Codan Radio MT-4E User Manual

MT-4E Analog and

P25 Digital

Radio Systems

MAINTENANCE GUIDE

www.codanradio.com

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

Codan MT-4E

Analog and

P25 Digital

Radio Systems

Maintenance Guide

Page i

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

NOTE

DOCUMENT REVISION

DEFINITION

Document Number:

Revision:

Revision Date:

© 2013 Codan Limited.

No part of this guide may be reproduced, transcribed, translated into any language or transmitted in any form whatsoever without the prior written consent of Codan Limited.

CODAN™, NGT™, Easitalk™, CIB™ and CALM™ are trademarks of Codan Limited. Other brand, product, and company names mentioned in this document are trademarks or registered trademarks of their respective holders.

The English version takes precedence over any translated versions.

Documentation uses a three-level revision system. Each element of the revision number signifies the scope of change as described in the diagram below.

1

1 -

- 0

0 -

- 0

0

Major Revisions: The result of a major change to product function, process or requirements.

Minor Revisions: The result of a minor change to product, process or requirements.

Editorial Revisions:

The result of typing corrections or changes in formatting, grammar or wording.

Three-level revision numbers start at 1-0-0 for the first release. The appropriate element of the revision number is incremented by 1 for each subsequent revision, causing any digits to the right to be reset to 0.

For example:

If the current revision = 2-1-1 Then the next major revision = 3-0-0

If the current revision = 4-3-1 Then the next minor revision = 4-4-0

If the current revision = 3-2-2 Then the next editorial revision = 3-2-3

Document revision history is provided at the back of the document.

Codan Radio Communications

43 Erie Street, Victoria, BC

Canada V8V 1P8 www.codanradio.com

LMRsales@codanradio.com

Toll Free Canada and USA:

Phone: 1-800-664-4066

Fax: 1-877-750-0004

International:

Phone: 250-382-8268

Fax: 250-382-6139

PRINTED IN CANADA

MG-001 6-0-0

September 2013

Page ii

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

On August 7th, 2012 - Codan Limited (ASX: “CDA”) announced the acquisition of Daniels Electronics Limited, a leading designer, manufacturer and supplier of land mobile radio communications (LMR) solutions in North America. The acquisition of Daniels delivers on Codan’s stated strategy of growing market share and diversifying its radio communications product offering. Codan Limited designs, manufactures and markets a diversified range of high value added electronic products, with three key business divisions; radio communications, metal detection and mining technology.

Codan Radio Communications is a leading international designer and manufacturer of premium communications equipment for High Frequency (HF) and Land Mobile Radio (LMR) applications. We’ve built our reputation for reliability and customer satisfaction over 50 years in radio communications, in some of the toughest conditions on the planet.

For over 50 years Codan has provided customers in North America and internationally with highly reliable Base Stations and Repeaters that are environmentally robust to operate in rugged and extreme temperature conditions where low current consumption (solar powered) is a key requirement.

Codan is a pioneering member of the P25 Digital standard, for radio system interoperability between emergency response governmental organizations, providing enhanced functionality and encryption. Our products operate between 29 - 960 MHz and are available in a variety of Base Station and Repeater configurations for two way voice and mobile data applications.

Our self-servicing customers range from Forestry and National Park services through Police and Fire departments and on to Utility and Transportation groups. Our products have been deployed in every imaginable situation from the Antarctic to Hawaiian mountaintops to Alaska, enabling respondents to Forest Fires, Ground Zero rescue and routine patrols.

