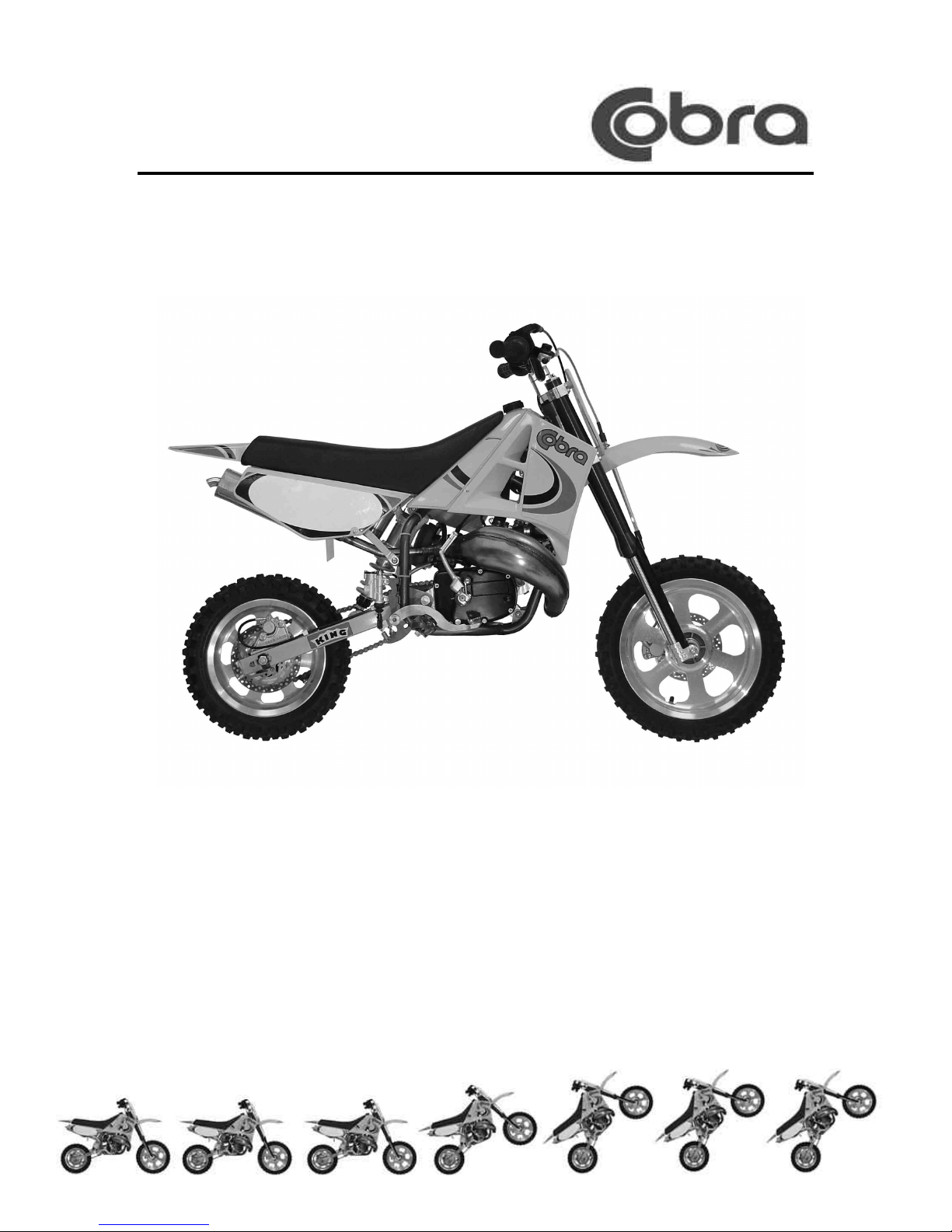

Page 1

2004 KING

Owners / Service / Parts

“CHAMPIONS START HERE”

Page 2

For parts orders contact your local dealer

To locate your closest Cobra dealer

log on to

www.cobramotorcycle.com

or call

(330) 549-9600

If you need technical assistance

contact your local dealer or call

the Cobra Technical Support Hotline at

(330) 549-9603

Cobra Motorcycle MFG., Inc.

