Page 1

Copyright © 2015 ComAp a.s.

ComAp a.s..

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 266 790 611, Fax: +420 266 316 647

Technical support hotline: +420 266 790 666

E-mail: info@comap.cz, www.comap.cz

Compact Controller for Stand-by and Parallel Operating Gen-sets

Inteli New Technology

Modular Generator Controller

Multiple Internal engines application – SW configuration

SPI

IG-NT GC, IG-NTC GC, IS-NT, IG-NT-BB, IG-NTC-BB, IS-NTC-BB

Software version IGS-NT-GeCon-MARINE-3.2, July 2015

REFERENCE GUIDE

Page 2

2

Table of Contents

Table of Contents ............................................................................................................................................... 2

General guidelines .............................................................................................................................................. 4

What is described in this manual? ................................................................................................................. 4

Dangerous voltage ......................................................................................................................................... 5

Adjust set points ............................................................................................................................................. 5

Clarification of notation ................................................................................................................................... 5

Available Firmware and Archive sets ................................................................................................................. 6

General description ............................................................................................................................................ 7

Description of the controller system (with all options) .................................................................................... 7

Comparing of IGS-NT-GeCon-MARINE 3.2 with standard gen-set fw .......................................................... 7

Available documentation ................................................................................................................................ 7

Example of interconnection GeCon x Engine controller ..................................................................................... 9

Functions .......................................................................................................................................................... 11

Basic description of SPI application ............................................................................................................. 11

Modified setpoints ........................................................................................................................................ 12

Controller modes .......................................................................................................................................... 13

Mains parameters out of limits during synchronising ................................................................................... 17

Active Power control modes in SPI .............................................................................................................. 17

PF control modes ......................................................................................................................................... 18

Load shedding .............................................................................................................................................. 19

Test on load – SPtM ..................................................................................................................................... 21

Power derating ............................................................................................................................................. 22

Protection mode settings .............................................................................................................................. 22

Circuit breakers operation sequence, GCB/MCB fail detection ................................................................... 23

External breaker control ............................................................................................................................... 29

Peak shaving based on Active and Apparent power ................................................................................... 29

Remote Alarm Messaging ............................................................................................................................ 30

Variable speed support ................................................................................................................................ 31

Force value – step by step guide ................................................................................................................. 32

Values for continuous writing from external sources ................................................................................... 34

User Buttons................................................................................................................................................. 34

User Mask function ...................................................................................................................................... 35

Remote Control Function ............................................................................................................................. 36

Virtual Peripheral Inputs-Outputs (VPIO) module ........................................................................................ 37

Shared Inputs and Outputs .......................................................................................................................... 37

Distributed Binary Inputs and Outputs ......................................................................................................... 39

Modbus Reading and Writing ....................................................................................................................... 40

User MODBUS ............................................................................................................................................. 40

Modbus Switches ......................................................................................................................................... 41

Power Formats ............................................................................................................................................. 41

PLC functions ............................................................................................................................................... 41

Multi language support ................................................................................................................................. 42

ECU interface customizing ........................................................................................................................... 42

Volt/PF control adjustment ........................................................................................................................... 42

Sync/load control adjustment ....................................................................................................................... 44

Protections and Alarm management ................................................................................................................ 47

Gen-set operation states .................................................................................................................................. 57

Inputs and Outputs ........................................................................................................................................... 58

Virtual and physical modules ....................................................................................................................... 58

Analog outputs ............................................................................................................................................. 58

Setpoints ........................................................................................................................................................... 60

ProcessControl ............................................................................................................................................. 60

Basic settings ............................................................................................................................................... 67

Comms settings............................................................................................................................................ 72

Delays/Timers .............................................................................................................................................. 78

Analog protect .............................................................................................................................................. 81

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 3

3

Gener protect ............................................................................................................................................... 83

Mains protect ................................................................................................................................................ 90

AMF settings ................................................................................................................................................ 92

Sync/Load ctrl............................................................................................................................................... 93

Volt/PF ctrl .................................................................................................................................................... 97

Force value ................................................................................................................................................... 99

Load shedding ............................................................................................................................................ 101

Timer settings ............................................................................................................................................. 103

Act. calls/SMS ............................................................................................................................................ 104

Date/Time ................................................................................................................................................... 107

Table of values ............................................................................................................................................... 108

Group: Gener values .................................................................................................................................. 108

Group: Mains values .................................................................................................................................. 115

Group: Sync/Load ctrl ................................................................................................................................ 120

Group: Volt/PF ctrl ...................................................................................................................................... 121

Group: Force value .................................................................................................................................... 121

Group: Load shedding ................................................................................................................................ 123

Group: Analog CU ...................................................................................................................................... 123

Group: Bin inputs CU ................................................................................................................................. 125

Group: Bin outputs CU ............................................................................................................................... 125

Group: Log Bout ......................................................................................................................................... 125

Group: Info ................................................................................................................................................. 129

Group: Statistics ......................................................................................................................................... 136

Table of binary input functions........................................................................................................................ 140

Table of analog input functions ...................................................................................................................... 177

Table of binary output functions ..................................................................................................................... 187

Controller configuration and monitoring ......................................................................................................... 222

Direct connection to the PC ....................................................................................................................... 222

GenConfig functions ................................................................................................................................... 222

InteliMonitor ................................................................................................................................................ 223

Modbus protocol ......................................................................................................................................... 223

Value and setpoint codes ........................................................................................................................... 223

Technical data ............................................................................................................................................ 223

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 4

4

General guidelines

Following described machine complies with the appropriate basic safety and health

requirement of the EC Low Voltage Directive No: 73/23 / EEC and EC

Electromagnetic Compatibility Directive 89/336 / EEC based on its design and type,

as brought into circulation by us.

What is described in this manual?

This manual describes IGS-NT -GeCon-MARINE- „MINT“ software configuration. The Generator controller

software configuration is designed for multiple sets applications with internal load sharer and synchronizer.

What is the purpose of this manual?

This manual provides general information on how to configure and operate the controller.

This manual is intended for use by:

Operators of gen-sets/generators

Gen-set/generator control panel builders

For everybody who is concerned with installation, operation and maintenance of the genset/generator

!! Warnings !!

Remote control

The IGS-NT controller can be remotely controlled. In case that maintenance needs to be done to the genset, check the following to ensure that the engine cannot be started.

To be sure:

Disconnect remote control via RS232 line

Disconnect input REMOTE START/STOP

or

Disconnect output STARTER and output GCB CLOSE/OPEN

The controller contains a large number of configurable setpoints, because of this it is impossible to describe

all of its functions. These are subject to change from SW version to SW version. This manual only describes

the product and is not guaranteed to be set for your application on arrival.

Text

PAGE (Capital letters in the frame) buttons on the front panel

Break Return (Italic) set points

Generator protections (Bold) Set point group

REMOTE START/STOP (Capital letters) binary inputs and outputs

Cyan background Valid for IS-NT only

Conformity declaration

Note:

ComAp believes that all information provided herein is correct and reliable and reserves the right to update

at any time. ComAp does not assume any responsibility for its use unless otherwise expressly undertaken.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 5

5

Be aware that the binary outputs can change state during and after software

reprogramming (before the controller is used again ensure that the proper

configuration and setpoint settings are set in the controller)!!!

Be aware that gen-set can automatically or remotely start !!!

Switch the controller to SEM mode and disconnect the Binary outputs Starter and Fuel

to avoid unexpected automatic start of gen-set and GCB closing.

!!! CAUTION !!!

Dangerous voltage

The terminals for voltage and current measurement should never be touched.

Properly connect the grounding terminals.

Do not disconnect the CT terminals for any reason.

Adjust set points

All setpoints are preadjusted to their typical values. But the set points in the “Basic settings” settings

group !!must!! be adjusted before the first startup of the gen-set.

!!! WRONG ADJUSTMENT OF BASIC PARAMETERS

CAN DESTROY THE GEN-SET !!!

The following instructions are for qualified personnel only. To avoid personal injury do

not perform any action not specified in this User guide !!!

WARNING – VERY IMPORTANT !!!

Clarification of notation

HINT

This type of paragraph points out details to help user installation/configuration.

NOTE:

This type of paragraph calls readers’ attention to a notice or related theme.

CAUTION!

This type of paragraph highlights a procedure, adjustment, etc. which may cause damage or improper

functioning of the equipment if not carried out correctly and may not be clear at first sight.

WARNING!

This type of paragraph indicates things, procedures, adjustments, etc. which demand a high level of

attention, otherwise personal injury or death may occur.

EXAMPLE:

This type of paragraph indicates examples of usage for illustrational purposes.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 6

6

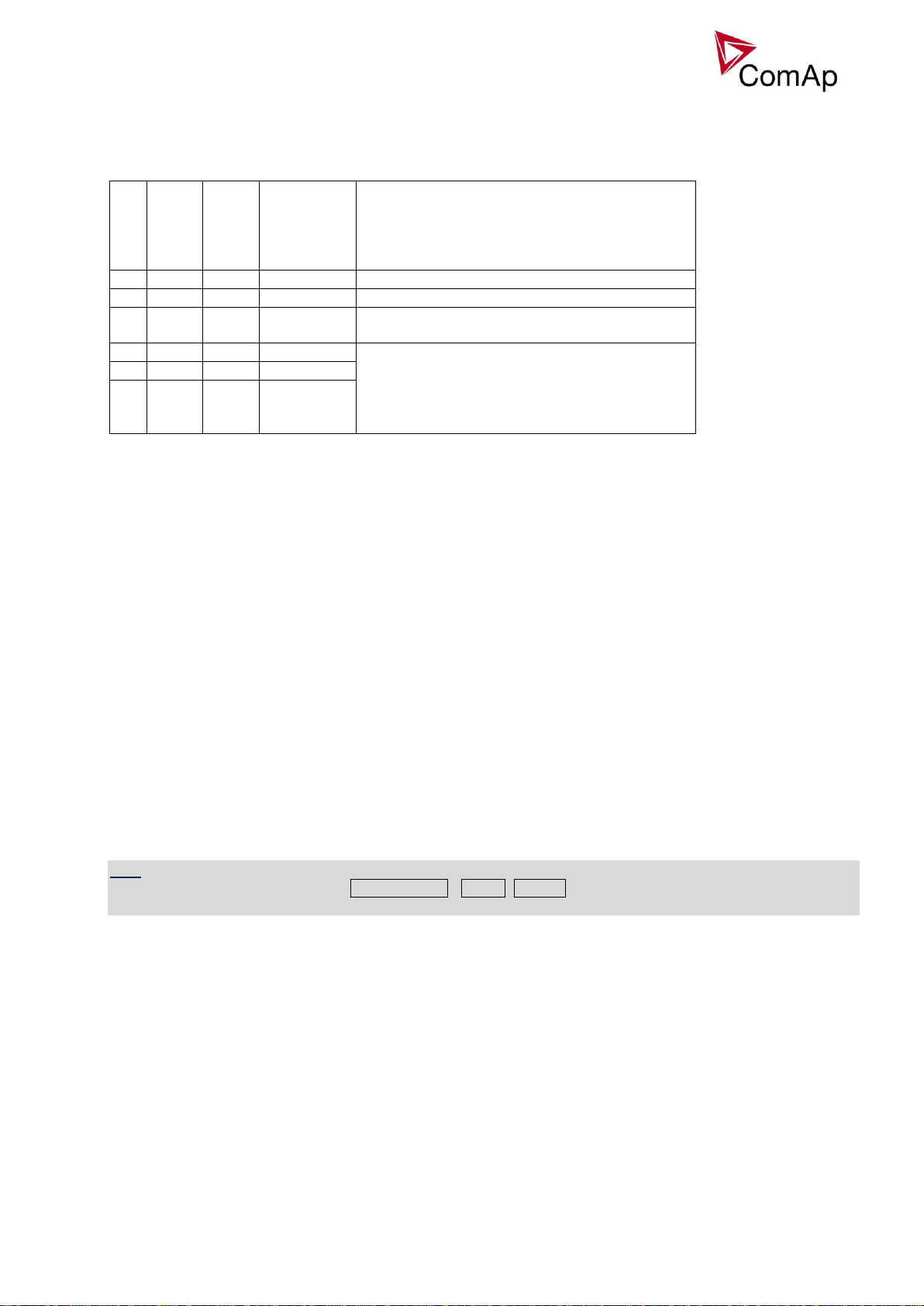

Available Firmware and Archive sets

InteliGen NT GC

InteliGen NTC GC

InteliGen NT BaseBox

InteliGen NTC BaseBox

InteliSys NT BaseBox

InteliSys NTC BaseBox

IG-NT-GC-GeCon-MARINE-3.2

IG-NT-BB-GeCon-MARINE-3.2

IS-NT-GeCon-MARINE-3.2

InteliGen NT GC

InteliGen NTC GC

InteliGen NT BaseBox

InteliGen NTC BaseBox

InteliSys NT BaseBox

InteliSys NTC BaseBox

IG-GC-GeCon-MARINE -SPTM-

3.2

IG-BB-GeCon-MARINE -SPTM-

3.2

IS- GeCon-MARINE-SPTM-3.2

IG-GC-GeCon-MARINE -SPI-

3.2

IG-BB-GeCon-MARINE -SPI-3.2

IS- GeCon-MARINE-SPI-3.2

IG-GC-GeCon-MARINE -MINT-

3.2

IG-BB-GeCon-MARINE -MINT-

3.2

IS- GeCon-MARINE-MINT-3.2

IG-GC-GeCon-MARINE -

COMBI-3.2

IG-BB-GeCon-MARINE -

COMBI-3.2

IS- GeCon-MARINE-COMBI-3.2

For suitable firmware for your controller please consult this table:

Firmware (*.mhx)

Archives (*.ant)

Some features are available only in InteliGen NT Basebox, InteliGen NTC Basebox and InteliSys NT. These

features are highlighted by green background.

Features which are not available in InteliGenNT GC controller:

User MODBUS

Distributed Binary Inputs and Outputs

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 7

7

General description

PDF FILE

DESCRIPTION

IGS-NT & ID-DCU Accessory Modules 02-

2015.pdf

Thorough description of accessory modules for IGS-NT

family, technical data, information about installation of the

modules, how to connect them to controller and set them

properly.

IGS-NT Troubleshooting Guide 08-2014.pdf

How to solve most common troubles with InteliGen NT and

InteliSys NT controllers. Including the list of alarm massages.

