Page 1

Copyright © 2006-7 ComAp s.r.o.

ComAp, spol. s r.o.

Světova 7, 180 00 Praha 8, Czech Republic

Tel: +420 266 790 611, Fax: +420 266 316 647

Technical support hotline: +420 266 790 666

E-mail: 73Hinfo@comap.cz

, 74Hwww.comap.cz

USER GUIDE

Compact Controller for Stand-by and Parallel Operating Gen-sets

Inteli New Technology

Modular Generator Controller

Multiple Internal engines application – SW configuration

MINT - GeCon

IG-NT, IG-NTC, IG-EE, IG-EEC

Software version IGS-NT-GeCon-1.4, June 2007

Page 2

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

2

Table of Contents

Table of Contents ...............................................................................................................................................2

General guidelines..............................................................................................................................................3

What is described in this manual? .................................................................................................................3

General description ............................................................................................................................................5

Description of the controller system (with all options)....................................................................................5

Comparing of IG-NT-GeCon-1.3 to the standard IG-NT-MINT-2.0................................................................5

Available documentation ................................................................................................................................5

Functions ............................................................................................................................................................6

Modified setpoints ..........................................................................................................................................6

Power management .......................................................................................................................................8

PLC functions ...............................................................................................................................................14

Multi language support.................................................................................................................................14

Protections and Alarm management ................................................................................................................15

Gen-set operation states ..................................................................................................................................18

Inputs and Outputs ...........................................................................................................................................19

Virtual and physical modules .......................................................................................................................19

Binary Inputs - Control .................................................................................................................................19

Binary inputs – Status information ...............................................................................................................24

Binary outputs – Breaker control..................................................................................................................24

Binary outputs – Control loops.....................................................................................................................25

Binary outputs – Status information .............................................................................................................26

Binary outputs – Fixed protection outputs....................................................................................................28

Binary outputs – Configurable prog. States .................................................................................................30

Binary outputs – Power management..........................................................................................................32

Analog inputs................................................................................................................................................33

Analog outputs .............................................................................................................................................33

Analog values...............................................................................................................................................33

Setpoints...........................................................................................................................................................34

ProcessControl.............................................................................................................................................34

Basic settings ...............................................................................................................................................39

Engine protect ..............................................................................................................................................43

Analog protect ..............................................................................................................................................46

Gener protect ...............................................................................................................................................46

Pwr management .........................................................................................................................................52

Sync/Load ctrl...............................................................................................................................................56

Volt/PF ctrl....................................................................................................................................................59

Force value...................................................................................................................................................61

Load shedding..............................................................................................................................................62

Timer settings...............................................................................................................................................63

Act. calls/SMS ..............................................................................................................................................63

Date/Time.....................................................................................................................................................65

Controller configuration and monitoring ...........................................................................................................66

Direct connection to the PC .........................................................................................................................66

GenConfig functions.....................................................................................................................................66

InteliMonitor..................................................................................................................................................67

Modbus protocol...........................................................................................................................................67

Value and setpoint codes.............................................................................................................................67

Technical data..............................................................................................................................................67

Page 3

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

3

General guidelines

What is described in this manual?

This manual describes IGS-NT-GeCon - „MINT“ software configuration. The Generator controller software

configuration is designed for multiple sets applications with internal load sharer and synchronizer.

What is the purpose of this manual?

This manual provides general information on how to configure and operate the controller.

This manual is intended for use by:

Operators of gen-sets

Gen-set control panel builders

For everybody who is concerned with installation, operation and maintenance of the gen-set

!! Warnings !!

Remote control

The IG-NT controller can be remotely controlled. In case that maintenance needs to be done to the gen-set,

check the following to ensure that the engine cannot be started.

To be sure:

Disconnect remote control via RS232 line

Disconnect input REMOTE START/STOP

or

Disconnect output STARTER and output GCB CLOSE/OPEN

The controller contains a large number of configurable setpoints, because of this it is impossible to describe

all of its functions. These are subject to change from SW version to SW version. This manual only describes

the product and is not guaranteed to be set for your application on arrival.

Text

PAGE (Capital letters in the frame) buttons on the front panel

Break Return (Italic) set points

Generator protections (Bold) Set point group

REMOTE START/STOP (Capital letters) binary inputs and outputs

Cyan background Valid for IS-NT only

Conformity declaration

Following described machine complies with the appropriate basic safety and health

requirement of the EC Low Voltage Directive No: 73/23 / EEC and EC

Electromagnetic Compatibility Directive 89/336 / EEC based on its design and type,

as brought into circulation by us.

Note:

ComAp believes that all information provided herein is correct and reliable and reserves the right to update

at any time. ComAp does not assume any responsibility for its use unless otherwise expressly undertaken.

Page 4

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

4

WARNING – VERY IMPORTANT !!!

Be aware that the binary outputs can change state during and after software

reprogramming (before the controller is used again ensure that the proper

configuration and setpoint settings are set in the controller)!!!

Be aware that gen-set can automatically or remotely start !!!

Switch the controller to MAN mode and disconnect the Binary outputs Starter and Fuel

to avoid unexpected automatic start of gen-set and GCB closing.

!!! CAUTION !!!

Dangerous voltage

The terminals for voltage and current measurement should never be touched.

Properly connect the grounding terminals.

Do not disconnect the CT terminals for any reason.

Adjust set points

All setpoints are preadjusted to their typical values. But the set points in the “Basic settings” settings

group !!must!! be adjusted before the first startup of the gen-set.

!!! WRONG ADJUSTMENT OF BASIC PARAMETERS

CAN DESTROY THE GEN-SET !!!

The following instructions are for qualified personnel only. To avoid personal injury do

not perform any action not specified in this User guide !!!

Page 5

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

5

General description

Description of the controller system (with all options)

NT Family controllers are comprehensive AMF-controllers for single and multiple generating sets operating

in stand-by or parallel modes. A modular construction allow upgrades to different levels of complexity in

order to provide the best solution for various customer applications.

NT Family controllers are equipped with a powerful graphic display showing icons, symbols and bar-graphs

for intuitive operation, which sets, together with high functionality, new standards in Gen-set controls.

The controller automatically starts the gen-set, closes the Gen-set C.B. when all conditions are met, then

stops the engine on external signal or by pressing push buttons.

Parallel to the Mains operation is a standard feature. Isolated parallel and Power Management System

support are optional. Forward and reverse synchronizing, Generator protections, Mains protection including

vector shift, load and power factor control are the major functions provided. Interfacing to foreign

synchronizers and load sharers is supported.

The key feature of the controller is its easy-to-use operation and installation. Predefined configurations for

typical applications are available as well as user-defined configurations for special applications.

Comparing of IG-NT-GeCon-1.3 to the standard IG-NT-MINT-2.0

• GeCon does not take care of Engine control – option adjustable by setpoints.

• GeCon does not directly control GCB – option adjustable by setpoints.

• GeCon accepts external – “by hand” Engine and GCB control.

• GeCon can control the engine via Binary start/stop output signals only – see below. The independent

Engine controller (e.g. ID-DCU) is expected.

• Synchronizing and unloading timeouts can be disabled by setpoint setting (or Force value function).

• Interface GeCon to engine controller is provided by I/O wires no by communication line.

Available documentation

IGS-NT-Application guide-2.1.pdf

IGS-NT-Installation guide-2.1.pdf

IGS-NT-Operator guide-2.1.pdf

GenConfig-2.1.pdf

InteliMonitor-2.1.pdf

Application examples.

All modules wiring.

Brief panel buttons, display handling guide.

PC configuration tool guide.

PC monitoring tool guide.

Page 6

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

6

Functions

The IGS-NT-LSM+PMS dongle enables the Load sharing and Power management functions.

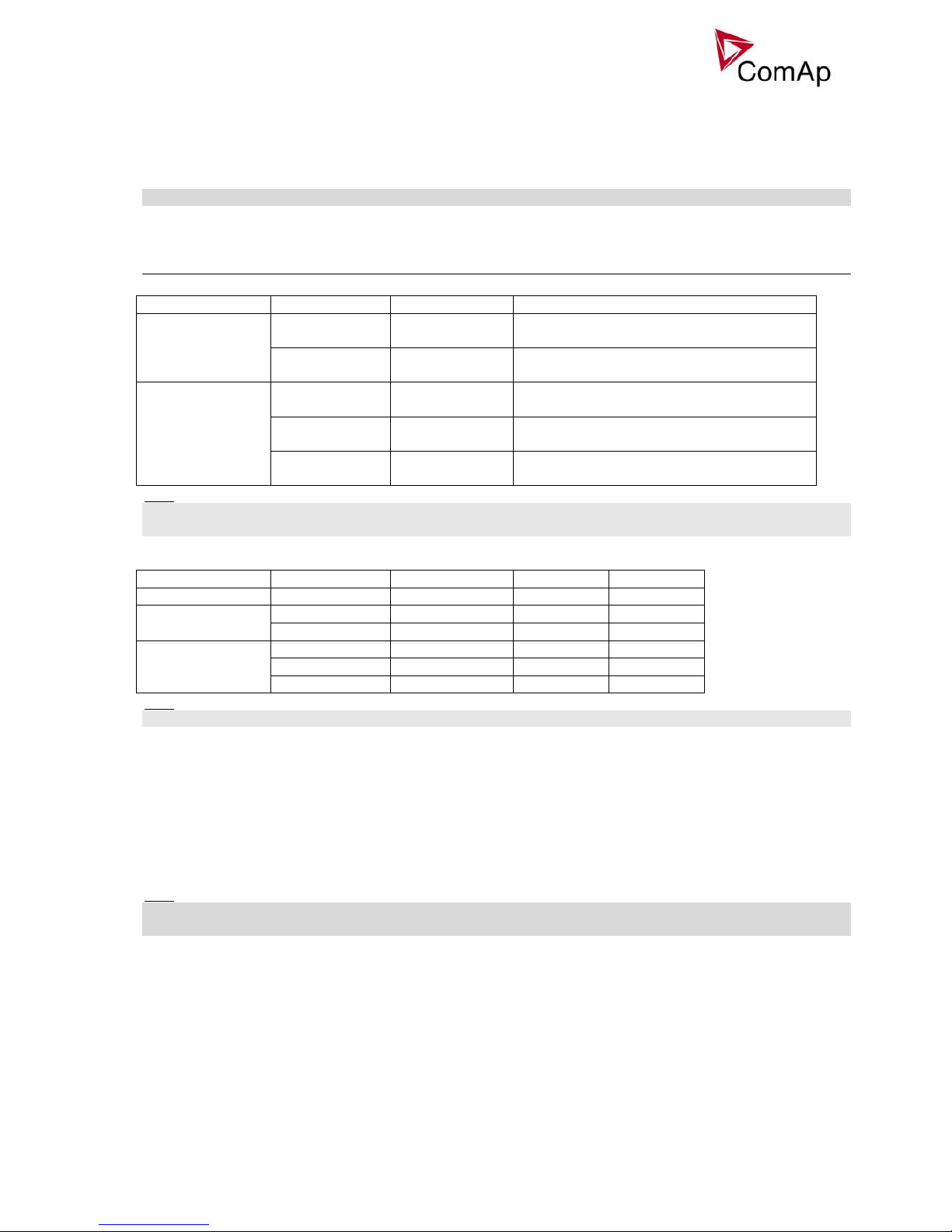

Modified setpoints

Below mentioned are GeCon specific setpoints only.

Group Setpoint Option Function

StartStopBtn

ENABLED

DISABLED

Standard panel Start/Stop buttons function.

Panel Start/Stop buttons are disabled.

Process control

ProtectionMode

ACTIVE

NOT ACTIVE

Standard MINT function.

2-nd level protections are blocked.

Sync timeout

1-1800s

NO TIMEOUT

Standard MINT function.

Unlimited synchronizing time.

GCB open level

1-100%

NO LEVEL

Standard MINT function.

No generator power open level detection.

Sync/Load ctrl

GCB open del

1-1800s

NO TIMEOUT

Standard MINT function.

Unlimited unloading procedure.

Hint:

All setpoints can be Forced by Binary input(s) to another value (or switched between ENABLED and

DISABLED).

Based on setpoint settings there are three possible operational modes HAND – MAN - AUT:

“HAND” MAN AUT

Basic setting ControllerMode

MAN MAN AUT

StartStopBtn

DISABLED ENABLED ENABLED

Process control

ProtectionMode

NOT ACTIVE ACTIVE ACTIVE

Sync timeout

NO TIMEOUT 1-1800s 1-1800s

GCB open level

NO LEVEL 1-100% 1-100%

Sync/Load ctrl

GCB open del

NO TIMEOUT 1-1800s 1-1800s

Hint:

It is possible to configure (Force value) “HAND” – MAN switching via Binary input.

OFF mode

Use OFF mode to block controller functions (even if is switched on). OFF mode is used for controller

firmware or configuration change.

Binary outputs (e.g. GCB CLOSE/OPEN) are not energized, all closed Binary outputs are opened when

controller is switched to OFF mode.

Gen-set cannot be started and operated from IG-NT-GeCon controller – no response for panell buttons and

Binary input commands.

Hint:

Switching to OFF mode is blocked on running engine to avoid accidental engine stop by mode change or by

firmware or configuration programming.

