Coldelite EPS 60 XP Instruction Handbook Manual

INSTRUCTIONS HANDBOOK

EPS 60 XP

APPLICARE

TARGA

CARATTERISTICHE

EPS XP

:enoizidE 2 :ataD 01/90 :ehcifidoM 7.5.zeS,3.5.zeS,1.4.zeS,1.4.3.zeS,2.2.1.zeS

:ottadeR MA :otacifireV LR :otavorppA VR

We wish to thank you for the preference granted to us by purchasing one of

COLDELITE machines.

To the best guarantee, since 1993 COLDELITE has submitted its own Quality

System to the certification according to the international Standard ISO 9001-94,

nowadays its production has got UNI-EN-ISO 9001-2000 Certified Quality System.

Moreover, Carpigiani machines comply with following European Directives:

- “Machinery” Directive 98/37/EC,

- “Low Voltage” Directive 2006/95/EC,

- “EMC” Directive 2004/108/EC,

- “PED” Directive 97/23/EC,

- Regulation 2004/1935/EC relating to “Materials and articles in contact with

foodstuffs”

COLDELITE

Via Emilia, 45 - 40011 Anzola Emilia (Bologna) - Italy

Tel. 051-6505111 - Fax 051-732178

This handbook may not be reprinted, transferred, registered, recorded in a retrieval system,

nor translated in other languages unless otherwise previously agreed with COLDELITE.

The purchaser has the wright to reprint it for his own office use.

COLDELITE policy pursues a steady reasearch and development, thus it reserves the right

to make changes and revisions whenever deemed necessary and without being bound to

previous statements to the purchaser.

eps xp_EN - 09/10 - ed. 2

- 2 -

INDEX

SECT. FOREWORD ............................................................................................................ 5

INSTRUCTION HANDBOOK ................................................................................... 5

PURPOSE ................................................................................................................... 5

HANDBOOK STRUCTURE ...................................................................................... 5

ADDITIONAL DOCUMENTATION ......................................................................... 5

CONVENTIONAL SYMBOLS ................................................................................... 6

SAFETY ..................................................................................................................... 7

QUALIFICATION OF THE STAFF ......................................................................... 7

WARNING ................................................................................................................. 7

SECT. 1 GENERAL INFORMATION

1.1 GENERAL INFORMATION ..................................................................................... 9

1.1.1 MANUFACTURER'S IDENTIFICATION DATA ......................................... 9

1.1.2 INFORMATION ABOUT SERVICE .............................................................. 9

1.1.3 INFORMATION TO THE USER ................................................................... 9

1.2 INFORMATION ABOUT THE MACHINE .............................................................. 9

1.2.1 GENERAL DATA .......................................................................................... 9

1.2.2 TECHNICAL FEATURES ............................................................................ 10

1.2.3 MACHINE GROUPS LOCATION ............................................................... 11

1.3 INTENDED USE ...................................................................................................... 11

1.4 NOISE ...................................................................................................................... 11

1.5 STORING A MACHINE ......................................................................................... 11

1.6 DISPOSAL OF PACKING STUFFS ..................................................................11

1.7 WEEE (Waste Electrical and Electronic Equipment) .................................12

EPS XP

SEC. 2 INSTALLATION

2.1 ROOM NECESSARY TO THE MACHINE USE .................................................. 13

2.2 WATER SUPPLY CONNECTION ......................................................................... 13

2.3 MACHINES WITH AIRCOOLED CONDENSER ................................................. 13

2.4 MACHINES WITH WATERCOOLED CONDENSER .......................................... 14

2.4.1 WATER VALVE ADJUSTMENT ................................................................ 14

2.5 ELECTRICAL CONNECTION ............................................................................... 14

2.5.1 REPLACING A POWER CABLE ................................................................. 14

2.6 LOCATION ............................................................................................................. 15

2.7 REFILLING .............................................................................................................. 15

2.8 MACHINE TESTING .............................................................................................. 15

SEC. 3 INSTRUCTIONS FOR USE

3.1 MACHINE SAFETY WARNINGS .......................................................................... 17

3.2 MACHINE CONFIGURATION ............................................................................... 17

3.3 CONTROLS ............................................................................................................ 18

