Page 1

2003 DCx65

Owners / Service Manual

“CHAMPIONS START HERE”

Page 2

For parts orders contact your local dealer

To locate your closest Cobra dealer

log on to

www.cobramotorcycle.com

or call

(330) 549-9600

If you need technical assistance

contact your local dealer or call

the Cobra Technical Support Hotline at

(330) 549-9603

1

Cobra Motorcycle MFG., Inc.

11511 Springfield Road

North Lima, Ohio 44452

MCDC2003.1

Page 3

DISCLAIMER OF WARRANTY

This motorcycle is sold “as is” with all faults, obvious or not. There are no warranties

expressed or implied, including any warranty of merchantability and warranty of fitness

for any particular purpose.

“WARNING”

THE COBRA DC65 IS A COMPETITION MODEL ONLY AND IS NOT

MANUFACTURED FOR, NOR SHOULD IT BE USED ON PUBLIC STREETS, ROADS

OR HIGHWAYS.

THE USE OF THIS BIKE SHOULD BE LIMITED TO PARTICIPATION IN

SANCTIONED COMPETITION EVENTS UPON A CLOSED COURSE BY A

SUFFICIENTLY SKILLED RIDER AND SHOULD NOT BE USED FOR GENERAL

OFF-ROAD RECREATIONAL RIDING.

IMPROPER USE OF THIS MOTORCYCLE CAN CAUSE INJURY OR DEATH.

THIS BIKE IS INTENDED FOR EXPERIENCED RACERS ONLY AND NOT FOR

BEGINNERS.

IT IS YOUR RESPONSIBILITY AS THE OWNER OF THIS COBRA MOTORCYCLE

OR AS THE PARENT, OR LEGAL GUARDIAN OF THE OPERATOR, TO KEEP THIS

COBRA MOTORCYCLE IN PROPER OPERATING CONDITION.

THIS BIKE WAS DESIGNED FOR RIDERS THAT WEIGH LESS THAN 80 LBS WITH

FULL RIDING GEAR AND SHOULD NOT BE OPERATED BY RIDERS THAT WEIGH

MORE THAT.

BE SURE THAT THE RIDER ALWAYS WEARS ADEQUATE SAFETY GEAR

EVERYTIME HE OR SHE RIDES THEIR COBRA MOTORCYCLE.

IMPORTANT SAFETY NOTICE

Failure to follow WARNING instructions could result in severe injury or death to

the machine operator, a bystander, or a person inspecting or repairing the

machine.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to

the machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

2

Page 4

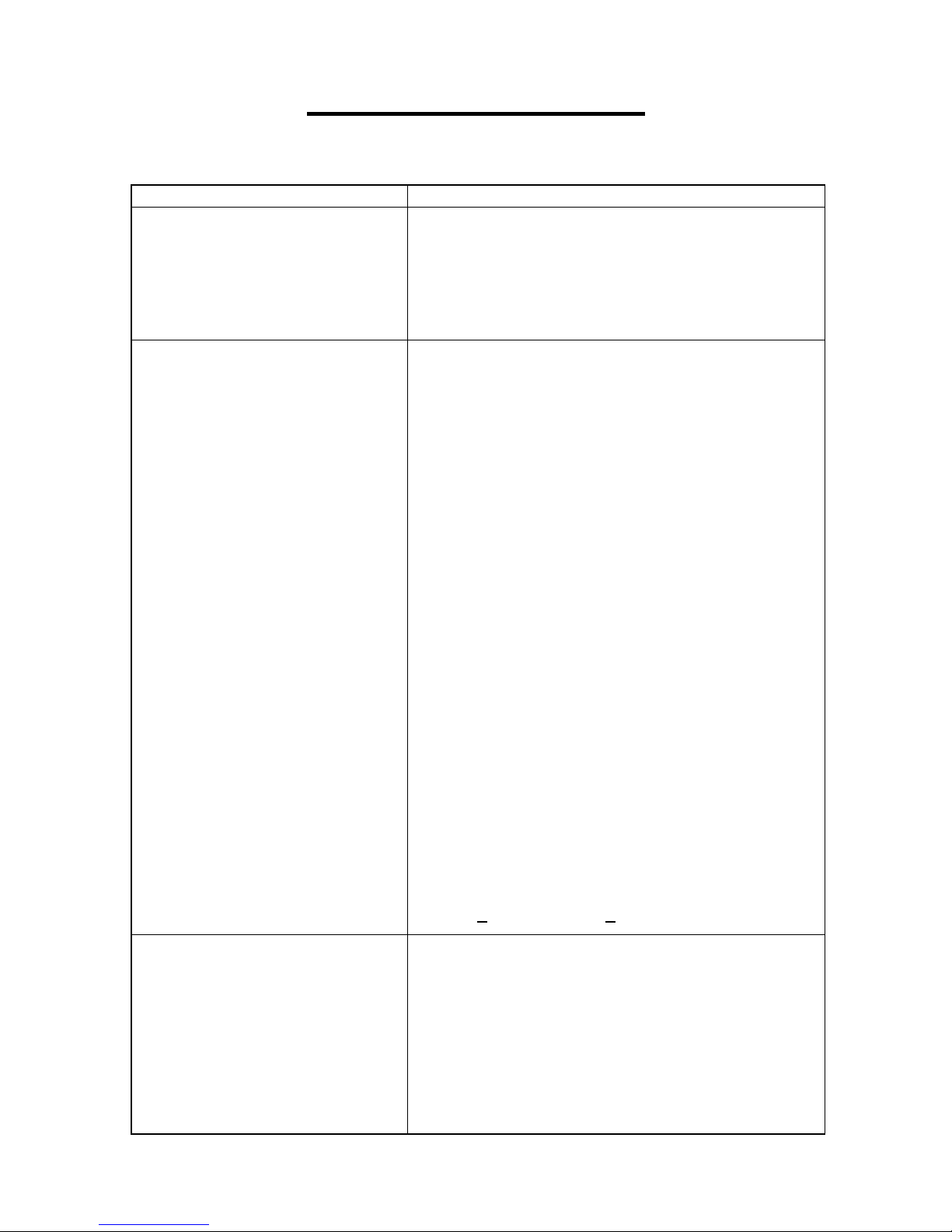

Table Of Contents

General Information.........................................................................................................5

Specifications - General..............................................................................................5

Specifications - Torque Values ..................................................................................6

Specifications – Suspension.......................................................................................8

Optional Components......................................................................................................9

Break-In Procedure....................................................................................................10

Starting Procedure.....................................................................................................11

General Tips ................................................................................................................12

Maintenance....................................................................................................................13

Schedule & Tips .........................................................................................................13

M1: Replacing Transmission Lubricant ...................................................................14

M2: Chain adjustment................................................................................................15

M3: Front brake adjustment......................................................................................16

M4: Clutch lever adjustment.....................................................................................16

M5: Rear brake adjustment ......................................................................................17

M6: Air Filter Cleaning ...............................................................................................18

M7: Fork Oil Replacement........................................................................................19

Engine Parts / Service...................................................................................................20

ES1: Top End Parts ...................................................................................................20

ES2: Bottom end & transmission.............................................................................20

ES3: Clutch and Shifter components......................................................................21

ES4: Ignition................................................................................................................24

ES5: Cooling System.................................................................................................25

ES6: Fuel & Air System.............................................................................................25

3

Page 5

ES7: Exhaust ..............................................................................................................26

Tuning ..............................................................................................................................27

Tuning 1: Carburetor..................................................................................................27

Jetting Decisions ....................................................................................................27

Jetting Changes......................................................................................................30

Tuning 2: Suspension................................................................................................34

1 Suspension Guidelines ......................................................................................35

2 Proper Suspension Adjustments for Your Rider............................................36

3 Symptoms of Incorrect Suspension Adjustment............................................40

4 Proactive Suspension Adjustments .................................................................41

5 How to Adjust the Suspension ..........................................................................42

6 Suspension Reference.......................................................................................43

Troubleshooting..............................................................................................................44

Index.................................................................................................................................45

4

Page 6

General Information

Specifications - General

Items DC65

Dimensions

Wheelbase 44.75” (1136 mm)

Wheel size 14” (356 mm) front, 12” (305 mm) rear

Seat height

Engine

Type 2-stroke, single cylinder, reed valve

Cooling system Liquid-cooled

Displacement 64.8 cc (3.95 Cubic inches)

Bore and stroke 43 mm x 44.6 mm

Ignition system Electronic

Spark plug Splitfire SF406B

Gap 0.023” – 0.025” (0.58 – 0.64 mm)

Fuel type Sunoco MO2X or 93 octane pump gasoline

Oil type Cobra Venom 2-cycle Race Oil

Fuel / oil mix ratios 32:1 to 40:1

Ignition timing 0.050”

Carburetion 28 mm PWK style

OTHER RACE FUELS ARE NOT RECOMMENDED

Slow (Pilot) jet 38

Float height 19 mm + 0. 5mm (0.75” + 0.020”)

Transmission

Speed Six speed

Clutch Manual hydraulic

Final drive ratio 13/46 T

Transmission / clutch oil type 85W 90 Gear Lubricant

5

Main jet 128

Jet needle JJH 3rd position from the top

Quantity 530 ml (18 oz)

Page 7

Chassis

Front tire 60/100 x 14

Pressure 10 - 15 psi.

Rear tire 80/100 x 12

Pressure 10 - 15 psi.

