Page 1

SEARCHLIGHT SYSTEM

BY COLORLIGHT

INSTALLATION MANUAL

Revision nr: F1.3

Revision date: 2014-05

Page 2

Safety reminder

Remember to break all electrical power to system before

starting any work in the electrical box or the searchlight

unit.

All information in this manual was correct at time of publication. However, as our engineers are

always updating and improving our products, your system's software might provide a slightly

different appearance or modified functionality than presented in this manual.

If your system lacks any function presented in this manual, there is possibly a software update

available to resolve this, please contact ColorLight for more information.

COPYRIGHT COLORLIGHT © 2014. All rights reserved

Page 2 INSTALLATION MANUAL CL20

Page 3

CONTENT

WARNINGS AND INFORMATION ..................................................................................... 5 1.

WARRANTY CONDITIONS ................................................................................................ 7 2.

MAINTENANCE AND SERVICE PLAN .............................................................................. 8 3.

COLORLIGHT SEARCHLIGHT SYSTEM .......................................................................... 9 4.

INSTALLATION .................................................................................................................10 5.

Physical handling of the searchlight .......................................................................10 5.1

CLI-30001, ANTI VIBRATION KIT.....................................................................................11

6.

CLI-30005, REPLACING THE BULB ................................................................................14 7.

ELECTRICAL SYSTEM .....................................................................................................20 8.

Electrical-box (115/230VAC) .....................................................................................20 8.1

Cabinet card ..............................................................................................................21 8.2

Electrical-box overview (115/230VAC) .....................................................................22 8.3

Electrical-box overview (24VDC) .............................................................................23 8.4

Electrical box installation .........................................................................................24 8.5

Operator panel connections.....................................................................................25 8.6

Ethernet wiring ................................ ................................................................ ..........26 8.7

OPERATOR PANEL, OVERVIEW.....................................................................................27

9.

DISPLAY SYMBOLS AND MESSAGES ........................................................................28 10.

Ebox alarm relay ................................................................................................ .......29 10.1

ACTIONS AFTER INSTALLATION OR POWER FAILURE ...........................................30 11.

STARTING SYSTEM .....................................................................................................31 12.

JOYSTICK FUNCTIONS ................................................................................................32 13.

SWITCH ON LIGHT .......................................................................................................33 14.

FOCUS...........................................................................................................................34 15.

Type 1, continuous focus (standard) .......................................................................34

15.1

CABINET CARD MENU SYSTEM ................................................................ .................35 16.

Menu navigation........................................................................................................35 16.1

16.1.1 Down Button ........................................................................................................................ 35

16.1.2 Right Button ......................................................................................................................... 35

16.1.3 OK Button ............................................................................................................................ 35

Category 1: About .....................................................................................................36 16.2

16.2.1 (1.1) MAC Address .............................................................................................................. 36

16.2.2 (1.2) IP Address .................................................................................................................. 36

16.2.3 (1.3) Light Model ................................................................................................................. 36

16.2.4 (1.4) SW Version ................................................................................................................. 36

Category 2: Diagnostics (support tool) ...................................................................37 16.3

16.3.1 (2.1) Start ............................................................................................................................ 37

16.3.2 (2.2) View Results ............................................................................................................... 37

INSTALLATION MANUAL CL20 Page 3

Page 4

Approvals

written by:

Anders Holst

reviewed by:

Jonas Boslander

approved by:

Mattias Svensson

Category 3: Usage Stats ...........................................................................................38 16.4

16.4.1 (3.1) Left Light ..................................................................................................................... 38

16.4.2 (3.2) Right Light ................................................................................................................... 38

16.4.3 (3.3) Reset Left .................................................................................................................... 38

16.4.4 (3.4) Reset Right ................................................................................................................. 38

Category 4: Settings .................................................................................................39 16.5

16.5.1 (4.1) OP WDT ...................................................................................................................... 39

16.5.2 (4.2) OP WDT Stats ............................................................................................................ 40

16.5.3 (4.3) OP WDT Reset ........................................................................................................... 40

TECHNICAL DATA CL20 ..............................................................................................41 17.

Specifications CL20 ..................................................................................................41 17.1

Mechanical drawings ................................................................................................42 17.2

17.2.1 Operator Panel .................................................................................................................... 42

17.2.2 Electrical box CL20, 115/230VAC ....................................................................................... 43

17.2.3 Electrical box CL20, 24VDC ................................................................................................ 44

17.2.4 Searchlight CL20 ................................................................................................................. 45

SUPPORT ......................................................................................................................46 18.

Page 4 INSTALLATION MANUAL CL20

Page 5

WARNINGS AND INFORMATION 1.

High voltage!

Before opening any part of the searchlight system, make sure all power is switched

off!

Halogen bulbs

Make sure the bulb is properly installed into socket to obtain good electrical

contact and to avoid damaging bulb and/or socket.

To avoid damage to bulb, do not twist. Pull old lamp straight out and push new

bulb straight in.

Never bump, drop, apply excessive stress, or scratch the bulb. This could cause

the bulb to burst! Do not operate any bulbs with any traces of scratches, cracks, or

physical damage

Always transport the bulb in the provided protective case or cover until installation!

Save the protective case or cover and packaging materials (box) for bulbs that

have been used to their rated service life. Use the protective case when disposing

of the bulbs.

Always use safety glasses when installing or removing the bulbs.

When changing bulbs be sure to not touch the surface of the bulbs with bare

fingers. If inadvertently touched with bare fingers it should be degreased

immediately with alcohol and a soft lint free cloth. Be sure to wipe dry the bulb

surface afterwards.

Never touch the bulb when it is on, or soon after it has been turned off, as it is hot

and will cause serious burns. Bulbs should be allowed to cool for a minimum of ten

(10) minutes after the light is turned off.

The light should never under any circumstances be turned on without frontglass.

Reflectors

The parabolic reflectors developed by ColorLight have an extremely smooth

surface to focus the light in wide or narrow beam. Bare fingers should never touch

the reflector surface. If inadvertently touched, the reflector surface should

immediately be degreased with alcohol and a soft lint free cloth.

INSTALLATION MANUAL CL20 Page 5

Page 6

Light beam heat damage and Ethernet communications guard OP WDT

This searchlight is built for use on long distances and the high-intensity light from

the searchlight can, if set at a narrow beam, cause severe damage to surfaces

closer than 1 meter. To avoid that the searchlight is forgotten with the light on,

always use the feature “off and park” when not using the searchlight.

If however a hardware failure occurs that breaks the Ethernet communication

between the box and operator panel, a safety function will step in and

automatically turn off the light within 3 seconds, the OP WDT will also interrupt an

ongoing sweep or surveillance activity.

OP WDT is disabled by default, to enable see 16.5.1 (4.1) OP WDT.

If protection hoods are used over searchlight body the system main power switch

in the electric box should be off; this is a precaution to reduce the risk of fire if the

hoods are not removed before turning the lights on.

Cleaning

Never wash the searchlight with water under high pressure because this can

penetrate through the seals and cause damage to mechanical and electrical

components.

Do not use strong solvents such as thinner or acetone to clean the searchlight

body or the operator panel.

Deicing

Removal of ice should be done with caution. Physical violence can damage the

front glass or the searchlight driving mechanics. Instead turn on the lights and let

the heat melt the ice.

Recycling and disposal

Disposal of spent lamps must be in accordance with local and national regulations.

Page 6 INSTALLATION MANUAL CL20

Page 7

WARRANTY CONDITIONS 2.

A correctly installed searchlight system from ColorLight requires no planned regular

maintenance or service during the first 10 years in operation (except changing the bulbs after

they are used up).

The “Maintenance and Service plan” describes how to keep the product in good condition.

The warranty is conditioned by below mentioned key points.

Before powering up the unit, make sure that:

Vibration dampers are mounted correctly according to installation manual.

The mechanical fundament where the searchlight is placed is robust.

Warranty seal on the service hatch is unbroken.

Outgoing cable radius from the searchlight is smooth and not stressed.

All cables used for the installations are as per ColorLight’s specifications or as per

separate made agreement.

Signal cables are not placed together with high power cables.

Electrical connections are made according to electrical scheme and wiring diagram.

Length of cables are not exceeding the recommended maximum lengths as stated

below:

Power/signal cables between searchlight and E-box for 230 VAC-system: Max 30

meter

Power cables between searchlight and E-box for 24 VDC-system: Max 5 meter

Remote cable / Ethernet cable between E-box and remote control: Max 100 meter

(longer distance requires an amplifier or fibre optic version).

E-box (EB) is placed in an non-condense environment with a minimum temperature of

+5 C (indoor) if not customised for other installation.