11511 Springfield Road

North Lima, Ohio 44452

MCKG2004.7

1

Page 3

DISCLAIMER OF WARRANTY

This motorcycle is sold “as is” with all faults, obvious or not. There are no warranties

expressed or implied, including any warranty of merchantability and warranty of fitness

for any particular purpose.

“WARNING”

THE COBRA KING IS A COMPETITION MODEL ONLY AND IS NOT

MANUFACTURED FOR, NOR SHOULD IT BE USED ON PUBLIC STREETS, ROADS

OR HIGHWAYS.

THE USE OF THIS BIKE SHOULD BE LIMITED TO PARTICIPATION IN

SANCTIONED COMPETITION EVENTS UPON A CLOSED COURSE BY A

SUFFICIENTLY SKILLED RIDER AND SHOULD NOT BE USED FOR GENERAL

OFF-ROAD RECREATIONAL RIDING.

IMPROPER USE OF THIS MOTORCYCLE CAN CAUSE INJURY OR DEATH.

THIS BIKE IS INTENDED FOR EXPERIENCED RACERS ONLY AND NOT FOR

BEGINNERS.

IT IS YOUR RESPONSIBILITY AS THE OWNER OF THIS COBRA MOTORCYCLE

OR AS THE PARENT, OR LEGAL GUARDIAN OF THE OPERATOR, TO KEEP THIS

COBRA MOTORCYCLE IN PROPER OPERATING CONDITION.

THIS BIKE WAS DESIGNED FOR RIDERS THAT WEIGH LESS THAN 80 LBS WITH

FULL RIDING GEAR AND SHOULD NOT BE OPERATED BY RIDERS THAT WEIGH

MORE THAT.

BE SURE THAT THE RIDER ALWAYS WEARS ADEQUATE SAFETY GEAR

EVERYTIME HE OR SHE RIDES THEIR COBRA MOTORCYCLE.

IMPORTANT SAFETY NOTICE

Failure to follow WARNING instructions could result in severe injury or death to

the machine operator, a bystander, or a person inspecting or repairing the

machine.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to

the machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

2

Page 4

Table Of Contents

GENERAL INFORMATION............................................................................................5

SPECIFICATIONS - GENERAL...........................................................................................5

OPTIONAL COMPONENTS................................................................................................6

SPECIFICATIONS - TORQUE VALUES ..............................................................................7

BREAK-I N PROCEDURE...................................................................................................8

STARTING PROCEDURE ..................................................................................................9

GENERAL TIPS................................................................................................................9

MAINTENANCE .............................................................................................................10

SCHEDULE & TIPS.........................................................................................................10

REPLACING TRANSMISSION / CLUTCH LUBRICANT ......................................................11

CHAIN ADJUSTMENT......................................................................................................13

REAR BRAKE MAINTENANCE ........................................................................................13

AIR FILTER CLEANING...................................................................................................14

FORK OIL REPLACEMENT.............................................................................................15

PARTS .............................................................................................................................17

PARTS – BARS AND CONTROLS ...................................................................................17

PARTS - CARBURETOR .................................................................................................18

PARTS – COOLANT SYSTEM.........................................................................................19

PARTS – ELECTRICAL SYSTEM.....................................................................................20

PARTS – ENGINE – BOTTOM END AND TRANSMISSION...............................................21

Parts – Engine – Clutch and Kick Starter...........................................................22

Parts – Engine – Ignition and Water Pump........................................................23

Parts – Engine – Top End.....................................................................................24

PARTS – EXHAUST SYSTEM .........................................................................................25

PARTS – FORKS & TRIPLE CLAMPS.............................................................................26

Parts – Forks – Leg Assembly.............................................................................27

Parts – Forks – Damper Assembly......................................................................28

Parts – Forks – Damper – Base Valve Assembly.............................................29

Parts – Forks – Damper – Mid Valve Assembly................................................30

PARTS – FRAME – BRAKE MOUNTS, PLASTIC SHIELD & FOOTPEGS.........................31

3

Page 5

Parts – Frame - Exhaust, Radiator, & Engine Mounts.....................................32

Parts - Frame – Subframe, Shock, & Bodywork Mounts.................................33