Codan is an industry leader in Analog and P25 radio systems design. We offer modular rack-mounted Base Stations and Repeaters capable of operating in Low Band VHF,VHF AM , VHF FM, UHF FM, 700 MHz, 800 MHz, 900 MHz

DANIELS ELECTRONICS IS NOW CODAN RADIO

COMMUNICATIONS

ABOUT CODAN RADIO

COMMUNICATIONS

Page iii

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

RESOURCES |

|

Codan Radio Communications provides many resources for the |

|

|

testing, tuning, maintenance and design of your Codan MT-4E |

|

|

Analog and P25 Digital Radio System. |

|

|

|

|

|

Instruction Manuals |

|

|

Codan instruction manuals are very comprehensive and include |

|

|

information on: |

|

|

Theory of operation |

|

|

Detailed Specifications |

|

|

Testing and tuning instructions |

|

|

Component layout illustrations |

|

|

Instruction manuals can be obtained from the factory. |

|

|

|

|

|

Technical Notes |

|

|

Technical notes outline key aspects of tuning, installing, |

|

|

maintaining and servicing Codan Radio Systems. |

|

|

Technical Notes can be found online at www.codanradio.com. |

|

|

|

|

|

Codan MT-4R/D and IFR 2975 Test Procedures (TN950) |

|

|

Technical Note TN950 is an aid to configuring and testing Codan |

|

|

MT-4R/D radios using an IFR 2975 Service Monitor by Aeroflex. |

|

|

TN950 is intended to be used with IFR 2975 Setup files that can be |

|

|

loaded into the Service Monitor. |

|

|

TN950 and Setup Files can be found online at www.codanradio.com |

|

|

and can also be found on the Aeroflex web page at www.p25.com. |

|

|

|

|

|

Application Notes |

|

|

Application Notes provide an overview of the range of applications |

|

|

in which Codan Radio systems can be used. |

|

|

Application Notes can be found online at www.codanradio.com. |

|

|

|

|

|

P25 Training Guide |

|

|

The P25 Training Guide provides the reader with a simple, concise |

|

|

and informative description of Project 25. |

|

|

The P25 Training Guide can be found online at |

|

|

www.codanradio.com. |

|

|

|

|

|

MT-4E Analog and P25 Digital Radio Systems User Guide |

|

|

The MT-4E User Guide provides an overview of the configuration, |

|

|

operation and programming of Codan MT-4E radios. |

|

|

The MT-4E User Guide can be found online at www.codanradio.com. |

|

|

|

Page iv

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

Contents |

|

Chapter 1: Codan Radio Maintenance................................... |

1 |

Introduction to Codan MT-4E ..................................................................... |

1 |

Recommended Maintenance Schedule ..................................................... |

2 |

Repair Note................................................................................................ |

2 |

ESD - Electrostatic Discharge.................................................................... |

2 |

Audio and Carrier Levels Reference.......................................................... |

3 |

Audio Levels ................................................................................................... |

3 |

Carrier Levels ................................................................................................. |

3 |

Chapter 2: Installation ............................................................ |

5 |

Installation of Codan Subracks .................................................................. |

5 |

Chapter 3: Test Equipment and Spares ................................. |

9 |

Recommended Test Equipment................................................................. |

9 |

Recommended Spares ............................................................................ |

10 |

Recommended Maintenance Items ......................................................... |

11 |

Chapter 4: Radio Site Survey .............................................. |

13 |

Introduction to a Radio Site Survey ......................................................... |

13 |

Codan Radio Site Checklist and Inventory .................................................... |

13 |

Preparation for a Site Survey................................................................... |

14 |

Exterior Site Survey ................................................................................. |

15 |

Interior Site Survey .................................................................................. |

15 |

Radio Site Inventory................................................................................. |

15 |

Radio System Testing .............................................................................. |

16 |

Departure Checklist ................................................................................. |

16 |

Page v

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

Chapter 5: Codan Radio System Testing............................. |

17 |

MT-4E Testing with the IFR 2975 by Aeroflex .......................................... |

17 |

General Set-Up and Connections ............................................................ |

18 |

Uploading Codan Configurations to the IFR 2975......................................... |

18 |

Radio Service Software (RSS) ...................................................................... |

19 |

Control Cards ................................................................................................ |

19 |

Adapters, Cables and Extender Cards .......................................................... |

19 |

Codan MT-4E Radio System Test Sheet ....................................................... |

