Page 1

Page 2

INTRODUCTION

Thank you very much for selecting this Serpent rc car and thus become a member of the ever growing

worldwide Serpent racing family. Serpent started in 1980 and has been growing its product-line and fan

-base ever since.

The Serpent Cobra SRX8 is a state of the art 1/8 scale 4wd buggy which will give you the true Serpent

racing experience. The assembly manual will guide you through all the steps to complete the car, so you

can hit the track with a good base-set-up soonest. The Serpent design department succeeded to create a

superbly performing car combined with eas of assembly and maintenance. The high quality standards of

all parts and hardware will make racing your Serpent car a very rewarding activity !

Through our team, website and social media we will keep you up-to-date on all developments of the Serpent

cars. We hope to meet you on the track and through our various media! Enjoy the drive !

Team Serpent

Multiple World Champions

INSTRUCTIONS

Serpent’s long tradition of excellence extends to the instruction manuals, and this instruction manual is no

exception. The easy-to-follow layout is richly illustrated with 3D-rendered full-color images to make your

building experience quick and easy. Following the instructions will result in a well-built, high-performance

race-car that will soon be able to unleash its full potential at the racetrack. The kit includes bags, with

bagnumbers, which refer to the same step in the manual. Open only the indicated bag(s) per step and nish

that part of the assembly. Remaining parts will be needed lateron in the assembly process.

plaSTIC paRTS

The Serpent moulded parts are very durable and hard. When assembling longer screws in new composite

parts, make sure to use new hex bits in your (power) tools. Pre-threading also helps to avoid screw damage.

SETUp

In certain assembly steps you need to make basic adjustments, which will give you a good initial setup for

your Serpent Cobra SRX8. Fine-tuning the initial setup is an essential part of building a high-performance

racecar like your Serpent Cobra SRX8.

EXplODED VIEWS aND paRTS lIST

The exploded views and parts lists for the Serpent Cobra SRX8 are presented in the Reference Guide

section in the back of this manual. The exploded views show all the parts of a particular assembly step

along with the Serpent part number and hotlink to the Serpent website. Partnumbers in orange indicates

that this part is an optional. Optionals part names and numbers are showed below.

CUSTOmER SERVICE

Serpent has made a strong effort to make this manual as complete and clear as possible. Additional info

may be published in our website: www.serpent.com or you may ask your dealer or the Serpent distributor

for advice, or email Serpent direct: info@serpent.com. The Serpent Facebook, Twitter and Youtube pages

give additional means of support and communications.

SafETy

Read and take note of the ‘Read this First section’ before proceeding to assemble the car-kit. This car-kit is

intended for persons aged 16 or older.

REaD ThIS fIRST!

- This is a highly technical hobby product, intended to be used in a safe racing environment. This car

is capable of speeds in excess of 80 km/h or 50mph. Please follow these guidelines when building and

operating this model.

- Parental guidance is required when the builder/user of this car is under 16.

- Follow the building instructions. If in doubt, contact your dealer or importer.

- Be sure to use the proper tools when assembling the car. Always exercise caution when using electric

tools, knives and other sharp objects.

- Be careful when using liquids like lubrication oil, fuel or glue. Do not swallow.

- Follow the manufacturer’s instruction in case you experience irritation after using the product.

- Be careful when operating the car. Stay away from any rotating parts such as wheels, gears and

transmission. Stay away from motor, engine and exhaust pipe system or speedo during and immediately

after use, as these parts may be very hot. We advise to use protective hand cloves.

- Only operate this car in a safe environment, like a special racing track or a closed parking lot. Avoid using

this car on public roads, crowded places or near infants.

- Before operating this car, always check the mechanical status of the car. Also check that the transmitter

and receiver frequencies correspond and are not used by any other racer at the same time. Check that the

batteries of the transmitter and receiver- are fully charged.

- After use, always check all the mechanics of the car. We advise to clean the car immediately after use,

and inspect the parts for wear or fractures. Replace when necessary. Do not use water, methanol, thinner

or other solvents to clean the car.

- Empty the fuel tank (depending on model) if needed and disconnect the receiver battery.

- Store the car in a dry and heated place to avoid corrosion of metal parts.

- Avoid using this car in wet conditions as the water will cause corrosion on the metal parts and bearings

and these parts will cease to function properly. If driven in the wet, ensure that all the electric equipment is

waterproofed and after use, that all moving parts are dried immediately.

CONTENTS

•

CENT ERDIFF ASSE MBLY 4

•

FR/RRDIFFASSEMBLY 6

•

CENTRALASSEMBLY 8

•

REARASSEMBLY 11

•

FRONTASSEMBLY18

•

STEERINGASSEMBLY24

•

RADIOASSEMBLY28

•

SHOCKASSEMBLY 32

•

FINALASSEMBLY35

•

CLUTCHASSEMBLY36

•

EXPLODEDVIEWS42

•

TEA MSERP ENTN ETWORK 53

Page 3

3

hOW TO USE ThE maNUal

Each step contains a variety of numbers, lines, and symbols. The numbers represent the order in

which the parts should be assembled. The lines are described below.

Each step contains a variety of symbols described below.

Assembly path of one item into another

Group of items (within lines) should be

assembled first

Direction the item should be moved

Glue one item to another

Press/Insert one item into another

Connect one item to another

Gap between two items

ICONS DESCRIpTIONlINES DESCRIpTION

Carefull, read and check very well.

Apply a small amount of cyano glue. Use wear protection for eyes and hands.

Detail view to explain assembly or order of parts better.

Default set-up: This symbol indicates the default setup.

Grease: apply a small amount of grease to the parts shown.

Left and right parts should be assembled in the same way.

Silicone oil: use the indicated silicone oil for the shocks and differentials.

Parts or items not included in the kit.

Optional part, not standard in the kit.

Thread lock: apply a small amount on the parts shown. Before to apply the threadlock,

make sure to degrease the parts very well, as otherwise the threadlock will not work.

Step number; the order in which you should

assemble the indicated parts

1 32

Length after assembly

Page 4

4

CENTER DIff aSSEmbly

6x11.75x0.2

6x11.75x0.2

8x16x5

8x16x5

M3x4

2.5x12

2.5x12

Use silicone oil to

hold seal in position.