The remote panel (OP) is bridge mounted in an IP54 environment. If placed outside it

must be under a protection hood when not in use.

Remote panel is screwed in bridge panel, properly grounded and correct installed.

After above checkpoints are verified the system should be started up as per User’s

Manual to verify the functionalities.

In case of any questions related to the warranty, please contact us at info@colorlight.com for

additional support.

INSTALLATION MANUAL CL20 Page 7

Page 8

MAINTENANCE AND SERVICE PLAN 3.

Although the system does not require regular maintenance to function, we recommend,

however, that this preventive maintenance plan is followed in order to keep the searchlight in

good condition and in time detect if something is wrong and needs to be corrected.

Recommended inspection on a weekly basis

1. Make visual inspection of the searchlight housing and cabling. Look for any potential

mechanical damage caused by external force. A damage can lead to reduced or nonfunctionality.

2. Make a visual inspection of the searchlight glasses. Verify that they are without any

crack or broken in any way. A crack can lead to water penetration inside the housing

followed by potential electrical and mechanical problem.

3. Perform a function test. Start up the searchlight system, rotate the searchlight in

horizontal and vertical direction. Check the “lamp life” statistics in order to plan any

potential replacement of bulb. The system is programmed to give a warning when there

is less than 130h of lamp bulb lifetime remaining.

4. Clean the searchlight. Rinse with fresh water to wash away the salt deposits. If more

dirty, use a very soft sponge and soap that is not caustic, contains strong solvents such

as acetone or thinner base. The house can be both polished and waxed for a shiny and

durable surface, but the glass should under no circumstances be waxed. Under no

circumstances can the searchlights be washed with high pressure water as this can lead

to penetration inside the housing followed by potential electrical and mechanical

problem.

5. Deicing. Winter time the system should be deiced with caution. First turn the lights on to

let the heat melt the ice before operating the system horizontally and vertically.

Page 8 INSTALLATION MANUAL CL20

Page 9

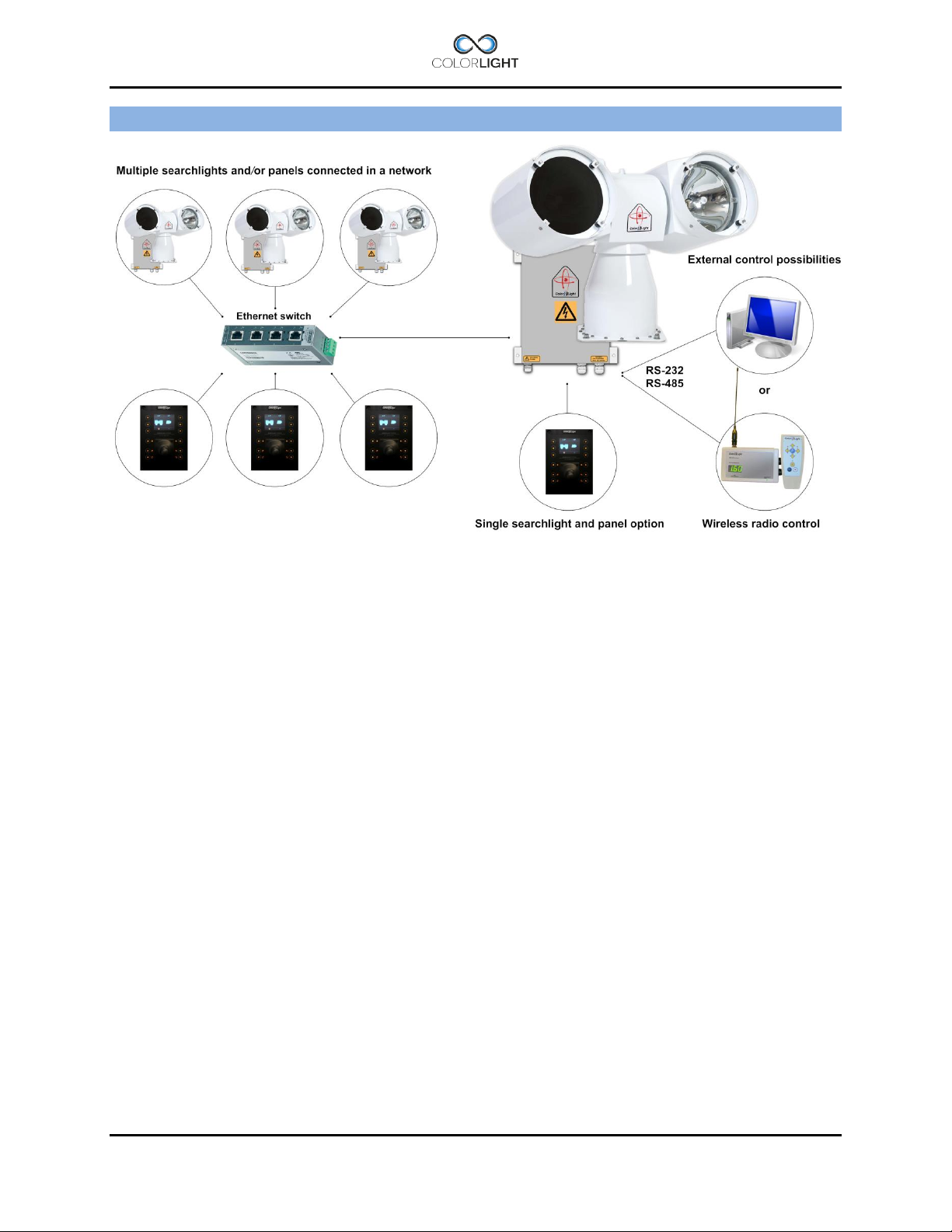

COLORLIGHT SEARCHLIGHT SYSTEM 4.

ColorLight has with its newly developed control system for searchlights opened for a flexible and

future-proof system in which several searchlight assemblies (CL20, CL25 and CL35) and

operator panels can be connected to a dedicated network and communicate via the Ethernet

infrastructure.

Control-computers and navigation equipment are other examples of devices that can be part of

this network.

For external communication between the electrical box and its various controllers we use the

TCP/IP protocol through the Ethernet infrastructure, but for internal communication between the

box and searchlight we have chosen to work with CAN bus technology.

CAN (Controller Area Network) is a network standard originally developed for the automotive

industry and with only two wires it’s possible to transmit a variety of control data and

information.

The searchlights drive motors (horizontal and vertical) are of the type brushless servo motors,

with excellent performance, long lifetime and high reliability.

The motor drivers are located inside the searchlight and are of an "intelligent" type, which

constantly analyzes the motor condition, and if problems arise, such as tripped over current

protection; this will be presented as an alarm in the operator panel.