IGS-NT Communication Guide 09-2014.pdf

Communication guide for IG/IS-NT controllers. It contains

information how to connect control unit and all

communication features descriptions

IGS-NT Installation Guide 08-2014.pdf

Installation guide for IG/IS-NT controllers. It contains

technical information about controler and extension modules

IGS-NT Application Guide 05-2013.pdf

Application guide for IG/IS-NT controllers. It refers to

application and typical installation settings and sites

structures

Description of the controller system (with all options)

NT Family controllers are comprehensive AMF-controllers for single and multiple generating sets operating

in stand-by or parallel modes. A modular construction allows upgrades to different levels of complexity in

order to provide the best solution for various customer applications.

NT Family controllers are equipped with a powerful graphic display showing icons, symbols and bar-graphs

for intuitive operation, which sets, together with high functionality, new standards in Gen-set controls.

The controller automatically starts the gen-set, closes the Gen-set C.B. when all conditions are met, then

stops the engine* (* sw GeCon opens GCB only, not stops the engine) on external signal or by pressing

push buttons.

Parallel to the Mains operation is a standard feature. Isolated parallel and Power Management System

support are optional. Forward and reverse synchronizing, Generator protections, Mains protection including

vector shift, load and power factor control are the major functions provided. Interfacing to foreign

synchronizers and load sharers is supported.

The key feature of the controller is its easy-to-use operation and installation. Predefined configurations for

typical applications are available as well as user-defined configurations for special applications.

Comparing of IGS-NT-GeCon-MARINE 3.2 with standard gen-set fw

GeCon does not take care of Engine control

GeCon accepts in SEM mode external control of GCB and Engine

GeCon can control the engine via Binary start/stop output signals only – see below. The independent Engine

controller (e.g. ID-DCU) is expected.

Synchronizing and unloading timeouts can be disabled by setpoint setting (or Force value function)

All regulations (load, VAr sharing, frequency, voltage) can be disabled by setpoint change or by Force value.

Interface GeCon to engine controller is provided by I/O wires no by communication line.

Available documentation

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 8

8

IGS-NT Operator Guide 01-2014.pdf

Operator guide for IG/IS-NT

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 9

9

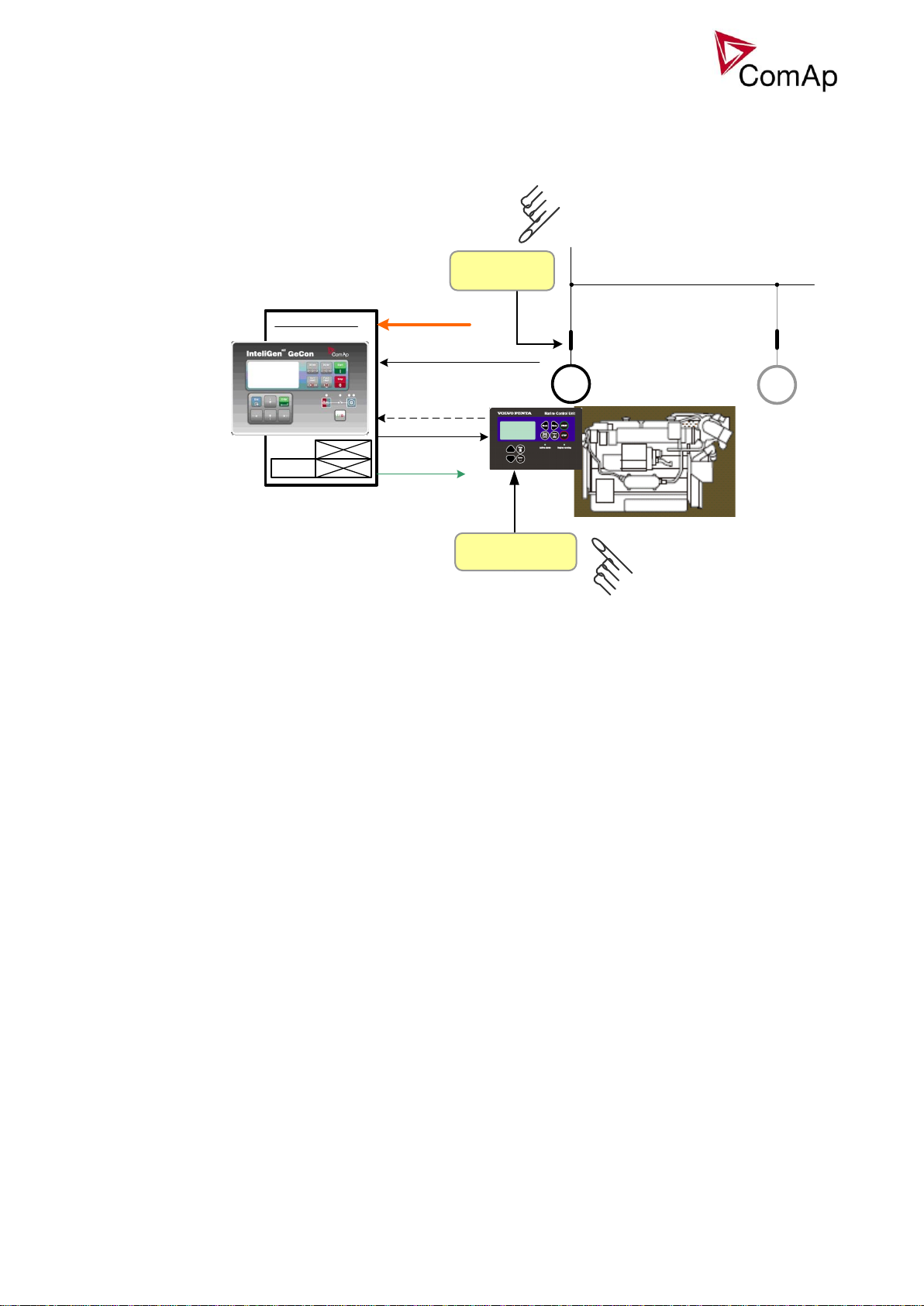

Example of interconnection

GeCon x Engine controller

Schematic wiring:

Important signals/ interconnections:

From GeCon side:

BO: Start pulse, Stop pulse - for sending Start and Stop signals

Speed control (during synchronisation, regulation):

BO: Speed Up, Speed Down or Aout SG out

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 10

10

BI: ReadyToLoad – signal from Engine unit – it means that Engine is ready (speed is ok, no 2nd level

alarms) and can be loaded.

Other signals:

- Information about Warnings / SD in one unit can be sent to second unit.

- ECU – in case of Ecu communicating via CAN bus J1939 – GeCon can be connected to CAN1 for

showing ECU values on the display

- Interconnection on CAN2:

o For Time and Date synchronisation only- in case of IGS-NT and ID-DCU

o In case of connection IB-NT or I-LB+ - you can monitor both kind of units (IGS-NT, ID-DCU)

o In case of connection display – you can switch between both kind of units (IGS-NT, ID-DCU)

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 11

11

Functions

Basic description of SPI application

The SPI application is intended for single gen-sets and includes following main features:

Automatic startup and stop sequences with adjustable timing

Wide range of generator and engine protections, additional freely configurable protections

Parallel to the mains operation, many different load control modes (baseload, import/export control

and other)

Island operation

Integrated mains protection (mains decoupling relay) including vector shift

One breaker control (GCB) including synchronizing

MCB position sensing

Soft loading and unloading

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 12

12

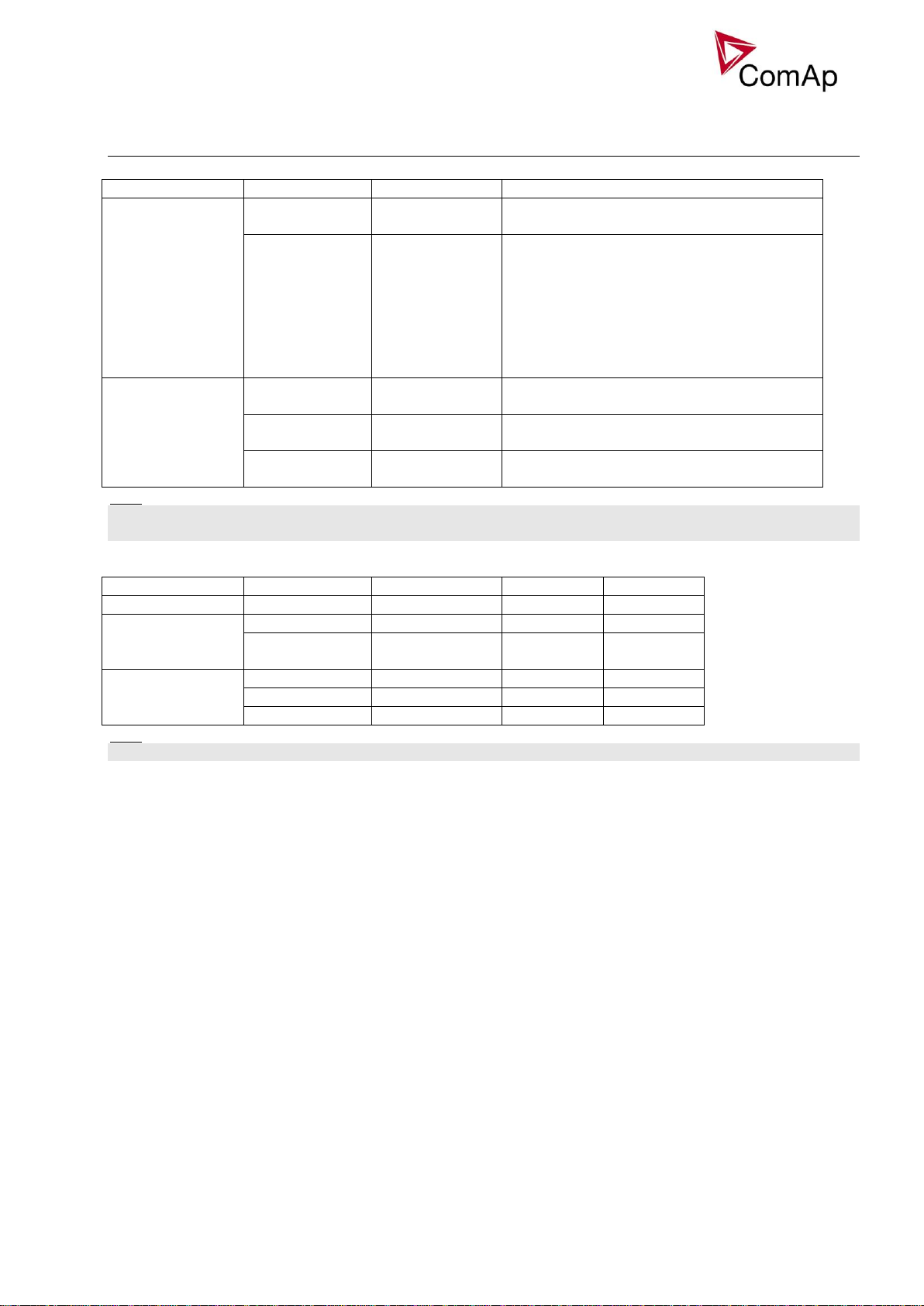

Modified setpoints

Group

Setpoint

Option

Function

Process control

StartStopBtn

ENABLED

DISABLED

Standard panel Start/Stop buttons function.

Panel Start/Stop buttons are disabled.

ProtectionMode

ACTIVE

NOT ACTIVE

ACTIVE:

2-nd level protections are evaluated, GCB

or MCB is controlled.

NOT ACTIVE:

2-nd level protections are evaluated, GCB

or MCB is NOT opened.

Exceptions are Emerg Stop and alarms

types Sdoverride.

Sync/Load ctrl

Sync timeout

1-1800s

NO TIMEOUT

Standard MINT function.

Unlimited synchronizing time.

GCB open level

1-100%

NO LEVEL

Standard MINT function.

No generator power open level detection.

GCB open del

1-1800s

NO TIMEOUT

Standard MINT function.

Unlimited unloading procedure.

“HAND”

SEM

AUT

Basic setting

ControllerMode

SEM

SEM

AUT

Process control

StartStopBtn

DISABLED

ENABLED

ENABLED

ProtectionMode

NOT ACTIVE

/ACTIVE

ACTIVE

ACTIVE

Sync/Load ctrl

Sync timeout

NO TIMEOUT

1-1800s

1-1800s

GCB open level

NO LEVEL

1-100%

1-100%

GCB open del

NO TIMEOUT

1-1800s

1-1800s

Below mentioned are GeCon specific setpoints only.

Hint:

All above mentioned setpoints can be Forced by Binary input(s) to another value (or switched between

ENABLED and DISABLED).

Based on setpoint settings there are three possible operational modes HAND – SEM - AUT:

Hint:

It is possible to configure (Force value) “HAND” – SEM switching via Binary input.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 13

13

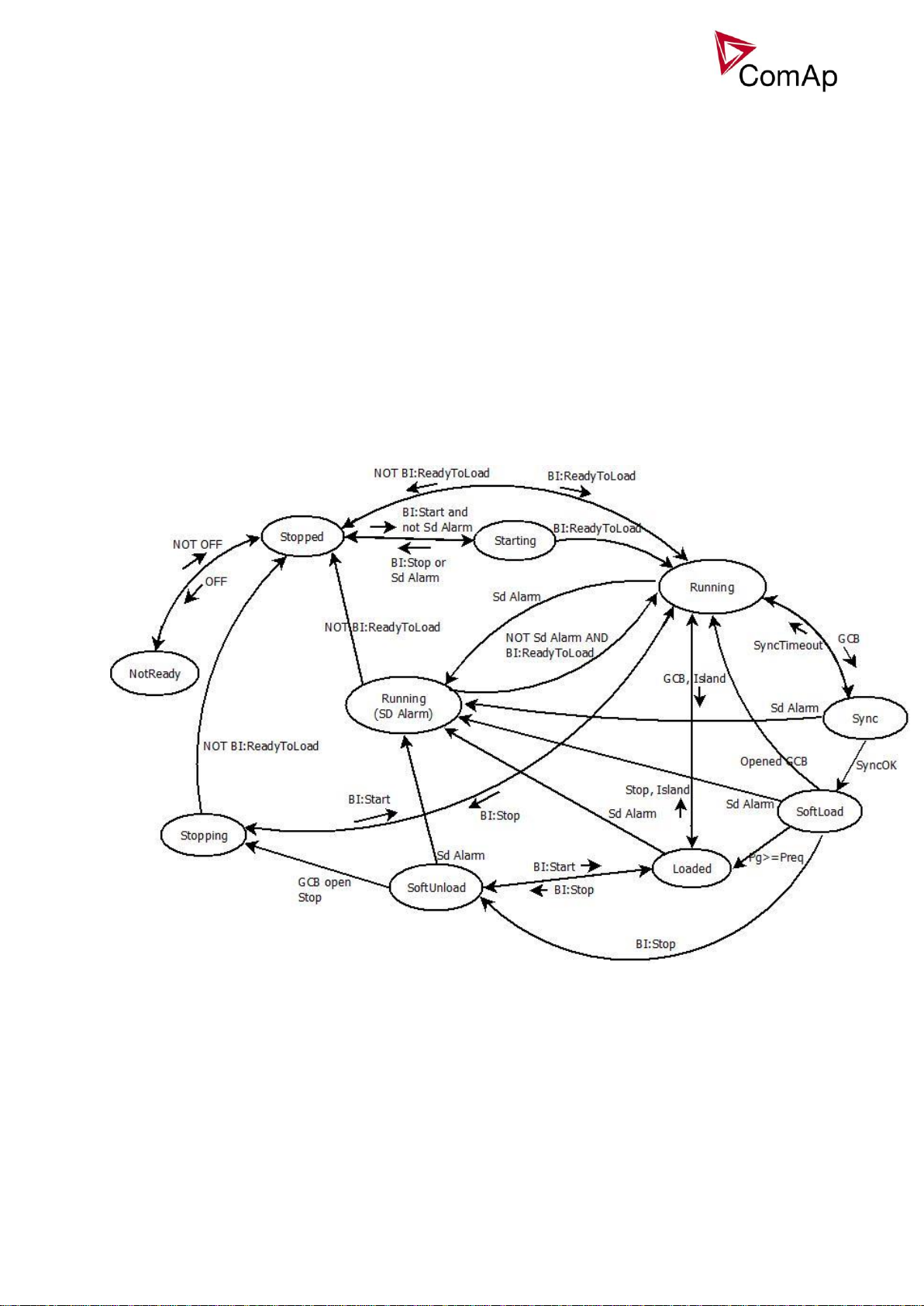

Controller modes

OFF mode

Use OFF mode to block controller functions (even if is power on). OFF mode is used for controller firmware

or configuration change.