STEp 1

CENTER DIff bag

1.1

1.2

3

1

2

8x16x5

6x11.75x0.2

2.5x12

M3x4

STEp 2

Add just enough oil to cover the large gear

before assembling the small satellite gears and

cross pins.

Use the silicone oil supplied in the kit. For the

correct cst value please check the default

setupsheet.

2.2

2.1

Note the correct

pin location.

Note the correct pin location.

14.7 - 14.9 mm

VOLUMECOMPENSATORS

When the differential gets hotter, the foam

inserts will absorb the pressure of the expansion

of the oil.

1- The supplied foam tube must be cut to size as

indicated here below.

2- Penetrate them fully with same differential oil .

3- Insert them in the compensator holes.

Page 5

5

STEp 4STEp 3 STEp 5

M3x14

3.5x7x0.1

M3x14

Fill the differential with silicone oil 1 mm above the crosspin, do NOT

overll. Use the silicone oil supplied in the kit. For the correct cst value

please check the default setupsheet.

Use a digital scale to measure the

exact amount of oil in the diff.

Differential weight with volume

compensators = 40.8 grams

Differential weight without volume

compensators = 41.0 grams

1mm

AMOUNT OF OIL IN

THEDIFFS

OILLEVEL

3.5x7x0.1

3.5x7x0.1

Page 6

6

fR/RR DIff aSSEmbly

STEp 6 STEp 7

fR/RR DIff bag

6x11.75x0.2

6x11.75x0.2

8x16x5

8x16x5

M3x4

2.5x12

2.5x12

Use silicone oil to

hold seal in position.

6.1

7.2

7.1

6.2

3

1

2

Add just enough oil to cover the large gear

before assembling the small satellite gears and

cross pins.

Use the silicone oil supplied in the kit. For the

correct cst value please check the default

setupsheet.

8x16x5

6x11.75x0.2

2.5x12

M3x4

Note the correct

pin location.

Note the correct

pin location.

14.7 - 14.9 mm

VOLUMECOMPENSATORS

When the differential gets hotter, the foam

inserts will absorb the pressure of the expansion

of the oil.

1- The supplied foam tube must be cut to size as

indicated here below.

2- Penetrate them fully with same differential oil .

3- Insert them in the compensator holes.

Page 7

7

STEp 9STEp 8 STEp 10

M3x14

3.5x7x0.1

M3x14

Fill the differential with silicone oil 1 mm above the crosspin, do NOT

overll. Use the silicone oil supplied in the kit. For the correct cst value

please check the default setupsheet.

1mm

Use a digital scale to measure the

exact amount of oil in the diff.

