Page 1

ECON-4

Digital Speed Governor

SW version 1.4.0

1 Document information 4

2 System overview 7

3 Applications overview 8

4 Installation and wiring 9

5 ECON-4 setup 22

6 Communication 40

7 Technical data 41

8 Appendix 43

Copyright © 2017 ComAp a.s.

Written by Jiří Schiller

Prague, Czech Republic

ComAp a.s., U Uranie 1612/14a,

170 00 Prague 7, CzechRepublic

Tel: +420 246 012 111

E-mail: info@comap.cz, www.comap-control.com

Global Guide

Page 2

Table of contents

1 Document information 4

1.1 Clarification of notation 4

1.2 About this guide 4

1.3 Legal notice 4

1.4 Symbols in this manual 6

2 System overview 7

2.1 Description of thegovernorsystem 7

2.1.1 Control by CAN-bus 7

3 Applications overview 8

3.1 Wiring overview 8

4 Installation and wiring 9

4.1 Package content 9

4.2 Module installation 10

4.2.1 Dimensions andmounting 10

4.3 Jumperposition 11

4.4 Recommendedwiring 12

4.4.1 General 12

4.4.2 Grounding 13

4.4.3 Power Supply 13

4.4.4 Binary inputs 13

4.4.5 Analog inputs 15

4.4.6 Analog output 17

4.4.7 Interface to actuators 18

4.4.8 Speed Pick-up 20

4.4.9 Communication wiring 20

5 ECON-4 setup 22

5.1 Quick start - how to set ECON4 andcontroller 22

5.1.1 Breakers feedback handling (CB request modes) 22

5.1.2 Speed control handling (Speed request modes) 23

5.2 Entering password 28

5.2.1 Modify password from WinScope 28

5.2.2 Modify password from GenConfig 28

5.3 Data 28

5.3.1 Data Binary inputs 28

ECON-4 1.4.0 GlobalGuide

2

Page 3

5.3.2 Data Binary outputs 29

5.3.3 Data Analog inputs 29

5.3.4 Data Analog outputs 29

5.3.5 ECON adjustement for various types of actuators 29

5.4 ECON-4 configuration and PC tools 32

5.4.1 Setpoints adjustements in WinScopeSW: 32

5.4.2 Econ-4firmware update 33

5.5 ECON adjustement for various types of actuators 34

5.5.1 Adjustment for LINEAR actuator type (typically Woodward 34

5.5.2 Adjustment for LINEAR NO FDB actuator type (typically GAC, Woodward) 35

5.5.3 Adjustment for BRIDGE actuator type (typically Heinzmann) 35

5.6 Detailed fucntion 37

5.6.1 Block schematics - speedgovernor 37

6 Communication 40

6.1 Connection to ECON-4 40

7 Technical data 41

8 Appendix 43

8.1 Setpoints 44

8.1.1 List of setpoint groups 44

8.1.2 List of setpoints 45

8.1.3 Group: Engine StartGroup: ECON4-EngRPM 46

8.1.4 Group: Engine StartGroup: ECON4-EngStart 51

8.1.5 Group: Main PIDGroup: ECON-4-MainPID 53

8.1.6 Act type1 – predefined for Woodward ITB 0-200 mA 69

8.1.7 Act type2 – predefined for Woodward ITB PWM 71

8.1.8 Act type3 –predefined for Woodward F-series PWM 71

8.1.9 Act type4 – predefined for Heinzmann STG 10 72

8.1.10 Group: Analog sensors 72

8.1.11 List of tested actuators by ComAp 74

ECON-4 1.4.0 GlobalGuide

3

Page 4

1 Document information

1.1 Clarification of notation 4

1.2 About this guide 4

1.3 Legal notice 4

1.4 Symbols in this manual 6

1.1 Clarification of notation

Note: This type of paragraph calls readers attention to a notice or related theme.

IMPORTANT: This type of paragraph highlights a procedure, adjustment etc., which can cause a

damage or improper function of the equipment if not performed correctly and may not be clear at

first sight.

Example: This type of paragraph contains information that is used to illustrate how a specific function

works.

1.2 About this guide

This guide describes usageof ECON-4 forcontrol of engine. ECON-4Global Guide provides basic information

how to install and operate ECON-4 Extension module.

1.3 Legal notice

This End User's Guide/Manual as part of the Documentationis an inseparable part of ComAp’s Product and

may be used exclusively according to the conditions defined in the “END USER or Distributor LICENSE

AGREEMENT CONDITIONS – COMAP CONTROL SYSTEMS SOFTWARE” (License Agreement) and/or in

the “ComAp a.s. Standard terms for sale of Products andprovision of Services” (Terms) and/or in the

“Standardní podmínky projektů komplexníhořešení ke smlouvě o dílo, Standard Conditions for Supply of

Complete Solutions” (Conditions) as applicable.

ComAp’s License Agreement is governed by the Czech Civil Code 89/2012 Col., by the Authorship Act

121/2000 Col., by international treaties andby other relevant legal documents regulating protection of the

intellectual properties (TRIPS).

The End User and/or ComAp’s Distributor shall only be permitted to use this End User's Guide/Manual with

ComAp Control System Registered Products. The Documentation is not intended andapplicable for any other

purpose.

Official version of the ComAp’s End User's Guide/Manual is the version published in English. ComAp reserves

the right to update this End User's Guide/Manual at any time. ComAp does not assume any responsibility for its

use outside of the scope of theTerms or the Conditions and the License Agreement.

Licensed End Useris entitled to make only necessary number of copies of the End User's Guide/Manual. Any

translation of this End User's Guide/Manual without the prior written consent of ComAp is expressly prohibited!

Even if the prior writtenconsent from ComAp is acquired, ComAp does not take any responsibility for the

content, trustworthiness and quality of any such translation. ComAp will deem a translation equal to this End

ECON-4 1.4.0 GlobalGuide

4

Page 5

User's Guide/Manual only if it agrees to verify such translation. The terms and conditions of such verification

must be agreed in the written form and in advance.

For more details relating to the Ownership, Extent of Permitted Reproductions Term of Use of the

Documentation and to the Confidentiality rules please review and comply with the ComAp’s License

Agreement, Terms and Conditions available on www.comap-control.com.

ECON-4 1.4.0 GlobalGuide

5

Page 6

1.4 Symbols in this manual

Battery

Breaker

Connector -

female

Connector -

male

Controller

simplified

ECON-4

simplified

Fuel

solenoid

Fuse

Mains

Pick - up

Resistor

Resistor

adjustable

RS232

female

Starter

Voltage

measureme

nt

Fuse switch

Generator

Generator

schematic

Grounding

Jumper

Load

Mains

ECON-4 1.4.0 GlobalGuide

6

Page 7

2 System overview

2.1 Description of the governor system

ECON-4 is a flexible speed governor capable to operate in various configurations. Possible configurations can

be:

a. Control via CAN – it reads the values of control bits and required analog values from the CAN bus line and

not from its terminals (expect from BIN S4.6 Run/Stop, this signal must be present in all 3 modes)

b. Control via Binary signals

c. Control via Analogue and binary inputs.

Speed and power of a single fuel engine is always controlled by the actuator connected to ACT terminals or

Analog Output in case of actuator with 0-20mA(4-20mA) usage. This actuator can control a fuel rack for diesel

engines or a mixture throttle valve for gas engines.

ECON-4 ADV is advanced version, it is dedicated specially to control of engine in island operations where load

steps are expected.

2.1.1 Control by CAN-bus

ECON-4 can receive values of somebinary and analog control inputs via CAN-bus communication line from

engine controller, (see setpoints Speed request (page 49) or CB request (page 50) for more information). This

arrangement can significantly simplify the wiring on site.

Control of speed request by CAN-bus is active only if setpoint Speed request (page 49) has value DATA

Control of GCB and MCB feedback by CAN-bus is active only if setpoint CB request (page 50) has value DATA.

6 back to Table of contents

ECON-4 1.4.0 GlobalGuide

7

Page 8

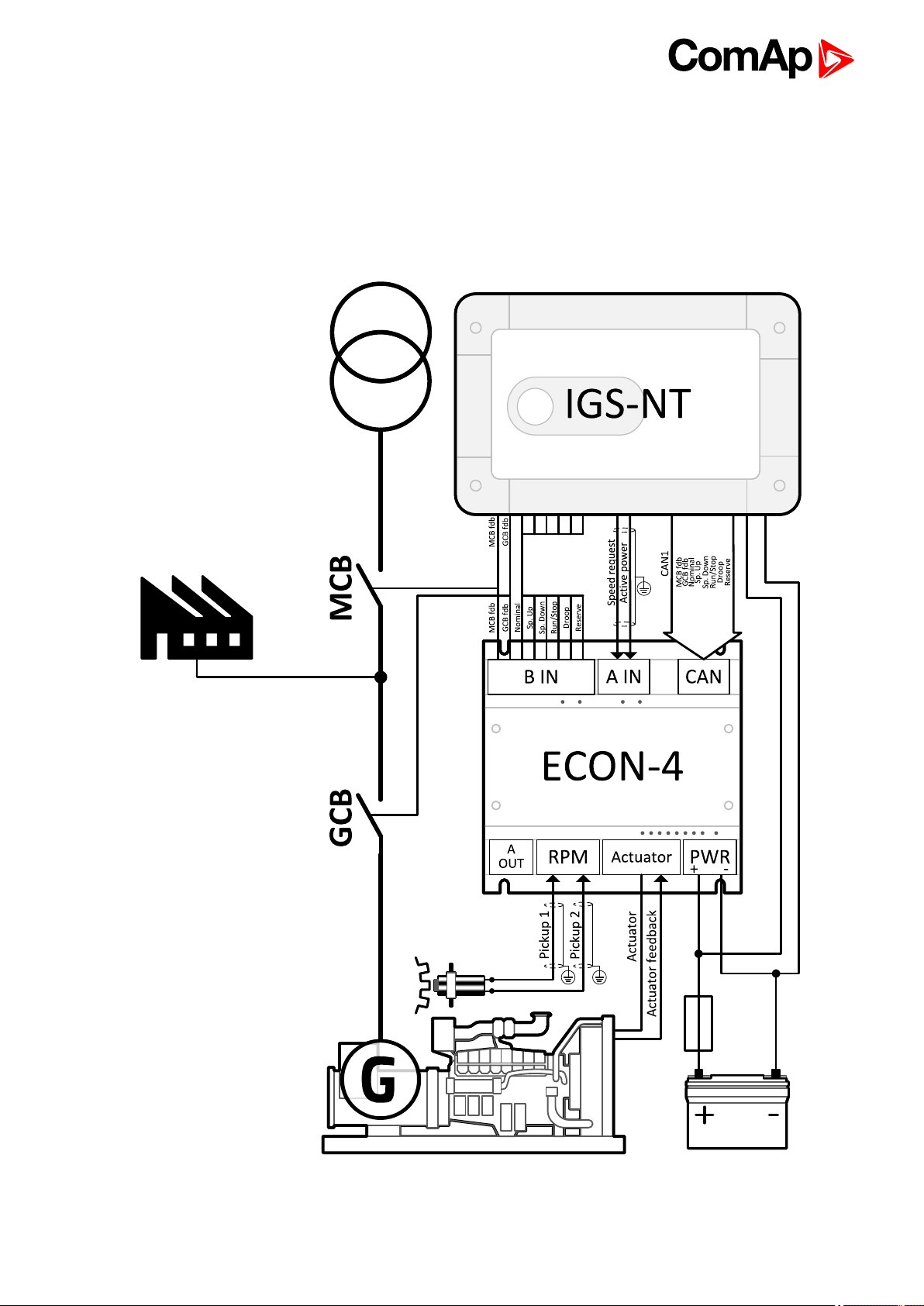

3 Applications overview

3.1 Wiring overview

6 back to Table of contents

ECON-4 1.4.0 GlobalGuide

8

Page 9

4 Installation and wiring

4.1 Package content 9

4.2 Module installation 10

4.3 Jumperposition 11

4.4 Recommendedwiring 12

6 back to Table of contents

4.1 Package content

The package contains:

ECON-4 module

Terminal blocks

ECON-4 1.4.0 GlobalGuide

9

Page 10

4.2 Module installation

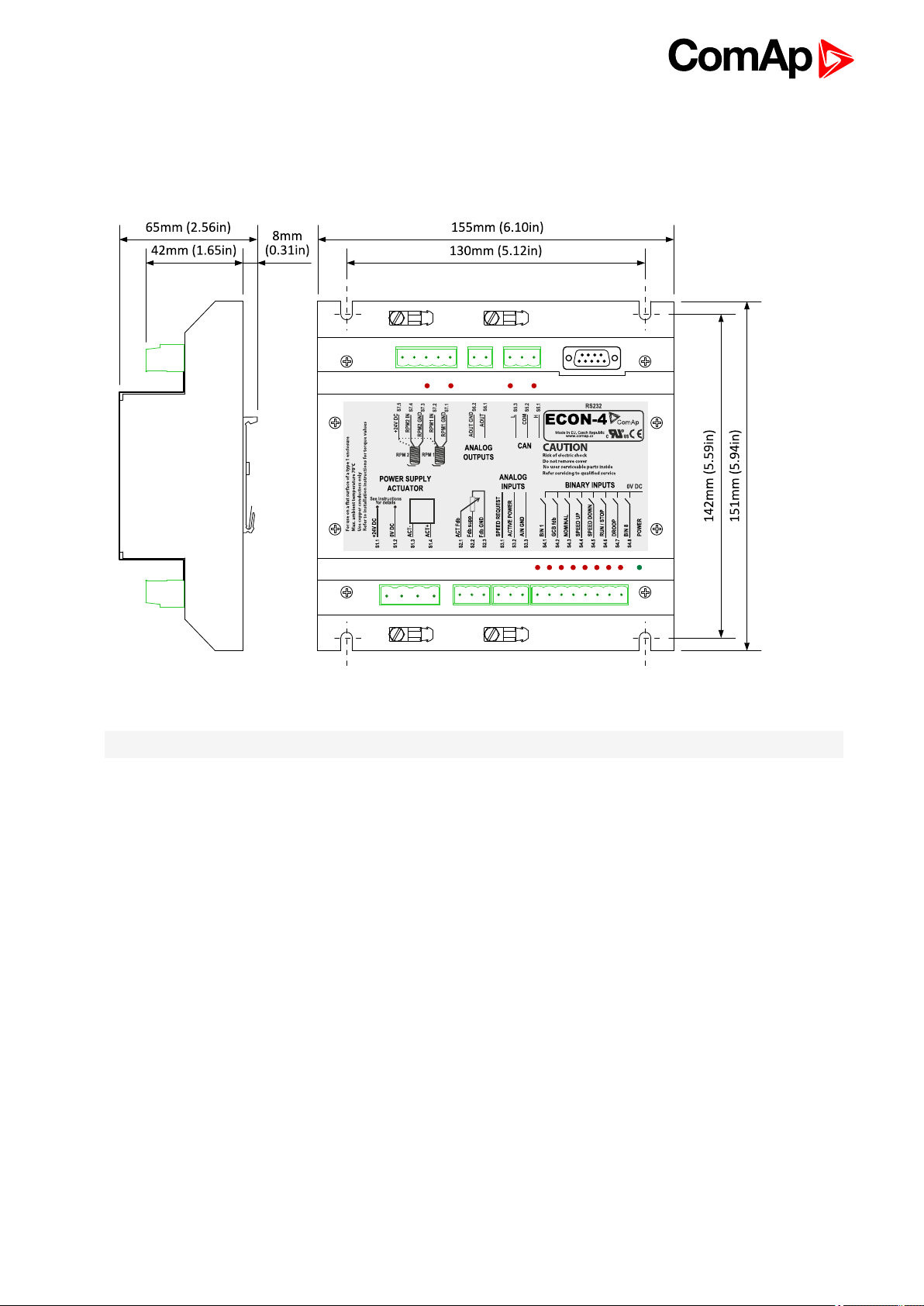

4.2.1 Dimensions and mounting

Image 4.1 Dimensions, terminals and mounting

Note: ECON-4 unit is mounted on DIN rail 35 mm.

ECON-4 1.4.0 GlobalGuide

10

Page 11

4.3 Jumper position

Jumper

P6

P7

P9

P10

Meaning

AOUT switch between current and voltage analogue output

Current: link the 2 pins fromright side

Voltage: link the 2 pins from left side

120 Ohm resistor for CAN line termination

Boot

Reset

ECON-4 1.4.0 GlobalGuide

11

Page 12

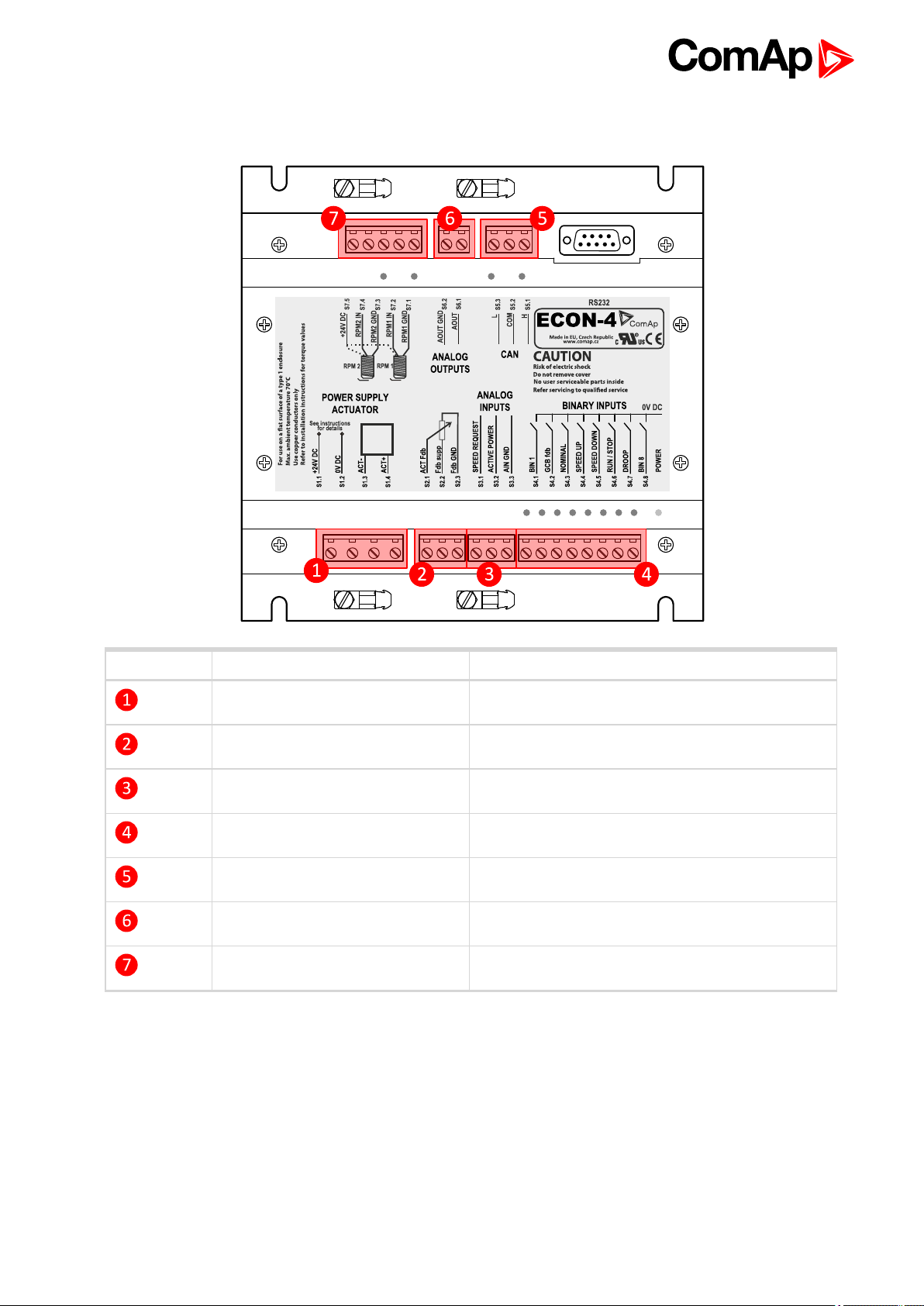

4.4 Recommended wiring

Postion Terminal groups Link

Power supply Actuators Power Supply (page 13)

Actuator feedback Interface to actuators (page 18)

Analog inputs Analog inputs (page 15)

Binary inputs Binary inputs (page 13)

Magnetick Pick-up Speed Pick-up (page 20)

Analog outputs Analog output (page 17)

Communications Communication wiring (page 20)

6 back to Installation and wiring

4.4.1 General

Use grounding terminals.

The “-“terminal of the battery has to be properly grounded.

Cables for binary inputs and analogue inputs must not be placed along power cables.

Analogueinputs should use shielded cables, especially when length >3m.

Always use shielded cable for Magnetic pick-up.

ECON-4 1.4.0 GlobalGuide

12

Page 13

4.4.2 Grounding

Use as short as possible cable to thegrounding point on the switchboard.

Use cable min. 2,5 mm2.

The “-“terminal of the battery has to be properly grounded.

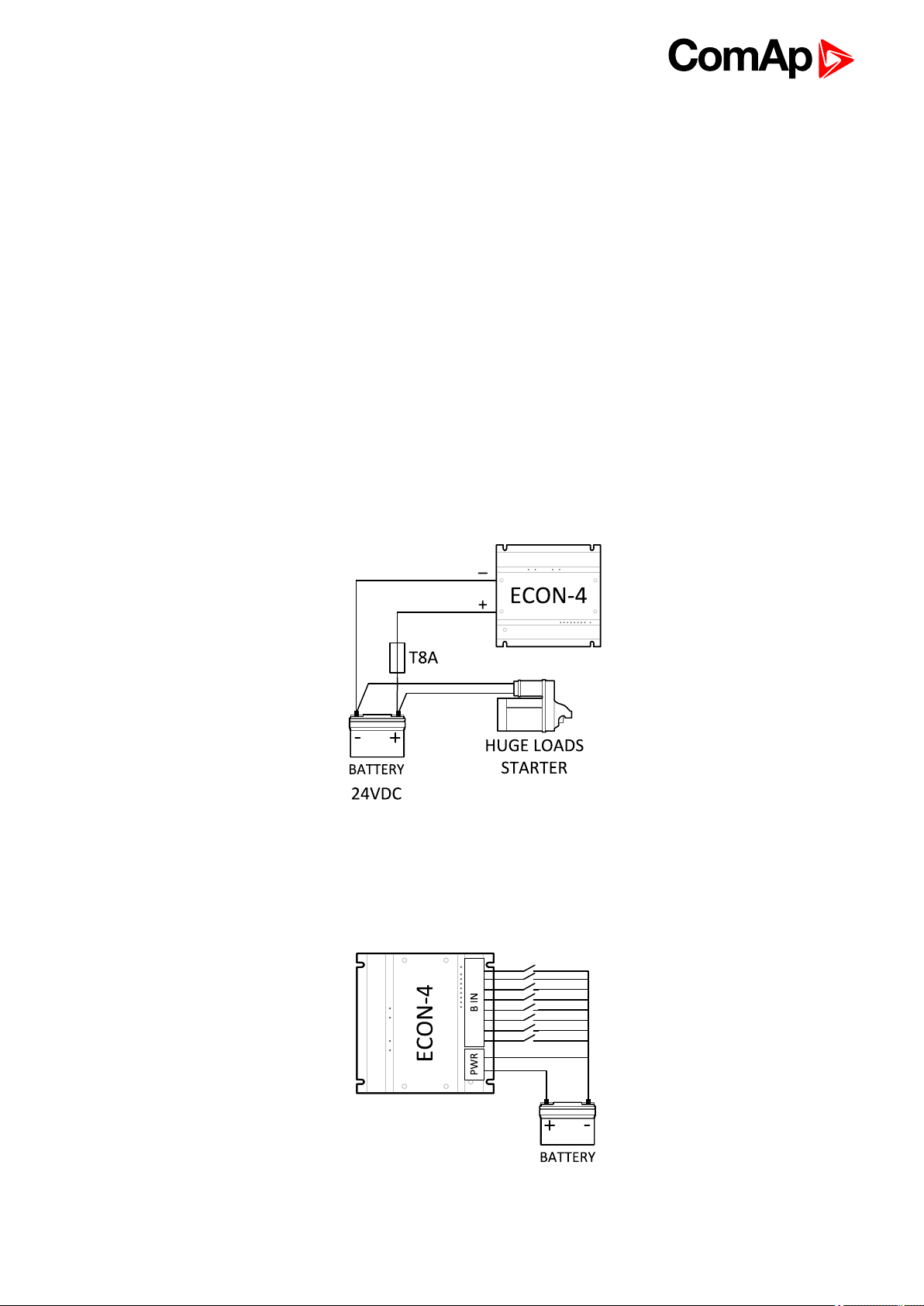

4.4.3 Power Supply

Use min. power supply cable of 4mm2.

