Collomix VISCO 550, DYNAX 450, BIAX 45P Instructions Manual

Instructions

Biaxial Mixer

VISCO 550

Keep this manual within immediate

reach of the machine

Translation of the original instructions -en Englisch

Version 1.1-17

VISCO 550 Collomix GmbH

2 Version 1.1-17

Collomix GmbH VISCO 550

Contents

1. Layout Drawings ........................................................................................................ 4

1.1 Machine components 4

1.2 Operating and display components 5

2. About this document ................................................................................................. 6

2.1 Pictograms and symbols 6

3. For your safety .......................................................................................................... 7

3.1 General Safety Information 7

3.2 Intended Use 7

3.3 Foreseeable Misuse 8

3.4 Qualifications of operating personnel 8

3.5 Safety-relevant components 9

3.6 Residual Risks 9

4. Equipment Description .............................................................................................. 9

5. Set-up and using the Mixer for the first time ............................................................. 9

5.1 Content 9

5.2 Set-up the equipment 10

5.3 Transport rollers 10

5.4 Mains connection 10

5.5 Trial run 10

6. Operation ................................................................................................................ 11

6.1 Switching on the machine 11

6.2 Load a container 11

6.3 Starting the mixing cycle 12

6.4 Ending the mixing cycle 12

6.5 End of work 12

6.6 EMERGENCY STOP switch 12

7. Errors and Troubleshooting ..................................................................................... 13

7.1 Possible errors messages 13

7.2 E080 MU unlocked 14

7.3 Unlock door manually 15

7.4 Fuses on the device 15

7.4.1 Device fuse 15

7.4.2 DC fuse 15

8. Cleaning, maintenance, and repair .......................................................................... 16

8.1 Cleaning 16

8.2 Maintenance 16

8.3 Repair 17

8.4 Expendable items 17

9. Storage, disposal ..................................................................................................... 18

9.1 Storage 18

9.2 Disposal 18

10. Appendix ................................................................................................................. 19