Front fork Cobra USD 35 mm

Fork oil type SAE 5 weight

Fork oil amount

Fork oil level

4 oz (118 ml)

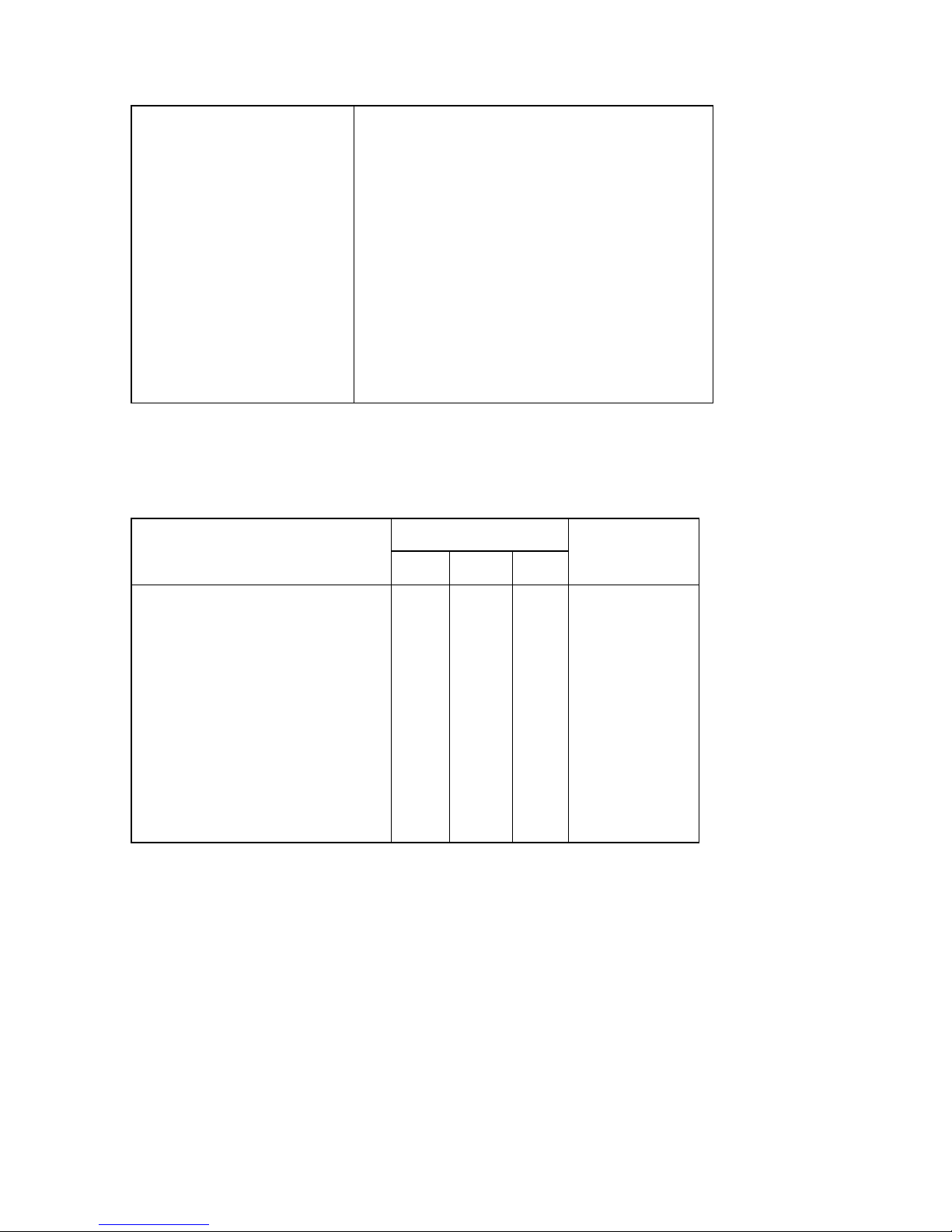

Specifications - Torque Values

ENGINE Fastener

Cylinder head nuts 9.2 110 12 ¼” x 20

Engine oil drain 3 36 4 8 x 1.25

Engine oil fill 2 24 2.7 14 x 1.0

Spark Plug (SP) (SP) (SP)

Crank case half 5 60 6.8 6 x 1.0

Crank case cov er 5 60 6.8 6 x 1.0

Flywheel rotor nut 40 480 54 10 x 1.25 (G)

Torque Value

ft-lb in-lb Nm

Remarks

14 x 1.25

Size &

Clutch hub 40 480 54 10 x 1.25 (G)

Units of mm unless otherwise specified

(G) denotes the use of wicking / bearing retainer (green) thread locking agent to

applied to the mating surfaces of the two components but not the threads.

(SP) To apply the proper torque to the spark plug when inserting, one must first

screw the spark plug in until the metal gasket ring causes resistance and then

turn another 1/8 to ¼ turn.

6

Page 8

CHASSIS Fastener

Front axle nut 25 300 34 12 x 1.25

Front brake caliber 22 264 30 8 x 1.25

Front brake rotor 6 72 8 6 x 1.0 (B)

Triple clamp bolts 6 72 8 6 x 1.0

Fork cap 5 60 6.7 1.25” x 18

Steering head 30 350 40 1.0” x 12 (R)

Handle bar mounts 15 177 20 8 x 1.25

Handle bar clamps 15 177 20 8 x 1.25

Front engine mount 22 265 30 8 x 1.25

Rear brake lever pivot 10 120 13.6

Subframe fasteners 22 265 30 8 x 1.25

Upper shock mount 40 480 54 10 x 1.5

Torque Value

ft-lb in-lb Nm

Size &

Remarks

8 x 1.25

Lower shock mount 40 480 54 10 x 1.5

Swingarm pivot 21 250 28 14 x 2.0

Rear axle nut 25 300 34 12 x 1.25

Rear sprocket bolts 13 160 18 8 x 1.25 (B)

Rear brake caliper bolts 22 264 30 8 x 1.25

Rear brake rotor bolts 6 72 8 6 x 1.0 (B)

Units of mm unless otherwise specified

(R) designates that the application requires the use of high strength (red) thread

locking agent applied to the threads.

(B) designates that the application requires the use of medium strength (blue)

thread locking agent applied to the threads.

7

Page 9

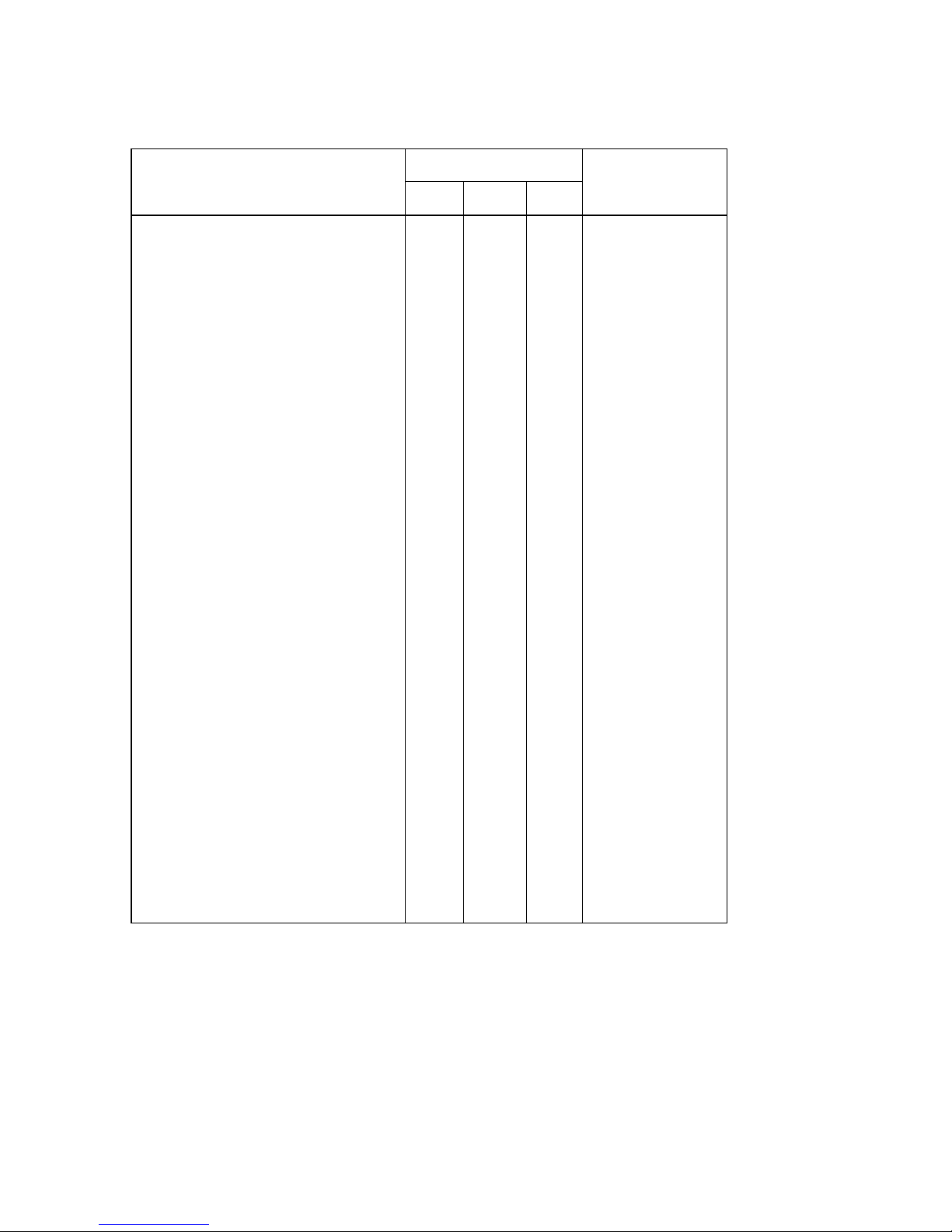

Specifications – Suspension

Fork Oil

Viscosity

Oil Height

(amount)

Fork Spring

Shock Spring

Preload height

Rebound

Damping (clicks

from full damp)

Compression

Damping (clicks

from full damp)

Factory

setting

5 wt

4 oz

(118 ml)

STD.