19 |

Turning OFF the MT-4E Receiver and Transmitter Modules ......................... |

20 |

Audio Connections ........................................................................................ |

21 |

System Regulator Testing ........................................................................ |

22 |

System Voltage Testing ................................................................................. |

22 |

Receiver Testing....................................................................................... |

23 |

Receiver Analog Testing ................................................................................ |

23 |

Receiver Digital Testing ................................................................................. |

28 |

Receiver Bit Error Rate Testing ..................................................................... |

30 |

Receiver RF Preselector Alignment and Tuning............................................ |

32 |

Receiver Reference Oscillator Adjustment .................................................... |

34 |

Transmitter Testing................................................................................... |

37 |

Transmitter Analog Testing ............................................................................ |

37 |

Transmitter CTCSS Testing ........................................................................... |

42 |

Transmitter Digital Testing ............................................................................. |

45 |

Transmitter Modulation Fidelity Testing ......................................................... |

47 |

Transmitter Reference Oscillator Adjustment ................................................ |

49 |

System Testing......................................................................................... |

51 |

Duplex Analog Testing ................................................................................... |

51 |

Duplex Digital Testing .................................................................................... |

54 |

Chapter 6: Additional Radio System Tests........................... |

57 |

Radio System Testing Through Filtering Equipment ................................ |

58 |

Radio System Testing with the Antenna Connected ................................ |

59 |

VSWR............................................................................................................ |

59 |

Receiver Desense ......................................................................................... |

60 |

RF Carrier Signal Levels on Links between Sites ......................................... |

61 |

Spurious Signals over the Air ........................................................................ |

62 |

Chapter 7: Blank Worksheets .............................................. |

63 |

Page vi

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

CHAPTER 1: CODAN RADIO MAINTENANCE

This document is written as a maintenance guide to Codan MT-4EAnalog and P25 Digital Radio Systems. The document assumes the reader is familiar with conventional Two-Way Radio Communications systems and general electronics maintenance practices. This document is a companion document to the Codan Radio Communications MT-4E Analog and P25 Digital Radio Systems User Guide.

INTRODUCTION TO CODAN MT-4E

Codan MT-4E radio systems are designed for operation in highly varied conditions. Your application may require high performance radio systems (intermodulation and selectivity) for operation in congested radio sites, operation over wide temperatures using battery solar powered systems (low current drain), or a configurable system for emergency deployment in a transportable case. Codan manufactures a diverse range of radio products tailored to the type of operation you need.

The MT-4E radio system is characterized by high performance and reliability, whether it is a remote, low current repeater or a high performance base station. The total system is designed to provide dependable, low maintenance performance and great flexibility for expansion and servicing.

The MT-4E series of radio and control modules are packaged in the compact Eurostandard housing with anodized aluminum front panels, and are ruggedly designed for remote or transportable applications. All of the modules use high reliability components and corrosion resistant fasteners.

The MT-4E radio system is specifically designed to deliver high performance under adverse conditions. Voltage stress testing and a 24 hour burn-in is performed on the radio system and performance of the system at room temperature (25°C) is documented and measured. As an option, extensive environmental testing can be conducted over the temperature range - 30°C to + 60°C and the performance measured to ensure compliance with the design specifications.

A Codan MT-4E radio system consists of separate RF receiver and transmitter modules plugged into a standard 19” subrack. Each subrack also requires a control card and system regulator. External connections to the system (COR, PTT, audio, channel select, etc.) are made through an auxiliary connector on the rear of the subrack. An optional cable or terminal strip connector is available to connect externally through the auxiliary connector to the radio system.

Chapter 1: Codan Radio Maintenance Page 1

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

RECOMMENDED MAINTENANCE SCHEDULE

Codan Radio Communications does not recommend any specific maintenance schedule for our MT4E radio systems. Many organizations have annual preventative maintenance scheduled as part of their standard maintenance procedures; other organizations will only maintain the radio system when a system failure occurs; and other organizations will use a combination of preventative maintenance and maintenance for failures.

