Page 1

INSTALLATION

& OPERATION

MANUAL

SERIES 87/88/89

STROBE AND HALOGEN

PERIMETER

LIGHT HEADS

SERIES 87/88/89

IMPORTANT:

STROBE AND HALOGEN

PERIMETER LIGHT HEADS

Contents:

Introduction ................................................................... 2

Unpacking & Pre-Installation ............................................. 2

Installation ................................................................... 3-5

Parts & Exploded View ...................................................5-6

Maintenance ................................................................6-7

Options ......................................................................... 7

Warranty ....................................................................... 8

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

Page 2

Introduction

The 87/88/89 Series Perimeter Light Heads are designed for the emergency vehicle market. The light heads are

to be connected to the Code 3® 475, 460, 235, or 440 Strobe Power Supplies (Strobe Model 87), or +12 VDC

output electromechanical or solid state flasher units (Halogen Models 88, 89), by the optional cable assemblies.

These light heads with unique faceted shape are designed for optimum lighting at all angles. The Strobe Model 87

meets and exceeds the SAE J1318 and California Title XIII output requirements for directional gaseous discharge

lamps. The Halogen Model 88 exceeds the requirements of KKK-A-1822E when used with the Transverse filament lamp assembly, S95285.

Consisting of a lens, lamp assembly, reflector assembly, optional bezel and mounting fasteners the Series 87, 88

and 89 Light Heads are easy to install. The design allows for interchangeability between virtually all 9"X7 " Series

Light Heads giving the user freedom to customize the vehicle’s lighting system.

The use of this or any warning device does not insure that all drivers can or will observe or react

to an emergency warning signal. Never take the right-of-way for granted. It is your responsibility

to be sure you can proceed safely before entering an intersection, driving against traffic,

responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and wiring.

!

WARNING!

Read and follow the manufacturer’s instructions before installing or using this device. The

vehicle operator should insure daily that all features of the device operate correctly. In use, the

vehicle operator should insure the projection of the warning signal is not blocked by vehicle

components (i.e.: open trunks or compartment doors), people, vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility

to understand and obey all laws regarding emergency warning devices. The user should check

all applicable city, state and federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of this

warning device.

Proper installation is vital to the performance of this warning device and the safe operation of

the emergency vehicle. It is important to recognize that the operator of the emergency vehicle

is under psychological and physiological stress caused by the emergency situation. The

warning device should be installed in such a manner as to: A) Not reduce the output

performance of the system, B) Place the controls within convenient reach of the operator so

that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly

protect and use caution around live electrical connections. Grounding or shorting of electrical

connections can cause high current arcing, which can cause personal injury and/or severe

vehicle damage, including fire. Do not touch the strobe light tubes, the strobe light head

assemblies or the strobe power supply while the system is in operation. Wait 10 minutes after

turning off the power from system before touching any internal components. Always wear hand

and eye protection when handling strobe tubes or halogen lamps. The lamps are pressurized

and if broken, could result in injury from flying glass.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE

OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF

EMERGENCY PERSONNEL AND THE PUBLIC.

Unpacking And Pre-Installation

Carefully remove the light head from its protective packaging. Inspect the unit for transit damage (broken lamp

assembly, etc). Report any damage to the carrier and keep the shipping carton. Verify that four #6 x 1-1/2” screws

per lighthead are included. (If the bezel option was ordered a total of eight #6 x 1-1/2" screws should be included).

The optional three wire cable comes in a 15, 20 or 25 foot length. Both ends have Amp #60619-1 sockets attached

to each wire. The cable comes with a parts bag consisting of 2 AMP #1-480303-0 Mate-N-Lock socket housings

and 1 #8 noninsulated ring terminal. Verify that these items are also included.

2

Page 3

Installation

!

WARNING!