STD.

Track 1 Track 2 Track 3 Track 4

8

Page 10

Optional Components

• Carburetor jets

• Sprockets

o Front

o Rear

• Suspension Springs

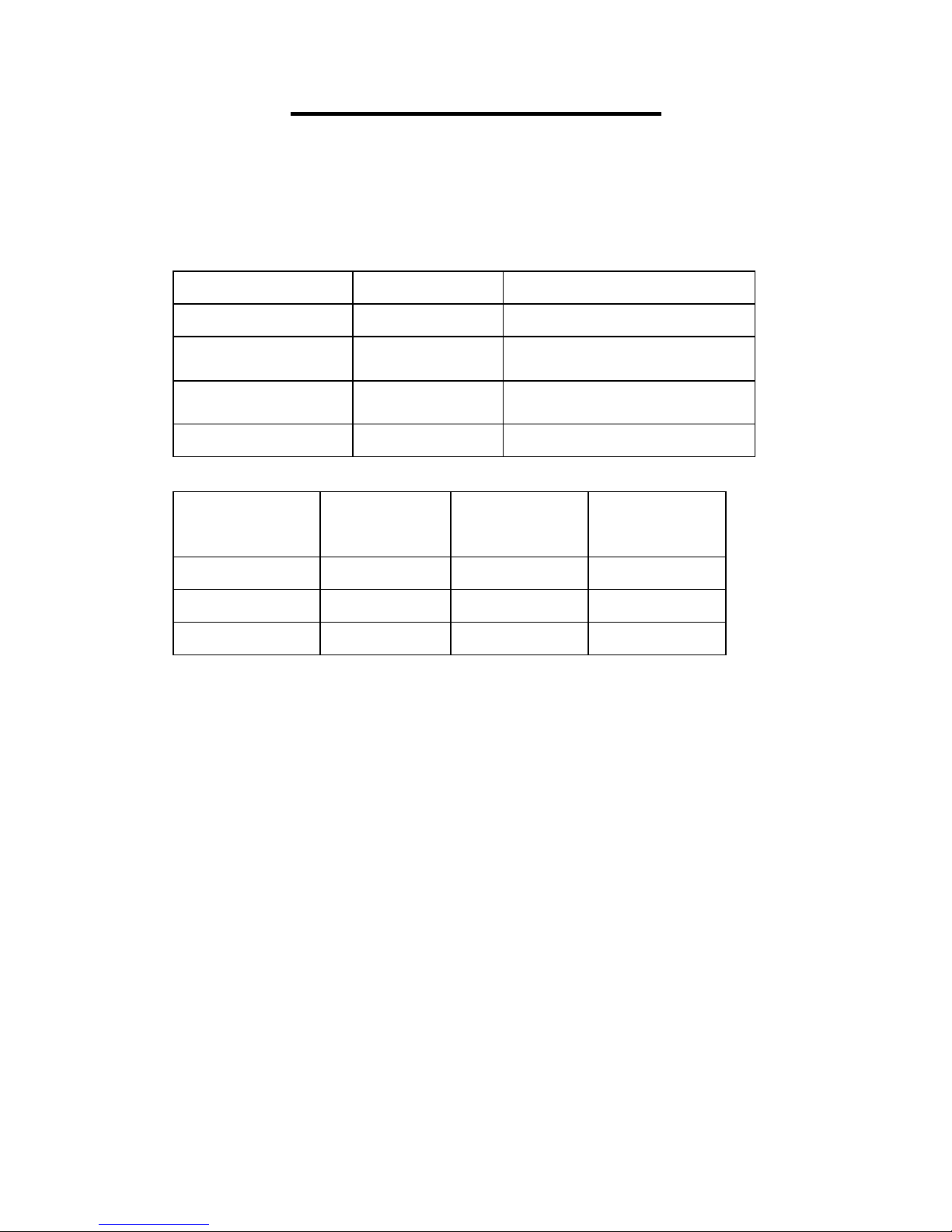

Weight of Rider (lb) Fork Spring Shock Spring

Less than 51 - SCDC0285 (285 lb/in)

51 - 60 KCDCSP01

Greater than 60 KCDCSP02

SCDC0350 (350 lb/in)

• Suspension Valving

Damping Rate Fork Valving

Soft (fast) KCDCBV01 KCDCMV01 SCDCOH01A

Standard KCDCBV02 KCDCMV02 SCDCOH01

Hard (slow) KCDCBV03 KCDCMV03 SCDCOH01B

• Flywheel weights

o Middle weight #ECDC0200

o Heavy weight #ECDC0201

(blue, 14 lb/in)

(red, lb/in)

Compression

(base valve)

SCDC0300 (300 lb/in)

SCDC0325 (325 lb/in)

Fork Valving

Rebound

(mid valve)

Shock Valving

(kit)

9

Page 11

Break-In Procedure

Your Cobra Motorcycle is a close-tolerance high performance machine and

break-in time is very important for maximum life and performance. The DC65 can

be ridden hard after the first ½ hour break-in time but it is recommend ed that no

adjustments are made to the carburetion or suspension until the full 8 hours of

bike break-in has elapsed. Also, after the engine, transmission, and drive train

have been broken -in for the full 8 hours, the bike will be faster!

Use a fuel / oil mixture of 32:1 for the full 8 hour break-in period. Be sure to use

93 octane pump gas, or Sunoco MO2X , with Cobra’s specially formulated Cobra

Venom 2-cycle Race Oil. (Part # MCMUOL02)

CAUTION:

Failure to use proper fuel or oil may result in premature engine wear, or damage

to the machine.

Adhering to the following break-in schedule will result in long lasting high

performance machine.

• First ½ hour of operation

o Follow the starting procedure listed in this manual.

o Avoid prolonged operation at Wide Open Throttle.

• After 1 hour of operation

o Check for loose bolts and nuts on the bike and retighten as

necessary (proper toque values are listed under Specifications).

o Clean the carburetor bowl.

o Change the transmission / clutch lubricant.

o Replace the fuel filter.

• After 8 hours of operation

o Change the fork oil.

o Have a Certified Cobra Mechanic change the shock oil.

• Your bike is now ready for the highest level of competition!

10

Page 12

Starting Procedure

Before starting the machine inspect the following:

• Insure that the fuel tank contains an adequate volume of fuel / oil mixture to

complete the distance required. (Sunoco MO2X or 93 octane pump gas with

Cobra’s specially formulated Cobra Venom 2-cycle Race Oil)

• Check for proper tire pressure in both tires.

• Observe the chain tension and adjust if necessary.

• Observe the coolant level and fill if necessary.

• Verify that the chain rollers do not have improper wear.

• Inspect the frame, for;

o Cracks in the metal.

o Cracking paint which might indicate overly stressed material.

• Verify that the handlebars are tight.

• Check the throttle for;

o Smooth operation and sound closing.

o Frayed strands of the cable inside the throttle housing.

• Check for loose bolts and nuts, and re-torque as necessary.

• Verify that the air filter is cl ean and properly saturated with oil.

• Turn the fuel on by rotating the fuel petcock knob to the vertically downward

position (reserve position is horizontally forward).

CAUTION:

For best results from your Cobra Motorcycle use only the recommended fuels.

Testing has shown that most ‘race’ fuels actually degrade performance.

When your pre-ride inspection is complete the bike may be started. For a cold

engine follow this procedure.

1. Reaching down to the carburetor, on the left side of the bike, pull up the

black choke knob and rotate it so that it locks in this ‘up’ position.

2. Kick start the engine.

3. Rev the engine in short spurts, turning the throttle no more than 1/4 open

until the engine will run without the choke.

4. Verify a functional engine shut-off switch by shutting off the engine.

5. Restart the engine and proceed with riding when the engine is sufficiently

warm (i.e. the side of the cylinder is warm to touch).

CAUTION:

Never rev an engine full throttle when it's cold or slightly warmed up. Cobra

recommends that you tell your child to take it easy the first couple of minutes in

practice until the engine comes up to full operating temperature. Make sure your

engine is properly warmed up before racing.

11

Page 13

General Tips

1. Always wear a helmet and other protective riding gear.

2. Cobra recommends that you tell your child to take it easy the first couple of

minutes in practice until the engine comes up to full operating

temperature.

3. Make sure your riders’ foot is not resting on the rear brake pedal while they

are riding.

4. Evaluate the bikes jetting only after it has been warmed up to race

temperatures.

5. A properly maintained machine is safer, faster, and more fun to ride.

6. When washing the bike, be careful to not directly aim the hose at the

bottom edge of the seat, or water is apt to enter the airbox.

7. Some people have found cable ties (zip ties) more favorable for securing

the rear brake line to the swingarm.

8. Also, some people are moving the rear brake line (hose between the

master cylinder and the reservoir) from it’s stock position, to a position

slightly more forward and securing it with a cable tie (zip tie). This moves it

further from the heat of the exhaust pipe.

9. Mare sure that there is adequate free play in both the front lever and rear

brake pedal .