PARTS – FRONT BRAKES..............................................................................................34

PARTS – FRONT WHEEL...............................................................................................35

PARTS – PLASTIC BODYWORK & SEAT........................................................................36

PARTS – REAR BRAKE..................................................................................................37

PARTS – REAR WHEEL.................................................................................................38

PARTS – SHOCK ...........................................................................................................39

PARTS – SWINGARM ASSEMBLY ..................................................................................40

SERVICE.........................................................................................................................41

ENGINE SERVICE...........................................................................................................41

Engine Removal.....................................................................................................42

Complete Engine Disassembly Procedure.........................................................43

Top End Disassembly Procedure........................................................................43

Splitting the Cases.................................................................................................44

Engine assembly....................................................................................................45

CLUTCH .........................................................................................................................50

I GNITION ........................................................................................................................54

COOLING SYSTEM.........................................................................................................56

FUEL & AIR SYSTEM.....................................................................................................60

EXHAUST.......................................................................................................................63

WHEELS & TIRES..........................................................................................................64

BRAKES.........................................................................................................................65

SUSPENSION.................................................................................................................69

Rear Shock..............................................................................................................71

Front Forks..............................................................................................................72

TROUBLESHOOTING ..................................................................................................73

INDEX..............................................................................................................................75

4

Page 6

General Information

Specifications - General

Items KING

Dimensions

Wheelbase 39” (991mm)

Wheel size 10” (254mm) rear, 12” (305mm) front

Seat height 26” (660mm)

Engine

Type 2-stroke, single cylinder, reed valve

Cooling system Liquid-cooled

Displacement 49.8 cc

Bore and stroke 39 mm x 41.7 mm

Ignition system Electronic, analog advance

Spark plug Champion 8339-1, 8332-1 hotter, 8904-1 colder

Gap 0.023” – 0.025” (0.58 – 0.64 mm)

Ignition timing 0.045” (1.14 mm) Before To Dead Center (BTDC)

Fuel type High octane pump gasoline

Oil type Cobra Venom 2-cycle Race Oil

Fuel / oil mix ratios Between 32:1 and 40:1 (after engine Break-In is

Carburetion 19 mm Dell’Orto

RACE FUELS ARE NOT RECOMMENDED

complete)

Slow (Pilot) jet 65

Float Height 16mm + 0.5mm (0.63” + 0.020”)

Coolant Liquid Performance Mini Coolant / Antifreeze

Transmission

Speed Single

Final drive ratio 14/39 T

Chain 100 links 420

Transmission / clutch oil type Cobra Venom 3 Shoe Clutch Milk, or Dexron III

5

Main Jet 95

Quantity 235 ml (8.0oz)

Page 7

Chassis

Front tir e 2.50 - 12

Pressure 16 psi minimum

Rear tire 2.75 - 10

Pressure 16 psi min. (20 psi for hard pack or rocky conditions)

Front fork Cobra 30mm USD

Fork oil type SAE 10 weight

Fork oil amount 105 ml (3.5oz)