REPAIR NOTE

The MT-4E Radio System employs a high percentage of surface mount components which should not be removed or replaced using an ordinary soldering iron. Removal and replacement of surface mount components should be performed only with specifically designed surface mount rework and repair stations complete with Electrostatic Discharge (ESD) protection. When removing Surface Mount Solder Jumpers, it is recommended to use solder wick braid in place of vacuum type de-soldering tools. This will help prevent damage to the circuit boards.

ESD - ELECTROSTATIC DISCHARGE

Static Electricity can damage electronic equipment, causing it to stop functioning immediately, or degrading it, leading to breakdown later. Static sensitive parts should be handled by technicians grounded with wrist and/or two heel straps. Transferring of ESD sensitive components to or from different areas should be conducted in ESD safe bags, tote boxes or carts.

Page 2 Chapter 1: Codan Radio Maintenance

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

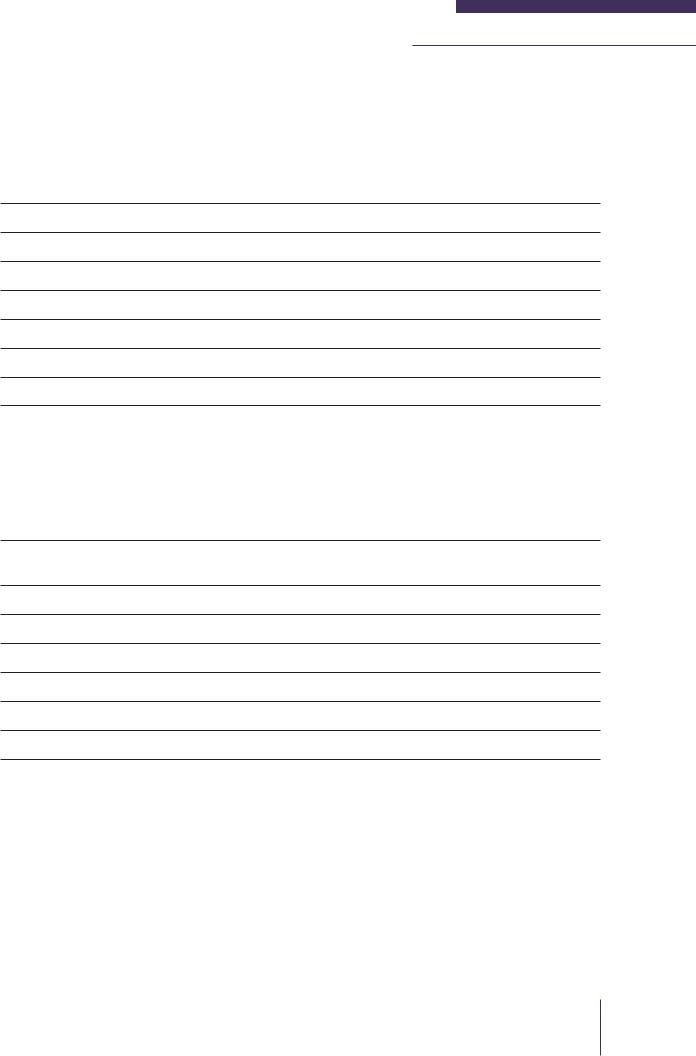

AUDIO AND CARRIER LEVELS REFERENCE

The following are conversions for both audio levels and RF carrier levels.