Binary outputs (e.g. GCB CLOSE/OPEN) are not energized, all closed Binary outputs are opened when

controller is switched to OFF mode.

Gen-set cannot be started and operated from IGS-NT-GeCon controller – no response for panel buttons and

Binary input commands.

Hint:

Switching to OFF mode is blocked on running engine to avoid accidental engine stop by mode change or by

firmware or configuration programming.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 14

14

SEM mode

Engine start can be activated from

o Engine controller (e.g. ID-DCU, ID-MCU)

o GeCon panel – Start button

o GeCon BI: StartButton

o Remotely e.g. from InteliMonitor

GeCon BI: ReadyToLoad initiates GeCon “Running” state” - activates Gener protect: Min stab time a Max

stab time within the generator electric protections are activated.

Gen-set is loaded/unloaded from

o GeCon panel – GCB button

o GeCon BI: GCBButton

o Direct GCB “hand” control

o Remotely e.g. from InteliMonitor

o LBI: Gen unload

GCB closing from controller can be blocked by BI: GCB disable (does not block synchronization process)

Controller flow chart in SEM mode:

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 15

15

HAND mode

IG-EE GeCon

MINT

MCU

GCB feedback

GCB

close/open

Vg, Ig, Vb

RS232 - PC

Speed control

(Sync/Load ctrl)

GCB

START

STOP

(ReadyToLoad)

G

G

External Engine

Start / Stop

External GCB

Close / Open

generator

measuring

Process control: StartStopBtn = DISABLED

ProtectionMode = NOT ACTIVE

Sync/Load ctrl: Sync timeout = NO TIMEOUT

GCB open level = NO LEVEL

GCB open del = NO TIMEOUT

MCU

Hand mode is a special type of SEM mode. In Hand mode, the panel Start, Stop buttons are not working,

GCB is supposed to be controlled externally. The Hand mode is achieved by setpoints adjustment - see the

following picture.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 16

16

AUT mode

No.

Island

enable

Parallel

enable

Synchro

enable

Function

1

YES

YES

FORWARD

Basic SPI application

2

YES

NO

NO

SPM application

3

NO

YES

FORWARD

SPI application, no island (stand-by) operation

allowed

4

NO

NO

NO

Gen-set start is blocked. Binary output

StartBlocked indicates those states.

NO

NO

FORWARD

NO

YES

NO

Automatic mode is influenced by ProcessControl: Island enable, ParallelEnable, Synchro enable setpoints.

Following procedure corresponds to setting No.1 from table above.

1) After the input Rem start/stop is energized, controller starts the gen-set. If MCB feedack is active, the

controller will synchronize the gen-set to mains and ramp up the load, depending on the ProcessControl

set points adjustment.

2) If a mains failure is recognized, the controller will open the GCB to separate the failed mains from the

generator. After the mains breaker has been open (MCB feedback is de-energized), the controller will

close the GCB again to the island (stand-by) operation.

3) If mains recovers again, the GCB is open again to allow the MCB to be closed (manually or in general

not with a command from the controller). After both mains is present and MCB closed, the controller will

synchronize again with the healthy mains and close the GCB.

4) If input Rem start/stop is de-energized, controller will softly unload the gen-set back to the mains, then

open the GCB, cool down and stop the gen-set.

TEST mode

Use TEST mode for Gen-set start test if the Mains is OK or to transfer the load to the gen-set when Mains

fail is announced in advance.

HINT

The controller does not respond to GCB ON/OFF , STOP, START in Return To mains = ENABLED.

Gen-set automatically starts, when TEST mode is selected.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 17

17

ProcessControl: Load ctrl PtM

Mode

Function

Related Setpoints – LBI – LBO - LAI

BASELOAD

Gen-set power is regulated to value

given by Base load setpoint.

ProcessControl: Base load

IM/EX

Gen-set load is controlled so, that the

mains import is maintained constant at

the level given by Import load setpoint –

I/E power is measured by controller on

auxiliary CT input or by analog input.

ProcessControl: Import load, I/E Pmmeas

ANEXT BASELOAD

Gen-set power is set by analog input.

Analog input: LdCtrlAnextBld

ANEXT IM/EX

Gen-set load is controlled so, that the

mains import is maintained constant at

the level given by the analog input

LdCtrl:AnExI/E – I/E power is measured

by controller on auxiliary CT input or by

analog input.

ProcessControl: I/E Pm-meas, Analog

input: PFCtrl:AnExI/E

T BY PWR

Gen-set power is controlled to keep the

required temperature, that is measured

via an analog input.

ProcessControl: TempByPwr Treq,

TempByPwr gain, TempByPwr int,

Analog input: LdCtrl:TByPwr

Another modes of active power control

Mode

Function

Related Setpoints – LBI – LBO - LAI

Export limit

Limits export to the mains in the

baseload mode. If the function is

enabled, the gen-set power is limited so

that mains import is always higher or

equal to the setpoint Import Load.

ProcessControl: Export limit = ENABLE,

Import load

Warming

The controller limits gen-set power for

requested time or until the water

temperature reach the requested value.

After warming the gen-set goes to the

requested (e.g. Baseload) power.

ProcessControl: Warming load;

Warming temp; Max warm time

Peak shaving

Automatic gen-set start/stop based on

object (load) consumption. Can be

based on measured kW or kVA.

ProcessControl: PeakLevelStart;

PeakLevelStop; PeakAutS/S del, Peak

kVA Start, Peak kVA Stop, PeakKVAS/S

del, LBO: PeakShaveAct

Mains parameters out of limits during synchronising

In case that mains parameters get out of permitted limits during synchronizing to mains (reverse or forward),

the regulation of gen-set speed and voltage according to mains frequency and voltage is interrupted. During

the state, when parameters reach out of limits, until “Mains fail” is issued, the engine speed and voltage

regulation output is kept on the last value.

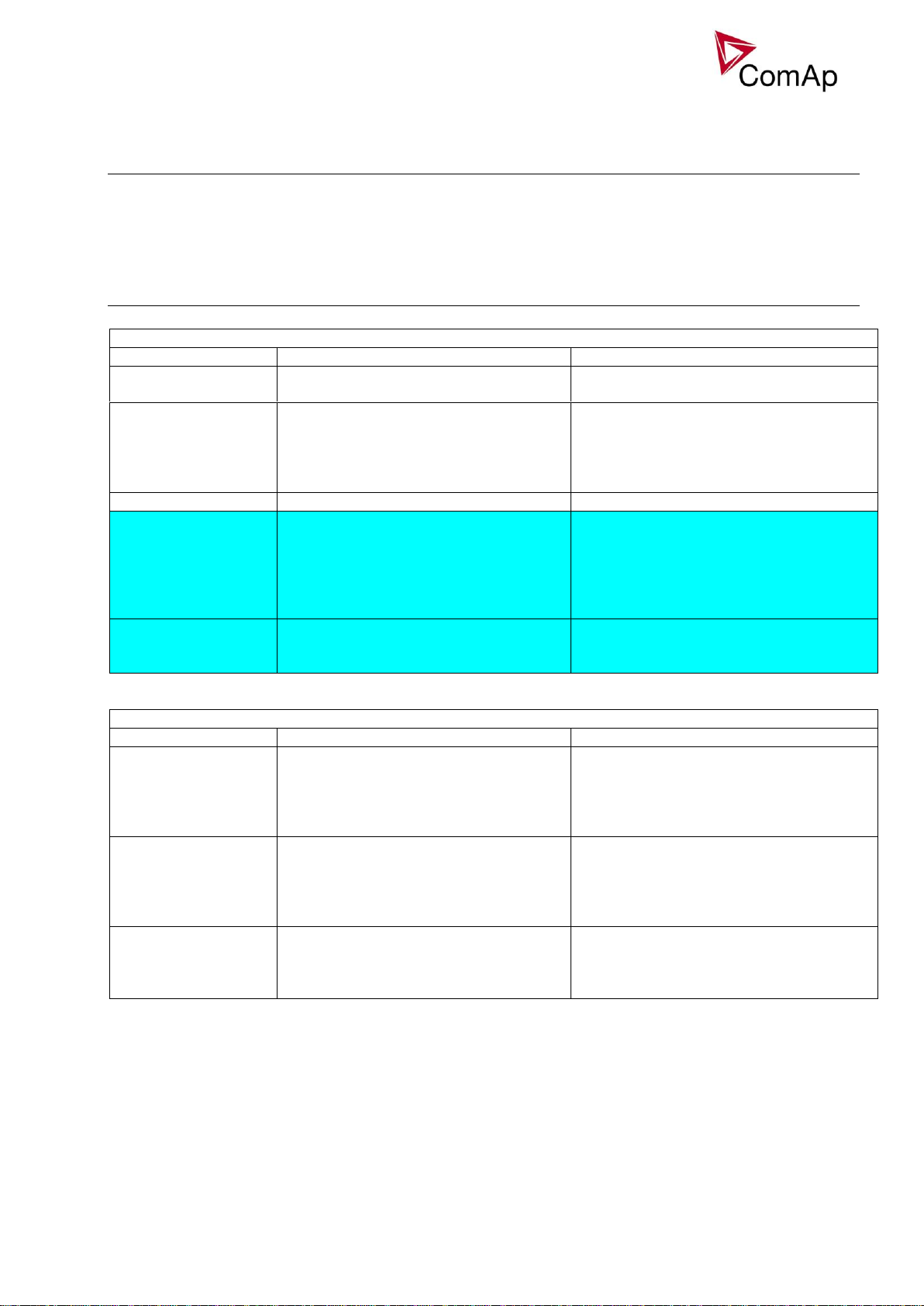

Active Power control modes in SPI

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 18

18

Requested power

Actual power

Vgen

Igen

SpeedGoverrnor

output

Speed

governor

ProcessControl: Load ctrl PtM = ANEXT BASELOAD

LOAD

GCBMCB

Controller

LdCtrl:AnExtBld

Analog input:

Requested power

Actual power

ProcessControl: Baseload

Vgen

Igen

SpeedGoverrnor

output

Speed

governor

ProcessControl: Load ctrl PtM = BASELOAD

LOAD

GCBMCB

Controller

SpeedGoverrnor

output

Speed

governor

LOAD

GCBMCB

Controller

LdCtrl:I/E-Pm

Analog input:

Vmains

Imns 3

LoadCtrlPtm = IM / EX

I / E- Pm meas =

ANALOG INPUT

ProcessControl :

ProcessControl :

ProcessControl :

IM/ EX

Requested I/E power

Actual I/ E power

SpeedGoverrnor

output

Speed

governor

LoadCtrlPtm = IM / EX

LOAD

GCBMCB

Controller

Vmains

Imains ph3

ProcessControl :

IM/EX

ProcessControl :

I/E -Pm meas = IM3 CT INPUT

ProcessControl :

Requested I/

E power

Actual I/ E power

ProcCtrlSingle: PF ctrl PtM

Mode

Function

Setpoints

BASEPF

Gen-set power factor is maintained at

constant level adjusted by the setpoint

Base PF.

ProcCtrlSingle: PF ctrl PtM

PF-IM/EX

Gen-set power factor is controlled so, that the

mains power factor is maintained constant at

the level adjusted by setpoint Import PF

ProcCtrlSingle: Import PF,

I/E Qm-meas

ANEXT BASEPF

Gen-set power factor is maintained at

constant level given by the analog input

PFCtrl:AnExBPF

Analog input: PFCtrl:AnExBPF

ANEXT PF-IM/EX

Gen-set load is controlled so, that the mains

power factor is maintained constant at the

level given by the analog input PFCtrl:AnExI/E

– I/E power factor is measured by controller

on auxiliary CT input or by analog input.