Optional Components

• Carburetor jets

• Sprockets

o Front

o Rear

• Suspension Springs

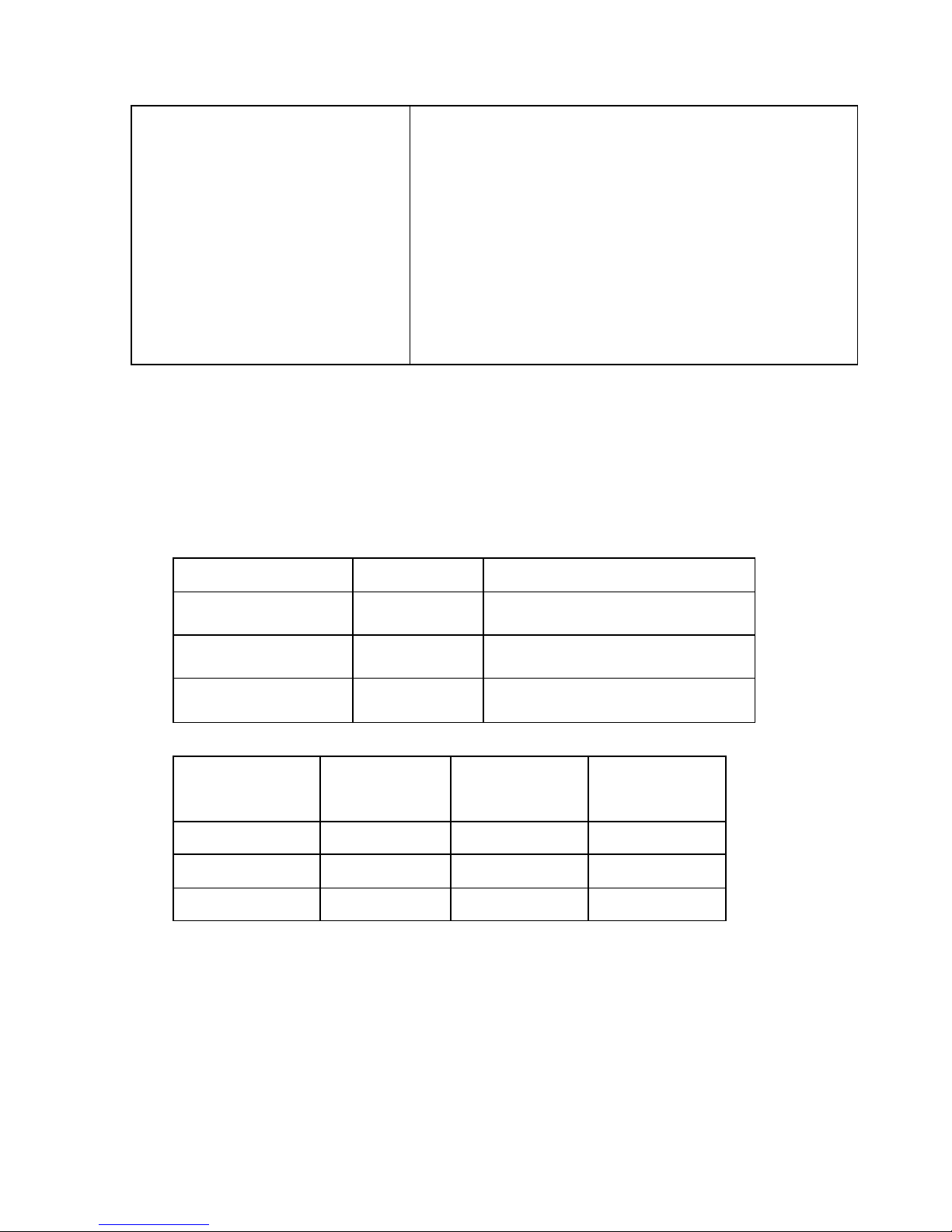

Weight of Rider (lb) Fork Spring Shock Spring

Less than 51 9 lb/in,

KCKG0109

51 - 60 12 lb/in,

KCKG1201

Greater than 60 15 lb/in,

KCKG0015

• Suspension Valving

Damping Rate Fork Valving

Compression

(base valve)

Soft (fast) KAKG0013 KAKG0016 SCKGOH24A

Standard KAKG0014 KAKG0017 SCKGOH24

Hard (slow) KAKG0015 KAKG0018 SCKGOH24B

SCKGOH85 (gray, 185 lb/in)

SCKG0H95, (yellow, 195 lb/in)

SCKG0205, (gold, 205 lb/in)

Fork Valving

Rebound

(mid valve)

Shock Valving

(kit)