Page 7

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

7

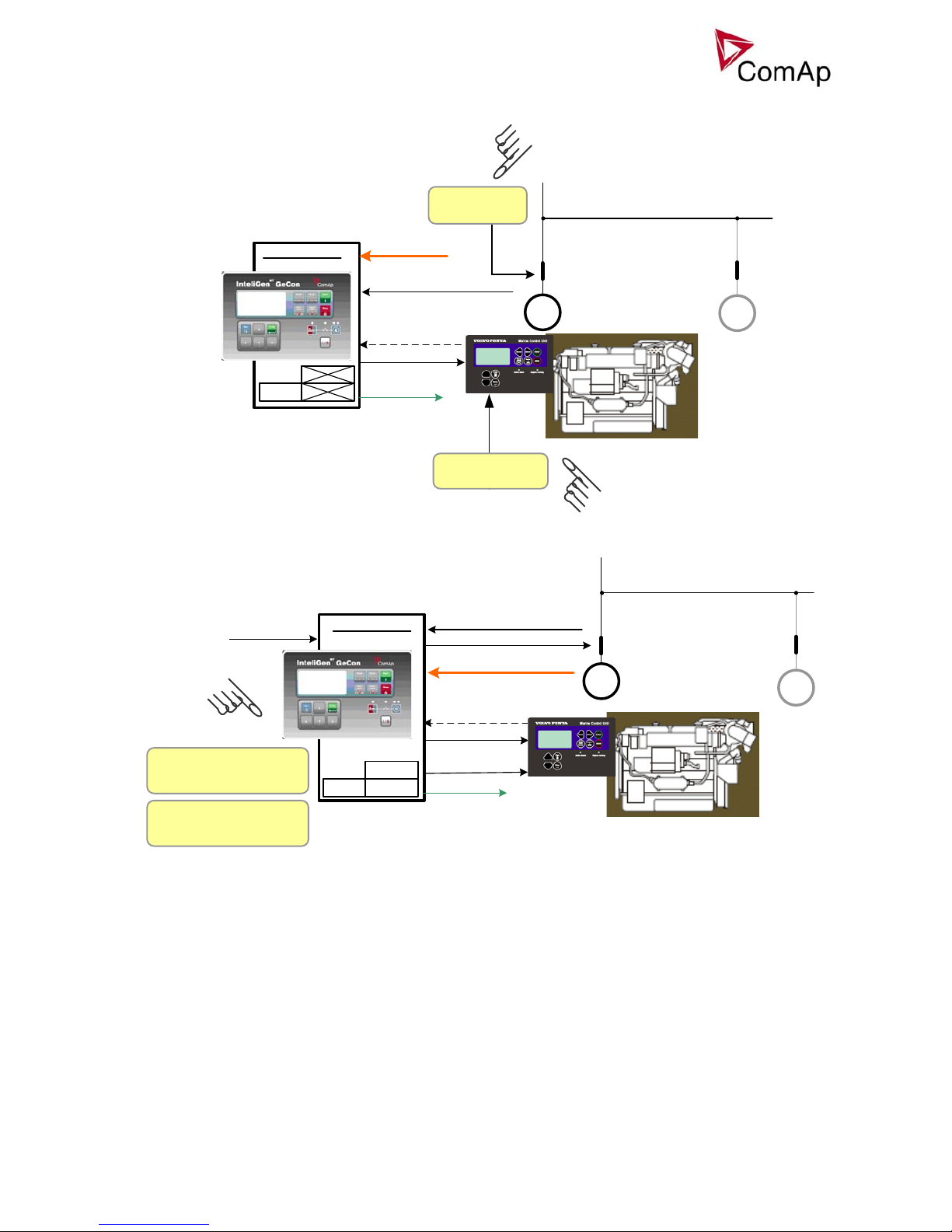

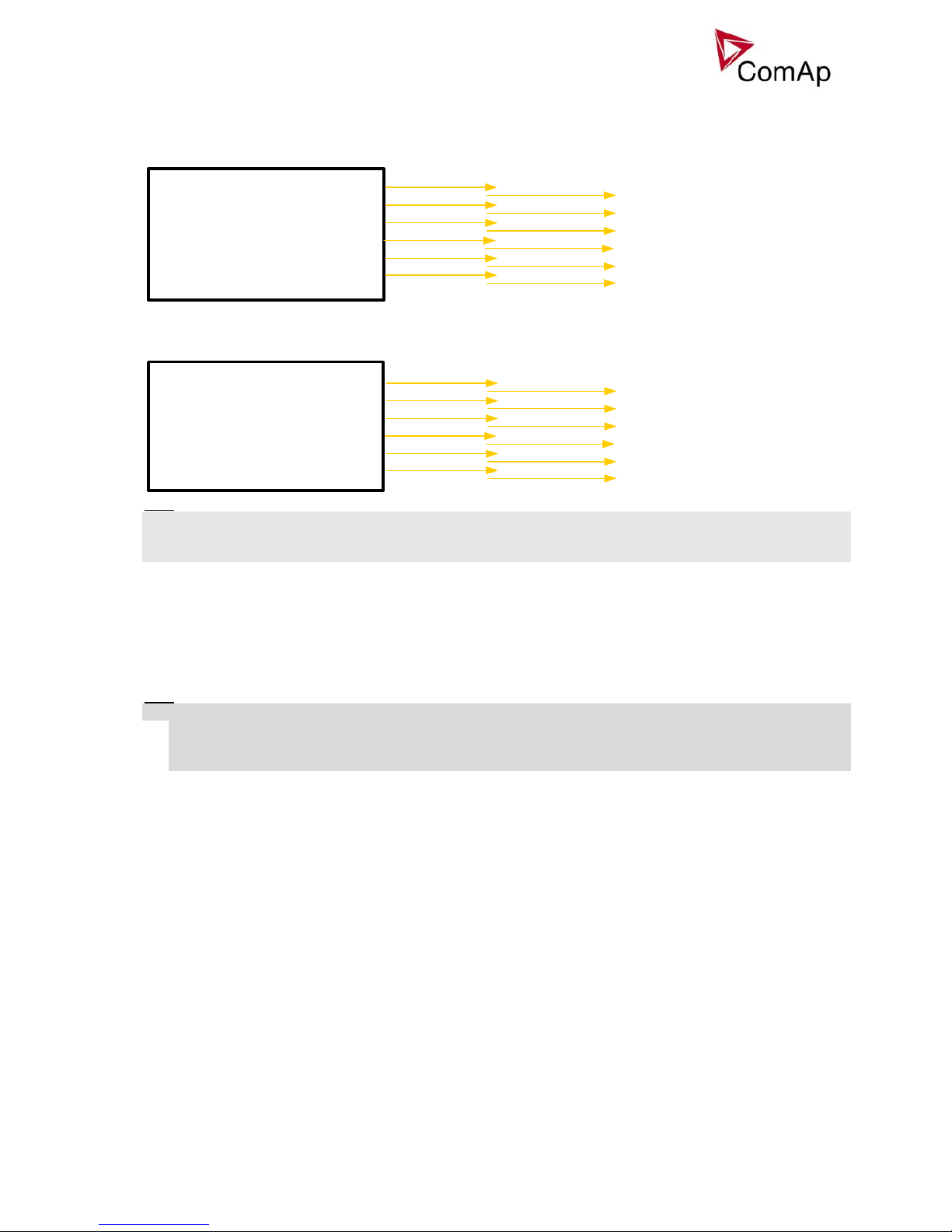

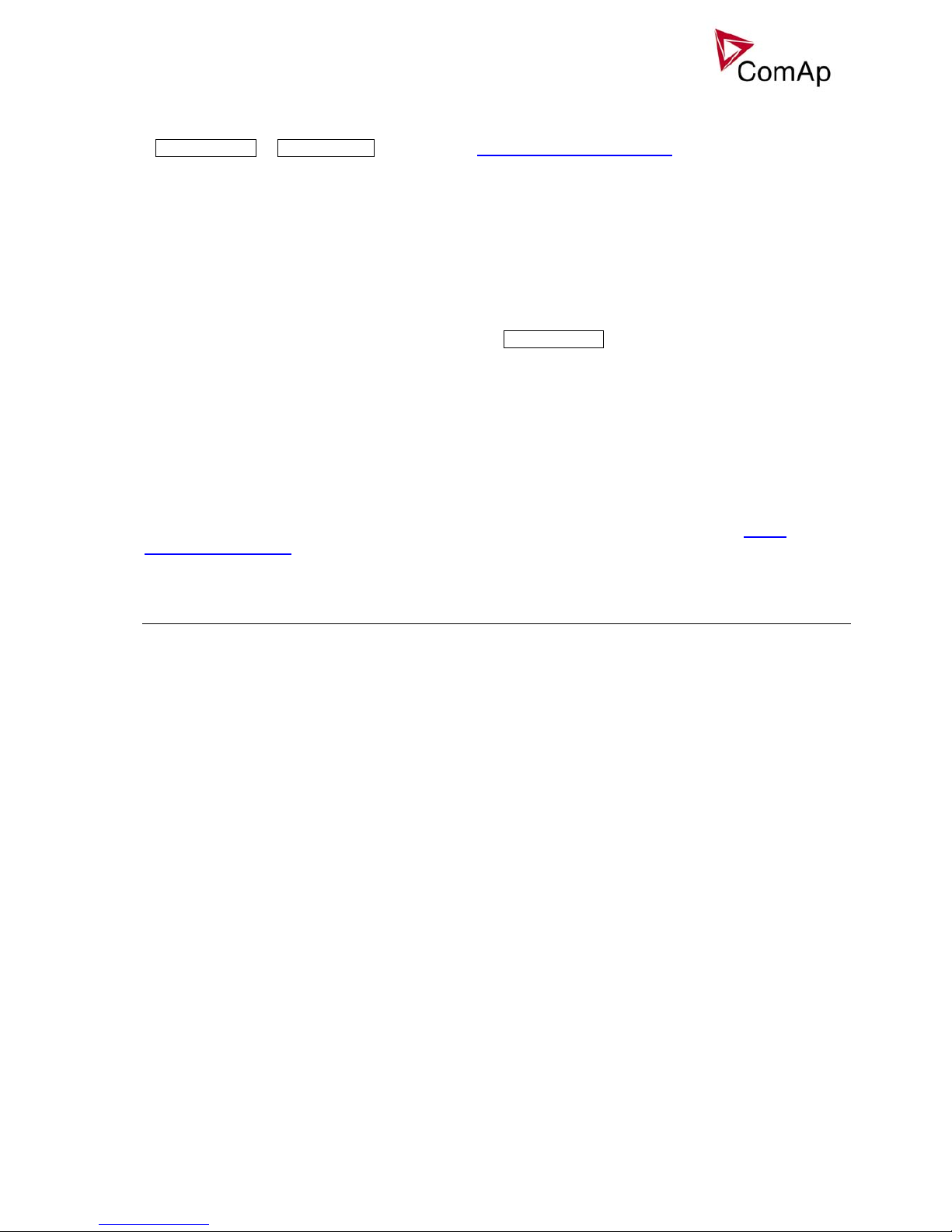

HAND mode

IG-EE GeCon

MINT

MCU

GCB feedback

GCB

close/open

Vg, Ig, Vb

RS232 - PC

Speed control

(Sync/Load ctrl)

GCB

START

STOP

(ReadyToLoad)

G

G

External Engine

Start / Stop

External GCB

Close / Open

generator

measuring

Process control: StartStopBtn = DISABLED

ProtectionMode = NOT ACTIVE

Sync/Load ctrl: Sync timeout = NO TIMEOUT

GCB open level = NO LEVEL

GCB open del = NO TIMEOUT

MCU

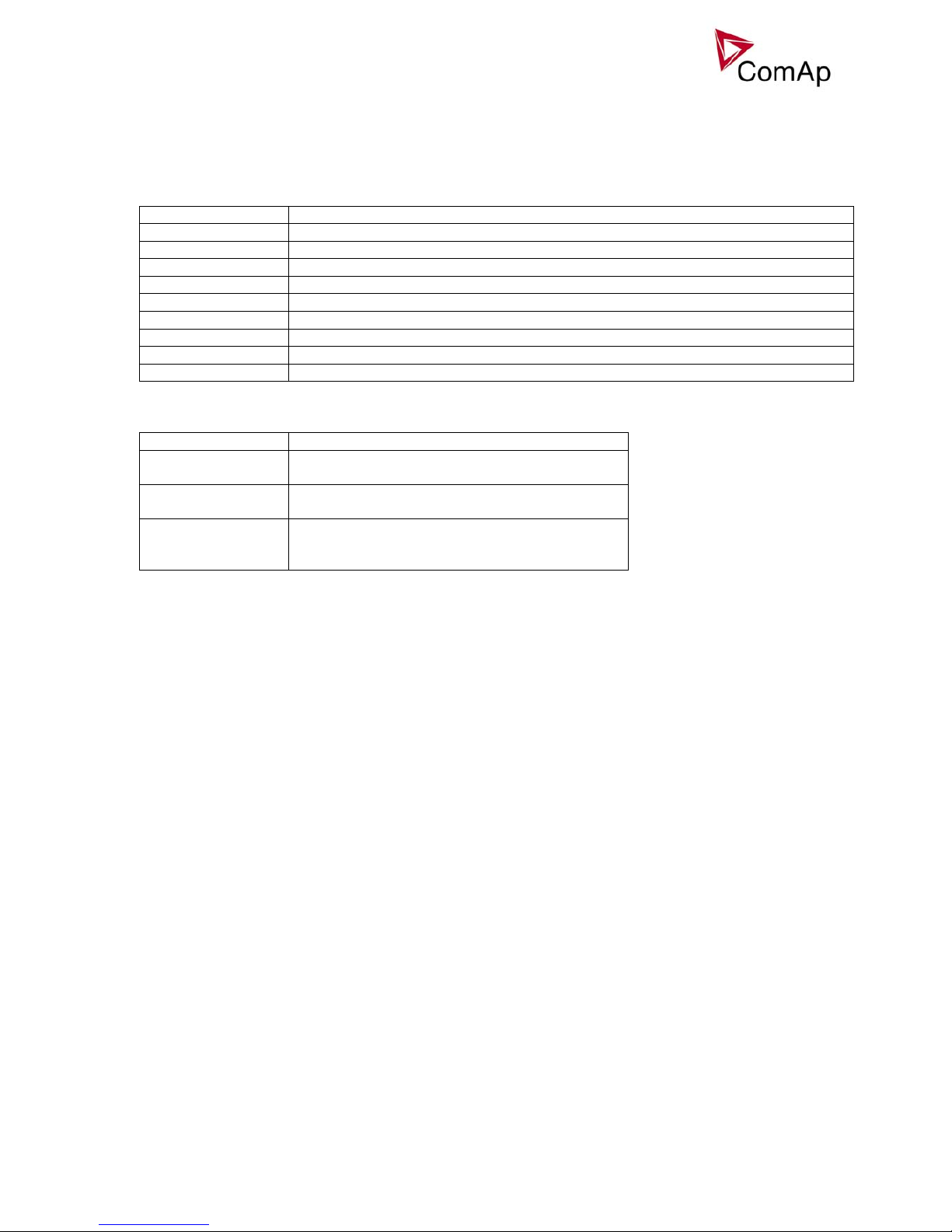

MAN mode

IG-EE GeCon

MINT

MCU

RS232 - PC

GCB

START

STOP

(ReadyToLoad)

G

GCB close/open

Remote start/stop

System s/s

G

Vg, Ig, Vb

Generator measuring

Process control: StartStopBtn = ENABLED

ProtectionMode = ACTIVE

Sync/Load ctrl: Sync timeout =

GCB open level =

GCB open del =

GCB feedback

Speed control

(Sync/Load ctrl)

Engine Start / Stop

is activated from GeCon

or externaly

GCB Close / Open is

activated from GeCon

or externaly

MCU

Engine start can be activated from

o Engine controller (e.g. ID-MCU)

o GeCon panel – Start button

o GeCon BI: StartButton

o Remotely e.g. from InteliMonitor

GeCon BI: ReadyToLoad initiates GeCon “Running” state” - activates Gener protect: Min stab time a Max

stab time within the generator electric protections are activated.