INSTALLATION MANUAL CL20 Page 9

Page 10

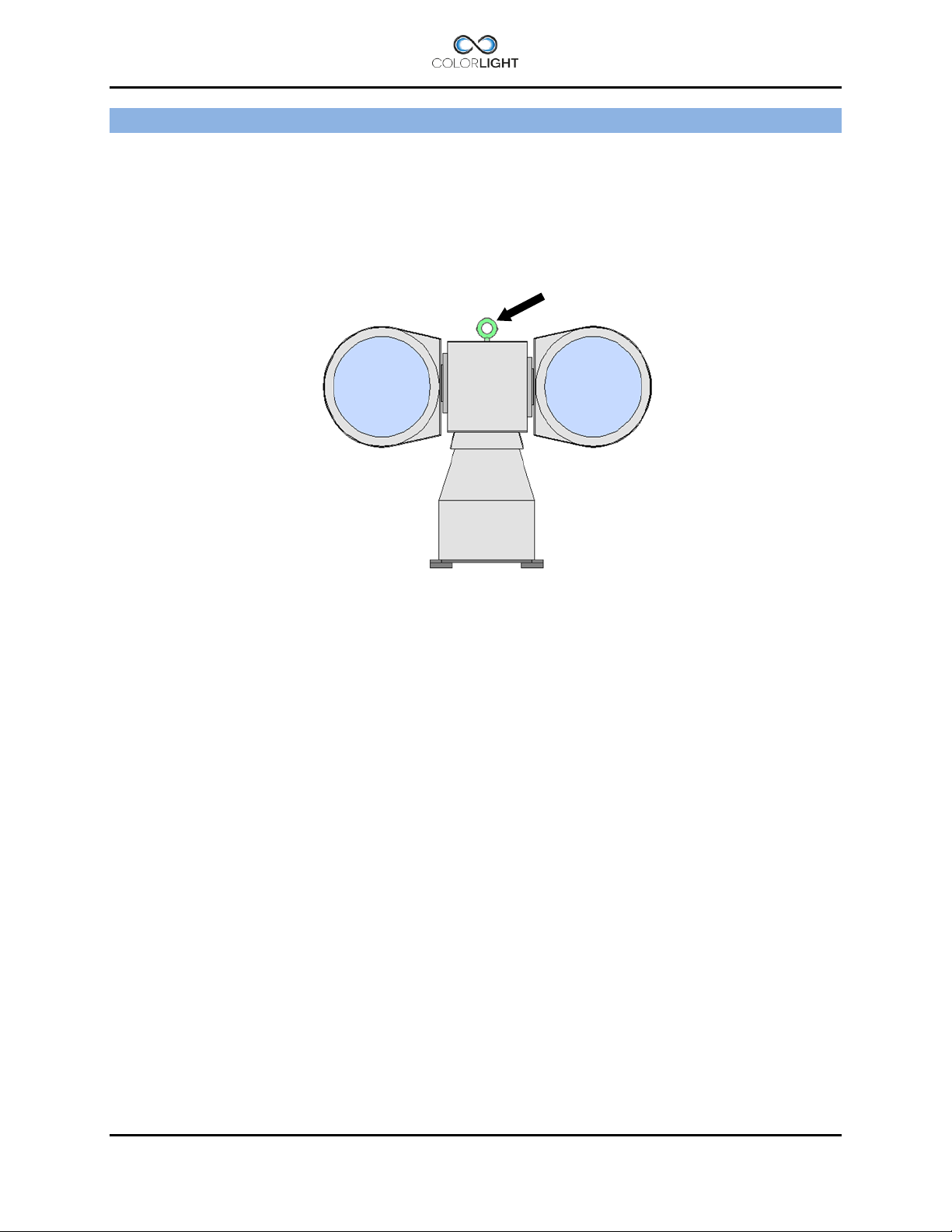

Lift here!

INSTALLATION 5.

5.1 Physical handling of the searchlight

Lift only the searchlight by the temporary lift loop on top of the center house. Lifting at the lamp

houses may damage the construction. After safely fixed the searchlight, remove the lift loop.

Page 10 INSTALLATION MANUAL CL20

Page 11

1 2

1

17mm ratchet wrench × 1

2

17mm wrench × 1

3

4

CLI-30001, ANTI VIBRATION KIT 6.

Service instruction no: CLI-30001

Revision date: 2012-12-19

Applicable models: CL20-11, CL25-**, CL35-**

Spareparts needed (refer to CL spareparts list)

Tools and supplies required:

Important information

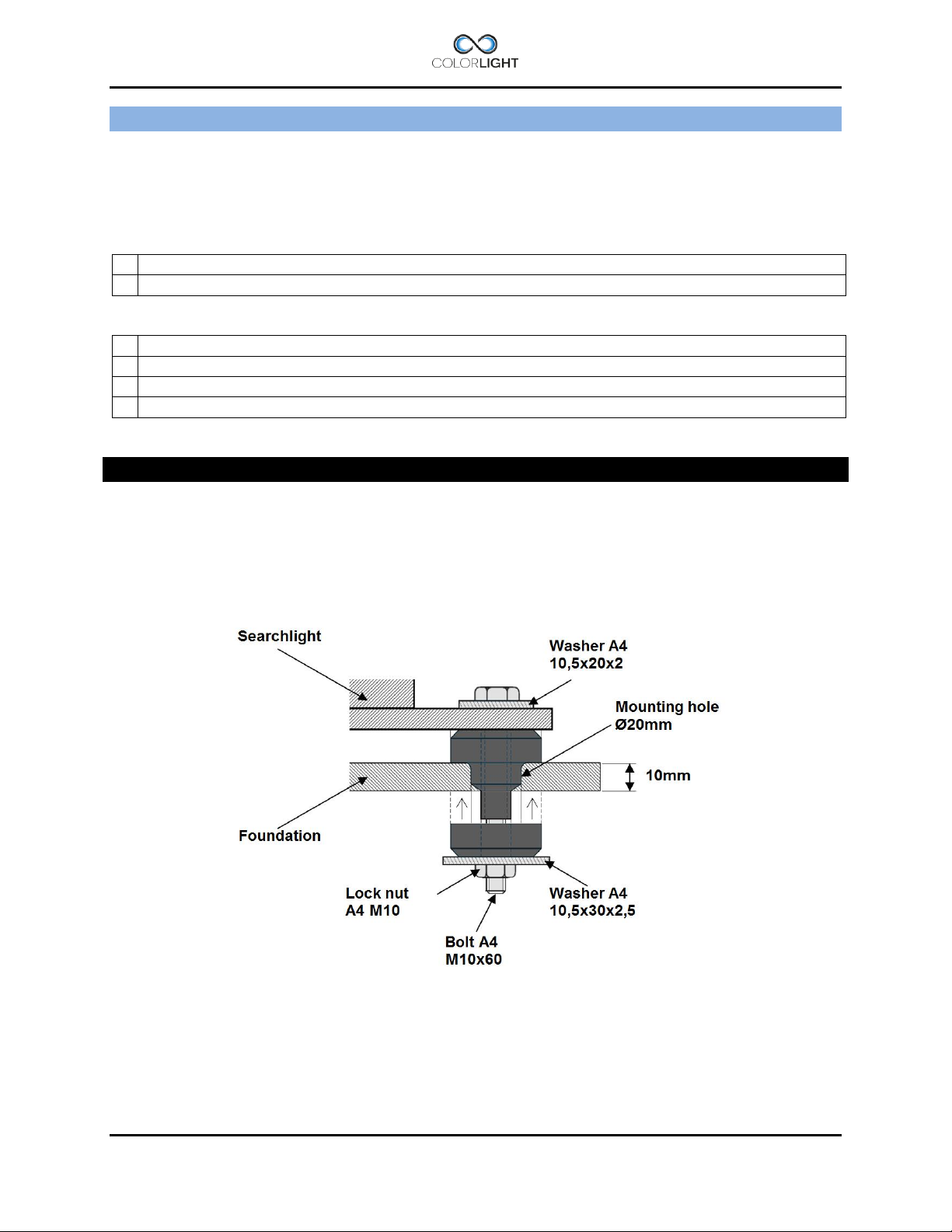

This instruction shows how to install the anti-vibration kit which consists of four dampers with

integrated stainless steel tubes.

The dampers main function is to absorb the harmful vibrations that can damage the mechanics

and shorten the life of the bulbs. Searchlight installations without dampers will

uncompromisingly, void the warranty.