10.1 Technical Specifications 19

10.2 Dimensions 20

10.3 EC Conformity Declaration 21

10.4 Warranty 21

Version 1.1-17 3

2

4

5

3

1 6 7

8

VISCO 550 Collomix GmbH

1. Layout Drawings

1.1 Machine components

Machine components

1. Machine legs 5. Manual door release

2. Sliding door 8. Control panel CSE

3. Main switch and DC fuse 7. Lower clamping plate

4. Emergency Stop 8. Locking lever

4 Version 1.1-17

Collomix GmbH VISCO 550

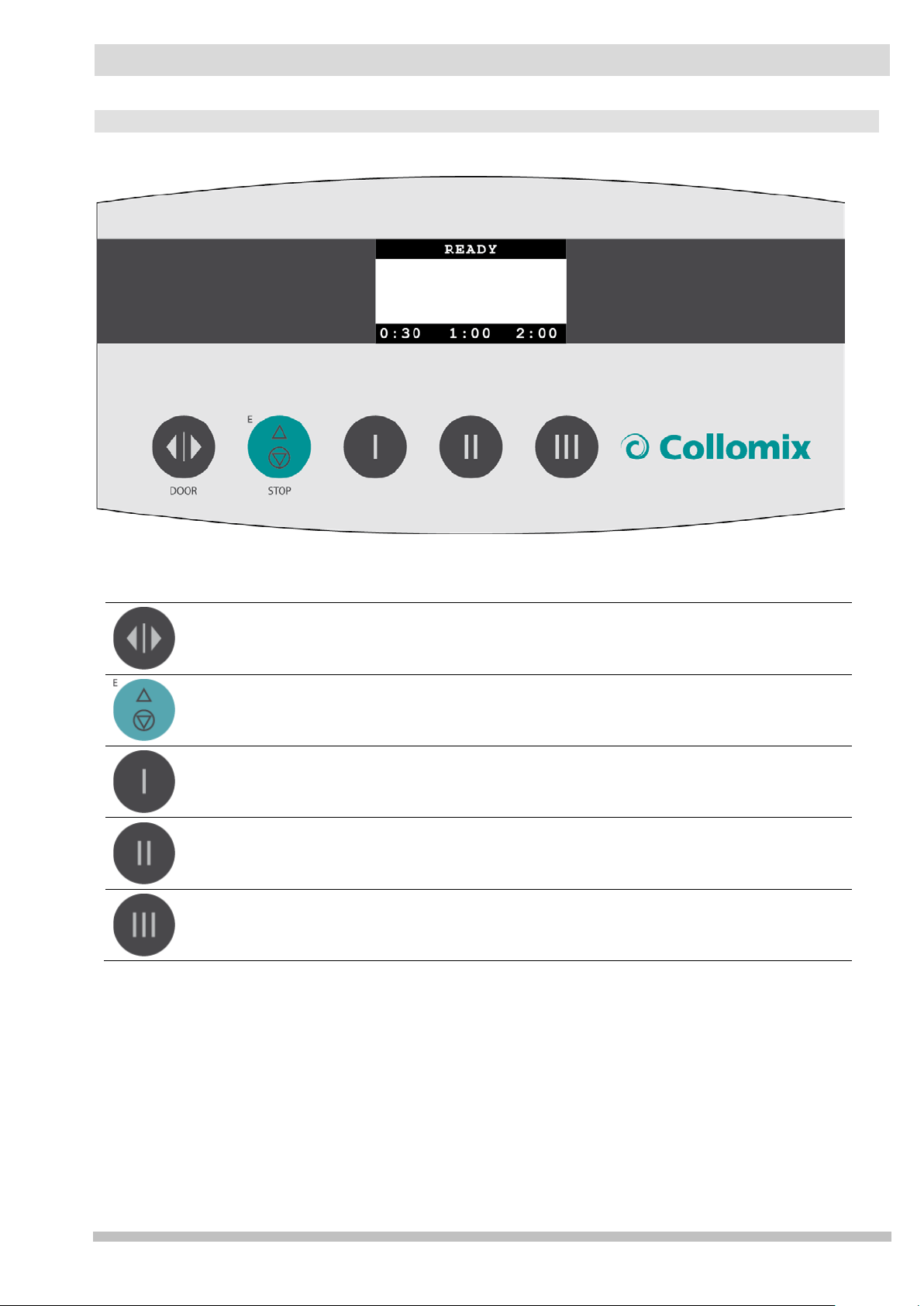

1.2 Operating and display components

Button for DOOR

• OPEN door

• OPEN the mixing unit

Button E

Button I

Button II

Button III

• STOP – stop mixing cycle prematurely

• ACKNOWLEDGE messages

• Mixing cycle I (Factory settings 4:00 Minute)

• Mixing cycle II (Factory settings 6:00 Minute)

• Mixing cycle III (Factory settings 8:00 Minute)

For changing the Mixing times, please contact an authorized service technician.

Version 1.1-17 5

measures.

VISCO 550 Collomix GmbH

2. About this document

This instruction uses symbols and labels, which should make it easier for you to find information

swiftly. Please read the explanations in the following Section. Please read the safety and warning

information in these instructions especially carefully. Safety information is in Chapter 2. You find

information on warnings in the introduction of Chapters and before instructions.

Collomix GmbH owns the copyright of images and text.

Please read the operating instructions prior to first use. Pay attention to safety instructions. Keep for

future use. This documentation is not subject to change services.