Maximum continuous DC Power supplyvoltageis 36 V DC. Maximum short term allowable power supply

voltage is 39 V DC. The ECON-4’s power supply terminals are protected against large pulse power

disturbances. When there is a potential risk of the controller being subjected to conditions outside its

capabilities, an outside protection device should be used.

Power Supply Fusing

An eight-amp fuse should be connected in-line with the battery positive terminal to the controller andmodules.

ECON-4 should never be connected directly to the starting battery.

Recommended fuse is slow type– T8A.

4.4.4 Binary inputs

Binary inputs have internal load resistor 4.4 kΩ connected to the battery plus.

Image 4.2 Binary inputs wiring scheme

ECON-4 1.4.0 GlobalGuide

13

Page 14

Binary inputs are used to control the function of the ECON-4 digital governor.

Binary inputs can be read from:

the physical Binary inputs (terminals S4.x),

from the CAN-bus (byte Command in the Receive PDO),

in dependence on the value of thesetpoint Speed request.

Speed Request value CB Request value

Input

MCB fdb (S4.1) (page 14) MCB fd b

GCB fdb

NOMINAL

SPEED UP

SPEED DOWN

RUN / STOP

DROOP

RESERVE

BIN ANA DATA BIN DATA

S4.1 Cmd.1

S4.2 Cmd.2

S4.3 S4.3 Cmd.2

S4.4 X X

S4.5 X X

S4.6 S4.6

S4.7 S4.7 Cmd.4

S4.8

S4.6 &

Cmd.3

Note: Cmd.x is bit x in the byte Command of the Receive PDO, see description of CAN protocol. S4.x

isECON-4 terminal. Both the physical Binary input S4.6 and the corresponding bit Cmd.3 received via

CANbus must be active to activate Binary input RUN in DATA mode. In case of lost communication on

CANbus, all bits of the byte Command are set to 0 – it deactivates

MCB fdb (S4.1)

Inputs GCB andMCB fdb decide which setpoints are used in PID speed regulation loop and which type of

regulation is used (Iddle/Island/Parallel):

MCB

state

OFF OFF NO Speed gain, Speed int, Speed der

OFF OFF YES Speed gain, Speed int w, Speed der w

ON OFF NO Speed gain, Speed int, Speed der

ON OFF YES Speed gain, Speed int w, Speed der w

OFF ON - Load gain, Load int, Load der

ON ON - Load control according Speed/Fuel Line

GCB

state

lRPM - Requested RPMl > RPM window PID constants

Note: There is more Load gain and Load der values in ECON-4 ADV. Which set will be used depends on actuall

power.

GCB fdb (S4.2)

Inputs GCB andMCB fdb decide which setpoints are used in PID speed regulation loop and which type of

regulation is used (Iddle/Island/Parallel):

MCB

state

OFF OFF NO Speed gain, Speed int, Speed der

OFF OFF YES Speed gain, Speed int w, Speed der w

ON OFF NO Speed gain, Speed int, Speed der

GCB

state

lRPM - Requested RPMl > RPM window PID constants

ECON-4 1.4.0 GlobalGuide

14

Page 15

ON OFF YES Speed gain, Speed int w, Speed der w

OFF ON - Load gain, Load int, Load der

ON ON - Load control according Speed/Fuel Line

Note: There is more Load gain and Load der values in ECON-4 ADV. Which set will be used depends on actuall

power.

NOMINAL (S4.3)

The Required speed is set to Nominal RPM if the Nominal input is closed, otherwise is the Request set to Idle

RPM.

SPEED UP (S4.4)

Inputs SPEED UP and SPEED DOWN are used for setting of the speed reference of the engine. The speed

reference can be changed in the range from Nominal RPM - PerChSpdNom% to Nominal RPM +

PerChSpdNom%. Setpoint: EngineRPM:PerChSpdNom [1-20%] defines the maximum Percentage change of

Speed from Nominal in case BIN or ANA mode of control is used.

Setpoint BI Speed ramp decides how fast the speed reference changes, if the inputs SPEED UP or SPEED

DOWN are active.

Note: Inputs SPEED UP and SPEED DOWN are active only if the setpoint Speed request has value BIN.

SPEED DOWN (S4.5)

Inputs SPEED UP and SPEED DOWN are used for setting of the speed reference of the engine. The speed

reference can be changed in the range from Nominal RPM - PerChSpdNom% to Nominal RPM +

PerChSpdNom%. Setpoint: EngineRPM:PerChSpdNom [1-20%] defines the maximum Percentage change of

Speed from Nominal in case BIN or ANA mode of control is used.

Setpoint BI Speed ramp decides how fast the speed reference changes, if the inputs SPEED UP or SPEED

DOWN are active.

Note: Inputs SPEED UP and SPEED DOWN are active only if the setpoint Speed request has value BIN.

RUN (S4.6)

If the input is not active, governor immediately set the actuator to stop position.

DROOP (S4.7)

The input activates droop function – see setpoint Droop (page 62).

BIN 8 (S4.8)

BIN 8 is reserved for next functions.

4.4.5 Analog inputs

There are 2 analog inputs available on the ECON-4. Each of them can be configured either as 0-20mA or 0-10V

range by jumper setting – seein table below. The analoginput function is fixed.

ECON-4 1.4.0 GlobalGuide

15

Page 16

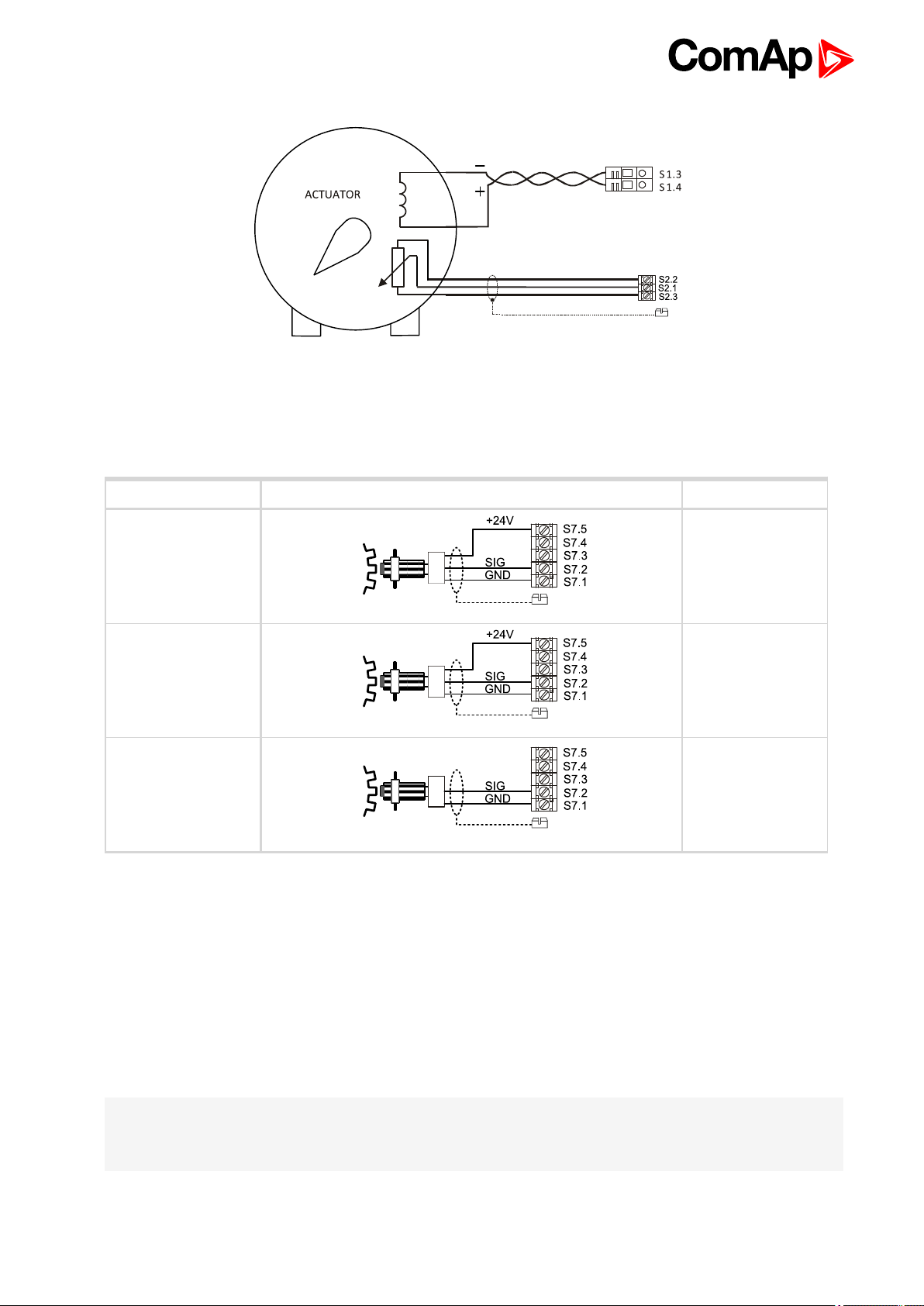

Range Recommended wiring Input Terminals Jumpers

SPEED REQUEST S3.1 P22 – 20 mA

0-20 mA

ACTIVE POWER S3.2 P23 – 20 mA

SPEED REQUEST S3.1 P22 – 10 V

0-10 V

ACTIVE POWER S3.2 P23 – 10 V

SPEED REQUEST (S3.1)

The input defines speedreference. It can be set in the range from Nominal RPM - PerChSpdNom% to Nominal

RPM + PerChSpdNom%. Setpoint: EngineRPM:PerChSpdNom [1-20%] defines the maximum Percentage

change of Speed from Nominal in case BIN or ANA mode of control is used.

Example: Analog input SPEED REQUEST is set to range 0 – 10 V, Nominal RPM is 1500 RPM, Input

voltage is 6 V. Speed reference is then ReqSpeed = 1500 + (PerChSpdNom/100)*1500*(6-5)/5 = 1524 RPM.

PerChSpdNom = 8 in the previous calculation.

Note: Input SPEED REQUEST is active only if the setpoint Speed request has value ANA.

ACTIVE POWER (S3.2)

Input from the external transmitter of Active power. Value of the Active power is used to improve load step

response of the governor. Input ACTIVE POWER is active only, if the setpoint Speed request has not value

DATA. The input sensitivity can be adjusted by setpoint Load anticip.

Note: Input ACTIVE POWER is active only if the setpoint Speed request has value BIN or ANA and setpoint

Load anticip > 0.