Figure 1

1. Overview of the damper assembly and its parts.

INSTALLATION MANUAL CL20 Page 11

Page 12

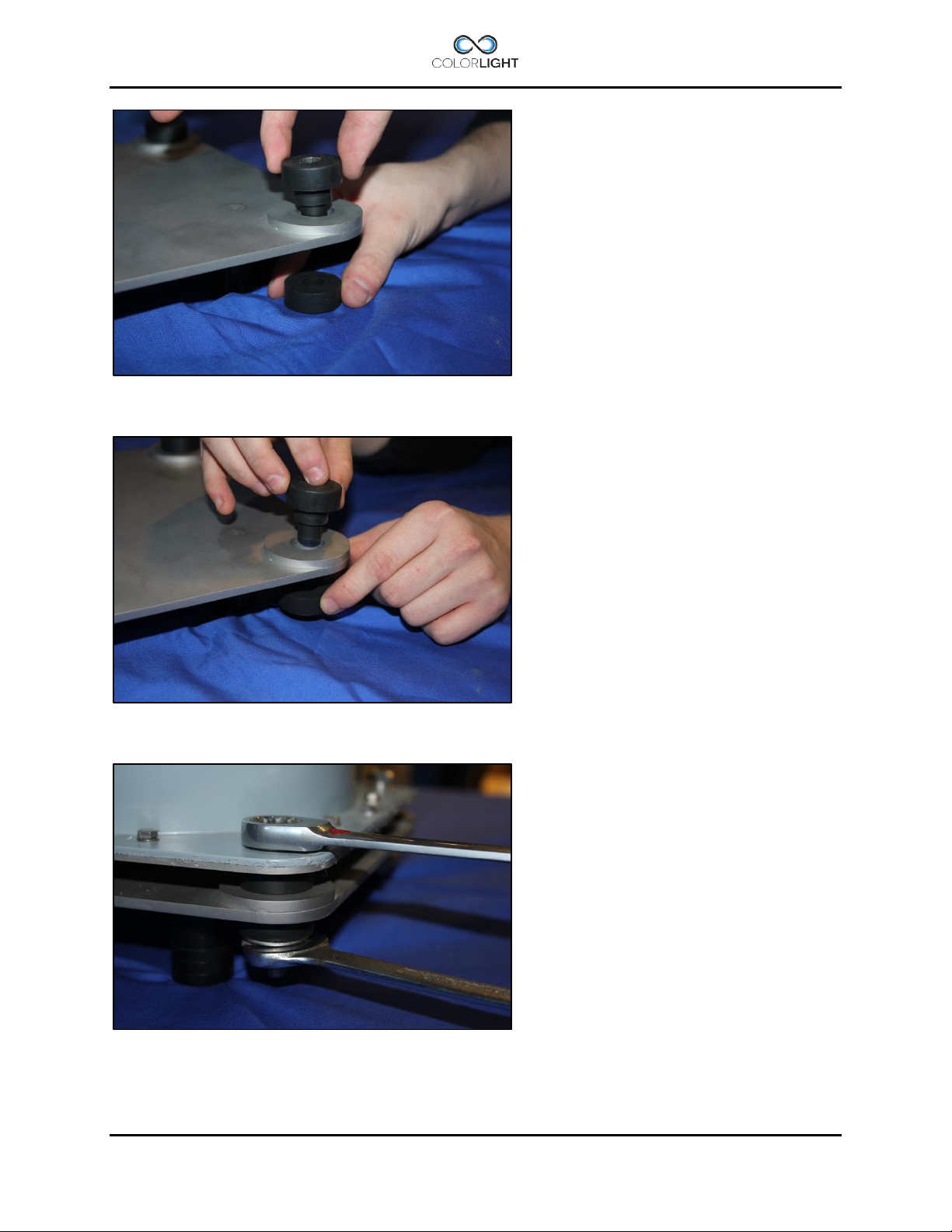

2. Push the dampers tube part thru the mounting holes in the foundation.

3. Mount the dampers rubber part from other side of the foundation.

4. Lower the searchlight on top of dampers and mount bolt washers and nuts as shown in

figure 1.

Page 12 INSTALLATION MANUAL CL20

Page 13

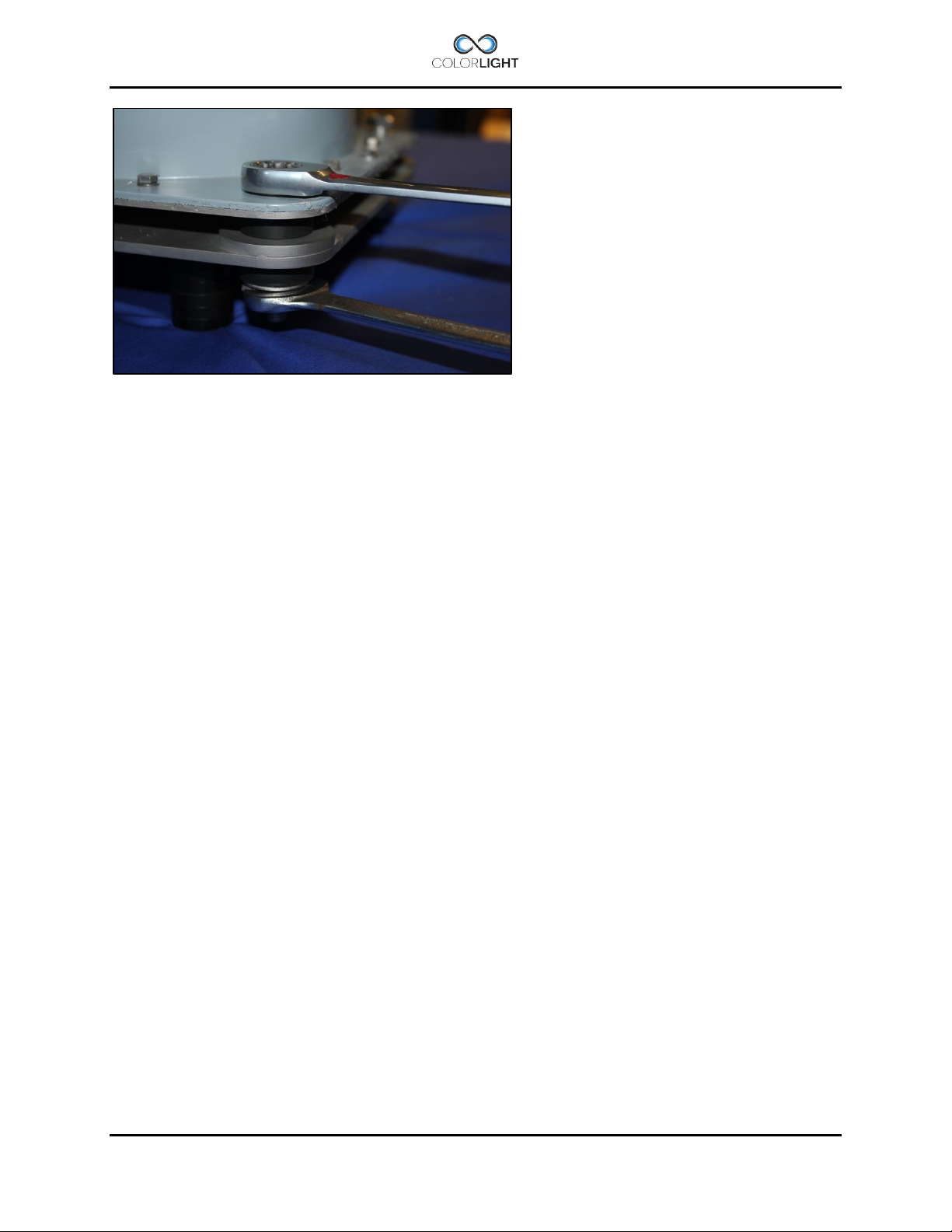

5. The lock nut is tightened with two wrenches size 17mm, tighten nut firmly.

The dampers rubber part will be compressed slightly, after assembly the searchlight will be

rigidly secured but still resistant to vibrations.

INSTALLATION MANUAL CL20 Page 13

Page 14

CL20-11

1

CLN0093 (Halogen bulb 250W) × 1

2

CLS-25330 Front glass sealing × 1

CL25-**

1

CLN0166 (HMI / UV bulb 400W) × 1

2

CLS-25330 Front glass sealing × 1

CL35-**

1

CLN0094 (HMI / UV bulb 575W) × 1

2

CLS-35318 Front glass sealing × 1

1

8mm Ratchet Wrench × 1

2

Suction cup tool × 1

3

Lint-free cloth

4

Isopropyl (rubbing) alcohol

CLI-30005, REPLACING THE BULB 7.

Service instruction no: CLI-30005

Revision date: 2013-09-09

Applicable models: CL20-11, CL25-**, CL35-**

Spareparts needed (refer to CL spareparts list)

Tools and supplies required:

Important information

This instruction shows how to replace the bulb and front glass sealing on the CL25 model

equipped with white or UV light but the procedure is the same for CL20 and CL35.

It’s recommended to replace the front glass sealing when replacing the bulb, reflector or front

glass to reduce the risk of water ingress between front glass and lamp housing.