6

Page 8

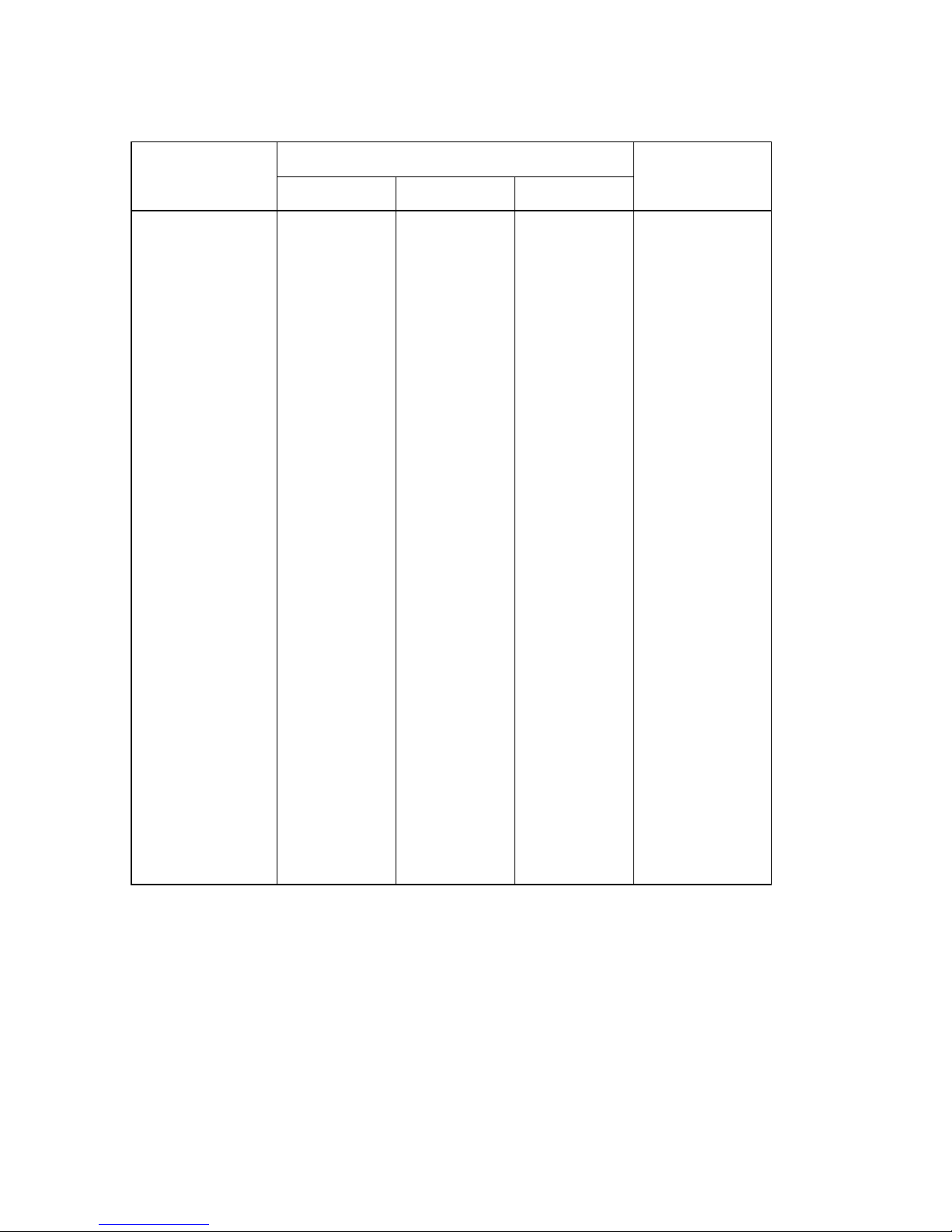

Specifications - Torque Values

Fastener

Cylinder head

nuts

Crankcase

bolts

Spark plug (SP) (SP) (SP) 14 x 1.25

Stator bolts 2.1 25 2.8 #8

Stator cover

bolts

Clutch cover

bolts

Clutch 40 480 54 10 x 1.25***

Front axle nut 25 300 34 12 x 1.25

Engine mount

bolts

Swingarm

Pivot

Intake manifold

bolts

Torque Value

ft-lb in-lb Nm

9.2 110 12 ¼”-20

6.6 80 9 6 x 1.0

1.7 20 2.3 #8

5.8 70 7.9 6 mm

22 265 30 8 mm

21 250 28 14 mm

4.6 55 6.2 6 mm

Size &

Remarks

Rear Axle Bolt 25 300 34 12 mm

Rear Sprocket

Bolts

Fork cartridge

rod

Triple clamp

bolts

Fork cap 5 60 6.7 1.25” x 18

Ignition rotor

nut

** Use green (wicking / bearing retainer) thread locker, with primer, on the

flywheel / crankshaft taper but none on the threads.

*** Use green (wicking / bearing retainer) thread locker, with primer, on the

crankshaft / clutch taper but use red (high strength) thread locker, with primer, on

the nut.

(SP) To apply the proper torque to the spark plug when inserting, one must first

screw the spark plug in until the metal gasket ring causes resistance and then

turn another 1/8 to ¼ turn.

