CODUME sa.

X

-

V

ent

II 300

Installations and Operations Guide

Version 2011-06-24

CODUME Page 2

DANGER SYMBOLS

Non-observance of instructions indicated with a danger symbol

entails a risk of injury or material damage.

Read and save these instructions

By following these instructions, we guarantee you correct

installation and safe use of this product.

Airmaster A/S disclaims any liability for damage or injury resulting

from use, non-compliant with this manual.

This guide applies to the ventilation unit X-Vent II 300.

WARNINGS

Prior to installation and commissioning, read and observe the

instructions provided in this manual.

Do not operate the unit until the service cover and grates on duct

connections have been mounted.

Do not open the service cover until the power has been cut off.

CODUME Page 3

Contents

1. GENERAL INFORMATION ....................................................................................................................................................... 4

1.1 P

REFACE

................................................................................................................................................................................... 4

1.2 Z

ONE OF USE

............................................................................................................................................................................. 4

2. DESCRIPTION ............................................................................................................................................................................. 4

2.1 M

AIN CONTROLLER FUNCTIONALITIES

....................................................................................................................................... 4

2.2 R

EGULATED EQUIPMENT

........................................................................................................................................................... 4

2.3 T

ECHNICAL SPECIFICATIONS AM II

300 .................................................................................................................................... 4

2.4 B

ASIC CIRCUIT DIAGRAM

........................................................................................................................................................... 5

2.5 C

OMPONENT NAME

................................................................................................................................................................... 5

2.6 S

TRUCTURE

.............................................................................................................................................................................. 6

3. MECHANICAL INSTALLATION ............................................................................................................................................. 7

3.2 M

OUNTING UNIT IN WALL FRAME

.............................................................................................................................................. 8

3.3 M

OUNTING PIPES AND GRATES

................................................................................................................................................ 12

3.4 C

ONNECTING THE WATER HEATING SURFACE

........................................................................................................................... 12

3.5 C

ONNECTING THE ELECTRIC HEATING SURFACE

....................................................................................................................... 15

4. ELECTRICAL INSTALLATION ............................................................................................................................................. 15

4.1 C

ONNECTING THE POWER

........................................................................................................................................................ 15

4.2 C

ONNECTING THE DISPLAY PANEL

........................................................................................................................................... 16

4.3 C

ONNECTING A

CO

2

SENSOR (OPTION

) .................................................................................................................................... 16

4.4 C

ONNECTING A

PIR

SENSOR (OPTIONAL

) ................................................................................................................................. 16

4.5 E

XTERNAL CONNECTIONS

....................................................................................................................................................... 17

4.6 S

CREEN TERMINATION

............................................................................................................................................................ 17

5. APPENDIX .................................................................................................................................................................................. 19

5.1 M

AIN DIMENSIONS

X-V

ENT II

300 WALL MODEL .............................................................................................................. 19

5.2 M

AIN DIMENSIONS

X-V

ENT II

300 WALL MODEL

PARTIALLY INTEGRATED

......................................................................... 20

5.3 M

AIN DIMENSIONS

X-V

ENT II

300 WALL MODEL

COMBI

3 .................................................................................................. 21

5.4 M

AIN DIMENSIONS

X-V

ENT II

300 ROOF MODEL

PARTIALLY INTEGRATED

......................................................................... 22

5.5 E

LECTRICAL DIAGRAM

............................................................................................................................................................ 23

5.6 C

APACITY DATA

..................................................................................................................................................................... 24

5.7 ON-

SITE TESTING OF AIR VOLUMES

.......................................................................................................................................... 26

5.9 EU

DECLARATION OF CONFORMITY

......................................................................................................................................... 27

CODUME Page 4

1. General information

1.1 Preface

This installations and operations guide contains

technical information as well as information regarding

installation and maintenance of the unit.

1.2 Zone of use

The tolerated zone of use for the air extraction

temperature is -12 ... 35 °C.

2. Description

The X-Vent II 300 is a ventilation unit with air diffusion and extraction ventilators, filters in diffusion and exhaust,

countercurrent heat exchangers and compact electronic control.

The unit is designed for installation in the room to be ventilated. Ducts for supply and exhaust air are connected either to

the back of the unit and lead out through the wall, or to the top of the unit and out through the roof.

X-Vent Controller is a compact electronic controller designed for full control of the X-Vent ventilation unit, fitted with

effective heat recovery and energy-efficient EC ventilators.

2.1 Main controller functionalities

• Unlimited control of air volume

• Control of air supply temperature

• Bypass operation (optional)

• Night cooling and background ventilation

• Manual operation or automatic operation via

weekly timer

• Operation via CTS, movement sensor or CO2

sensor

• The defrost functionalities protects the counterflow

heat exchanger from freezing over when outdoor

temperatures are low.

• Monitoring and alarm functionalities

2.2 Regulated equipment

• Inlet- and extract ventilators

• Closing damper, intake

• Bypass damper (optional)

• Electric heating surface (optional)

• Adjustment valve for water heating surface

(optional)