10. Your Cobra Motorcycle has a 12 digit VIN (Vehicle Identification Number).

The first four digits indicate the model and the nineth indicates the model

year (MY).

a. The exception is that ’03 MY DC65 which came out late so the

model year is off by one.

b. Example, DC65-xxx-x2xxx is a 2003 MY DC65.

12

Page 14

Maintenance

Schedule & Tips

It is important that you adhere to this maintenance schedule so as to promote the

longevity of your Cobra Motorcycle.

• Between each ride

o Inspect the fuel filter for contaminates.

o Check the air filter (clean and re-oil as necessary).

o Insure the smooth operation of the throttle cable (throttle soundly

‘clacks’ shut).

o Check for frayed strands of the throttle cable inside the throttle housing

and replace if necessary.

o Check for adequate tire pressures and adjust if necessary.

o Check all nuts and bolts for proper torque and re-torque if necessary.

o Spray all moving parts with WD40 or other light oil.

o Check drive chain for

§ Proper tension and adjust if necessary.

§ Adequate lubrication and lubricate if necessary.

o Insure that the ignition stator and rotor are clean and dry.

o Check the frame for cracks in the metal or cracks in the paint that

might indicate that the metal has been stressed beyond it’s safe limits.

Replace or get properly rewelded as necessary.

• Every 2 hours of operation

o Replace the transmission oil.

• Every 10 hours of operation

o Replace the fork oil.

o Have the shock oil replaced by a Certified Cobra Mechanic.

CAUTION:

1. If you ever need to weld anything on the bike, disconnect the spark plug

cap, unplug the ignition, disconnect the kill switch, scrape the paint bare

near the area to be welded and put the ground clamp as close to the area

to be welded as possible.

Be sure the fuel tank and carburetor have been removed and safely located

away from the welding process.

2. The frame is 4130 Chrome Moly and it is important to weld it with the proper

rod and heat settings set as light as possible. Cobra recommends replacing

the frame with a new one if the old one becomes damaged.

13

Page 15

M1: Replacing Transmission Lubricant

Tools needed:

• 530 ml (18 oz ) 85W 90 gear lubricant

• large flat blade screwdriver

• 13 mm wrench or socket

Procedure:

1. Begin this procedure with a bike that has been ridden more than 5 minutes

but less than 10 minutes. It is desired to have the engine warm enough so

that the oil ‘runny’ but not so hot that there is risk of being burned by the

engine or the oil.

Hot oil and hot components on the motorcycle may cause burns.

2. Lean bike against something or set on stand with oil drain hole.

3. Using the 13 mm wrench, remove the oil drain bolt located on the right side

of the engine (figure 1).

4. After it has drained, reinstall the drain screw with gasket.

5. Remove the oil fill plug and pour in 530 ml (18 oz) 85W 90 gear lubricant.

NOTE: Leaning the bike over onto it’s left hand side will facilitate the oil filling

procedure.

6. Reapply the oil fill screw, securely, being sure the gasket is in place.

14

Figure 1

Page 16

M2: Chain adjustment

Tools needed:

• Two 19 mm wrenches or sockets

• 13 mm wrench or socket

• Measuring device

Procedure:

1. Loosen the rear axel nut (two 19 mm wrenches).

2. Adjust the chain adjusters in the end of the swingarm (clockwise for tighter

chain) until proper chain tension, 37 – 42mm (1.50” – 1.63”) is achieved (13

mm wrench). See figure 2 for proper measurement location.

NOTE:

This measurement is to be made with the motorcycle setting on a stand and

the rear wheel suspended in the air while lifting on the chain.

Figure 2

3. From the back, sight down the length of the chain to confirm that the rear

wheel is running true (rear sprocket is not forcing the chain to turn).

4. Verify that the wheel is all the way forward against the adjusters.

5. One way to do this is to place a shop rag between the chain and sprocket

while rotating the wheel backwards (figure 3) thus pulling the wheel forward.

15

Page 17

Figure 3

6. Tighten the rear axel nut to 25 ft-lb (34 Nm) (two 19 mm wrenches).

Rotate the wheel forward and remove the shop rag.

M3: Front brake adjustment

Tools recommended for front brake maintenance:

• 10mm open end wrench

• 3 mm hex key

CAUTION:

Adequate lever free play is required so that the brake pads do not wear

prematurely.

1. Loosen the lock nut (10mm wrench).

2. Screw the adjuster in (Clockwise) to remove free play, or out (Counter

Clockwise) to add free play (3mm hex key).

M4: Clutch lever adjustment

The clutch lever adjuster requires no tools. Rotate the red adjusting knob in

(Clockwise) to remove free play, or out Counter Clockwise) to add free play

16

Page 18

M5: Rear brake adjustment

Tools required

• 10 mm wrench

1. Set pedal position first, then

2. Set pedal free play.

Setting rear brake pedal position (see figure 4):

1. Loosen the lock nut (10mm wrench).

2. Adjust the brake lever stop (10mm wrench) so that the lever is comfortably

reachable in both:

a. Standing riding position, and

b. Sitting riding position.

3. Tighten the lock nut (10 mm wrench).

Figure 4

Setting rear brake pedal free play

CAUTION:

Adequate pedal free play is required so that the brake pads do not wear

prematurely.

To adjust (see figure 4):

1. Loosen the lock nut (10mm).

2. Undo the free play locking clip from around the brake adjuster (plunger),

with your hand by pushing it forward.

3. Slide the pin of the locking free play locking clip from the brake lever

4. Adjust as needed by rotating the clevis on the end of the adjuster (plunger).

NOTE:

Turning the clevis Clockwise will lengthen the adjuster (plunger), removing free

play from the system, and turning the clevis Counter-Clockwise will shorten the

adjuster (plunger) addin g free play to the system.

17

Page 19

M6: Air Filter Cleaning

This Cobra Motorcycle comes with a unique air filter / air boot unit designed to

facilitate motorcycle service.

Tools recommended for air filter maintenance:

•

• Foam filter oil

Procedure

1. Removed the front fastener from the left side number plate (?? Hex key).

NOTE:

This fastener holds a spacer between number plate and the frame, which will

drop into the airbox when the fastener is pulled from the number plate. Merely

grab the spacer with one hand while removing the spacer from the number plate

with the other.

2. Rotate the number plate counter clockwise (downward) exposing the

aluminum air box side plate.

3. Remove the two fasteners holding the air box side plate (Hex key)

4. Separate the air filter from the carburetor a

5. Clean the filter with cleaning solvent and then again with hot soapy water.

6. Allow it to dry thoroughly.

7. Saturate with foam filter oil and remove excess.

Do not clean the air filter with gasoline or other highly volatile petroleum product.

Cleaning solvent, diesel fuel, or kerosene would be preferred but caution should

still be taken.

NOTE:

The biodegradable air filter oils, greases, and cleansers work acceptably with this

Cobra Motorcycle.

CAUTION:

Cobra does not recommend using the spray on air filter oils due to their limited

saturation.

NOTE:

It is very important to keep the air filter clean and properly oiled with high quality

water-resistant foam filter oil. It’s very important to oil your filter consiste ntly each

time because varied amounts of oil will change your carburetor jetting.

NOTE:

Make sure you change or clean your filter after each moto. We recommend

carrying three or more filters in your toolbox.

18

Page 20

• 1 for practice

• 1 for each moto

CAUTION:

It is recommended to apply medium strength (blue) thread locking agent to the

threads of the air box side fasteners as well as the number plate fastener.

M7: Fork Oil Replacement

Tools required

• Two 19 mm sockets or wrenches

• 4 & 5 mm hex key (Allen wrench)

• 10 mm wrench

• 1” wrench or socket

NOTE:

It is strongly recommended that you leave the front brake caliper attached to

the fork leg for this procedure. The mounting bolts are all that hold the two

halves of the caliper together, and disassembly would require bleeding the brake

system.

Disassembly

1. Remove the front wheel (19 mm wrenches).

2. Remove the front brake lever perch from the handlebars (4 mm hex

3. Remove the fork legs from the triple clamps (5mm hex key).

4. Perform the following on one leg at a time.

Assembly

1. Remove the fork cap (1” wrench)

2. Turn upside down over a suitable pan and allow to drain.

3. Work the fork in and out several times.

4. Allow to drain at least 15 minutes.

5. Fill the leg with 118 ml (4 Oz) 5 wt fork oil.

1. Measure the fork oil level to the top of the fork tube with the leg collapsed,

and record for tuning purposes.

2. Install the fork spring.

3. Reconnect the damper rod to the fork cap (12 ft-lb, 16 Nm).

CAUTION:

The damper rod is hollow and will break if the nut is over tightened.

4. Reinstall the for cap into the fork leg (5 ft-lb, 6.7 Nm)

5. Reinstall the fork legs into the clamps (6 ft-lb, 8 Nm).

6. Reinstall the brake caliper.

6. Reinstall the front wheel (25 ft-lb, 34 Nm).

19

Page 21

Engine Parts / Service

At this time, the service instructions for are not yet available your Cobra

Motorcycle.

If you don’t feel comfortable with the service work, simply take your engine out of

the frame and sent it to:

Cobra Precision Engines

11511 Springfield Road

North Lim a, Ohio 44452

Cobra’s technicians will go through the entire engine, replacing gaskets, bolts,

any old part that is worn. The engine will be rebuilt using the same precision

gauging and assembly fixtures as when it was assembled new. Before being

returned, the engines performance will be measured on a dynamometer to

ensure that your engine is operating at its highest potential. All this for one low

nominal fee, plus cost of parts. Call (330) 549-9603 for details.