Audio Levels

2.500 Vrms |

6.928 Vpp |

+10 dBm (@ 600 ohms) |

|

|

|

0.975 Vrms |

2.758 Vpp |

+2 dBm |

|

|

|

0.775 Vrms |

2.191 Vpp |

0 dBm |

|

|

|

0.388 Vrms |

1.098 Vpp |

-6 dBm |

|

|

|

0.308 Vrms |

0.872 Vpp |

-8 dBm |

|

|

|

0.245 Vrms |

0.692 Vpp |

-10 dBm |

|

|

|

0.098 Vrms |

0.276 Vpp |

-18 dBm |

|

|

|

0.077 Vrms |

0.219 Vpp |

-20 dBm |

|

|

|

Carrier Levels

70.71 uV |

-70 dBm (@ 50 ohms) |

|

|

0.707 uV |

-110 dBm |

|

|

0.398 uV |

-115 dBm |

|

|

0.354 uV |

-116 dBm |

|

|

0.316 uV |

-117 dBm |

|

|

0.282 uV |

-118 dBm |

|

|

0.251 uV |

-119 dBm |

|

|

0.224 uV |

-120 dBm |

|

|

0.199 uV |

-121 dBm |

|

|

0.178 uV |

-122 dBm |

|

|

0.158 uV |

-123 dBm |

|

|

Chapter 1: Codan Radio Maintenance Page 3

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

This Page Intentionally Left Blank

Page 4 Chapter 1: Codan Radio Maintenance

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

CHAPTER 2: INSTALLATION

INSTALLATION OF CODAN SUBRACKS

1.Ensure the 19” rack has enough room for the Codan subrack to be installed. Each Codan subrack requires 5 1/4” height (3 RU) and 13.5” (maximum) depth clearances.

2.Install the subrack unit(s) in the 19” rack using four #10 x 3/4” screws as shown in Figure 2-1. Eight screw holes are available, only four screws are required to mount the subrack properly. Use stainless steel screws if the equipment is to be placed in a corrosive environment.

#10 x 3/4”  screws

screws

Figure 2-1: Subrack Installation

Chapter 2: Installation Page 5

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

3. Connect the primary power (+10 Vdc to +17 Vdc, +13.8 Vdc nominal) to the Barrier Strip power input on the rear of the subrack as shown in Figure 2-2. Ensure that the power source does not exceed +18 Vdc. Use a wire gauge suitable for delivering the power required by the subrack(s). If the subrack is using a DC-DC or AC-DC Power Supply, refer to the specific manual supplied with the equipment for installation instructions.

Reverse voltage protection and over voltage protection (transient suppressor) is provided at the main power (+13.8 Vdc) input as well as the +9.5 Vdc line. The main power input is protected with a standard fast-blow 15 amp fuse. These components may require replacing if the power supply is not connected properly, or even after a power surge or a lightning strike. The two transient suppressors have different voltage ratings for the main power input and +9.5 Vdc lines.

4. Install the System Regulator, Receiver, Transmitter, Power Amplifier and Control Card modules in to the subrack using the proper guide rail slots if not already done. When installing modules, ensure the quick release fasteners on the top and the bottom of the modules are in the unlocked (slot should be horizontal) position before insertion to the guide rails. To lock the quick release fasteners, push and turn the fastener 90 degrees clockwise with a flat screwdriver.

Note: MT-4E modules may be removed or inserted from the subrack while power is supplied without damaging the equipment.

5. Interconnect +9.5 Vdc and +13.8 Vdc power between subrack units if one of the subracks does not include a system regulator (no system regulator is required for a second subrack with only power amplifiers mounted in it). If a CI-RC-4M Multiple Link Controller is part of the system, connect the +9.5 Vdc from the subrack to the controller. Connect the audio, channel select and control signal lines from a CI-RC-4M Multile Link Controller to the optional screw-type A-PNL-AUX96-3 auxiliary terminal connector or use the DB25 connector to connect the to a CI-RC-4M-G2 Multiple Link Controller.

+9.5 Vdc Regulated

Power Input / Output (used for interconnecting

2 subracks or powering Power Input CI-RC-4M)

+10 to +17 Vdc

+13.8 Vdc Nominal

P1 Auxiliary

Connector

|

Fuse |

Reverse and |

|

CI-RC-4M-G2 |

Over Voltage |

||

|

|||

|

Protection |

||

connector |

|

|

Figure 2-2: Subrack Power Connections

Page 6 Chapter 2: Installation

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

6. If an external controller (eg. Telex tone-remote adapter) is to be connected to the system, all wiring should be made to the DB25 connector or to the optional screw-type A-PNL-AUX96-3 auxiliary terminal connector shown in Figure 2-3.