3.3.1 PUSH-BUTTON PANEL .............................................................................. 18

3.3.2 FUNCTIONS ................................................................................................. 18

3.4 MACHINE STARTING ........................................................................................... 20

3.4.1 USE OF THE DISPENSING SPIGOT ............................................................ 20

SEC. 4 SAFETY DEVICES

4.1 ALARMS ON DISPLAY ...................................................................................... 21

4.2 BLACKOUT ........................................................................................................... 22

- 3 - eps xp_EN - 09/10 - ed. 2

EPS XP

SEC. 5 CLEAN OUT, DISASSEMBLING AND REASSEMBLING OF PARTS IN

CONTACT WITH THE PRODUCT

5.1 EXTERIOR CLEAN OUT ....................................................................................... 23

5.2 PRELIMINARY CLEAN OUT ................................................................................ 23

5.3 DISASSEMBLING THE SPIGOT PISTON .......................................................... 23

5.4 DISASSEMBLING THE TANK COVER ............................................................... 24

5.5 DISASSEMBLING THE BEATER ......................................................................... 24

5.6 HYGIENE ................................................................................................................. 25

5.7 SANITIZATION ...................................................................................................... 25

SEC. 6 MAINTENANCE

6.1 SERVICE TYPOLOGY ........................................................................................... 27

6.2 WATERCOOLING .................................................................................................. 27

6.3 AIRCOOLING ......................................................................................................... 27

6.4 ORDERING SPARE PARTS ................................................................................. 27

6.5 TABLE OF EQUIPMENT ....................................................................................... 28

SEC. 7 TROUBLESHOOT GUIDE

7.1 TROUBLESHOOT GUIDE ..................................................................................... 29

eps xp_EN - 09/10 - ed. 2

- 4 -

FOREWORD

INSTRUCTION HANDBOOK

Editing this handbook, it was taken into due account European Community directions on

safety standards as well as on free circulation of industrial products within E.C.

PURPOSE

This handbook was conceived taking machine users' needs into due account.

Topics relevant to a correct use of the machine have been analyzed in order to keep unchanged

in the long run quality features charachterizing COLDELITE machines all over the world.

A significant part of this handbook refers to the conditions necessary to the machine use

and to the necessary procedure during cleanout as well as routine and special maintenance.

Nevertheless, this handbook cannot meet all demands in details. In case of doubts or missing

information, please apply to:

COLDELITE Via Emilia, 45 - 40011 Anzola Emilia (Bologna) - Italy

Tel. 051- 6505111 - Fax 051-732178

HANDBOOK STRUCTURE

This handbook is divided in sections, chapters and subchapters in order to be consulted

more easily.

EPS XP

SECTION

A section is the part of the handbook identifying a specific topic related to a machine part.

CHAPTER

A chapter is that part of a section describing an assembly or concept relevant to a machine

part.

SUBCHAPTER

It is that part of a chapter detailing the specific component of a machine part.

It is necessary that each person involved in the machine operation reads and clearly

understands those parts of the handbook of his/her own concern, and particularly:

- The Operator must read the chapters concerning the machine star-up and the operation of

machine components.

- A skilled technician involved in the installation, maintenance, repair, etc., of the machine

must read all parts of this handbook.

ADDITIONAL DOCUMENTATION

Along with an instruction manual, each machine is supplied also with additional documentation:

- Part list: A list of spare parts which is delivered together with the machine for its

maintenance.

- Wiring diagram: A diagram of wiring connections is placed in the machine.

ATTENTION

Before using the machine read carefully the instruction handbook.

Pay attention to the safety instructions.

- 5 - eps xp_EN - 09/10 - ed. 2

EPS XP

CONVENTIONAL SYMBOLS

CAUTION: ELECTRIC SHOCK DANGER

The staff involved is warned that the non-obsevance of safety rules in carrying out the

operation described may cause an electric shock.

CAUTION: GENERAL HAZARD

The staff involved is warned that the operation described may cause injury if not performed

following safety rules.

NOTE

It points out significant information for the staff involved.

WARNINGS

The staff involved is warned that the non-observance of warning may cause loss of data

and damage to the machine.

PROTECTIONS

This symbol on the side means that the operator must use personal protection against an

implicit risk of accident.

QUALIFICATION OF THE STAFF

MACHINE OPERATOR

He/she is an unskilled person, who has no specific expertise and can only carry out easy

chores, such as the machine operation by means of controls available on the push-button

panel, and filling and drawing of products used during operations.