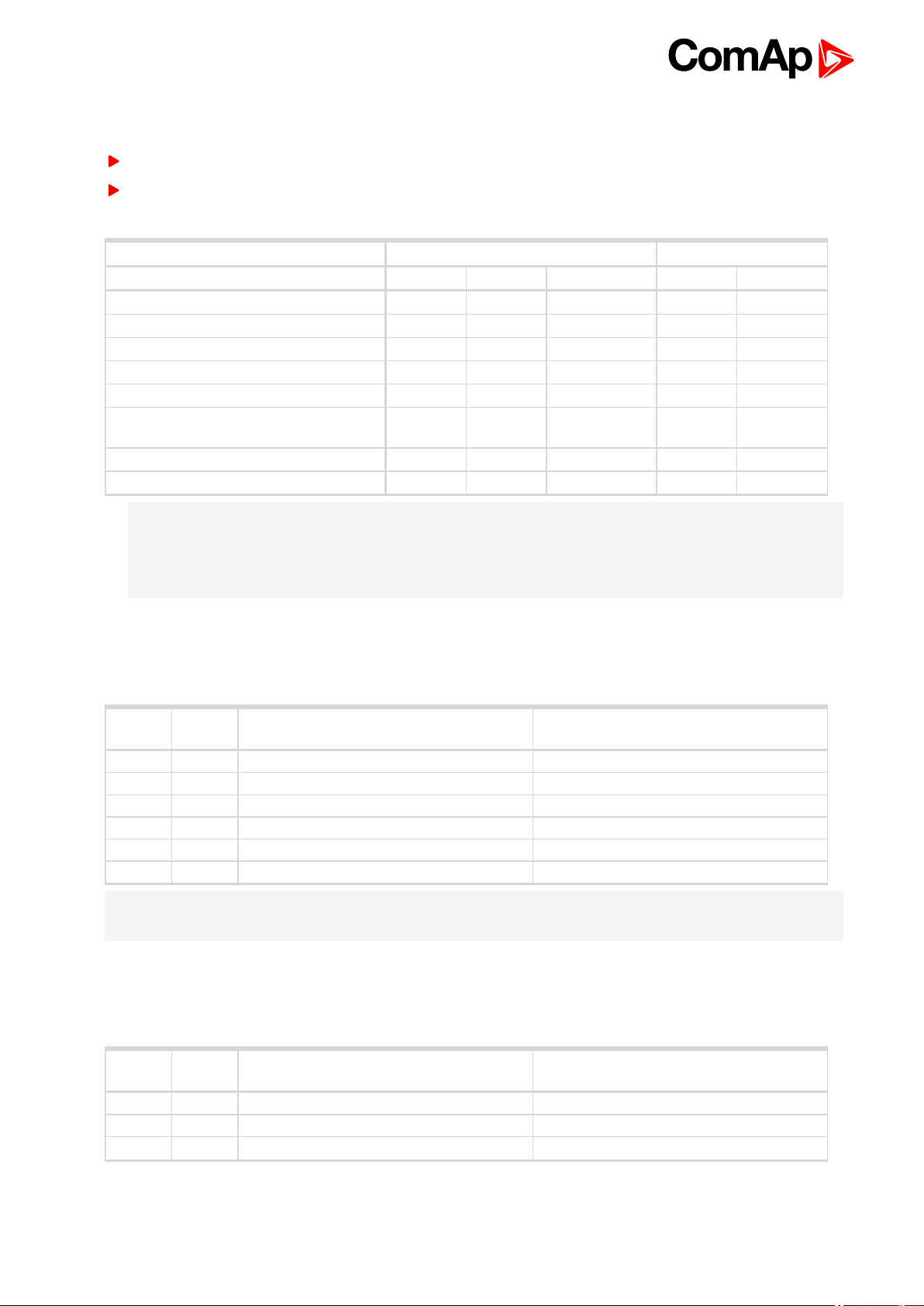

Collaboration with ECON-4Slave

Physical analog input on terminal S3.2 canbe used also when ECON4-Slave is used. In this case feedback

from slave actuator is put on analogue output on slave and can be connected back to masterto see it in one

Winscope (connected to master) and in controller thru CAN as Misf Angle.

Original Misf Angle calculation is not used in latest version of ECON4 and in version 1.4 is used to show

feedback from Slave. If feedback from slave is connected to analog input on S3.2 setpoint LoadAnticipationhas

to be =0. Othervise wrong value will be used forload anticip resulting unstability and unpredictive control

Principle of connection Master Slave is shown on next picture.

ECON-4 1.4.0 GlobalGuide

16

Page 17

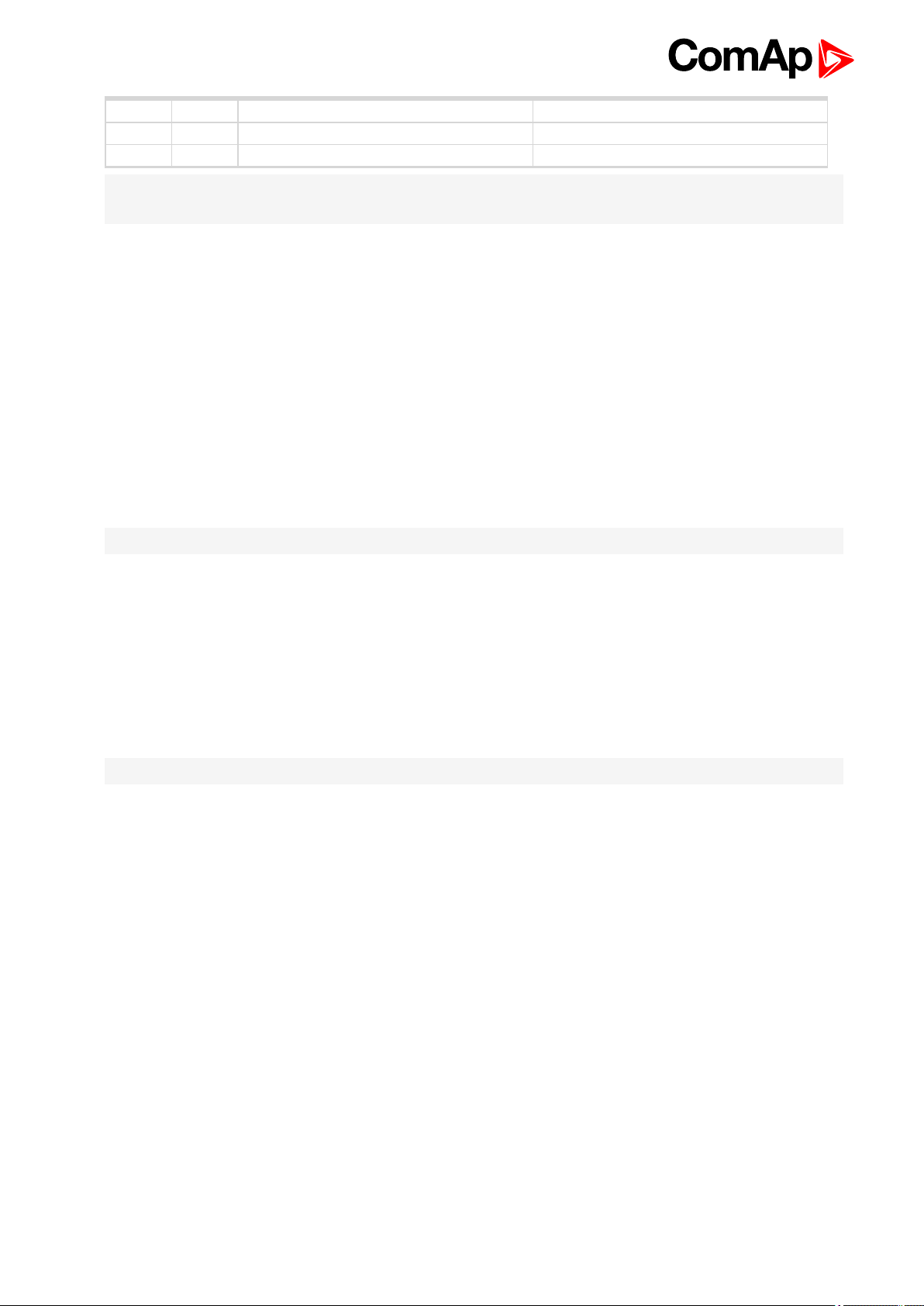

4.4.6 Analog output

ECON-4 has one analogoutput configurable to 0-10V or 0-20mA range by jumper setting – see in table below. If

configuredto 0-20mA range, output works as an active current source. The analogoutput function is fix (copy of

the value sent to ACT output - GAS DOSE). Analogueoutput range is fully programmable in range 0-10V or 020mA – see setpoints: Analog settings: AOUT 0%and AOUT 100%.

Range Recommended wiring Output Terminals Jumpers

0-20

mA

0-10 V AOUT

AOUT

S6.1

S6.2

S6.1

S6.2

P6 - 20 mA

P6 - 10 V

Gas Dose (S6.1)

Output signal corresponds to actuator requested position. The limits are fully scaleablein range 0-10V (020mA).

E.g an actuator with input 4-20mA is used, theAOUT2 range setpoints should be adjusted in the following way:

ECON-4 1.4.0 GlobalGuide

17

Page 18

Analog sensors: AOUT2 0% = 20% (20% from 20mA = 4mA)

Analog sensors: AOUT2 100% = 100%

andjumper P6 adjusted to current option.

In case an actuator with an input 0-5V is used, the AOUT2 setpoints should be adjusted in the following way:

Analog sensors: AOUT2 0% = 0%

Analog sensors: AOUT2 100% = 50%

andjumper P6 adjusted to voltage option.

4.4.7 Interface to actuators

ECON-4 has one interface to actuator. The interface has a bipolar PWM output in bridge configuration and

position feedback input.

It is recommended to connect PWM output by a twisted cable and connect feedback input by a shielded cable.

Range Recommended wiring Terminals Jumpers

Ooutput

0 - 8 A

Feedback

0 - 5 V

Feedback

0 - 10 V

Types of actuators supported by ECON-4

With current input 200mA

Example: Typical example is Woodward UG-A.

S1.3 -

S2.2

S2.1

S2.3

S2.2

S2.1

S2.3

P21

P21

10V

5V

It is electro-hydraulic actuator – in principle a small electromagnetic actuator with hydraulic booster. It has

proportional characteristic – the bigger is the current, thebigger is the angle of the actuator, the polarity of the

current is not important. Actuatoris usually without electrical position feedback. For this actuator choose option

ActType: Wiring: LINEAR NO FEEDBACK

ECON-4 1.4.0 GlobalGuide

18

Page 19

With current input max. 10A

Example: Typical examples are actuators from GAC, Woodward Flowtech ITB.

It is electro-magnetic actuator with a strong return spring. This is in principle electromagnet with proportional

characteristic – the bigger is the current to the actuator, the bigger is the angle of the actuator. The polarity of the

current is not important. This type of actuator can be with or without position feedback. For this actuator choose

option ActType: Wiring: LINEAR or LINEAR NO FEEDBACK.

Motor driven actuators

Example: Typical examples are actuators from Heinzmann (STG 6, 10, 30, 2040.)

It is in principle a DC electromotor driving actuator lever. Since it is a motor, it has integrating characteristic – as

longas the current flows through the actuator, actuator’s lever moves. Direction of movement of the actuator

lever depends on polarity of the current. This typeof actuator has always position feedback. For this actuator

choose option ActTypex: Wiring: BRIDGE. For Heinzmann actuators, Jumper P21 – supply of the position

feedback must be set to option 0-10V. For Woodward and GAC actuators this jumper must be set to position 05V.

ECON-4 1.4.0 GlobalGuide

19

Page 20

4.4.8 Speed Pick-up

Always use a shieldedcable, connect shieldingto a grounding screw. ECON-4 supports both active (powered)

andpassive (magnetic) pickups.

Pick-up Recommended wiring Jumpers

Active NPN

Active PNP Link 1 and 2

Passive Link 2 and 3

If the jumper is in position 2-3, terminals GND and SIG areseparated from all other terminals. This enables to

share one pick-up by two modules, for instance by a speed governor and by an ignition, without danger of

creating a ground loop.

Link 1 and 2

Link 4 and 5

4.4.9 Communication wiring

CAN bus connection

ECON-4 is equipped by CAN communication line. CAN bus terminals are electrically isolated from any other

terminals.

Note: Following ECON-4 CAN setting is necessary to communicate with InteliSys NT:

CAN mode (Object number 10338) = 1 sets ComAp protocol

CAN NODE-ID (Object number10306) = 88 (decimal) sets address of the module

ECON-4 1.4.0 GlobalGuide

20

Page 21

Connection rules

CAN bus line must be connected in series, from one unit to the next (no star, no cable stubs, and no branches)

both ends must be by the 120-ohm (internal or external) resistorterminated. Maximal CAN bus length is 200

meters.

ECON-4 contains internal 120-ohm resistor, connected through a removable jumper P7.

For CAN data cables details seechapter Technical data – Communication interface. CAN cable shielding

connect to CAN COM terminal.

6 back to Recommended wiring

ECON-4 1.4.0 GlobalGuide

21

Page 22

5 ECON-4 setup

5.1 Quick start - how to set ECON4 andcontroller 22

5.2 Entering password 28

5.3 Data 28

5.4 ECON-4 configuration and PC tools 32

5.5 ECON adjustement for various types of actuators 34

5.6 Detailed fucntion 37

6 back to Table of contents

5.1 Quick start - how to set ECON4 and controller

The following description should help you to quick adjust the ECON-4speed governor. The ECON-4 can be

found in different modes used for control of moduleand engine.

Basically any input signal of ECON4 can be suppliedeither using wired signal or using data from CAN1 line.

Input signals of ECON4 areseparated in to two groups each group can be controlled in different way.

Group Setpoint Signal

Breaker`s

feedback

Speed control

Block schema where data flow in different modes is shown is located in Setpoints section CB request (page 50)

andSpeed request (page 49)

There is separated description of setting for different modes for CB request and Speed request on following

pages.

CB

request

Speed

request

GCB feedback

MCB feedback

Speed request analogue signal

Actual power analogue signal

SpeedUp and SpeedDown binary

signal

Idle/Nominal binary signal

Droop binary signal

RUN binary signal

Possible control

mode

BIN/ANA/DATA

BIN/DATA

5.1.1 Breakers feedback handling (CB request modes)

CB request set to BIN mode

Image 5.1 CB request - BIN mode

ECON-4 1.4.0 GlobalGuide

22

Page 23

In case of binary control of breaker`s feedback, signals from breakers has to be wired to terminals S4.1 and

S4.2. You do not needto link any source to Binary outputs of ECON4 in Genconfig.