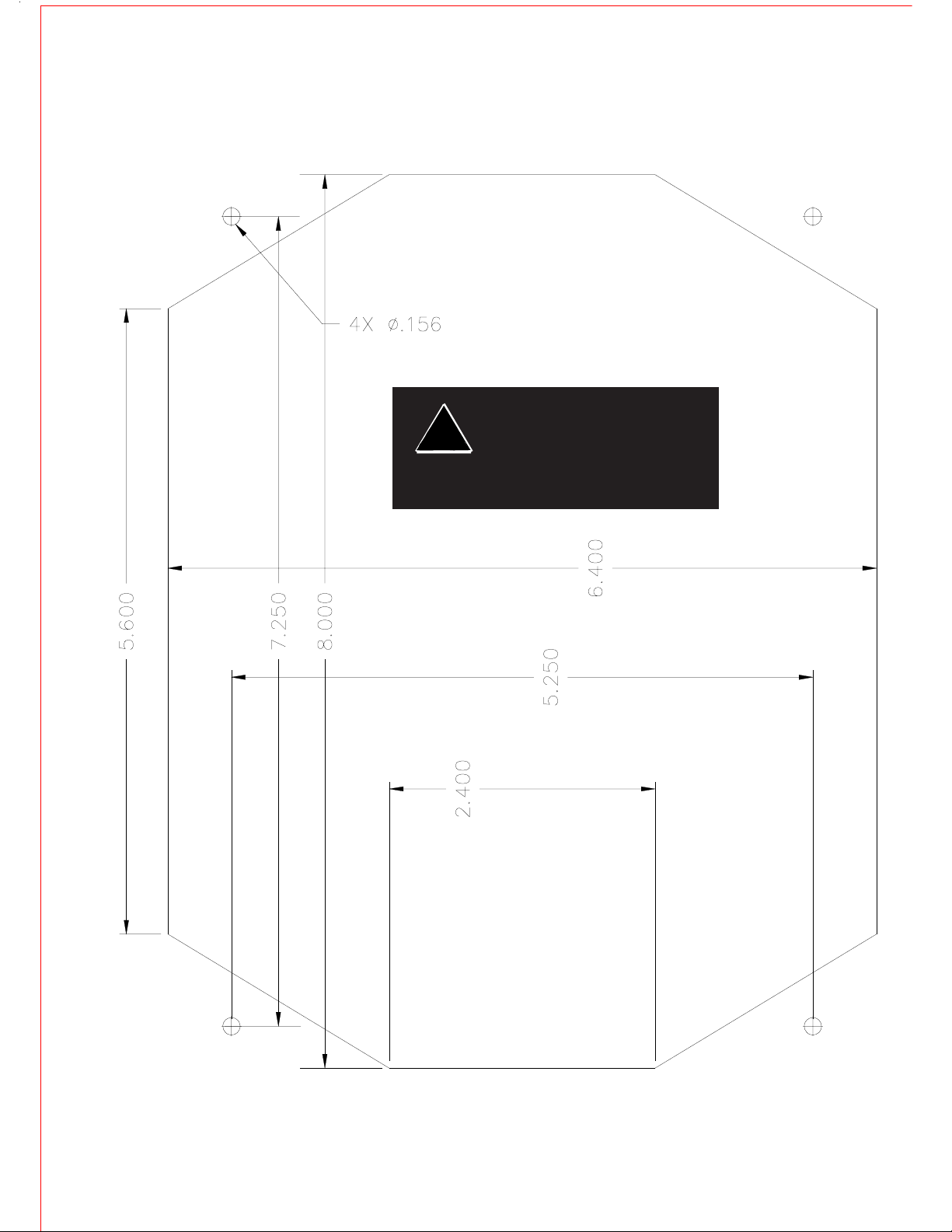

This is a full size template.

Do not use a facsimile or

copied reproduction. Do

not use this template if the

largest dimension in each

direction is not within +/-.010.