ES1: Top End Parts

(Parts list coming soon.)

ES2: Bottom end & transmission

(Parts list coming soon.)

CAUTION:

Take caution when handling the crankshaft. It is the main power transfer to the

rest of the engine. If it is out of alignment, it will cause premature failure of your

bearings which can lead to serious damage to the cylinder and the rest of the

engine. Do not try to true the crank yourself. Truing the crank should be done

professionally.

Cobra trues every crank before it leaves the factory, and also welds the pin to

keep it true. If there are any problems send the engine in, or call tech support

(330) 549-9603 to determine what the problem is.

CAUTION:

• If you split the cases, check the gear tooth faces for chapping & signs of

fatigue.

• Check the small needle bearings for fatigue. If the bearings are damaged,

the engine cases should be checked to make sure the needle -bearing casing

didn’t oblong the bearing hole in the case.

• Needle bearings should be replaced every racing season.

20

Page 22

ES3: Clutch and Shifter components

Figure 5

21

Page 23

REF. #

1 ECDC0129 CASE,RIGHT,DC65-MACHINED

2 ECDC0031 DOWEL,HOLLOW,CENTERING 6X13

3 HCBB0612 6X12 MET SOC BUT BOLT-ZINC YEL

4 ECDC0022 BEARING,SHIFT DRUM 65CC

5 ECMU0016 BEARING-50 CRANK

6 ECDC0024 SEAL, CRANKSHAFT DC65

7 ECDC0073 CRANK DRIVE GEAR - DC65

8 ECDC0036 SNAP RING,EXT.16MM-SPRING RET.

9 ECDC0075 IMPELLER,65CC WATERPUMP

10 HCWF0501 WASHER FLAT 5MM

11 HCBB0001 10-32X1/2 STAINLESS SCREW

12 ECDC0063 CLUTCH WASHER-DC65

13 ECDC0064 CLUTCH BUSHING DC65 - INNER

14 ECDC0165 CLUTCH BASKET BILLET DC65

15 ECDC0063 CLUTCH WASHER-DC65

16 ECDC0066 CLUTCH PRESSURE PLATE -DC65

17 ECDC0068 CLUTCH DISC-FRICTION-DC65

18 ECDC0067 CLUTCH DISC-STEEL-DC65

19 ECDC0069 CLUTCH HUB - DC65

20 ECDC0070 SPRING, CLUTCH - DC65

21 ECDC0100 5X25 SOCKET HEAD CAP SCREW

22 ECDC0072 1.12X30CS M10

23 ECDC0019 CLUTCH BEARING SEAT

24 ECDC0018 BEARING,CLUTCH THROW OUT-DC65

25 ECDC0020 CLUTCH PUSH ROD

26 ECDC0111 SPACER,KICKSTARTER-DC65

27 ECDC0040 SPRING,KICKSTARTER RETURN-DC65

28 ECDC0036 SNAP RING,EXT.16MM-SPRING RET.

29 ECDC0043 WASHER,KICKSTART BACKUP -DC65

30 ECDC0042 SPRING,KICK STARTER RAMP-DC65

31 ECDC0034 SHAFT,KICK STARTER - DC65

32 ECDC0037 SNAP RING,EXT.15MM-IDLER RET.

33 ECDC0032 GEAR,KICK STARTER IDLER-DC65

34 ECDC0059 BOLT,SHOULDER,M6X11,8X5SB

35 ECDC0057 LEVER,NEUTRAL POSITIONING

36 HCBC0803 SCREW M8X35 SOCKET HEAD CAP

37 ECDC0035 SNAP RING,EXT.12MM-GEAR RET.

38 ECDC0058 LEVER, DRIVE GEAR POSITIONING

39 ECDC0060 SCREW,M6X16PF

40 ECDC0056 BEARING RETAINER PLATE

41 ECDC0052 CASETTE

42 ECDC0060 SCREW,M6X16PF

43 ECDC0038 RAMP GEAR - DC65

44 ECDC0055 SHIFTER SPRING

45 ECDC0054 SHIFTER SHAFT

46 ECDC0033 GEAR,KICKSTARTER - DC65

47 ECDC0167 CLUTCH BASKET BUSHING-OUTER

48 ECDC0071 PLATE, CLUTCH SPRING - DC65

49 ECDC0039 RAMP - DC65

PART # CLUTCH / SHIFTER COMP. DESCRIPTION

22

Page 24

Figure 6

Clutch cover components

REF. # PART # DESCRIPTION

1 ECDC0176 CLUTCH COVER-DC65-MACHINED

2 ZCDC0002 GASKET-CLUTCHCOVER-DC65

3 HCBC0625 6X25 SOCKET HEAD CAP SCREW

4 HCBH0805 M8X12 OIL DRAIN SCREW

5 HCWC0000 GASKET 10MM COPPER WASHER

6 ECDC0046 KICKSTARTER LEVER-DC65

7 HCBH0602 SCREW M6X25 HEX HEAD

8 ECDC0078 SEAL,KICKSTARTER DC65

9 ZCMU0001 GASKET-OIL FILL PLUG-ALL 50'S

10 ECMU0037 OIL FILL PLUG

11 ZCDCOR03 ORING-CLUTCH CAP-DC65

12 HCNL0602 M6 CONICAL TOP LOCKNUT

13 ECDC0074 CLUTCH CAP, DC65, FINISHED

14 ZCDCOR04 ORING,CLUTCH SLAVE CYLINDER

15 CCDC0002 SLAVE CYLINDER-DC65

16 HCBC0601 6X16 SOCKET HEAD CAP SCREW

17 ECDC0082 SNAP RING-CLUTCH CAP

18 ECDC0180 IMPELLER COVER-DRILLED-DC65

19 ZCDC0003 GASKET-IMPELLER COVER

20 HCBC0516 5x16CS-IMPELLER COVER-DC65

23

Page 25

ES4: Ignition

Figure 6

Ignition components

REF. # PART # DESCRIPTION

1 ECDC0085 IGNITION COVER-DC65

2 ZCDC0004 GASKET-IGNITION COVER

3 HCBC0402 4X35 SOCKET HEAD CAP SCREW

4 ECDC0100 5X25 SOCKET HEAD CAP SCREW

5 ECDC0084 5X35 SOCKET HEAD CAP SCREW

6 HCWF0501 WASHER FLAT 5MM

7 HCNS1001 NUT M10

8 HCWF0038 3/8 FLAT WASHER

9 ICMU0006 ROTOR

10 ICMU0007 STATOR

11 ECDC0024 SEAL, CRANKSHAFT DC65

12 ECDC0087 SHIFTER LEVER - DC65

13 INCLUDED WITH SHIFTER LEVER

14 ECKGSR03 SNAP RING-OUTPUT -COBRA

15 PCKG0013 SPROCKET 13T COBRA

16 ECDC0009 SPACER,SPROCKET

17 ECDC0025 SEAL,OUTPUT DC65

18 ECDC0026 SEAL,SHIFTER DC65

19 HCBC0604 SCREW M6X35, SOCKET HEAD CAP

20 HCBC0606 SCREW M6X45, SOCKET HEAD CAP

21 MCKGGR00 GROMMET-ENGINE CASE-COBRA-STAT

22 ECDC0128 CASE,LEFT,DC65-MACHINED

CAUTION:

• Make sure ground

wires are secure. If

the bike is not

grounded it will not

ru n.

• Make sure

connections are free

of dirt.

24

Page 26

ES5: Cooling System

(Parts list coming soon.)

ES6: Fuel & Air System

(Parts list coming soon.)

Reeds

CAUTION:

• The reeds must lay flat on the reed cage.

• If the reed tips aren’t lying flat, replace them immediately.

• The reeds must have a tight seal on the reed cage.

• If the reed is damaged in any way, replace it. This means cracks, chips,

and ruptures. Anything abnormal, replace the reeds.

Take the reed cage out and hold it up to the light and look in through the cage. If

you see light between the reed pedals and the frame, then replace the reeds. If

you do not see light, then the reeds should be ok. (See figure 7)

The presence of light indicates that the reeds should be replaced, or possibly

turned over.

The presence of light indicates that the reeds should be replaced, or possibly

turned over.

25

Figure 7

Page 27

Carburetor Cleaning

Clean the carburetor in a well-ventilated area, and take care that there is no

spark or flame anywhere near the working area; this includes any appliance with

a pilot light. Because of the danger of highly flammable liquids, do not use

gasoline or low flash -point solvent to clean the carburetor.

1. Make sure the fuel is shut off.

2. Remove the carburetor.

3. Drain the fuel in the carburetor.

4. Disassemble the carburetor.

CAUTION:

Do not use compressed air on an assembled carburetor. Or the pressure may

deform the float. Do not use a strong carburetor cleaning solution, which could

attack the parts of the carburetor; instead, use a mild high cleaning solution safe

for plastic parts.

5. Immerse all the metal parts in a carburetor cleaning solution.

6. Rinse the parts in water.

7. After the parts are cleaned, dry them with compressed air.

8. Blow out the fuel passages with compressed air.

9. Assemble the carburetor

10. Install the carburetor onto the motorcycle.

ES7: Exhaust

The pipe is a crucial element to a motorcycle. Any kinks, dents, or damage done

to the pipe will result in a performance loss.

NOTE:

Be sure to take the pipe off, and remove any carbon that may be built up.

Carbon build up is created from exhaust. Exhaust has oils in it, and the oils cling

to the walls of the inside of the pipe. Over a long period of time, the diameter of

the pipe will decrease, due to carbon build up. So it is essential to clear the

residue.