MAINTENANCE ENGINEER

He/she is a skilled engineer for the operation of the machine under normal conditions; he/she

is able to carry out interventions on mechanical parts and all adjustments, as well as

maintenance and repairs. He/she is qualified for interventions on electrical and refrigeration

components.

COLDELITE ENGINEER

He/she is a skilled engineer the manufacturer assigned to field interventions for complex jobs

under particular conditions or in accordance with agreements made with the machine's owner.

eps xp_EN - 09/10 - ed. 2

- 6 -

SAFETY

When using industrial equipment and plants, one must be aware of the fact that drive

mechanisms (rotary motion), high voltage components, as well as parts subject to high

temperatures may cause serious damage to persons and things.

Who is in charge of plant safety must be on the look-out that

- An incorrect use or handling shall be avoided

- Safety devices must neither be removed nor tampered with

- The machine shall be regularly serviced

- Only original spare parts are to be used especially as far as those components with

safety functions are concerned (ex.: protection microswitches, thermostats).

To achieve the above, the following is necessary:

- At the working place an instruction manual relevant to the machine should be available.

- Such documentation must be carefully read and requirements must conse quently be met.

- Only adequately skilled personnel should be assigned to electrical equipment.

- Be on the look out that no technician will ever carry out interventions outside his own

knowledge and responsibility sphere.

QUALIFICATION OF THE STAFF

Staff attached to the machine can be distinguished according to training and responsibility as

follows:

EPS XP

OPERATOR

- A person who has not necessarily a high technical knowledge, just trained for ordinary

operation of the machine, such as: startup, stop, filling, basic maintenance (cleanout, simple

blocking, instrumentation checkings, etc.).

SKILLED ENGINEER

- A person enganged on more complicated operations of installation, maintenance, repairs, etc.

IMPORTANT!

One must be on the look-out that the staff does not carry out any operation outside its own sphere

of konwledge and responsibility.

NOTE:

According to the standard at present in force, a SKILLED ENGINEER is who, thanks to

- training, experience and education,

- knowledge of rules, prescriptions and interventions on accident prevention,

- knowledge of machine operating conditions,

is able to realize and avoid any danger and has also been allowed by the person in charge of

plant safety to carry out all kinds of interventions.

WARNING

When installing the machine, insert a differential magnetothermal protection switch on all

poles of the line, adequately sized to the absorption power shown on machine data plate and

with contact opening of 3 mm at least.

• Never put your hand into the machine, alike during production and cleaning operations.

Before carrying out any maintenance operation, make sure that the machine is in “STOP”

position and main switch has been cut out.

• It is forbidden to wash the machine by means of a bolt of water under pressure.

• It is forbidden to remove panels in order to reach the machine inside before having

disconnected the machine.

• COLDELITE is not responsible for any accident that might happen during operation,

cleaning and/or servicing of its units, if this warning has not been fully complied with.