Differential weight with volume

compensators = 40.15 grams

Differential weight without volume

compensators = 40.35 grams

AMOUNT OF OIL IN

THEDIFFS

OILLEVEL

3.5x7x0.1

3.5x7x0.1

Page 8

8

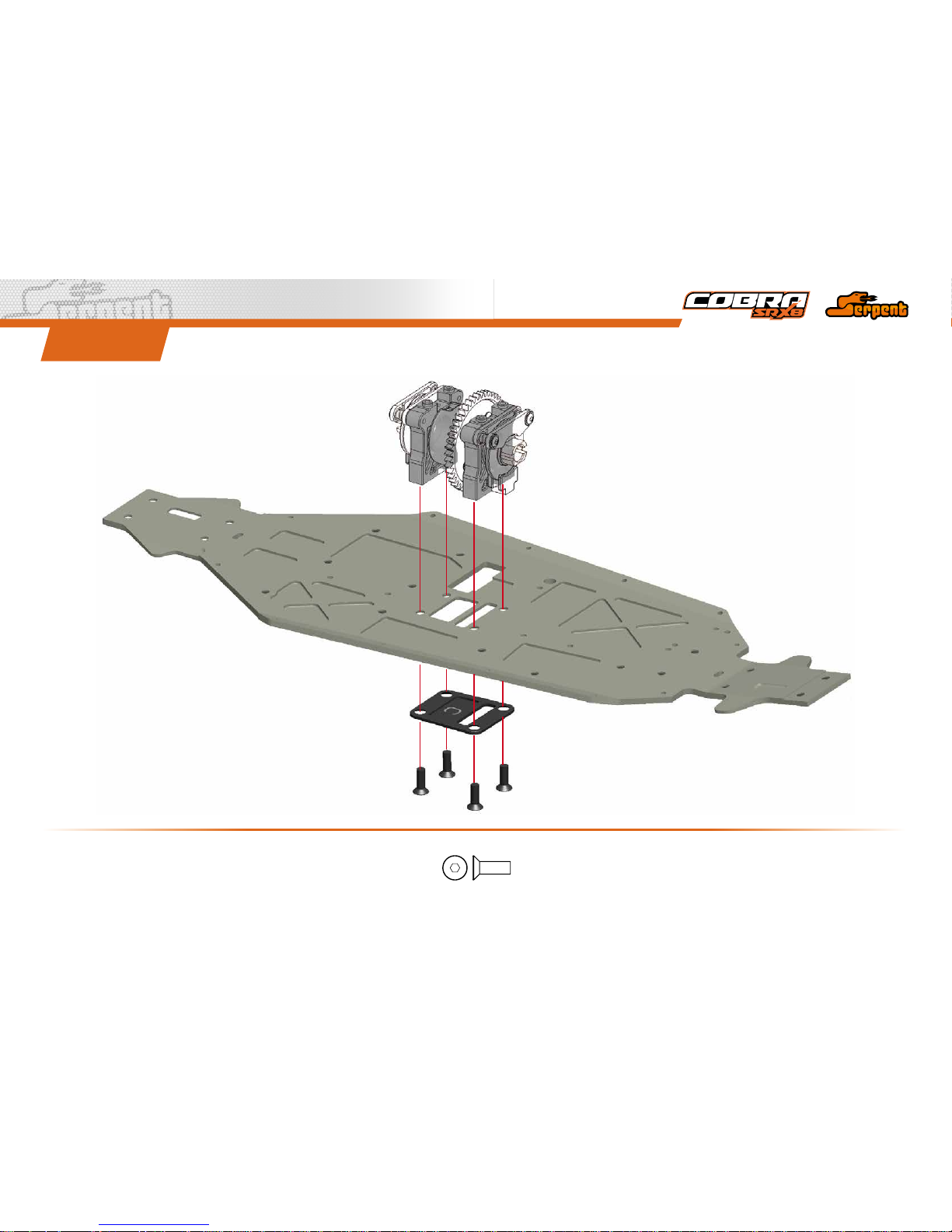

CENTRal aSSEmbly

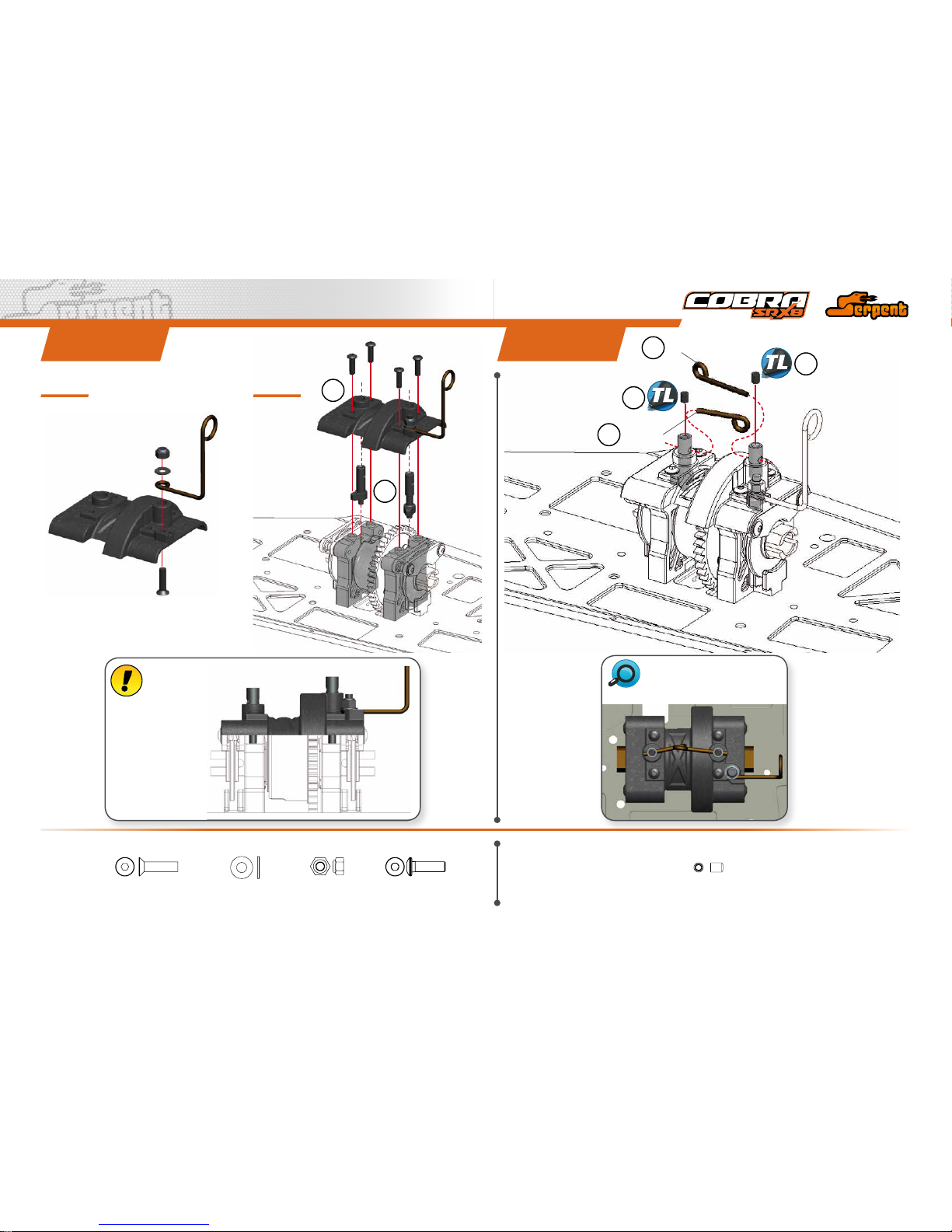

STEp 12STEp 11

bag 1

1

2

12.1

12.2

M3x16

Flanged

M3x6

M3x16 Flanged

M3x6

Front

Front

Front

Rear

Rear

Rear

Diff mounts are NOT symmetrical.

Please check below picture to

ensure front and rear bracket assembly are

assembled properly.

Do NOT overtighten

the screws.

Page 9

9

STEp 13

M4x12

M4x12

Page 10

10

STEp 14 STEp 15

14.1 14.2

M3x12

Nylock nut M3

3.2x7x0.5

M3x10

M3x4

M3x4

1

1

2

2

3

4

M3x12

3.2x7x0.5

Nylock Nut M3

M3x4

Note the correct brake wires

position.

M3x10

Front

Long

Short

Rear

FrontRear

The long cam is

assembled in the front

bracket, the short one

in the rear bracket .