Gen-set is loaded/unloaded from

o GeCon panel – GCB button

o GeCon BI: GCBButton

o Direct GCB “hand” control

o Remotely e.g. from InteliMonitor

Page 8

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

8

GCB closing from controller can be blocked by BI: GCB disable.

AUT mode

Engine start or Power management is activated from GeCon BI: Sys start/stop

GeCon BI: ReadyToLoad initiates GeCon “Running” state” - activates Gener protect: Min stab time a Max

stab time within the generator electric protections are activated.

Gen-set starts synchronizing and is loaded/unloaded automatically based on

o Power management setting

o GeCon BI: Sys start/stop

GeCon will stop engine started from MCU when BI Sys start/stop or due to Power management function.

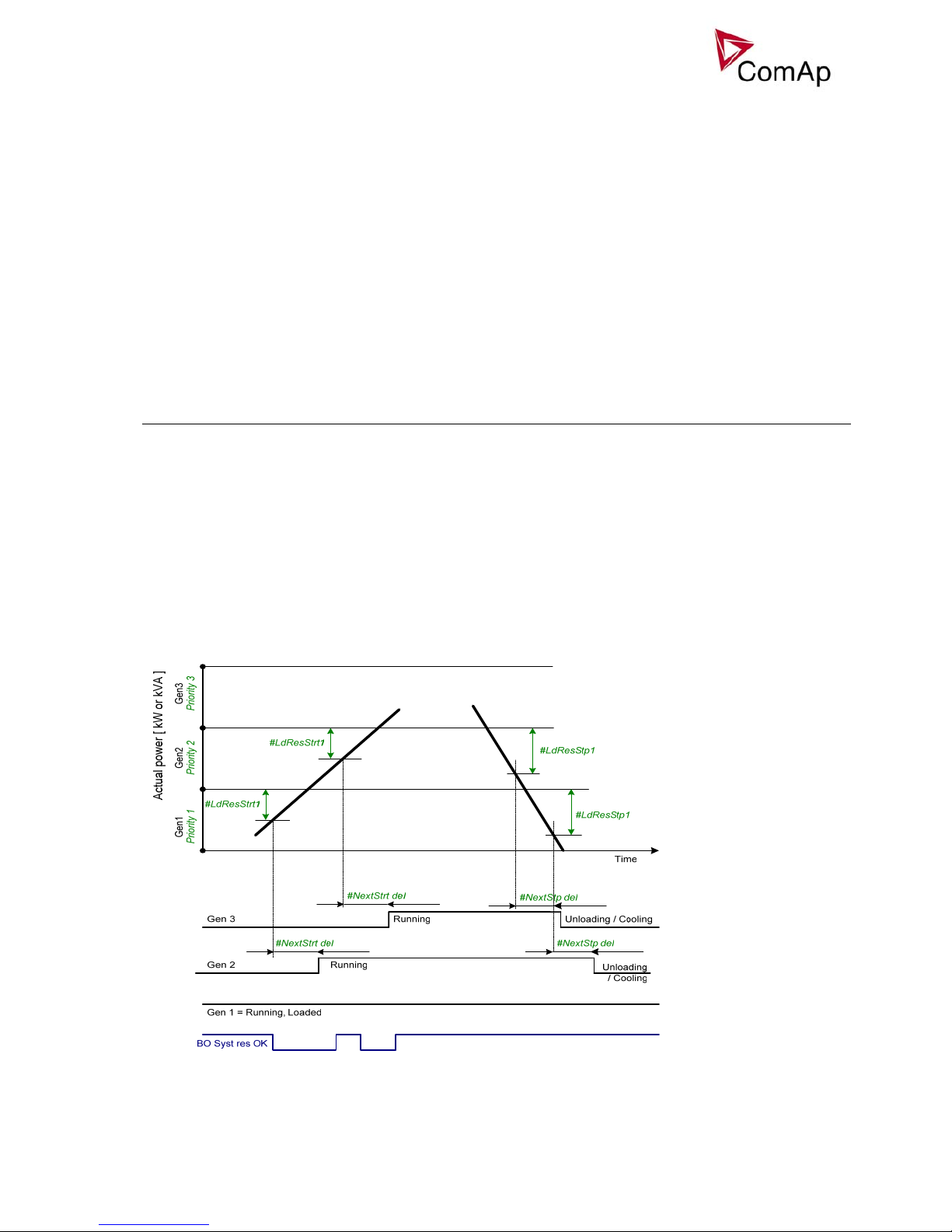

Power management

Automatic gen-set start / stop function based on load changes and/or Running hours or Engine size.

Following functions are available:

Power management in kW

Guarantees adjustable load reserve (load step) in kW. Suitable for load demand-based optimization.

Activation: #Pwr mgmt mode = ABS (kW)

Power management in kVA

Guarantees adjustable load reserve (load step) in kVA. Suitable for generator- or busbar dimensioningbased optimization.

Activation: #Pwr mgmt mode = ABS (kVA)

Page 9

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

9

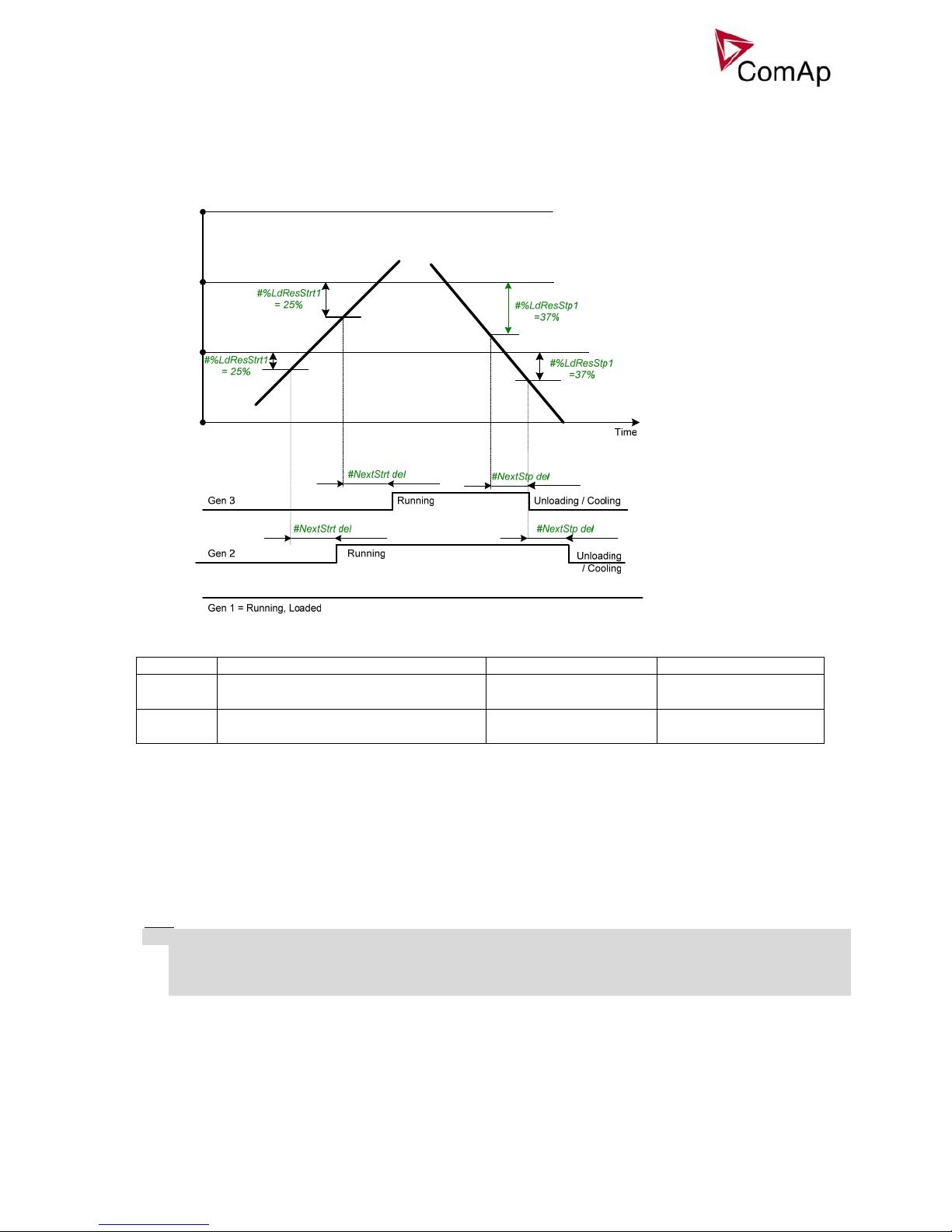

Relative power management in %

Guarantees that the engines be not continuously loaded more than to a certain level, leaving less than

selected relative load reserve. Suitable for engine life-based optimization.

Activation: #Pwr mgmt mode = REL (%)

Gen1

Priority 1

Gen2

Priority 2

Gen3

Priority 3

Actual power [ kW or kVA ]

Start/Stop conditions in Power management

Reserve Actual Reserve Start condition Stop condition

Absolute

kW / kVA

ARstrt = ΣPg

Nom

– ΣPg

Act

ARstp = ΣPg*

Nom

– ΣPg

Act

ARstrt < #LdResStrt ARstp > #LdResStp

Relative % RRstrt = (ΣPg

Nom

– ΣPg

Act

) / ΣPg

Nom

RRstp = (ΣPg*

Nom

– ΣPg

Act

) / ΣPg*

Nom

RRstrt < #%LdResStrt RRstp > #%LdResStp

Where

ARstrt Actual Absolute reserve in kW or kVA - for engine start calculation.

ARstp Actual Absolute reserves in kW or kVA - for engine stop calculation.

RRstrt Actual Relative reserve in % - for engine start calculation.

RRstp Actual Relative reserves in % - for engine stop calculation.

ΣPg

Nom

Sum of Nominal power of all gen-sets on the bus.

ΣPg*

Nom

Sum of Nominal power of all gen-sets on the bus apart of the one, which is going to be stopped.

ΣPg

Act

Sum of Actual power of all gen-sets on the bus = system load.

Hint:

Optional functions in absolute or relative Power management are:

- Running hours balancing (equalization),

- Load demand (different size) engines swap and

- Power management of two or more gen-set groups (bus tie support).

Page 10

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

10

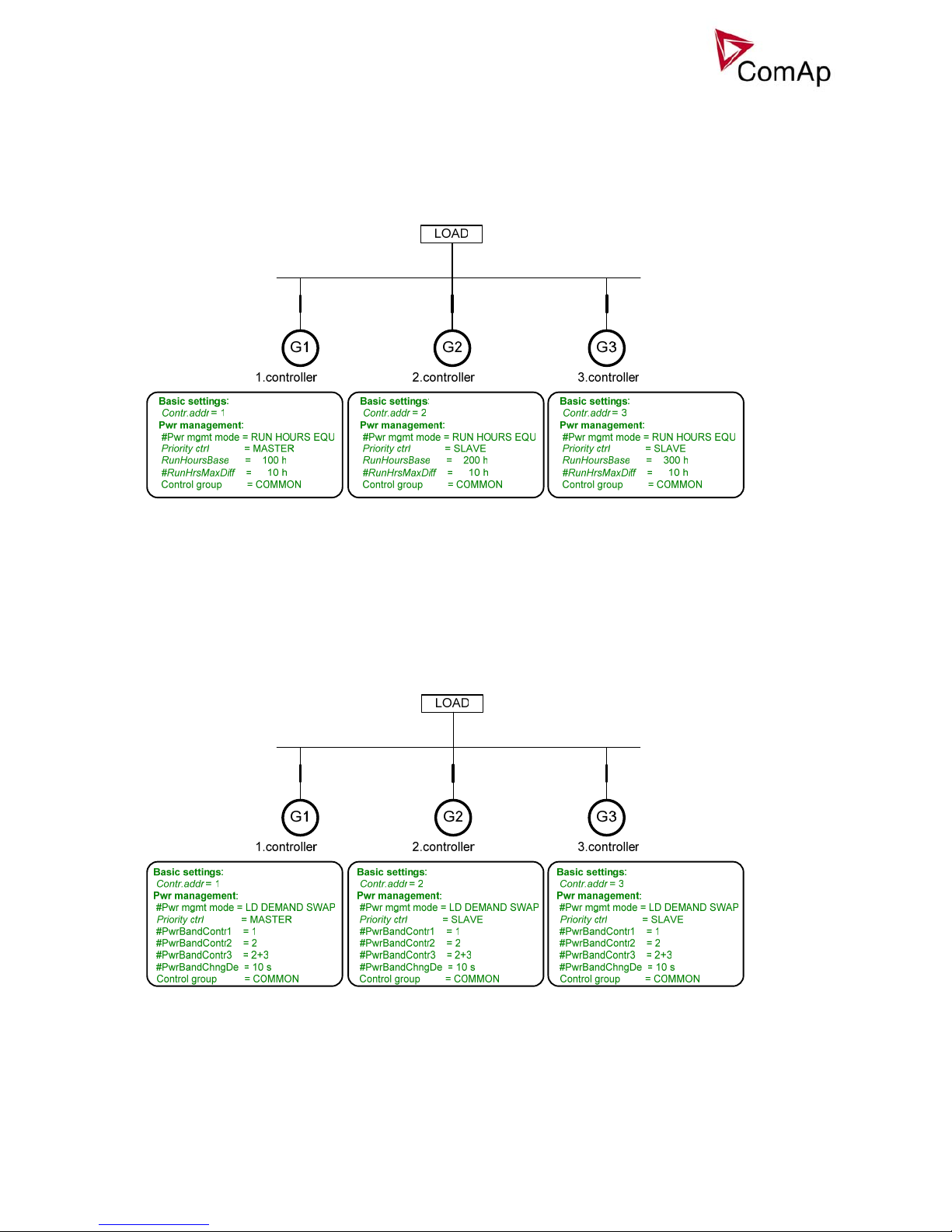

Running hours balancing

The gen-sets priorities are automatically swapped to balance engine running hours. Up to 32 controllers are

supported.