CAUTION:

For optimum performance it is important to repack the silencer. Signs of your

silencer needing to be repacked are:

• The bike is louder than normal.

• A loss of power.

26

Page 28

Tuning

Tuning 1: Carburetor

Topics included are:

1. Jetting Decisions

2. Jetting Changes

C1: Jetting Decisions

Although your Cobra is sent from the factory with the carburetor jetted for optimal

performance, you may find it necessary to adjustment your particular jetting due

to current weather conditions, altitude, fuel variations, and/or engine

modifications.

CAUTION:

Proper jetting is very important for engine performance and engine life.

Symptoms of improper jetting are listed below.

• Symptoms of incorrect oil or oil / fuel ratio

o Poor acceleration

o Misfire at low engine speeds

o Excessive smoke

o Spark plug fouling

o Excessive black oil dripping from exhaust system

• Symptoms of too rich a fuel mixture

o Poor acceleration

o Engine will not ‘rev’ out, blubbers on top

o Misfire at low engine speeds

o Excessive smoke

o Spark plug fouling

o Wet, black, or overly dark spark plug (when removed for inspection)

• Symptoms of too lean a fuel mixture

o Pinging or rattling

o Erratic acceleration

o Same actions as running out of fuel

o High engine temperature

o White spark plug (when removed for inspection)

NOTE:

When inspecting the spark plug to evaluate jetting, a properly jetted machine will

produce a spark plug that is dry and light tan in color.

27

Page 29

Environmental and altitude related mixture adjustments

Condition Mixture will be Required adjustment

Cold air Leaner Richer

Warm air Richer Leaner

Dry air Leaner Richer

Very humid air Richer Leaner

Low altitude Standard None

High altitude Richer Leaner

Low barometric pressure Richer Leaner

High barometric pressure Leaner Richer

NOTE:

• Before making any carburetor jetting changes verify that:

o You are using the proper fuel and oil

o The fuel is fresh and uncontaminated

o The oil and fuel have been mixed in the proper ratio

o The carburetor is clean (no plugged jets)

o The air filter is properly clean and oiled

o The float height is within proper specification (proper measuring technique

is described later in this section)

NOTE:

Perform all jetting changes on a motorcycle that has been warmed up to proper

operating temperature.

The carburetor on your Cobra motorcycle is quite adjustable. Figure 8 shows its

range of adjustment and in particular what adjustable component affects what

range of operation (specifically throttle posit ion).

AIR SCREW ADJUSTMENT: Adjust for maximum idle speed

The air adjustment screw is located on the left side of the carburetor. It is the

smaller of the two adjustment screws and requires the use of a small flat blade

28

Figure 8

Page 30

screw driver for adjustment. After adjusting for maximum idle speed, use the idle

screw to adjust the desired idle speed.

NOTE:

If the air screw requires more than 3 turns out, replace the pilot jet for one that is

one size leaner (smaller number) then readjust the air screw.

Figure 9

IDLE ADJUSTMENT: Adjust for desired idle speed

The idle speed screw is located on the left side of the carburetor. It is the larger

of the two screws on the side of the carburetor and is unique with its knurled

head for easy fingertip adjustment. To raise the idle, turn the screw in, clockwise,

(in 1/4 turn increments) and rev the engine after each adjustment. To lower the

idle, turn the screw counter-clockwise.

TOP END JETTING: Adjust for clean full throttle acceleration

Jet your top end (main jet) based on the acceleration of your Cobra Motorcycle

on the longest straight at the track. Observe any of the lean or rich symptoms

(spark plug appearance and bike performance) listed above and change your

jetting accordingly.

PART THROTTLE Adjust for desired acceleration

Using an area of the track that allows the rider to operate and mid throttle and

transition (accelerate, or ‘roll on’) from closed, or mostly closed throttle, to a

larger throttle opening. Observe the rich and lean symptoms listed above.

Adjust the jet needle position by moving the clip from its current position (move

the clip higher on the needle to make the bike run leaner, or move the clip lower

on the needle to make the bike run richer) to one higher or lower.

29

Page 31

C2: Jetting Changes

STOCK CARBURETOR SETTINGS

• 19 mm + 0.5mm (0.75” + 0.020”) float height

• Air screw ½ turn out

• 38 pilot jet

• JJH – 3 (3rd position from top) jet needle

• 128 main jet

To check and/or adjust float height:

REQUIRED TOOLS

• Flat blade screwdriver

• #1 (small) Phillips screw driver

• Accurate measuring device

1. Insure that the fuel petcock is turned to off.

2. Using a flat blade screwdriver loosen the hose clamps to the front and rear of

the carburetor.

3. Work the carburetor from the inlet and airbox.

4. Detach the fuel line from the top of the carburetor.

5. Detach the carburetor from the cable and slide by unscrewing the cap off the

top of the carburetor

CAUTION:

The jet needle is attached to the end of the slide. Take care not to bend or

abuse it.

6. Remove the float bowl by removing the two Phillips head screws.

CAUTION:

Perform step six in a well ventilated area and over a small pan as some

flammable fuel is likely to drain from the bowl as it is removed from the

carburetor.

7. Hold the carburetor (with the float bowl removed) as shown in figure 10,

measuring from the bottom of the float to the carburetor body gasket surface.

30

Page 32

Figure 10

NOTE:

When measuring the float height, the float should be resting, but not depressing,

the spring loaded float valve pin (his can be done by tilting the carburetor until the

float tab just makes contact with the valve pin). If adjustment is needed, bend the

metal tab on the float arm until correct height is obtained (19 mm + 0.5mm (0.75”

+ 0.020”)).

To replace the main jet:

REQUIRED TOOLS

• Flat blade screwdriver

• 17 mm wrench

• 6 mm socket or Keihin jet wrench

Removal

1. Insure that the fuel petcock is turned to off.

2. Loosen the hose clamps at the front and rear of the carburetor (screwdriver).

3. Rotate the carburetor so that the float bowl is exposed (may need to dislocate

from the air boots)

4. Remove the jet access plug from the bottom of the float bowl (17 mm

wrench).

5. Remove the jet (6mm socket or jet wrench).

6. The jet size is stamped in the side.

CAUTION:

When making main jet changes, make changes in single step sizes and always

take the conservative approach if you are unsure (experiment rich before

experimenting lean).

Installation

1. Lightly seat the new jet (6 mm socket or jet wrench).

2. Reinstall the jet access plug in the bottom of the float bowl (17 mm wrench).

3. Reinstall the carburetor properly in the inlet and air boot.

CAUTION:

Make certain that the carburetor completely inserted into the inlet and that the air

31

Page 33

boot is pulled at least 8mm over the inlet of the carburetor body.

To replace the pilot jet:

REQUIRED TOOLS

• Flat blade screwdriver

• 17 mm wrench

Removal

1. Insure that the fuel petcock is turned to off.

2. Loosen the hose clamps at the front and rear of the carburetor (screwdriver).

3. Rotate the carburetor so that the float bowl is exposed (may need to dislocate

from the air boots)

4. Remove the jet access plug from the bottom of the float bowl (17 mm

wrench).

5. Remove the jet (flat screw driver).

6. The jet size is stamped in the side.

CAUTION:

When making main jet changes, make changes in single step sizes and always

take the conservative approach if you are unsure (experiment rich before

experimenting lean).

Installation

4. Lightly seat the new jet (flat screw driver).

5. Reinstall the jet access plug in the bottom of the float bowl (17 mm wrench).

6. Reinstall the carburetor properly in the inlet and air boot.

CAUTION:

Make certain that the carburetor completely inserted into the inlet and that the air

boot is pulled at least 8mm over the inlet of the carburetor body.

To adjust the jet needle clip position:

REQUIRED TOOLS

• Flat blade screw driver

1. Insure that the fuel petcock is turned to off.

2. Using a flat blade screwdriver loosen the hose clamps to the front and rear of

the carburetor.

3. Work the carburetor from the inlet and airbox.

4. Detach the fuel line from the top of the carburetor.

5. Detach the carburetor from the cable and slide by unscrewing the cap off the

top of the carburetor.

CAUTION:

The jet needle is attached to the end of the slide. Take care not to abuse it.

CAUTION:

The carburetor will likely still hold some flammable fuel, which is likely to drain

out when laid in a horizontal position, so place it in a well ventilated area where it

32

Page 34

may drain.

6. To remove the slide from the cable, hold the slide in one hand and compress

the spring into the cap with the other.

7. While compressing the spring, hold the slide upside down such that the

retaining plate drops free.

8. Snake the cable through the proper grooves to remove the cable from the

slide.

9. With the slide free from the cable, lightly push on the pointed end of the jet

needle to remove it from the slide.

10. Make note of what groove the clip is in on the end of the needle (groove one

is at the top and groove 5 is furthest away from the top).

11. To adjust richer, move the clip further from the top (to a higher number) and

conversely to adjust the bike leaner, move the clip closer to the top.

NOTE:

Make adjustment by one step at a time.

NOTE:

The clip can be easily removed and reinstalled by pressing the needle (with the

clip in position) against the top of a table.

33

Page 35

Tuning 2: Suspension

Topics included are:

1. Suspension Guidelines

2. Proper Suspension Adjustments for Your Rider

3. Symptoms of Incorrect Suspension Adjustment

4. Proactive Suspension Adjustments

5. How to Adjust the Suspension

6. Suspension Reference

Factory

setting

Track 1 Track 2 Track 3 Track 4

Fork Oil

Viscosity

Oil Height

(amount)

Fork Spring

Shock Spring

Preload height

Rebound

Damping (clicks

from full damp)

Compression

Damping (clicks

from full damp)

5 wt

4 oz

(118 ml)

STD.