BRAKE

CAMS

Page 11

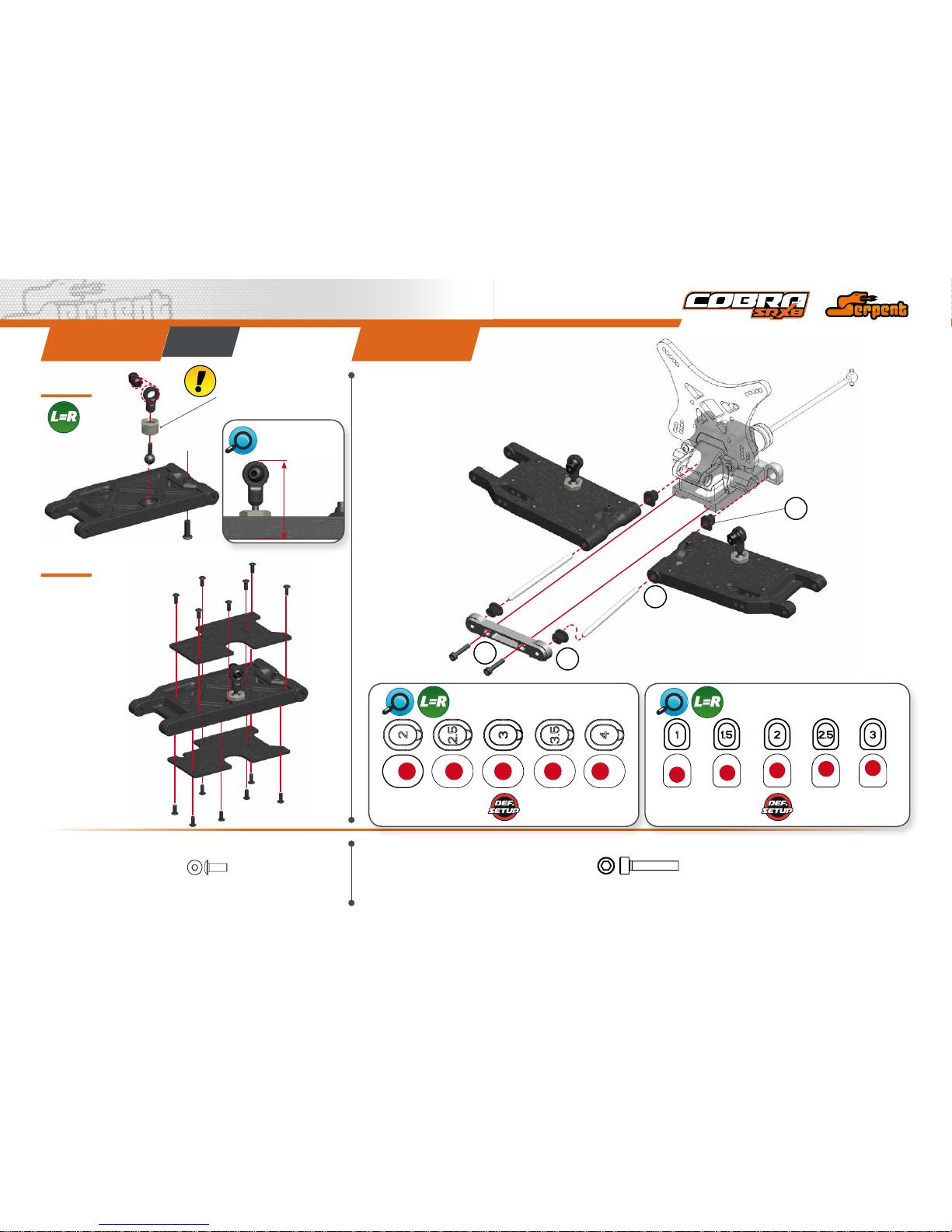

11

REaR aSSEmbly

STEp 16 STEp 17

Note the correct grommet position.

After building the differential with new gears, new dif ferential case

and bearings, the diff may feel a lit tle tight. The connected parts need

at least an hour run-time to create a per fect match. Attention: When

you assemble the diff with too much initial play, the gears will not run-in

properly and may wear quickly. After 1 or 2 hours of

running the car, re-check the gear-mesh between the

ring gear and the pinion. All parts should have run-in

properly n ow. You may add or remove 8x 11x0.1 shims

as needed.

16.1

16.2

1

2

3

4

2.5x13

8x16x5

8x11x0.1

5x13x4

M5x6

M3x14

M3x12

Flanged

1

2

2

3

8x11x0.1

2.5x13

8x16x5

5x13x4

M3x14

M3x12 Flanged

Note the correct

coupler assemby.

bag 2

Page 12

12

STEp 18 STEp 19

18.1

18.2

13x16x0.1

M3x22

13x16x0.1

2

1

1

M3X16

M3x22 M3x16

13x16x0.1

After 1 or 2 hours

of running the car,

re-check the gearmesh between the ring gear

and the pinion. All parts

should have run-in properly.

You may add or remove

13x16x0.1 shims as needed.

Page 13

13

2

3

4

1

M2.5X6

M2.5X6

STEp 20 STEp 21

M3X16

20.1

20.2

REARTOEININSERTSCHART REARANTISQUATINSERTSCHART

M3x16

M2.5x6

bag 3

34 mm

ANTIROLL BAR

RODLENGTH

Tighten anti-roll bar cap until

there is no play, and it moves

freely.

Page 14

14

STEp 23STEp 22

REARANTIROLLBARASSEMBLY

Make correct holes in the

mudguards as required.

M3X3

M3X8

M3X8

M3X3

5X8X2.5

Flanged

M3x3

5X8X2.5 Flanged

M3x8

Page 15

15

STEp 24

3x17

13x19x4

8x16x5

M3x6

2.5mm

1.25mm

Nylock Nut M3

M5x4

2.5x13

24.1

24.2

4

3

5

6

1

2

7

8

M3x6

2.5x13 3x17

Nylock Nut M3

8x16x5

13x19x4

M5x4

bag 4

Note the correct

coupler assemby.

REAR UPRIGHT ROLL

CENTERINSERTS CHART

LOW

MID LOW

MID HIGH

HIGH

REARDEFAULT

WHEELBASESHIMS

Apply shims s ize 8x11x0.1

and/or 8x11x0.2mm as

needed to remove play.

8x11x0.1

8x11x0.2

Page 16

16

25.1

25.2

STEp 25

M3X20

M3X20

3.2x7x0.5

Nylock Nut

M3 Flanged

Nylock Nut M3

1

2

M3x20 3.5x7x0.5

Nylock Nut M3

Nylock Nut M3

Flanged

M3x20

bag 5

17.7 mm

REARCAMBERLINKLENGTH

REARCAMBERLINK

DEFAULTPOSITION

Page 17

17

STEp 26

M3X25

M3X16

Nylock Nut

M3

STEp 27

M4x12

M4x20

Nylock Nut M3

M3x25 M3x16

M4x12M4x20

Page 18

18

fRONT aSSEmbly

28.1 29.1

28.2

29.2

1

2

4

3

2.5x13

8x16x5

8x11x0.1

5x13x4

M5x6

M3x22

M3x16

STEp 28 STEp 29

13x16x0.1

13x16x0.1

2

1

1

After building the differential with new gears, new differential

case and be arings, the diff may feel a lit tle tight. The conne cted

parts need at least an hour run-time to create a perfect match.

Attention: When you assemble the dif f with too much initial play, the

gears will not run-in properly and may wear quickly. After 1 or 2 hours

of running the car, re-check the gear-mesh

between the ring gear and the pinion. All parts

should have run-in properly now. You may

add or remove 8x11x0.1 shims as needed.