Activation: #PriorAutoSwap = RUN HOURS EQU

Important setpoints: RunHoursBase , #RunHrsMaxDiff

Different sized engines (Load demand) swap

Three running engines (priorities) are swapped based on load demand (one “small” engine runs on “small”

load and swaps to another one “big” engine that runs when load increases).

Activation: #PriorAutoSwap = LD DEMAND SWAP

Important setpoints: #PwrBandContr1, #PwrBandContr2, #PwrBandContr3, #PwrBandContr4,

#PwrBandChngDe.

Page 11

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

11

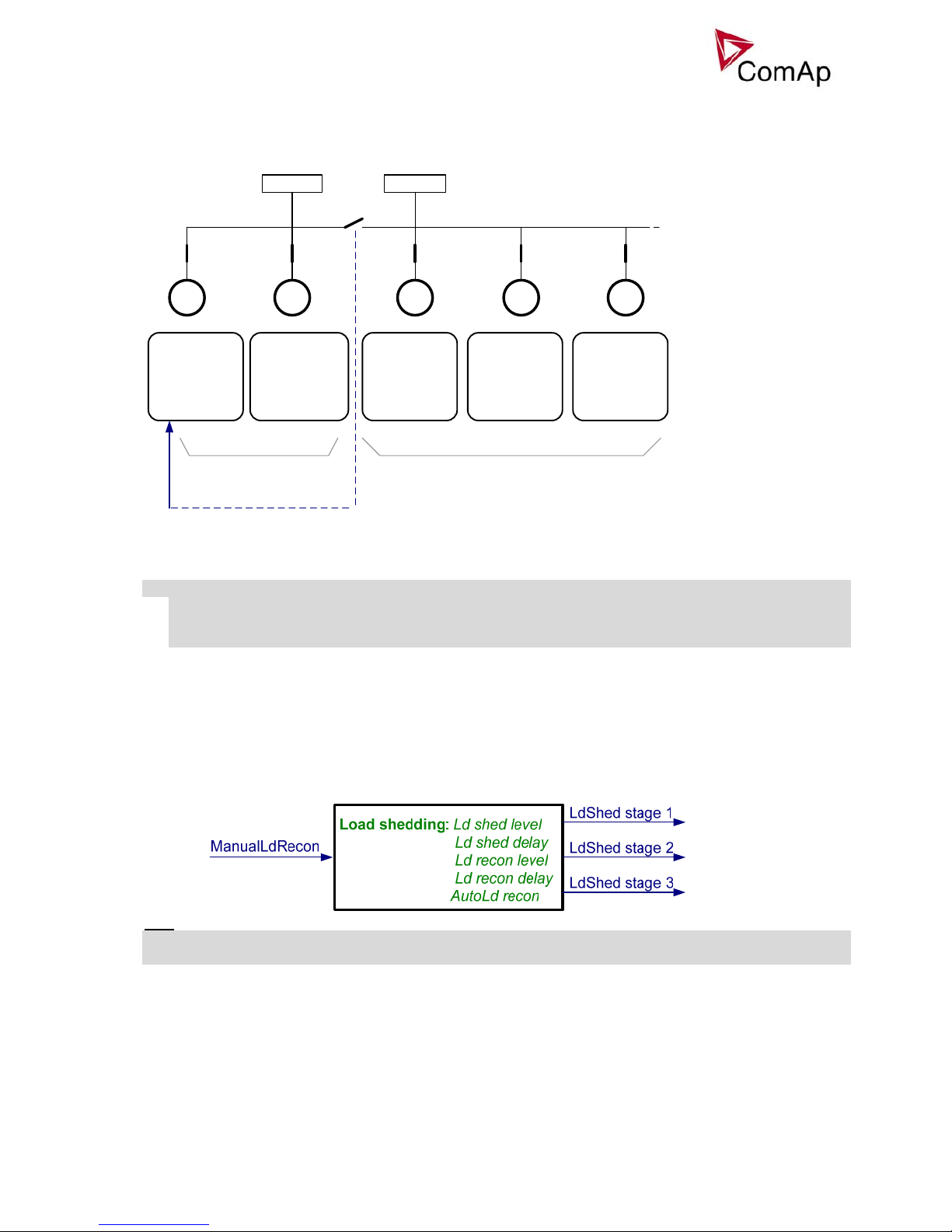

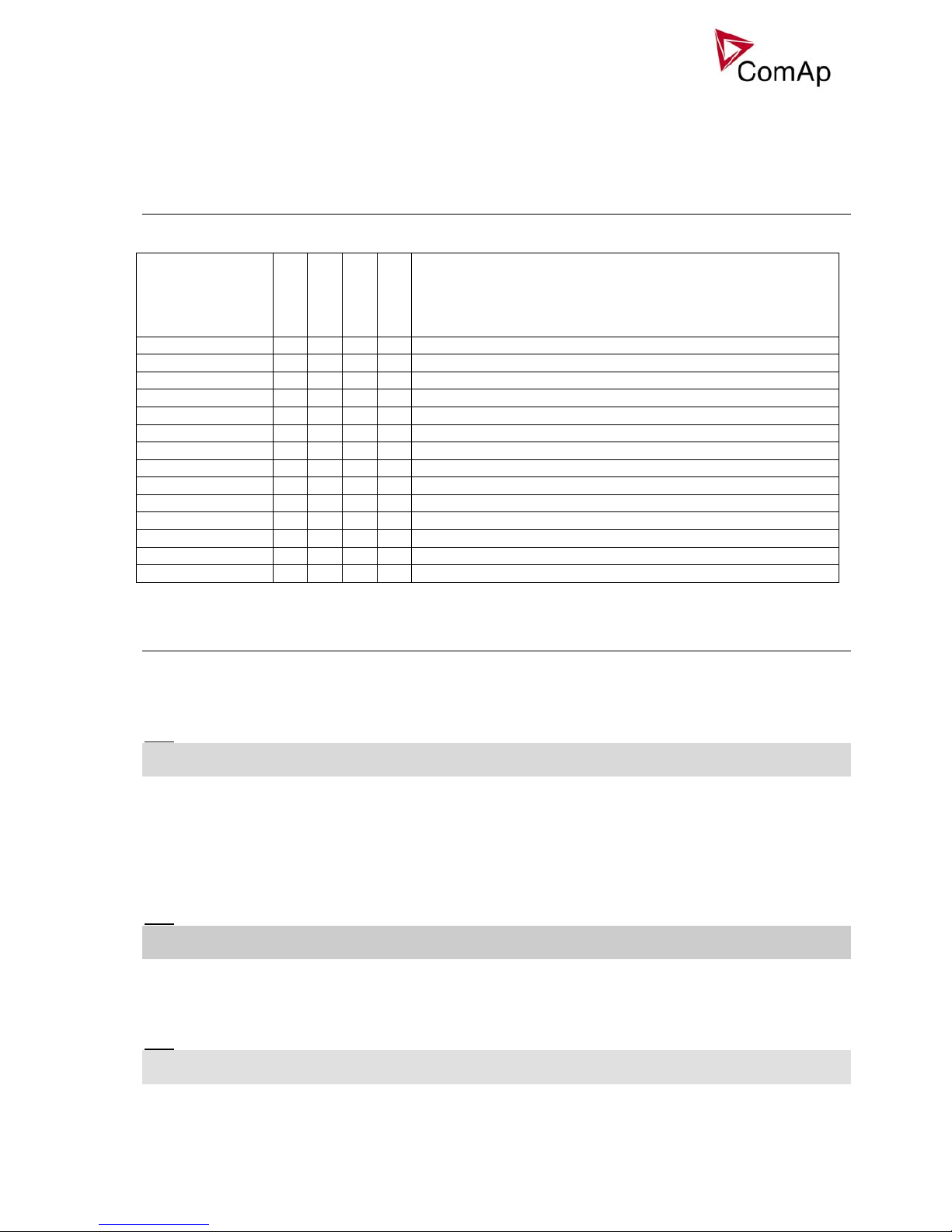

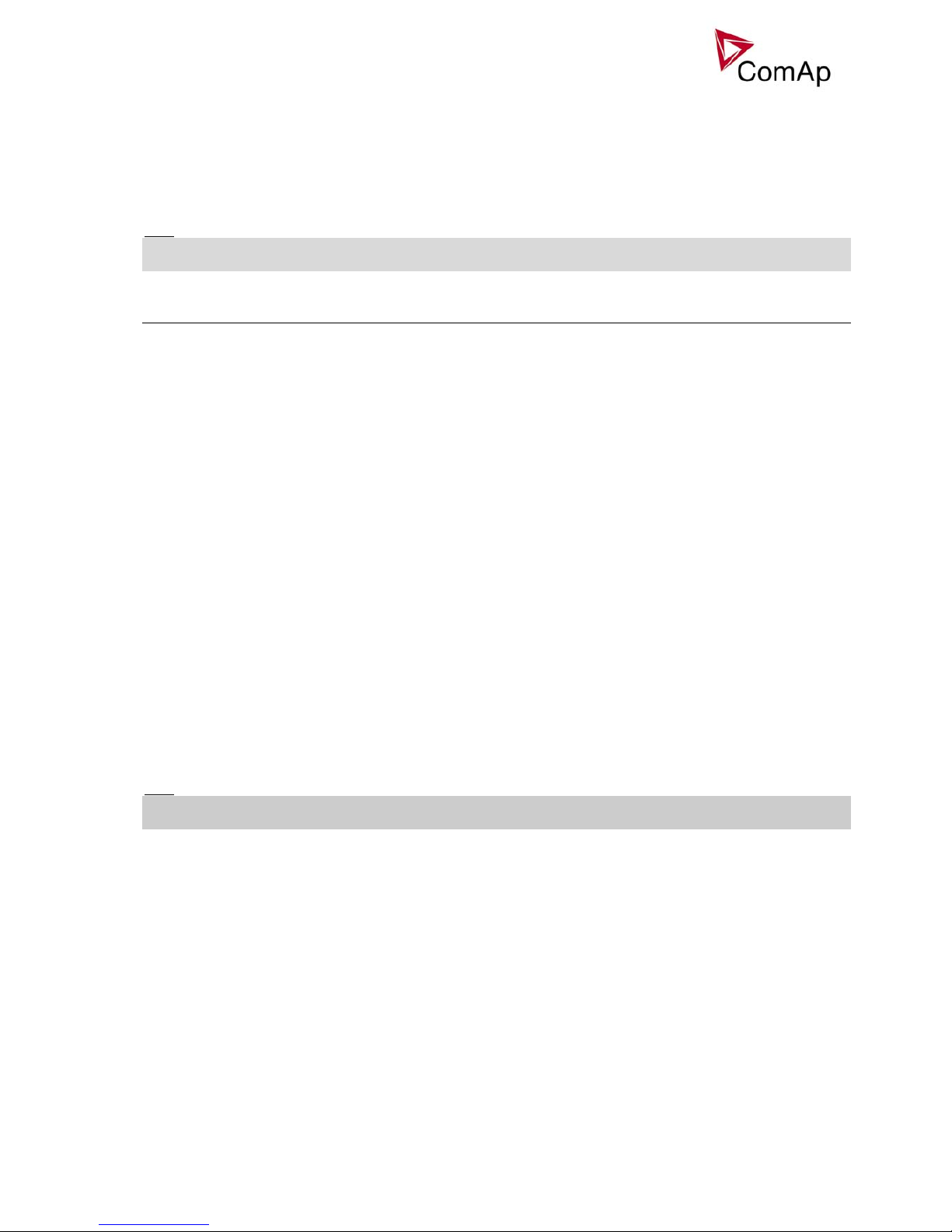

Pwr management of splitted group

Important setpoints: Control group, GroupLinkLeft, GroupLinkRight

When a Bus-tie disconnects the gen-set group the Power management can operate separately on each of

them.

G1 G2 G3 G4 G5

LOAD1 LOAD 2

Basic settings:

Contr.addr = 1

Pwr management:

Control group = 1

GroupLinkLeft = 1

GroupLinkRight = 2

BTB

BI Group link

1.controller

2.controller

3.controller 4.controller 5.controller

Basic settings:

Contr.addr = 2

Pwr management:

Control group = 1

GroupLinkLeft = C

GroupLinkRight = C

Basic settings:

Contr.addr = 3

Pwr management:

Control group = 2

GroupLinkLeft = C

GroupLinkRight = C

Basic settings:

Contr.addr = 4

Pwr management:

Control group = 2

GroupLinkLeft = C

GroupLinkRight = C

Basic settings:

Contr.addr = 5

Pwr management:

Control group = 2

GroupLinkLeft = C

GroupLinkRight = C

Control group 2.

Control group 1.

