

Installation data ....................................................................................................................................... 4

Unpacking the unit - what is in the package ....................................................................................... 4

Mechanical mounting .......................................................................................................................... 4

Terminal diagram ................................................................................................................................5

Voltage and current inputs .................................................................................................................. 5

Binary inputs........................................................................................................................................ 7

Binary outputs ..................................................................................................................................... 7

Analog inputs....................................................................................................................................... 8

Tristate inputs ................................................................................................................................. 9

Recommended wiring ................................................................................................................... 10

Configurability.................................................................................................................................... 11

Options system ................................................................................................................................. 13

User Interface ........................................................................................................................................ 15

Control and navigation Pushbuttons - basic operation ..................................................................... 15

Sinalization LEDs .............................................................................................................................. 15

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-2

Page 5

Introduction

Thank you for buying ComAp InteliPro protection relay unit. InteliPro is a microprocessor-based doormounted protective device, providing a comprehensive set of protective and supplementary

functionalities. ComAp unique modular concept of HW extension modules, SW options and full

configurability allow perfect solution for most of the generator-to-mains parallel applications.

For the complete list of protective functions please refer to the chapter "Protective functions in detail"

in the Application guide. The full configurability feature allows to cover advanced requirements for

mains-decoupling (inter-tie, „G59/2“), as well as other advanced protection applications.

Conformity declaration

Following described machine complies with the appropriate basic safety and health

requirement of the EC Low Voltage Directive No: 73/23 / EEC and EC

Electromagnetic Compatibility Directive 89/336 / EEC based on its design and type,

as brought into circulation by us.

Warnings

Be aware that the relay outputs can change state during and after the unit

setting (before the unit is used again ensure that the proper setting is done)!!!

Be aware that the devices connected to binary outputs of the unit may operate

upon disconnection of power supply, measurement inputs and/or binary

inputs!!!

!!! CAUTION !!!

Dangerous voltage

In no case touch the terminals of voltage measurement!

Adjust set points

All setpoints are pre-adjusted to their typical values. Before putting into operation, the setpoints must

be checked and/or adjusted to the required values.

Installation may be done by qualified personnel only.

To avoid personal injury do not perform any action not specified in this guide!!!

Note:

ComAp believes that all information provided herein is correct and reliable and reserves the right to

update at any time. ComAp does not assume any responsibility for its use unless otherwise expressly

undertaken.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-3

Page 6

Inst allation data

Unpacking the unit - what is in the package

The package contains:

• InteliPro unit

• Relay Card CT2-REL2 plug-in module (plugged in the unit)

• Mounting holders

• Terminal blocks

NOTE:

The package does not contain any communication module nor any extension module. The required

module should be ordered separately.

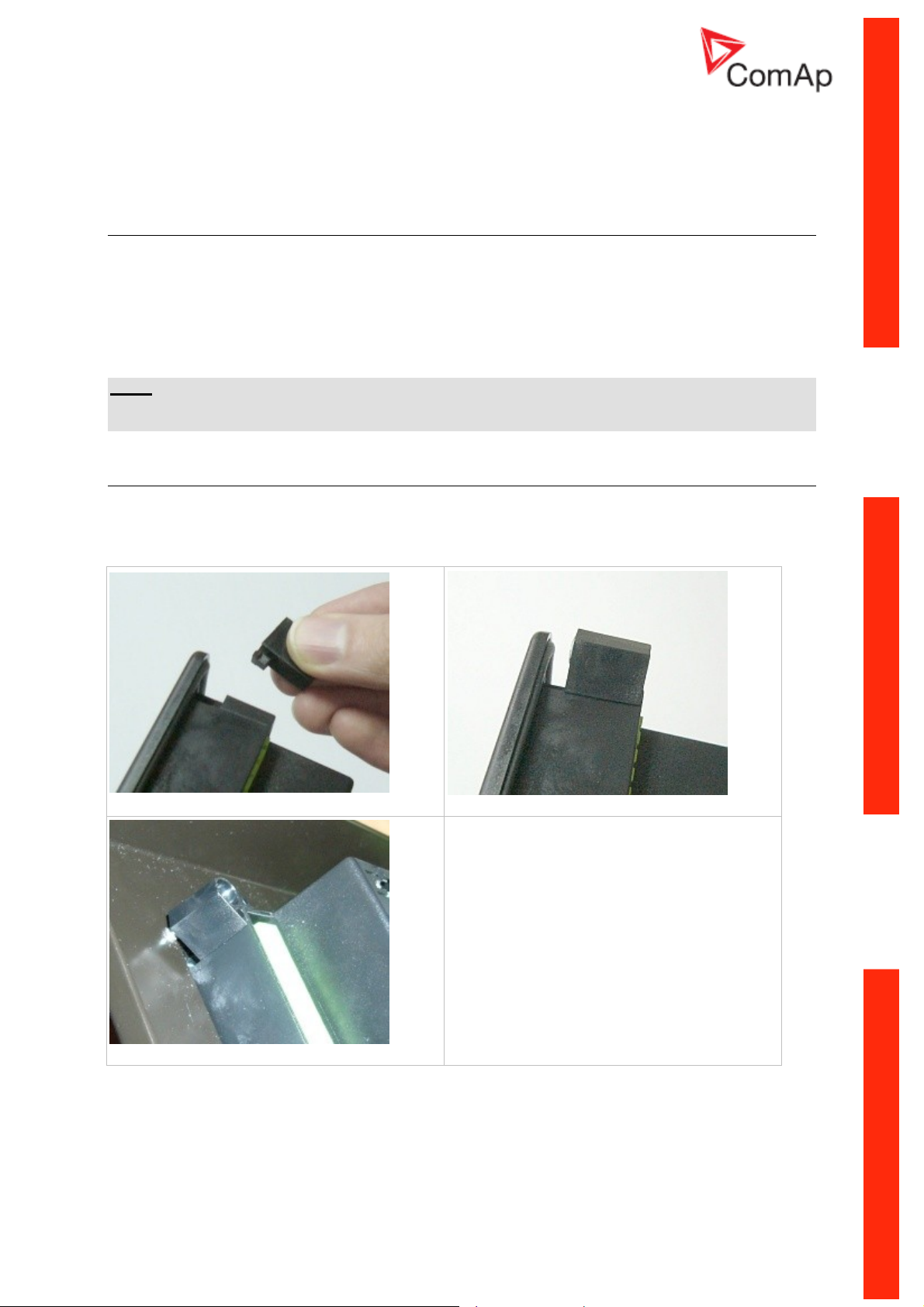

Mechanical mounting

The unit is to be mounted onto the switchboard door. Requested cutout size is 175x115mm. Use the

screw holders delivered with the unit to fix the controller into the door as described on pictures below.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-4

Page 7

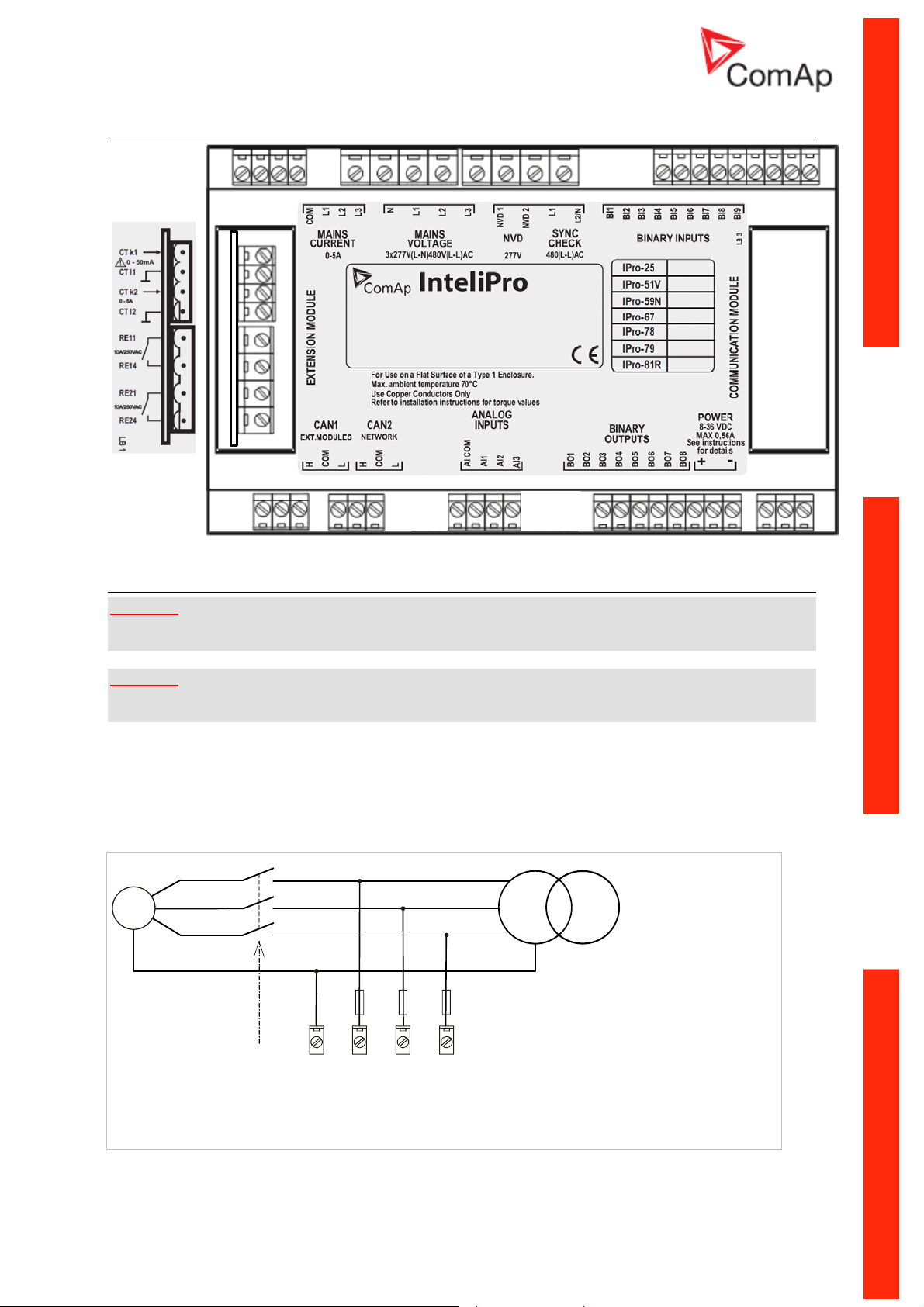

Terminal diagram

Voltage and current inputs

WARNING!

Risk of personal injury due to electric shock when manipulating with voltage terminals under voltage!

Be sure the terminals are not under voltage before touching it.

WARNING!

Do not open secondary circuit of current transformers when primary circuit is closed!!! Open the

primary circuit first!

Use 1.5 mm

Adjust nominal voltage, nominal current, CT ratio and PT ratio by appropriate setpoints in the Basic

Settings group. Learn about how to view and change setpoints in the User interface chapter.

VOLTAGE MEASUREMENT WIRING

G

2

cables for voltage connection and 2.5 mm

L1

2

for current transformers connection.