ProcCtrlSingle: I/E Qm-meas

Analog input: PFCtrl:AnExI/E

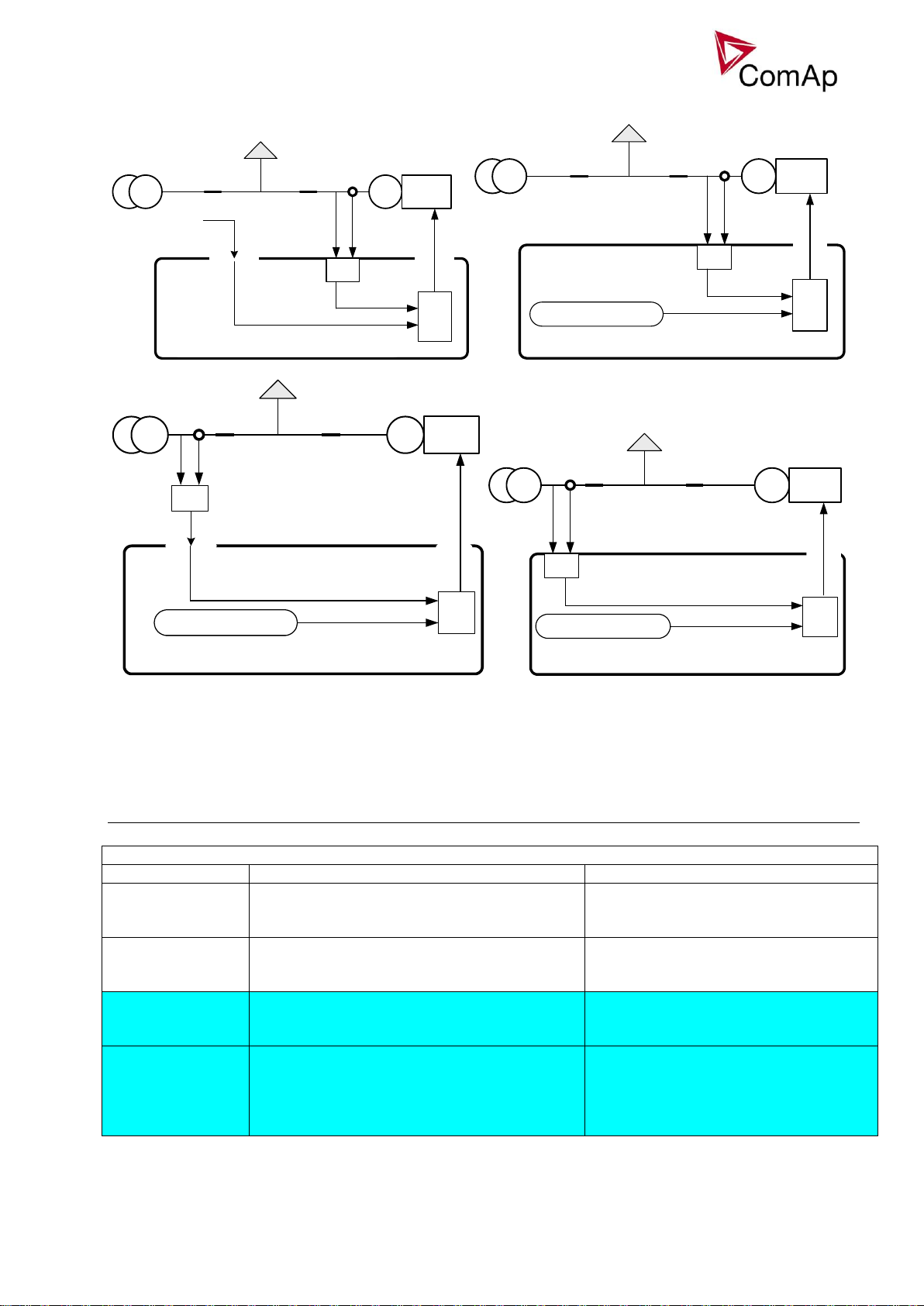

PF control modes

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 19

19

Requested PF

Actual PF

ProcessControl: Base PF

Vgen

Igen

AVRi output

AVR

ProcessControl: PF ctrl PtM = BASEPF

LOAD

GCBMCB

Controller

IG-AVRi

ProcessControl :

Import PF

AVR

ProcessControl :

ProcessControl :

LOAD

GCBMCB

Controller

IG-AVRi

Vmains

Imains ph3

PF ctrl PtM = PF IM/ EX

Actual I/ E PF

Requested I /E PF

I / E- Qm meas = IM3 CT INPUT

AVRiout pu t

Import PF

AVRi output

AVR

LOAD

GCBMCB

Controller

IG-AVRi

PfCtrl:I/E-Qm

Analog input:

Vmains

Imns 3

Actual I/E PF

Requested I/E PF

PF ctrl PtM = PF IM/EX

ProcessControl :

ProcessControl :

ProcessControl : I/E- Qm meas

= ANALOG INPUT

Load shedding

Load shedding function is dedicated for tripping of non-essential load in case of high generator current, or

drop of generator frequency above/below preadjusted limits, for preadjusted time.

All LOAD SHED outputs are activated (closed) to trip the unessential load when gen-set goes to island:

a) When GCB is closed after mains fail and gen-set starts in AUT mode.

b) When MCB opens from parallel to mains operation in AUT mode.

c) Before MCB is opened in SEM mode by button.

The load shedding function is active in all controller modes except OFF and MAN.

Load shedding has ten steps and each step is linked with its own Load shed x binary output. The non

essential load shedding is based on generator current and generator frequency. There is only one level for

current load shedding and one level for frequency load shedding for all 10 steps, as well for reconnection

level and delay. Load shed can only move from one step to the next, e.g. No LoadShed to LdShed S1 to

LdShed S2 to LdShed S10 and vice versa.

If manual reconnection of the load is desired, the AutoLd recon setpoint needs to be disabled (AutoLd recon

= DISABLED) and the MAN load recon binary input needs to be configured.

Rising edge on this input resets the controller to a lower stage, but only if the load is under the Ld recon level

at that moment.

The current load shedding can be activated in case any of phase current exceeds the adjusted limit. The

reconnection is able only in case all of the current values are below reconnection level.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 20

20

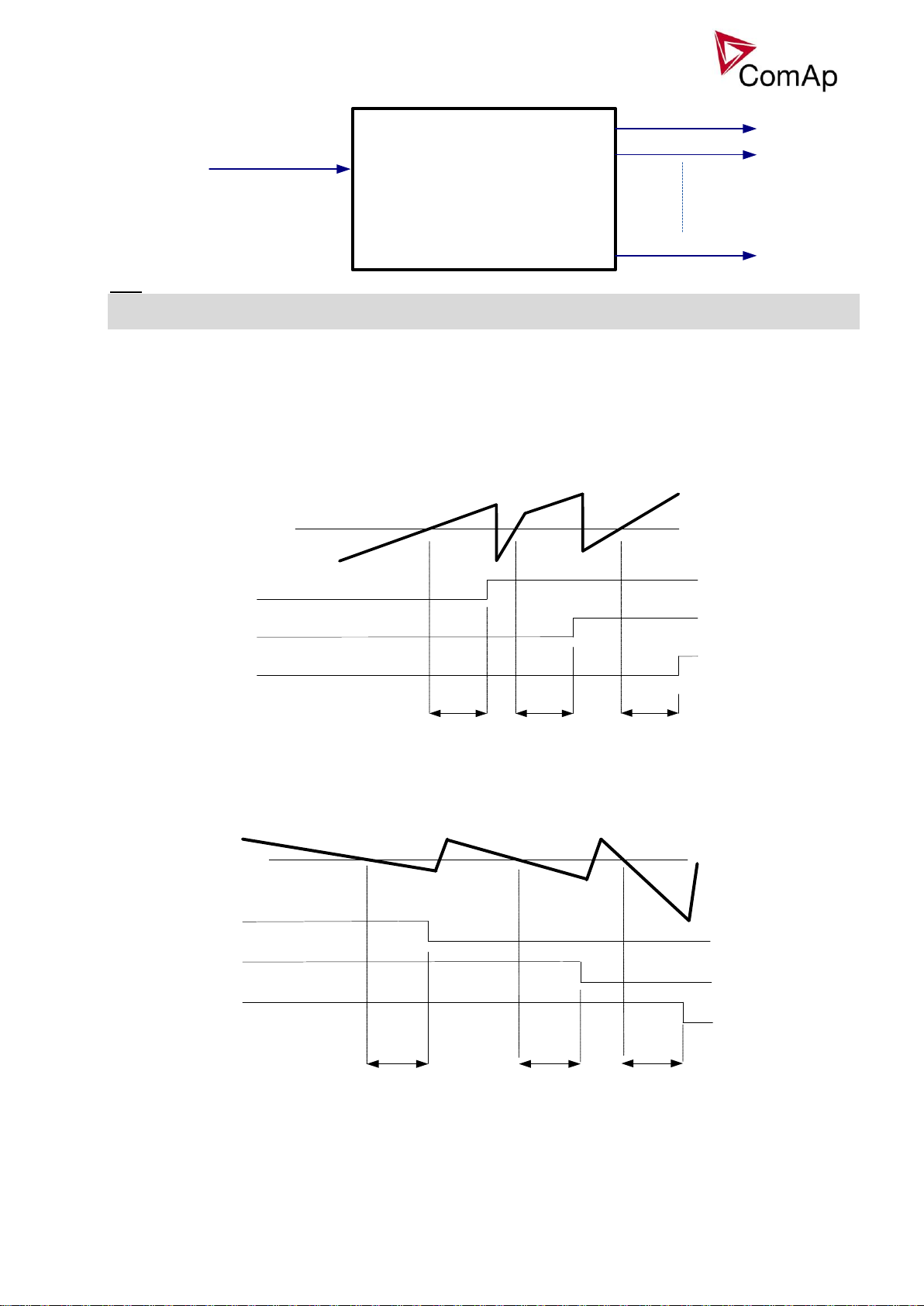

CurShedLev

CurRecLev

FreqShedLvl

FreqRecLvl

LdShed stage 1

LdShed stage 2

LdShed stage 10

ManualLdRecon

Load shedding:

Ld Shed delay

Ld recon delay

Ld shed

del

Ld shed

del

Ld shed

del

BO Load shed 1

BO Load shed 2

BO Load shed 3

Curr shed level

Gen-set current

closed

closed

closed

Ld recon del Ld recon delLd recon del

BO Load shed 2

Curr recon level

Gen-set current

BO Load shed 3

BO Load shed 1

opened

opened

opened

Hint:

If no Load Shedding outputs are configured, there is no record to history and no screen timer indication of

the activity of this function.

On the following pictures, the generator current load shedding is depicted. The current is evaluated from all 3

phases, each phase can activate the load shedding. On the picture, due to transparency, only 3 load shed

outputs are depicted, not all 10.

The generator frequency based load shedding is in fact the same, but fall below preadjusted limit is watched,

instead of exceeding of the limit as in case of current load shedding.

Load reconnection – automatic -> AutoLd recon = ENABLED

Load reconnection – manual -> AutoLd recon = DISABLED

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 21

21

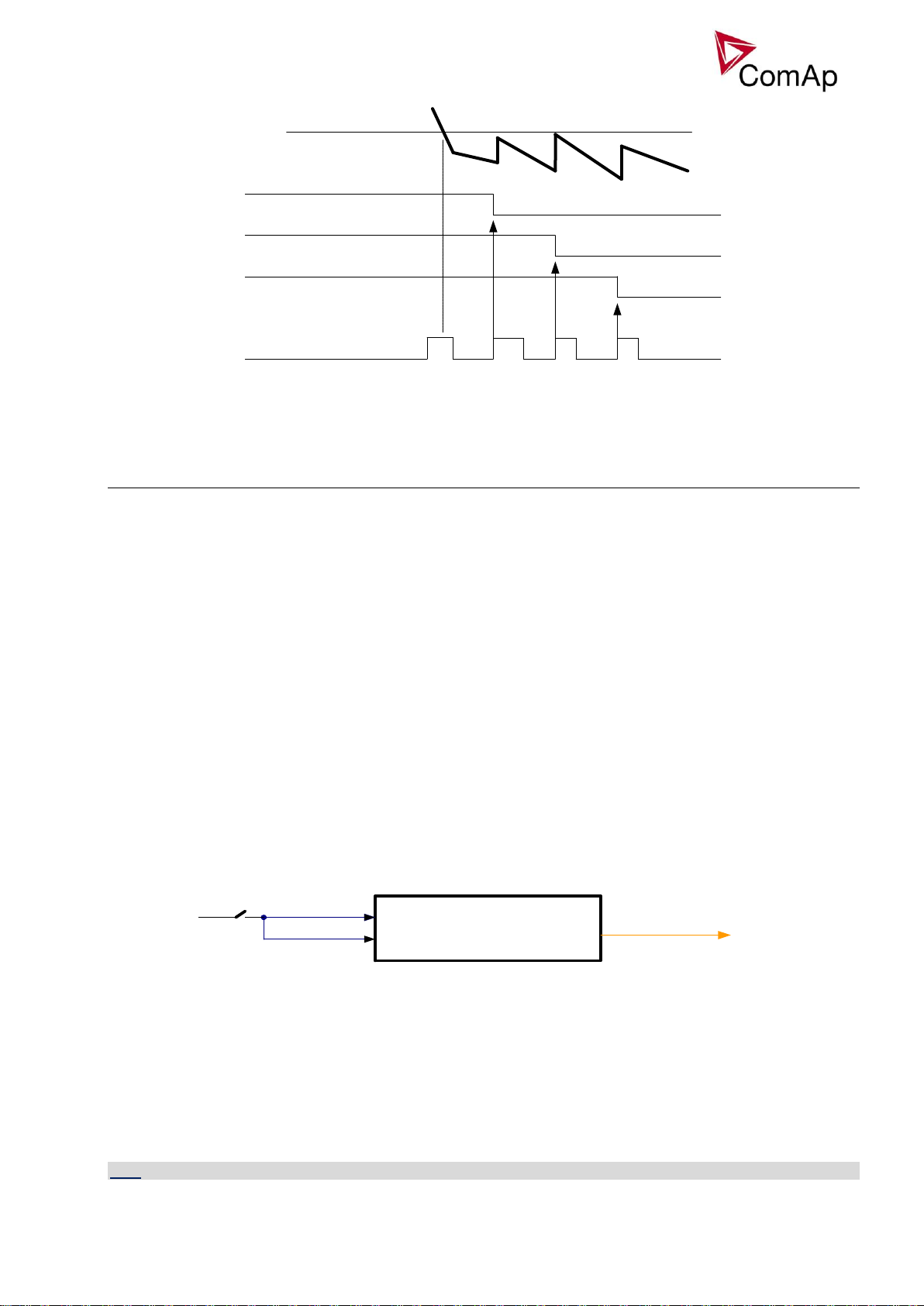

BO Load shed 2

Curr recon level

BO Load shed 3

BO Load shed 1

BI Man load recon

opened

opened

opened

no action

Gen-set current

0 V batt

Test on load

Remote TEST

AMF settings:

ReturnTo mains = DISABLED

WrnTstOnLdFail

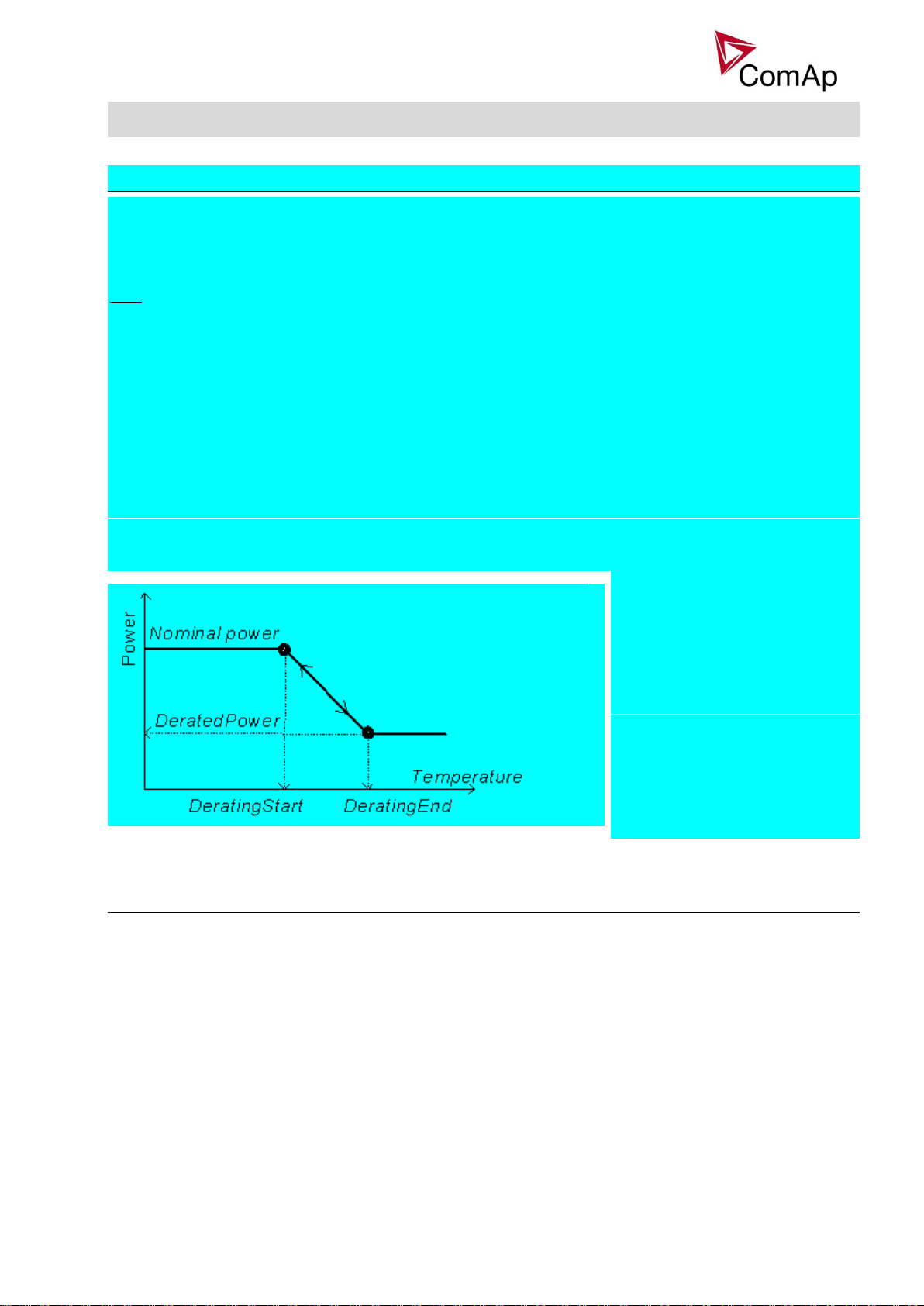

Test on load – SPtM

Affects the behavior in TEST mode. Before the activation of this function

1. adjust setpoint AMF settings: ReturnTo mains = DISABLED

2. adjust Process control: MFStart enable = YES.

3. switch controller to Test on load mode (see drawing below)

Gen-set starts and goes to load (synchronizes to the mains, closes GCB and opens MCB) automatically

when this input is closed even if Mains is OK.

Transmition of power from mains to generator

Behaviour of function depends on settings of setpoint ProcessControl:I/E-Pm meas. If the mains import is

measured (ProcessControl:I/E-Pm meas = IM3 CT INPUT or ANALO INPUT) then there is no time

limitation for unloading and opening of MCB. The MCB is opened when the Import/Export goes below 0 ± 5%

of Basic settings: Nomin power. If the setpoint ProcessControl:I/E-Pm meas = NONE then the MCB is

opened after delay given by setpoint AMF settings: BreakerOverlap.

Transmition of power from generator back to mains

GCB is opened when the power on gen-set is drops under level given by setpoint Sync/Load ctrl: GCB

open level at the least after delay given by setpoint AMF settings: BreakerOverlap.

Test on load with break (interruption)

The transfer of the load in TEST mode can be performed with interruption in case that the parallel to mains

operation is undesirable. Set setpoints ProcessControl:Parallel enable = NO or ProcessControl:Synchro

enable = NONE or REVERSE, ProcessControl:Island enable = YES: If the LBI Test on Load gets active the

load is passed from the mains to the gen-set with interruption. Controller opens MCB and closes GCB after

delay given by AMF settings:FwRet break. After deactivation of LBI Test on Load GCB is opened and and

MCB Is closed after delay given by AMF settings:FwRet break.

HINT

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 22

22

Temperature derating function

decreases genset power depend

on setpoints DeratingX strt,

DeratingX end and DeratedX pwr.

Temperature derating starts at

DeratingX strt temperature.

At DeratingX end temperature runs

genset at DeratedX pwr level.

Above DeratingX end temperature

Genset runs at constant DeratedX

pwr.

It is possible to configure both binary inputs (Remote TEST and Test on load) to only one controller physical

binary input internally.

Power derating

This function linearly decreases genset nominal power according to analog input value.

Gen-set power starts decreasing when temperature measured by Analog input PowerDeratingX exceeds

DeratingX strt value.

Gen-set power is at DeratedX pwr value when temperature measured by Analog input Power deratingX is

equal or higher than DeratingX end value.

Hint:

To use Power derating function configure at first Analog input PowerDeratingX to any IGS-NT or IS-AIN

analog input terminal by GenConfig.

When Power derating function is active the generator overload protection is based on the Derated power! ! !

Derated power value Pg derated is visible in the controller measure screen.

When derating function is not active the Derating power is equal to Nominal power.

Example :

Nomin power = 200 kW, Derating1 strt = 70 °C, Derating1 end = 100 °C, Derated1 pwr = 70 %.

Genset is running at Nominal power 200 kW. When temperature reached 70 °C the genset power starts

decreasing. When temperature reached 100 °C genset runs at 70 % of Nominal power = 140 kW. When

temperature increased above DeratingX end temperature level, gen-set power stays at DeratedX pwr level

140 kW.

Protection mode settings

Protections in this application are affected by Setpoint ProtectionMode (group ProcessControl).

This setpoint is active in MAN,SEM and AUT mode.

Setpoint ProtectionMode has 2 options of settings:

ACTIVE:

Standard setting – all protections are active, in case of 2nd level alarm the breaker is opened/controlled.

(2-nd level alarms are evaluated, GCB or MCB is controlled)

NOT ACTIVE:

2-nd level alarms are evaluated only , but GCB or MCB are NOT controlled (no actions).

Exceptions are Emergency Stop and Sd override alarms type.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 23

23

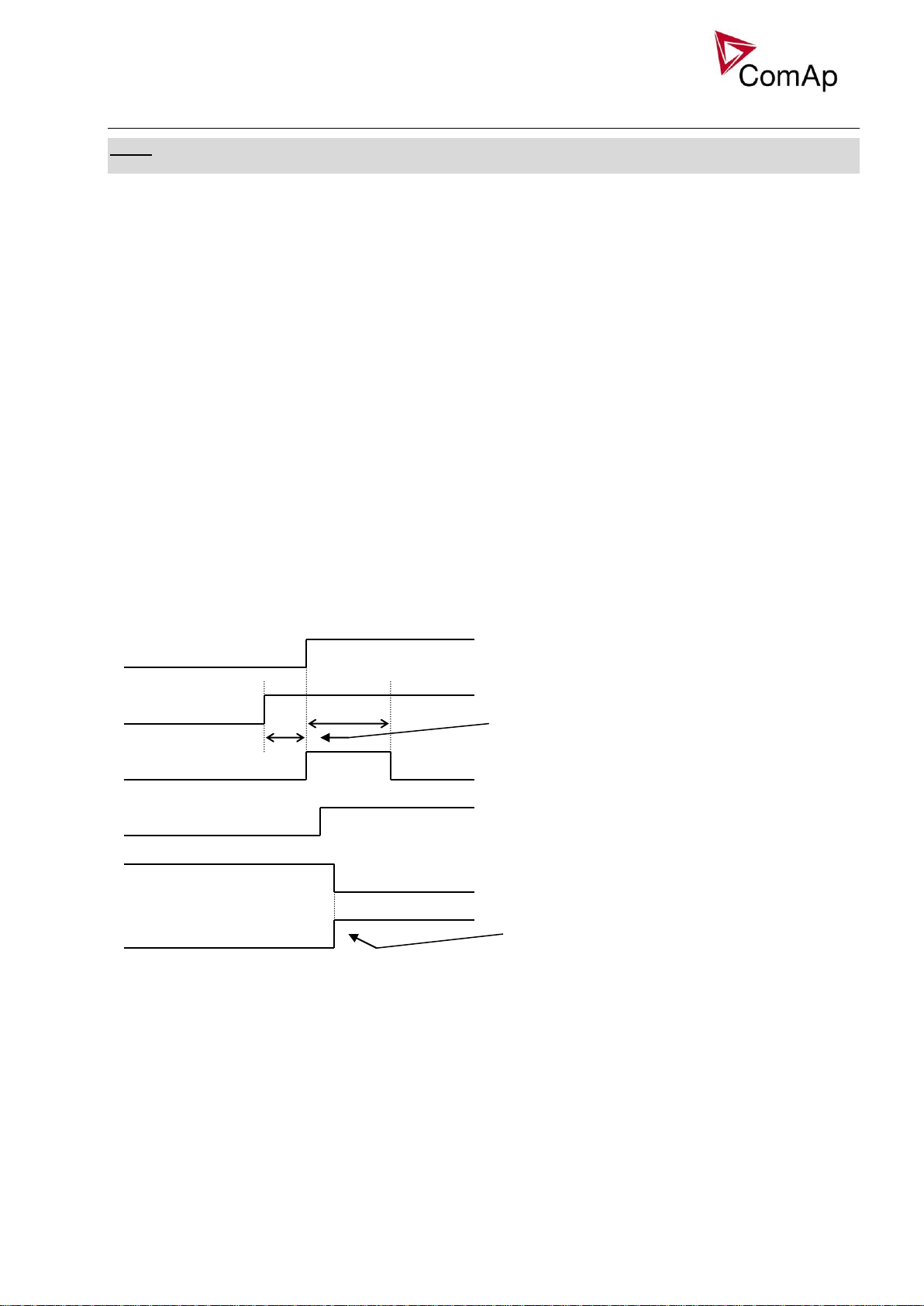

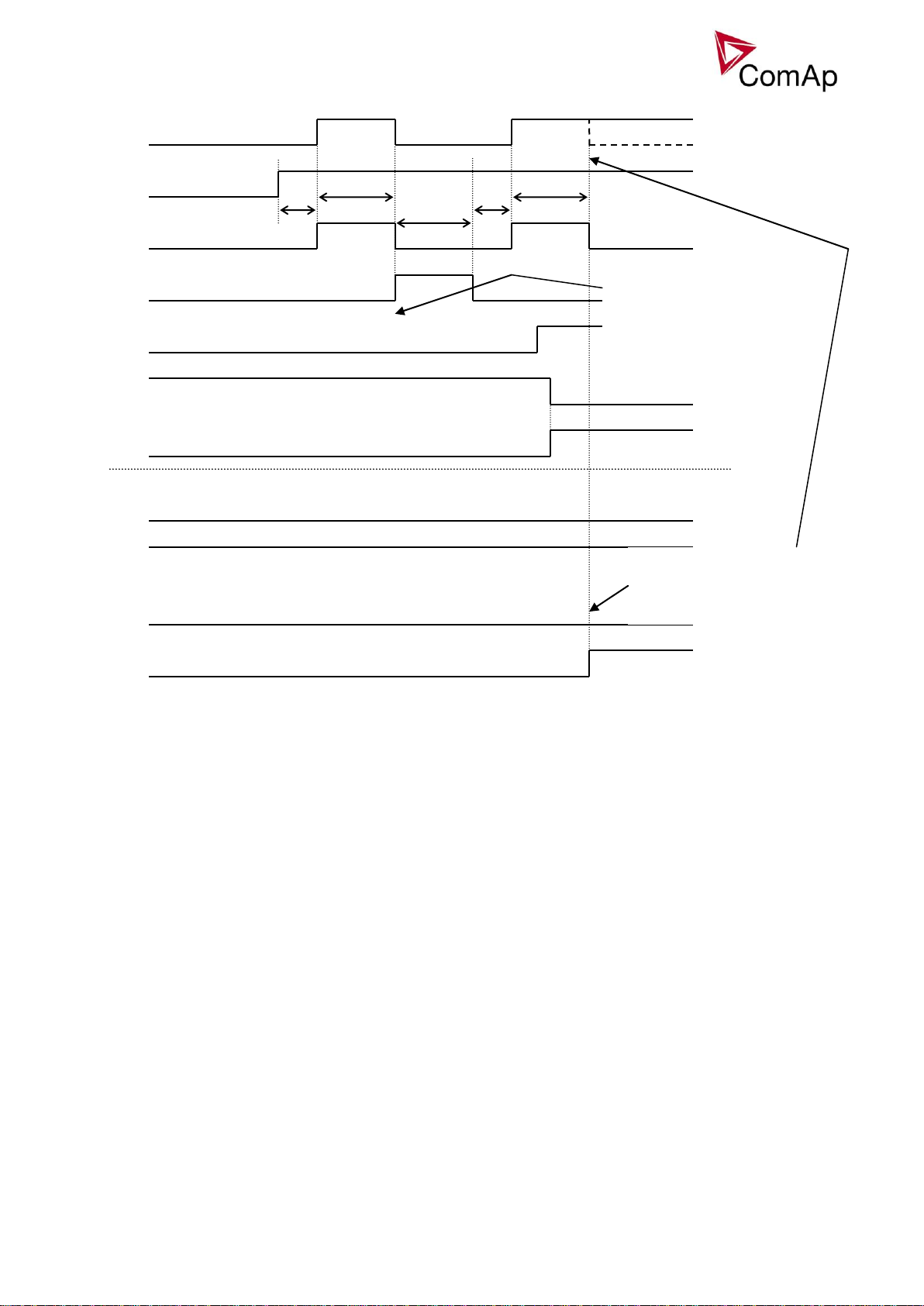

Circuit breakers operation sequence, GCB/MCB fail detection

2s

BO: CB status

BI: CB fdb neg

BI: CB fdb

BO: CB ON coil

1s

BO: CB close/open

BO: CB UV coil

minimum 1s from UV switching on,

together with MinStab time elapsing is

necessary before the CB is allowed to

close

When closing the CB, the CB status LBO

switches over only when both feedbacks

are in correct position

NOTE:

In the following text, “CB” abbreviation is used for MCB or GCB respectively.