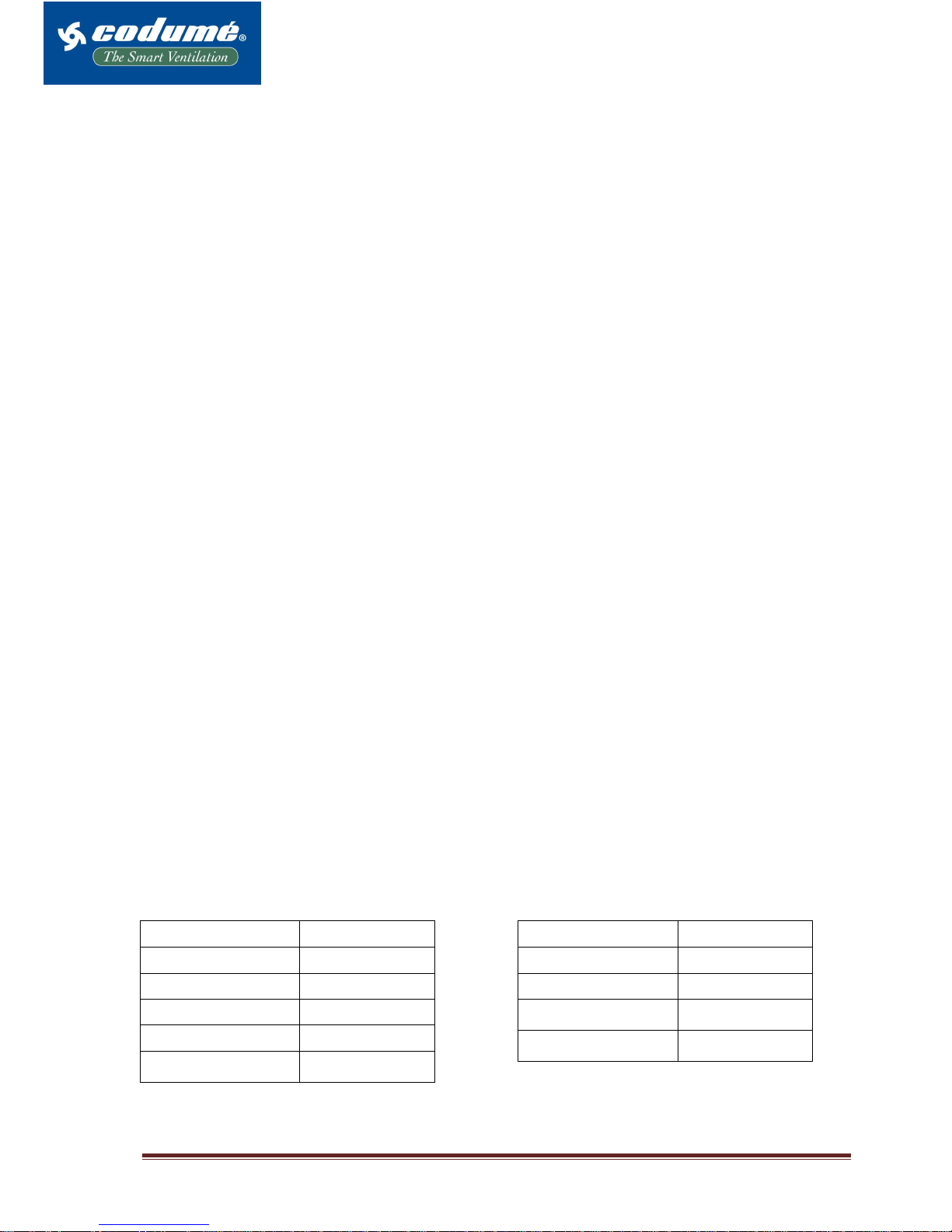

2.3 Technical specifications AM II 300

Power supply: 1 ~ 230 V, 50 Hz, N+PE

Duct connections: Ø200 mm.

Condensation drain: Ø16 mm

Net weight: 49.8 kg

Transportation weight (incl.

packaging):

62.9 kg

Heat exchanger: Counterflow

Filters: F5 standard

Main dimensions: 1274 x 327x 578 (WxHxD) excl. connecting pieces, incl. wall frame

Colour: Cover panels Ral 9010 (white), sub panels Ral 7024 (grey)

Specifications water heating surface

Max. operating temp.:

90 °C

Max. operating pressure: 10 bars

Capacity: * 400 W

Connection dimensions: ⅜” (DN 10)

Material pipes/fins: copper/aluminium

Open/shut time motorised

valve

< 60 s

* Capacity at:

in/out temperature 70/40 °C, water volume 15 L/h

Specifications electric heating surface

Heating stick: 1 x 230 V

Output: 1500 W

Minimum air velocity: 0.3 m/s

Thermal cutout, aut.

reset:

70 °C

Thermal cutout, man.

reset:

120 °C

CODUME Page 5

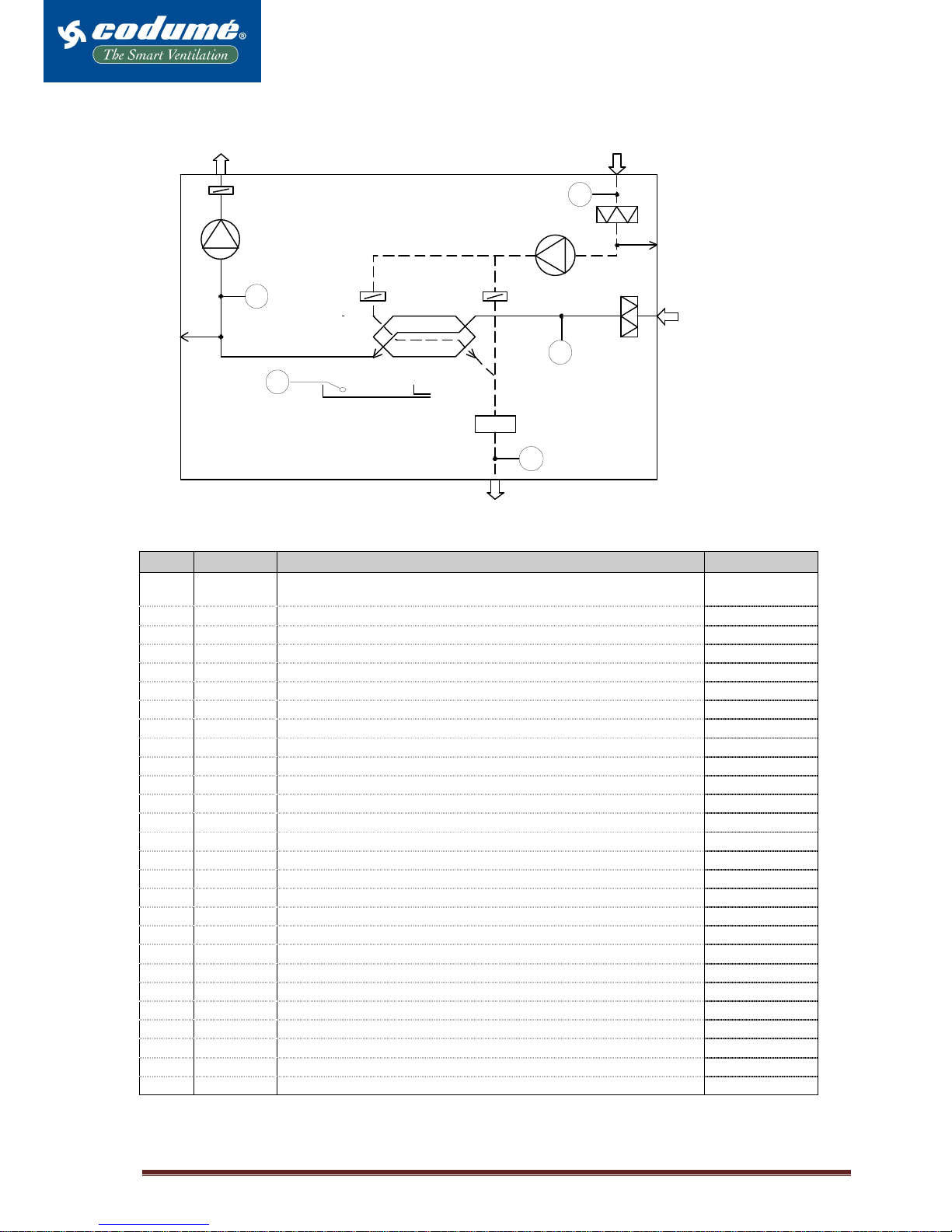

2.4 Basic circuit diagram

UDSUGNING

AFKAST

UDELUFT

F2

OT

FT CT

ET

IT

INDBLÆSNING

+

HE

CH *

BP *

MD

PU

PI

IF

EF

FI

RT

ED

FL

2.5 Component name

Pos. Description Function Spare part :

1 - Connecting spigot for exhaust air (wall model), placed at top (roof

model)

2 - Connecting spigot for intake air (wall model), placed at top (roof model)