Regarding safe handling of bulbs please read: Warnings and Information, page 5

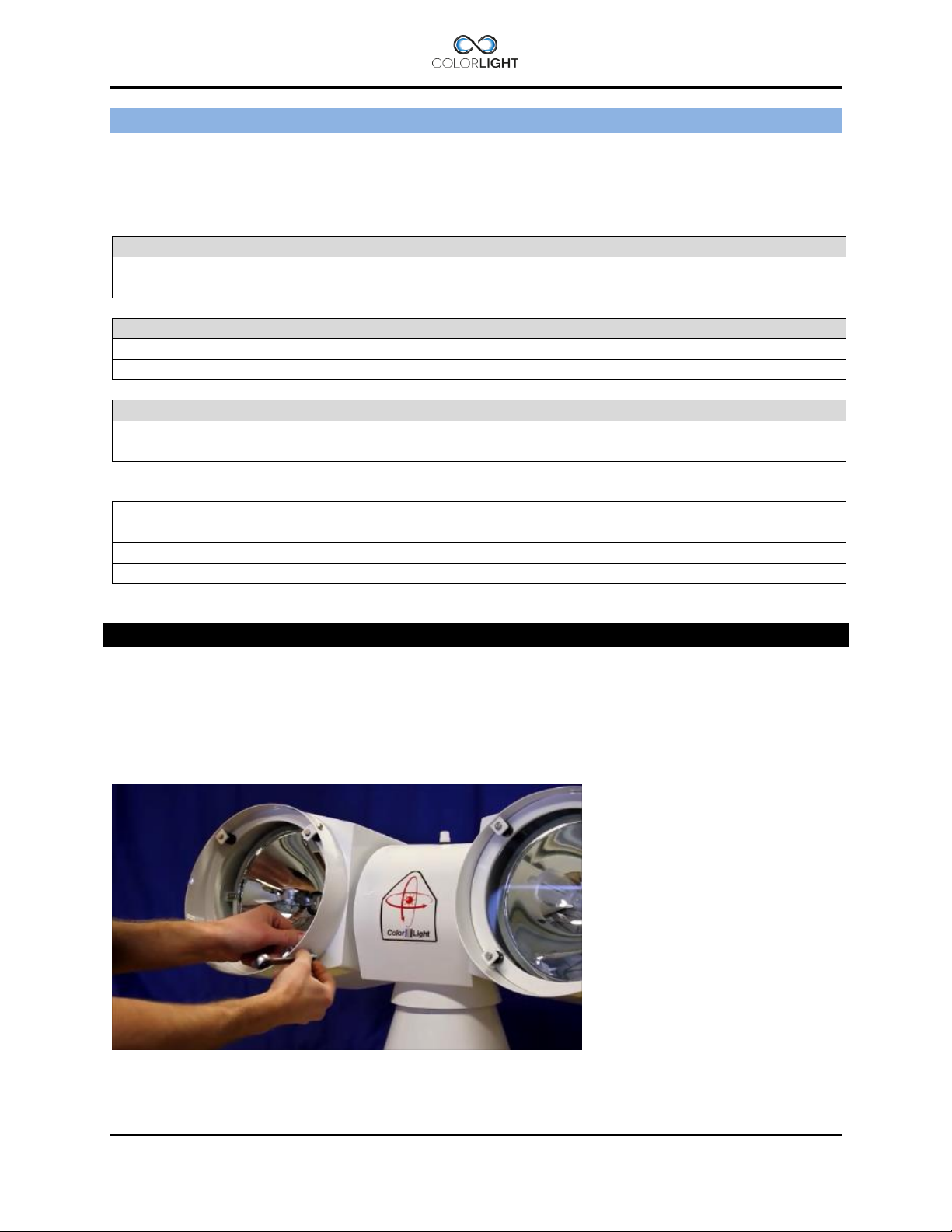

1. Turn off system power before servicing.

2. Start by removing all the four glass holder brackets that keeps the glass in place. Use a

ratchet wrench size 8mm.

Page 14 INSTALLATION MANUAL CL20

Page 15

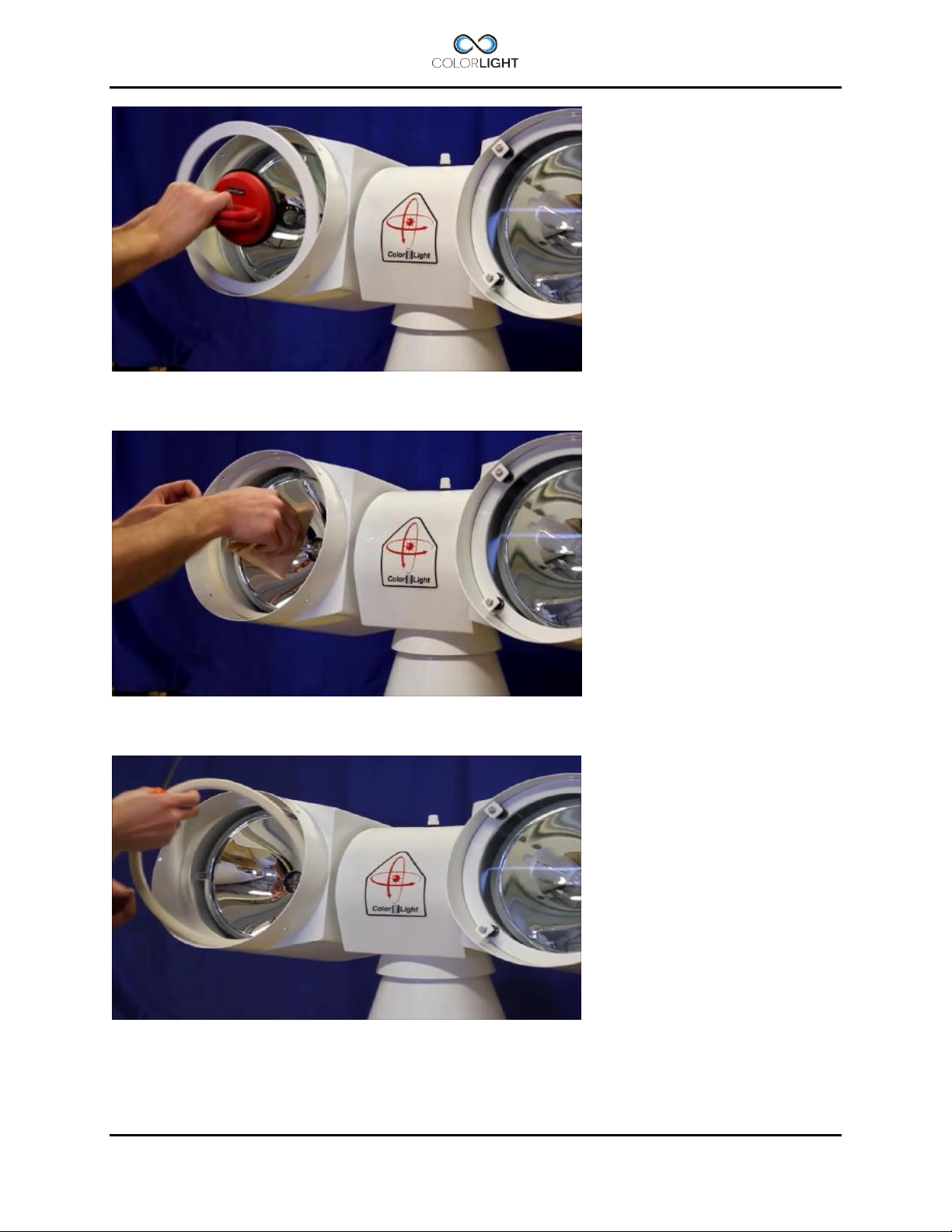

3. Remove the front glass; this is best done with a suction cup tool.

4. Remove the defective bulb from the socket.

5. Remove the old sealing.

Make sure that the flange surface is clean.

INSTALLATION MANUAL CL20 Page 15

Page 16

6. Fit the new sealing against the flange.

Make sure to place the sealing joint in line with the lower inner hole of the glass holder

bracket.

7. Press the new sealing against the flange with your hands.

8. Open a package with a new bulb.

Avoid touching the bulb glass with your fingers.

Page 16 INSTALLATION MANUAL CL20

Page 17

9. Wipe the bulb with a dry, lint-free cloth dipped in isopropyl (rubbing) alcohol.

10. Make sure the bulb is dry before installing it in the socket.

11. Put back the glass again.

INSTALLATION MANUAL CL20 Page 17

Page 18

12. Fit brackets again by loosely attaching all the screws a few turns.

13. Turn the brackets in the correct position.

14. Tighten all screws crosswise with ratchet wrench size 8mm.

Page 18 INSTALLATION MANUAL CL20

Page 19

15. Tighten all screws crosswise.

16. Done, turn on power and test the bulb, also remember to perform searchlight

synchronization, please see: 11. Actions after installation or power failure.

INSTALLATION MANUAL CL20 Page 19

Page 20

ELECTRICAL SYSTEM 8.

IMPORTANT!

The electric supply to the e-box must be disconnected before beginning any work inside

the box; it’s not enough to turn off the internal main switch.

8.1 Electrical-box (115/230VAC)

The e-box is designed to be as compact as possible but still allow service personnel to easily

replace any broken component.

The design consists of a sandwich construction where the upper section plate is the searchlight

connection part and the bottom section plate is the electronic lamp driver part.

By removing the entire assembly plate from the cabinet, you can lift and slide out the bottom

section plate and if needed replace individual driver or replace the entire plate.

The cabinet is fan cooled and the fan starts only when the lights are on.

Page 20 INSTALLATION MANUAL CL20

Page 21

Color///Light

Relay NC

Relay NO

Relay Common

0V (white)

Ext. Fan (grey)

n/c (pink)

CAN L (yellow)

CAN H (green)

+24V (brown)

RS232

RS485

Opto 1A ->

0V

24Vdc from

PSU

To system

fan in box

Fuse T6,3A

Relay driver

Right(CL20)

Relay driver

Left(CL20)

Alarm Output

Signalcable

to searchlight

Buttons for

navigation

LD01, Left

lampdriver

LD02, Right

lampdriver

8.2 Cabinet card

Color Lights control system is stable and future-proof, and the cabinet card is equipped with a

number of inputs and outputs as to allow the communication with the searchlight but also

communicate with computers, radio receivers, limit switches etc. (via optocoupler).