BTB feedback

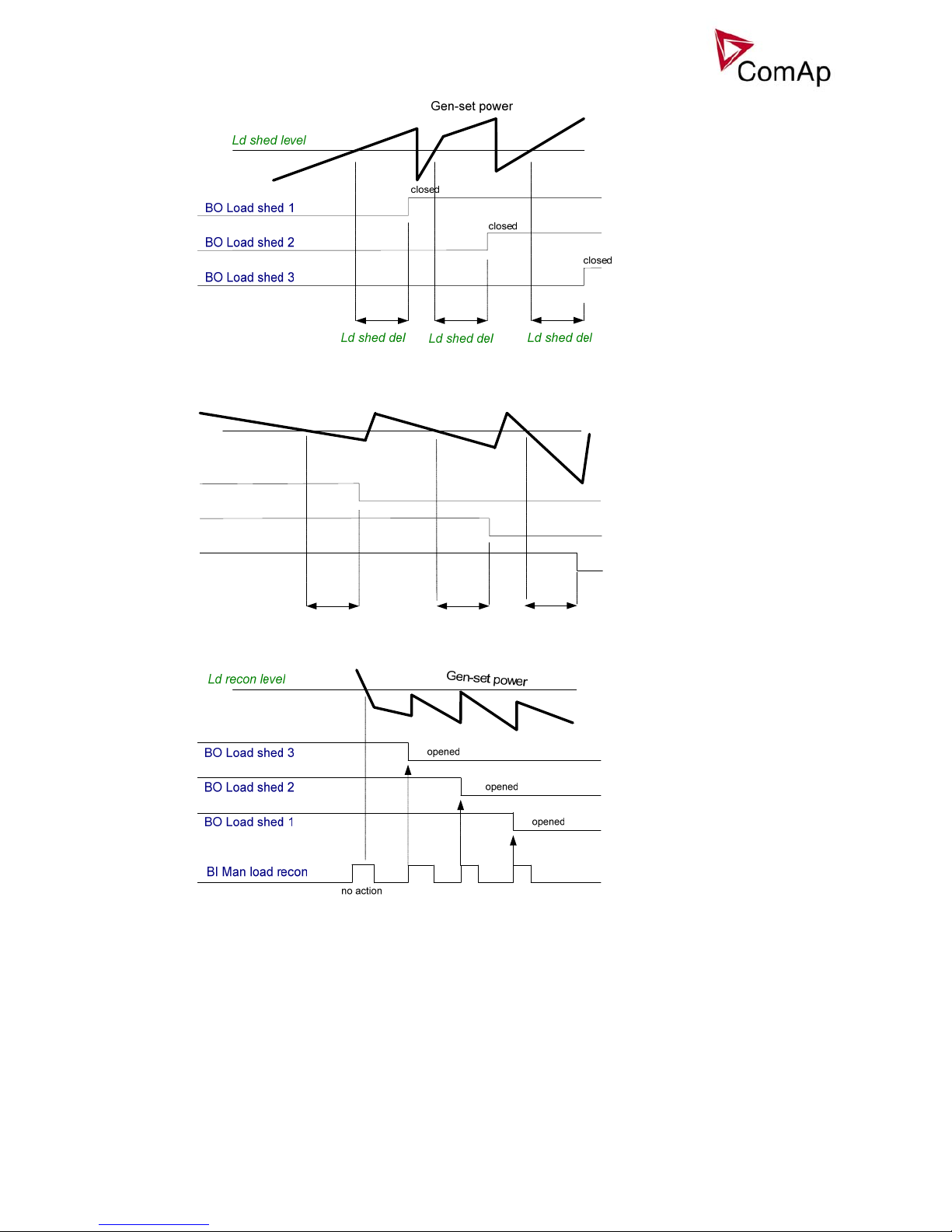

Load shedding

All LOAD SHED outputs are activated (closed) to trip the unessential load when gen-set goes to island:

a) When GCB is closed after mains fail and gen-set starts in AUT mode.

b) When MCB opens from parallel to mains operation in AUT mode.

c) Before MCB is opened in MAN mode by button.

The load shedding function is active in all controller modes except OFF.

Load shedding has three steps and each step is linked with its own Load shed x binary output. There is only

one load shed level and delay for all three steps as well as recon level and delay. Load shed can only move

from one step to the next, e.g. No LoadShed to LdShed S1 to LdShed S2 to LdShed S3 and vice versa.

If manual reconnection of the load is desired, the AutoLd recon setpoint needs to be disabled (AutoLd recon

= DISABLED) and the MAN load recon binary input needs to be configured.

Rising edge on this input resets the controller to a lower stage, but only if the load is under the Ld recon level

at that moment.

Hint:

If no Load Shedding outputs are configured, there is no record to history and no scrren timer indication of the

activity of this function.

Page 12

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

12

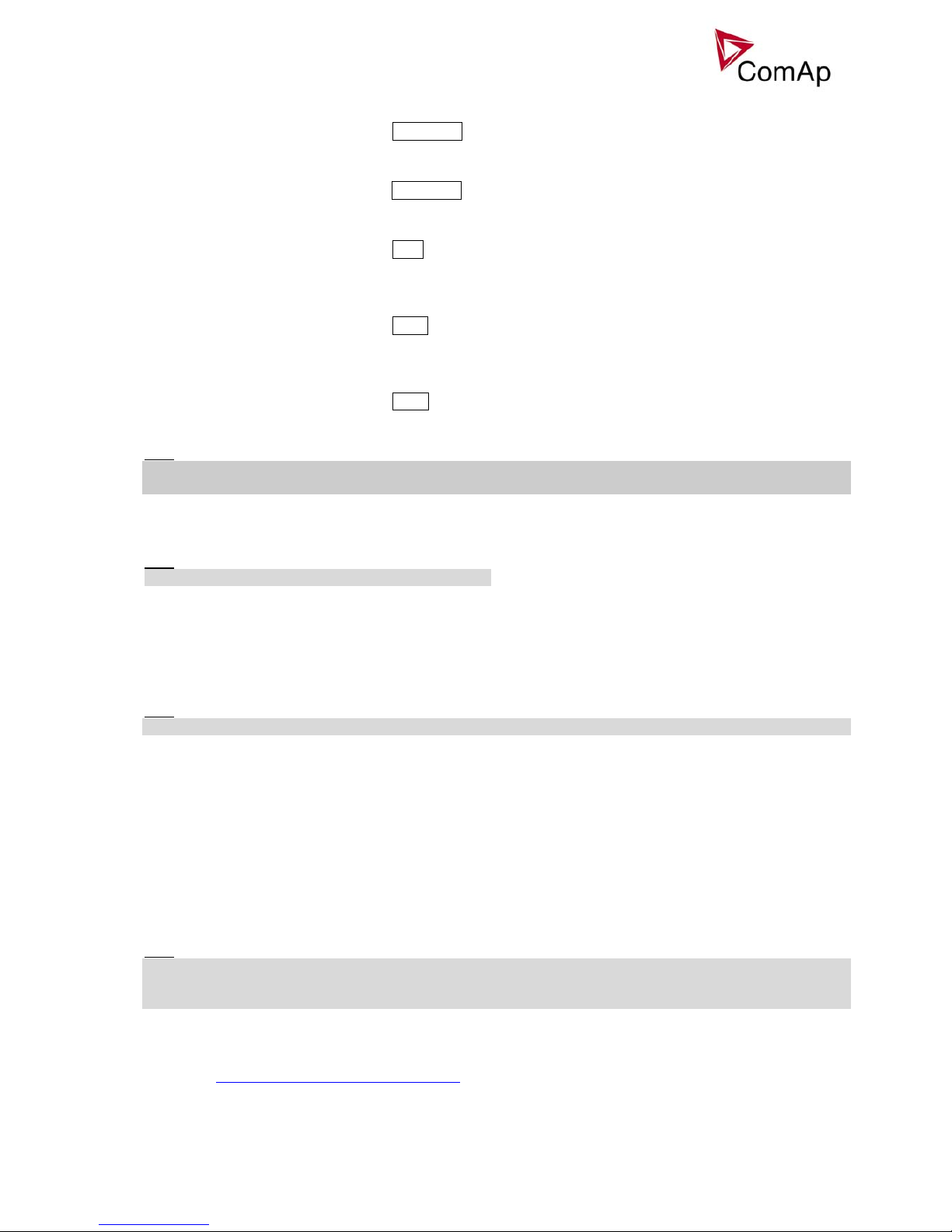

Load reconnection – automatic -> AutoLd recon = ENABLED

Ld recon del Ld recon delLd recon del

BO Load shed 2

Ld recon level

Gen-set power

BO Load shed 3

BO Load shed 1

opened

opened

opened

Load reconnection – manual -> AutoLd recon = DISABLED

System Base load

Gen-set group is controlled on constant (or adjustable) power. The Baseload value can by changed by

setpoint or via analog input.

Important setpoints: ProcessControl: #SysLdCtrlPtM = BASELOAD; #SysBaseload; SysBaseLdMode.

Local Baseload

Selected gen-set from island or mains parallel running group can be loaded to constant LocalBaseload

value. This engine is taken out from Load sharing and Power management. LocalBaseload value is reduced

only when common group (actual) load is lower than this value.

The gen-sets in the group will try to match their LocalBaseloads (when more than one) based on their

controller addresses, so the first limited would be the one with the highest CAN address. I.e. this function will

Page 13

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

13

switch-off automatically in one or more controllers if there is not enough load to cover all the requested

LocalBaseloads.

Important setpoints: ProcessControl: LocalBaseload.

System Base power factor

Gen-set group is controlled in mains parallel to keep a constant (or adjustable) power factor.

Important setpoints: ProcessControl: #SysPFCtrlPtM = BASEPF; #SysPwrFactor.

Import-Export

Gen-set group is controlled to keep constant (or adjustable) Import or Export value. The external controller

InteliMains NT must be connected on the CAN2 to control gen-set group kW I/E.

Important setpoints: ProcessControl: #SysLdCtrlPtM = LDSHARING.

Import/Export power factor

Gen-set group is controlled to keep constant (or adjustable) Import or Export power factor.

Important setpoints: ProcessControl: #SysLdCtrlPtM = VSHARING. The external InteliMains NT controller

must be connected on the CAN2 to control gen-set group PF I/E.

Service time alarm

Engine starting procedures

• Independent Engine controller (e.g. InteliDrive) is expected.

• Interface GeCon to InteliDrive is provided by single BI/BO wires (no communication line).

• GeCon does not directly control engine via Starter, Fuel, Ignition – only sends Start request and Stop

requests.

• Automatic engine start/stop is allowed in GeCon - AUT mode when Power management function is

active.

• GeCon does not measure RPM from pickup.

Engine stopping procedures

• Active Generator protection does not stop running engine (except Power management in AUT mode).

• Engine stop command from MCU opens GCB (via BO Ready to load without Unloading).

Engine “running” conditions

• The additional condition to close GCB (start synchronizing) is GeCon BI Ready to load (coming from

MCU) in both MAN, AUT modes.

Page 14

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

14

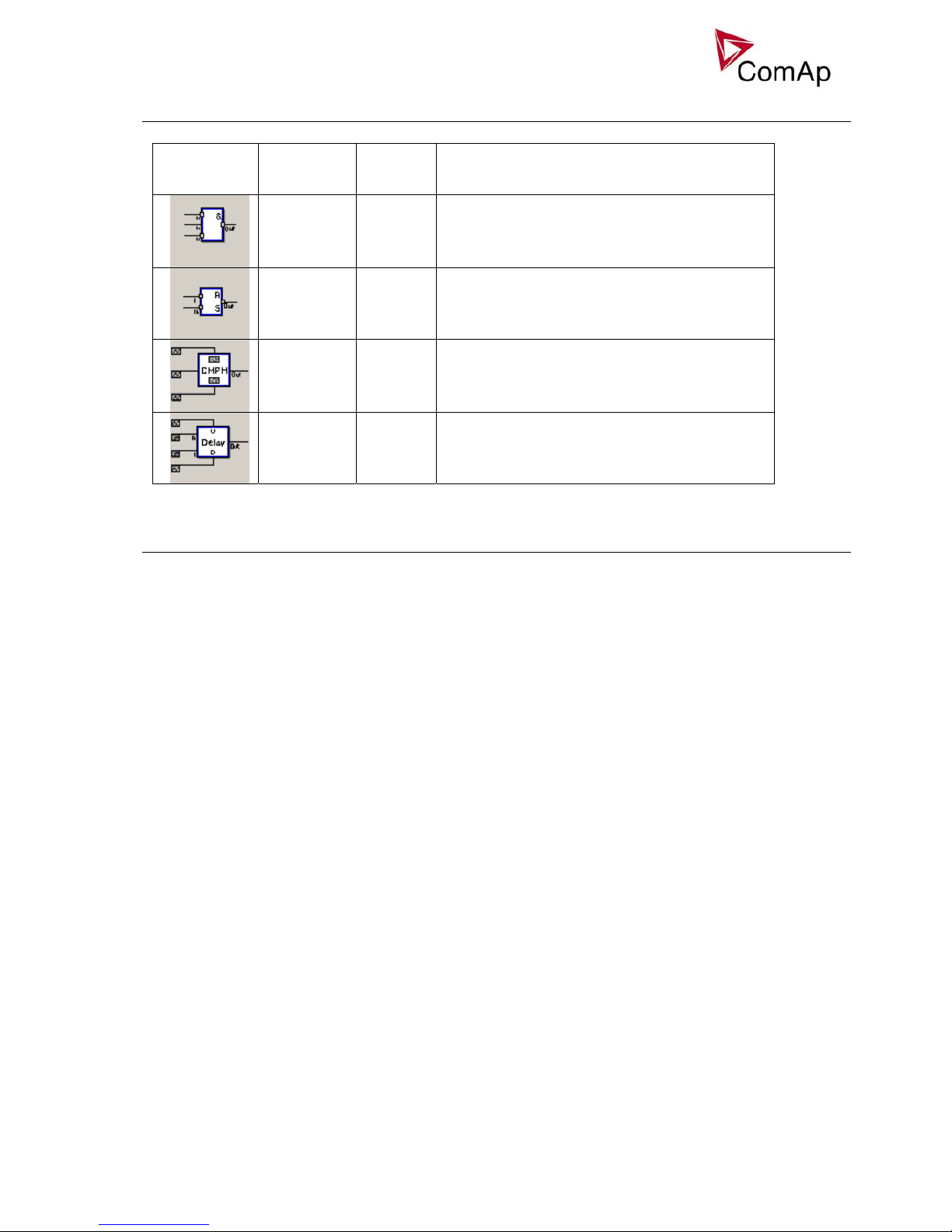

PLC functions

Following functions are available in IG-NT-GeCon firmware.

Config item Selection

Available

IG-NT/EE

Note

Log Func I.

16

AND, OR

2 to 8 inputs

Log Func II.

2

XOR, RS

2 inputs

Comp Hyst

2

Analog input

Two limits

Binary output

Delay

4

Adjustable rising and falling edge delay or pulse

on edge.

Multi language support

NT Family controllers support up to five Languages that is possible to switch during controller duty. Every

terminal (i.e. Remote display or PC-InteliMonitor) can be switched to different language. Use PC-GenConfig

- Translator tool to translate texts to another language.

Default application archives contain all texts in English only.

Page 15

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

15

Protections and Alarm management

Protection groups

There are two groups of protections in the controller: fix and customer configurable.

Setpoint group

Analog protections Configurable Analog protect

Generator protections Configurable Gener protect

Mains protections –

should not be used in

MINT application

Configurable Mains protect

Fix protections Fix Engine params,

Gener protect,

Analog protect

Protection types

Because of limited (adjustable) GeCon influence to the Engine and GCB (depends on configuration and

wiring) the GeCon protection system is more focused to fail indication. All Protection types are available

because of IGS-NT system compatibility even if some Protection types has the same result in GeCon (e.g.

BOC, Stp, Sd).

Level Protection

types

Abbre

viation

Gen-set action Record

1

History record

Hst none History only

1

Alarm only

Al none Alarmlist only

1

Warning

Wrn none Alarmlist and History

2

Off load

OfL AUT modes:

Controller opens GCB without soft

unloading, gen-set runs 1 minute at

Nominal RPM. Gen-set state changes to

Running 1 minute after Off load activation.

Controller starts automatically GCB

synchronizing (or closes GCB) when Off

load is deactivated (no fault reset

necessary).