CB request set to DATA mode

Image 5.2 CB request - DATA mode

In case of DATA control of breaker`s feedback, logical signals from breakers has to be linked to Binary outputs

of ECON4 in Genconfig. Terminals S4.1 and S4.2. do not need to be wired.

5.1.2 Speed control handling (Speed request modes)

Speed request set to ANA mode

Image 5.3 Speed request - ANA mode

ECON-4 1.4.0 GlobalGuide

23

Page 24

In case of ANAlogue mode, the required speed is controlled via Analogue input S3.1 (voltage or current signal,

connected between terminals S3.1 and S3.3). The binary control signals (Idle/Nominal, Run/Stop, Droop) are

evaluated from the binary terminals S4.3 – S4.8 as in case of BINary mode.

In case the source of the Analogue input Speedrequest to ECON-4 is ComAp controller (e.g. InteliSysNT),

adjust the ComAp setpoints in the following way:

Sync/Load ctrl: SpeedGov Bias = 5 Volts (for 1500 RPM sets)

Sync/Load ctrl: SpeedGovLoLim = 0 Volts

Sync/Load ctrl: SpeedGovHiLim = 10 Volts

Sync/Load ctrl: Freq gain = 5 %

Sync/Load ctrl: Freq int = 5 %

Sync/Load ctrl: Angle gain= 10 %

You do not need to link any source to Binary outputs of ECON4 in Genconfig. This type of control can be used

with firmwarewithout support of ECON4 or even for collaboration with thirt party controlleror without any

controller just as standalone speed controller (no Data communication to ECON4 is needed).

Necessary signal – RPM signal – connected to RPM1 terminal – S7.2 and S7.1

Speed request set to BIN mode

Image 5.4 Speed request - BIN mode

In case of BINary control, the ECON-4 is fully controlled via binary inputs – terminals S4.3 – S4.8.(except CB

control). The input S4.6 is the ON/OFF signal to ECON-4, in case it is not active, speed governor will not open

the throttle. In case it is deactivated during engine running, throttle is immediately closed. Use BIN S4.3 to

switch from Idle running to Nominal speedrunning (Idle and Nominal speedadjustment is in ECON-4 setpoints:

Engine RPM). Do not put the Idle RPM and Nominal RPM to the same value. In case you want engine to be

running at Nominal RPM without Idle period, leave BIN S4.3 activated all the time.

Use BIN S4.4 and S4.5 (SpeedUP and Speed Down) to control the speed or load (in case of parallel with mains

operation).

You do not need to link any source to Binary outputs of ECON4 in Genconfig. This type of control can be used

with firmwarewithout support of ECON4 or even for collaboration with thirt party controlleror without any

controller just as standalone speed controller (no Data communication to ECON4 is needed).

Necessary signal – RPM signal – connected to RPM1 terminal – S7.2 and S7.1

Speed request set to DATA mode

In case of DATA control almost all the data can be sent from ComAp IGS-NT controllers to ECON-4 via CAN1

line. The only binary input RUN/STOP – S4.6 must be activated physically as well. To use theDATA mode,

adjust the IGS-NT inputs/outputs in thefollowing way:

ECON-4 1.4.0 GlobalGuide

24

Page 25

a. Configurationof ECON-4 module

Go to GenConfig, card Modules – Extension modules – Others – ECON-4 > Insert

b. Configurationof Binary outputs of IGS-NT

All the ECON-4inputs are in fact IGS-NT outputs (IGS-NT controller sends the signals to ECON-4 unit).

BO1 – this configuration of feedback is independent andis described in previous chapter Breaker`s

feedback handling (CB request modes)

BO2 – this configuration of feedback is independent andis described in previous chapter Breaker`s

feedback handling (CB request modes)

BO3– Idle/Nominal – configure on this output signal which defines switching from Idle operation to Nominal

ROM run. The Logbout signal: Idle/Nominal of IGS-NT canbe used. In case the Idle period is required to be

skipped, configure on this output signal Log bout: Logical 1.

BO4 – Run Stop – together with binary input S4.6 RUN/STOP this signal must be activated to unblock

ECON-4 function. Signal Log Bout: Fuel solenoid can be used.

BO5 – Droop – use the Droop function in case of in Mains parallel operation to make the load control function

more stable (protectagainst power swing). Use signal e.g. GCB feedback.

ECON-4 1.4.0 GlobalGuide

25

Page 26

BO1 and2 setting is separated and described in previous chapter

c. Configuration of Analogue inputs from IGS-NTto ECON-4 (those are signals from ECON4 to controller, in

ourconfiguration it is namedfrom controllers point of view, so inputs)

AIN1 – Engine RPM

The engine RPM can be sent from ECON-4 into the IS-NT via CAN line as well. Configure the AIN1 in the

following way:

Function – RPM pick-up

Sensor– Electronic

the IGS-NT controller.

d. Configurationof Analogue outputs from IGS-NT to ECON-4

AOUT1 – Active Power Rel

ECON-4 is equipped with the Load anticipationfunction to react as quickly as possible to the sudden

changes of the engine power. For this function ECON-4 needs information about power and in case of DATA

mode this can be sent to ECON-4 via CAN. Adjust theAOUT1 in the following way:

Source: Genervalues: ActPwr rel

Normalize: YES

Resolution: 0,1

AOUT2 – Speed RequestThe Speed request in case of DATA mode is sent via CAN line. Configure the

output AOUT2 in the following way:

Source: Sync.

ECON-4 1.4.0 GlobalGuide

26

Page 27

Load ctrl: SpeedReqRPM

IMPORTANT: Configuration of Analog output AOUT2from IS2GASXX to ECON-4 has to be

configured as SpeedReqRPMx8

Controller setting in case ECON4 is set to communicate with controller via CAN1 (Speed request set to DATA

mode)

Besides the above mentioned inputs/outputs adjustment, the IGS-NT setpoints shall be adjusted in the

following way:

Sync/Load ctrl: SpeedGov Bias = 0 Volts

Sync/Load ctrl: SpeedGovLoLim = -10 Volts

Sync/Load ctrl: SpeedGovHiLim = 10 Volts

Sync/Load ctrl: Freq gain = 5 %

Sync/Load ctrl: Freq int = 5 %

Sync/Load ctrl: Angle gain= 10 %

IMPORTANT: Please, take in account, there are several setpoints of ECON-4, which are not

accessible via IGS-NT control unit in case of DATA mode. These parameters are crucial for ECON-4

and used Actuator adjustment and so these are accessible via ECON-4 connection ONLY. Use

ComAp PC sw WinScope to adjust these setpoints.

For all modes of ECON-4 usage adjust

Type of used Actuator – Main PID: Actuator type, PWM rate. The ACT1-4 are preadjusted, see: Act type 1 –

predefined forWoodwardITB 0-200mA, PWM rate [Hz].Speed PID loop – MAIN PID: Speed gain= 10%,

Speed Int = 10%, Speed der = 40%Type of ECON-4 communication mode: Engine RPM: Speed RequestIdle,

Nominal, Overspeed RPM: Engine RPM: Idle RPM, Nominal RPM, Overspeed.

ECON-4 1.4.0 GlobalGuide

27

Page 28

5.2 Entering password

5.2.1 Modify password from WinScope

WinScope PCprogram is used for modifying Setpoints.

Enter password

Password is a four-digit number. Password enables to change set points from WinScope PC program. Use icon

to activate a dialog box for password.

Change password

Use icon to activate a dialog box for password change. The password has to be entered to activated this

icon.

5.2.2 Modify password from GenConfig

Certain Setpoints can be modified directly from GenConfigPCtool. For information how to enter password in

GenConfig please see GenConfig Global Guide.

5.3 Data

Followingdata arecommunicated between IS-NT (specific sw branches only) and ECON-4 via CAN bus.

Correct function depends on configuration by PC GenConfig software.

5.3.1 Data Binary inputs

Followingdata from ECON-4 can be used for states indication or alarms activation.

ECON-4 Name Function

BI1 Bin1 Physical input state, reserve

BI2 Bin2 GCB Fdbck Physical input state

BI3 Bin3 Nominal Physical input state

BI4 Bin4 SpeedUp Physical input state

BI5 Bin5 SpeedDown Physical input state

BI6 Bin6 Run/Stop Physical input state

BI7 Bin7 Droop Physical input state

BI8 Bin8 Physical input state, reserve

BI9 Reserve

BI10 Reserve

BI11 Engine running ECON-4 state indication

BI12 OverSpeed Sd ECON-4 state indication

BI13 PID limit Fuel is on limit

ECON-4 1.4.0 GlobalGuide

28

Page 29

BI14 ActFdbErr Active actuatorfeedback error

BI15 ActOverldProt Active overload protection

BI16 InvalSetpoints Setpoints CRC fail

5.3.2 Data Binary outputs

ECON-4 accepts the data from InteliSys-NT (specific sw branches only) instead from Physical Binary inputs,

when setpoint Engine RPM: Speed request = DATA.

ECON-4

BO1 MCB feedback

BO2 GCB feedback

BO3 Nominal

BO4 Run/StopÂÂ

BO5 Droop

Name

The physical RUN/STOP – S5.6 binary input must be closed in any type of control to run ECON-4 i.e. in “DATA

mode” together with data commandBO4 Run/Stop to enable speed control function (unblock the actuator from

0% position).

5.3.3 Data Analog inputs

ECON-4 Name Logical function

AI1 Engine RPM

AI2 Misfiring Amplitude

1

No RPM pickup is needed in IS-NT. Configure IS-NT – I /O – ECON-4– AIN1 Engine RPM for

Function = RPM pick-up

RPM pick-up;

(RPM value source forIS-NT)

Sensor= Electronic

5.3.4 Data Analog outputs

ECON-4 Name Function

AOUT1 Active power - relative 0,0 - 100,0 % (option)

AOUT2 SpeedReq RPM In RPM/8 (option)

Active power value is required for Load anticipationfunction – see Main PID: Load anticip. In GenConfig choose

value: Gener values: Act Pwr rel, option Normalize – YES, resolution 0,1.

For AOUT2 choose: Sync/Load ctrl: SpeedReqRPM and leave the default settings of this output.

5.3.5 ECON adjustement for various types of actuators

Basically there are available 3 types of actuator types:

LINEAR – actuator is driven by a current, which acts against a spring which pushes the actuator to close

position. Actuator is equipped with position feedback signal. Available feedback signal for ECON is 0,4 to

4,6 Volts DC.

1

Misfiring evaluation from ECON-4 is not implemented in version 1.0

ECON-4 1.4.0 GlobalGuide

29

Page 30

LINEAR NO FDB – actuator is driven by a current, which acts against a spring which pushes the actuator

to close position. Actuatoris not equipped with position feedback signal.

BRIDGE – in principal electromotor, one current polarity moves the actuator to one position, reverse polarity

moves the actuator to another position.

Adjustment for LINEAR actuator type (typically Woodward

A. At first check the position feedback level, in case it is not within limits 0.4 to 4,6 Volts, then use the LINEAR

NO FDB adjustment.

B. Connect to ECON-4 via USB connector, using PC program WinScope.

C. Adjust the Position feedback limits in parameter group: AnalogSensors: Fdb 0 pos to voltage of feedback in

case the actuator is fully closed, and Fdb 100 pos to value of voltage when actuator is fully opened.

D. ECON-4 does not measure the current through actuator. The output signal is PWM, with adjustable

frequency. The maximum ECON-4 current is given by resistance of the actuator and power supply of

ECON-4. ECON-4 is rated to maximum 8 Amps. In case the actuator has resistance 32 Ohms and power

supply is 24V, then maximum ECON-4 current is: 24/32 = 0,75A = 750mA. This means 100% of ECON

current is 750mA. In case the maximum allowable actuator current is 250mA, then this is 33.3% of

maximum ECON-4 current. This value will be used for the maximum current limitation.

E. Choose one ActType x group, e.g. ActType 1 and adjust parameter Wiring to LINEAR, and adjust

parameters Act gain to 10%, Act int to 10% and Act der to 10%

F. Parameters: ActTypex (In this case ActType 1): ActCur 0% and ActCur 100% are not used, so their value is

not important

G. Parameters: ActTypex (In this case ActType 1): Act MaxCur is maximum allowable current, in case bigger

current is detected (in fact bigger output PWM signal is detected)for longer then: ActMaxCurDel, then the

output is limited to value ActReduced Cur. So in case we have actuator with resistance 32Ohms, ECON

powersupply is 24Volts and maximum allowable actuator is 250mA, then it is recommendedto adjust: Act

MaxCur = 33,3%, (24V / 32Ω = 750mA, 250mA is 33,3% from 750mA), Act MaxCurDel = 5 sec, Act

ReducedCur = 10%.