3 F1 Inlet fan

4 F2 Exhaust fan

5 EF Exhaust filter

6 IF Intake filter (fresh air)

7 MD Motor for closing damper (motorised)

8 ED Exhaust damper (overpressure)

9 BP Bypass damper (optional)

10 HE Counter-flow heat exchanger

11 CT Condensation tray

12 FT Floater

13 - Connecting piece for condensation drainage

13 a - Lead-in for condensation drainage

14 RT/ FL Room temperature sensor / flow sensor

15 OT Outdoor temperature sensor

16 ET Exhaust temperature sensor

17 PI Pressure tap for air volume measurement, supply

18 PU Pressure tap for air volume measurement, exhaust

19 - Extract opening right side

20 - Inlet opening in front

21 - Power hook-up on right side

22 - Power hook-up on mounting plate for main box

23 - Main box

24 CH Post-heating surface (optional)

25 IT Inlet temperature sensor

26 Condensate Pump (optional)

INTAKE EXHAUST

EXTRACT

INLET

CODUME Page 6

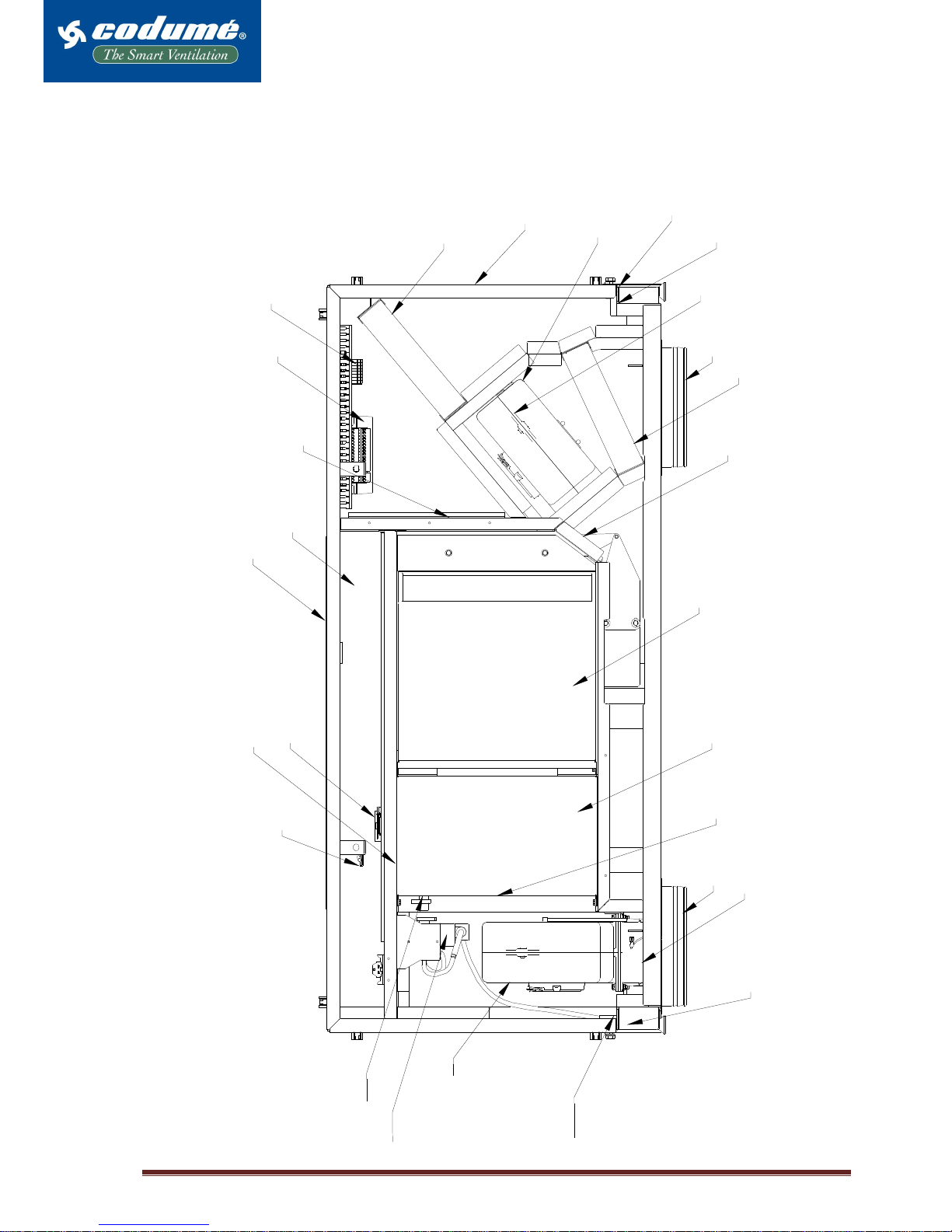

2.6 Structure

The unit seen from below, without service cover.

1

2

3

4

6

5

7

8

9

10

13

11

20

23

22

14

19

15

17

21

12

24

25

13a

18

16

2

6

CODUME Page 7

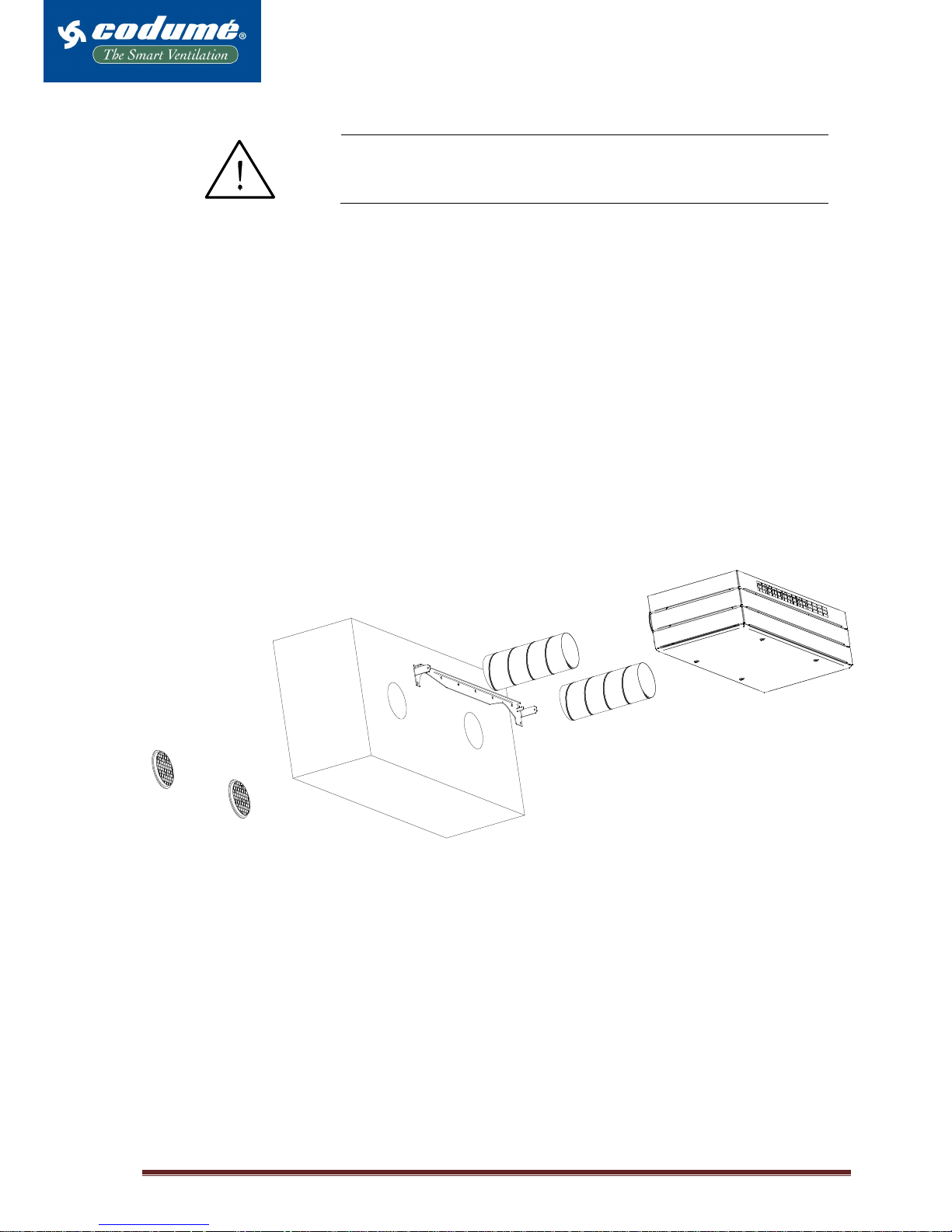

3. Mechanical installation

The installer is responsible for safely and securely fastening the unit to the wall.