MAN mode:

Controller opens GCB without soft

unloading and the gen-set runs without

load until operator intervention.

All generator protections are active during

Off load duty.

Alarmlist and History

2

Breaker Open

& Cool-down

BOC Controller opens GCB without soft

unloading, gen-set state changes to

Running.

Alarmlist and History

2

Slow stop

Stp Soft unloading then the GCB opens, BO:

Stop pulse; the gen-set state changes to

Stopping.

Alarmlist and History

2

Shutdown

Sd Controller opens GCB without soft

unloading.

Alarmlist and History

X

Sensor fail

Fls Can be indicated when Analog input value

is ±6% out of sensor characteristic range.

Fls can optionally activate corresponding

(e.g. Sd) Analog input protection as well.

Alarmlist and History

Page 16

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

16

Default protections in MINT

Fix – firmware based

Generator: Corresponding setpoints

IDMT overcurrent BOC Basic settings: Nomin current; Gener protect:

2Inom del

IDMT Active power BOC Gener protect: OverldStrtEval; 2POvrldStrtEvDel

Shortcurrent BOC Gener protect: Ishort; Ishort del

Generator voltage: Ug1>, Ug1<,

Ug2>, Ug2<, Ug3>, Ug3<

BOC Gener protect: Gen >V BOC; Gen <V BOC; Gen

V del.

Generator voltage: Ug1>>,

Ug2>>, Ug3>>

Sd Gener protect: Gen >V Sd; Gen V del.

Generator frequency: fg<, fg> BOC Gener protect: Gen >f; Gen <f; Gen V del

Bus:

Bus voltage (limits derived from

generator protections)

- Gener protect: Gen >V BOC; Gen <V BOC; Gen

V del.

Bus frequency (limits derived from

generator protections)

- Gener protect: Gen >f; Gen <f; Gen V del

Default - configurable

Reverse power (UnivState 1) BOC Gener protect: Reverse power; ReversePwr del

Batt <V, Batt >V (UnivState 2) Wrn Analog protect: Batt >V; Batt <V; Batt V del

EarthFaultCurr (UnivState 5) BOC Gener protect: EarthFaultCurr; EthCurr del

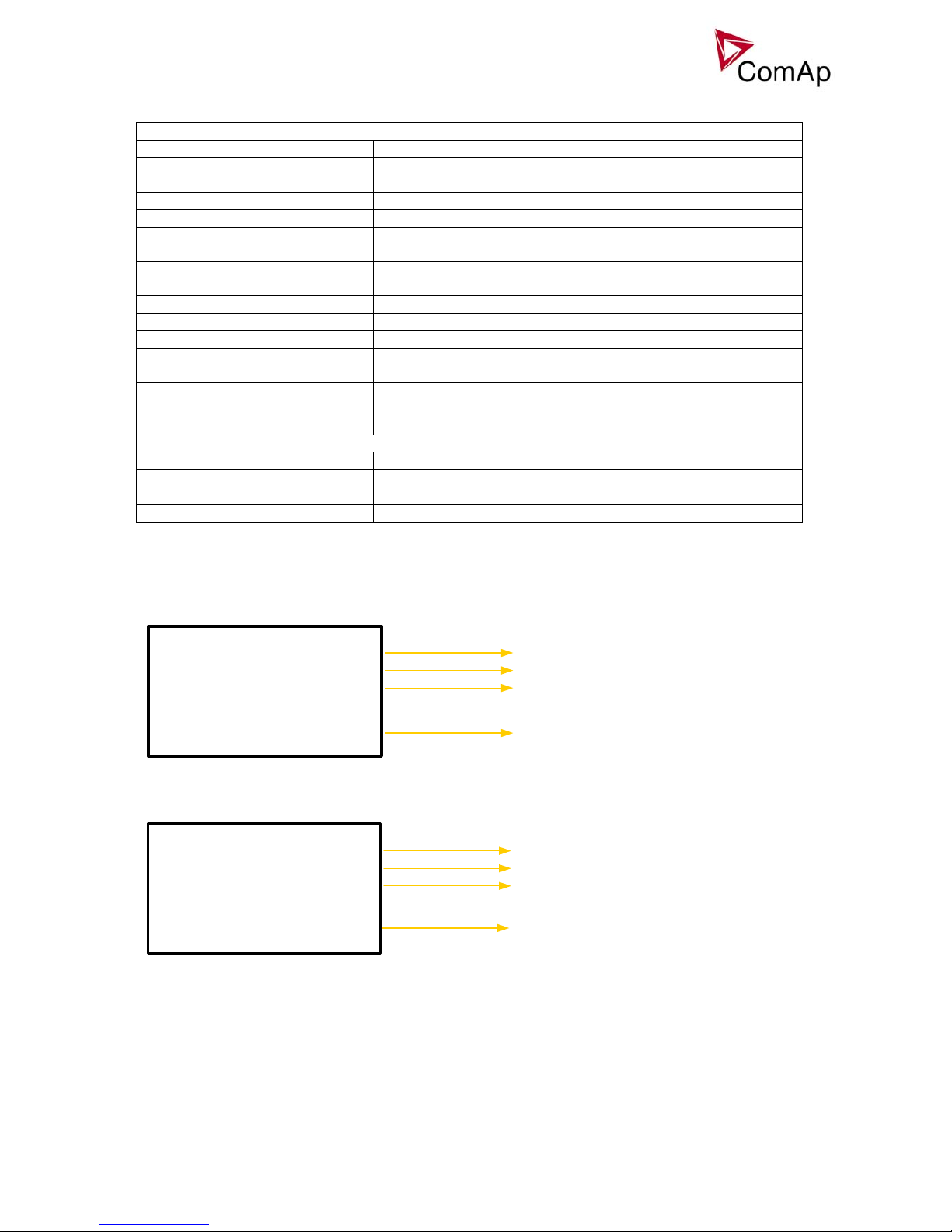

Bus voltage and frequency protections - limits and indications

Basic settings:

VoltProtSelect = PHASE-NEUTRAL

Gener protect: Gen >V BOC

Gen <V BOC

Gen >V Sd

Gen V del

Gen >f

Gen <f

Gen f del

Bus V L1-N

Bus freq

Bus V L2-N

Bus V L3-N

Basic settings:

VoltProtSelect = PHASE-PHASE

Gener protect: Gen >V BOC

Gen <V BOC

Gen >V Sd

Gen V del

Gen >f

Gen <f

Gen f del

Bus V L1-L2

Bus V L2-L3

Bus V L3-L1

Bus freq

Page 17

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

17

Generator voltage and frequency protections - limits and indications

Basic settings:

VoltProtSelect = PHAS E-NEUTRAL

Gener protect: Gen >V BOC

Gen <V BOC

Gen V Sd

Gen V del

Gen >f

Gen <f

Gen f del

BOC L1 under

BOC L2 under

BOC L3 under

BOC L1 over

BOC L2 over

BOC L3 over

Gen V L1-N

BOC fg under

BOC fg over

Gen freq

Gen V L2-N

Gen V L3-N

BOC L12 under

BOC L23 under

BOC L31 under

BOC L12 over

BOC L23 over

BOC L31 over

Gen V L1-L2

BOC fg under

BOC fg over

Gen freq

Gen V L2-L3

Gen V L3-L1

Basic settings:

VoltProtSelect = PHASE-PHASE

Gener protect: Gen >V BOC

Gen <V BOC

Gen V Sd

Gen V del

Gen >f

Gen <f

Gen f del

Hint:

Additional protections can be configured using the Protection – Universal states tool. Limits for additional

generator/bus voltage Universal protections are in Phase-Neutral format not depends on Basic settings:

VoltProtSelect setpoint.

Shutdown override

If the Binary input Sd override is closed, all 2nd level protections are disabled to allow engine run in an

emergency situation, e.g. sprinkler devices power supply.

All protections are shown in Alarmlist and recorded into History, but the controller doesn’t stop the engine

because of them. If the input is deactivated and some protections are still active or not yet reset, the

controller starts to take these protections into account and consequently stops the engine.

Hint:

All 2nd level protections are locked out, except of these:

- Emergency stop

- Overspeed

- Underspeed (only if Fuel solenoid = GAS ENGINE)

Page 18

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

18

Gen-set operation states

Gen-set can operate in following states

Not ready Gen-set is not ready to start

Init After controller power supply switch on

Stopped No Running indication

Starting Waiting for ReadyToLoad signal

Running Waiting for GCB connection or start synchronizing

Soft load Gen-set power is ramping up

Loaded Gen-set is loaded

Soft unld Gen-set power is ramping down

Stopping Stopping procedure before the BI ReadyToLoad is opened.

Stopped Stopped - initial state – waiting for engine start

Breakers conditions

Brks Off GCB opened

Synchro Gen-set is synchronizing (bus voltage OK, GCB is

open)

MultIslOp Multiple Island - gen-set is running loaded in island

parallel mode (MCB is open, GCB is closed)

MultParOp Multiple Parallel – gen-set is running loaded in

mains parallel mode (MCB is closed, GCB is

closed)

Page 19

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

19

Inputs and Outputs

Virtual and physical modules

Number of I/O can be extended and project wiring can be reduced using the following extension and virtual

modules.

Module name

BIN

BOUT

AIN

AOUT

Note

IGS-NT controller

x x x x Number of I/O depends on type.

IGS-PTM

8 8 4 1 Standard I/O extension module.

IS-AIN8

- - 8 - Standard I/O extension module.

IS-BIN16/8

16 8 - - Standard I/O extension module.

I-CB

x x x x Configurable communication bridge.

IGL-RA15

- 15 - - 15 Green, Red, Yellow LED panel.

I-AOUT8

- - - 8 8 Analog outputs

VPIO

8 8 - - Virtual periphery I/O module.

SHBIN

8 - - - SHared (virtual) Binary INput module

SHBOUT

- 8 - - SHared (virtual) Binary OUTput module

SHAIN

- - 4 - Shared (virtual) Analog Input module

SHAOUT

- - - 4 Shared (virtual) Analog OUTput module

PLC

x x x x Programmable (internal) logic module.

Binary Inputs - Control

AccessLock int

If the input is closed, no setpoints can be adjusted and no commands can be issued from the controller front

panel.

Hint:

As the controller mode (OFF-MAN-AUT-TEST) is one of the setpoints, not even that can be changed.

The START, STOP, FAULT RESET and other control buttons are disabled as well.

AccessLock D#2

If the input is closed, no setpoints can be adjusted and no commands can be issued from IG/IS-Display #2.

AccessLock ext

If the input is closed, no setpoints can be adjusted and no commands can be issued from any external

terminal = via direct/modem/internet connection to the controller.

Hint:

Use these inputs to lock out the selected terminals for setpoint changes and commands. Such a terminal can

only be used for monitoring.

Alt brightness

Active binary input switches controller display backlight to the alternative setting. Alternative intensity of the

backlight can be set independently using the controller panel buttons.

Hint:

Input available in IG-NT/EE and modifications only. For IG-Display and IS-Display modules, this binary input

is located in the Power connector and it’s function is fixed (not configurable).

Page 20

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

20

FaultResButton

Binary input has the same function as Fault reset button on the controller front panel.

HornResButton

Binary input has the same function as Horn reset button on the controller front panel.

StopButton

Binary input has the same function as Stop button on the controller front panel. It is active in MAN mode

only.

StartButton

Binary input has the same function as Start button on the controller front panel. It is active in MAN mode

only.

GCBButton

Binary input has the same function as GCB button on the controller front panel. It is active in MAN and

TEST modes only. In TEST mode in some special cases only (see description of the TEST mode in chapter

Mode and functions description).

Hint:

All Binary inputs, which simulate controller front panel buttons, are edge (no level) sensitive, and they react

on the rising edge only. Minimal input pulse duration is 0,2 seconds.

Remote OFF

If closed, the controller mode is forced to OFF. When opened controller is switched to previous mode.

Hint:

Use this input to block the engine start during service.

Remote MAN

Active binary input forces the controller mode to MAN.

Remote AUT

Active binary input forces the controller mode to AUT.

Hint:

Use this input to switch the controller to automatic operation, e.g. using the external key switch.

Force block 1 …3

Three binary inputs for user-specific blocking of programmable protections. If the particular input is active, all

the protections with the corresponding “Force block X” block type are blocked.

Force value 1 …16

If any of the particular 16 input s is active, the Force value function on that corresponding channel gets

active, forcing an alternative value to the selected setpoint.

IssueActCallC1 …3

Rising edge on these binary inputs forces an active call to be issued via the corresponding channel.

Hint:

Can be used to send e.g. SMS in the case of a mains failure to report that the engine has successfully

started (linked from the output Gen params OK) and later on to report that the engine has stopped again

(linked from the inverted output Fuel solenoid).

Sys start/stop

If the input closes, the controller may start the engine (in AUT mode only). Request to start depends on state

of setpoint

Pwr management: Pwr management state and, if ENABLED, on the actual need of load reserve.

I.e. all controllers in the system should have their Sys start/stop inputs active, but it doesn’t mean that all

engines are running.

Page 21

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

21

If

Pwr management: Pwr management is DISABLED, the closed input requests the engine to start

regardless of the load reserves.

Gen-set is running both in mains parallel or island parallel (depends on mains condition). Reaction on input

state change is delayed by setpoints #SysAMFStrtDel / #SysAMFStopDel in island mode, by 1 sec in mains

parallel mode (= input MCB feedback active).

Emergency stop

If the input is activated, engine shutdown is immediately issued. It has a character of a “Shutdown” protection type, however some special behaviour follows in the case of its activation:

Sd override

If the input is closed, all 2nd level protections are disabled to allow engine run in an emergency situation, e.g.

sprinkler devices power supply.

All protections are shown in Alarmlist and recorded into History, but the controller doesn’t stop the engine

due to their occurence. If the input is deactivated and some protections are still active or not yet reset, the

controller starts to take these protections into account and consequently stops the engine.

Hint:

All 2nd level protections are locked out, except of:Emergency stop

Emerg. manual

The controller behaves like when switched to OFF mode if input is closed. Opens all binary outputs Fuel

solenoid, Cooling pump signals, etc... except:

Stop solenoid output does not close.

The output terminals that are configured with inversion are closed.

Detection of "running engine" condition and subsequent alarm message "Sd Stop fail" is blocked. The

controller shows "Emerg Man" state and the engine can not be started. Generator current and power

(energy) measurement is active in this mode, regardless of the actual state of the engine.