Related binary inputs:

- CB fdb – CB feedback binary input

- CB fdb neg – negative CB feedback binary input. Used for increasing the reliability of CB status

evaluated by the controller. In case that it is not configured, negative value of CB fdb is calculated

internally within the controller.

Related binary outputs:

- CB close/open – output for circuit breaker. Equals to 1 during the time when CB is requested o be

closed.

- CB ON coil – output for closing coil of the CB. 2s pulse (5s if synchronising is not provided by the

particuilar CB) is used for closing the CB.

- CB OFF coil – output for opening coil of the CB. 2s pulse (5s if synchronising is not provided by the

particuilar CB) is used for opening the CB.

- CB UV coil – output for undervoltage coil of the CB. Permanently active, 2s negative pulse (5s if

synchronising is not provided by the particuilar CB) is used for CB opening request

- CB status – output indicating CB status as evaluated by the controller. This signal is used for lighting

LEDs on the panel, switching the regulations, CB fail evaluation, etc.

Possible CB sequences:

CB close command:

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 24

24

2s

2s

1s

BO: CB OFF coil

2s

BO: CB status

BI: CB fdb neg

BI: CB fdb

BO: CB ON coil

1s

BO: CB close/open

BO: CB UV coil

If the CB is not closed after

the first attempt, it is only reset

by OFF pulse and no CB fail is

issued. This would be issued

after the second unsuccessfull

attempt.

BO: CB status = 0

BI: CB fdb neg = 1

BI: CB fdb = 0

BO: CB fail

ON pulse has finished and CB

status is not =1. CB fail is

issued immediatelly

Repeated CB close command:

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 25

25

2s

BO: CB OFF coil

BO: CB fail

500 ms

<2s

BO: CB status = 0

BI: CB fdb neg = 1

BI: CB fdb

BO: CB ON coil

1s

BO: CB close/open

BO: CB UV coil

CB fail – If any inconsistence between

the two feedback signals is detected, CB

fail is issued.

ON pulse is shortened/interrupted

and replaced by UV and OFF pulse

OFF pulse is activated until both

feedbacks return to the correct

position +2 seconds.

2s

BO: CB OFF coil

BI: CB fdb neg

BI: CB fdb

BO: CB close/open

BO: CB UV coil

During CB opening the CB status

LBO is deactivated with change of

the first feddback status

Further behavior of UV output

depends on the system status. In

case of transition to cooling stays

off, if the Cb was opened manually

and the engine keeps running, it

activates again after timeout

elapses.

BO: CB status

CB fail – fdb mismatch:

CB open command:

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 26

26

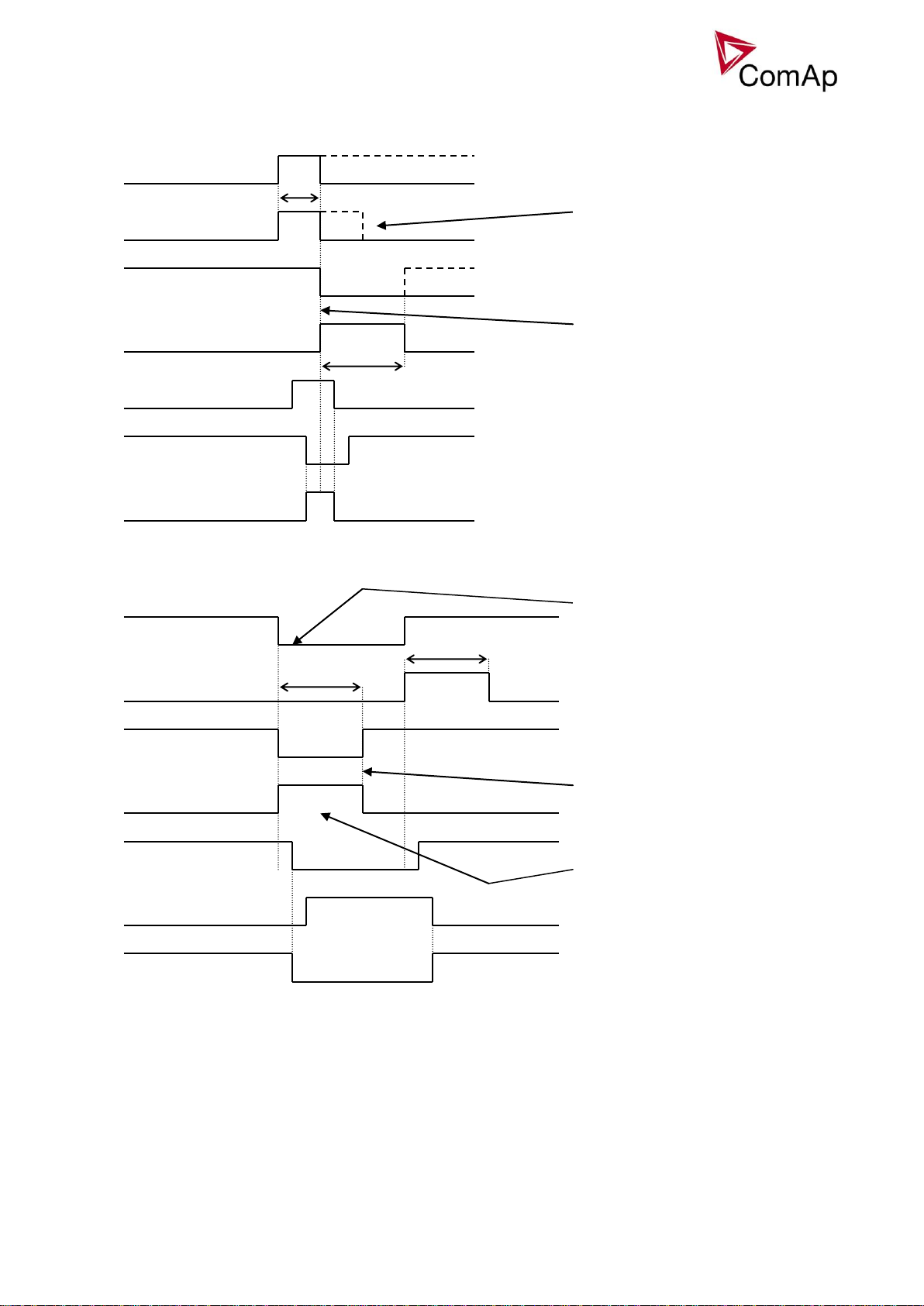

Transition closing -> opening (opening command is issued during closing pulse):

<2s

2s

BO: CB OFF coil

BI: CB fdb neg

BI: CB fdb

BO: CB close/open

BO: CB UV coil

BO: CB status

BO: CB ON coil

Closing pulse is shortened, opening

sequence is started immediatelly

CB opening by protection or manual

command (button pressed)

2s

2s

BO: CB OFF coil

BI: CB fdb neg

BI: CB fdb

BO: CB close/open

BO: CB UV coil

BO: CB status

BO: CB ON coil

OFF a UV pulse is always activated for

the full time. manual control (= CB

button) is deactivated during opening

pulse.

Here starts the standard closing

sequence – see CB close command.

In this moment, the reason for closing the

CB is activated again (e.g. Remote

Start/Stop is activated)

Transition opening -> closing (closing command is issued during opening pulse)

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 27

27

Alarm: GCB fail

BO GCB close/open

BI GCB feedback

Alarm detection:

immediatelly

active

closed

opened

Alarm: GCB fail

BI GCB feedback

BO GCB close/open

Alarm detection:

immediatelly

active

opened

closed

BO: MCB UV coil

FwRet break

RPM / fg / Ug

EmergStart del

2s

BO: MCB OFF coil

BI: MCB fdb neg

BI: MCB fdb

BO: Mains OK

BO: MCB status

BO: Fuel solenoid

FwRet break dealy is between MCB

status deactivation and command for

GCB closing.

BO: MCB close/open

Generator voltage is within limits

BO: GCB close/open

BO: GCB ON coil

If mains returns in this moment,

starting sequence is interrupted

and MCB stays closed. It is valid

until the moment when generator

voltage is within limits.

MCB opens on = GENRUN:

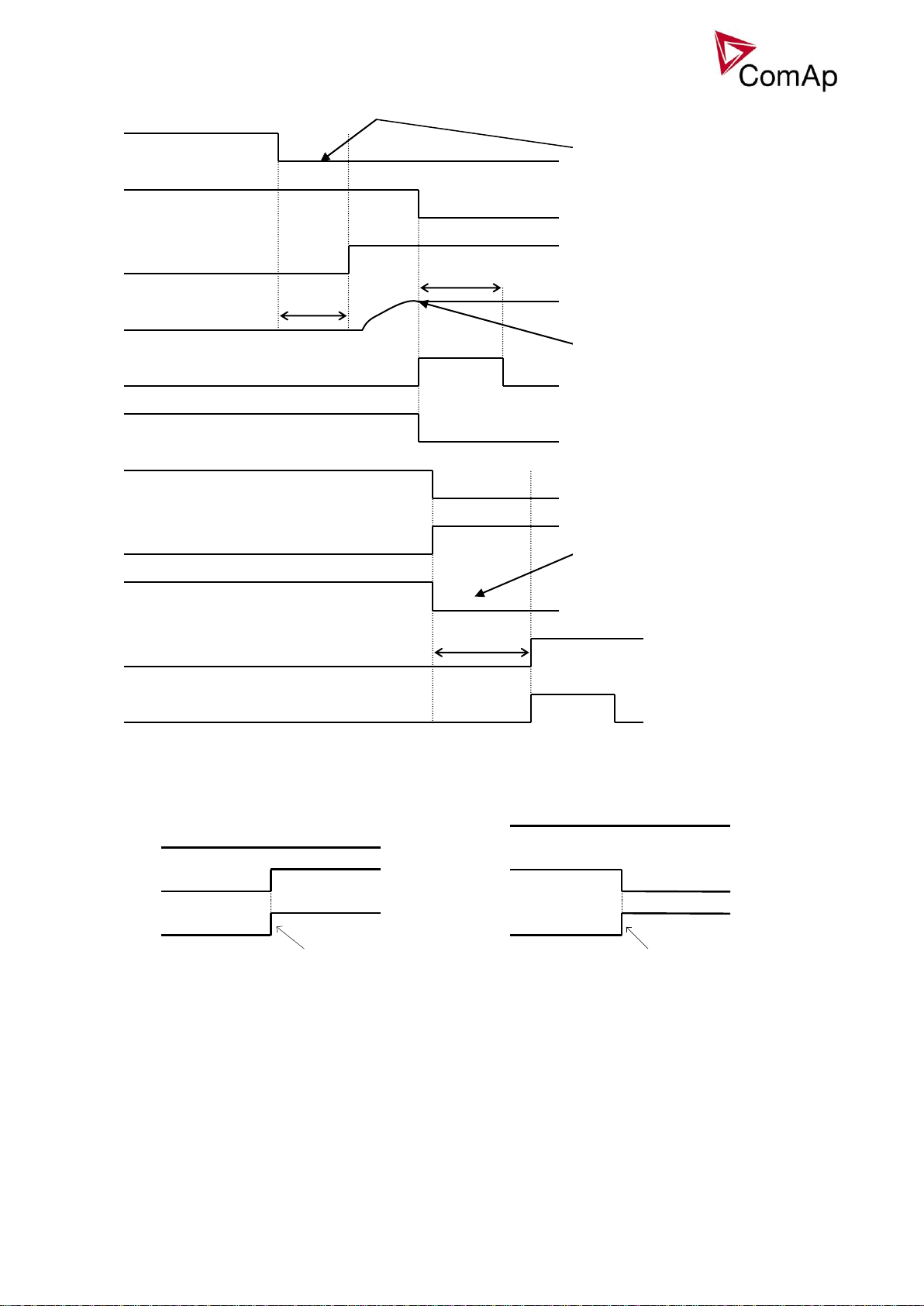

Other CB fail reasons:

When the BO CB close/open is in steady state and CB feedback is changed, the CB fail is detected

immediately (no delay).

When the BO CB close/open opens, there is 5 resp. 2 sec delay for the breaker to respond before a CB

fail is detected. In such case, if CB OFF coil is used for opening the CB and CB fail occurs during

opening the CB, the signal CB OFF coil is automatically extended until the breaker opening is detected

(evaluated as CB status).