STD.

34

Page 36

S1: Suspension Guidelines

Proper suspension adjustment is a crucial component for a winning combination

of rider and machine. As important as the rider’s abilities, health, and fitness, or

the performance of the engine, the suspension controls what the rider feels and

how the engine’s power is delivered to the ground. A good rider will struggle on a

poorly suspended machine and a lesser rider will shine on a machine that is

properly adjusted for his or her abilities, physical stature, and the terrain. Properly

adjusted suspension instills confidence in the rider.

While tuning the suspension keep the following important points in mind:

• If the machine is new, the suspension will require a couple of hours of ‘breakin’ time. Adjustments made during this time may need to be redone after

‘break-in’.

• Before making adjustments be sure that the machine is properly

maintained, lubricated, and in fine working order.

• The most important factors to consider when adjusting the suspension are; 1)

rider weight, 2) rider ability, and 3) track conditions. Also consider your

particular rider’s style and personal riding position.

• Before making drastic changes to suspension settings, consult a riding expert

to ensure that an improper riding style, or body position, is not the cause

of the problem.

• The front forks are designed to operate without any gas pressure. Continually

bleed off any pressure that builds up during riding or this will effect the feel

of the front forks.

• A properly adjusted machine is a balance of front and rear suspension

adjustments. Adjustments to one end may require compensating adjustments

to the other end.

• Adjustments to improve the feel of one portion of the race track may

adversely effect the feel in another portion of the track. Make small

adjustments to improve the feel at a problem area, but continually evaluate

the effects of those adjustments on all other areas.

• A tired rider will behave differently than an energetic rider.

• Make notes. Write down what works, and what doesn’t work for a particular

track.

• The suspension on this Cobra Motorcycle has many degrees of adjustment.

This is to provide a machine, which can be set up most precisely to the rider

and tracks requirements. Unfortunately, this also means that there many

ways to do it wrong. You will achieve the best results if you:

1. Read and understand this whole suspension tuning portion of the

manual and,

2. Precisely follow the steps spelled out in the following section called

“Proper Suspension Adjustments for Your Rider” and,

3. If you get confused, overwhelmed, or feel that you have just made

things worse, take a step backward in adjustment to what DID work

best. Perhaps even requiring you to return to stock settings.

4. If all else fails, call the Cobra Technical support hotline (330) 549-

9603.

35

Page 37

S2: Proper Suspension Adjustments for Your Rider

Free length – measurement of available suspension travel with bike on stand

(wheels suspended).

No load sag – amount that the free length measurement is reduced by taking the

machine off the stand (fluids filled to race

quantities).

Race sag – amount that the free length is

reduced with a rider onboard in riding

position (fluids filled to race quantities).

Ride height – The height of the bike while

the rider is onboard.

Fork height – The amount of fork tube

extending above the top triple clamp (figure

11).

Figure 11

STEP 1: Fork Spring Selection

The standard fork spring should be fine for the typical Cobra rider. Although,

depending on your racers weight, and alternative spring may suit him/her better.

If your child weights more than 85 lb (39 kg) then the optional stiffer spring is

recommended.

If you child weights less than 60 lb (27 kg) then the optional softer spring is

recommended.

STEP 2: Proper Ride Height

Taller riders will want the ride height set as high as possible. Conversely shorter

riders will want to set ride height as low as possible. Keep in mind that you need

a front to rear balance. The bike is balanced when the rear frame spars are

vertical.

A proper ride height is established by first adjusting the rear of the bike to the

desired height, and then readjusting the fork height to rebalance the bike. The

height of the rear of the bike is adjusted with the shock (eye to eye) length.

Adjust the ride height such that the rider feels most comfortable touching the

ground when not moving.

The shock on your Cobra Motorcycle has an

adjustable (eye to eye) length. It is not to be extended

any longer than when one groove is visible below the

locknut after tightening.

Figure 12

36

Page 38

Adjustment Procedure

1. Adjust the height of the rear of the bike.

1.1. Remove the shock as covered in the service portion of this manual.

1.2. Using a vice and a thin 17 mm wrench, adjust the length of the shock.

1.3. Reinstall the shock.

2. Rebalance the bike by readjusting the front fork height.

2.1. Loosen the fork triple clamps.

2.2. Slide the forks up or down until the rear frame spars are vertical (see

figure13 and notes below).

2.3. Tighten the front fork clamps 6 ft-lb (8 Nm).

NOTE:

Measuring how vertical the frame spar is can be most accurately done by placing

the motorcycle on a level surface and attaching a magnetic protractor to the

frame spars. Make the measurement while the bike is off the stand and with no

rider onboard.

NOTE:

This measurement only needs to be approximately close to vertical at this point

as some suspension setting to be made later will effect the precise value of this

measurement.

Figure 13

37

Page 39

STEP 3: Proper Race Sag

Tools required

Measuring tape

Shock preload spanner

Calculator or the ability to subtract without one

NOTE:

Always be consistent with measuring units. Stick with inches (“) or millimeters

(mm).

Adjustment Procedure

1. Place the bike on a suitable stand to suspend the rear wheel off the ground.

2. Measure the distance between the centers of the rear fender bolt and the rear

axel bolt (see figure 14).

3. Write this number in table 1 as the Free Length.

4. Remove the bike from the stand and with your rider sitting aboard the bike,

record this measurement again and record it in Table 1 as the Race Length.

NOTE:

Have the rider bounce on the seat

a couple of times to overcome any

static friction (stiction) forces.

5. Calculate the Race Sag by

subtracting the Race Length

from the Free Length and

record it in the table.

6. The desired number is 75 mm

(3.0”)

Figure 14

38

Page 40

Free

Length

Measure Measure

Race

Length

Race Sag

Target 75 mm (3.0”)

Calculate as

Free Length –

Race Length

No Load

Length

Measure

No Load Sag

Target 19 mm (3/4”)

Calculate as

Free Length –

No Load Length

Table 1 Sag calculations

7. If your race sag number does not equal 75 mm (3.0”) adjust the preload on

the shock to achieve this value.

7.1. If your race sag is greater than 75 mm (3.0”) increase the shock preload

by one turn.

7.1.1. Loosen the shock preload lock nut.

7.1.2. Turn the preload adjuster in towards the spring one more turn.

7.1.3. Resecure the lock nut.

7.2. If your race sag is less than 75 mm (3.0”) reduce the shock preload by

one turn.

7.2.1. Loosen the shock preload lock nut.

7.2.2. Turn the preload adjuster back from the spring by one turn (NOTE:

If you unload the spring while performing this task, you must

purchase a softer spring).

7.2.3. Resecure the lock nut.

7.3. Remeasure the race length as described above.

7.4. Repeat this procedure until you are sufficiently close to the target value.

STEP 4: Proper No Load Sag

Tools required

Measuring tape

Shock preload spanner

Calculator or the ability to subtract without one

NOTE:

Always be consistent with measuring units. Stick with inches (“) or millimeters

(mm).

Adjustment Procedure

1. Again measure the distance between the centers of the rear fender bolt and

the rear axel bolt with the bike off the stand, but this time without a rider.

NOTE:

Bounce the seat a couple of times by hand to overcome any static friction

(stiction) forces.

39

Page 41

2. Record the measurement in table 1 as the No Load Length.

3. Calculate the No Load Sag by subtracting the No Load Length from the

Free Length and record it in the table.

4. The target 19 mm + 6mm (3/4” + ¼”).

5. If your calculated No Load Length is not within this value you need to

replace the spring and start at Step 2.

5.1. If your value is greater than 25 mm (1.0 “) then you need a softer spring.

NOTE: This may be counter intuitive. It is because your current spring

rate is sufficiently stiff that very little preload distance is required to get the

proper Race Sag that is not enough distance for the spring to return it to

full stroke.

5.2. If your value is less than 13 mm (1/2 ”) then you need a stronger spring.

NOTE: This may be counter intuitive. It is because your current spring

rate is sufficiently soft that it requires so much preload to get the proper

Race Sag that there is not enough loading of the bike itself to cause

enough sag in the suspension.

6. If your No Load Sag is acceptable then verify the following:

6.1. Ride height is still acceptable – if not readjust.

6.2. Front to back balance is still acceptable (Step 1 vertical frame spar) – if

not readjust.

Other parameters such as Fork oil type and level as well as compression and

rebound damping you should adjust based on symptoms of incorrect suspension

discussed in the next section.

S3: Symptoms of Incorrect Suspension Adjustment

Front Forks Bottoming Too Frequently Fork oil level

If the front forks bottom harshly more than a couple of times per lap and the fork

springs are proper for the weight of rider (as detailed above), try raising the fork

oil level in increments of 10mm. Raising the fork oil level, reduces the air volume,

and increases the stiffness of the forks late in the travel, thus adding a

progressive’ feel.

Front forks feel too stiff over small bumps. Fork oil weight

If the forks feel too stiff over small bumps try decreasing the weight (increasing

the viscosity) of the fork oil.

Rear suspension troubleshooting. Damping

Always start with standard settings and make damping changes in no more than

two click increments and only make one change at a time.