After the binary input EMERG. MANUAL is open again, the controller recovers to previous mode and

behaves according to the actual situation. Should the engine run and any of the conditions to start the engine

was active, it will keep the engine running.

Function is active in any controller mode and activation of this input is written to history.

Hint:

The function is intended especially for Marine gen-sets which are supposed to be started manually while the

controller has no power supply. To recover successfully from this state, only the signals Stop solenoid, GCB

ON/OFF coil should be used for engine and breaker control, as the other outputs are continuous active

during engine run (e.g. Fuel solenoid) and it is not possible to switch them between more control sources.

Load res 2 …4

If the input LOAD RES 2 or 3 or 4 is closed, the setpoint set Pwr management: #LoadResStrt X +

#LoadResStop X (#%LdResStrt X + #%LdResStop X) will be selected. Higher index has higher priority when

more these binary inputs are closed together. When not configured or not active, setpoint set

#LoadResStrt

1 + #LoadResStop 1 (#%LdResStrt 1 + #%LdResStop 1) is used.

Hint:

All controllers operating in Power management must have the same Load reserves selected.

It is possible to use Virtual periphery to share the signals between more controllers on the CAN bus. In such

case one controller is a server which physically has the signals connected and other controllers get these

signals via CAN bus.

Setpoint set selection depends on the #Pwr mgmt mode – if set to ABS (kW or kVA), #LoadResStrt X type

setpoints are active, if set to REL (%), #%LdResStrt X type setpoints are active.

MinRun power 1 …3

When binary input MinRun power 1 or 2 or 3 is closed, the corresponding setpoint Pwr management:

#MinRun power 1 or 2 or 3

is selected. Higher index has higher priority when more these binary inputs are

closed together. When not configured or not active, minimal running power is 0, i.e. the system works only

based on Load reserves.

Hint:

All controllers operating in Power management must have selected the same MinRun power input.

Page 22

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

22

It is possible to use Virtual periphery to share the signals between more controllers on the CAN bus. In this

case one controller is a server which physically has the signals connected and other controllers get these

signals via CAN bus.

Priority sw A (Priority switch A) …D …C …

Binary inputs for priority selection.

Priority value

Priority

1 2 34567891011 12 13 1415

Priority sw A 0 or nc 1 0 1010101 0 1 0 1 0 1

Priority sw B 0 or nc 0 1 1001100 1 1 0 0 1 1

Priority sw C 0 or nc 0 0 0111100 0 0 1 1 1 1

Priority sw D 0 or nc 0 0 0000011 1 1 1 1 1 1

Hint:

Priority value is defined by setpoint Priority when all Priority switches are opened or not configured.

The priority value defined by a combination of binary inputs Priority sw X is accepted with 1s delay. So if a

change is made to more inputs simultaneously, it is accepted 1s after the last change sensed.

GroupLink

If the input is configured, the group linking function is active, i.e. this controller becomes the status server for

two groups of gen-sets and informs them about the BTB status.

If this input is closed, the controller reports BTB status as closed, if open, the controller reports open BTB

status.

ManualLdRecon

The rising edge on this input switches the controller to the lower Load Shedding stage when Load

shedding: AutoLd recon = DISABLED and the load is under Load shedding: Ld recon level.

GCB disable

The input blocks the GCB closing, even if all other conditions for its closing are fulfilled. Valid in all modes.

Hint:

If you want to lock out the GCB closing during synchronizing loop test, set Sync/Load ctrl: Phase window =

0. This allows the control loop to be tested while actual GCB closing is blocked.

Conditions for closing:

1) voltage only on generator side of GCB

2) voltage on both sides of GCB and all synchronizing conditions fulfilled.

ReadyToLoad

The output closes when the engine is running, no 2nd level protection is active and the GCB is already closed

or is able to be closed (i.e. all generator parameters are within limits).

ExtValue1reset … ExtValue4reset

Active binary input causes ExtValueX to be reset and held at its default value, given by the setpoint

ExtValueXdeflt.

Hint:

These inputs, if configured, do not block the external set commands (in contrast to ExtValueX up / ExtValueX

down inputs). However, if the reset input is activated, the corresponding ExtValueX is reset to its default

(ExtValueXdeflt) value. This default value is kept in ExtValueX until the reset input is deactivated, and the

external set commands received meanwhile are ignored.

PulseCounter 1

PulseCounter 2

PulseCounter 3

PulseCounter 4

The inputs are linked with corresponding counters, which integrate the pulses sensed at these inputs. Each

rising edge of the signal at input increases the internal counter value.

Page 23

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

23

Hint:

Pulse width (both high/low levels) must be at least 100 ms in order to be correctly sensed!

Conversion ratio can be selected using the setpoints ConvCoefPulseX. The converted values are visible in

statistics – values PulseCounter X. These values can be reset using Statistics window in InteliMonitor.

Timer block 1 … 16

Sixteen blocking inputs for particular timer module channels. The input can lock out its assigned channel – if

this input is active, the channel won’t activate its output (Timer active X) to e.g. start the engine.

Lang sel int A … Lang sel int C

Set of binary inputs for forcing alternative languages. This set of inputs is switching the controller’s internal

terminal – for IG-based controllers the front panel, for IS-based controllers the IS-Display with address #1.

Encoding of binary inputs’ combinations:

Language index -> given by display setting 1 2 3 4 5 6 7

Lang sel int A 0 1 0 1 0 1 0 1

Lang sel int B 0 0 1 1 0 0 1 1

Lang sel int C 0 0 0 0 1 1 1 1

Hint:

Warning – each language change causes the restart of the respective display (not the whole controller), so

the display’s control panel won’t react until the restart has finished (~ 5s).

Value 0 in the table denotes that the corresponding input is not active or not configured.

If more than 7 languages are present in the controller, it is not possible to force languages with index higher

than 7 using these binary inputs.

The reaction on BI combination change is 1s delayed not to react on transient combinations if a rotary

selector switch is used.

Lang sel D#2 A

Lang sel D#2 B

Lang sel D#2 C

Set of binary inputs for forcing alternative languages. This set of inputs is switching the controller’s external

terminal with address #2 – for IG-based controllers the IG-Display, for IS-based controllers the IS-Display

with address #2.

Encoding of binary inputs’ combinations:

Language index -> given by display setting 1 2 3 4 5 6 7

Lang sel D#2 A 0 1 0 1 0 1 0 1

Lang sel D#2 B 0 0 1 1 0 0 1 1

Lang sel D#2 C 0 0 0 0 1 1 1 1

Hint:

Warning – each language change causes the restart of the respective display (not the whole controller), so

the display’s control panel won’t react until the restart has finished (~ 5s).

Value 0 in the table denotes that the corresponding input is not active or not configured.

If more than 7 languages are present in the controller, it is not possible to force languages with index higher

than 7 using these binary inputs.

The reaction on BI combination change is 1s delayed not to react on transient combinations if a rotary

selector switch is used.

Lang sel D#3 A

Lang sel D#3 B

Lang sel D#3 C

Set of binary inputs for forcing alternative languages. This set of inputs is switching the IS-Display with

address #3.

Page 24

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

24

Encoding of binary inputs’ combinations:

Language index -> given by display setting 1 2 3 4 5 6 7

Lang sel D#3 A 0 1 0 1 0 1 0 1

Lang sel D#3 B 0 0 1 1 0 0 1 1

Lang sel D#3 C 0 0 0 0 1 1 1 1

Hint:

Warning – each language change causes the restart of the respective display (not the whole controller), so

the display’s control panel won’t react until the restart has finished (~ 5s).

Value 0 in the table denotes that the corresponding input is not active or not configured.

If more than 7 languages are present in the controller, it is not possible to force languages with index higher

than 7 using these binary inputs.

The reaction on BI combination change is 1s delayed not to react on transient combinations if a rotary

selector switch is used.

Binary inputs – Status information

GCB feedback

Generator Circuit Breaker positive feedback input (closed if GCB is closed). This is a primary source for the

controller about the status of the GCB.

GCB fdb neg

Generator Circuit Breaker negative feedback input (closed if GCB is open). Additional signal, can be used if

both positive and negative feedback signals are available from the breaker.

Hint:

If both feedbacks are used and there is a mismatch between these signals, longer than 500 ms, a GCB fail

alarm is activated.

MCB feedback

Mains Circuit Breaker positive feedback input (closed if MCB is closed). This is a primary source for the

controller about the status of the MCB.

Hint:

The controller decides based on this signal whether the gen-set is running in mains parallel or island

operation.

MCB fdb neg

Mains Circuit Breaker negative feedback input (closed if MCB is open). Additional signal, can be used if both

positive and negative feedback signals are available from the breaker.

Hint:

If both feedbacks are used and there is a mismatch between these signals, longer than 500 ms, a MCB fail

alarm is activated.

NeutralCB fdb

Use this input to detect, whether the Neutral circuit breaker is open or closed. See also setpoint Process

control: #Neutral cont. and binary output Neutral CB C/O.

Binary outputs – Breaker control

GCB close/open

The output controls the generator circuit breaker. It is intended for contactors – provides a continual active

signal if GCB should be closed.

Page 25

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

25

GCB ON coil

The pulse output for GCB closing. If GCB synchronizing is enabled, the pulse length is 2s, if not, pulse length

is 5s.

Hint:

ON coil can only be closed if UV coil is already active for at least 1s and MinStab time has elapsed.

GCB OFF coil

The pulse output for GCB opening. If GCB synchronizing is enabled, the pulse length is 2s, if not, pulse

length is 5s.

GCB UV coil

GCB undervoltage coil. Output is closed if generator values are within limits and GCB is ready to be closed.

It is opened if GCB should be open, and then closed again if generator electric values are in limits. If GCB

synchronizing is enabled, the opening pulse length is 2s, if not, pulse length is 5s.

Hint:

UV coil automatically opens and OFF coil closes if GCB is closed spontaneously, not from controller’s

activity. This state lasts until the GCB status has been deactivated.

The only exception is during synchronization state, as an external device is allowed to close the GCB.

GCB status

Indicates breaker state expected by controller (based on gen-set state, controller commands and breaker

feedback). Can be used for external indication of breaker status according to controller’s information.

MCB status

Indicates breaker state expected by controller (based on gen-set state, controller commands and breaker

feedback). Can be used for external indication of breaker status according to controller’s information.

Neutral CB C/O

Neutral circuit breaker close /open output controls the generator Neutral circuit breaker. It is intended for

contactors – provides a continual active signal if NCB should be closed. See also setpoint Neutral cont.

LdShed stage 1

LdShed stage 2

LdShed stage 3

Load shedding outputs for partial load switching.

Binary outputs – Control loops

AVR up

AVR dn

Binary outputs for Volt / PF control by motorized or electronic potentiometer.

Speed up

Speed dn

Binary outputs for Synchronizing and Load control. Outputs can be used instead of analog Speed governor

output for older engine types. Minimum pulse duration is 0,15 sec. Maximum pulse duration is 10,0 sec.

Hint:

When Speed governor output stays near to the limit value (SpeedGovLowLim+0,2 V or SpeedGovHiLim-0,2

V) for more than 2 sec, the “Wrn SpdRegLim” message is displayed in the Alarm list and recorded to History.

When AVRi output stays on <2% or >98% for more than 2 sec, the “Wrn VoltRegLim” is displayed in the

Alarm list and recorded to History.

Page 26

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

26

Corresponding warning is blocked when Binary outputs Speed Up, Speed Dn or AVR up, AVR dn are

configured.

It is not recommended to process these signals via the internal PLC, as the precise signal timing would be

distorted.

Binary outputs – Status information

Ready for load

The output closes when the engine is running, no 2nd level protection is active and the GCB is already closed

or is able to be closed (i.e. all generator parameters are within limits).

Gen-set active

The output closes together with Starting state and opens after the BI: ReadyToLoad deactivation.

Hint:

The output also closes if the engine begins to rotate spontaneously. It stays closed until “still engine”

condition is achieved.

Operational

The output is closed when no protection is active and the gen-set is ready for operation or is currently in

operation.

Ready

The output is closed, if following conditions are fulfilled:

- Gen-set is not running and

- No 2

nd

level protection is active (or not yet reset)

- The controller has no “engine running” indication from any source

- The controller is not in OFF mode

Not ready

The output is closed, if following conditions are fulfilled:

- The controller in OFF mode or

- Any 2

nd

level alarm is active or not yet reset

Starting

The output is closed during the controller Starting state.

Running

The output is closed in Running state and stays closed if the engine is loaded.

ForwardSynchro

The output is closed during forward synchronizing and opens when GCB status gets active (= GCB was

closed). The output can be used for external synchronizing module control.

Loaded

The output is closed when gen-set is loaded – GCB is closed and no load ramp is active.

Soft unload

The output is closed during gen-set soft unloading state – gen-set power is ramping down.

Stopping

The output closes after the command to stop has been issued. It opens if “still engine” conditions are fulfilled.

The output also closes if the engine begins to rotate spontaneously. It stays closed until “still engine”

condition is achieved.

Page 27

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

27

Off mode

The output is closed, if OFF mode is selected.

Man mode

The output is closed, if MAN mode is selected.

Aut mode

The output is closed, if AUT mode is selected.

Start pulse

One sec pulse is generated when engine start is requested:

OFF mode Inactive

MAN mode Activated by panel START button or BI:StartButton when no 2nd level protection is

active.

AUT mode Activated when BI Sys start/stop is closed - depends on Power management function

setting.

Stop pulse

One sec pulse is generated when engine stop is requested:

OFF mode Inactive

MAN mode Activated by STOP button or BI:StopButton.

AUT mode Activated when BI Sys start/stop is opened - depends on Power management function

setting.

Gen params OK

The output is copy of generator status LED on controller front panel. The output is closed if gen-set is

running and all generator electric values are in limits and no 2

nd

level alarm is active (when only 1st level

alarm is active, the output is closed).

Hint:

Use this output for switching on of auxiliary device (e.g. cooling pump) driven from generator voltage

independently on the GCB status.

Bus params OK

The output is copy of bus status LED on controller front panel. The output is closed if bus electric values are

in limits.

In synchronism

The output closes during synchronizing if all matching conditions are fulfilled. It opens if corresponding

breaker is closed (xCB status output get active).

Hint:

Synchronizing matching conditions:

- Slip frequency < 0,25 Hz

- Gen to Mains/Bus voltage phase shift within Sync/Load ctrl:Phase window

- Gen and Mains/Bus voltages within Sync/Load ctrl:Voltage window

- Sync/Load ctrl:Dwell time elapsed

GCBCloseEna

The output can be used for safe “by hand” GCB closing. The output activity is based on condition “In

synchronism” OR “Dead bus” (any bus phase voltage is below 15 VAC). Output is opened when GCB is

closed.