2.1 Pictograms and symbols

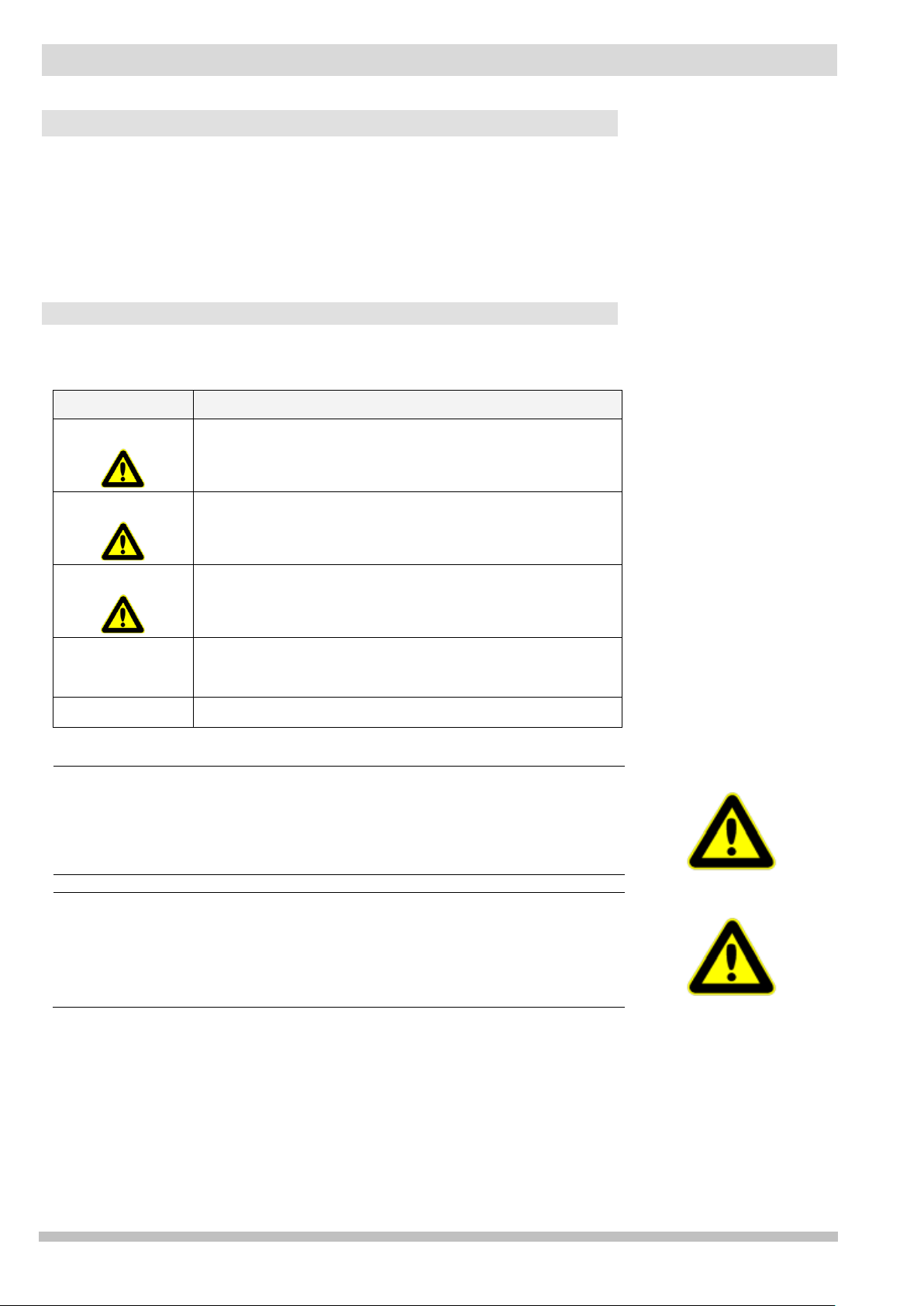

Warnings

The following symbols and signal words are used in this documentation.

Symbol Meaning

DANGER

WARNING

ATTENTION

CAUTION

IMPORTANT

This signal word is used, if death or severe physical injuries is the result of

not paying attention to the corresponding precautionary measures.

This signal word is used, if death or severe physical injuries may result

from not paying attention to the corresponding precautionary measures.

This signal word is used, if slight physical injuries occur from not paying

attention to the corresponding precautionary measures.

This signal word is used, if malfunction of functions or property damages

may occur from not paying attention to the corresponding precautionary

This signal word is used for easing operation or for pointing to references.