L2

L3

N

<Comm Trp> /

<Trip 1> /

<Trip 2>

MAINS

VOLTAGE

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

L3L2L1N

1-5

Page 8

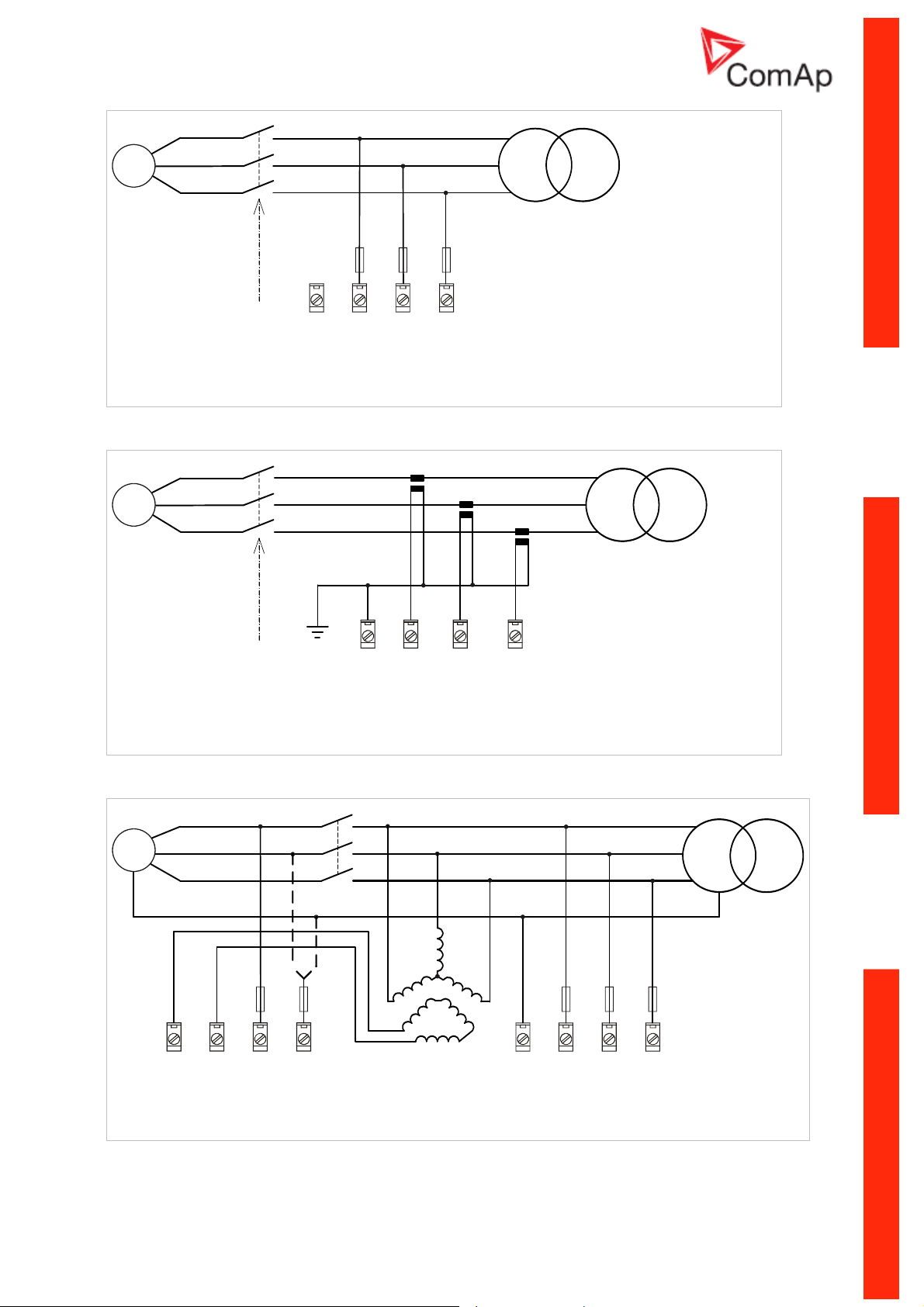

L1

G

<Comm Trp> /

<Trip 1> /

<Trip 2>

VOLTAGE

CURRENT MEASUREMENT WIRING

G

MAINS

K L

k l

L3L2L1N

L2

L3

K L

k l

K L

k l

L1

L2

L3

<Comm Trp> /

<Trip 1> /

<Trip 2>

NVD

AND SYNC CHECK WIRING

G

NVD 1

NVD 2

SYNC

NVD

CHECK

L1

COM

L2

L3

MAINS

CURRENT

L1

L2

L3

N

L2/NL1

N

L1

MAINS

VOLTAGE

L3L2

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-6

Page 9

Binary inputs

Use min. 1 mm

NOTE:

The name and function or alarm type for each binary input have to be assigned during the

configuration.

2

cables for wiring of binary inputs.

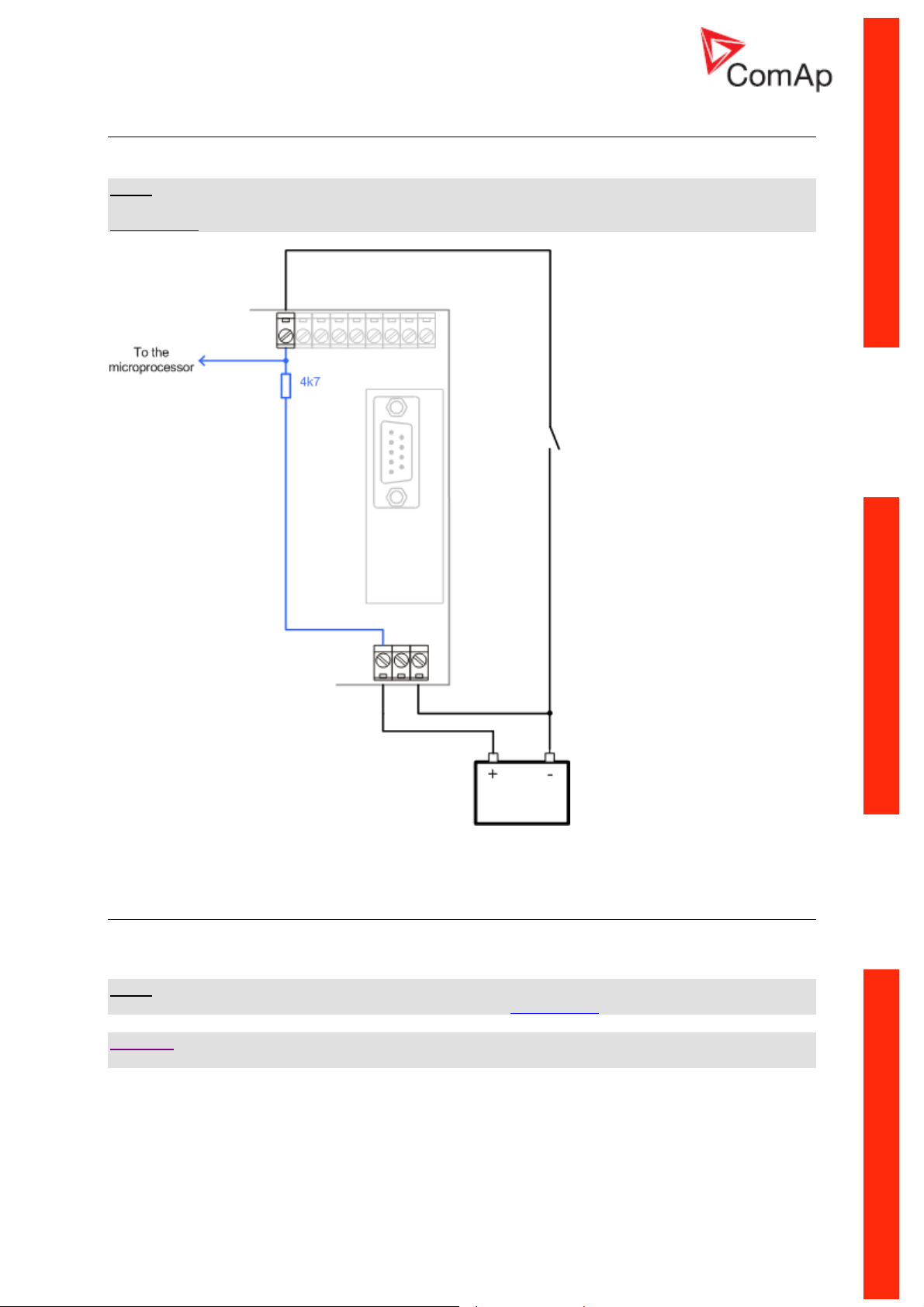

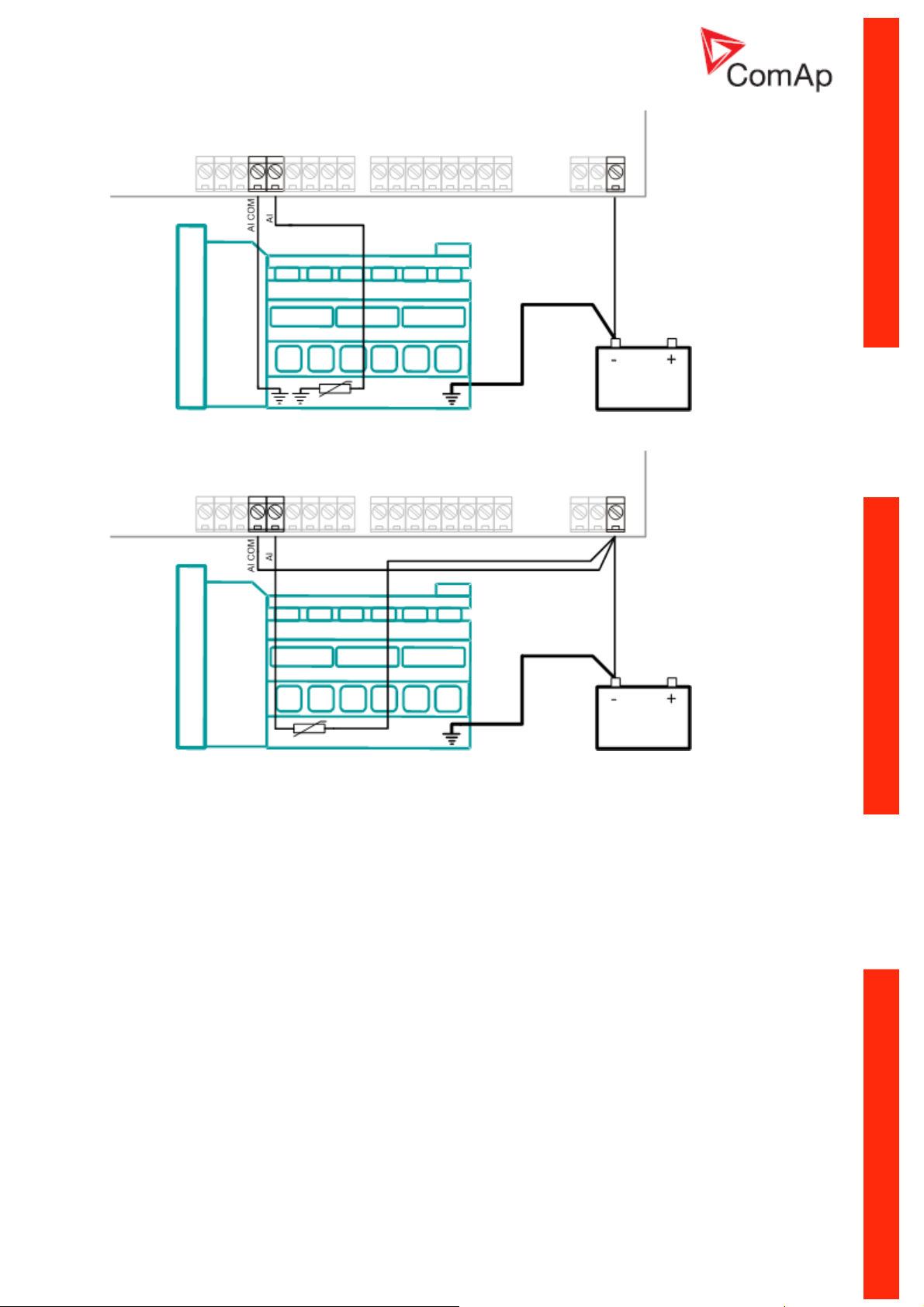

WIRING OF BINARY INPUTS

Binary outputs

Use min. 1 mm

below for all outputs except those where low-current loads are connected (signalization etc..).