H. Adjust parameter: Main PID: ActuatorType to the actuator which youuse, so in this case ActType 1.

I. Connect the actuator to ECON-4, outputs ACT+ ACT- (take care about polarity)

J. Adjust ECON-4 parameter: Main PID: ECON-4 mode to MANUAL and run WinScope recording with values:

Gas Dose and Act1 Fdbck in range 0.0 – 100.0%.

K. When recording is active, change parameter: Main PID: Act position from 0 to 10, 20, 30, .. 100 and check

the response of the actuator (via feedback signal in WinScope). In case theresponse is too lazy or too fast,

then update thecorresponding Act gain, Act int and Act der parameters in ActTypex (in ourcase ActType1)

to get required response.

L. After adjustment is finished, put parameter: Main PID: ECON-4 mode to AUTOMATIC

M. Based on the chosen type of control (BIN, ANA, DATA) connect the required signal

N. Adjust all other parameters like Nominal, Idle speed, Geer teeth, Overspeed, Speed and Load PID, (to the

number which ECON-4 output you areusing)

O. ECON-4 is ready forstart attempt.

Adjustment for LINEAR NO FDB actuator type (typically GAC, Woodward)

A. Connect to ECON-4 via USB connector, using PC program WinScope.

B. Choose one ActType x group, e.g. ActType 1 and adjust parameter Wiring to LINEAR NO FDB

ECON-4 1.4.0 GlobalGuide

30

Page 31

C. ECON-4 does not measure the current through actuator. The output signal is PWM, with frequency 6000 Hz.

The maximum ECON-4current is given by resistance of the actuator and power supply of ECON-4. ECON4 is ratedto maximum 8 Amps. In case the actuator has resistance 32 Ohms and power supply is 24V, then

maximum ECON-4 current is: 24/32 = 0,75A = 750mA. This means 100% of ECON current is 750mA. In

case the maximum allowable actuator current is 250mA, then this is 33.3% of maximum ECON-4current.

Adjust Act Cur0% to 0% and Act Cur 100% to 34% (250mA from 750mA). By this the output is scaled from

0 to 250 mA.

D. Parameters: ActTypex (In this case ActType 1): Act MaxCur is maximum allowable current, in case bigger

current is detected (in fact bigger output PWM signal is detected)for longer then: ActMaxCurDel, then the

output is limited to value ActReduced Cur. The Act Max Curr is calculated from the value Act Cur 100%, so

it means, that the current limitation is in this case already done by adjustment of ActCur 100%, and Act Max

Cur shall be adjusted to 100%. Act MaxCurDel and ActReducedCur then can be adjusted to any value.

E. Parameters: ActTypex ()ActType 1 in this case) Act gain, Act int, Act der has no meaning for the LINEAR

NO FDB adjustment.

F. Adjust parameter: Main PID: Actuator Type to theactuator which you use, so in this case ActType 1.

G. Connect the actuator to ECON-4, outputs ACT+ ACT- (take care about polarity)

H. Adjust ECON-4 parameter: Main PID: ECON-4 mode to MANUAL andrun WinScope recordingwith values:

Gas Dose and Act1 Fdbck in range 0.0 – 100.0%.

I. After adjustment is finished, put parameter: Main PID: ECON-4 mode to AUTOMATIC

J. Based on the chosen type of control (BIN, ANA, DATA) connect the requiredsignal

K. Adjust all other parameters like Nominal, Idle speed, Geer teeth, Overspeed, Speedand Load PID,

ActChannel (to the number which ECON-4 output you areusing)

L. ECON-4 is ready for start attempt.

Adjustment for BRIDGE actuator type (typically Heinzmann)

A. At first check the position feedback level, in case it is not within limits 0.4 to 4.6 Volts, then the bridge

actuator cannot be controlledwith ECON.

B. Connect to ECON-4 via USB connector, using PC program WinScope.

C. Adjust the Position feedback limits in: AnalogSensors: Fdb 0 pos to voltageof feedback in case the actuator

is fully closed, and Fdb 100pos to value of voltage when actuator is fully opened.

D. Choose one ActType x group, e.g. ActType1

E. ECON-4does not measure the current through actuator. The output signal is PWM, with frequency 6000Hz.

The maximum ECON-4current is given by resistance of the actuator and power supply of ECON-4. ECON4 is ratedto maximum 8 Amps. In case the actuator has resistance 2,5 Ohms and power supply is 24V, then

maximum ECON-4 current is: 24/2.5 = 9,6A but ECON max allowable current is 8 Amps!! So the output

must be limited. This means 100% of ECON theoretical current is 9,6A. In case the maximum allowable

actuator current is 5A, then this is 52% of maximum ECON-4 theoretical current. This value will be used for

the maximum current limitation. So adjust ActType1: Act Max Cur = 52%, Act Max Cur Del = 5 sec and Act

ReducedCur = e.g. 20%.

In case bigger current is detected (in fact bigger output PWM signal is detected) forlonger then:

ActMaxCurDel, then the output is limited to value ActReduced Cur.

F. Adjust parameter Wiring to BRIDGE, and adjust parameters Act gain to 10%, Act int to 10% and Act der to

10%

ECON-4 1.4.0 GlobalGuide

31

Page 32

G. Parameters: ActTypex (In this case ActType 1): ActCur 0% and ActCur 100% are not used, so their value is

not important

H. Adjust parameter: Main PID: ActuatorType to the actuator which youuse, so in this case ActType 1.

I. Connect the actuator to ECON-4, outputs ACT+ ACT- (take care about polarity!!)

J. Adjust ECON-4 parameter: Main PID: ECON-4 mode to MANUAL and run WinScope recording with values:

Gas Dose and Act1 Fdbck in range 0.0 – 100.0%.

K. When recording is active, change parameter: Main PID: Act position from 0 to 10, 20, 30, .. 100 and check

the response of the actuator (via feedback signal in WinScope). In case theresponse is too lazy or too fast,

then update thecorresponding Act gain, Act int and Act der parameters in ActTypex (in ourcase ActType1)

to get required response.

L. After adjustment is finished, put parameter: Main PID: ECON-4 mode to AUTOMATIC

M. Based on the chosen type of control (BIN, ANA, DATA) connect the required signal

N. Adjust all other parameters like Nominal, Idle speed, Geer teeth, Overspeed, Speed and Load PID,

ActChannel (to the number which ECON-4 output you areusing)

O. ECON-4 is ready forstart attempt.

5.4 ECON-4 configuration and PC tools

5.4.1 Setpoints adjustements in WinScope SW:

Connect RS232 port on your PC to RS232 port on ECON-4. Open connection and select Controller type

EMCON5, ECON-3, INCON, RailCon, select your RS232 com port and press OK

Image 5.5 Direct connection of WinScope SW to ECON-4

Then open setpoint Tab and work with setpoints. For rest of operations (channel selection, trend recording...)

see manual for WinScope SW.

Click on the iconSetpoints to open the Setpoints groups. To be able to change any setpoints, the password

has to adjust at first (otherwise the setpoints are grayed andcannot be changed).

ECON-4 1.4.0 GlobalGuide

32

Page 33

5.4.2 Econ-4 firmware update

For ECON-4 firmware upgrade use ComAp FlashProgrammer – see below, choose card ECON-4 (common for

ECON-4). Tick the button Program and choose theappropriate firmware using icon “Locate…”

You can save your setpoints from an existing site andprogram them together with the new firmware. However

the program change does not influence the setpoints, so you can keep them in ECON-4.

Choose theright COM port number and press “Start” button.

Hint:

ECON-4 1.4.0 GlobalGuide

33

Page 34

To be able to program ECON-4 using the FlashProg, you must be disconnected with the WinScope or

InteliMonitor from ECON-4. (There can be always only one active connection to ECON-4 through com port)

5.5 ECON adjustement for various types of actuators

Basically there are available 3 types of actuator types:

LINEAR – actuator is driven by a current, which acts against a spring which pushes the actuator to close

position. Actuator is equipped with position feedback signal. Available feedback signal for ECON is 0,4 to

4,6 Volts DC.

LINEAR NO FDB – actuator is driven by a current, which acts against a spring which pushes the actuator

to close position. Actuatoris not equipped with position feedback signal.

BRIDGE – in principal electromotor, one current polarity moves the actuator to one position, reverse polarity

moves the actuator to another position.

5.5.1 Adjustment for LINEAR actuator type (typically Woodward

A. At first check the position feedback level, in case it is not within limits 0.4 to 4,6 Volts, then use the LINEAR

NO FDB adjustment.

B. Connect to ECON-4 via USB connector, using PC program WinScope.

C. Adjust the Position feedback limits in parameter group: AnalogSensors: Fdb 0 pos to voltage of feedback in

case the actuator is fully closed, and Fdb 100 pos to value of voltage when actuator is fully opened.

D. ECON-4 does not measure the current through actuator. The output signal is PWM, with adjustable

frequency. The maximum ECON-4 current is given by resistance of the actuator and power supply of

ECON-4. ECON-4 is rated to maximum 8 Amps. In case the actuator has resistance 32 Ohms and power

supply is 24V, then maximum ECON-4 current is: 24/32 = 0,75A = 750mA. This means 100% of ECON

current is 750mA. In case the maximum allowable actuator current is 250mA, then this is 33.3% of

maximum ECON-4 current. This value will be used for the maximum current limitation.

E. Choose one ActType x group, e.g. ActType 1 and adjust parameter Wiring to LINEAR, and adjust

parameters Act gain to 10%, Act int to 10% and Act der to 10%

F. Parameters: ActTypex (In this case ActType 1): ActCur 0% and ActCur 100% are not used, so their value is

not important

G. Parameters: ActTypex (In this case ActType 1): Act MaxCur is maximum allowable current, in case bigger

current is detected (in fact bigger output PWM signal is detected)for longer then: ActMaxCurDel, then the

output is limited to value ActReduced Cur. So in case we have actuator with resistance 32Ohms, ECON

powersupply is 24Volts and maximum allowable actuator is 250mA, then it is recommendedto adjust: Act

MaxCur = 33,3%, (24V / 32Ω = 750mA, 250mA is 33,3% from 750mA), Act MaxCurDel = 5 sec, Act

ReducedCur = 10%.

H. Adjust parameter: Main PID: ActuatorType to the actuator which youuse, so in this case ActType 1.

I. Connect the actuator to ECON-4, outputs ACT+ ACT- (take care about polarity)

J. Adjust ECON-4 parameter: Main PID: ECON-4 mode to MANUAL and run WinScope recording with values:

Gas Dose and Act1 Fdbck in range 0.0 – 100.0%.

K. When recording is active, change parameter: Main PID: Act position from 0 to 10, 20, 30, .. 100 and check

the response of the actuator (via feedback signal in WinScope). In case theresponse is too lazy or too fast,

ECON-4 1.4.0 GlobalGuide

34

Page 35

then update thecorresponding Act gain, Act int and Act der parameters in ActTypex (in ourcase ActType1)

to get required response.

L. After adjustment is finished, put parameter: Main PID: ECON-4 mode to AUTOMATIC

M. Based on the chosen type of control (BIN, ANA, DATA) connect the required signal

N. Adjust all other parameters like Nominal, Idle speed, Geer teeth, Overspeed, Speed and Load PID, (to the

number which ECON-4 output you areusing)

O. ECON-4 is ready forstart attempt.

5.5.2 Adjustment for LINEAR NO FDB actuator type (typically GAC, Woodward)

A. Connect to ECON-4 via USB connector, using PC program WinScope.

B. Choose one ActType x group, e.g. ActType 1 and adjust parameter Wiring to LINEAR NO FDB

C. ECON-4 does not measure the current through actuator. The output signal is PWM, with frequency 6000 Hz.

The maximum ECON-4current is given by resistance of the actuator and power supply of ECON-4. ECON4 is ratedto maximum 8 Amps. In case the actuator has resistance 32 Ohms and power supply is 24V, then

maximum ECON-4 current is: 24/32 = 0,75A = 750mA. This means 100% of ECON current is 750mA. In

case the maximum allowable actuator current is 250mA, then this is 33.3% of maximum ECON-4current.

Adjust Act Cur0% to 0% and Act Cur 100% to 34% (250mA from 750mA). By this the output is scaled from

0 to 250 mA.