FIGURE 1

3

Page 4

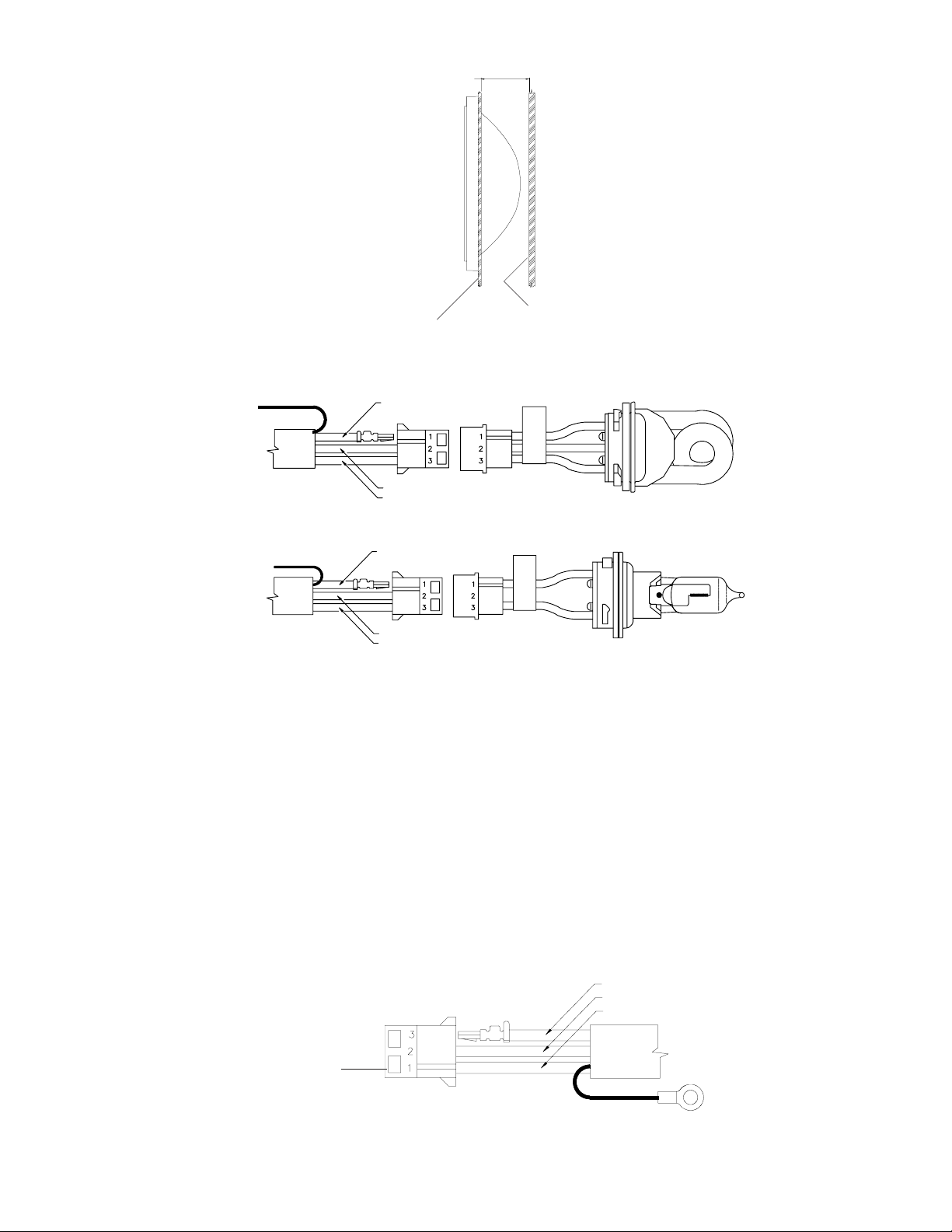

2.000 MINIMUM

EXTERIOR WALL OF VEHICLE

SHIELD WIRE

(CUT FLUSH)

SHIELD WIRE

(CUT FLUSH)

RED WIRE - +12/24 VDC

FIGURE 2

RED WIRE - HIGH VOLTAGE

BLACK WIRE - GROUND (EARTH)

WHITE WIRE - TRIGGER

BLACK WIRE - (NOT USED)

WHITE WIRE - GROUND(EARTH)

INTERIOR WALL OF VEHICLE OR

NEAREST OBSTACLE DIRECTLY BEHIND

LIGHT HEAD

FIGURE 3

1. Select the desired mounting location for the light head assembly.

2. Verify 2 inches minimum free clearance behind the mounting surface, see Figure 2.

3. Cut the opening and drill the holes, use Figure 1 template or the trim bezel if your light head is so equipped.

4. With one end of the cable at the light head mounting location, route the three wire cable to the Power

Supply.

5. At the light head end of the cable, insert the 3 AMP sockets into the AMP socket housing as shown in Figure

3. Cut the shield wire flush with the jacket. (Halogen Lamp Assemblies are shown. Procedure is the same

for Strobe Lamp Assembly.)

6. Allow 3 inches minimum slack at the light head to facilitate lamp assembly replacement. Secure the cable.

7. At the power source end of the cable determine if the cable length is acceptable. If a shorter length is

required, coil the cable and tie with an electrical tie.

8. Insert the 3 AMP sockets into the AMP socket housing as shown in Figure 4.

9. Crimp the #8 ring terminal to the shield wire and attach to nearest grounded structure.

THIS END TO POWER

SUPPLY

FIGURE 4

4

WHITE WIRE - TRIGGER

BLACK WIRE - GROUND (EARTH)

RED WIRE - HIGH VOLTAGE

(STROBE)

12/24 VDC (HALOGEN)

SHIELD WIRE (Not used on

Model 88.)