NOTE:

The function of each output has to be assigned during the configuration.

CAUTION!

Use suppression diodes on all relays and other inductive loads!

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

2

cables for wiring of binary outputs. Use external relays as indicated on the schematic

1-7

Page 10

WIRING OF BINARY OUTPUTS

Analog inputs

The analog inputs are designed for resistive automotive type sensors like VDO or DATCON. The

sensors are connected either by one wire (the second pole is sensor body) or by two wires.

• In case of grounded sensors connect the AI COM terminal to the engine body as near from

the sensors as possible.

• In case of isolated sensors connect the AI COM terminal to the negative power supply

terminal of the controller as well as the opposite poles of the sensors.

NOTE:

The fail sensor alarm is issued if the measured resistance is smaller than one half of the first (lowest)

point of the sensor curve characteristic or is greater than 112,5% of the last (greatest) point of the

sensor curve characteristic.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-8

Page 11

W

IRING OF ANALOG INPUTS - GROUNDED SENSORS

WIRING OF ANALOG INPUTS - ISOLATED SENSORS

Tristate inputs

Analog inputs can be used also as binary or tristate, i.e. for contact sensors without or with circuit

check. The threshold level is 750Ω. In case of tristate, values lower than 10Ω and values over 2400Ω

are evaluated as sensor failure (short or open circuit).

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-9

Page 12

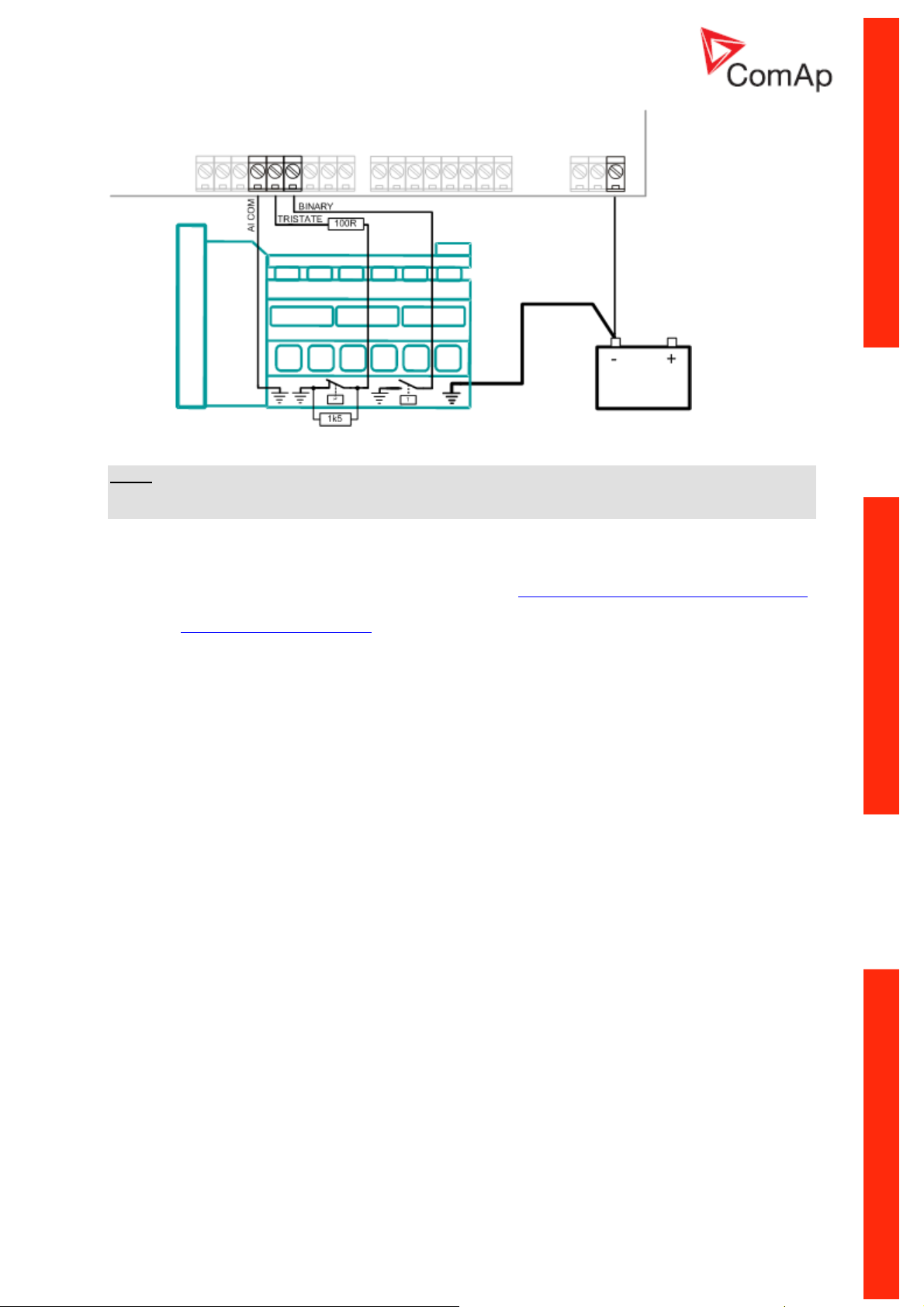

WIRING OF ANALOG INPUTS - USED AS BINARY OR TRISTATE

NOTE:

The name, sensor characteristic and alarm types for each analog input have to be assigned during the

configuration.