2 sec when the CB is used for synchronizing

5 sec in other cases

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 28

28

Alarm: GCB fail

BO GCB close/open

BI GCB feedback

active

opened

opened

Time delay

5 sec

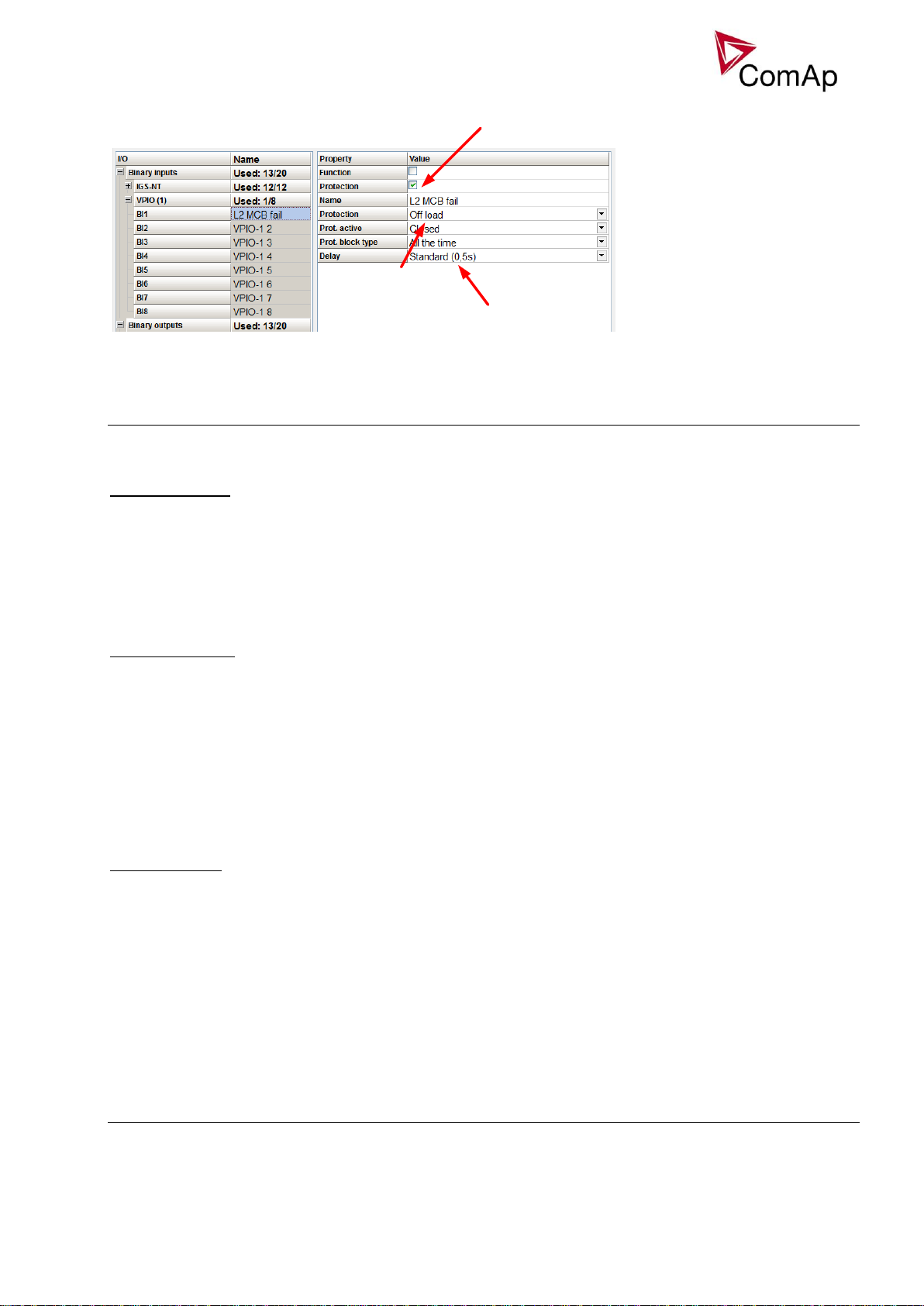

Rename the VPIO to suitable name

(e.g. L2 MCB fail, which indicates that it is

Level 2 alarm)

Choose Wrn MCB fail from Prg. States group on

any VPIO output

In case that CB fail is detected after switching the controller on (CB is closed), the CB OFF coil output is

activated immediatelly.

NOTE:

If the MCB or GCB feedback gets active during synchronization the breaker is imediately closed.

CAUTION!

In case that MCB feedback is active (MCB is expected as closed) and “MCB fail” is reported due to previous

incorrect manipulation of MCB, in the moment of Fault reset, the MCB fail is cleared and the controller

internally goes to “closed” state. I.e. MCB fdb status is confirmed and the output MCB close/open is

energized.

MCB fail Information

Opening of the MCB externally is allowed because external protection device may open it based on its

protections. The controller will try to reclose the breaker if Mains protect type protection is not configured

accordingly (e.g. external protection device/relay does not allow user to send this type of signal or such

wiring is impractical). After failed attempt to close the breaker, the controller issues standard alarm and in

AUT mode starts the engine and consequently closes GCB breaker.

Warning!

In this case, if the supposed opening of the MCB is caused merely by MCB feedback failure and

the actual position of the MCB is still closed, the controller will close GCB to the Mains voltage

directly without synchronizing because it cannot be distinguished what exactly happened. This

situation can be possibly harmful to the personnel or the equipment. Should this be the case, the

following solution is proposed:

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 29

29

Adjust the delay if required (since the start of the engine

can take up considerable time, 0.5s should be sufficient)

Toggle on the protection for the interconnected VPIO input

(e.g. BI VPIO-1 1 is interconnected with BO VPIO-1 1)

Set the type of the

protection to Off load

External breaker control

This application accepts external breaker control in these situations:

MINT application:

Mode:MAN, SEM

External breaker control is accepted only when LBI:ReadyToLoad=1

Exceptions:

If the BUS voltage is >15V and GCBfdb=1 and LBI:ReadyToLoad=0 then BO GCB Fail and History record

are performed

SPtM application:

Mode:SEM

External MCB control is accepted

External GCB control is accepted only when LBI:ReadyToLoad=1

Exceptions:

If the Mains parameters are out of limits (voltage and frequency) and GCB and MCB are closed and

LBI:ReadyToLoad=1 – external control is not accepted – Wrn MCB fail and Wrn GCB fail are evaluated.

If the Mains voltage is > 15V and MCBfdb=1 and GCBfdb=1 and LBI:ReadyToLoad=0 then BO GCB Fail

and History record are performed.

SPI application:

Mode: SEM

External GCB control is accepted only when LBI:ReadyToLoad=1

Exceptions:

If the Mains parameters are out of limits (voltage and frequency) and GCB and MCB are closed and

LBI:ReadyToLoad=1 – external control is not accepted – Wrn MCB fail and Wrn GCB fail are evaluated.

If the Mains voltage is > 15V and MCBfdb=1 and GCBfdb=1 and LBI:ReadyToLoad=0 then BO GCB Fail

and History record are performed.

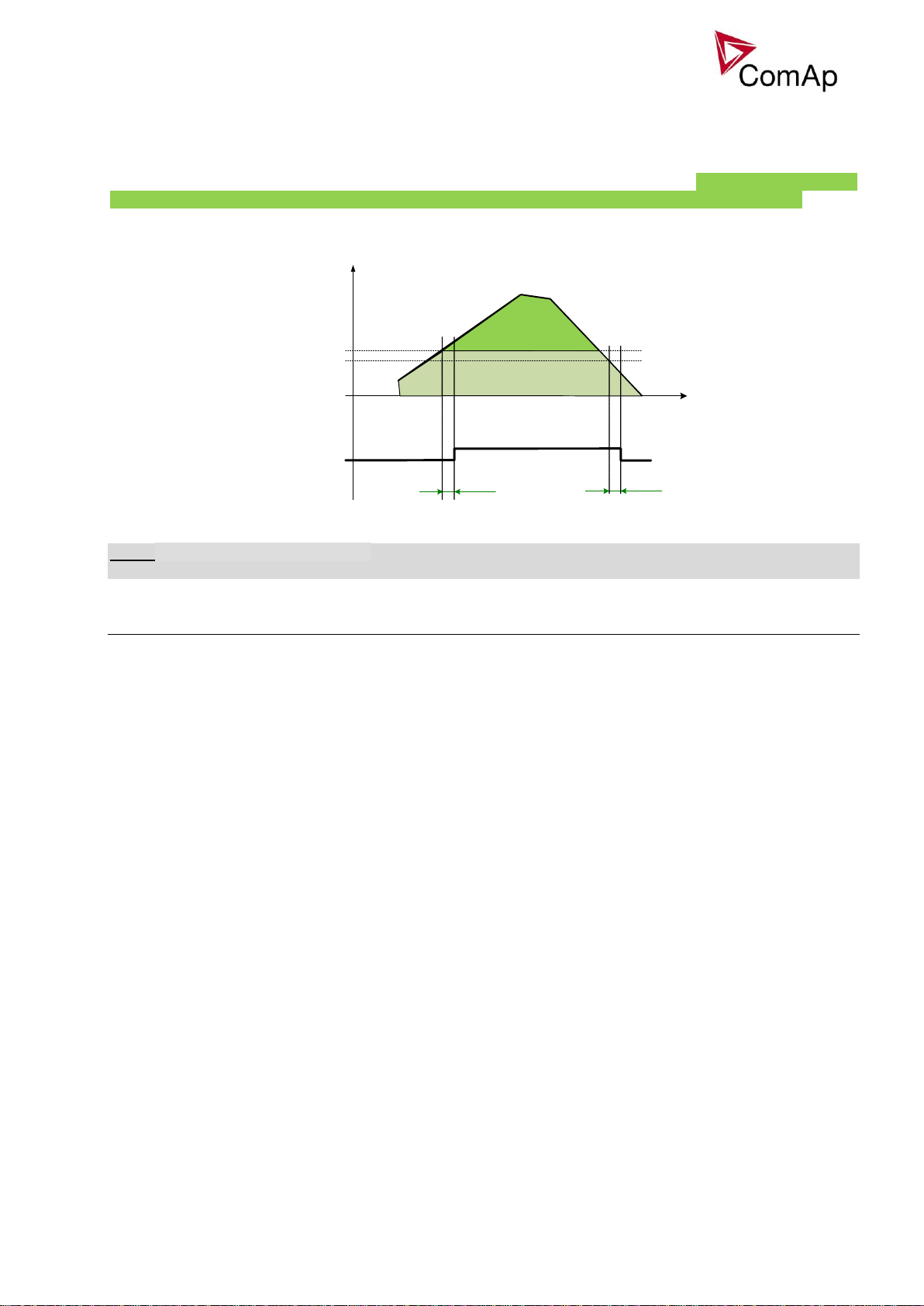

Peak shaving based on Active and Apparent power

The Peak shaving function is active only in AUT mode in parallel to Mains operation. Peak shaving is based

on Object P or Object Q (consumption of load). If load consumption increases over

ProcessControl:PeakLevelStart or ProcessControl:PeakKVAStart for period longer than

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 30

30

PeakLevelStart

PeakAutS/S del

Actual power [ kW

]

Time

PeakLevelStop

PeakAutS/S del

Sys start/stop

ProcessControl:PeakAutS/S or ProcessControl:PeakKVAS/S del the gen-set is started (BO Sys start/stop

is activated). If load consumption decreases below ProcessControl:PeakLevelStop or

ProcessControl:PeakKVAStop for period longer than ProcessControl:PeakAutS/S del or

ProcessControl:PeakKVAS/S del the gen-set is stopped. Both Peak shaving based on kW and kVA can

work simultaneously (SYS START/STOP is activated if at least one condition is fulfilled). Peak shaving based on

Apparent power is available in InteliGen-NT Basebox, InteliGen-NTC Basebox and InteliSys-NT only.

Figure: Example of peak shaving function based on Active power (the same function for Reactive power)

NOTE:

Function Peak Shaving based on Apparent power is not available for IG-NT-GC controller.

Remote Alarm Messaging

It is possible to use up to five channels for Active Call, Email and SMS upon defined type of Alarm. It is

possible to define protection type for all ENABLED channels to react. All the possibilities in the controller are:

History record, Alarm only, Warning, Mains protect and Mains protect with Reset. Find more information

about alarm types in the chapter Protections and alarm management.

Communication Types for Remote Alarm Messaging

Below there all types of communication available for each Active Call channel.

DATA-ANA: This option sends a complete archive to the recipient's PC via analog modem. An analog

modem must be connected either to one of controller COM ports or to one of I-LB modules connected to the

controller via CAN2 bus. The channel address must contain complete telephone number of the recipient's

PC where InteliMonitor is running in Active call receiving mode.

DATA-GSM: This option sends a complete archive to the recipient's PC via GSM modem. A GSM modem

with activated CSD data transfers must be connected either to one of controller COM ports or to one of I-LB

modules connected to the controller via CAN2 bus. The channel address must contain complete telephone

number of the recipient's PC where InteliMonitor is running in Active call receiving mode.

DATA-ISDN: This option sends a complete archive to the recipient's PC via ISDN modem. An ISDN modem

must be connected either to one of controller COM ports or to one of I-LB modules connected to the

controller via CAN2 bus. The channel address must contain complete telephone number of the recipient's

PC where InteliMonitor is running in Active call receiving mode.

DATA-CDMA: This option sends a complete archive to the recipient's PC via CDMA modem. A CDMA

modem must be connected either to one of controller COM ports or to one of I-LB modules connected to the

controller via CAN2 bus. The local CDMA network must allow point-to-point data transfers. The channel

address must contain complete telephone number of the recipient's PC where InteliMonitor is running in

Active call receiving mode.

SMS-GSM: This option sends a short text message (SMS) containing the actual Alarmlist contents to the

recipient's mobile phone via the GSM modem. The channel address must contain complete telephone

number of the recipient's mobile phone.

SMS-CDMA: This option sends a short text message (SMS) containing the actual Alarmlist contents to the

recipient's mobile phone via the CDMA modem. The channel address must contain complete telephone

number of the recipient's mobile phone.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 31

31

IB-E-MAIL: This option sends an e-mail containing the actual Alarmlist contents and latest 20 history records

(only date, time, reason) to the recipient's mailbox via the IB-COM module or IG-IB module. The channel

address must contain valid e-mail address of the recipient.

NOTE:

The SMTP settings (SMTP authent,SMTP user name, SMTP password, SMTP address, Contr mailbox) must

be properly adjusted for sending e-mails.

Example of setting

There is an example of setting of Remote Alarm Messaging. In this case active calls we be triggered on

Mains protect and Mains protect with Reset alarms. Message is sent via email to

emailAddress@domain.com (Channel 1 – available for NTC controller or with any controller with connected

IB-NT or I-LB+), archive is sent via ISDN modem to the number +111222333444 (Channel 2) and SMS is

sent to the number +999111333555 (Channel 3).

It is also possible to adjust number of attempts that controller performs in case of not successful Active Call –

Comms settings:ActCallAttempt. The language of messages can be changed –

Comms settings:Acall+SMS lang (use Translator and Languages tabs in GenConfig to adjust languages).

Up to five channels can be used.

Variable speed support

This fw contains variable speed support which is used on Hybrid ship (ship with DC bus).

Variable speed control is usually used on ship where the gen-sets work in long term period on small load. By

changing speed on genset is possible to achieve lower fuel consumption.

Frequency (and Voltage) are usually control according to current load.

For variable speed is used:

Setpoints:

Nominal freq 30..65 Hz (step 1 Hz) FV (Basic settings Group)

ForceBlock6Del 0-60s (step 0,1s) FV (Delays/Timers Group)

GenNomV, BusNomV FV (Basic settings Group)

Voltage dependence on frequency

In generator is induced magnetic flux, which is almost constant in various RPM.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 32

32

30Hz

50Hz

138V

230V

voltage

frequency

Magnetic flux =U/f ~konstant

It is necessary to change nominal frequency together with nominal voltage – due to their dependence.

Temporary blocking of fix frequency and voltage protections

Temporary blocking of frequency and voltage fix protections

After submitting a request for change of nominal frequency and voltage the generator needs some time for

performing the changes. During this time the fix frequency and voltage protections (connected to nominal

values) must be blocked.