8x11x0.1

2.5x13

8x16x5

5x13x4

M3x22

13x16x0.1

M3x16

bag 6

After 1 or 2 hours

of running the car,

re-check the gearmesh between the ring gear

and the pinion. All parts

should have run-in properly.

You may add or remove

13x16x0.1 shims as needed.

Note the correct

coupler assemby.

Page 19

19

31.1 31.2

STEp 30 STEp 31

M2.5X6

M2.5X6

M3x16

M3x16

34 mm

M2.5x6

bag 7

ANTIROLL BAR

RODLENGTH

Tighten anti-roll bar cap until

there is no play, and it moves

freely.

Page 20

20

STEp 32 STEp 33

M3x16

M3x3

M3x3

5X8X2.5

Flanged

M3x16

M3x3

5X8X2.5 Flanged

FRONTANTIROLLBARASSEMBLY

FRONTSUSPENSION

KICKUPINSERTS

FRONTREAR

INSERTS

Page 21

21

STEp 34

34.1

3x17

13x19x4

8x16x5

M3x10

M5x4

2.5x13

4

3

5

6

7

1

2

M4x6

2.5x5x0.4

2.5x13

3x17

Nylock Nut M3

8x16x5

13x19x4

M5x4

M3x10

M2.5x6

M3x3

bag 8

Note the correct

coupler assemby.

3

2

Nylock Nut M3

1

M3x3

34.334.2

M4x6

M2.5X6

2.5x5x0.4

M4x6

4

1

3

2

2

3

Align the at spot

on the shaft with the

grubscrew.

Steering arm 1 is

included in the kit.

STEERINGARMS

Apply shims size 8x11x0.1 and/

or 8x11x0.2mm as needed to

remove play.

8x11x0.1

8x11x0.2

Page 22

22

35.1

35.2

STEp 35

M3x20

M3x20

3.2x7x0.5

Nylock Nut

M3 Flanged

Nylock Nut M3

1

2

M3x20 3.5x7x0.5

Nylock Nut M3

Nylock Nut M3

Flanged

M3x20

bag 9

16.7 mm

FRONTCAMBERLINKLENGTH

FRONTCAMBERLINK

DEFAULTPOSITION

Page 23

23

STEp 36

M4x20

M4x12

M4x12M4x20

Page 24

24

STEERINg aSSEmbly

STEp 37 STEp 38

38.1

38.2

1

1

2

M4x8

M2x10

M3x12

3x6x0.5

3x6x0.5

M3x12

M4x10

The servo saver spring

should be preloaded

4.5mm. Also notice the

correct orientation of the

collar.

Nylock Nut M3

4.5 mm

M4x8M4x10

M2x10

M3x12

3x6x0.5

Nylock Nut M3

bag 10

Page 25

25

STEp 39

STEp 40

6x10x3

6x10x3

3x7.5x1

Conical

3x7.5x1

Conical

3x7.5x1

Conical

3x7.5x1

3x7.5x1

M3x18

M3x18

M3x20

M3x20

Note correct

position of the

conical shim.

Note correct position

of the conical shim.

Note correct orientation of

the outer steering balljoints.

Nylock Nut M3

Nylock Nut

M3 Flanged

Nylock Nut

M3 Flanged

1

1

2

2

39.1

39.2

11 mm

3x7.5x1 Conical

6x10x3

M3x18

M3x20

Nylock Nut M3

3x7.5x1 Conical 3x7.5x1

Nylock Nut M3

Flanged

STEERINGTRACKRODLENGTH

Page 26

26

STEp 41 STEp 42

M4x12

M3x12

M4x30

M4x10

M3x14

M3x10

M3x12

Nylock Nut M3

Nylock Nut M3

Nylock Nut

M4 Flanged

1

1

1

1

2

2

2

2

3

3

M3x12 M3x10 M3x14

Nylock Nut M3

Nylock Nut M3

M4x10 M4x12

M3x12

M4x30

Nylock Nut M3

Flanged

bag 11

Page 27

27

STEp 43

M3x6

M3x6

M3x6

Put thread lock in all the M3x6 screws

that x the side guards to the chassis.

Page 28

28

RaDIO aSSEmbly

STEp 44

44.1

44.2

M3x8

M3x16

Flanged

M3x16

Flanged

Nylock Nut M3

3x7.5x1 Conical

3x7.5x1 Conical

Nylock Nut M3

1

1

2

M3x8

M3x16 Flanged

bag 12

19.3 - 19.6 mm

STEERINGLINKLENGTH

Note correct

position of the

conical shim.

STEp 45

Use enough servo spacers so both servos are ush with the bottom of the radiotray

posts. This will prevent the servo to touch the chassis under torsion – ex.

SERVOSPACERS

Between differnet servo brands

there could be slight differences.

Check how many teeth your

servo spline has (23, 24 or

25) and use the right lever.

Page 29

29

STEp 47

Assembly detail in case of using a larger transponder.

M2x10

M3x5

M3x5

M2x10

M2x10 M2x10

M3x5

STEp 46

Assembly detail in case

of NOT using a switch.

M2x10

Page 30

30

STEp 48 STEp 49

48.1

48.2

M2x10

M4x12

M4x12

M4x12

M2x10

M2x10

M3x4

3x7.5x1

Conical

1

1

2

2

Nylock Nut M3

M2x10 M3x4

3x7.5x1 Conical

M4x12

Nylock Nut M3

Apply the supplied decal

on the battery cover.

Apply the supplied decal

on the receiver cover.

Page 31

31

STEp 50 STEp 51

M3x3

M3x8

3.5x7x0.5

M3x5

M3x3

M3x3

M3x12

M3x8

THROTTLE/BRAKE

ASSEMBLY

THROTTLE/BRAKESPOKELENGTHS

Cut the spoke at the non threaded side

THROTTLEASSEMBLY

Note the correct

orientation of the

brake balls .

M3x12

M3x3

M3x3

M3x5

M3x3

3.5x7x0.5

1

2

2

3

4

5

5

6

4

46 mm

THROTTLE

65 mm

BRAKE

Check how many teeth

your servo spline has

(23, 24 or 25) and use

the right lever.