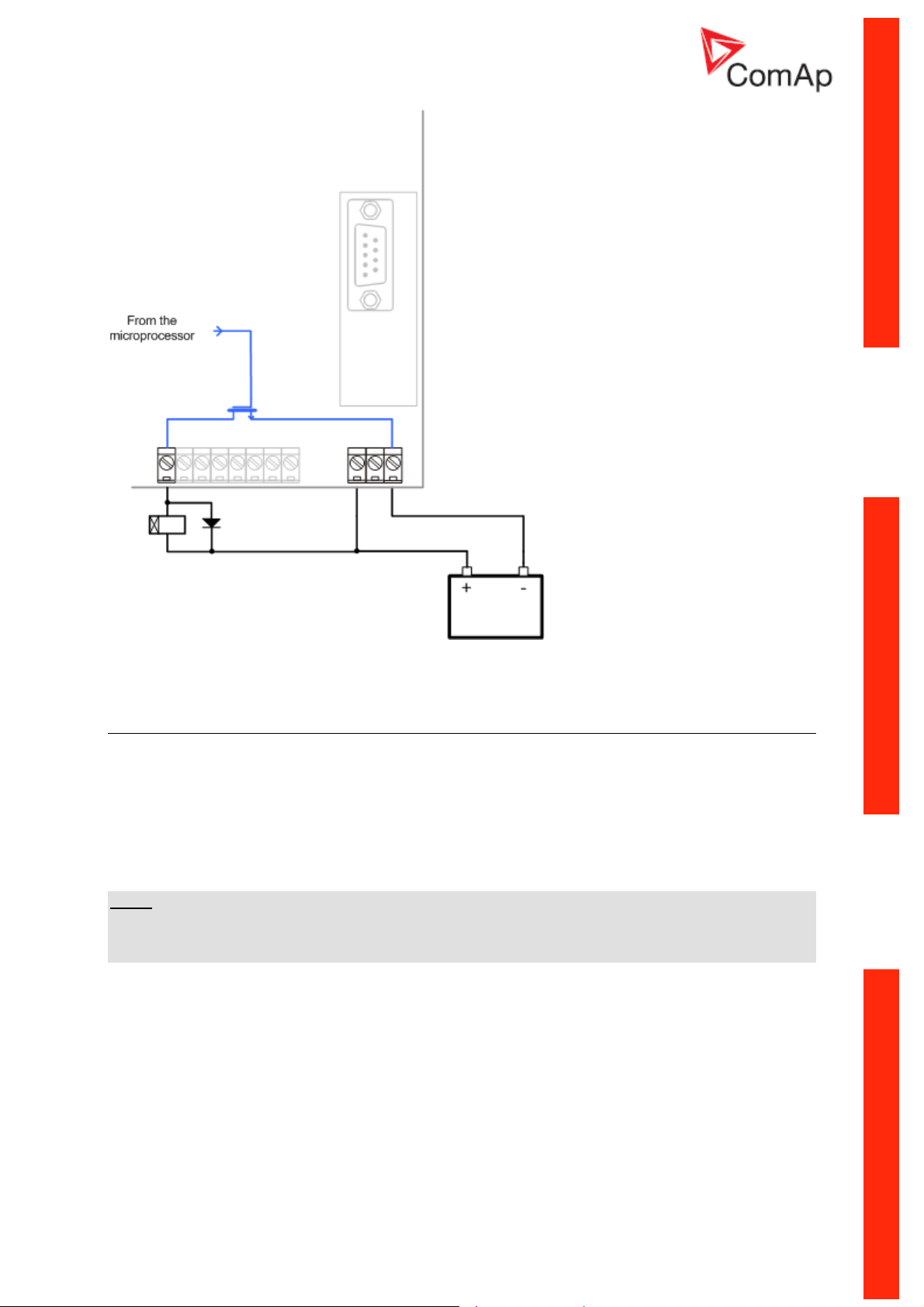

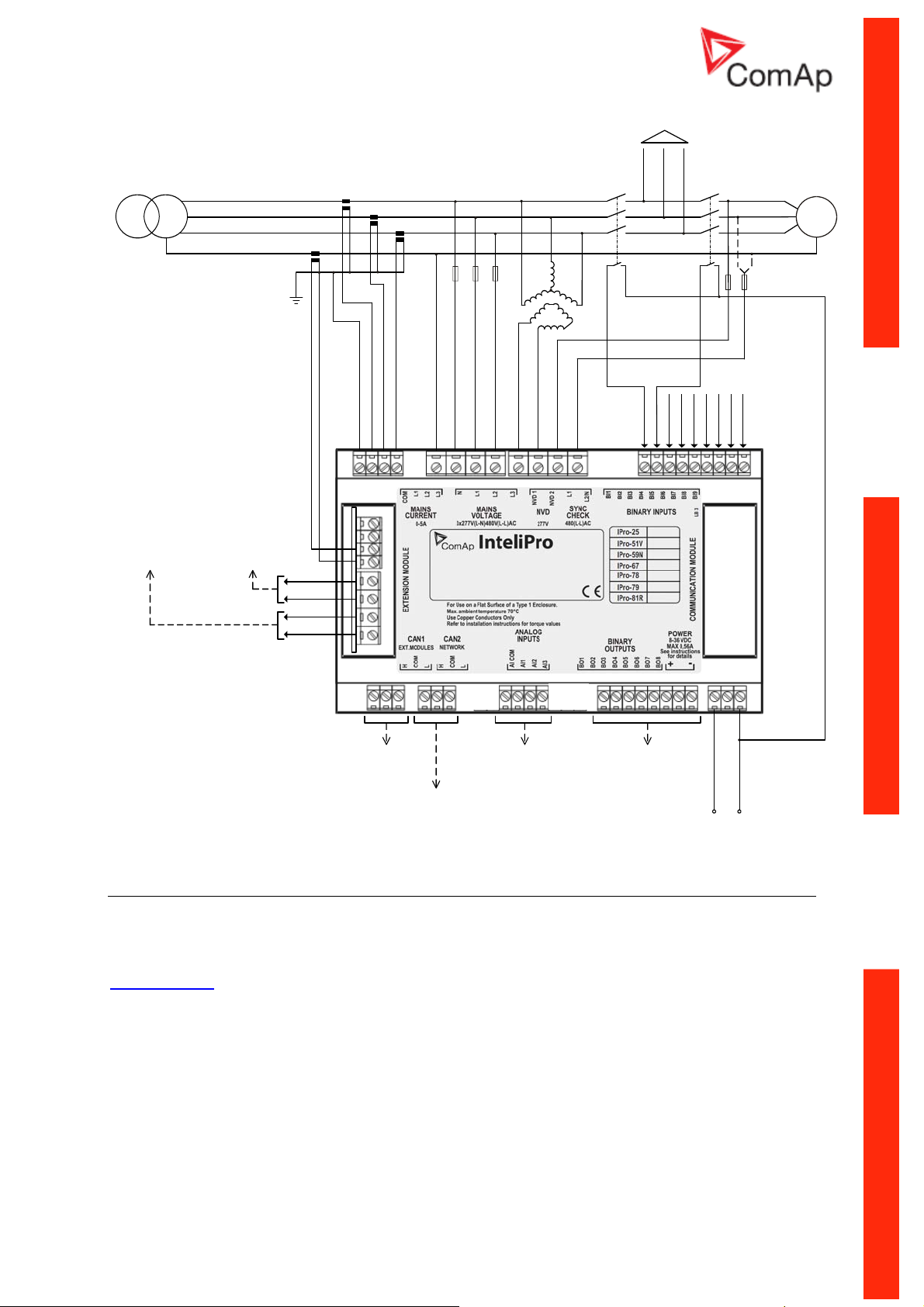

Recommended wiring

In the diagram below, see the typical wiring of the InteliPro unit inputs and outputs. The wiring is to be

considered as an example for the default configuration and operation mode with 1 common trip output

The relay contacts of Relay Card CT2-REL2 module can be reconfigured to Trip 1 and Trip 2 outputs

in case of operation with 2 trip outputs

particular needs of the application.

, as well as any inputs and outputs can be reconfigured to the

.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-10

Page 13

LOAD

dry contact to

CB1 backup

L1

L2

L3

N

dry contact to

CB1 OFF coil

K L

k l

!Comm Trp

K L

k l

K L

k l

K L

k l

CB1

(MCB)

CB2

(GCB)

G

Block 2

Block 1

CB1 Feedback

CB2 Feedback

Alar m 8

F.R. But ton

Alar m 9

Access Lock

DC Tri p Cir cuit

!Bak Comm Trp

CAN bus to

extension

analog

inputs

open collector bin.

outputs (signalling)

modules

CAN bus to

ComAp

controllers

+ -

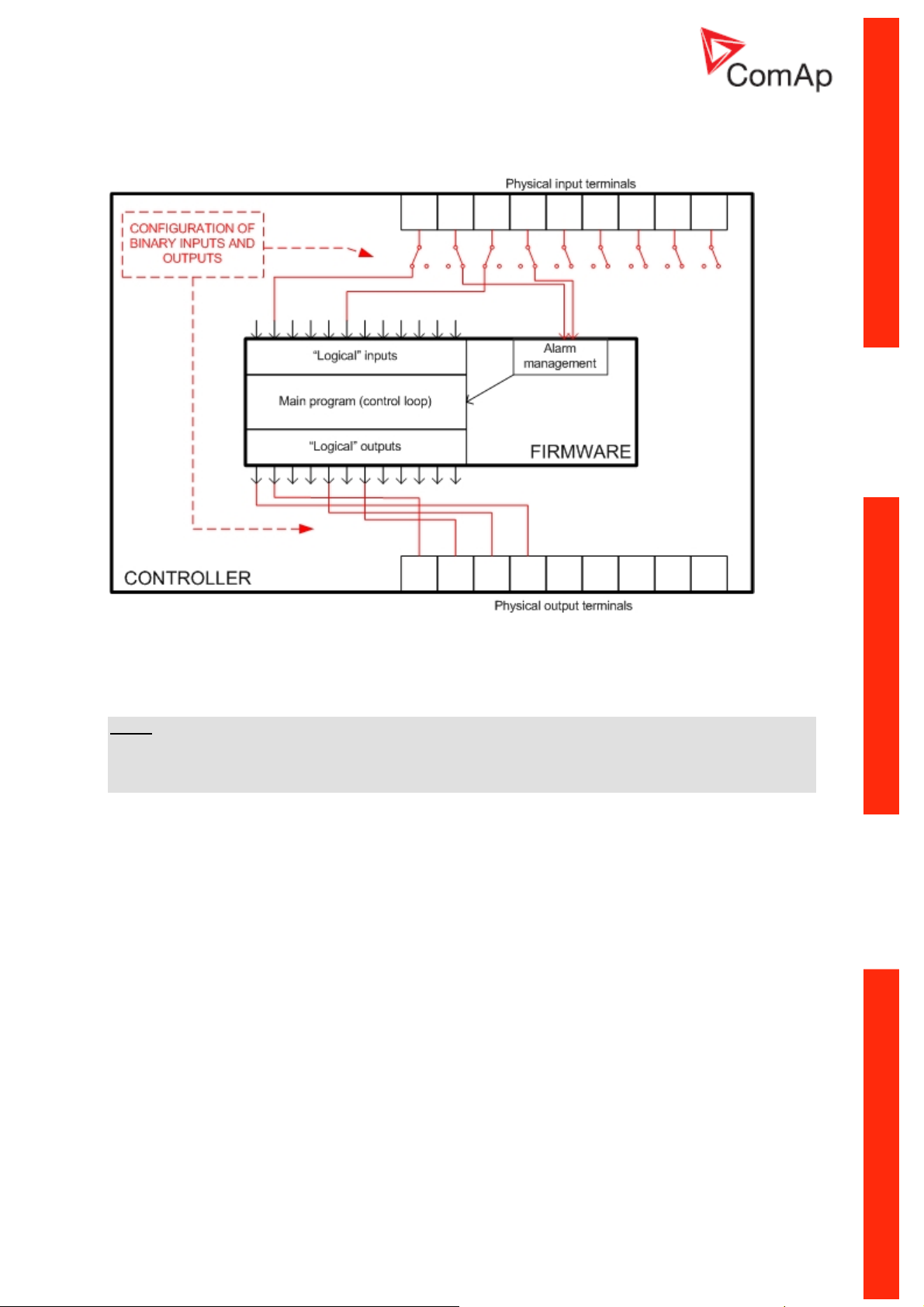

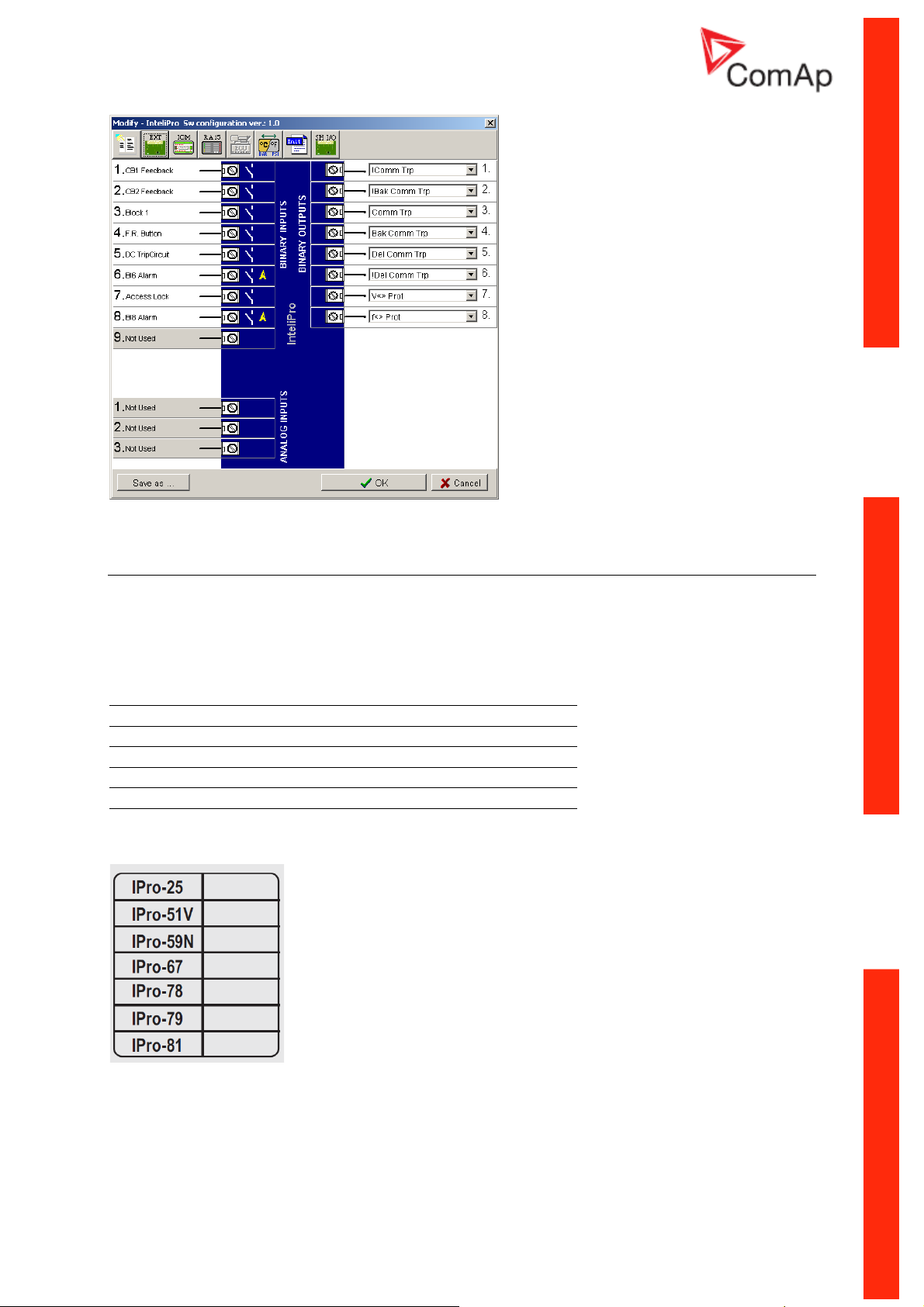

Configurability

One of the key features of InteliPro unit is high level of flexibility and adaptability of the system to the

particular application. The way how to achieve this is the configuration. Use LiteEdit PC software to

read the configuration from the controller or disk, view it, modify it and write the configuration to

controller or disk. To work with InteliPro, LiteEdit version 4.5.2 or higher is necessary. Visit

www.comap.cz

The firmware contains large number of binary inputs and outputs. However, not all functions are

required the application, also the controller hardware does not as many input and output terminals.