The female DB25 connector can be used for basic base connections to a Telex DSP-223 or IP-223, using a standard straight-through male-to-male DB25 cable. The IP-223 also requires that 2 pins on the DB25 (PTT COM - pin2 and MON COM - pin 16) are wired to ground for proper operation.

WARNING: JU108 must be configured correctly for DSP-223 or IP-223 or damage can occur. JU108 A for +13.8 Vdc / DSP-223 or JU108 B for Rx A COR / IP-223

The plug in screw connectors on the A-PNL-AUX96-3 can be removed to allow for easy connection of the wires.

For some applications, a cable, not a terminal strip connector, is used to connect to the auxiliary connector. The cable must be plugged into the P1 auxiliary connector shown in Figure 2-2 on the rear of the subrack. Ensure locking tabs on the connector are completely engaged.

Telex CI-DSP-223 or CI-IP-223 connector

A-PNL-AUX96-3 optional screw-type auxiliary terminal connector

Figure 2-3: Auxiliary Terminal Connector

7.Connect the RJ45 cables between the Receiver, Transmitter and Control Card for repeater operation.

8.Connect the RF cables to the Receiver and Transmitter and ensure they are firmly screwed on. Ensure the RF cables are properly connected to the Duplexer / Antenna Relay / Multicoupler / Combiner and Antenna.

Chapter 2: Installation Page 7

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

This Page Intentionally Left Blank

Page 8 Chapter 2: Installation

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

CHAPTER 3: TEST EQUIPMENT AND SPARES

RECOMMENDED TEST EQUIPMENT

Codan Radio Communications recommends the following test equipment for maintenance of an MT-4E radio system:

+13.8 Vdc Power Supply |

Codan PSA-12-40-RB-00 |

(rated for current draw of equipment) |

(40 Amp rack-mounted power supply) |

|

ICT ICT24012 (60 Amp desktop power supply) |

|

ICT ICT12012 (10 Amp desktop power supply) |

|

|

Current Meter / Multimeter |

Fluke 75 Multimeter |

|

|

Communications Service Monitor |

Marconi Instruments 2965A |

(Analog) |

Aeroflex IFR 1200 (Super S) |

|

Aeroflex IFR COM-120 |

|

|

Communications Service Monitor |

Aeroflex IFR 2975 |

(P25 Digital and Analog) |

Aeroflex IFR 3920 |

|

Aeroflex IFR 3500 |

|

Aeroflex IFR 3550 |

|

General Dynamics R2670 |

|

General Dynamics R8000 |

|

|

Alignment Tools |

Codan A-TK-04 |

|

|

RF Signal Sampler |

Bird Model 4275 Variable RF Signal Sampler |

|

|

Wattmeter |

Bird Model 43 Wattmeter |

|

|

It is recommended that when in the shop / service area, the Communications Service Monitor be frequency locked to an external reference (WWVH, GPS, Loran C) so that the high stability local oscillator may be accurately set to within its ±1 ppm frequency tolerance.

The test equipment should be calibrated on an annual basis to ensure accurate measurements.