Page 32

32

ShOCKS aSSEmbly

STEp 52 STEp 53

52.1

53.1

53.2

52.2

52.3

1

2

Use some silicone oil

during the assembly.

Use some silicone oil

during the assembly.

Insert the o-ring

inside the spring

collar.

Nylock Nut M2.5

2.5x6x0.5

2.5x6x0.5

Nylock Nut M2.5

bag 13 fR ShOCKS / bag 14 RR ShOCKS

Note the correct

orientation of the

shock spacers .

Note the correct

position of the

o-ring .

Page 33

33

STEp 54

STEp 55

54.1

54.2

54.3

SHOCKSLENGTH:Measure the

shock length fully extended.

Push the membrane

into the shock cap.

FRONT REAR

36.5

mm

44

mm

1- Fill up with sillicone oil

fully using the silicone

oil supplied in the kit.

For the correct cst value

please check the default

setupsheet.

2- Extend the shockrod fully

3- Move the shockrod

slowly up and down

to let ALL air bubbles

escape.

4- Close top only 3/4.

1-Bleed: push the

shockrod all the way

in slowly, to allow

excessive oil to escape.

2- Close completely the

shock cap.

Assemble the spring and springcup (align correctly) to complete

the shock.

Page 34

34

STEp 56 STEp 57

M3x6

M3x6

M3x6

M3x6

M3x25

M3x25

Nylock Nut

M3 Flanged

Nylock Nut

M3 Flanged

1

2

2

3

3

Nylock Nut M3

Flanged

Nylock Nut M3

Flanged

M3x6

M3x6

M3x25 M3x25

1

3

3

2

2

FRONTSHOCKS

DEFAULTPOSITION

REARSHOCKS

DEFAULTPOSITION

Page 35

35

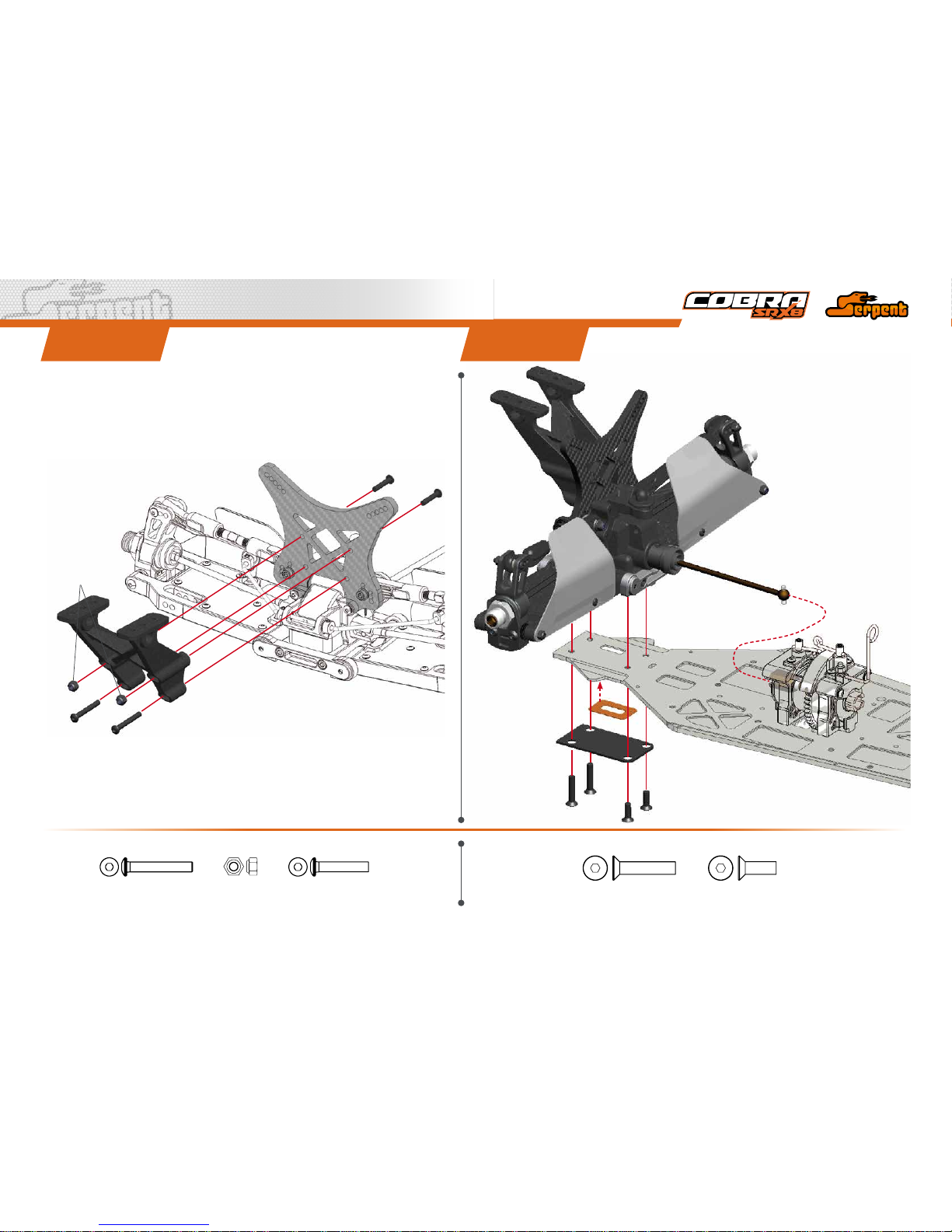

fINal aSSEmbly

STEp 58

58.1 58.3

58.2

M3x18

M3x12

M3x12

M3x16 Flanged

M2x6

M2x6

M2x6

Nylock

Nut M3

M2x6

M3x18

Nylock Nut M3

M3x12

M3x16 Flanged

bag 15

M3x14

M3x14

The fuel-tank features a premounted 3cc insert.

You can remove it if needed as shown.

FUELTANKINSERTS

Page 36

36

ClUTCh aND ENgINE aSSEmbly

M3x14

M3x14

STEp 59 STEp 60

59.1

59.2

5x8x0.1

5x8x0.3

M3x8

3.2x7x0.5

5x10x4

3.2x7x0.5

5x8x0.1 5x8x0.3

5x10x4

M3x8

M3x14

Push the long leg of the

spring in the inner hole

of the clutch shoe.