GCB on pulse

GCB on Button

BO: GCBCloseEna

+

Page 28

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

28

StartButnEcho

StopButnEcho

FltButnEcho

HrnButnEcho

GCBButnEcho

These outputs are active for 1s if the corresponding button is pressed or binary input gets active or

corresponding remote command is issued (from PC software, SMS, ...).

CtrlHeartBeat

The output signalizes watchdog reset. In a healthy state it flashes at 500ms : 500ms rate. It stops flashing

when the unit reset occurs and the new controller start-up fails.

Logical 0

Constant value that can be configured to any output.

Logical 1

Constant value that can be configured to any output.

Binary outputs – Fixed protection outputs

Horn

The output closes if any alarm comes up. It opens if FAULT RESET or HORN RESET is pressed or if

Engine protect: Horn timeout has elapsed. The output closes again if a new fault comes up.

Alarm

The output closes if any alarm comes up. It opens if FAULT RESET is pressed. The output closes again if a

new fault comes up.

Common Wrn

The output closes if any “Warning”-type alarm appears. The output opens, if no “Warning”-type alarm is

active and FAULT RESET has been pressed.

Common Sd

The output closes if any “Shutdown”-type alarm appears. The output opens, if no “Shutdown”-type alarm is

active and FAULT RESET has been pressed.

Common Stp

The output closes if any “Slow stop”-type alarm appears. The output opens, if no “Slow stop”-type alarm is

active and FAULT RESET has been pressed.

Common Fls

The output closes if any “Fail sensor”-type alarm appears. The output opens, if no “Fail sensor”-type alarm is

active and FAULT RESET has been pressed.

Common OfL

The output closes if any “Off load”-type alarm appears. The output opens, if no “Off load”-type alarm is

active. No FAULT RESET needed.

Page 29

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

29

Common BOC

The output closes if any “Breaker Open & Cool-down”-type alarm appears. The output opens, if no “Breaker

Open & Cool-down”-type alarm is active and FAULT RESET has been pressed.

Common Al

The output closes if any “Alarm only”-type alarm appears. The output opens, if no “Alarm only”-type alarm is

active and FAULT RESET has been pressed.

Common Hst

The output closes if any “History record”-type alarm appears. The output opens after 1s.

CommonActLev 1

The output is a logical OR of Common Al and Common Wrn outputs.

CommonAlLev 1

The output is active if at least one of the 1st level alarms (Al, Wrn) is active or not yet confirmed.

Hint:

See picture below with signal behaviour description. The same behaviour like for “Warning”-type alarm would

be for “Alarm only”.

The same behaviour, but with signals CommonActLev 2 and CommonAlLev 2 would be for

“BreakerOpen&Cool-down”, “Slow stop” and “Shutdown”-type alarms

CommonActLev 2

The output is a logical OR of Common BOC, Common Stp and Common Sd outputs.

CommonAlLev 2

The output is active if at least one of the 2nd level alarms (BOC, Stp, Sd) is active or not yet confirmed.

Alarm flashing

If any alarm comes up, the output starts periodic closing/opening with period 1s/1s. It opens and stays open

if FAULT RESET is pressed.

Page 30

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

30

Horn flashing

If any alarm comes up, the output starts periodic closing/opening with period 1s/1s. It opens and stays open

if FAULT RESET or HORN RESET is pressed or if

Engine protect: Horn timeout has elapsed.

Vgen <>

The output closes if the generator over/under voltage alarm activates.

Vbus <>

The output closes if the bus over/under voltage is detected.

Overcurrent

The output closes if the generator IDMT Overcurrent or Current Unbalance or Shortcurrent alarm activates.

The output opens, if none of these alarms is active and FAULT RESET has been pressed.

ECU comm error

Output closes if there is an error in the communication with ECU. It doesn’t matter how the ECU is

connected – J1939 link or RS232 line.

PeriphCommErr

Output closes if there is an error in the communication with any peripheral unit (e.g. IS-AIN8, IGS-PTM, ...).

Bus meas error

The output closes when bus measurement protection is activated according to description of Gener

protect:BusMeasError setpoint.

Binary outputs – Configurable prog. States

SHBinCfGErr

Shared Binary module configuration error – i.e. more than one source was configured (is on the CAN2 bus).

SHAinCfgErr

Shared Analog module configuration error – i.e. more than one source was configured (is on the CAN2 bus).

PLC State 1 .. 4

PLC state indication.

ECUDiagBlocked

Output is active when Basic setting: ECU diag = DISABLED.

WrongConfig

Wrong configuratio indication.

Reverse power

Output is active when reverse power protection is active. Based on Gener protect: Reverse power and

RevPower del.

Batt volt

Indication of battery voltage protection based on Analog protection: Batt >V, Batt <V, Batt V del.

EarthFaultCurr

Indication of Earth fault current protection based on Gener protect: EarthFaultCurr and EthFltCurr del.

Page 31

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

31

Dongle incomp

Incompatible dongle indication.

Emergency stop

Activity of Emergency stop (from Binary input Emergency stop) indication.

Hint:

Any Binary output alarm indication that follows the corresponding internal state is activated with alarm and

stays active until alarm reason disappears and the Fault reset (panel button or remote) is activated.

Stp GCB fail

Output closes when GCB fail is detected.

BOC NCB fail

Output closes when NCB (Neutral circuit breaker) fail is detected.

Stp Sync fail

The output is closed when the alarm Sync timeout is active.

WrnSpdRegLim

Output indicates the controller Speed governor output is on limit.

WrnVoltRegLim

Output indicates the controller AVRi output is on limit.

Hint:

When Speed governor output stays near to the limit value (SpeedGovLowLim+0,2 V or SpeedGovHiLim-0,2

V) for more than 2 sec, the “Wrn SpdRegLim” message is displayed in the Alarm list and recorded to History.

When AVRi output stays on <2% or >98% for more than 2 sec, the “Wrn VoltRegLim” is displayed in the

Alarm list and recorded to History.

UnivState 1 … Univ state 15

Universal state 1 to Universal state 15 activity indication. Universal state can be used for additional

protection configured to any internal value.

RPM

Indication of RPM state.

CAN2 bus empty

The output closes if the controller doesn’t “see” any other controllers on the CAN2 bus. The output activation

can be blocked by setpoint

Basic settings:DetectOtherCAN (So it should be DISABLED for single

applications.)

WrnService time

The output closes when at least one of gen-set Service count down timers Service time X has reached zero.

To reset the output (and the related Wrn alarm), it is necessary to set again a non-zero value to the

corresponding setpoint.

Generator Voltage and Frequency alarms indication

Basic settings: VoltProtSelect = PHASE-NEUTRAL

Binary output name Protection type Based on setpoint

BOC L1 under

BOC L2 under

BOC L3 under

BreakerOpen & Cool-down

Gener protect: Gen <V BOC, Gen V del

BOC L1 over

BOC L2 over

BOC L3 over

BreakerOpen & Cool-down

Gener protect: Gen >V BOC, Gen V del

Page 32

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

32

Sd L1 over

Sd L2 over

Sd L3 over

Shut-down

Gener protect: Gen >V SD

Gener protect: Gen V del

Gen V L1-N

Gen V L2-N

Gen V L3-N

BreakerOpen & Cool-down

Shut-down

Gener protect: Gen <V BOC

Gener protect: Gen >V BOC

Gener protect: Gen >V SD

Gener protect: Gen V del

Basic settings: VoltProtSelect = PHASE-PHASE

Binary output name Protection type Based on setpoint

BOC L12 under

BOC L23 under

BOC L31 under

BreakerOpen & Cool-down

Gener protect: Gen <V BOC

Gener protect: Gen V del

BOC L12 over

BOC L23 over

BOC L31 over

BreakerOpen & Cool-down

Gener protect: Gen >V BOC

Gener protect: Gen V del

Sd L12 over

Sd L23 over

Sd L31 over

Shut-down

Gener protect: Gen >V SD

Gener protect: Gen V del

Gen V L1-L2

Gen V L2-L3

Gen V L3-L1

BreakerOpen & Cool-down

Shut-down

Gener protect: Gen <V BOC

Gener protect: Gen >V BOC

Gener protect: Gen >V SD

Gener protect: Gen V del

BOC fgen under

Generator protect: Gen <f and Gen f del.

BOC fgen over

Generator protect: Gen >f and Gen f del.

Gen freq

BreakerOpen & Cool-down

Generator protect: Gen >f, Gen <f and Gen f del.

Hint:

L1-N, L2-N, L3-N alarm indications are active when Basic settings: VoltProtSelect = PHASE-NEUTRAL.

L1-L2, L2-L3, L3-L1 alarm indications are active when Basic settings: VoltProtSelect = PHASE-PHASE.

OfL StartBlck

Output indicates wrong setpoints setting that disables the engine start or taking the load.

Binary output name Protection type Based on setpoint

BOC IDMT

BreakerOpen & Cool-down Generator protect: 2Inom del.

BOC ShortCurr

BreakerOpen & Cool-down Generator protect: Ishort and Ishort del.

BOC Overload

BreakerOpen & Cool-down Generator protect: OverldStrtEval

Generator protect: 2POverldStEvDel

BOC NCB fail

BreakerOpen & Cool-down

Binary outputs – Power management

SystReady

The output is closed when the system is able to reach (not reached !) requested power reserve.

Syst res OK

The output closes when selected system load reserve is achieved within the gen-set group.

P

BNom

> P

Akt

+ Reserve

P

BNom

Sum of the nominal power of all gen-sets in the gen-set logical group

P

Akt

System load

Reserve selected setpoint

Pwr management: #LoadResStrt X

In relative mode, actual relative load reserve of the gen-sets is calculated and compared with required

relative load reserve (

Pwr management: #%LdResStrt X).

Page 33

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

33

The output can be used for closing of MGCB (Master generator circuit breaker), because it activates if

sufficient number of gen-sets is available on the bus.

Hint:

Gen-set has to be included in Power Management System by closing of input Sys start/stop.

Gen-set has to be in AUT mode.

Setpoint Pwr management: Pwr management has to be ENABLED or EXTERNAL.

Syst res 1 OK … 4 OK

The corresponding output X is closed when Pwr management: #LoadResStrt X (or #%LdResStrt X in

relative mode) is achieved, independent to which #LoadResStrt X (or #%LdResStrt X) reserve is selected.

Analog inputs

RPM pick-up

Logical Analog input for RPM receiving from various types of Engine Control Units (and optionally via I-CB).

MLC:AnExSysBld

External requested System Baseload power value (Multi Load Control)

• Configure MLC:AnExSysBld to selected analog input

• Configure Analog input range

• Adjust

ProcessControl: SysBaseLdMode = EXTERNAL

LCD brightness

Analog input for external LCD brightness setting (e.g. via potentiometer). Keyboard LCD brightness setting

and binary input Alt brightness do not work when input is configured. Expected value is in the range 0 to

100%.

Hint:

Input available in IG-NT/EE and modifications only and valid only for the built-in display. For attached IGDisplay module, this input has no meaning. Input is not present in IS-NT.

Analog outputs

No analog output is available on IG-NT controller. Use extension unit IGS-PTM (one analog output) or IAOUT8 (eight analog outputs).

Analog values

EnginePriority Actual engine priority Act Reserve Actual load reserve kX = kW or kVA

Reserve Load reserve for start kX = kW or kVA

Reserve Stp Load reserve for stop kX = kW or kVA

ActRes rel Actual relative load reserve %

Res rel Load reserve for start %

ResStp rel Load reserve for stop %

MinR PWR Actual Min run power

TotRunPact Q Sum of reactive power kW

TotRunPact P Sum of active power kVAr

netPgnomPh

Sum of Nominal power on the

bus

kW

Page 34

Inteli NT GeCon MINT, SW Version 1.4, ©ComAp – June 2007

IGS-NT-GeCon-MINT-1.4.PDF

34

Setpoints

Password protection

Any setpoint can be password protected - 7 levels of password is available. The password is a four-digit

number. Only setpoints associated with the entered password level can be modified.

Even though one level may have been set from the front panel, the affected setpoints are not

accessible from InteliMonitor (direct or Modem) until this level is set in IMON.

Setpoints opened from front panel are automatically closed 15 minutes after the last key has been

pressed or when wrong value of password is set.

Any password can be changed once that level password or higher has been entered. The controller

programming (configuration) requires the highest - password 7 level.

ProcessControl

#SysBaseLoad [ kW ]

From this value, the requested gen-set load is calculated, according to the number of gen-sets running. The

complete system produces the power equal to this value. Active only when SysLdCtrl PtM = BASELOAD.

Step: 1 kW

Range: 0 – 65000 kW

Hint:

If you set this setpoint to a higher value than the system is available to produce, the total produced power is

limited with the sum of Nomin power setpoints of all gen-sets in the system.

LocalBaseload [ kW ] (FV)

If the value is OFF, the gen-set takes part in the #SysBaseload production or in Load Sharing. If it is set to a

certain value, the gen-set produces this power regardless of the other gen-sets. It is taken out from the PMS

in this case.

Step: 1 kW

Range: OFF, 1 - Nomin power

Force value: Yes

Hint:

If the gen-sets operate in island parallel mode, the requested LocalBaseload value can be reduced if the

actual load is lower than this value. The gen-sets in the group will try to match their LocalBaseloads based

on their addresses, so the first limited would be the one with the highest CAN address.

#SysPwrFactor [ ]

Requested gen-set power factor when #SysPFCtrl PtM = BASEPF. Values 0,60 – 0,99 correspond to lagging

(inductive, L) PF, 1,01 – 1,20 correspond to leading (capacitive, C) PF.

Step: 0,01

Range: 0,60 - 1,20

#SysLdCtrl PtM [ BASE LOAD / LDSHARING ]

BASE LOAD The gen-set is a part of the System delivered power control (#SysBaseLoad) and

produces a certain part of it, according to the actual number of running gen-sets and

self Nomin power. This option is only active in parallel with mains, in island parallel

operation the mode is always internally set to LDSHARING.

LDSHARING The gen-set load is shared with other gen-sets according to the actual load.

#SysPFCtrl PtM [ BASEPF / VSHARING ]

BASEPF The gen-set power factor is controlled to a preadjusted level #SysPwrFactor. This

option is only active in parallel with mains, in island parallel operation the mode is

always internally set to VSHARING.

Page 35