Page 5

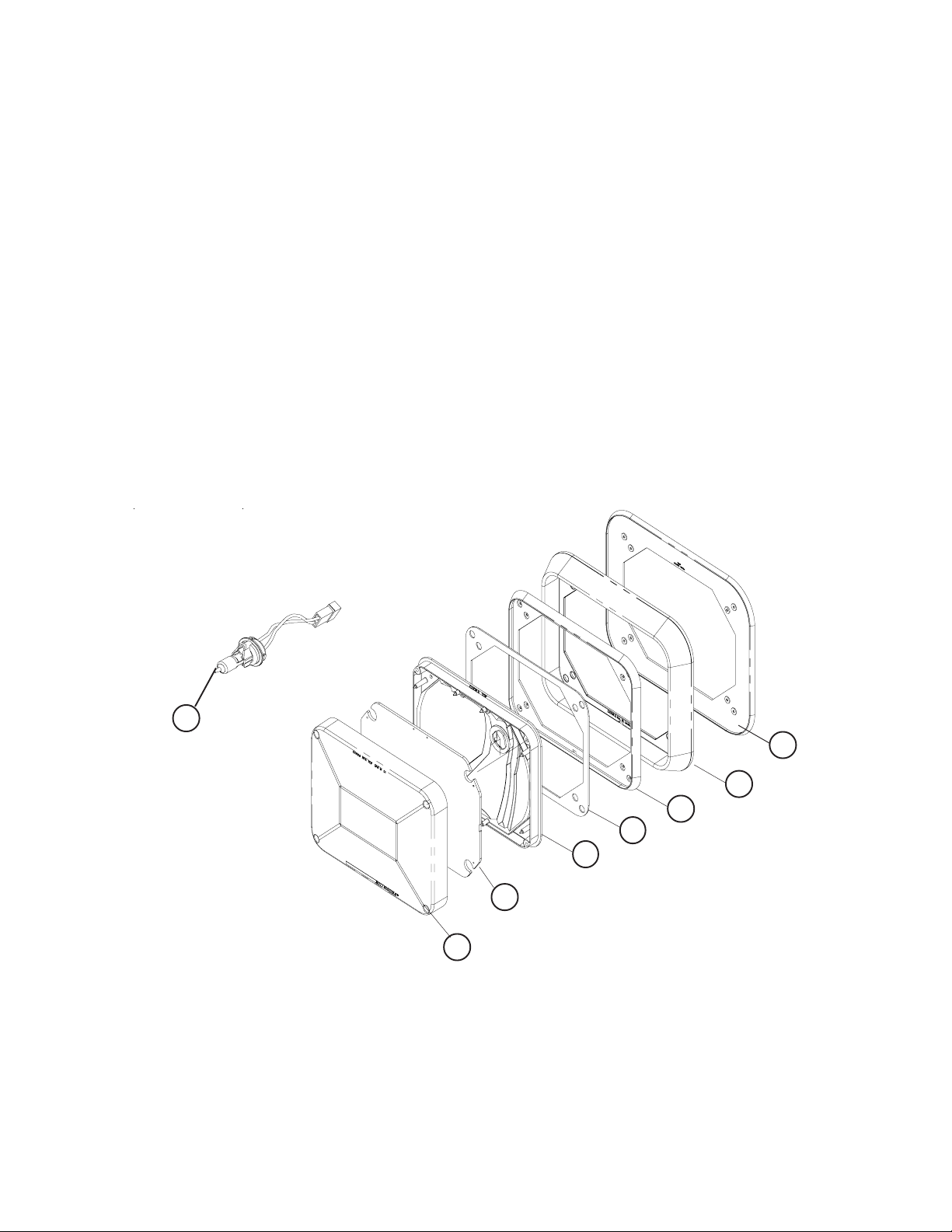

For 87, 88 or 89 series models with optional bezel see instructions below otherwise continue

10. Test the lamp assembly (strobe or halogen) tube by connecting the reflector assembly to the cable and the

cable to the power source per the instructions with the power source.

11. Push the assembled AMP Mate-N-Lock connectors through the cut out in the vehicle.

12. Verify the "TOP" lens engraving is on the top. Mount the reflector and lens by installing the four screws.

For 87, 88, or 89 series models with optional bezel

10. Remove the backing from the T07940 Bezel/Reflector gasket and apply it to the back of the reflector

11. Snap the reflector into the bezel making sure the reflector’s “TOP” aligns with the bezel’s top. When using

the molded bezel gasket, make sure that the gasket is properly aligned with the back of the bezel. Failure

to properly align gasket could result in a poor seal between the bezel and the mounting surface.