Note: When lifting the unit, it is important to place a protective underlay, to avoid scratching the base plate. The underlay

can consist of, e.g. thick cardboard or a similar material.

The mechanical installation involves

• Marking, drilling of holes for connecting ducts and mounting of wall frame

• Mounting of unit in wall frame

• Installation of pipes and grates through walls or over roof, depending on model

• Mounting of panels

Important: Before drilling holes in wall or roof, check that there is at least 0.5 m between the wall and the unit’s exhaust

end. If the exhaust end is facing out towards glass panes, that distance must be greater. If these minimum distances are

not observed, there is a risk of increased noise from the unit.

Simplified picture illustrating mounting of unit on wall frame.

CODUME Page 8

3.2 Mounting unit in wall frame

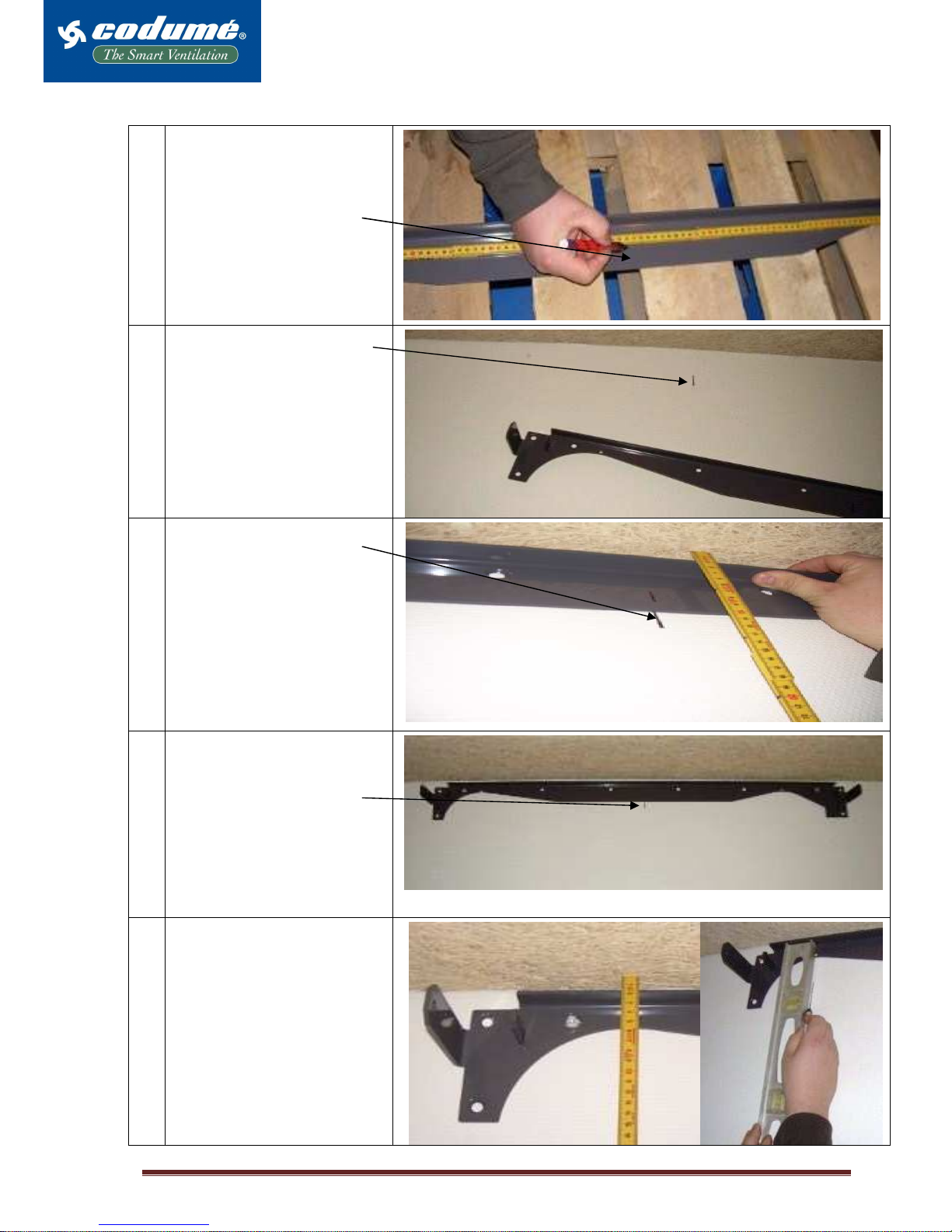

1

Start by finding the centre of

the wall frame using a ruler.

The centre measurement for

the wall frame is 62 cm. Mark

the measurement.

2

Next mark the middle of the

wall or the location you wish

to place the centre of the unit.

3

Now line up the two marks.

If you like, you can place the

wall frame all the way up to

the ceiling. If you do this,

there will be a 6 mm gap

between the top of the unit

and the wall.

4

Now that the wall frame is

provisionally hung, you can

mark holes for screws and the

centre of supply and exhaust.

The duct size is Ø200mm.

The recommended hole

diameter is Ø210-215 mm, so

the pipes can be insulated

subsequently.

5

Horizontally measure and

mark distance down to centre

of supply/exhaust, and mark

centre in vertical direction.