On the output side, we have relay controlled alarm output (NO, NC) for external alarm handling

and outputs for controlling relays (via optocoupler).

Opto 1C <Opto 2A ->

Opto 2C <24Vdc

RS422

Menu

navigation

See:

Menu

INSTALLATION MANUAL CL20 Page 21

Page 22

Power supply

240W/24V

Light fuse F01

(Left light)

Main switch

Light fuse F02

(Right light)

1- Earth (PE)

3- Phase (L)

4- Earth (PE)

8- LD02 +

15 – 0V

16 – 24Vdc/2A

Mains

Powercable to

searchlight

24Vdc for

Ethernetswich

8.3 Electrical-box overview (115/230VAC)

E-box

LD01

LD02

Q01

Fuse T6,3A

Fuse F03

T2A

Fuse F04

T2A

2- Neutral (N)

Page 22 INSTALLATION MANUAL CL20

5- LD01 -

6- LD01 +

7- LD02 -

panels and/or

Page 23

1- Earth (PE)

4- Earth (PE)

15 – 0V

16 – 24Vdc/2A

Light fuse F01

(Left light)

Main switch

Light fuse F02

(Right light)

9 – Relay (NO)

11 – Relay (NC)

12 – RS232/485

14 – GND

Mains

Powercable to

searchlight

Alarm output

RS232/RS485

24Vdc for

Ethernetswitch

Light-relay R01

Light-relay R02

8.4 Electrical-box overview (24VDC)

(Left light)

(Right light)

Q01

LD01

LD02

Fuse T6,3A

Fuse F03

T2A

panels and/or

2- 0V (-) 3- 24V (+)

5- LD01 – 6- LD01 + 7- LD02 – 8- LD02 +

13 – RS232/485

10 – Relay (COM)

INSTALLATION MANUAL CL20 Page 23

Page 24

1

Screwdriver 0,6×3,5 mm

2

Adjustable wrench type Bacho 8071

3

Wrench 13 mm

4

1 Electrical box

1 Shield Connection

8.5 Electrical box installation

Tools and supplies required:

Important information

The complete system is undergoing final testing before delivery and therefore has the

searchlight cables installed in box.

1. Ensure that the switch Q01in box is set to off.

2. Remove all the cables in the terminals, the terminals are push-in type and the wire is

released easily by pressing the orange button with a screwdriver while pulling lightly in

the wire.

3. Loosen the cable glands with an adjustable wrench and pull out the cables.

4. Mount the electric box on a firm foundation with the help of the wall brackets.

5. Install in reverse order and pay special attention so that the cables shields are mounted

correct in the cable glands, see figure 2 below for guidance.

Cables are connected according to the wiring diagram and double-checked before the

power is turned on using the main switch Q01 in the electric box.

Page 24 INSTALLATION MANUAL CL20

Page 25

1. Power cable

Fuse Holder

2. Ethernet cable

3. Earth wire

3 2 1

Wire #2

+

Wire #1

-

8.6 Operator panel connections

The operator panel is designed to be immersed into the bridge panel, for dimensions, see

drawing in section 17.2.1 Operator Panel.

The following connections are available on the back of the panel:

1. Power supply 9-28 VDC via local power supply on the boat or 24VDC via terminals in

the E-box. One of the benefits of supplying power to the panel from the box is that the

panel will be de-energized together with the e-box via the main switch.

2. Ethernet connection directly to the electrical cabinet or Ethernet switch via RJ45

connector. Shielded Keystone Modular Feed through Coupler, RJ45-RJ45 included.

3. Earth connection to the panel, this is needed to suppress electrical disturbances and

prevent ESD discharge damaging.

Electrical protection:

The panel is protected against wrong polarity and over-current protected by a fuse on the back,

type: T1A (Slow-Blow glass fuse 5x20mm).

INSTALLATION MANUAL CL20 Page 25

Page 26

Pin

T568A

Pair

T568B

Pair

T568A

Color

T568B

Color

Pins on plug face

1 3 2

white/green

stripe

white/orang

e stripe

2 3 2

green solid

orange solid

3 2 3

white/orang

e stripe

white/green

stripe

4 1 1

blue solid

blue solid

5 1 1

white/blue

stripe

white/blue

stripe

6 2 3

orange solid

green solid

7 4 4

white/brown

stripe

white/brown

stripe

8 4 4

brown solid

brown solid

1

8

8.7 Ethernet wiring

ColorLight searchlight systems should be connected to their own dedicated network; they

should never be connected into the vessels existing computer network.

An Ethernet cable supplied from ColorLight complies with the standard TIA/EIA-568-B and is

always tested together with the complete searchlight system to ensure full functionality.

If customers choose to assemble their own Ethernet cables they must be of type FPT Cat5 or

better and the connections should be done according to the following information.

Note that the only difference between T568A and T568B is that pairs 2 and 3 (orange and

green) are swapped. Both configurations wire the pins "straight through", i.e., pins 1 through 8

on one end are connected to pins 1 through 8 on the other end. Also, the same sets of pins

connect to the opposite ends that are paired in both configurations: pins 1 and 2 form a pair, as

do 3 and 6, 4 and 5, and 7 and 8.

One can use cables wired according to either configuration in the same installation without

significant problem. The primary thing one has to be careful of, is not to accidentally wire the

ends of the same cable according to different configurations

Page 26 INSTALLATION MANUAL CL20

Page 27

1

8

7

6

5 9 2

3

4

1

OPERATOR PANEL, OVERVIEW 9.

1. "Soft button": the function appears in the display window next to the button.

2. Left lamp on/off optional for CL20-11 if “Single lamp mode” = On *1).

3. Left focus (same function as No.4 *2), (move left to spot *3).

4. Left focus (same function as No.3 *2), (move left to flood *3).

5. Right lamp on/off, optional for CL20-11 if “Single lamp mode” = On *1).

6. Right focus (same function as No.7 *2), (move right to spot *3).

7. Right focus (same function as No.6 *2), (move right to flood *3).

8. Joystick.

9. Display.

*1 See User’s Manual 11.8.6.5 Single lamp mode (standard function available from ver. 0.5.3.11).

*2 Continuous focus (standard), see 15.1 Type 1, continuous focus.

Note: Several sections of the manual refer to the above figures.

INSTALLATION MANUAL CL20 Page 27

Page 28

DISPLAY SYMBOLS AND MESSAGES 10.

Symbol for switched off white light.

Symbol for switched on white light.

Error symbol for white light indicates a problem during switch on or if the bulb

breaks down during operation. The operator has three switch-on attempts in a two

minute interval without setting the sum alarm output (Not valid for CL20).

Symbol for switched off UV light (black light) (Not valid for CL20).

Symbol for switched on UV light (black light) (Not valid for CL20).

Error symbol for UV light indicates a problem during switch on or if the bulb breaks

down during operation. The operator has three switch-on attempts in a two minute

interval without setting the sum alarm output (Not valid for CL20).

Symbol for any electro-mechanic error. Might be referred as an over voltage or

over current for motor drivers. Communication error with motor drivers will result in

the same symbol. This error symbol can be reset by simply enter the main menu

and select status. Then press “dismiss”. If over current have occurred the problem

might be referred as a stucked lamp housing – check for any icing issues. Each

axis has its own symbol showing in upper left or right corner of the display.

Page 28 INSTALLATION MANUAL CL20

Page 29

Message

Fault

Communication error

Transmission issues on the CAN bus

Over current

Overcurrent protection triggered, movement blocked

Over voltage

Overvoltage protection triggered, voltage to searchlight motordriver/s

have exceeded 30Vdc.

Under voltage

Undervoltage protection triggered, voltage to searchlight

motordriver/s has fallen below 10Vdc

OPWDT (message in box only)

Ethernet communication broken to all panels, see (4.1) OP WDT.

Fault auto-resets if contact is restored with at least one panel

This symbol indicates that the bulb has less than 200 hours left of expected

lifetime. This warning can be chosen by the operator to be shown or not. please

see User’s Manual, 11.8.4 Lamp life for more detailed instruction.

Each bulb has its own symbol showing in the lower left or right corner of the

display.

This symbol indicates that the expected lifetime of the bulb now has expired. The

only way to reset this symbol is by entering the “Usage Stats” menu at the

diagnostic display inside the electrical box. See 16.4 Category 3: Usage Stats.

Certainly this reset should only be done together with a bulb replacement!

This symbol and a similar symbol indicate the direction of the lamp housing both

for the vertical axis and for the horizontal axis. The arrows in the shown symbol

indicate the elevation angle for the vertical axis according to the horizontal-plane.

For the horizontal symbol and axis these small arrows indicate if the housing is

directed to the left, front, right or back of the centerline.