Structure of warnings

DANGER

The first line describes the type and source of danger.

The second line describes the consequences which occur if no actions are taken to avert the danger.

The last line describes the actions to take in order to avoid the danger.

WARNING

Danger of injury through disregard of safety symbols

Ignoring the warnings on the equipment and in the operating instructions can lead to injuries and

additional risks.

Pay attention to the warnings on the equipment and in the operating instructions.

6 Version 1.1-17

Collomix GmbH VISCO 550

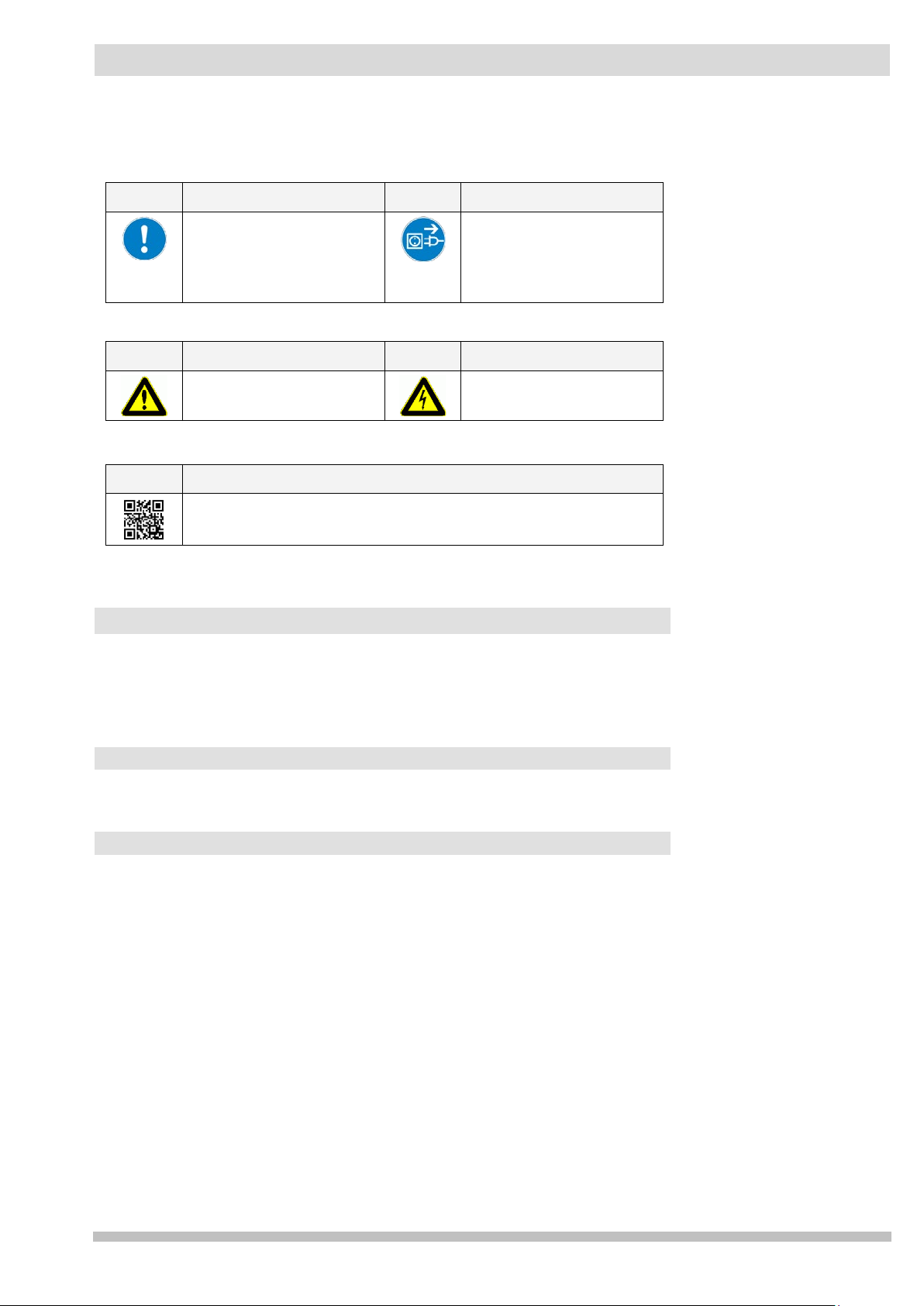

The following special safety symbols are used in the appropriate text portions of these Operating

Instructions.