One of main tasks of the configuration is mapping of "logical" firmware input and output signals to the

"physical" hardware inputs and outputs.

Configuration parts:

1. Mapping of logical binary inputs (functions) or assigning alarms to physical binary input

terminals

2. Mapping of logical binary outputs (functions) to physical binary output terminals

3. Assigning sensor characteristics and alarms to analog inputs

4. Assigning control values and output characteristics to analog outputs

for download or update of this PC application.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-11

Page 14

5. Selecting of peripherial modules which are connected to the controller and doing the same as

above for them

6. Changing language of the unit texts

PRINCIPLE OF BINARY INPUTS AND OUTPUTS CONFIGURATION

The unit is delivered with a default configuration, which should fit to most standard applications.

This default configuration can be changed only using PC and LiteEdit software. See LiteEdit

documentation for details.

NOTE:

You need one of communication modules to connect the controller to a PC with LiteEdit. There is a

special easy removable service module for cases, where there is no communication module

permanently attached.

Once the configuration is modified, it can be stored in a file for later usage with another controller or

for backup purposes. The file is called archive and has file extension "aic". An archive contains full

image of the controller at the moment of saving (if the controller is online to the PC) except firmware,

i.e. besides configuration there are also current adjustment of all setpoints, all measured values, copy

of history log and copy of alarm list.

The archive can be simply used for cloning of InteliPro units, which means preparing units with

identical configuration and settings.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-12

Page 15

CONFIGURATION WINDOW IN LITEEDIT

Options system

The unit offers wide range of protective functionalities. To allow flexibility of the protective functions at

the particular application, some of the features are provided as SW options. These functions are

unlocked by a software dongle, delivered by ComAp or its approved distributors. The SW dongle is a

unique number generated according to the serial number of the unit and the selected protective

functions. The functions are referred by their ANSI numbers, according to the following table:

IPro-25 Synch Check

IPro-51V Time over current with voltage control

IPro-59N Neutral voltage displacement

IPro-67 Directional overcurrent

IPro-78 Vector shift

IPro-79 AC reclosing relay

IPro-81R Rate of change of frequency + rocof filter

The appropriate selection of InteliPro optional functions is to be marked on the rear side of the unit:

For unlocking the desired functions or changing those functions that are already unlocked, contact

your sales person for the appropriate SW dongle. The following information will be needed:

- Serial number of the unit

- List of requested functions to unlock

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-13

Page 16

Entering the SW dongle:

once received the appropriate SW dongle relative to the unit serial number, go to the setpoint Basic

Settings: Dongle and enter the numerical string, which you have obtained. Though it is more

convenient to enter the SW dongle via LiteEdit PC software, it is also possible to enter it through the

controller screen and pushbuttons.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-14

Page 17

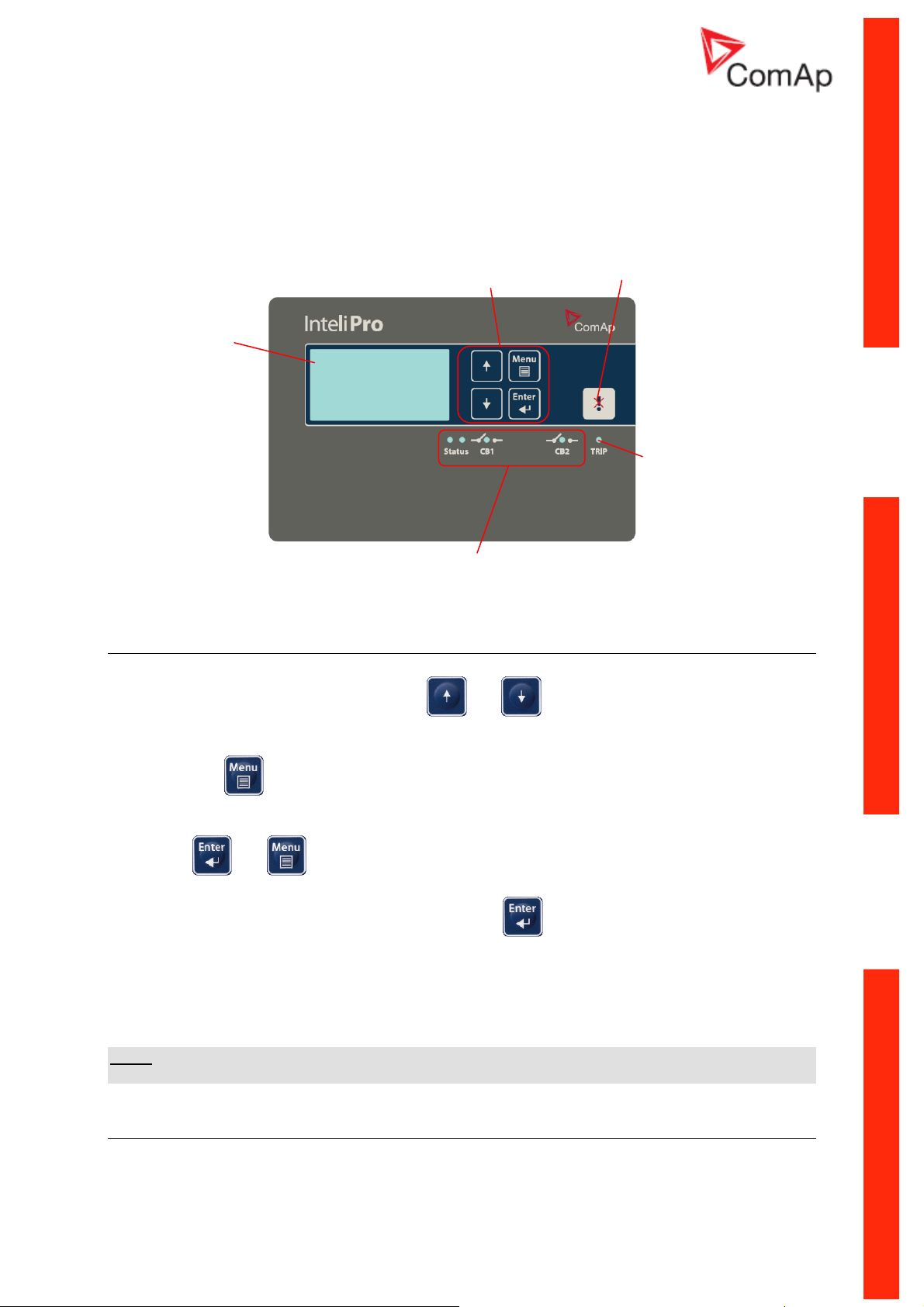

User Interface

128 x 64

pixels

graphical

display

Control and

navigation

pushbuttons

Fault Reset

button

TRIP LED

Signalization

LEDs

Control and navigation Pushbuttons - basic operation

General operation using buttons:

• In the measurement screens, use the

measured values as displayed on the graphical display. See the chapter Measurement

screens to get the basic orientation.

• Use the

view the history table. For setpoints change, see the following chapter.

• To enter the init screen, change language or read the list of unlocked InteliPro options, push

the

performs lamp test by simultaneous blinking of all LEDs.

• For confirmation of change any setpoint, use the

Entering the password

The password must be entered prior adjusting setpoints, that are password-protected. Password is

located in the first group of setpoints and the way how to enter or change password is similar to

change of setpoints.

button to cycle through display of measurement screens, adjust setpoints and

and buttons at the same time. Together with the init screen display, the unit

and , arrow buttons to browse through the

button.

NOTE:

It is possible to change only passwords of the same or lower level than actually entered password!

Sinalization LEDs

There are 5 LEDs for indication of InteliPro status with the meaning indicated in the table below:

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

1-15

Page 18

LED state Meaning

-

(red)

-

(green)

ON

(green)

OFF

Status of the InteliPro unit - used in combination with green LED, see the table below

Status of the InteliPro unit - used in combination with red LED, see the table below

CB1 feedback - activated - state "I"

CB1 feedback - deactivated - state "0"

ON

CB2 feedback - activated - state "I"

(green)

OFF

ON

CB2 feedback - deactivated - state "0"

Indicates TRIP state, measured values are in fault conditions (out of limits)

(red)

blinking

Indicates TRIP state, measured values are in fault-free conditions (within limits)

(red)

OFF

The unit is not in TRIP state

Status LED signalization:

red green state Display reading Meaning

OFF OFF

blink OFF

ON OFF

ON ON

"Program Corrupted" or

"System Error" or "System

Error + Wrong config

format"

Normal reading Wrong checksum of parameters → Check the complete settings

Normal reading Wrong checksum of "R" parameters → Contact technical support

No power supply or PowerFail occured

Transient SW failure → Contact technical support with

information abut the display message

of your unit and change any one of the parameters. If the state

persists, contact technical support

blink ON

OFF ON

blink blink

Normal reading Watchdog reset was performed → Save the archive, contact

Normal reading Normal operation of the unit

Not initialized Unit HW failure → Request repair of the unit

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Installation and Operation Guide

technical support and attach the archive

1-16

Page 19

InteliPro

Protection Relay for Parallel Applications

Application Guide

SW version 1.0, May 2011

Application Guide

Copyright © 2011 ComAp s.r.o.

Written by Tomas Jelen

Prague, Czech Republic

ComAp, spol. s r.o.

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 246 316 647

E-mail: info@comap.cz, www.comap.cz

Page 20

Table of contents

Introduction.............................................................................................................................................. 2

Operation mode with 1 common trip output........................................................................................ 3

Operation mode with 2 trip outputs ..................................................................................................... 4

Priority switching ................................................................................................................................. 4

TRIP and Fault Reset description ....................................................................................................... 5

TRIP................................................................................................................................................ 5

Fault reset ....................................................................................................................................... 5

Shared peripheries.............................................................................................................................. 5

Protective functions ................................................................................................................................. 7

The concept......................................................................................................................................... 7

Protective functions in detail ............................................................................................................... 8

Overvoltage, Undervoltage (ANSI 59, 27) ...................................................................................... 8

Overfrequency, Underfrequency (ANSI 81 H, L)............................................................................ 8

Voltage unbalance (ANSI 47) ......................................................................................................... 8

"Loss of mains" protections ............................................................................................................ 8

Vector shift (ANSI 78) ..................................................................................................................... 8

Rate Of Change Of Frequency (df/dt, ROCOF, ANSI 81R) ........................................................... 9

Overcurrent: definite-time, IDMT and with voltage control ........................................................... 10

Neutral overcurrent (ANSI 50N, ANSI 51N) ................................................................................. 11

Current unbalance (ANSI 46) ....................................................................................................... 11

Directional overcurrent (DOC, ANSI 67)....................................................................................... 11

Neutral Voltage Displacement (NVD, ANSI 59N)......................................................................... 12

Directional power (ANSI 32) ......................................................................................................... 12

Synchro check (ANSI 25) ............................................................................................................. 13

AC reclosing (ANSI 79)................................................................................................................. 13

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-2

Page 21

Introduction

InteliPro protection relay provides high range of flexibility to the users and their applications. In the

most common cases, one output for tripping is used. In this case, InteliPro allows provides the

common trip output, which represents logical "OR" of all activated and pre-set protective functions of

the unit. If needed, InteliPro also allows to operate two circuit breakers, where some protective

functions are assigned to one of them and other functions to the other. In such case, the circuit

breakers can provide backup for each other, so that in "fail to trip" situation the other circuit breaker

opens under pre-set conditions to clear the first breaker failure.