Do not fully tighten the M3x14 screws till Step 61.

bag 16

Page 37

37

STEp 61 STEp 62

M4x10

M5x4

M3X8

M4x10

M5x4

M3x8

If the engine used is an OS (or OS

based engines like Mx), Alpha and SH,

it might be needed to trim off some

plastic from the center diff cover to give

the carburetor enough clearance over

the brake plates. This could be done

with a hobby knife.

1- Assemble and fully tighten the M4x10 screws.

2- Position the engine in such way on the engine

mount that the gearmesh is correct.

3- Fully tighten M3x14 screws assembled during the

Step 60.

Page 38

38

STEp 63

Page 39

39

STEp 65

1

2

STEp 64

64.2

64.1

ANGLEDWING

SPACERSCHART

AIRFILTERASSEMBLY

1

2

3

M3x18

M3x6

M3x6

Body Clip

M3x18

2º

4º

6º

Oil the airlter with a high quality foam-airlter

oil ( not included). Do NOT use silicone oil.

Use tie raps to x the the air lter boot

to the airlter and to the carburator.

bag 17

FRONTREAR

Page 40

40

STEp 66

Page 41

41

STEp 67

M3x5

M3x5

1- Cut the body along the cutting line with special

scissors (not included). Make holes for the

bodypost and antenna as needed with a body

reamer (not included). Make a longer bodypost

hole in the rear, to allow for chassis ex movement.

2- Before painting the body, apply the precut

masking sheet elements to the inside of the

body. Follow the cleaning & painting instructions

supplied by the polycarbonate paint supplier you

choose.

3- Apply the Serpent and Cobra logo-decals on

the body and wing.