CODUME Page 9

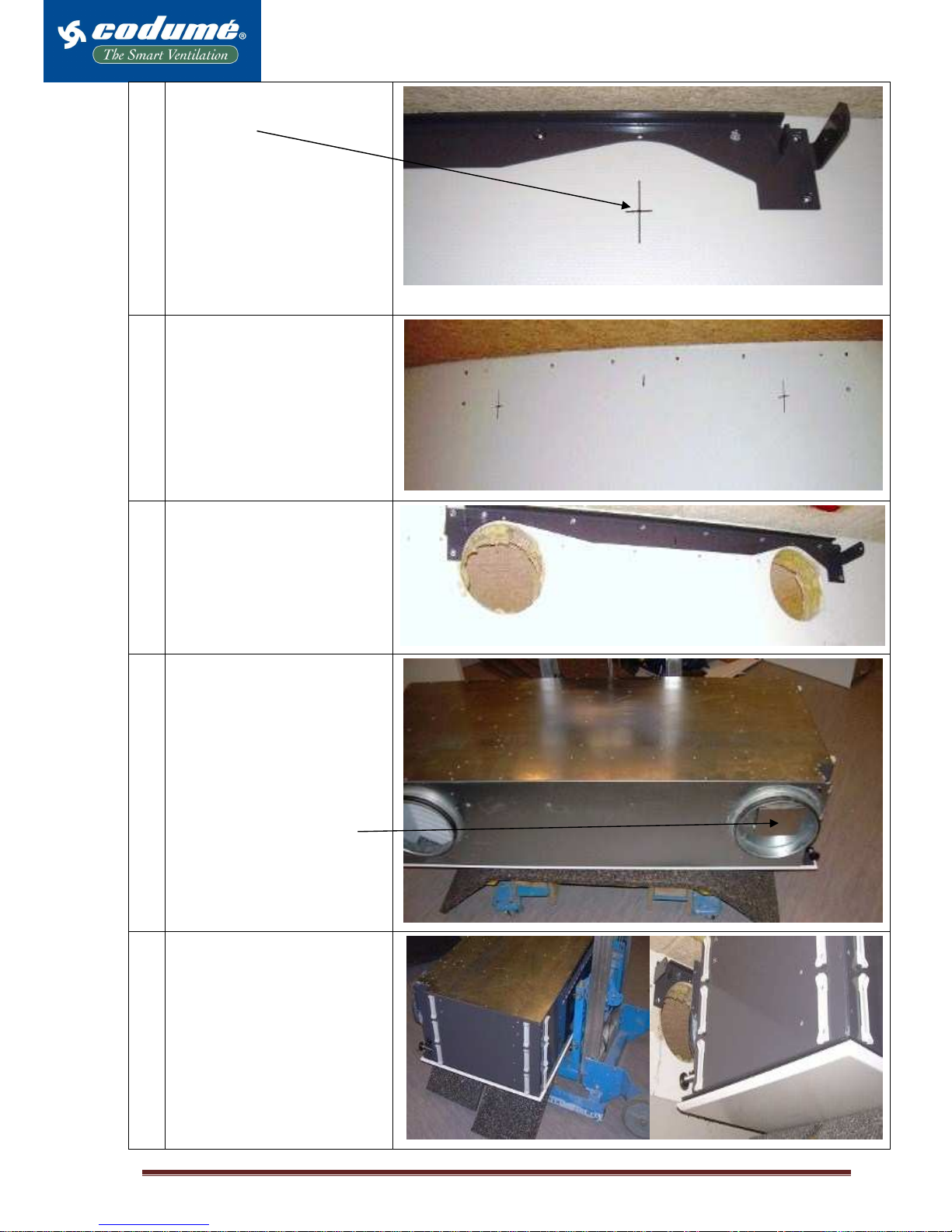

6

This clearly indicates the

marking of the centre of the

intake hole.

Note: The length of the two

pipes depend of the wallthickness.

7

All necessary markings show.

Note: The holes for the pipes

should have a downward start

of 1-2%, to prevent hard rain

from penetrating the unit.

8

Here, both holes have been

drilled, and the wall frame is

now securely fastened to the

wall.

Note: The screw type used

depends on the wall material.

9

Place the unit on a thick

underlay, such as cardboard

or the like, to prevent

scratches in the base plate. It

is important that the unit is

stable on the lift.

Note: Remember to remove

tape holding the discharge

damper in the transport

position.

10

The unit is on the underlay

and is safely and securely

placed on the lift.

In the picture on the right, the

unit is raised and can now be

adjusted to the two guide

hooks placed on the wall

frame.

CODUME Page 10

11

Make final adjustments to the

unit to unable it to be pushed

far enough over the hooks

that it cannot fall back out

again.

In the picture on the right, the

unit is hanging from the two

guide hooks.

At the bottom of the picture

one of the adjustment screws

shows.

12

Now, fasten the unit to the

wall frame, using the two

factory-supplied M8 bolts,

one on each side.

To get the unit to hang

properly relative to the wall,

adjust it by screwing the two

adjustment screws situated

just over the base plate.

Use a no. 13 screw wrench.

13

The unit must hang

horizontally; therefore, it is

important to check and

readjust.

CODUME Page 11

14

Attach the display panel.

The photo shows the

protected earth terminal.

L = Phase brown

0 = Blue

AC = Connection of cooling

module (optional)

Terminal block X3

Display panel attached.

15

The unit is now hung, and the

factory-supplied panels can

be clicked onto the mounted

clips.

CODUME Page 12

3.3 Mounting pipes and grates

Mount two Ø200 mm pipes through the wall with a 1-2% outward slant. The length of the pipes is calculated based on

the thickness of the wall.

Remember to remove tape holding the damper in the exhaust in transport position.

Finally, mount Ø200 mm grates with slats pointing down. Remember to joint between grate and outer wall. It is important

that the penetrations not are twisted or forced onto the unit’s connecting pieces, to avoid an elevated noise level.

3.4 Connecting the water heating surface

The unit can be purchased complete with water heating

surface (optional), motorised valve, automatic heatretaining thermostat and air escape valve internally

mounted and threaded. The heating unit has been

tested for leaks and undergone final inspection in

accordance with DS 469.

Dimensioning of pipes, valves and connections

to the unit must always be carried out by authorised

personnel.

36.0

102.0

40.0

Connection

Lead the hot water connection through the cabinet on the right side or at the top to the connecting pieces placed inside

the unit, behind the service cover. Connect the forward hot water connection to the connecting piece market FORWARD

and the return to the connecting piece marked RETURN. See the below dimensioned sketch for further instructions

regarding lead-through of the water connection.

Note: The regulating valve (3) requires clean unit water in order to function optimally, without disruptions from blockage

in the valve. Airmaster A/S recommends that a dirt trap and continuous regulating valve be fitted in the hot water

connection according to the below-mentioned simplified diagram.

Simplified diagram for external connection

Simplified diagram for internal structure

1: Water heating surface

2: Valve housing with presetting N

3: Valve housing with presetting 6

4: Air escape valve

IT/FS: Temperature and flow sensor

TM: Thermo motor

TV: Thermostatic heat-retaining valve

Shutoff valve (not Airmaster delivery)

X-Vent II unit

RETURN

FORWARD

RETURN 3/6” (DN 10)

FORWARD 3/6” (DN 10)

AIRFLOW

CODUME Page 13

5: Union connections (if mounted)

6: Remote sensor

Continuous regulating valve (not Airmaster

delivery)

Dirt trap (not Airmaster delivery)

Ventilation

Open water flow and aerate the system using the air release valve (4). After a short while the water flow should be silent,

with no noise from air.

The aeration is carried out with fully open valves, dismounted heat-retaining thermostat (TV) and thermal motor

(TM).

Adjustment of motorised valve

The unit comes with regulating valve (3) type TRV-2S preset to 6 – fully open valve. The regulating valve is preset

according to the diagram below, such that the prescribed flow is achieved with differential pressure of ∆H, which is

available to the unit in nominal operating conditions.

Remember that the unit must be aerated and rinsed prior to adjustment.

It is important to preset the valve so the maximum water flow is not exceeded.

If the differential pressure over the regulating valve is greater than 30 kPa, you risk a flow noise from the valve.