Mandatory signs

Symbol Explanation Symbol Explanation

Please read the information

Disconnect from power

after use

Disconnect from power

before opening the housing

Warning signs

Symbol Explanation Symbol Explanation

Warning from a danger zone

Danger of electric shock

Online Information

Symbol Explanation

QR Code, follow the link for additional online information.

Position numbers to the illustrations are stated in parenthesis in the text.

3. For your safety

The biaxial mixer was developed, manufactured, and tested in accordance with the basic safety

requirements. Despite, there is an element of risk.

Therefore, please read these Operating Instructions before working with the machine.

Keep the Operating Instructions within immediate reach of the machine.

Please hand the Operating Instructions to any subsequent owners.

3.1 General Safety Information

The basic safety information of this Chapter is supplemented by precise warnings in further chapters

of the Operating Instructions.

3.2 Intended Use

The VISCO is a stationary mixing unit for homogenization of printing inks and comparable material

with a viscosity up to ~ 500 Pa·s in closed, tightly closing, round containers made of metal or plastic.

Any other or expanded use of the biaxial mixer is a non-intended and therefore, improper use. In this

case, the safety mechanisms and the protection provided by them may be compromised. Collomix

GmbH is not liable for any damages caused by it. Parts of the intended use are:

Complying with all information in these Operating Instructions

Complying with all safety information

Complying with the inspection and maintenance work

Version 1.1-17 7

Working area

Expertise

Installation, transport and storage

Specialised staff

Commissioning, decommissioning

Trained personnel

Operation

Trained personnel

Servicing and maintenance

Specialised staff

Troubleshooting

Specialised staff

VISCO 550 Collomix GmbH

3.3 Foreseeable Misuse

Any reasonably foreseeable misuse, which can be hazardous for the user, third parties, or for the

biaxial mixer are:

The use of the biaxial mixer and its accessories contrary to the intended use.

The use of damaged containers or containers not suitable for mixing.

The mixing of explosive substances.

The use of substances, which react chemically with one another; in particular, expanding

substances.

The use of the equipment outside the physical use limitations described in the Chapter

"Commissioning / Operating".

The modification of the control software without the prior coordination with Collomix GmbH.

Modifications on the biaxial mixer as well as add-ons and retrofits without the prior coordination

with Collomix GmbH.

Operating the system contrary to the requirements of the Operating Instructions concerning

safety information, installation, operation, servicing, and maintenance, set-up, and malfunctions.

Bridging or decommissioning of safety and protective actions of the system.

Operating the system if malfunctions are obvious / with obvious malfunctions

Repair, cleaning, and maintenance work without disconnecting the system from power.

WARNING

Danger of injury through improper modifications

Hazards exist through unauthorized modifications to the system and the use of third party spare

parts.

Use only original spare parts and accessories of the manufacturer.

Do not change, add to, or retrofit the system without the consent of the manufacturer.

3.4 Qualifications of operating personnel

These Operating Instructions are directed toward operators and personnel with the following areas

of competency:

Definition acc. to DIN EN 60204-1:

Trained personnel:

A person, who was instructed by an expert in the responsibilities he or she has been assigned and any

possible hazards in case of improper behaviour and a person, who was trained in the necessary

protective devices and protective actions, if needed.

Expert staff:

Persons who can evaluate the work assigned to them and recognize possible dangers on the basis of

their specialised training, knowledge, experience, and familiarity with the relevant norms.

8 Version 1.1-17

Loading...

Loading...