Furthermore, InteliPro provides two independent blocking inputs, which can be used to activate or

deactivate any of the protective functions of the unit. All necessary inputs and outputs can be freely

configured to any input or output of the unit. In case of outputs, any of the 2 relay outputs or 8 opencollector outputs can be selected.

In case that any of the configured protective functions is activated, InteliPro relay provides a Trip

signal. This signal is provided in both positive and negative logic in order to follow the requirements of

the application:

• Due to increased safety requirements, some protective relays require that negative logic is

used, assuring that loss off power supply always causes the relay to trip. I.e. the relay

contacts are used, with fault-free position maintained in energized state. In case of power

supply fail, the unit goes to “fault” indication position. The outputs using negative logic are

marked with exclamation mark "!" as the first character of their name.

• In some applications, the negative logic is not a required functionality. The function of opening

the circuit breaker in case of loss of power supply is not accepted as a safety point and the

safety is assured by different means e.g. in the superior system or within the protection relays

intertripping scheme. In such case, the outputs with positive logic (without the exclamation

mark) can be used to signal the detected failure state.

In any case, it must be assured that the InteliPro relay has full control at opening the appropriate

breaker by the trip command - i.e. in case of Trip state the unit receives the appropriate CB

feedback, confirming its open position. The feedback must repond within preset time to the trip

command. A special attention should be paid to opening of motorized circuit breakers, as it could

take more than 2s on some types. In such cases it is necessary to use undervoltage coil for fast

opening.

Operation mode with 1 common trip output

• This is the essential mode of operation of the protection relay InteliPro. In this case, CB1

circuit breaker or contactor is considered as the main connection device, protected by

InteliPro. In the ComAp controllers, this breaker is called "Mains Circuit Breaker" = MCB.

• Second circuit breaker or contactor is not expected in the protection scheme, but there is still

possibility to use the "backup trip" signal from InteliPro relay to operate any backup device, if

present on the installation. As such device may be considered another circuit breaker in the

line of mains-connection, CB1 undervoltage coil, or any device which serves as a backup in

case of the CB1 fail.

• The Comm Trp (or !Comm Trp) output is used as the main signal to open the CB1 circuit

breaker. InteliPro expects that in such case, the CB1 Feedback input deactivates as a result of

the protection trip. Adjustable delay can be set by the setpoint General: BackupTrp Del, to

provide backup functionality for the CB1 breaker. If the feedback does not deactivate within

this delay, the output Bak Comm Trp activates (or !Bak Comm Trp deactivates) immediately.

• An function, which is activated and not blocked within the InteliPro unit activated the Comm

Trp signal. Use the blocking inputs to control which protective functions will be used under the

appropriate circumstances.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-3

Page 22

Operation mode with 2 trip outputs

• In some cases, the protection relay is requested to operate two circuit breakers. Usually, one

of them is considered as the main circuit breaker, with most of the functions configured to

operate this cicrcuit breaker. As mentioned above, this breaker often corresponds to the

"Mains Circuit Breaker" = MCB as used in ComAp controllers.

• The second circuit breaker can be from the point of view of the protection relay considered as

a supplementary connection device in the power connection scheme. It can provide back-up

functionality in case that the CB1 does not trip on command, or can be operated individually

by selected protective functions. It can, but does not necessarily have to correspond to the

"Generator Circuit breaker" = GCB as used in the ComAp controllers applications. In such

case, e.g. NVD function is the most often case, when GCB (CB2) is tripped instead of MCB

(CB1).

• In case that 2 circuit breakers are controled by InteliPro unit, it is possible to freely assign,

swap or configure the functionalities of both circuit breakers and provide appropriate back-up

function of the breakers by the "Priority switching" functionality. It is not practical to use the

Comm Trp output in this case. To distinguish between the 2 breakers, outputs Trip 1 and Trip

2 are available.

• For each protective function in InteliPro, it is possible to assign either Trip 1 or Trip 2 function,

none of them, or both. The setpoint xxx Trp BO in the appropriate group of protection setting is

used for this assignment. By this setting, the output Trip 1 or 2 will then contain only those

functions which were assigned to it.

• Trip 1 output is internally interconnected with CB1 operation, i.e. in case of activation of Trip 1,

the CB1 feedback is expected to deactivate. The same applies for Trip 2: in case of activation

of Trip 2, the CB2 feedback is expected to deactivate.

Priority switching

Priority switching feature allows using the circuit breakers CB1 and CB2 as a backup to the other one.

To clearly understand this, it is necessary first to understand the possibility of assignment of any of the

operated two circuit breakers to the appropriate protective function (see the chapter Operation mode

with 2 trip outputs).

Though both of the breakers are equivalent and fully assignable within the InteliPro relay, the most

common application for generator-to-mains connection is as follows:

• CB1 is considered as the main connection device of the generator to the mains. In ComAp

products, this breaker is called "Mains Circuit Breaker" = MCB.

• CB2 is considered as a supplementary connection device on the power connection between

generator and mains. There can be specific protection functions assigned the trip CB2 only

and it can provide back-up functionality to the CB1. It can, but does not necessarily have to

correspond to the "Generator Circuit breaker" = GCB as used in the ComAp products.

• As both circuit breakers are equivalent, it is possible to assign CB2 as the main one and CB1

as the backup, or provide a symmetrical backup of both breakers "one to each other".

Depending on setting the setpoint General: Prio Switching, the following backup function is provided:

DISABLED - no CB backup is provided

CB1 -> CB2 - CB1 is considered as the primary switch. If the feedback is not deactivated within preset

period after Trp 1, the output Trp 2 is issued immediately to trip CB2 as backup. Bak Trp 1 is issued at

the same time.

CB1 <- CB2 - CB2 is considered as the primary switch. If the feedback is not deactivated within preset

period after Trp 2, the output Trp 1 is issued immediately to trip CB2 as backup. Bak Trp 2 is issued at

the same time.

CB1 <-> CB2 - both CBs provide a backup switching for each other. If the CB1 feedback doesn't

deactivate in preset period, CB2 is tripped, if the CB2 feedback doesn't come in preset period, CB1 is

tripped.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-4

Page 23

TRIP and Fault Reset description

TRIP

TRIP may be considered as event or status of the unit:

TRIP event:

− Starts in the moment of terminating the count-down of any protective function with delay, or in the

moment of activation of any immediate protective function.

− As a result of the trip event, are e.g. the following consequences:

o Immediate deactivation of outputs !Comm Trp

o LED TRIP goes to red

o History record is created

TRIP status:

− Starts at the moment of TRIP event

− During this status, the !Comm Trp output keeps in the fault position

− During this status, it is not possible to perform Fault reset

− TRIP status is active until a successful Fault reset. This may not be done before all measured and

evaluated values are within preset limits.

− If during the TRIP status, caused by some value, another value overreached its limits for TRIP

evaluation, this second overreach is not considered as TRIP. It does not cause a second TRIP

event. However, as a consequence of this, the TRIP duration may be prolonged until the moment

when both (all) values are within limits.

Fault reset

Fault reset is an event, caused by either of the following reasons:

− Fault reset

− Input input F.R. Button is activated

− Automatic fault reset is performed according to the setting of General: Auto FR setpoint.

− By activation or deactivation of binary input Block 1 or Block 2.

The abovementioned reasons are a trigger to provide Fault reset, however, it is successfully done only

in case that the TRIP status is activated and all evaluated values have returned back into limits. If the

TRIP status is not activated, or it is activated, but any of the values is still out of limits, Fault reset is

not done and any of the mentioned triggers is forgotten. I.e., the unit may not be „provisionally“ faultreset.

By a successful Fault reset, the TRIP status is terminated.

button is pressed

Shared peripheries

The function is compatible with IG/IS-NT controllers. CAN2 interconnection between the gen-set

controllers and InteliPro is necessary to allow this feature. Use the LiteEdit configuration window to

configure the appropriate binary and analog values to be transmitted from InteliPro via the CAN2

communication. In the Configuration window, click the

button. The following window opens:

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-5

Page 24

Using the "Module address" selection box to adjust the address of the shared peripheries module and

avoid collision with other module already present on CAN2 bus. Click on the appropriate Binary output

or Analog output in the list to set-up the value to be transmitted via CAN2 bus to the gen-set

controllers. The transmitted values are received by the IG/IS-NT controllers connected via the CAN2

bus. See more about configuring shared peripheries (Shared and Internal virtual I/O periphery and

PLC) in IGS-NT-Application guide.

The shared binary and analog outputs can be used for communicating out the binary statuses of CBs,

trips of the particular protective functions or transmitting the value of mains import in kW, kVAr or kVA

and further processing e.g. for the gen-set control or visualization of the site.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-6

Page 25

Protective functions

The concept

InteliPro is a modular electronic protective relay, providing complete list of protective functions. Each

of the functions works as an autonomous protective stage, with its independent activation, setting of

the limits and assigning of the Trp 1 and/or Trp 2 output and Block 1 and/or Block 2 input. Besides

that, each activated protective function activates the Comm Trp output as described above. These

settings are done in the setpoints menu, using the appropriate group of setpoints, assigned to its

function. E.g. setting of overcurrent limits, trip outputs and blocking inputs is done in the setpoint group

I>.

Activation/deactivation of a protective function:

In order to activate or deactivate a protective function, it is possible to use 2 means:

- In the setpoint group General, find the appropriate name of the function (e.g. Overcurr Prot for

overcurrent protection stage) with the possible setting: ALLWAYS / PARALLEL / DISABLED.

To deactivate the complete protective stage in general, set this setpoint to DISABLED. To

activate the protective stage in general, set the setpoint either to PARALLEL to activate this

protective in case of both CB1 and CB2 are closed, or to ALWAYS to activate the function

permanently regardless of the circuit breakers status.

- In order to e.g. activate only one adjustable pickup used within a multiple-stages protective

function, set this pickup limit to zero. E.g. InteliPro allows setting 2 stages of overvoltage

protection. To use only V> and block the V>> stage, set the pickup limit V>> to 0V. In general,

setting of any pickup limit of any protective function blocks this protection stage.

- To operatively enable or disable a protective stage during regular operation of the unit, assign

the Block 1 and Block 2 inputs to the appropriate protective function. By activation and

deactivation of those inputs, enable or disable the appropriate protective stage. Enabling of a

protection stage is delayed by ProtActiv del after deactivation of the blocking input.

- It is possible, that in your unit, some optional protective functions are not activated. In such

case, the function is permanently blocked and even the setpoints related to it are not visible. In

case that this protection is requested, please consult your sales representative regarding the

options unlocking.

How to set-up trip outputs

To assign the appropriate trip outputs, which are operated by a particular protective stage, find the

setpoint group, which contains the setting of this protective stage. E.g. for overcurrent, go to the

setpoint group I>. In the setpoint group find the setpoint xxx Trp BO, where "xxx" is the abbreviation of

the protective stage. It is possible to use the following setting:

- None: neither Trp 1 nor Trp 2 is activated in case of this protective stage trip. In such case,

only the Comm Trp output contains information about trip by this protection stage.

- Trp 1: binary output Trp 1 is activated in case of this protection stage trip.

- Trp 2: binary output Trp 2 is activated in case of this protection stage trip.

- Trp 1+2: both binary output Trp 1 and Trp 2 are activated in case of this protection stage trip.

- In all cases, the Comm Trp output contains information about trip from all activated protection

stages.