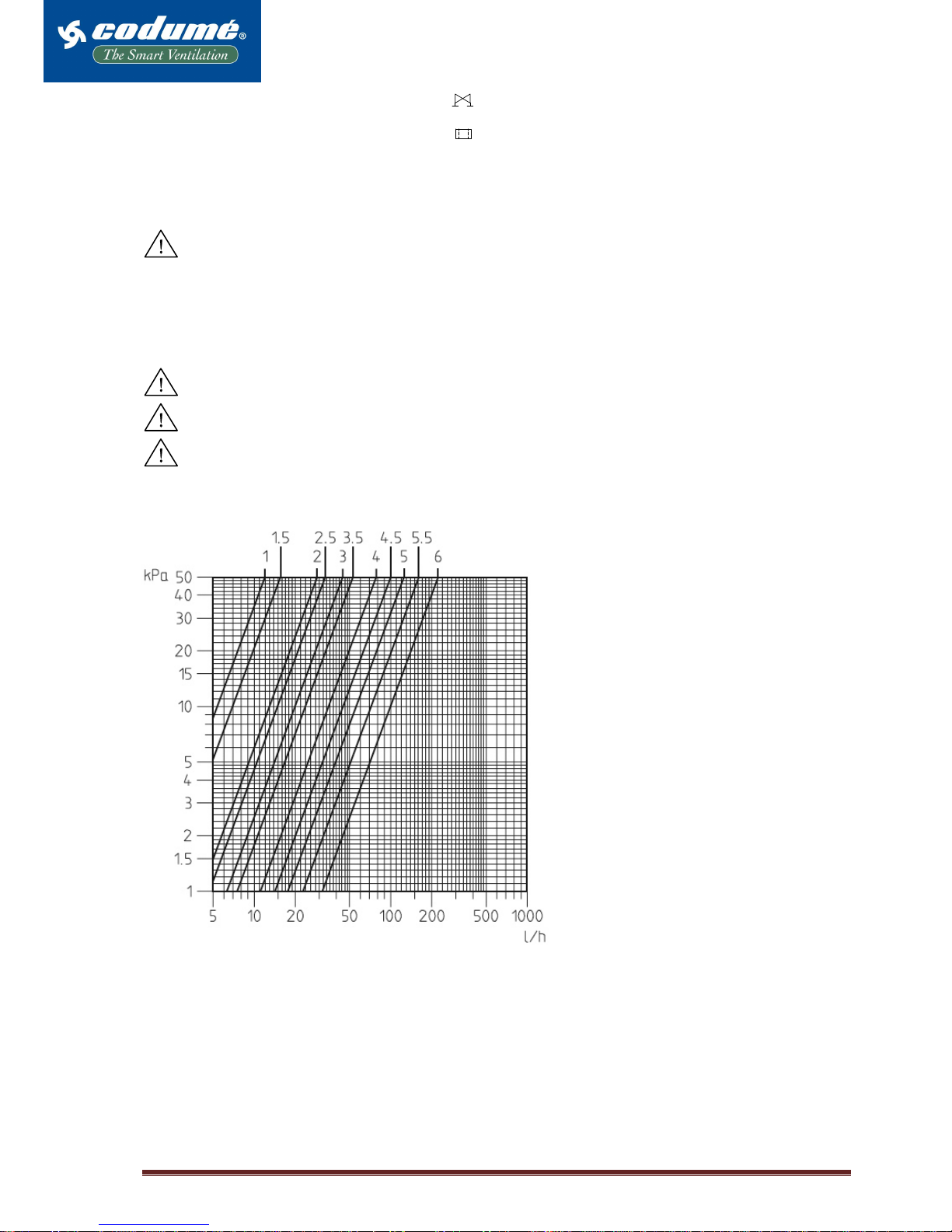

Diagram for determination of pressure loss in the water circuit and for presetting the regulating valve (3) TRV-2S.

Setting example:

Water flow: 15 l/h

Desired drop in pressure: 10 kPa

Setting value: 2,5

Presetting key for TRV-2S:

Plumbing no. 403399-411

Calculation of heating needs

The heat requirement for heating air from temperature

after heat recovery to the desired supply temperature is

calculated at 20 °C and 101.3 kPa:

Q = 0.34 ⋅⋅⋅⋅ qv ⋅⋅⋅⋅ (IT – t) [ W ]

where

q

v

air volume in m3/h

IT desired supply temperature

t = 15.9 °C temperature prior to post-heating

surface

Conditions: - outdoor temperature –12 °C

- room temperature 22 °C

- temperature rate of efficiency 82%

CODUME Page 14

Calculation of water volume

The flow-through volume of water is calculated at 20 °C

and 1 bar:

qw =

( )

RF

tt16,1

Q

−⋅

[ L / h ]

where

Q heating needs

tF water temperature forward

tR water temperature return

CODUME Page 15

Setting the heat-retaining valve

The heat-retaining valve (2) type RA-N 10 is factory-set to N, fully open valve. The valve is preset to 3.5.

The setting zone of the sensor element (TV) type RA is factory-set to a min. of 1.5 to ensure a minimum heating surface

temperature of approx. 14°C, provided that hot water is available.

Frost-resistance

• The heat supply or water flow must never be interrupted/shut off in frosty weather

conditions, e.g. on weekends and during holiday periods.

• The flow temperature must never drop below 40 °°°°C in frosty weather conditions.

3.5 Connecting the electric heating surface

The unit comes complete with electric heating surface and safety thermostats internally installed and wired.

Note the greater current collection with electric heating surfaces (see the electrical installation section).

Safety functionalities of electric heating surface

The electric heating surface is protected against overheating in accordance with DS 447 thanks to two safety thermostats

that disconnect the heating surface in case of overheating.

• One thermostat cuts out the heating surface at 70 °C and has an automatic reset

• The other thermostat cuts out the heating surface at 120 °C and has a manual reset

Furthermore, the unit is fitted with air volume monitoring

• which at air speeds of less than 0.3 m/s cuts out the heating surface and automatically re-connects it again when the air

speed is greater than 0.3 m/s.

4. Electrical installation

The electrical installation must be performed by an authorised electrician.

Fuse and supply separators must be mounted as regulated in the

permanent installation for the unit.

Fuse and supply separator are not delivered by Airmaster.

Electrical installation includes:

• Connection of conventional power

• Connection of display panel

• Connection of any other accessories, such as CO2 sensor, PIR sensor or CTS connection

4.1 Connecting the power

Connect the power according to the electrical diagram 23. Size the power cable according to applicable rules and

regulations, taking into account existing conditions at the installation site.

Mount the power cable in the terminal block on the right side of the unit (pos. 21) and connect terminals L, N and rack (see

item 14 in mounting unit on wall frame).

Note that the control panel and any other signalling devices must be installed before the power is switched on.

AM II 300

Without heating surface /

with heating surface

Electric heating surface

Elec. power supply: 1 ~ 230 V + N + PE / 50 Hz 1 ~ 230 V + N + PE / 50 Hz

Output: 78 W 1500 W

Full-load power: 0.6 A 6.5 A

* Connecting terminals: 0.75 mm2 0.75 mm2

Max. fuse: 20 A 20 A

CODUME Page 16

Leakage power: <= 3.O mA

Operation of spring terminal with screwdriver:

1. Open terminal by pressing on the spring.

2. Insert conductor

3. Remove the pressure on the spring.

4.2 Connecting the display panel

The delivery includes a separate display panel, with 3 m cable internally wired to the control box (pos. 23, see page 5

and 6). Connect the display panel according to the electrical diagram, page 23. Mount the connecting cable via the

cable lead-through on the right side of the unit (pos. 21, see page 5 and 6).