- 7 - eps xp_EN - 09/10 - ed. 2

EPS XP

eps xp_EN - 09/10 - ed. 2

- 8 -

1 GENERAL INFORMATION

1.1 GENERAL INFORMATION

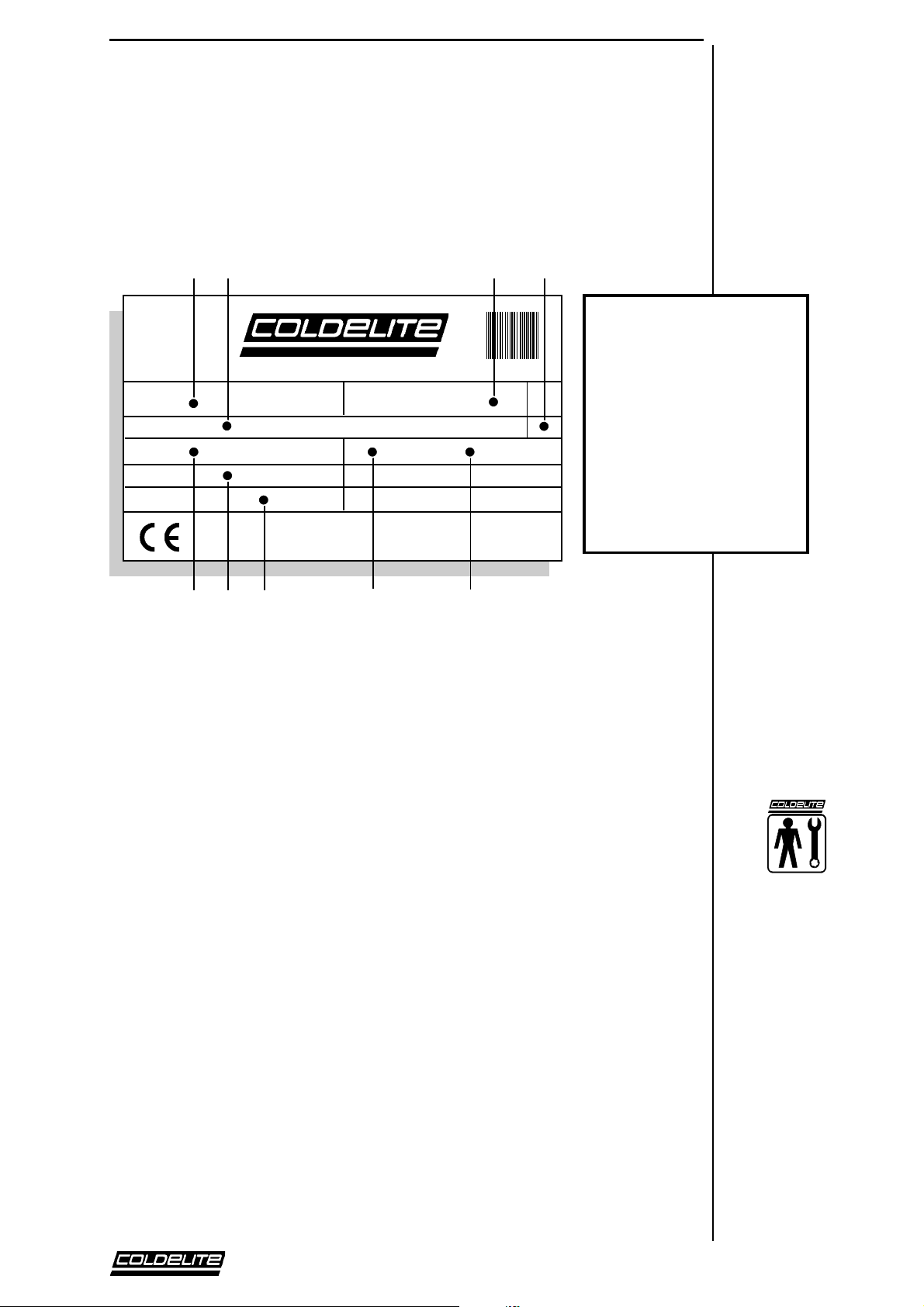

1.1.1 Manufacturer's identification data

The machine has a data plate carrying manufacturer data, machine type and serial number,

assigned when it is manufactured.

Copy of machine data plate to be found on first page of this handbook.

EPS XP

A B

ANZOLA EMILIA - BOLOGNA - ITALY

Matr.

Cod.

V Hz kW

A

Gas kg

C D E H

F G

100089654588-4

I

Legend:

A= Serial number

B= Machine type

C= Voltage

D= Main-switch amperometric

value

E= Gas type and weight

F= Machine code

G= Condensation

H= Frequency

I= Power input

1.1.2 Information about service

All operations of routine maintenance are here described in section "Maintenance"; any

additional operation requiring technical intervention on the machine must be cleared with

the manufacturer, who will also examine the possibility of a factory technician field

intervention.

1.1.3 Information to the user

l The manufacturer of the machine is at user's disposal for any explanation and information

about the machine operation.

l In case of need, please call the local distributor, or the manufacturer if no distributor is

available.

l Manufacturer's service department is available for any information about operation, and

requests of spare parts and service.

1.2 INFORMATION ABOUT THE MACHINE

1.2.1 General data

EPS XP are pasteurizers which prepare, pasteurize, homogenize and age ice cream mixes to

other units.

An electronic microprocessor steadily checks each working cycle selected.

Two alphanumerical monitors display all steps of a working cycle and send audio-visible

messages.

The following are the main components:

l two-speed beater;

l display console with low voltage 24 V controls;

l electrical, freezing and soundproofing units complying with international standards;

l graduated tank, with inside water dispenser for wash;

l high resistant steel frame, treated with rust inhibitors; varnisched aluminium panels.

- 9 - eps xp_EN - 09/10 - ed. 2

Loading...

Loading...