How to set-up blocking inputs

To assign the appropriate Block inputs to enable or disable the particular protective stage, find the

setpoint group, which contains the setting of this protective stage. E.g. for overcurrent, go to the

setpoint group I>. In the setpoint group find the setpoint xxx Block BI, where "xxx" is the abbreviation

of the protective stage. It is possible to use the following setting:

- None: neither Block 1 nor Block 2 is used to enable or disable the protective stage.

- Block 1: binary input Block 1 is used to enable or disable the protective stage.

- Block 2: binary input Block 2 is used to enable or disable the protective stage.

- Block 1+2: both binary inputs Block 1 and Block 2 are used to enable/disable the protective

stage. The input signals are connected by logical OR function.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-7

Page 26

Protective functions in detail

Overvoltage, Undervoltage (ANSI 59, 27)

The RMS value of measured voltage is compared with the preset limit of overvoltage or undervoltage.

When any of the preset limits is over/underreached, the output U Sig moves to fault-indicating position

immediately. If the voltage of the given phase keeps out of limits for the delay of the appropriate stage,

TRIP is issued. As the voltage returns back within limits in all measured phases, the U Sig output stop

to signal the fault state immediately, regardless of whether TRIP was issued or not or Fault reset was

performed or not.

Both overvoltage and undervoltage protective stages provide possibility of setting 2 levels with

independent delay assigned to each level.

Overfrequency, Underfrequency (ANSI 81 H, L)

The frequency value measured on phase L1 is compared with the preset limit of overfrequency or

underfrequency. When any of the preset limits is over/underreached, the output f Sig moves to faultindicating position immediately. If the frequency keeps out of limits for the delay of the appropriate

stage, TRIP is issued. As the frequency returns back within limits, the f Sig output stops to signal the

fault state immediately, regardless of whether TRIP was issued or not or Fault reset was performed or

not.

Both overfrequency and underfrequency protective stages provide possibility of setting 2 levels with

independent delay assigned to each level.

Voltage unbalance (ANSI 47)

The voltage unballance is evaluated in case that amplitude difference between any 2 phases

overreaches the preset limit V Unb: V Unb. It refers to the amplitude unbalance of the measured

voltage.

"Loss of mains" protections

InteliPro provides two different methods for fast evaluation of loss of mains (LOM), into which the generator

operates:

- Vector shift

- Rate Of Change Of Frequency

The loss-of-mains protections setting is done using the setpoints in the group LOM.

Vector shift (ANSI 78)

Vector shift is one of the LOM protections. It provides very fast detection of mains failure (in units or

tens of ms), based on the principle of shift of the synchronous generator displacement angle. The

displacement angle is an angle between magnetic field of a rotor and the rotating magnetic field of the

stator winding and relates strongly to the load of the generator. In case that this load changes, the

displacement angle immediately changes by a "jump". Compared to the frequency decrease, which

probably also occurs, this jump is an immediate phenomena and is detected as a shift of the

measured voltage sine curve - Vector shift or Vector jump. Depending on the preset limit in degrees

[°], it allows immediate disconnection of very fast failures and thus prevention of severe damages

which could not be prevented within the delay of frequency or voltage protections.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-8

Page 27

Vector shift reaction times are usually requested up to 30ms. Typical setting is shown e.g. in G59/2

standard (see below).

Rate Of Change Of Frequency (df/dt, ROCOF, ANSI 81R)

ROCOF is second most frequently requested method of LOM detection. In principle, the method uses

similar evaluation method like Vector shift, but the physical phenomena detected is different. It

calculates the change of speed of the generator, caused by sudden change in its load, together with

unintentional islanding situation (loss of mains), which is normally capable of keeping the frequency on

a stable level. The frequency change is expressed as tangent in time [Hz/s]:

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-9

Page 28

It is a fast protection, similar to Vector shift, however, unlike Vector shift, which detects immediate

phenomena, the tangent calculation requires a certain time for evaluation. In ComAp protection relays,

the evaluation time for ROCOF protection can be adjusted in number of sine curve cycles being taken

into evaluation from 1 to tens of cycles (each having 20ms). This allows to set up the ratio between the

evaluation speed and sensitivity to nuisance trips.

Overcurrent: definite-time, IDMT and with voltage control

InteliPro provides three types of mains-overcurrent with different setting of the protection delay:

Definite time overcurrent (ANSI 50):

The trip is issued in a given delay after the current exceeds preset limit. The setting is done using the

setpoints

IDMT overcurrent (ANSI 51)

The IDMT (inverse definite minimum time) overcurrent provides delayed overcurrent trip, based on

calculation of the trip delay according to the trip curve:

in the group I>.

I> Del

The delay, i.e. the IDMT curve shape is prescribed by the DNO, based on the calculations of shortcircuit conditions in the point of the generator connection. The grid protections are coordinated and

allow for isolating the faults by the protections which are located closer to the short-circuit area. This

way, the discrimination of the breakdown point is done by the short-circuit current magnitude allowing

the generator to ride-through a distant faults and contribute to recover the mains voltage after the fault

is disconnected. The setting is done using the setpoints

The shape of IDMT curve can be selected using the parameter I> T: I> T Curve. If the option IDMT is

selected, the shape is given by the following formula:

in the group I> T.

I> Del *

The parameter I> T: I> T Curve allows also to set other switching curves according to the IEC

standards.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-10

Page 29

Time overcurrent with voltage control and restraint (ANSI 51V)

The voltage control of time overcurrent assures that the protection is blocked in case that the

measured voltage is above the level set by the setpoint I> V: I> V Control.

The voltage restraint function is a modification of the IDMT overcurrent protection. It uses the same

mechanism of the delay calculation according to the IDMT trip curve, but the delay is further adjusted

according to the measured voltage:

This protection functionality uses the fact that voltage in the point of short-circuit drops to zero or very

low values and with growing distance from the fault, it increases up to the mains nominal voltage

value. Thus, increased sensitivity to the short-circuits localization and protection coordination is

provided. The setting is done using the setpoints

in the group I> V.

Neutral overcurrent (ANSI 50N, ANSI 51N)

To allow measurement of the neutral overcurrent, the plug-in module Relay Card CT2-REL2 is

necessary. The protection stage allows to set up instantaneous neutral overcurrent or IDMT

overcurrent, similar to the mains overcurrent protective functions. The setting is done using the

setpoints group EFC.

Current unbalance (ANSI 46)

The current unbalance protection is used to avoid unballanced load in the point of mains connection.

The setting is done using the setpoints in the setpoint group I Unb.

Directional overcurrent (DOC, ANSI 67)

DOC is sensitive for location of the fault with relation to the measurement point. This way, directional

protection is capable to detect whether the fault happened "in front of it" or "behind". Directional

overcurrent protection, applied in the point of generator connection to mains, is considered a loss of

mains protection, however it does not substitute the traditional loss of mains protections like Vector

shift or ROCOF. The typical application is a generator running in parallel to mains with its own load

consumption (e.g. peak shaving, soft transfer stand-by, or other applications). The generator is usually

used to support the local consumption with no export to the mains. In case of mains transition into an

island mode, the generators, running in parallel with the islanded area, would start to supply its

complete consumption, generating current in opposite direction. DOC protection is used to avoid this

situation, and trip the generator from the islanded mains, combining the overcurrent protection

together with its directional character. Compared to the "reverse power protection", DOC protection

detects also reactive currents from the given angle zone, what allows better sensitivity for tripping.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-11

Page 30

The following image shows the conditions of activation of Directional Overcurrent protection in

InteliPro – i.e. critical angles between voltage and current, given the voltage is placed at the 0°angle:

90°

150°

0°

DOC>

Base angle

-135°

The setting is done using the setpoints in the group DOC.

Trip area

-60°

-90°

Neutral Voltage Displacement (NVD, ANSI 59N)

NVD protective function is used in medium or high voltage systems with isolated or indirectly grounded

zero-point. Under healthy conditions of the system, the sum of the three phase-to-earth voltages

should balance to zero. When an earth-fault occurs, it does not cause a short-circuit, because of the

isolation of the system in the zero point. However, the fault provides connection of one phase with

earth what represents hazard for the system safety (ground-fault in any other phase would then mean

a phase-to phase short-circuit, phase-to-ground voltage of the other phases may fluctuate to multiples

of its nominal, providing increased stress to the isolation system, etc). One of the effects of the fault is

a rise in the neutral voltage, so called neutral voltage displacement. This neutral voltage displacement

is measured in a specific "open-delta" connection of voltage transformers, shown in the chapter

Voltage and current inputs. In some cases, it is required to clear the fault by tripping the appropriate

circuit breaker. However, the NVD protection itself does not allow detecting the location of a fault and

for this reason it is sometimes used only for providing an earth-fault alarm.

It is possible to set whether the NVD contributes to the common trip of the relay or uses its own

separate output for signalization of the NVD alarm. The setting is done using the setpoints in the group

NVD.

Directional power (ANSI 32)

InteliPro provides two stages of power protections, both of them allowing setting of either overreaching

the preset limit or underreaching it. This way, all of the following protections are realized:

- Mains reverse power (protection of unintentional export)

- Generator reverse power (protection of motoric operation)

- Minimum import underreaching (timely trip in case of unintentional export approaching)

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-12

Page 31

The setting is done using the setpoints in the group P<>.

Synchro check (ANSI 25)

This function checks state of synchronism at both sides of the circuit breaker. It is used as a

supplementary function to automatic reconnecting of the other functions to assure that the

synchronous conditions are met before the circuit breaker closes back by the protection relay, or is

unblocked to be closed by some other device. In InteliPro, either L1-L2 phase-to-phase voltage or L1N phase-to-neutral voltage is measured on the generator side of the circuit breaker and compared with

the corresponding measured mains voltage. Whether phase-to-phase or phase-to-neutral voltage is

used is decided by the setpoint Basic Settings: Voltage Setup. Synchronous conditions are evaluated

based on the preset window of voltage, frequency and angle match as set in the setpoint group Sync

Check.

AC reclosing (ANSI 79)

The automatic reclosing mechanism is generally used in situation, where temporary nature of the

failure is expected. The protection relay trips the breaker according to the standard protection settings.

As soon as the trip conditions disappear, i.e. the protection senses fault-free situation, the tripping

output deactivates and after a reclosing delay, the reclosing output issues a signal to automatically

reclose the breaker. There may be several reclosure attempts done in case of unsuccessful reclosure

cycle. The setting is done using the setpoints in the group AC Reclosing.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Application Guide

2-13

Page 32

InteliPro

Protection Relay for Parallel Applications

Application Guide

SW version 1.0, May 2011

Communication Brochure

Copyright © 2011 ComAp s.r.o.

Written by Tomas Jelen

Prague, Czech Republic

ComAp, spol. s r.o.

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 246 316 647

E-mail: info@comap.cz, www.comap.cz

Page 33

Table of contents

CAN bus and RS485 ............................................................................................................................... 2

Recommended CAN/RS485 connection............................................................................................. 4

CAN bus connection ....................................................................................................................... 4

RS485 connection........................................................................................................................... 4

Communication modules......................................................................................................................... 6

IL-NT-232 ............................................................................................................................................ 6

IL-NT-RS232-485................................................................................................................................6

IL-NT-S-USB ....................................................................................................................................... 7

IB-Lite .................................................................................................................................................. 7

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Communication Brochure

3-2

Page 34

CAN bus and RS485

For wiring of CAN bus communication, the following rules are to be maintained:

• Maximal length of the CAN bus depends on the communication speed. For the speed of

250kbps, which is used on the CAN1 bus (extension modules) and CAN2 bus if it is switched

to 32C mode the maximal length is 200m. If the CAN2 bus is switched to 8C mode by the

setpoint Comms settings: CAN Bus Mode, the speed is 50kbps and the maximal length is

800m.