D. Parameters: ActTypex (In this case ActType 1): Act MaxCur is maximum allowable current, in case bigger

current is detected (in fact bigger output PWM signal is detected)for longer then: ActMaxCurDel, then the

output is limited to value ActReduced Cur. The Act Max Curr is calculated from the value Act Cur 100%, so

it means, that the current limitation is in this case already done by adjustment of ActCur 100%, and Act Max

Cur shall be adjusted to 100%. Act MaxCurDel and ActReducedCur then can be adjusted to any value.

E. Parameters: ActTypex ()ActType 1 in this case) Act gain, Act int, Act der has no meaning for the LINEAR

NO FDB adjustment.

F. Adjust parameter: Main PID: Actuator Type to theactuator which you use, so in this case ActType 1.

G. Connect the actuator to ECON-4, outputs ACT+ ACT- (take care about polarity)

H. Adjust ECON-4 parameter: Main PID: ECON-4 mode to MANUAL andrun WinScope recordingwith values:

Gas Dose and Act1 Fdbck in range 0.0 – 100.0%.

I. After adjustment is finished, put parameter: Main PID: ECON-4 mode to AUTOMATIC

J. Based on the chosen type of control (BIN, ANA, DATA) connect the requiredsignal

K. Adjust all other parameters like Nominal, Idle speed, Geer teeth, Overspeed, Speedand Load PID,

ActChannel (to the number which ECON-4 output you areusing)

L. ECON-4 is ready for start attempt.

5.5.3 Adjustment for BRIDGE actuator type (typically Heinzmann)

A. At first check the position feedback level, in case it is not within limits 0.4 to 4.6 Volts, then the bridge

actuator cannot be controlledwith ECON.

B. Connect to ECON-4 via USB connector, using PC program WinScope.

ECON-4 1.4.0 GlobalGuide

35

Page 36

C. Adjust the Position feedback limits in: AnalogSensors: Fdb 0 pos to voltageof feedback in case the actuator

is fully closed, and Fdb 100pos to value of voltage when actuator is fully opened.

D. Choose one ActType x group, e.g. ActType1

E. ECON-4does not measure the current through actuator. The output signal is PWM, with frequency 6000Hz.

The maximum ECON-4current is given by resistance of the actuator and power supply of ECON-4. ECON4 is ratedto maximum 8 Amps. In case the actuator has resistance 2,5 Ohms and power supply is 24V, then

maximum ECON-4 current is: 24/2.5 = 9,6A but ECON max allowable current is 8 Amps!! So the output

must be limited. This means 100% of ECON theoretical current is 9,6A. In case the maximum allowable

actuator current is 5A, then this is 52% of maximum ECON-4 theoretical current. This value will be used for

the maximum current limitation. So adjust ActType1: Act Max Cur = 52%, Act Max Cur Del = 5 sec and Act

ReducedCur = e.g. 20%.

In case bigger current is detected (in fact bigger output PWM signal is detected) forlonger then:

ActMaxCurDel, then the output is limited to value ActReduced Cur.

F. Adjust parameter Wiring to BRIDGE, and adjust parameters Act gain to 10%, Act int to 10% and Act der to

10%

G. Parameters: ActTypex (In this case ActType 1): ActCur 0% and ActCur 100% are not used, so their value is

not important

H. Adjust parameter: Main PID: ActuatorType to the actuator which youuse, so in this case ActType 1.

I. Connect the actuator to ECON-4, outputs ACT+ ACT- (take care about polarity!!)

J. Adjust ECON-4 parameter: Main PID: ECON-4 mode to MANUAL and run WinScope recording with values:

Gas Dose and Act1 Fdbck in range 0.0 – 100.0%.

K. When recording is active, change parameter: Main PID: Act position from 0 to 10, 20, 30, .. 100 and check

the response of the actuator (via feedback signal in WinScope). In case theresponse is too lazy or too fast,

then update thecorresponding Act gain, Act int and Act der parameters in ActTypex (in ourcase ActType1)

to get required response.

L. After adjustment is finished, put parameter: Main PID: ECON-4 mode to AUTOMATIC

M. Based on the chosen type of control (BIN, ANA, DATA) connect the required signal

N. Adjust all other parameters like Nominal, Idle speed, Geer teeth, Overspeed, Speed and Load PID,

ActChannel (to the number which ECON-4 output you areusing)

O. ECON-4 is ready forstart attempt.

ECON-4 1.4.0 GlobalGuide

36

Page 37

5.6 Detailed fucntion

5.6.1 Block schematics - speed governor

Overspeed protection in ECON4-ADV

Instead of value in the middle between Nominal and Overspeed thereis additional RPM level defined in setpoint

Engine RPM: PreOverSpeed in ECON4-ADV versions. When RPM reaches this level, Gas Dose Value

(throttle position) goes to value in setpoint Engine RPM: PreOverSpReduct – can be set to Idle Fuel or Close.

This feature was added to prevent overspeedwhen Load is removed – typically switch off large load in island

operation.

Overspeed protection

In case the actual RPM crosses RPM value: Engine RPM: Overspeed, then the Gas Dose is immediately

forced to the zero – throttle is closed and shutdown is issued.

There is proactive action taken to try to keep engine running without shutdown, when actual RPM reaches value

in the middle between Nominal and Overspeed value. In this case, when RPM crosses this middle value, Gas

Dose is set to Idle position and when RPM drops back below this middlevalue, speed PID will continue to

regulate RPM.

Purpose of this behavior is to prevent the Overspeed situation by detecting the RPM increase and step change

of the fuel (closing the fuel). As the RPM are dropping down subsequently towards the Nominal RPM the fuel is

ECON-4 1.4.0 GlobalGuide

37

Page 38

changed again to maintain the RPM on Nominal value andnot to cause a dip in the RPM.

Speed governor function in Idle or local load mode

ECON-4 compares the Reference and Actual speeds of the engine and calculates theRegulation error.

The Actual speed is measured from the period of the signal generated by the magnetic pickup sensing gears of

the flywheel.

Speed reference canbe generated by 3 ways:

by Binary inputs,

by Analogue input

from CAN bus,

For more information see setpointSpeed request (page 49).

The Regulation error is then processed by the standard PID control structure with proportional, integration and

derivative parts. The PID setpoints – Gain, Int andDer define the quality of regulation.

The parameters of the PID control structure are different if the engine is in:

no-load operation,

loaded operation

For more information see setpoint .Description (page 53)

The output of the PID control structure is then added together with the Load anticipation feedback, which is

directly proportional to the engine power. The output from the last sum is limited by the Anti-windup Limiter

module, which reduces the integrator’s output signal so that the sum of the signals from the Gain, Integrator,

Differentiator and Loadanticipation blocks equals exactly the limit MaxFuel.

Speed governor function in parallel mode

When engineis in parallel to Mains, Econ4 works just as amplifierand converts Speed request signal to Gas

Dose signal according Speed/Fuel line as follows

ECON-4 1.4.0 GlobalGuide

38

Page 39

Transition to parallel from zero local load.

When engineis running without load, speed request from controller is in bias position and enginehas a throttle in

Idle position. So if those values are properly set in to ECON4 setpoints while going to parallel, engine startso to

runin SGO Bias and IdleFuel point on Speed/Fuel line. When request for load is increased in controller, Speed

request is increased andthrottle is opened and vice versa.

Transition to parallel from non-zero local load.

There could be situation in SPtm for example, when just GCB is closed and generator supply a local load. So

MCB is opened and GCB is closed and PID with Load parameters is used to control speedand Throttle position.

It is clear than Throttle is not in Idle position but on higher position. Now after synchronization, MCB is closed,

throttle stays in the same position because no Higher Power is generated just after synchronization and Actual

speed request is in Bias position because no power control has been done in previous stage. So there is

difference betweenactual speed request andspeed request corresponding to actual throttle position. This

difference is called Speed request offset and we keep it to make transition burpless. When controller increase

aped request to provide more powerto Mains, we move throttle to higher position on the Speed/fuel line andit

works fine. But we cannot keep speed request offset all time, because when controller decrease speed request

throttle would go to zero position and even to negative value (theoretically). So we keep Speed request offset

just for one minute from breaker closing and then starts to decrease this offset. This will move throttle down, but

controller will notify decreasing of power and increase speed request. After a while, using this mechanism

Speed request offset oi zero and actual throttle position respects speedrequest and Speed/fuel line.

Speed request offset is decreased according ramp, which is set in setpoint SGOoffsetRamp. Time in this

setpoint is time needed to change Speed request offset from 10V to 0V.

6 back to ECON-4 setup

ECON-4 1.4.0 GlobalGuide

39

Page 40

6 Communication

6.1 Connection to ECON-4

Connect RS232 cable and start WinScope software. Click on the Connection, Open Connection and choose

Direct connection type, EmCon5, ECON-4, INCON Controller type, choose the right COM port and press O.K.

button.

6 back to Table of contents

ECON-4 1.4.0 GlobalGuide

40

Page 41

7 Technical data

Actuator feedback input

Resolution

Analog inputs

Number

Resolution

Rang e

Analog measurement

tolerance

Analog outputs

Number

Resolution

Rang e

Analog measurement

tolerance

Binary inputs

Number

Input resistance

Input range

Switching voltage level for close con tact

indication

Max voltage level for open contact indication

10 bits non electrically separated

2 non electrically separated

10 bits

0 - 10 V; input resistance 11 kΩ

0 - 20 mA; load resistor 50 Ω

1 %

1 non electrically separated

0 - 100000

0 - 10 V; output resistance < 1 kΩ

0 - 20 mA; Active current source

1 %

8

4.4 kΩ

0 - 36 V DC

0 - 2 V

8 - 36 V

CAN bus interface

Maximal CAN bus length

Speed

Nominal impedan ce

Cable type

General information

Weight

Protect ion

Operating conditions

Operating temperature

Storage temperature

Humidity

Low voltage directive

Electromagnetic

compatibility

Vibratio ns

Shocks

200 m galvanically separated

250 kBd

120 Ω

twisted pair (shielded)

600 g

IP20

- 30 to +70 ˚C

-30 to +80˚C

95% without condensation

EN 61010-1:95 +A1:97

EN 50081-1:94, EN 50081-2:96

EN 50082-1:99, EN 50082-2:97

5 - 25 Hz, ± 1,6mm 25 - 100 Hz, a = 4 g

a = 200 m/s

2

ECON-4 1.4.0 GlobalGuide

41

Page 42

Power supply

Power supply rang e

Con sumption

RS232 interface

Maximal distance

Speed

Speed pick-up inputs

Type of sensor

Minimum input voltage

Maximum input voltage

Minimum measured

frequ ency

Maximum measured

frequ ency

Frequency measurement

tolerance

6 back to Table of contents

12-36 V DC

0,5 – 10 A, depends on supply voltage and used actuator

10 m

19 200 bps

Active or magnetic pick-up (connection by shielded cable is strongly recommended)

2 Vpk-pk (from 4 Hz to 4 kHz)

50 Veff

4 Hz

10 kHz (min. input voltage 6Vpk-pk)

0,2 %

ECON-4 1.4.0 GlobalGuide

42

Page 43

8 Appendix

8.1 Setpoints 44

6 back to Table of contents

ECON-4 1.4.0 GlobalGuide

43

Page 44

8.1 Setpoints

What setpoints are:Setpoints are analog, binary or special data objects which are used for adjusting the

controller to the specific environment. Setpoints are organized into groups according to their meaning. Setpoints

can be adjusted from the controller front panel, PC, MODBUS, etc. All setpoints canbe protected by a

password against unauthorized changes. Password protection can be assigned to thesetpoints during the

configurationprocedure.

See the chapter Entering password (page 28)forthe instructions how to enter and modify a password.

IMPORTANT: Setpoints are organized in logical groups for better orientation. Use WinScope or

InteliMonitor software to modify the setpoints. For details see chapter ECON-4 configuration and

PC tools (page 32)

8.1.1 List of setpoint groups

8.1.3 Group: Engine StartGroup: ECON4-EngRPM 46

8.1.4 Group: Engine StartGroup: ECON4-EngStart 51

8.1.5 Group: Main PIDGroup: ECON-4-MainPID 53

8.1.6 Act type1 – predefined for Woodward ITB 0-200 mA 69

8.1.7 Act type2 – predefined for Woodward ITB PWM 71

8.1.8 Act type3 –predefined for Woodward F-series PWM 71

8.1.9 Act type4 – predefined for Heinzmann STG 10 72

8.1.10 Group: Analog sensors 72

8.1.11 List of tested actuators by ComAp 74

For full list of Setpoints go to the chapter List of setpoints (page 45).