Chapter 3: Test Equipment and Spares Page 9

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

RECOMMENDED SPARES

Codan Radio Communications recommends one complete radio system spare for every ten radio systems (or less) in operation to account for lightning damage or other maintenance issues. The amount of spares could be dependant on the critical nature of the radio system and the availability of service for the system. Codan recommends a complete radio system spare for every critical / essential site in the system. The design of Codan MT-4E radio systems makes it easy to swap components of a radio system and can save valuable time and effort during maintenance. The exact spares would depend on the types of systems in operation, but would typically include:

Subrack / Motherboard |

SR-39-1 |

|

|

System Regulator |

SM-3-H0-014-00 (Standard) |

|

SM-3-H0-014-01 (with main power switch) |

|

SM-3-H0-R1N-00 (with single antenna relay) |

|

SM-3-H0-R2N-00 (with dual antenna relays) |

|

|

Control Card |

CI-RC-4L (Repeater Control Card) |

|

CI-BC-4E (Base Control Card) |

|

CI-RC-4M (Multiple Link Controller) |

|

|

Receiver |

VR-4E150-A0-000 (136 - 174 MHz Class A) |

|

UR-4E420-A0-000 (406 - 430 MHz Class A) |

|

UR-4E460-A0-000 (450 - 470 MHz Class A) |

|

VR-4E150-00-000 (136 - 174 MHz Class B) |

|

UR-4E380-00-000 (380 - 406 MHz Class B) |

|

UR-4E420-00-000 (406 - 430 MHz Class B) |

|

UR-4E440-00-000 (430 - 450 MHz Class B) |

|

UR-4E460-00-000 (450 - 470 MHz Class B) |

|

UR-4E500-00-000 (470 - 520 MHz Class B) |

|

UR-4E768-00-000 (768 - 776 MHz Class B) |

|

UR-4E800-00-000 (798 - 824 MHz Class B) |

|

UR-4E850-00-000 (851 - 869 MHz Class B) |

|

UR-4E900-00-000 (896 - 902 MHz Class B) |

|

UR-4E950-00-000 (930 - 960 MHz Class B) |

|

|

Transmitter |

VT-4E150-00-800 (136 - 174 MHz) |

|

UT-4E380-00-800 (380 - 406 MHz) |

|

UT-4E450-00-800 (406 - 470 MHz) |

|

UT-4E500-00-800 (470 - 520 MHz) |

|

UT-4E850-00-300 (768 - 869 MHz) |

|

UT-4E900-00-300 (896 - 960 MHz) |

|

|

Amplifier |

AMP-4-150-30-00 (136 - 174 MHz) |

|

AMP-4-410-30-00 (380 - 430 MHz) |

|

AMP-4-470-30-00 (450 - 470 MHz |

|

|

Auxiliary Connector |

A-PNL-AUX96-3 |

|

|

Page 10 Chapter 3: Test Equipment and Spares

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

RECOMMENDED MAINTENANCE ITEMS

Codan Radio Communications recommends the following maintenance items at each radio site:

A-TK-04 |

MT-4 Tool Kit |

|

|

EC-48RD |

48 pin Direct Connect Extender |

|

|

EC-96D1 |

96 pin Direct Connect Extender |

|

|

5059-TP110300 |

Test Points (included with all extender cards) |

|

|

Additional extender kits can also be located at the radio shop:

EC-48RK-1.22 |

48 pin Extender Kit with cable |

|

|

EC-96K-1.22 |

96 pin Extender Kit with cable |

|

|

Items included in the MT-4 Tool Kit include:

5192-WJ01BJ01 |

SMB to BNC Jack Adapter |

|

|

7910-WP0WP012 |

SMB to SMB Cable |

|

|

2007-1N637500 |

10V Transient Suppressor |

|

|

2007-1N637800 |

18V Transient Suppressor |

|

|

2001-MR751000 |

Reverse Voltage Diode (Qty=2) |

|

|

5604-5GAGC150 |

15 Amp Fast-Blow Fuse |

|

|

CBLC46-12506050 |

50 cm RJ45 Cable |

|

|

Radio Service Software (RSS)