Mount the display panel at a suitable height on the wall in the same room as the ventilation unit, and so that it can also

be pulled out to adjoining rooms. The maximum cable length is 30 m.

The connecting cable for the display panel is a 2x2 conductor, twisted-pair

screened cable which must be connected properly according to the following

instructions:

1. Sheath and screen foil are stripped as close to the connecting terminals

as possible for the sake of EMC noise (see photo on left).

2. Be careful removing the conductors’ insulation, so as not to damage or

break them.

3. Maintain the paired twisting of the conductors to the terminals.

4. Terminate the screen at the main box, as shown in section 4.6

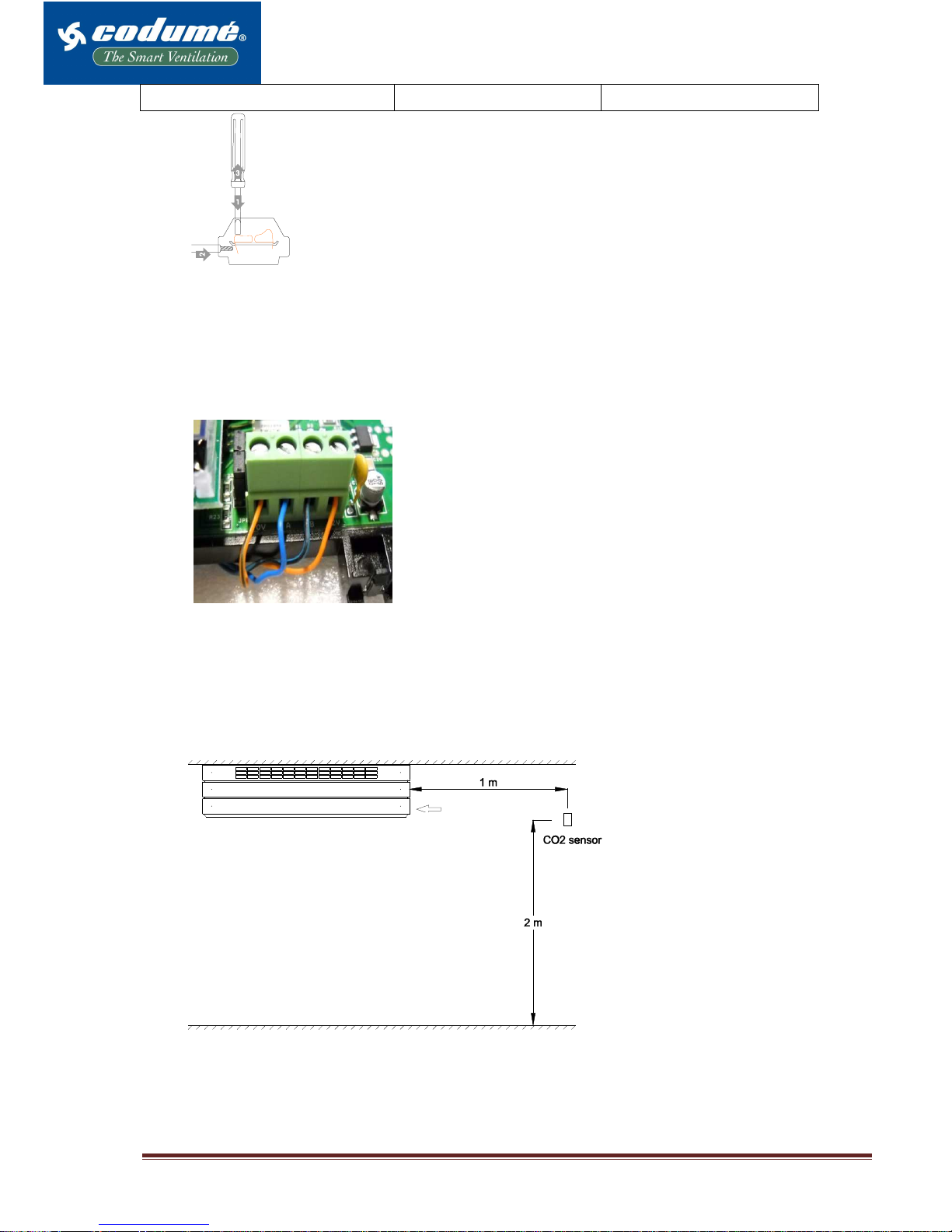

4.3 Connecting a CO2 sensor (optional)

Connection of CO2 sensor and transformer is done in accordance with the electrical diagram section, 5.5.

The CO2 sensor comes pre-programmed for use with the X-Vent II series. If you prefer a different configuration, please

contact Airmaster A/S. For configuration of the control, see the manual X-Vent Controller – function and menu

overview.

Terminate the screen at the main box, as shown in section 4.6

Recommended location of the X-Vent

CO2 sensor:

• Approx. 1 m from the unit’s

exhaust opening

• Approx. 2 m above floor level

• REMEMBER to keep a distance to

open windows and doors.

4.4 Connecting a PIR sensor (optional)

Connect (PIR) type ”Scantronic 420” movement sensors to the control box as instructed in the electrical diagram, page

23. On installation, refer to the instructions accompanying the PIR sensor (Sensor of movement). For configuration of

the control, see the guide X-Vent Controller – functionalities and menu overview.