Body Clip

1

2

3

3

Page 42

EXplODED VIEWS

42

INDEX

DIffERENTIalS EXplODED VIEW 42

CENTRal EXplODED VIEW 43

REaR EXplODED VIEW 44

fRONT EXplODED VIEW 45

STEERINg EXplODED VIEW 46

RaDIO EXplODED VIEW 47

ShOCKS EXplODED VIEW 48

ClUTCh EXplODED VIEW 49

fINal 1 EXplODED VIEW 50

fINal 2 EXplODED VIEW 51

Page 43

DIffERENTIal EXplODED VIEW

43

600726

600147

600213

600213

110454

600209

600283 opt

600421

600421

110207

110207

110 111

1396

1396

600200

600200

600831

110115

600727

600727

600728

600376

600376

600813

600814 opt

600815 opt

600283 Diff pin 10T alu (2)

600814 Spur gear 47T SRX8

600815 Spur gear 48T SRX8

600868 Diff set 44T front / rear SRX8

600869 Diff set 46T center SRX8

Page 44

44

CENTRal EXplODED VIEW

600721

600742

600747

600742

600745

600746

110115

110127

110109

600746

110115

110109

110402

110401

600742

110105

600808

110122

110122

600743

600743

110146

110146

600748

600748

600744

600744

600829

600829

Page 45

45

REaR EXplODED VIEW

600722

600738

600739

110191

110105

600834

110211

110211

600197

600197

600477

600174

600193

600485 opt

600774

600837 opt

600108

600189

600776

600225

110124110402

110402

600185

110224

1396

600774

600777

600365

600778

1393

110140

600820

600851 opt

600852 opt

110137

110148

600780

600102

600729

1070

600730

600847 opt

600725

110431

110431

110432

1396

1340

110145

600735

110402

110141

110142

110107

600823

600722

600733

600733

600734

600873

110121

600732

600853 opt

600770

600781

110116

110116

110116

600238 opt

600434 opt

600239 opt

600684 opt

600237

600339 opt

600338 opt

803134

110401

110 111

803134

600484 opt

600484 opt

1312

1312

600192

600622 opt

600828

600794

110441

110110

110130

110130

600823

110193

600795

110107

600338 Antiroll bar rear 1.8mm

600339 Antiroll bar rear 2.0mm

600434 Antiroll bar rear 2.4mm

600238 Antiroll bar rear 2.5mm

600239 Antiroll bar rear 2.7mm

600684 Antiroll bar rear 3.0mm

600484 Antirollbar spacer 3mm alu (2)

600485 Pivotball threaded anti roll bar alu (2)

600622 Pivotball antirollbar alu (4)

600837 Wishbone insert carbon RR (2+2)

SRX8

600838 Upright weight brass 15gr (2) SRX8

600847 Shocktower RR alu SRX8

600851 Wheelhexagon 0mm light (2) SRX8

600852 Wheelhexagon +1mm light (2) SRX8

600853 Gear coupler alu SRX8

Page 46

46

fRONT EXplODED VIEW

600775

600834

600108

600793

600723

600723

600725

600731

600795

600732

600102

600102

600873

600733

600733

600736

110141

600741

600737

600794

110441

600780

600781

600783

600782 opt

600788 opt

600784 opt

600790 opt

600791 opt

600792 opt

110440

110116

110119

110130

110130

600836 opt

110130

600785

110224

110148

1396

110109

1393

600786

600786

600787

600789

600821

600851 opt

600852 opt

600823

600823

600828

110107

600240

600241 opt

600242 opt

600337 opt

600336 opt

600225

110402

600174

600193

110211

600197

600197

110191

110105

110116

600192

110401

110140

110402

110110

110193

110431

1396

1340

110116

110116

803134

803134

1312

600185

110121

600622 opt

600485 opt

600484 opt

600336 Antiroll bar front 1.8mm

600337 Antiroll bar front 2.0mm

600241 Antiroll bar front 2.5mm

600242 Antiroll bar front 2.7mm

600484 Antirollbar spacer 3mm alu (2)

600485 Pivotball threaded anti roll bar alu (2)

600622 Pivotball antirollbar alu (4)

600782 C-hub 13deg L+R alu SRX8

600784 C-hub 17deg L+R alu SRX8

600788 Steering arm 0 carbon (2) SRX8

600790 Steering arm 2 carbon (2) SRX8

600791 Steering arm 3 carbon (2) SRX8

600792 Steering arm 4 carbon (2) SRX8

600836 Wishbone insert carbon FR (2+2)

SRX8

600846 Shocktower FR alu SRX8

600851 Wheelhexagon 0mm light (2) SRX8

600852 Wheelhexagon +1mm light (2) SRX8

600853 Gear coupler alu SRX8

110211

600853 opt

600846 opt

110431

110432

Page 47

47

STEERINg EXplODED VIEW

600724

600750

1321

1321

600167

600751

600751

600764

110101

110188

110102

600827

600751

600178

600178

110441

110441

110439

110159

600749

600749

110402

110405

110402

110127

110127

110402

110402

110184

600754

600724

110108

110108

110108

110108

600729

110105

110183

110102

110102

600752

600753

600170

600812

600330

110112

600180

110125

110125

600830

110192

600178

110439

600844 Transmission brace alu FR SRX8

600845 Transmission brace alu RR SRX8

600844 opt

600845 opt

Page 48

48

RaDIO EXplODED VIEW

600764

600227

600227

401355

110402

110402

600757

600757

600757

110149

110188

110188

1606

600757

110115

110105

110105

600759

600292 opt

600843 opt

600291 opt

600842 opt

600290 opt

600841 opt

110152

600760

110152

110127

110401

110128

600761

600761

804181

600333

600333

600761

600763

600763

600761

600762

110116

110116

110116

1639

1639

1639

600762

600761

600757

110146

110146

600757

110128

600757

600106

600178

600178

600290 Servo lever steering 23T alu

600291 Servo lever steering 24T alu

600292 Servo lever steering 25T alu

600841 Servo lever throttle alu 23T SRX8

600842 Servo lever throttle alu 24T SRX8

600843 Servo lever throttle alu 25T SRX8

600758 Radio + battery box skin carbon look SRX8

Page 49

49

ShOCKS EXplODED VIEW

600796

600818

110456

110438

600822 FR / RR

600797

600802

600803

600113

600111

600347

600158

600804

600805

600646 opt

600648 opt

600800 FRONT

600798 FRONT

600650 opt

600652 opt

600654 opt

600656 REAR

600647 opt

600649 opt

600651 FRONT

600653 opt

600655 opt

600801 REAR

600799 REAR

600657 opt

600816 opt

600817 opt

600848 opt

600850 opt

600875 opt

600849 opt

600646 Shockspring FR orange V2 (2)

600647 Shockspring FR red V2 (2)

600648 Shockspring FR blue V2 (2)

600649 Shockspring FR purple V2 (2)

600650 Shockspring FR green V2 (2)

600658 Shockspring set FR V2 (6x2)

600652 Shockspring RR orange V2 (2)

600653 Shockspring RR red V2 (2)

600654 Shockspring RR blue V2 (2)

600655 Shockspring RR purple V2 (2)

600657 Shockspring RR green V2 (2)

600659 Shockspring set RR V2 (6x2)

600357 Membrane webbed silicone (4)

600816 Shock piston blank (4) SRX8

600817 Shock piston 5 holes (4) SRX8

600819 Shock piston 8 holes (4) SRX8

600848 Shock shaft FR TiN coated (2) SRX8

600849 Shock shaft RR TiN coated (2) SRX8

600850 Shock cap pro hard coated (2) SRX8

600870 Shock set Pro front (2) SRX8

600871 Shock set Pro rear (2) SRX8

600875 Shock top gasket (4) SRX8

Page 50

50

ClUTCh EXplODED VIEW

1315

1315

600206

110423

110424

600163

600228

600262

110152

110401

600232 opt

600231opt

600175 opt

600355 opt

600298 opt

600230

600229 opt

600518 opt

600519 opt

600217 opt

600216

600233 opt

600518 Clutch bell 13T vented

600217 Clutch bell 14T

600519 Clutch bell 14T vented

600229 Clutch spring soft 0.85mm (4)

600231 Clutch spring hard 0.95mm(4)

600232 Clutch spring X hard 1mm(4)

600233 Clutch spring set (4x4)

600175 Clutchshoe alu (4)

600355 Clutch shoe set Alu / Carbon (2+2)

600244 Clutch-set alu / carbon

600298 Flywheel steel

Page 51

51

fINal 1 EXplODED VIEW

600755

110178

110178

600766

110144

600767

600115

600767

110195

110146

110402

600768

600835

600282 opt

600282 opt

600839 opt

600765

600768

600779

600824

110102

110127

110137

600824

600824

600824

600779

600779

600769

110194

110194

600769

600832

600835

110441

110441

110137

600282 Shock-pivot bushing delrin (4)

600839 Motormount mono alu SRX8

Page 52

52

fINal 2 EXplODED VIEW

600718

110157

600740

110104

1601

1601

1601

110148

600773

600756

600243

600340

600243

110108

600771

600825

600833

600301 opt

600143 opt

600277 opt

600439 opt

600440 opt

600826 opt

600840 opt

600872 opt

600263

110159

600772

600222

600297 opt

600620 opt

600719 opt

600621 opt

600297 Wheel-nut17mmanged/light(4)

600143 Wing white nylon

600277 Wing black nylon

600439 Wing white low 811

600440 Wing black low 811

600719 Body SRX8 High Downforce

600826 Wing straight MD white 1/8

600840 Wing lexan HD with gurney 1/8

600872 Wing gurney

600620 Rim 1/8 buggy White (4)

600621 Rim 1/8 buggy Yellow (4)

Page 53

SERPENTMERCHANDISING www.serpent.com/product/Merchandising/

TEam SERpENT NETWORK

SRX8SPAREPARTS www.serpent.com/600017/spares/

SRX8OPTIONALSPARTS www.serpent.com/600017/Optionals/

SERPENTTOOLS www.serpent.com/product/Tools/

Page 54

SERPENTWEBSITEANDBLOG

SERPENTSOCIALMEDIA

www.facebook.com/SerpentMRC

www.serpent.com

www.teamserpent.com

www.dragon-rc.com

www.youtube.com/user/SerpentMRC

www.twitter.com/SerpentMRC

www.plus.google.com/+SerpentModelcars/posts

www.weibo.com/teamserpent

SERPENTPROMOPAGES http://promo.serpent.com

SERPENTFACEBOOKGROUPS http://promo.serpent.com/indexfb.htm

SERPENTADVANCEDMANUALS http://promo.serpent.com/sam/

Page 55

Page 56

Manual Cobra SRX8 #82806-1

Loading...

Loading...