APP-RSS03-WC-XX |

Radio Service Software for programming and service of the Receiver |

|

and Transmitter modules. |

|

|

CBLC44-20704305 |

type A to 5 pin mini-type B USB cable to connect from computer to |

|

Receiver or Transmitter. |

|

|

Chapter 3: Test Equipment and Spares Page 11

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

This Page Intentionally Left Blank

Page 12 Chapter 3: Test Equipment and Spares

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

CHAPTER 4: RADIO SITE SURVEY

INTRODUCTION TO A RADIO SITE SURVEY

Radio sites (repeaters, base stations, etc.) can be located in remote locations and require extensive travel to visit. Remote radio sites could require helicopter transportation, be motor vehicle accessible, or even require travel by horseback in order to reach them. Typically when visiting these sites it is a good idea to perform a site survey to document and inspect the site for possible damage (weather related, vandalism, wildlife), and general maintenance of the site. Radio sites that are not remote can also benefit greatly from a site survey.

A site survey is a valuable tool in the preventative maintenance of the radio site. Documenting site condition, inventory and radio system operation on each visit can highlight action that is needed and allows the technician to prepare for subsequent visits.

While every site is different and many organizations may have their own procedures for site surveys, this chapter can be used as a general outline for a radio site survey.

Codan Radio Site Checklist and Inventory

A Codan Radio Site Checklist and a Codan Radio Site Inventory is included in Chapter 7 of this Maintenance Guide. It is recommended that the checklist and inventory be filled out each time the radio site is visited.

Chapter 4: Radio Site Survey Page 13

MAINTENANCE GUIDE | MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS

PREPARATION FOR A SITE SURVEY

When preparing for a site survey, remember to bring the following items:

•Communications Service Monitor

•Multimeter

•Spare radio equipment

•Standard tool box with wire strippers, screwdrivers, crimper, etc.

•Extra RF cabling to replace any damaged cables

•Adapters (N Type to BNC, etc.)

•Extender cards for radio maintenance

•Codan A-TK-04 Tool Kit

Optional Items:

•Paper, pens and pencils for documenting

•Soldering Iron, solder and de-soldering tool

•Portable radio

•Survival gear, food and drink

•Camera for photographing site condition

•Keys for the buildings / gates

•Documentation for the radio system (manuals, diagrams, previous site survey / inventory)

•Wildlife deterrent (pepper spray)

Check that all test equipment and spare radio equipment is operational and tuned to the correct frequency for that site.

Be aware of all applicable safety measures and regulations for working at, and travelling to and from a radio site (eg. does anyone know where you are going and when you are expected back?).

Page 14 Chapter 4: Radio Site Survey

MT-4E ANALOG & P25 DIGITAL RADIO SYSTEMS | MAINTENANCE GUIDE

EXTERIOR SITE SURVEY

When first arriving at the radio site, an external survey of the site and surrounding area should be conducted to identify any hazards. Actions or repairs that may be required for this or the next site survey can also be identified.

•Check that the building is in good condition (no cracks, leaks, vandalism or other damage)

•Check the antennas, and antenna structure (tower) for visible damage

•Check the external RF cables and connectors for visible damage or corrosion

•Check the external leased lines and / or power cables for damage

•Check the lightning protection for damage

•Check that there are no obstructions in the area (branches, overgrown brush, etc.)

•Exterior site photographs can be taken

INTERIOR SITE SURVEY

Once the radio site is entered an interior survey of the site should be conducted.

•Check the interior of the building, including the floor, for water leaks, animal entry or other damage

•Check the condition of the cabinet / equipment rack

•Check the internal RF cables and connectors for visible damage or corrosion

•Check the duplexers / combiners / multicouplers for damage, loose parts or corrosion

•Check the internal leased lines and / or power cables for damage

•Check the power supply / batteries / solar panels and ensure they are operating correctly

•Interior site photographs can be taken

RADIO SITE INVENTORY

It is a good idea to fill out a complete inventory of all model numbers and serial numbers of the radio equipment, duplexers, antennas, power supplies and all other equipment at the site when performing a site survey. Use the Codan Radio Site Inventory to record this information. Codan Radio Communications suggests that customers maintain a site inventory, as serial and model numbers can help the factory with any customer support issues.

Chapter 4: Radio Site Survey Page 15

Loading...

Loading...