If the arrows are replaced by question marks then the system needs to be

internally calibrated. This is the normal state after power up after a total power loss

to the system. The easiest way to do the internal calibration is by simply choose

the “Park” in the quick start menu, please see User’s Manual 10.6 Off and park.

10.1 Ebox alarm relay

The searchlights electrical and mechanical condition are constantly monitored

and if there is a malfunction in the system this is indicated by icons in the panel

display with clarifying warning messages found in the panels status menu.

The control box also has a relay output that can be connected to the boat

monitoring system; see the wiring diagram for connection details.

The following errors trigger the alarm output.

INSTALLATION MANUAL CL20 Page 29

Page 30

ACTIONS AFTER INSTALLATION OR POWER FAILURE 11.

At system startup, the panels will start to scan the network to find connected electrical boxes,

during this time, the panel software version will be displayed.

If not the panel made contact by displaying home screen within 30 seconds, it may be due to

the following:

Electrical box is not turned on, applies only if the panel has a separate power supply.

There are problems in the network cabling between the electrical box and the operator

panel.

At the first boot after installation or power failure, the searchlight must be synchronized with the

control system.

After installation or power failure of the electric box you can still use the searchlights main

functions like joystick control, light on/off and focus but in order to be able to use positioning

functions such as display indicator*, parking position, sweep*, fixed positions* or surveillance*,

the searchlight must be synchronized with the control system.

The easiest way to synchronize the system after reboot is to enter the quick start menu and

select the “Park” function. Now the searchlight will synchronize and then park if a parking

position has been set.

If necessary the origin can be set after the steps above to give an accurate readout of the

indicator*. To set the origin, please see User´s Manual, section 11.8.6.1 Store origin.

*Standard function for CL25/CL35, Optional for CL20

Page 30 INSTALLATION MANUAL CL20

Page 31

STARTING SYSTEM 12.

When the system is in sleep the buttons and symbols glows with orange light and the display is

totally shut down to save power. Buttons and symbols are always active but dimmed to a lower

intensity during sleep.

Pressing any button on the operator panel will activate the system and the display will now show

the position indicator* image or just the ColorLight logotype. Buttons and symbols are now

brighter and both buttons, symbols and display intensity can be adjusted, please see User’s

Manual, section 11.8.1 Backlight brightness.

*Standard function for CL25/CL35, Optional for CL20

INSTALLATION MANUAL CL20 Page 31

Page 32

JOYSTICK FUNCTIONS 13.

The joystick (8) moves the searchlight horizontally and vertically. There are no limitations to the

movement of the searchlight thanks to the slip ring technology developed by ColorLight.

The more the joystick is moved to its end position the faster the searchlight rotates.

Searchlight rotation speed can be set, see User´s Manual, section: 11.8.5 Maximum rotation

speed.

The vertical axis reaction according to the joysticks movement can be reversed if decided by

operator. To change this reaction please see User´s Manual, section: 11.8.3 Joystick direction.

The joystick can also be used to navigate in menus containing more than one choice.

Move the joystick up or down to navigate in the menu. In most menus joystick moved to the right

will act as “OK” button and moved to the left will go back one step as the “Back” button.

Page 32 INSTALLATION MANUAL CL20

Page 33

SWITCH ON LIGHT 14.

The searchlight is equipped with two halogen bulbs, the light can be turned on by pressing (2) or

(5), Both lights will be lit with a slight delay in between, no matter which button is used. To turn

off the light, press button (2) or (5) again.

There are however occasions when it may be useful to give each bulb a dedicated light button,

this setting is done in the "Single lamp mode" menu, please see User’s Manual, section 11.8.6.5

Single lamp mode.

There is a bulb warning feature in the system. This warning can be chosen by the operator to be

shown or not by switch on or off the function in the settings menu, please see User’s Manual,

section 11.8.4 Lamp life.

Note:

Halogen bulbs provide no status feedback to the Ebox and therefore the light function must be

visually verified to ensure that the bulbs light up.

This warning feature will show a white triangle symbol when the estimated bulblife left is

less than 200 hours. The symbol will be shown at the displays bottom left or right corner

according to left or right bulb

When the expected lifetime is expired the white triangle will change to a red triangle.

The only way to reset this symbol is by entering the “lamp life” menu at the diagnostic

display inside the electrical box. To get to the correct menu use the three buttons below

the display. Under the lamp life menu there are two choices: “usage statistics” and “reset

counters”. Select “reset counters” and select the corresponding lamp housing for which the

counter should be reset. Certainly this reset should only be done together with a bulb

replacement!

INSTALLATION MANUAL CL20 Page 33

Page 34

Flood

Spot

FOCUS 15.

15.1 Type 1, continuous focus (standard)

Note: Button numbers below refers to OPERATOR PANEL, OVERVIEW.

Pressing the focus buttons (3) or (4) changes the focus for the left lamp house and buttons (6)

or (7) changes focus for the right lamp house.

Release the button when the required focus is found.

As long as a focus button is pressed the bulb moves in and out which changes the focus of the

light between 4-20 degrees for model CL20, CL25 and 3-20 degrees for model CL35.

Note: Pressing button (3) and (6) or (4) and (7) at the same time will cause an electric collision

which stops the focus from changing. Releasing one of the buttons will continue the focusing of

the pressed button. To focus with both lights simultaneously hold (3) and (7) or (4) and (6).

Page 34 INSTALLATION MANUAL CL20

Page 35

1. About

1.1 MAC Address

1.2 IP Address

1.3 Light Model

1.4 SW Version

2. Diagnostics

2.1 Start

2.2 View Results

3. Usage Stats

3.1 Left Light

3.2 Right Light

3.3 Reset Left

3. 4 Reset Right

4. Settings

4.1 OP WDT

4.2 OP WDT Stats

4.3 OP WDT Reset

Right

OK

Down

CABINET CARD MENU SYSTEM 16.

This chapter describes the menu system of the ColorLight Cabinet Card displayed on the onboard LCD.

16.1 Menu navigation

The user interacts with the menu system using the three buttons, the “Down” button, the “Right”

button and the “OK” button.

16.1.1 Down Button

The main function of the “Down” button is to shift between the menu categories. It also has two

alternate generic functions.

1. While in submenus listing items of various types the “Down” button scrolls down in the list.

2. While entering a value of some sort, the “Down” button decrements that value.

16.1.2 Right Button

The main function of the “Right” button is to shift between the submenus of the selected menu

category. It also has two alternate generic functions.

1. While in submenus listing items of various types the “Right” button scrolls up in the list.

2. While entering a value of some sort, the “Right” button increments that value.

16.1.3 OK Button

The “OK” button enters and exits submenus.

INSTALLATION MANUAL CL20 Page 35

Page 36

16.2 Category 1: About

In this chapter all of Category 1 menu items will be explained.

16.2.1 (1.1) MAC Address

Displays the MAC address of the Cabinet Card, according to the standard (IEEE 802) in six

groups of two hexadecimal digits, separated by colons (‘:’), in transmission order, e.g.

“01:23:45:67:89:ab”. One exception from the standard is made, the leftmost colon is missing,

due to the 16 character limit of the LCD.

16.2.2 (1.2) IP Address

Displays the IPv4 address of the Cabinet Card, in four groups of one to three decimal digits,

separated by dots (‘.’), e.g. “169.254.17.5”.

16.2.3 (1.3) Light Model

Displays the searchlight model that the Cabinet Card is configured to use, e.g. “Model: CL2512”.

16.2.4 (1.4) SW Version

Displays the firmware version of the Cabinet Card, e.g. “0.1.2.3”.

Page 36 INSTALLATION MANUAL CL20

Page 37

16.3 Category 2: Diagnostics (support tool)

In this chapter all of Category 2 menu items will be explained.

16.3.1 (2.1) Start

Press the OK button to run the on-board diagnostic test suite to sense the electrical and

mechanical condition of the searchlight. (Contact ColorLight for help with this feature).

T1. Measurement of voltage and current when the searchlight is in “non operating mode”

T2 (HCW). Measurement of current drawn by the horizontal motor; motor rotates clockwise for

30 seconds.

T3 (HCCW). Measurement of current drawn by the horizontal motor; motor rotates

counterclockwise for 30 seconds.

T4 (VCW). Measurement of current drawn by the vertical motor; motor rotates clockwise for 30

seconds.

T5 (VCCW). Measurement of current drawn by the vertical motor; motor rotates

counterclockwise for 30 seconds and the value is temporary stored.

T6 (Rfoc). Measurement of current drawn by the right focus motor; runs for 30 seconds.

T7 (Lfoc). Measurement of current drawn by the left focus motor; runs for 30 seconds.