The time need for blocking of these protections is set by setpoint:

ForceBlock6Del 0-60s (step 0,1s) FV (Delays/Timers Group)

HINT

With larger frequency range the regulation can be rougher, in this case the AC/DC inverter is expected.

WARNING!

Used generator should be designed for variable rotation.

With frequency changes the nominal value of Voltage must be also changed.

Force value – step by step guide

In this chapter there is complete step by step guide which shows how to use Force value function of the

controller.

Forcing of values is used to change particular setpoint temporarily by activation of related Binary Input. This

is used to change function of controller under given conditions (e.g. there are two different periods during the

day when Export limit given by distribution network is required or not).

WARNING!

Setpoints must not be written continuously (e.g. via Modbus connection)! If continuous change of setpoints

is required, combination of External values and Force value function needs to be used. The memory that

holds setpoints is designed for up to 105 writings. Than memory may be damaged!

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 33

33

Add or remove Force value

Change position of Force value functions (priority)

Change the name of the source setpoint

(available only for Force value 1-16 setpoints)

Select the value that should be forced (i.e.

the value of the particular setpoint)

Rename binary input that

triggers the forcing

ID of binary input

(1 for ForceValueIn 1 etc.)

Select source setpoint or value

Setpoints that are available for forcing may be identified by Force value button on the right side in GenConfig

(see the figure below).

When the button is clicked, Force value dialog appears.

For example if we add Force value:Force value 1 to be forced to ProcessControl:Export limit as value 0

(DISABLED) by Binary Input FORCEVALUEIN 1 we can change the function of Export limit from ENABLED to

DISABLED by activation of FORCEVALUEIN 1. It is possible to rename the setpoint to e.g.

Force value:ExportDisabled and Binary Input as well to e.g. DISABLEEXPLIM. The function will not change

(only the corresponding names).

It is possible to use several force value functions for one setpoint. If more than one forcing Binary Input is

active, the one with the highest position (lowest number in the Force value dialog) is used.

It is possible as well to use one Binary Input to force multiple setpoints (e.g. in case of complex function

change).

NOTE:

It is possible only to force value or setpoint in other setpoint if their dimension and range are the same (e.g.

only value with dimension in hours and which is Integer 16 to a setpoint with dimension hours and which is

as well Integer 16). You may use PLC block Convert to change the dimension and range if needed.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 34

34

Values for continuous writing from external sources

This function is especially designed for continuous writing of setpoints from external sources (e.g. via

Modbus connection).

WARNING!

Setpoints must not be written continuously (e.g. via Modbus connection)! If continuous change of setpoints

is required, combination of External values and Force value function needs to be used. The memory that

holds setpoints is designed for up to 105 writings. Than memory may be damaged!

It is possible to use up to four different External values for continuous writing from external sources. The

values are adjusted by setpoints in Force value group. Default (also initial) value may be adjusted, rate of

change of ExtValueX (by Binary Inputs EXTVALUEX UP and EXTVALUEX DOWN) can be adjusted as well as

high and low limit of the value.

There are two way, how to adjust External values. One is using Binary Inputs mentioned above. Second one

is to write the value directly using e.g. Modbus. External values then may be converted using PLC block

convert and force into setpoint which is then continuously forced (note: NOT WRITTEN) by the value of

ExtValueX. This way internal memory is safe and no damage may occur.

External values are reverted back to their default (initial) value (given by corresponding setpoint) when

Binary Input for their reset is active (and they change to the previous value after Binary Input deactivates).

When the Binary Input is active the External value cannot be changed by Modbus writing or by using Binary

Inputs for up and down value.

NOTE:

External values are not available for external writing when any Binary Input (up, down or reset) related to

them is active.

Note also that when the controller is reset (powered down and up again), all external values are reverted

back to their default (initial) values.

HINT

For information on how to write (or read) objects from controller via Modbus, please refer to the latest

Communication guide for InteliGen and InteliSys.

User Buttons

There are several User Buttons available in the controller. It is possible to set them on Soft Buttons in

InteliVision 5 or 8.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 35

35

Selects which button is this function mapped to

(0 – first button, 1 – second button and so on)

Choose UserButton index and

its function (ON/OFF etc.)

Choose which colour will be

available for this button

Select which condition triggers

which coulour

Adjust text for the button

when it is active or inactive

ON

Pressing the button changes the state of log. Binary Output USER BUTTON X to closed.

When the output is closed and the button is pressed state is not changed.

OFF

Pressing the button changes the state of log. Binary Output USER BUTTON X to opened.

When the output is opened and the button is pressed state is not changed.

ON/OFF

Pressing the button changes the state of log. Binary Output USER BUTTON X to opened or

closed depending on previous state (it is changed to the opposite state).

PULSE ON

Pressing the button issues log. Binary Output USER BUTTON X to close for one second.

NOTE:

Repeated pressing of button during the closed period (one second) causes issuing other

puls of length of one second to be generated from the moment of button pushing.

Available functions for soft buttons are listed in the following table.

HINT

It is possible to lock User Button with password (go to tab Commands in GenConfig). User Buttons 1-5, 6-8

and 9-16 can be locked separately. It is also possible to use User Buttons in SCADA diagrams.

User Mask function

In GenConfig you can easily set any object in Screen Editor to show or hide based on activation of particular

Logical Binary Input available for users. Below, there is diagram showing the setup of User Mask function in

Screen Editor.

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 36

36

Select the proper function

Show = appears when LBI gets active

Hide = disappears when LBI gets active

None = no function

Select the object

Select which User Mask is used for

this object

NOTE:

Masking of screens in InteliVision 5 supports only Show function

Use also other masking functions (masking can react on several internal states, e.g. activation of Timers).

Remote Control Function

It is possible to remotely control several Binary Outputs in the controller. You can either use Remote

Switches tool in InteliMonitor (select Remote switches in menu for corresponding controller), import Remote

Switches tool to a SCADA diagram in Line Diagram Editor or use external device via Modbus (register

#46361 and command #26 (1A hex), for more information on Modbus please refer to the InteliGen/InteliSys

Communication guide).

Remote Switch will activate or deactivate depending on remote control so it can be used to manually control

devices, simulate malfunctions while commissioning etc.

Figure: Remote Switches tool in InteliMonitor, Remote Switches tools in Line Diagram Editor and Mobus commands

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 37

37

LBO:RemoteControl1 LBI:Emerg. manual

Remote Switch

command

Vitual Output

Virtual Input

1

2

3

4

5

6

7

8

VPIO module

Remote Switches may be easily used to trigger logical Binary Input function and all other related functions as

normal switch on Binary Input. Module VPIO (Virtual Peripheral Inputs- Outputs) can be added to

configuration and it will copy the state of Remote Switch on virtual output to its counterpart virtual input.

Refer to the figure below for example.

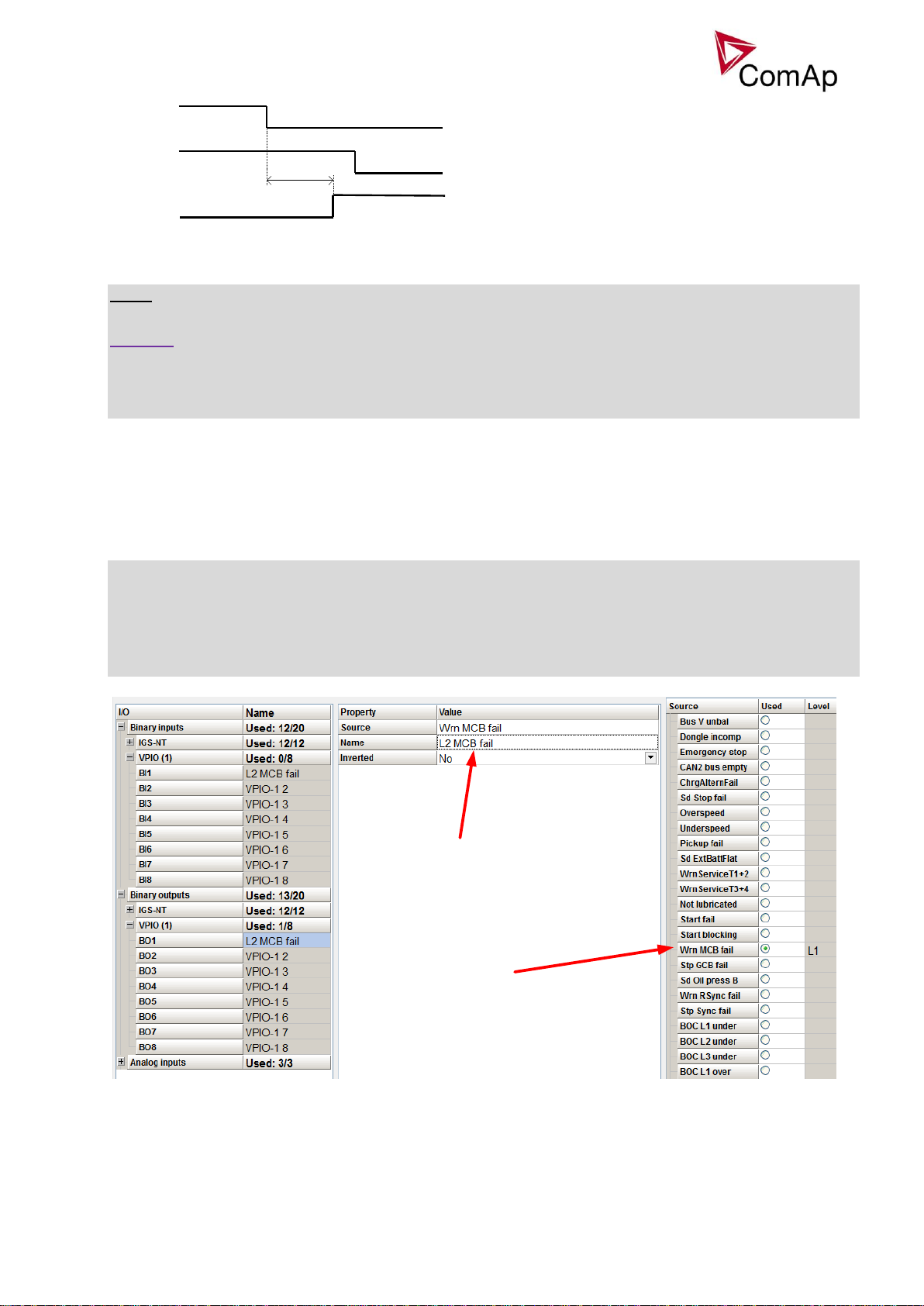

Virtual Peripheral Inputs-Outputs (VPIO) module

For the controller there are several modules available. One of them is Virtual Peripheral Inputs-Outputs

module which is particularly usefull for connection of logical Binary Output functions to logical Binary Input

functions. This way internal controller function may easily trigger other internal controller functions without

unnecessary wiring or usage of PLC functions.

Module is functioning the same way as normal module with 8 outputs and 8 inputs, but the difference is, that

each input copies its counterpart output. It is possible to select any logical Binary Output function for one of

the outputs of VPIO module. Inputs on VPIO module work the same way as standard input of the controller

(i.e. it can be assigned function and protection).

For example of this function please refer to the chapter Remote Control function.

Shared Inputs and Outputs

It is possible to share Binary and Analog values between all the controllers via CAN bus, thus saving

physical Inputs and Outputs and excess wiring.

Figure: Using of Remote Switches to trigger logical binary inputs

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 38

38

SHBOUT (1) SHBIN (1)

SHBOUT (2)

Not Received

Module SHBIN (2) is not

inserted

SHBOUT (3)SHBIN (3)

SHBIN (2)

Not Received

Module SHBIN (3) is not

inserted

Not Received

Module SHBIN (1) is not

inserted

CAN

CAN

Controller 1 Controller 2

Controller 3

Shared Binary Inputs and Outputs may be used exactly in the same way as standard physical Inputs and

Outputs. If SHBIN or SHAIN modules are configured, at least one corresponding module of SHBOUT or

SHAOUT (respectively) is needed. If it is not configured, corresponding protection appears because SHBIN

or SHAIN will be missing. See the figure below for more information.

CAUTION!

For proper function of Shared Binary and Analog Inputs and Outputs, only one source of Shared Binary or

Analog Outputs must be configured (i.e. it is not possible to configure in one controller SHBOUT1 and to

another one as well SHBOUT1).

HINT

Controller sends Shared Binary Outputs each 100ms if there are any changes in any bit position. If there are

no changes, controller sends the information with period 1s.

Figure: Adding of various modules

Figure: Principal Scheme (same for shared Binary I/O and shared Analogue I/O

Inteli NT GeCon-MARINE SPI, SW Version 3.2, ©ComAp – July 2015

IGS-NT-GeCon-MARINE-SPI-3.2.PDF

Page 39

39

SHBIN (1)

SHBOUT (2)

Not Received

Module SHBIN (2) is not

inserted

SHBOUT (3)SHBIN (3)

CAN

Controller 2

Controller 3

Not Transimitted

Module SHBOUT (1) is not

inserted

Level 1, Level 2 or no protection is displayed

DISTBOUT

DISTBIN

-01

DISTBIN

-02

DISTBIN

-03

DISTBIN

-04

Controller CAN 1

DISTBOUT

DISTBIN

-01

DISTBIN

-02

DISTBIN

-03

DISTBIN

-04

Controller CAN 2

DISTBOUT

DISTBIN

-01

DISTBIN

-02

DISTBIN

-03

DISTBIN

-04

Controller CAN 3

DISTBOUT

DISTBIN

-01

DISTBIN

-02

DISTBIN

-03

DISTBIN

-04

Controller CAN 4

CAN communication

Distributed Binary Inputs and Outputs

It is possible to share Binary and Analog values between all the controllers via CAN bus, thus saving

physical Inputs and Outputs and excess wiring.

DISTBIN and DISTBOUT work in a different way than SHBIN and SHBOUT. Each controller has one pack of

eight DISTBOUT available (if not configured or no function is assigned to any output, it does not broadcast

them). The number of DISTBOUT module is not shown in the configuration and it is always corresponding to

the CAN address of the controller (e.g. the controller with address 5 will be broadcasting DISTBOUT-05

which can be received if module DISTBIN-05 is configured in another controller. Up to 32 DISTBIN modules

can be configured (meaning that the controller will be receiving all DISTBOUT from all the controller, even

his own).

It is not possible to change the name of DISTBIN inputs or add protections.

In the example below you can see 4 controllers with various DISTBIN and DISTBOUT configuration.

NOTE:

HINT

Controller sends Distributed Binary Outputs each 100ms if there are any changes in any bit position. If there