Extract

CODUME Page 17

Terminate the screen at the main box, as shown in section 4.6

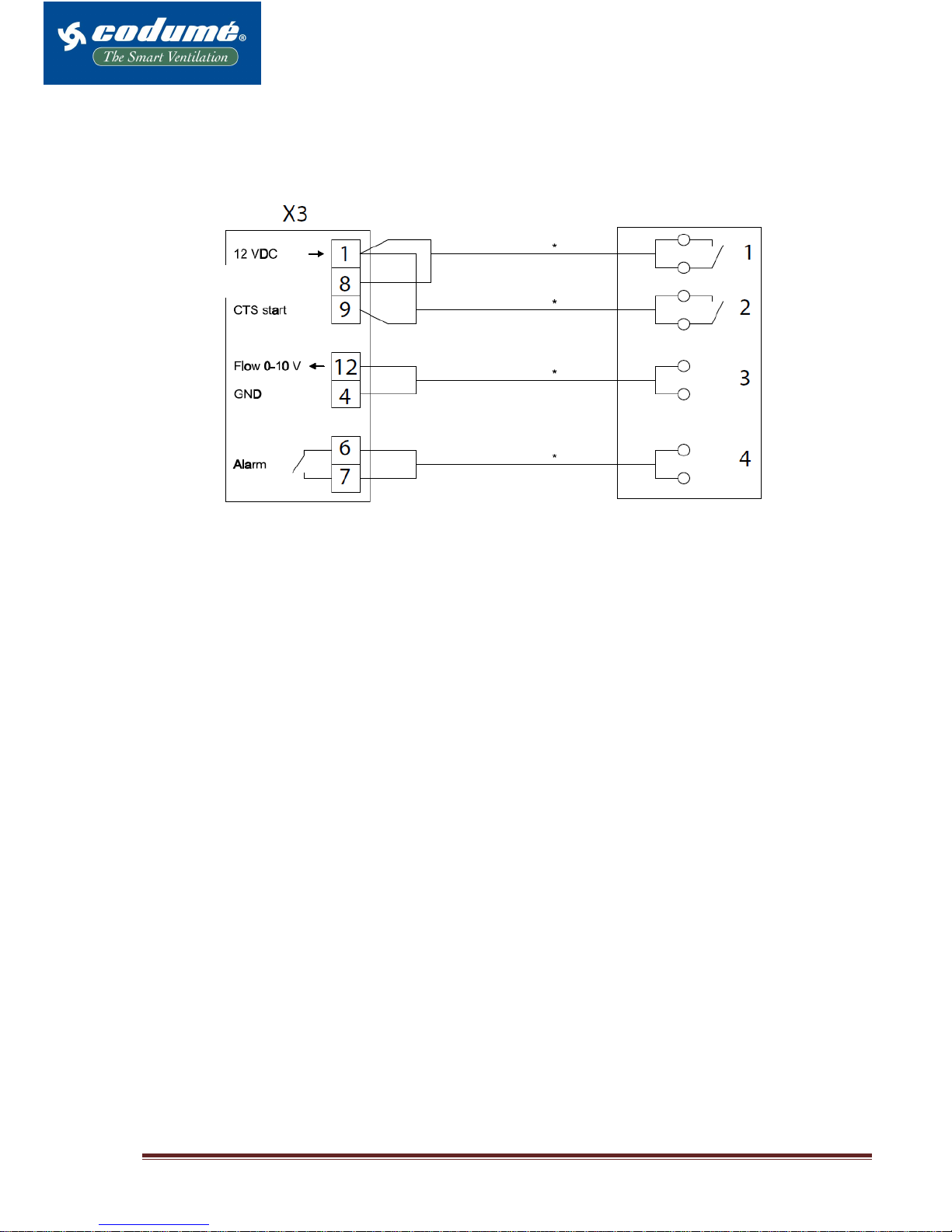

4.5 External connections

Make external connections as shown in the following diagram.

Terminate the screen as shown in section 4.6

4.6 Screen termination

Manual start

CODUME Page 18

Terminal block

X3

Display

connection

Bend screen and place under

clamps, then tighten screws.

Note: The screen is not

terminated at the display and

external sensors.

CODUME Page 19

5. Appendix

5.1 Main dimensions X-Vent II 300 WALL MODEL

a

g g

b

e

i

k

n

h

p

q

m

l

o

A

B

C

E

D

1

2

3

4

B

E

C

D

5

6

r

A

a b c d e f g h i k l m n o p q r s t u

AM II 300 1274 578 - - 327 - 200 130 157,5 897 324 152 6 20 36 35 45 - - -

A = Bottom

B = Inlet side

C = Left side

D = Right side

E = Back side

1 = Exhaust

2 = Intake

3 = Inlet

4 = Extract

5 = Wall frame

6 = Center holes

CODUME Page 20

5.2 Main dimensions X-Vent II 300 WALL MODEL partially integrated

b

A

B

E

d

B

3

C

D

e

C

D

o

i

k

p

q

E

4

5

6

g g

a

c

f

m

l

h

n

r

A

a b c d e f g h i k l m n o p q r s t u

AM II 300 1274 578 1244 214 327 564 200 130 157,5 897 324 152 6 20 36 35 45 - - -

1 = Exhaust

2 = Intake

3 = Inlet

4 = Extract

5 = Wall frame

6 = Centre holes

A = Bottom

B = Inlet side

C = Left side

D = Right side

E = Back side

CODUME Page 21

5.3 Main dimensions X-Vent II 300 WALL MODEL combi 3

A

B

C

E

D

1

2

3

4

B

E

C

D

5

6

a

g g

b

A

e

h

s

n

m

l

o

r

i

k

p

q

u

t

s

a b c d e f g h i k l m n o p q r s t u

AM II 300 1274 578 - - 327 - 200 130 157,5 897 324 152 6 20 36 35 45 125 210 547

1 = Exhaust

2 = Intake

3 = Inlet

4 = Extract

5 = Wall frame

6 = Centre holes

A = Bottom

B = Inlet side

C = Left side

D = Right side

E = Back side

CODUME Page 22

5.4 Main dimensions X-Vent II 300 ROOF MODEL partially integrated

a

b

k

h

d

f

i

n

m

l

g g

c

A

B

C

E

D

1

2

3

4

B

E

C

D

e

5

6

p

q

o

r

A

a b c d e f g h i k l m n o p q r s t u

AM II 300 1274 578 1244 214 327 564 200 217 157,5 897 324 152 6 20 36 35 45 - - -

1 = Exhaust

2 = Intake

3 = Inlet

4 = Extract

5 = Wall frame

6 = Center holes

A = Bottom

B = Inlet side

C = Left side

D = Right side

E = Back side

CODUME Page 23

5.5 Electrical diagram

PE

L

N

PE

P1

L

N

AC

A2

(*1)

X3-14

(*2)

S2

X3-1

X3-4

X3-2

X3-3

GND

12V

0V

B

A

X3-13

A1

B1

(*1)

1

2

7

8

X3-5

X3-11

X3-4

X3-12

GND

B2

(*1)

12V+

12V-

NC

NC

X3-1

X3-4

X3-10

GND

Manuel start

(*1)

1

2

X3-1

X3-8

CTS start

(*1)

X3-1

X3-9

X3-12

X3-4

CTS flow

(*1)

Alarm

(*1)

0-10V

GND

X3-6

X3-7

< 24V/100mA/2VA

S1

X3-1

12V (DC)

X3-2 -RS485(B)

X3-3 +RS485(A)

X3-4 GND (DC)

X3-5 24 VAC+ (*1)

X3-6 Alarm output terminal 1

X3-7 Alarm output terminal 2

X3-8 Manuel start input

X3-9 CTS start input

X3-10 PIR signal input

X3-11 24 VAC- (*1)

X3-12 0-10V signal input

X3-13 Condensed terminal 1

X3-14 Condensed terminal 2

(*1)

Option

(*2) Jumper has to be removed if A2 is mounted

A1 Ventilation unit

A2 Cooling unit

B1 CO2 sensor (*1)

B2 PIR sensor (*1)

P1 Display panel or LON module

S1 Alarm switch

S2 Condensed float switch

Manuel start (*1) See section ”4.3.5 External connections”

CTS start (*1) See section “4.3.5 External connections”

CTS flow (*1) See section ”4.3.5 External connections”

Alarm (*1) See section ”4.3.5 External connections”

CODUME Page 24

5.6 Capacity data

Operation/Capacity at 35 dbA

Operation/Capacity at 30 dbA

CODUME Page 25

CODUME Page 26

5.7 On-site testing of air volumes

CODUME Page 27

Test of air volumes are made with help from a differential pressure – manometer and can be read in the following

diagrams.

Placement of the pressure connecting piece:

Inlet air: Right side at the back.

Exhaust air: Left side at the back.

Air volume measured on pressure taps.

WALL MODEL

ROOF MODEL

5.9 EU declaration of conformity

Inlet air

Exhaust air

Inlet air

Exhaust air

CODUME Page 28

Product X-Vent II 300

Is compliant with the following directives:

Directives The Machinery Directive 2006/42/EC

The Low Voltage Directive (2006/95/EC)

The EMC Directive (2004/108/EU)

CODUME sa.

www.codume.eu

info@codume.eu

Tel : +32 2 511 20 10

Fax : +32 2 511 23 59

Loading...

Loading...