ECON-4 1.4.0 GlobalGuide

44

Page 45

8.1.2 List of

Group of setpoints:

setpoints

Group of setpoints:

Engine RPM

PreOverSpeed 50

PreOverSpReduct 51

Group of setpoints:

Engine Start

Group of setpoints:

Main PID

RPM Window 55

Speed int w 55

Speed der w 55

Load anticip 58

ActType 1,2,3,4

Act gain 69

Act int 69

Act der 69

Act MaxCur 70

ActmaxCurDel 70

Act ReducedCur 70

Wiring 71

6 back to Setpoints

Load 1 59

Load 2 60

Load 3 61

Load 4 62

LAder+limit 67

LAder-limit 67

LAder+ 67

LAder- 68

LAder+recover 68

LAder-recover 68

Group of setpoints:

Analog sensors

LoReqSpeed Inp 72

HiReqSpeed Inp 72

AOUT 0 73

AOUT 100 73

FBD 0 pos 73

FBD 100 pos 74

ECON-4 1.4.0 GlobalGuide

45

Page 46

8.1.3 Group: Engine StartGroup: ECON4-EngRPM

Idle RPM

1.4.0

Setpoint group Engine RPM Related FW

Range [units] Start RPM - Nominal RPM

Default value 1000 RPM Force value NO

Step 1 RPM

Comm object 7186 Related applications ALL

Description

Engine idle speed.

6 back to List of setpoints

Nominal RPM

Setpoint group Engine RPM Related FW

configuredECON-4 extension

module

1.4.0

configuredECON-4 extension

module

Range [units] 0 - 2500[RPM]

Default value 1500 RPM Force value NO

Step 1 RPM

Comm object 7187 Related applications ALL

Setpoint visibility Always

Description

Nominal enginespeed.

6 back to List of setpoints

Overspeed

1.4.0

Setpoint group Engine RPM Related FW

Range [units] 0 - 2500[RPM]

Default value 1800 RPM Force value NO

Step 1 RPM

Comm object 7168 Related applications ALL

configuredECON-4 extension

module

Setpoint visibility Always

Description

Maximum acceptable speed of the engine. If the actual engine speed is higher, ECON-4 immediately closes

the actuator. Normal function is restored after detection of zero engine speed.

6 back to List of setpoints

ECON-4 1.4.0 GlobalGuide

46

Page 47

Gear teeth

1.4.0

Setpoint group Engine RPM Related FW

Range [units] 32 - 400 [-]

Default value 256 Force value NO

Step 1

Comm object 7188 Related applications ALL

Setpoint visibility Always

Description

Number of teeth on the engine gear for the pick-up.

6 back to List of setpoints

configuredECON-4 extension

module

Idle-Nom ramp

1.4.0

Setpoint group Engine RPM Related FW

Range [units] 0 - 100 [s]

configuredECON-4 extension

module

Default value 10 s Force value NO

Step 1 s

Comm object 7169 Related applications ALL

Setpoint visibility Always

Description

Define how fast changes therequested enginespeed during transition from Idle RPM (page 46) to Nominal

RPM (page 46) and vice versa. Idle-Nom ramp is directly time that theramp needs to go from Idle RPM (page

46) to Nominal RPM (page 46) and vice versa. The ramping speedis the same for both up anddown

directions.

6 back to List of setpoints

ECON-4 1.4.0 GlobalGuide

47

Page 48

BI Speed ramp

1.4.0

Setpoint group Engine RPM Related FW

Range [units] 1.0 - 100.0 [s]

Default value 50 s Force value NO

Step 1.0 s

Comm object 7170 Related applications ALL

Setpoint visibility Always

Description

Define how fast changes therequested enginespeed if the binary inputs SPEED UP or SPEED DOWN are

active. BI Speed ramp is actually time that the ramp needs to go from Nominal RPM (page 46) - 8%

toNominal RPM (page 46) + 8% and vice versa. The ramping speed is the same for both up anddown

directions.

6 back to List of setpoints

configuredECON-4 extension

module

ECON-4 1.4.0 GlobalGuide

48

Page 49

Speed request

1.4.0

Setpoint group Engine RPM Related FW

Range [units] BIN, ANA, DATA

Default value DATA Force value NO

Step -

Comm object 7171 Related applications ALL

Setpoint visibility Always

Description

The setpoint defines source of the Speed reference of the engine.

Speed Request value Speed reference source

BIN SPEED UP, SPEED DOWN

ANA SPEED REQUEST

DATA CAN bus

configuredECON-4 extension

module

Speed request - BIN

Speed request - ANA Speed request - DATA

6 back to List of setpoints

ECON-4 1.4.0 GlobalGuide

49

Page 50

CB request

1.4.0

Setpoint group Engine RPM Related FW

Range [units] BIN / DATA

Default value DATA Force value NO

Step -

Comm object 14363 Related applications ALL

Setpoint visibility Always

Description

CB Request value CB position information source

BIN Terminal S4.1 and S4.2

DATA CAN bus

Note: If possible, use binary control for CB request and wire terminal S4.1 and S4.2 to feedback signal.

This will assure fastest reaction of ECON4 when breaker is closed or opened. This is crucial to avoid

over speed in case of opening GCB under load for example.

configuredECON-4

extension module

6 back to List of setpoints

PreOverSpeed

1.4.0

Setpoint group Main PID Related FW

Range [units] Nominal RPM – Overspeed RPM

Default value 1750 Force value NO

Step 1 RPM

Comm object 14408 Related applications ALL

Setpoint visibility WinScope only

Description

When actual RPM reaches this value Gas Dose (throttle position) is immediately set to Idle Fuel value or

zero (closed position) accordingsettingin setpoint PreOverSpReduct .

6 back to List of setpoints

ECON-4 1.4.0 GlobalGuide

configuredECON-4

ADVextension module

50

Page 51

PerChSpdNom

1.4.0

Setpoint group Engine RPM Related FW

Range [units] 1 - 20 [%]

Default value 8 % Force value NO

Step 1 %

Comm object 7193 Related applications ALL

Setpoint visibility Always

Description

Percentage Change of Requested RPM from Nominal RPM. This setpoint defines the maximum allowable

change of requested RPM from the Nominal RPM value in case the BIN or ANA control of RPM is used.

Use this setpoint to enlarge maximum allowable swingof the required RPM. Setpoint is by default adjusted

to 8% which should fulfill the most of installations.

6 back to List of setpoints

configuredECON-4 extension

module

PreOverSpReduct

1.4.0

Setpoint group Main PID Related FW

configuredECON-4

ADVextension module

Range [units] IDLE FUEL – CLOSE

Default value - Force value NO

Step -

Comm object 14409 Related applications ALL

Setpoint visibility WinScope only

Description

Value set to output GAS Dose when RPM reaches value in setpoint PreOverSpeed.

6 back to List of setpoints

8.1.4 Group: Engine StartGroup: ECON4-EngStart

InitStart dose

Setpoint group Engine RPM Related FW 1.4.0

Range [units] Start RPM - Nominal RPM

Default value 10% Force value NO

Step 1 %

Comm object 7172 Related applications ALL

Setpoint visibility Always

Description

Initial position of the actuator during start

6 back to List of setpoints

ECON-4 1.4.0 GlobalGuide

51

Page 52

MaxStart dose

Setpoint group Engine RPM Related FW 1.4.0

Range [units] Start RPM - Nominal RPM

Default value 50% Force value NO

Step 1 %

Comm object 7173 Related applications ALL

Setpoint visibility Always

Description

Maximum position of the actuator during start.

6 back to List of setpoints

Fuel ramp time

Setpoint group Engine RPM Related FW 1.4.0

Range [units] Start RPM - Nominal RPM

Default value 10 s Force value NO

Step 1 s

Comm object 7174 Related applications ALL

Setpoint visibility Always

Description

Time the actuator needs to move from the InitStart dose to MaxStart dose.

6 back to List of setpoints

RPM StartRamp

Setpoint group Engine RPM Related FW 1.4.0

Range [units] Start RPM - Nominal RPM

Default value 10 s Force value NO

Step 1 s

Comm object 7175 Related applications ALL

Setpoint visibility Always

Description

This setpoint defines speedof ramp from Starting RPM to Idle RPM. It is directly the time of ramp from.

6 back to List of setpoints

ECON-4 1.4.0 GlobalGuide

52

Page 53

Starting RPM

Setpoint group Engine RPM Related FW 1.4.0

Range [units] Start RPM - Nominal RPM

Default value 350 RPM Force value NO

Step 1 RPM

Comm object 7189 Related applications ALL

Setpoint visibility Always

Description

If ECON-4 detects speedhigher then Starting RPM, it terminates thestarting sequence end starts normal

speed regulation.

Note: ECON-4 can work only if Starting RPM < Idle RPM < Nominal RPM. If this condition is not met, ECON-4

activates bit Invalid setpoints in Transmit PDO 1, see description of CAN protocol. It is not possible to run the

engine if the bit Invalid setpoint is signalized.

6 back to List of setpoints

8.1.5 Group: Main PIDGroup: ECON-4-MainPID

Speed gain

1.4.0

Setpoint group Main PID Related FW

Range [units] 0.0 – 200.0 %

Default value 10% Force value NO

Step 0.1 %

Comm object 7176 Related applications ALL

Setpoint visibility Always

Description

Gain of the PID speed regulation loop.

Note: Setpoint is active for unloaded engine.

6 back to List of setpoints

configuredECON-4 extension

module

ECON-4 1.4.0 GlobalGuide

53

Page 54

Speed int

1.4.0

Setpoint group Main PID Related FW

Range [units] 0.0 – 100.0 %

Default value 10% Force value NO

Step 0.1 %

Comm object 7177 Related applications ALL

Setpoint visibility Always

Description

Integration of the PID speed regulation loop..

Note: Setpoint is active for unloaded engine.

6 back to List of setpoints

configuredECON-4 extension

module

Speed der

1.4.0

Setpoint group Main PID Related FW

configuredECON-4 extension

module

Range [units] 0.0 – 100.0 %

Default value 0% Force value NO

Step 0.1 %

Comm object 7178 Related applications ALL

Setpoint visibility Always

Description

Derivative part of thePID speed regulation loop.

Note: Setpoint is active for unloaded engine.

6 back to List of setpoints

ECON-4 1.4.0 GlobalGuide

54

Page 55

RPM Window

1.4.0

Setpoint group Main PID Related FW

Range [units] -

Default value - Force value NO

Step -

Comm object 12091 Related applications ALL

Setpoint visibility WinScope only

Description

In case the actual RPM differs from Requested RPM for more than RPM window [RPM], the Speed PID

constants fluently change from Speed int to Speed int w and from Speed der to Speed der w. The aim of the

RPM window is to changethe speed of regulation(reaction) in case the actual RPM differs significantly from

Requested RPM.

6 back to List of setpoints

configuredECON-4 extension

module

Speed int w

1.4.0

Setpoint group Main PID Related FW

configuredECON-4 extension

module

Range [units] 0-100 %

Default value 10% Force value NO

Step 1 %

Comm object 12092 Related applications ALL

Setpoint visibility WinScope only

Description

Integration part of the PID regulation loop in case theactual RPM differs from Requested RPM for more than

RPM window.

6 back to List of setpoints

Speed der w

1.4.0

Setpoint group Main PID Related FW

Range [units] 0,0-100,0 %

Default value 0% Force value NO

Step 0.1 %

configuredECON-4 extension

module

Comm object 12176 Related applications ALL

Setpoint visibility WinScope only

Description

Derivative part of thePID regulation loop in case the actual RPM differs from Requested RPM for more than

RPM window..

ECON-4 1.4.0 GlobalGuide

55

Page 56

6 back to List of setpoints

Load gain

1.4.0

Setpoint group Main PID Related FW

Range [units] 0.0 – 200.0 %

Default value 10% Force value NO

Step 0.1 %

Comm object 7179 Related applications ALL

Setpoint visibility Always

Description

Gain of the PID speed regulation loop.

There is 5 different setpoints Load gain:

Load gain 1

Load gain 2

Load gain 3

Load gain 4

configuredECON-4 extension

module

For more information about Load der setting please see Load 1 (page 59) ECON-4 Global Guide.

6 back to List of setpoints

Load der

1.4.0

Setpoint group Main PID Related FW

Range [units] 0.0 – 100.0 %

Default value 0% Force value NO

Step 0.1 %

Comm object 7181 Related applications ALL

Setpoint visibility Always

Description

Derivative part of thePID speed regulation loop.

There is 5 different setpoints Load der:

Load der 1

Load der 2

configuredECON-4 extension

module

Load der 3

Load der 4

For more information about Load der setting please see Load 1 (page 59) ECON-4 Global Guide.