18 216 24 7 mm

12 144 16

6 72 8 6 x 1.0

40 480 54 10 x 1.25**

7

Page 9

Break-In Procedure

Your Cobra KING is a close-tolerance high performance machine and break-in

time is very important for maximum life and performance. The KING can be

ridden hard after the first ½ hour break-in time but it is recommended that no

adjustments are made to the carburetion or suspension until the full 8 hours of

bike break-in has elapsed. Also, after the engine, transmission, and drive train

have been broken -in for the full 8 hours, the bike will be faster!

Use a fuel / oil mixture of 32:1 for the full 8 hour break-in period. Be sure to use

high octane pump gas, with Cobra’s specially formulated Cobra Venom 2-cycle

Race Oil. (Part # MCMUOL02)

CAUTION:

Failure to use proper fuel, oil, or fuel/oil mixture may result in premature engine

wear or damage to the machine.

Adhering to the following break-in schedule will result in long lasting high

performance machine.

• First ½ hour of operation

o Follow the starting procedure listed in this manual.

o Avoid prolonged operation at Wide Open Throttle.

• After 1 hour of operation

o Check for loose bolts and nuts on the bike and retighten as

necessary (proper toque values are listed under Specifications).

o Clean the carburetor bowl.

o Change the transmission / clutch lubricant.

• After 8 hours of operation

o Change the fork oil.

o Have a Certified Cobra Mechanic change the shock oil.

• Your bike is now ready for the highest level of competition!

NOTE:

During break-in the bike will likely lose some engine coolant through the radiator

overflow hose. Losing up to 4 oz (120 ml, ½ cup) is normal. Proper coolant level

will cover the top of the radiator cores. Removing the radiator cap and looking

inside is the only way to check the coolant level.

Never open the radiator cap of a machine that has a hot or warm engine or one

that has recently been ridden. Burning and scalding could occur.

CAUTION:

It is important that the radiator cap is installed correctly and completely otherwise

engine damage could occur.

8

Page 10

Starting Procedure

Before starting the machine inspect the following:

• Check for proper tire pressure in both tires.

• Observe the chain tension and adjust if necessary.

• Observe the coolant level and fill if necessary.

• Verify that the chain rollers and sliders do not have improper wear.

• Verify that the handlebars are tight.

• Check the throttle for smooth operation and sound closing.

• Check for loose bolts and nuts, and re-torque as necessary.

• Verify that the air filter is clean and properly saturated with oil.

• Insure that the fuel tank contains an adequate volume of fuel / oil mixture to

complete the distance required. (High octane pump gas with Cobra’s

specially formulated Cobra Venom 2-cycle Race Oil)

• Turn the fuel on by rotating the fuel petcock knob to the vertically downward

position (reserve position is horizontally forward)

CAUTION:

For best results from your Cobra Motorcycle use only the recommended fuels.

Testing has shown that most ‘race’ fuels actually degrade performance.

When your pre-ride inspection is compl ete the bike may be started. For a cold

engine follow this procedure.

1. Place the motorcycle on a stand of sufficient strength that positions the

motorcycle in a level upright position with the rear wheel off the ground.

2. Pull up the choke knob and turn it to lock it.

3. Kick start the engine.

4. Rev the engine in short spurts, turning the throttle no more than 1/4 open

until the engine will run without the choke.

5. Verify a functional engine shut-off switch by shutting off the engine.

6. Restart the engine and proceed with riding when the engine is sufficiently

warm (i.e. the side of the cylinder is warm to touch).

CAUTION:

Never rev an engine full throttle when it's cold or slightly warmed up. Also, for

best clutch performance, warm up the bike before taking off.

General Tips

1. Always wear a helmet and other protective riding gear.

2. Cobra recommends that you tell your child to take it easy the first couple of

minutes in practice until the engine comes up to full operating temperature.

3. Make sure your riders’ foot is not resting on the foot brake while they are

riding.

9

Page 11

4. Evaluate the bikes jetting only after it has been warmed up to race

temperatures.

5. A properly maintained machine is safer, faster, and more fun to ride.

6. Filling your transmission with more than 8.0 oz (235ml) of lubricant may

help to transfer heat from the clutch, but be aware that this extra oil will

increase the frictional drag on the engine, thus reducing power, and will

often get purged out the cran kcase vent during riding.