• The bus must be wired in linear form with termination resistors at both ends. No nodes except

on the controller terminals are allowed. Use cable with following parameters:

Cable type Shielded twisted pair

Impedance 120Ω

Propagation velocity >= 75% (delay <= 4.4 ns/m)

Wire crosscut >= 0.25mm2

Attenuation (@1MHz) <= 2dB/100m

CAN BUS TOPOLOGY

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Communication Brochure

3-3

Page 35

NOTE:

See the web page www.can-cia.org for information about CAN bus, specifications etc.

Recommended CAN/RS485 connection

CAN bus connection

The bus has to be terminated by 120 Ohm resistors at both ends. External units can be connected on

the CAN bus line in any order, but keeping line arrangement (no tails, no star) is necessary. Standard

maximum bus length is 200m for 32C CAN BUS MODE and 900m for 8C CAN BUS MODE. Shielded

cable has to be used, shielding has to be connected to PE on one side (controller side).

1. For shorter distances (all network components within one room) – picture 1

Interconnect H and L; shielding connect to PE on controller side

2. For longer distances (connection between rooms within one building) – picture 2

Interconnect H, L, COM; shielding connect to PE in one point

3. In case of surge hazard (connection out of building in case of storm etc.) – picture 3

We recommend to use following protections:

• Phoenix Contact (http://www.phoenixcontact.com

(base element)

• Saltek (http://www.saltek.cz

): DM-012/2 R DJ

): PT 5-HF-12DC-ST with PT2x2-BE

Recommended data cables: BELDEN (http://www.belden.com

1. For shorter distances: 3105A Paired - EIA Industrial RS-485 PLTC/CM (1x2 conductors)

2. For longer distances: 3106A Paired - EIA Industrial RS-485 PLTC/CM (1x2+1 conductors)

3. In case of surge hazard: 3106A Paired - EIA Industrial RS-485 PLTC/CM (1x2+1 conductors)

)

RS485 connection

The line has to be terminated by 120 Ohm resistors at both ends. External units can be connected on

the RS485 line in any order, but keeping line arrangement (no tails, no star) is necessary. Standard

maximum link length is 1000m. Shielded cable has to be used, shielding has to be connected to PE on

one side (controller side).

1. For shorter distances (all network components within one room) – picture 1

interconnect A and B; shielding connect to PE on controller side

2. For longer distances (connection between rooms within one building) – picture 2

interconnect A, B, COM; shielding connect to PE in one point

3. In case of surge hazard (connection out of building in case of storm etc.) – picture 3 We

recommend to use following protections:

• Phoenix Contact (http://www.phoenixcontact.com

(base element)(or MT-RS485-TTL)

• Saltek (http://www.saltek.cz

Recommended data cables: BELDEN (http://www.belden.com

): DM-006/2 R DJ

): PT 5-HF-5DC-ST with PT2x2-BE

)

1. For shorter distances: 3105A Paired - EIA Industrial RS-485 PLTC/CM (1x2 conductors)

2. For shorter distances: 3105A Paired - EIA Industrial RS-485 PLTC/CM (1x2 conductors)

3. In case of surge hazard: 3106A Paired - EIA Industrial RS-485 PLTC/CM (1x2+1 conductors)

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Communication Brochure

3-4

Page 36

PICTURE 1 - SHORTER DISTANCES (ALL NETWORK COMPONENTS WITHIN ONE ROOM)

PICTURE 2 - LONGER DISTANCES (CONNECTION BETWEEN ROOMS WITHIN ONE BUILDING)

ICTURE 3 - SURGE HAZARD (CONNECTION OUT OF BUILDING IN CASE OF STORM ETC.)

P

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Communication Brochure

3-5

Page 37

Communication modules

Communication module enables connection of a remote computer or other remote device such as

PLC to InteliPro. The module is to be plugged-in into the slot in the rear side of InteliPro. The slot is

accessible after slot cover is removed.

SLOT FOR COMMUNICATION MODULES

NOTE:

The modules are compatible with ComAp IL-NT and IC-NT controllers.

IL-NT-232

This module contains a RS232 port with all modem signals connected internally to the COM1 of the

controller. DB9M connector is used on the RS232 side.

RS232 PINOUT AND CABLE WIRING

IL-NT-RS232-485

The IL-NT-232-485 is a dual port module with RS232 and RS485 interfaces at independent COM

channels. The RS232 is connected to COM1 and RS485 to COM2.

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Communication Brochure

3-6

Page 38

IL-NT-RS232-485 MODULE

IL-NT-S-USB

This module contains USB slave port connected internally to the COM1 of the controller and is

designed as an easy removable service module.

This module requires a FTDI USB Serial converter driver installed in the PC. The driver creates a

virtual serial port (COM) in the PC, which must be used in LiteEdit as communication port when a

connection is beeing opened.

NOTE:

The FTDI driver is installed together with LiteEdit.

NOTE:

When the USB cable from the controller is plugged-in first time into different USB ports on the PC

including USB hubs, it can be recognized as new hardware and the drivers are installed again with

different number of the virtual serial port.

CAUTION!

Use shielded USB cable only!

IB-Lite

IB-Lite is a plug-in module with Ethernet 10/100 Mbit interface in RJ45 connector. The module is

internally connected to both COM1 and COM2 serial channels and provides an interface for

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Communication Brochure

3-7

Page 39

connecting a PC with LiteEdit or InteliMonitor through ethernet/internet network, for sending active emails and for integration of the controller into a building management (Modbus/TCP protocol).

IB-LITE MODULE

Use Ethernet UTP cable with RJ45 connector for connection of the module into your ethernet network.

The module can be also connected directly to a PC using cross-wired UTP cable.

C

ROSS-WIRED UTP CABLE

For more detail about communication of ComAp products, see the IL-NT, IA-NT, IC-NT

Communication Guide as published on ComAp download centre

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Communication Brochure

.

3-8

Page 40

InteliPro

Protection Relay for Parallel Applications

Reference Guide

SW version 1.0, May 2011

Reference Guide

Copyright © 2011 ComAp s.r.o.

Written by Tomas Jelen

Prague, Czech Republic

ComAp, spol. s r.o.

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 246 316 647

E-mail: info@comap.cz, www.comap.cz

Page 41

Table of contents

Library of binary inputs ............................................................................................................................ 2

Binary alarm and functional input configuration items.................................................................... 7

Alarm............................................................................................................................................... 7

CB1 Feedback ................................................................................................................................8

CB2 Feedback ................................................................................................................................8

F.R. Button...................................................................................................................................... 8

DC TripCircuit ................................................................................................................................. 8

Access Lock.................................................................................................................................... 8

External Trip.................................................................................................................................... 8

Block 1, Block 2 .............................................................................................................................. 8

Library of binary output functions ............................................................................................................ 9

Common Alarm............................................................................................................................... 9

Comm Trp ....................................................................................................................................... 9

!Comm Trp ...................................................................................................................................... 9

Bak Comm Trp................................................................................................................................9

!Bak Comm Trp............................................................................................................................... 9

Del Comm Trp................................................................................................................................. 9

!Del Comm Trp................................................................................................................................9

Trp 1................................................................................................................................................ 9

! Trp 1............................................................................................................................................ 10

Bak Trp 1 ...................................................................................................................................... 10

!Bak Trp 1 ..................................................................................................................................... 10

Trp 2.............................................................................................................................................. 10

! Trp 2............................................................................................................................................ 10

Bak Trp 2 ...................................................................................................................................... 10

!Bak Trp 2 ..................................................................................................................................... 10

U<> Prot........................................................................................................................................ 10

f<> Prot ......................................................................................................................................... 10

V Unb Protection........................................................................................................................... 10

PhaseRot Prot............................................................................................................................... 10

VectorS Prot.................................................................................................................................. 10

ROCOF Prot ................................................................................................................................. 11

DOC Prot ...................................................................................................................................... 11

P Prot ............................................................................................................................................ 11

I> Prot ........................................................................................................................................... 11

NVD Prot....................................................................................................................................... 11

!NVD Prot...................................................................................................................................... 11

EFC Prot ....................................................................................................................................... 11

IGS Prot ........................................................................................................................................ 11

I Unb Prot...................................................................................................................................... 11

DC Healthy.................................................................................................................................... 11

Watchdog...................................................................................................................................... 11

MaxParTime.................................................................................................................................. 11

!MaxParTime................................................................................................................................. 11

U Sig ............................................................................................................................................. 11

f Sig............................................................................................................................................... 11

U Unb Sig...................................................................................................................................... 12

LOM Sig ........................................................................................................................................ 12

I> Sig............................................................................................................................................. 12

I Unb Sig ....................................................................................................................................... 12

DOC Sig........................................................................................................................................ 12

DOC Test ...................................................................................................................................... 12

EFC Sig......................................................................................................................................... 12

IGS Sig.......................................................................................................................................... 12

NVD Sig ........................................................................................................................................ 12

P Sig ............................................................................................................................................. 13

Sync Check................................................................................................................................... 13

InteliPro, SW version 1.0, ©ComAp – May 2011

InteliPro Reference Guide

4-2

Page 42

AC Reclosing ................................................................................................................................13

CB1 Protection.............................................................................................................................. 13

CB2 Protection.............................................................................................................................. 13

Self Test........................................................................................................................................ 13

AL AIx Wrn/Trp, AL IOM AIx Wrn/Trp........................................................................................... 13

AIx Wrn/Trp Sig, IOM AIxWrn/Trp Sig .......................................................................................... 13

AL Aux Volt ................................................................................................................................... 13

AL Common Wrn .......................................................................................................................... 14

AL Common Fls ............................................................................................................................ 14

BIx Status, IOM BIx Status ........................................................................................................... 14

Library of setpoints ................................................................................................................................15

Basic Settings.................................................................................................................................... 15

ControllerName............................................................................................................................. 15

Mains CT Ratio [A/5A] ............................................................................................................... 15

EF CT Ratio [A/5A] .................................................................................................................. 15

Mains PT Ratio [V/V] ................................................................................................................. 15

NomVolts Ph-N [V] .................................................................................................................... 15

NomVolts Ph-Ph [V]................................................................................................................... 15

Nominal Freq [Hz]...................................................................................................................... 16

NominMainsPwr [kW] ................................................................................................................ 16

Voltage Setup [ Ph To N / Ph To Ph ]........................................................................................ 16

CB1 Prot Timer [s] ..................................................................................................................... 16

CB2 Prot Timer [s] ..................................................................................................................... 16

Comms Settings................................................................................................................................16

Contr. Addr.................................................................................................................................... 16

COM1 Mode [ DIRECT / MODEM / MODBUS ]....................................................................... 16

COM2 Mode [ DIRECT / MODEM / MODBUS ]....................................................................... 17

ModemIniString............................................................................................................................. 17

ModbusComSpeed [ 9600 / 19200 / 38400 / 57600 bps ]......................................................... 17

CAN Bus Mode [ 32C / 8C ] ...................................................................................................... 17

IBLite IP Addr................................................................................................................................17

IBLite NetMask.............................................................................................................................. 17

IBLite GateIP................................................................................................................................. 17