40

Page 42

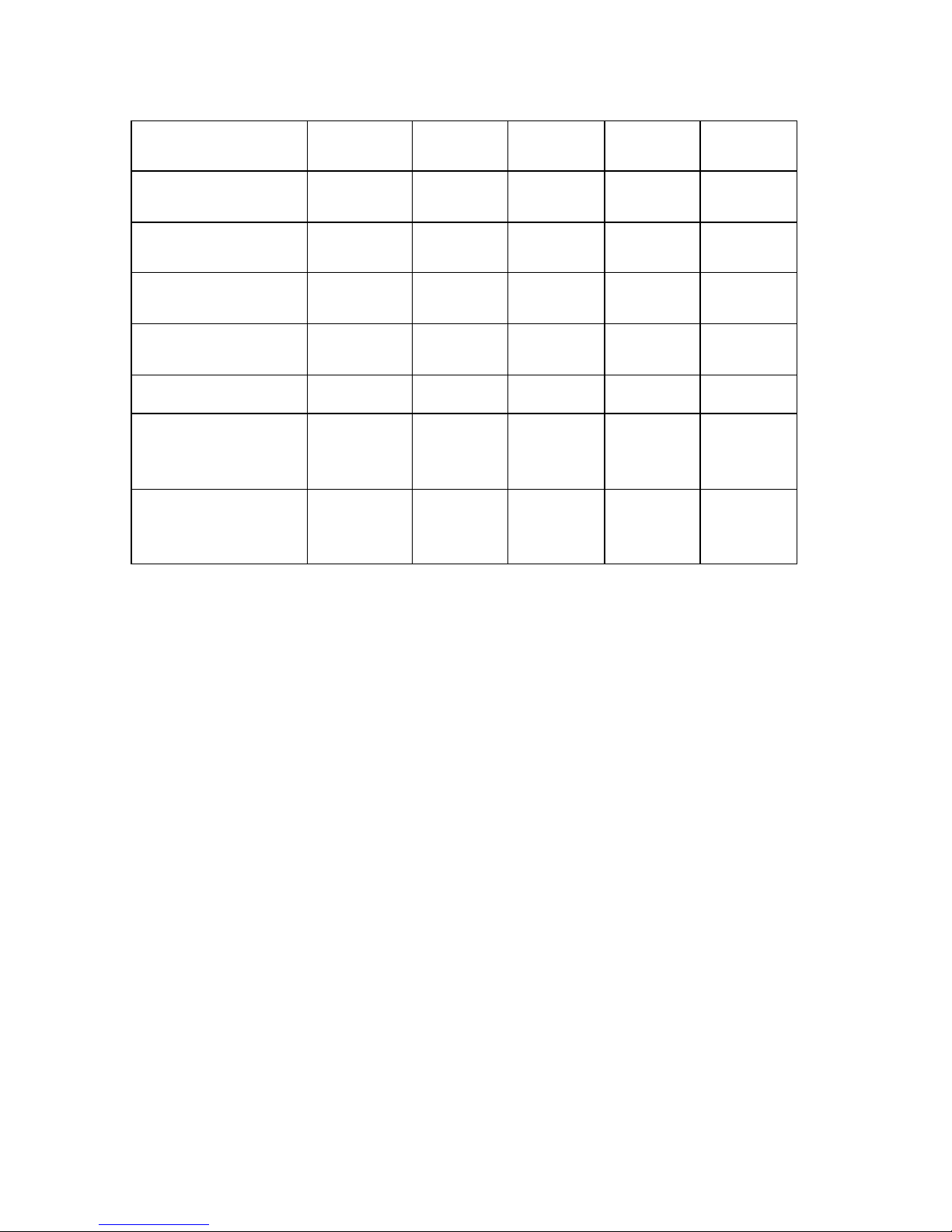

Symptom Action

Rear end feels stiff on small bumps Softer compression damping

Rear end ‘sways’ on straights Harder compression damping

Bike tends to jump ‘rear end high’ Harder rebound damping

Bike tends to jump ‘rear end low’ Softer rebound damping

Frequent rear end bottoming Harder compression damping

Bottoms after end of continuous bumps Softer rebound damping

Rear end ‘kicks’ over square edge bumps 1) Harder rebound, 2) Softer

Compression

S4: Proactive Suspension Adjustments

Once you have the suspension adjusted for decent overall feel, you can make

proactive adjustments when faced with different racing conditions.

Situation Actions

Sand track Lower the rear end (increase race sag).

Sand track Stiffer compression and rebound damping.

Long fast track Lower the forks in the clamps by 3 mm.

Tight slow track Raise the forks in the clamps by 3 mm.

Mud track Lower the bike if the rider has difficulties

touching the ground.

41

Page 43

S5: How to Adjust the Suspension

Shock preload

Shock Damping

Figure 15

Shock Length

The shock on your Cobra Motorcycle has an

adjustable (eye to eye) length. It is not to be

extended any longer than when one groove is

visible below the locknut after tightening.

Figure 17

42

Figure 16

Page 44

S6: Suspension Referen ce

1. Front forks

1.1. Fork oil

1.1.1. Oil type

1.1.1.1. Heavier weight oil – more damping – slower responding

1.1.1.2. Lighter weight oil – less damping – quicker responding

1.1.2. Oil quantity / level

1.1.2.1. Greater quantity / higher level – greater bottoming

resistance, stiffer near the end of the travel.

1.1.2.2. Smaller quantity / lower level – less bottoming resistance,

less stiff near the end of the travel.

1.2. Fork spring

1.2.1. Stiffer spring (higher spring rate) – stiffer throughout the travel.

1.2.2. Less stiff spring (lower spring rate) – less stiff throughout the travel.

1.3. Gas pressure – always bleed off any pressure.

1.4. Fork height (see figure ??)

1.4.1. Rise in clamps for quicker turning.

1.4.2. Lower in clamps for improved straight line stability.

2. Rear shock

2.1. Shock length (eye to eye)

2.1.1. Shorter shock length – lower ride height for shorter riders.

2.1.2. Longer shock length – higher ride height for taller riders.

2.2. Preload adjustment

2.2.1. More preload (greater distance) – less race sag.

2.2.2. Less preload (smaller distance) – more race sag.

2.3. Shock spring

2.3.1. Stiffer spring – stiffer throughout the travel.

2.3.2. Less stiff spring – less stiff throughout the travel.

2.4. Compression damping

2.4.1. Harder (more damping, slower) – adds resistance to the

suspension motion when the suspension is compressing.

2.4.2. Softer (less damping, quicker) – reduces resistance to the

suspension motion when the suspension is compressing.

2.5. Rebound damping

2.5.1. Harder (more damping, slower) – adds resistance to the

suspension motion when the suspension is returning to full length.

2.5.2. Softer (less damping, quicker) - reduces resistance to the

suspension motion when the suspension is returning to full length.

43

Page 45

Troubleshooting

1) Engine not behaving properly

a) Carburetor top is installed backwards (happens a lot)

b) The carburetor slide indexing pin is missing

2) Engine is down on power

a) Clutch engagement is not set properly

b) Jetting is incorrect

c) Silencer needs repacked

d) Exhaust pipe

i) Has excess carbon buildup

ii) Has large dent in it

e) Compression is low

i) Piston

ii) Rings

f) Reeds are damaged

g) Ignition timing is incorrect

3) Engine is excessively loud

a) Silencer needs repacking

4) Engine ‘blubbers’ at high RPMs

a) Jetting too rich

5) Engine won’t start

a) Fuel

i) None in tank

ii) Is sour or bad

b) Carburetor is dirty

c) Ignition

i) Spark plug fouled

ii) Spark plug cap off

iii) Engine Shut-off ‘kill’ switch is shorted

iv) Bad electrical ground

v) Stator winding damaged

d) Exhaust is plugged

6) Engine won’t idle

a) Idle knob needs adjusted

b) Carburetor jets are dirty

44

Page 46

Index

Air Filter

Maintenance..................................18

Bottom End

Service...........................................20

Break-In..............................................10

Carburetion

Specifications..................................5

Carburetor

Tuning ............................................27

Chain

Adjustment.....................................15

Chassis

Specification....................................5

Torque..............................................7

Clutch

Parts...............................................21

Service...........................................21

Clutch Lubricant

Replacing.......................................14

Engine

Parts List........................................20

Specifications..................................5

Torque..............................................6

Exhaust..............................................26

Fork Oil

Replacement.................................19

Front Brake

Adjustment.....................................16

Fuel

Petcock..........................................11

Fuel System

Parts list .........................................25

Service...........................................25

General Tips ......................................12

Ignition

Parts...............................................24

Service...........................................24

Jetting

Stock.................................................5

Troubleshooting............................27

Lubrication

Recommended ...............................5

Maintenance

Schedule........................................13

Tips.................................................13

Oil

Recommended ...............................5

Optional Components........................9

Parts

Bottom end ....................................20

Clutch.............................................21

Ignition............................................24

Inlet.................................................25

Reeds.............................................25

Top end..........................................20

Water pump...................................25

Petcock..............................................11

Rear Brake

Adjustment.....................................17

Reeds.................................................25

Spark Plug

Recommended ...............................5

Specifications......................................5

Torque Values.................................6

Starting...............................................11

Suspension

Troubleshooting............................34

Tuning ............................................34

Tips.....................................................12

Top End

Service...........................................20

Torque

Chassis............................................7

Engine ..............................................6

Transmission

Service...........................................20

Specifications..................................5

Transmission Lubricant

Replacing.......................................14

Troubleshooting

General..........................................44

Jetting.............................................27

Suspension....................................34

Tuning

Carburetor.....................................27

Suspension....................................34

VIN reading .......................................12

WARNING ...........................................2

Water pump.......................................25

45

Loading...

Loading...