7. Your Cobra Motorcycle has a 10 digit VIN (Vehicle Identification Number).

The first two digits indicate the model and the seventh indicates the model

year (MY).

a. Example, ACxxxx4xxx is a 2004 MY King.

Maintenance

Schedule & Tips

It is important that you adhere to this maintenance schedule so as to promote the

longevity of your Cobra Motorcycle.

• Between each ride

o Check the air filter (clean and re-oil as necessary).

o Insure the smooth operation of the throttle cable (throttle soundly

‘clacks’ shut).

o Check for frayed strands of the throttle cable inside the throttle housing

and replace if necessary.

o Check for adequate tire pressures and adjust if necessary.

o Check all nuts and bolts for proper torque and re-torque if necessary.

o Spray all moving parts with WD40 or other light oil.

o Check drive chain for

§ Proper tension and adjust if necessary.

§ Adequate lubrication and lubricate if necessary.

o Insure that the ignition stator and rotor are clean and dry.

o Check the frame for cracks in the metal or cracks in the paint that

might indicate that the metal has been stressed beyond it’s safe limits.

Replace or get properly rewelded as necessary.

o Inspect the rear sprocket damper plate for bendin g or warping.

Straighten or replace if more than 1/16” (1.6 mm) from flat.

o Check the rims for signs of stress, like cracks around the rim, spokes

and hub.

• Every 2 hours of operation

o Replace the transmission oil.

• Every 10 hours of operation

o Replace the fork oil.

o Have the shock oil replaced by a Certified Cobra Mechanic.

10

Page 12

CAUTION:

1. Because of the amount of heat generated by the clutch and engine during

extended periods of riding, it is advisable to remove the ignition cover

afterward to allow the ignition to cool off. The heat transfers through the

cases and can damage the stator as it cools off because of lack of airflow

around the stator.

2. If you ever need to weld anything on the bike, disconnect the spark plug

cap, unplug the ignition, disconnect the kill switch, scrape the paint bare

near the area to be welded and put the ground clamp as close to the area

to be welded as possible.

Be sure the fuel tank and carburetor have been removed and safely located

away from the welding process.

3. The frame is 4130 Chrome Moly and it is important to weld it with the proper

rod and heat settings set as light as possible. Cobra recommends replacing

the frame with a new one if the old one becomes damaged.

4. If your kick-starter lever does not return to the rubber bumper, use WD-40

or light penetrating oil under the plastic cover behind the spring on the

shaft. The shaft is a very close fit to the case and also has an O ring in it

and is difficult to get lubrication to which may cause binding. If it does not

loosen up, remove the kick-starter cover and kicking assembly. Grease the

shaft.

Replacing Transmission / Clutch Lubricant

Tools needed:

• 235 ml (8.0 oz) Cobra Venom 3 Shoe Clutch Milk (P art # MCMUGF01), or

Dexron III Automatic Transmission Fluid.

• 13 mm combination wrench

Procedure:

1. Begin this procedure with a bike that has been ridden more than 5 minutes

but less than 10 minutes. It is desired to have the engine warm enough so

that the oil ‘runny’ but not so hot that there is risk of being burned by the

engine or the oil.

Hot oil and hot components on the motorcycle may cause burns.