T8 (H MAG). Test of horizontal magnetic sensor; the horizontal motor is running at full speed for

a predetermined time and number of triggers is recorded.

T9 (V MAG). Test of vertical magnetic sensor; the vertical motor is running at full speed for a

predetermined time and number of triggers is recorded.

T10 (Lights). Lamp test; both lights should ignite and be lit for 30 seconds.

Halogen bulbs provide no status feedback to to the Ebox and the test result for T10 will always

show "OK", therefore this light test must be visually verified to ensure that the bulbs light up.

T11 (OP count). Counting the number of connected operator terminals in the network.

16.3.2 (2.2) View Results

Displays the result of the last run diagnostics test suite.

Use the Down button to cycle through the tests results.

Use the Right button to cycle through different test result information for the selected test. Only

applicable for test “T1” and test “T10”.

INSTALLATION MANUAL CL20 Page 37

Page 38

16.4 Category 3: Usage Stats

In this chapter all of Category 3 menu items will be explained.

16.4.1 (3.1) Left Light

Displays the usage of the left light source in hours:minutes:seconds, e.g. “Left: 1:23:45”.

16.4.2 (3.2) Right Light

Displays the usage of the right light source in hours:minutes:seconds, e.g. “Right: 1:23:45”.

16.4.3 (3.3) Reset Left

Resets the usage counter of the left light source.

A confirmation message, “If sure press OK”, is displayed upon entering the menu. Press the OK

button at this point to reset the counter and exit the menu. Press the Down or Right button to

exit the menu without resetting the counter.

16.4.4 (3.4) Reset Right

Resets the usage counter of the right light source.

A confirmation message, “If sure press OK”, is displayed upon entering the menu. Press the OK

button at this point to reset the counter and exit the menu. Press the Down or Right button to

exit the menu without resetting the counter.

Page 38 INSTALLATION MANUAL CL20

Page 39

16.5 Category 4: Settings

In this chapter all of Category 4 menu items will be explained.

16.5.1 (4.1) OP WDT

Ethernet communications guard OP WDT (Operator Panel Watchdog Timer)

This searchlight is built for use on long distances and the high-intensity light from the searchlight

can, if set at a narrow beam, cause severe damage to surfaces closer than 1 meter. To avoid

that the searchlight is forgotten with the light on, always use the feature “off and park” when not

using the searchlight.

If however a hardware failure occurs that breaks the Ethernet communication between the box

and operator panel, a safety function will step in and automatically turn off the light within 3

seconds, the OP WDT will also interrupt an ongoing sweep or surveillance activity.

If an OP WDT event has occurred an error message will be displayed in the electrical box and

the alarm relay (CL25/35) will trigger. When communication returns the message will disappear

and the alarm will be reset.

For multiple panel systems: OP WDT will step in only when communication is lost to all panels.

Possible reasons why OP WDT turn off the lights:

The power supply to the operator panel is broken.

The power supply to the Ethernet switch (if any) is broken.

Broken Ethernet cable between electrical box/ Ethernet switch (if any) and operator

panel.

OP WDT is disabled by default, to enable press “OK” button in menu “4.1 OP WDT” screen and

press the “Down” or “Right” button to toggle the function on/off.

INSTALLATION MANUAL CL20 Page 39

Page 40

16.5.2 (4.2) OP WDT Stats

Displays a counter that keeps track of the number of times the Ethernet communication has

been recovered from an OP WDT event.

In case of suspected cable problems with connected operator panels, this counter can be

helpful when troubleshooting.

16.5.3 (4.3) OP WDT Reset

Resets the OP WDT counter.

A confirmation message, “If sure press OK”, is displayed upon entering the menu. Press the

“OK” button at this point to reset the counter and exit the menu. Press the “Down” or “Right”

button to exit the menu without resetting the counter.

Page 40 INSTALLATION MANUAL CL20

Page 41

TYPE

MODEL

SOURCE

RANGE

Dual White

CL20-11, 24VDC

Halogen/Halogen

1400 m

Daytime camera module

Suffix -1 on above

Optional

Optional

IR-camera module

Suffix -2 on above

Optional

Optional

LIGHT

Technology

Halogen

Light source

2 x 250W

Color Temp

3000 K

CRI

> 95%

Luminus flux

15 000 lm

Light intensity

2,0 M candela

Range

1400 m

Beam width

4-20 deg

Firefighting

N/A

MECHANICAL

Technology

Slipring. Brushless digital controlled servo

Horizontal movement

Unlimited movement

Vertical movement

Unlimited movement

Speed both axis

Stepless 0-33 deg/sec

STANDARD DIRECT

CONTROLLED

Light on/off

Focus (adjustable)

Rotation speed, stepless

STANDARD

FUNCTIONS

System activation

Parking mode

Language version

User settings

System information

Single lamp mode

STANDARD PACK 1

Position indicator

OPTIONAL PACK 2

Auto sweeping

Fixed positions

Surveillance

OPTIONAL PACK 3

Synchronized control

OPTIONAL HARDWARE

Wireless radio control

Fiber optic control cable

Thermal camera unit (not for retrofitting)

Customized color

Daylight camera unit (not for retrofitting)

Wet paint (AWL grip or similar)

Extra remote panel (s)

Polished stainless

External power supply for panel (s)

Ethernet switch, 5 port and 8 port

Upside-down installation

Customization upon request

Power

consumption

650 W (max load)

27,1 A (max load)

Heat load

15 W / 85 W (standby/max load)

Refector size

2 x dia 210 mm

Bulb life

300 hours

Ballast

No external ballast

Signal cable

3x2x0,75 shielded, twisted pair (from 2014-03- 3x2x1)

Power cable

5G4 shielded

OP3G cable

Ethernet CAT5-FTP Fiber available for long distance

Serial cable

RS485/RS232 Optional. ICD for external control

SEARCHLIGHT BODY

EBOX

OPERATOR PANEL

Weight (kg)

30 8 0,5

Static size (cm)

42x75x53 cm *

30x30x13 cm *

13x9x6 cm *

Material

Acid proof stainless steel 1.4401

Coated steel

Anodized aluminum / ABS

Paint

Powder coat white RAL 9016

Powder coat grey RAL 7035

Anodized black

IP-Class

IP66

IP22

IP54

Operating temp range

-40º / +70º Celsius

+5º / +60º Celsius

-20º / +70º Celsius

Input power

Powered from ebox

24VDC

9-28 VDC (max 200 mA @ 24V)

TECHNICAL DATA CL20 17.

17.1 Specifications CL20

MODEL RANGE

PERFORMANCE

FUNCTIONS

TECHNICAL DATA

* see drawing for detailed info

INSTALLATION MANUAL CL20 Page 41

Page 42

17.2 Mechanical drawings

17.2.1 Operator Panel

Page 42 INSTALLATION MANUAL CL20

Page 43

17.2.2 Electrical box CL20, 115/230VAC

INSTALLATION MANUAL CL20 Page 43

Page 44

17.2.3 Electrical box CL20, 24VDC

Page 44 INSTALLATION MANUAL CL20

Page 45

17.2.4 Searchlight CL20

The searchlights cable glands are rated IP68 but for extra protection during heavy weather

situations it’s still recommendable to install the searchlight so the cable exits are facing the

stern.

The longer part of the lamp house peak shall be set down. This extra long peak is to reduce

disturbing reflections from the foredeck, if any.

INSTALLATION MANUAL CL20 Page 45

Page 46

SUPPORT 18.

If you have questions about the searchlight and its features, please contact ColorLight technical

support worldwide, see www.colorlight.com for contact details.

Or contact ColorLight head office:

ColorLight AB

Engineering-ColorLight

cl@colorlight.com

Phone: +46 353 8270

Fax: +46 35 38279

Need technical Support?

Follow the link below and fill out the form, we will contact you shortly.

http://www.colorlight.com/tech-support/service-request.html

If you want to upgrade your system with additional options as described in User’s Manual,

section (11.8.6.7), please contact:

ColorLight AB

Phone: +46 35 38280

Fax: +46 35 38279

www.colorlight.com

info@colorlight.com

Delivery address:

ColorLight AB

Kassakällor Erikslund 917

SE-313 95 Åled

Sweden

Notes:

Page 46 INSTALLATION MANUAL CL20

Page 47

INSTALLATION MANUAL CL20 Page 47

Page 48

VISIBILITY | VERSATILITY | VALUE

We look forward to serve you with the Future Searchlight Solution - wherever you are

ColorLight AB

Kassakällor

SE-313 95 Åled

Sweden

Phone: +46 35 38280

Fax: +46 35 38279 www.colorlight.com

e-mail: info@colorlight.com

Loading...

Loading...