12. Test the lamp assembly by connecting the reflector assembly to the cable and the cable to the power

source per the instructions with the power supply.

13. Push the assembled AMP Mate-N-Lock connectors through the cut out in the vehicle.

14. Verify the orientation of the reflector. Mount the bezel and reflector by installing four of the screws supplied.

See Figure 5 for bezel/reflector screw location.

15. Verify “TOP” lens engraving is on the top of the lens. Attach the lens to the unit with the other four screws.

Note: screw should pull the lens tight when screwed into the vehicle.

Parts & Exploded Views

5

9

6

4

10

3

2

1

FIGURE 5

5

Page 6

Parts List

Ref No. Description Part No.

1 Lens

T07914 (Clear)

T07911 (Red)

T07913 (Blue)

T07912 (Amber)

2 Scene Light Filter T02211 (8 deg-12 deg

optics)

T02212 (15 deg-26 deg

optics)

2 Filter Half T02260 (Green)

3 Reflector T04598 (Models 8788)

4 Reflector Gasket T07921

5 Lamp Assembly (Strobe) T07008

(Halogen) S82110 (12v 50w red dot)

6 Trim Bezel T07918

7 #10 Parts Bag T07928

8 Wiper Gasket (Not Shown) T02932

9 Bezel Gasket T07924

10 Bezel/Reflector Gasket T07940

T02262 (Red)

T02263 (Blue)

T02264 (Amber)

T02265 (Din Blue)

T07856 (Model 89)

S95285 (12v 65w

Transverse black dotFor KKK-A-1822E Model 89

only)

S85347 (24v 50w upgrade

puple dot)

S82120 (12v 35w blue dot)

Maintenance

Lamp Assembly Replacement

High voltages and /or temperatures are present inside the unit. Disconnect from power and

wait 10 minutes prior to servicing or troubleshooting. Use hand and eye protection when

!

WARNING!

1. Turn off power to the power supply and allow the lamp assembly to cool for 10 minutes.

2. Remove the lens by unscrewing the four mounting screws. (When equipped with a bezel it is not necessary

to remove the bezel/reflector from the vehicle)

3. Carefully grab the base of the lamp assembly and twist counterclockwise 1/8 turn. Pull straight out. (When

equipped with a bezel or the reflector is mounted separately carefully pull the connected AMP Mate-N-Lock

connectors through the socket hole. If the Mate-N-Lock connectors either disconnect or will not pull through

the socket hole, unscrew the remaining four screws and remove the bezel/reflector from the vehicle.)

changing halogen lamps or flashtubes as they are pressurized and accidental breakage can

result in flying glass. Lamps are extremely hot! Allow to cool completely before attempting to

remove. Gloves and eye protection should be worn handling halogen lamps or flashtubes as

they are pressurized and accidental breakage can result in flying glass.

6

Page 7

4. Disconnect the lamp assembly from the cable.

5. Insert the replacement lamp assembly into the reflector. Twist clockwise 1/8 turn until you feel the locking

features of the socket engage.

6. Test the lamp by connecting the lamp assembly to the cable. Switch the power supply on. After verifying the

tube is good, turn off the power supply.

7. Push the assembled AMP Mate-N-Lock connectors through the cut out in the vehicle for the reflector.

8. Verify the "TOP" reflector engraving is on the top of the reflector. Verify “TOP” lens engraving is on the top

of the lens. Mount the reflector and lens by installing the four screws.

Lens Cleaning

1. Remove the lens by unscrewing the four mounting screws. (When equipped with a bezel it is not necessary

to remove the bezel/reflector from the vehicle).

2. Using plain water and a soft cloth, or Code 3 lens polish and a very soft paper towel or facial tissue clean

both surfaces of the lens.

3. Because plastic scratches easily, cleaning is recommended only when necessary (about every six months).

4. Do not subject the lenses to car washes that use brushes, as these will scratch the lenses.

!

If attempting to clean the reflector, use only a mild glass cleaner and a very soft cloth. Do not

attempt to use any wax type products as these will burn onto the reflector and impair

effectiveness.

WARNING!

Options

The 87/88/89 Series Strobe and Halogen Perimeter Lighting Product Group includes the following models:

Single Products

Strobe

87 Strobe tube assembly, reflector and lens choice of four lens colors: amber, blue, clear, and red. Clear

lens can be specified with optional inserted half lenses. Available in amber, blue, din blue, green and red.

87BZ Strobe tube assembly, bezel, reflector and lens choice of four lens colors: amber, blue, clear, and red.

Clear lens can be specified with optional inserted half lenses. Available in amber, blue, din blue, green

and red.

NFPA

88 Halogen lamp assembly, reflector and lens choice of four lens colors: amber, blue, clear, and red. Clear

lens can be specified with optional inserted half lenses. Available in amber, blue, green and red.

88BZ Halogen lamp assembly, bezel, reflector and lens choice of four lens colors: amber, blue, clear, and red.

Clear lens can be specified with optional inserted half lenses. Available in amber, blue, din blue, green

and red.

7

Page 8

Scene Lighting

88-08 Halogen lamp assembly, reflector and clear lens with an eight degree scene light filter.

88-12 Halogen lamp assembly, reflector and clear lens with a twelve degree scene light filter.

88-15 Halogen lamp assembly, reflector and clear lens with a fifteen degree scene light filter.

88-26 Halogen lamp assembly, reflector and clear lens with a twenty-six degree scene light filter.

88Z08 Halgon lamp assembly, reflector, bezel and clear lens with an eight degree scene light filter.

88Z12 Halogen lamp assembly, reflector, bezel and clear lens with a twelve degree scene light filter.

88Z15 Halogen lamp assembly, reflector, bezel and clear lens with a twelve degree scene light filter.

88Z26 Halogen lamp assembly, reflector, bezel and clear lens with a twenty-six degree scene light filter.

KKK-A-1822E

89 Halogen lamp assembly (S82140, 50W Transverse), reflector and lens choice of three lens colors:

amber, clear and red.

89BZ Halogen lamp assembly (S82140, 50W Transverse), bezel, reflector and lens choice of three lens

colors: amber, clear and red.

Case Products

87K Case of ten model 87 Strobe light heads, all of the same color

87BZK Case of ten model 87 Strobe light heads with bezels, all of the same color

88K Case of ten model 88 halogen light heads, all of the same color.

88BZK Case of ten model 88 halogen light heads with bezels, all of the same color.

88-08K Case of ten model 88-08 halogen scene light modules.

88-12K Case of ten model 88-12 halogen scene light modules.

88-15K Case of ten 88-15 halogen scene light modules.

88-26K Case of ten 88-26 halogen scene light modules.

88Z08K Case of ten 88Z08 halogen scene light modules with bezel.

88Z12K Case of ten model 88Z12 halogen scene light modules with bezel.

89K Case of ten model 89 KKK-A-1822E halogen light heads, all of the same color.

89BZK Case of ten model 89 KKK-A-1822E halogen light heads with bezels, all of the same color.

8

Page 9

NOTES

9

Page 10

NOTES

10

Page 11

NOTES

11

Page 12

WARRANTY

This product was tested and found to be operational at the time of manufacture. Provided

this product is installed and operated in accordance with the manufacturer's recommendations,

Code 3, Inc. guarantees all strobe reflector assemblies and all other parts and components for

a period of 1 year from the date of purchase or delivery, whichever is later. Units demonstrated

to be defective within the warranty period will be repaired or replaced at the factory service center

at no cost.

Use of a lamp or other electrical load of a wattage higher than installed or recommended

by the factory, or use of inappropriate or inadequate wiring or circuit protection causes this

warranty to become void. Failure or destruction of the product resulting from abuse or unusual

use and/or accidents is not covered by this warranty. Use of non-Code 3 components and

assemblies may cause damage to the system and/or personal injury, and voids all warranties.

Code 3, Inc. shall in no way be liable for other damages including consequential, indirect

or special damages whether loss is due to negligence or breach of warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY,

WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

In order to provide you with faster service, if you are going to return a product for repair

or replacement*, please contact our factory to obtain a Return Goods Authorization Number

(RGA number) before you ship the product to Code 3. Write the RGA number clearly on the

package near the mailing label. Be sure you use sufficient packing materials to avoid

damage to the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace product at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses

incurred for the removal and/or reinstallation of products requiring service and/or repair.

NEED HELP? Call our Technical Assistance Hotline - (314) 996-2800

St. Louis, Missouri 63114-2029—USA

10986 N. Warson Road

www.code3pse.com

Code 3, Inc.

Code 3 is a registered trademark of Code 3, Inc. a subsidiary of Public Safety Equipment, Inc.

Revision 1, 02/2006 - Instruction Book Part No. T07941

©2002-6 Code 3, Inc. Printed in USA

Loading...

Loading...