2. Lean bike against something or set on stand with oil drain hole.

11

Page 13

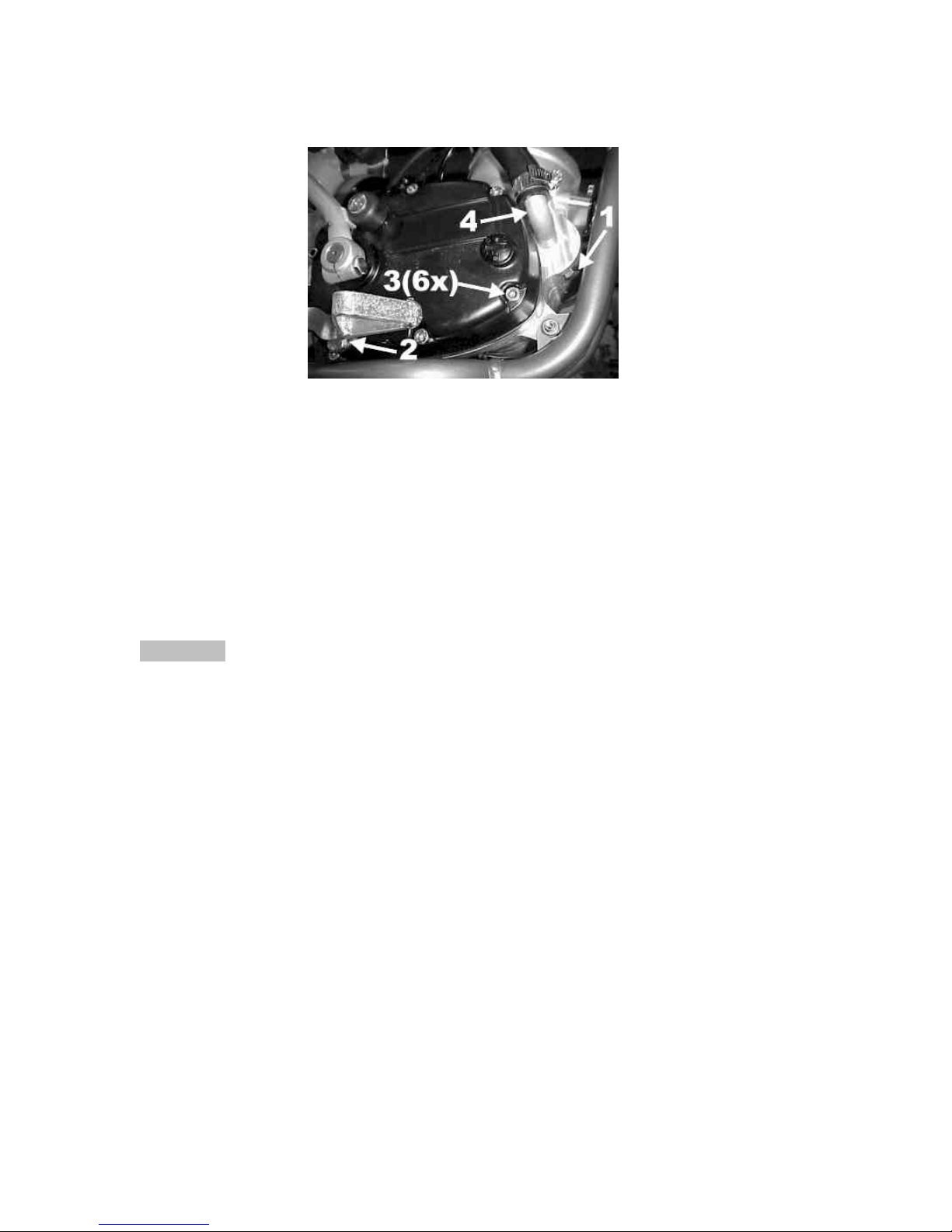

3. Using a 13 mm wrench, remove the oil drain bolt located on the right side of

the engine, on the clutch cover, near the brake lever (Item 2, figure 1).

Figure 1

4. After it has drained, reinstall the bolt being sure that the copper gasket is in

place. Torque to 15 Nm (11 ft-lb).

5. Reapply oil from oil fill plug 235 cc (8.0 oz) Cobra Venom 3 Shoe Clutch Milk,

or Dexron III Automatic Transmission Fluid, thru the oil fill plug.

NOTE:

Lean bike over onto it’s left hand side so that the clutch cover is up unless you

have a squeeze bottle.

6. Reapply the oil fill plug, hand tight, being sure the fiber gasket is in place.

CAUTION:

Cobra has spent considerable time and money developing the proper lubrication

to handle the harsh environment of the automatic clutch and transmission of this

motorcycle. Cobra’s specially developed Cobra Venom 3 Shoe Clutch Milk (Part

# MCMUGF01) was formulated to provide superior lubrication and cooling

capability over extended periods of time and is the recommended lubricant for

your Cobra motorcycle.

12

Page 14

Chain adjustment

1. Make sure that the rear

wheel is aligned properly.

2. Push down on the seat,

compressing the suspension down to where the

chain is tightest. At this

point, there should be a

minimum of 1” of slack.

3. With the rear wheel

Figure 2

elevated, there should be

a minimum of 2.5” of

slack between the swing

arm and the chain.

Rear Brake Maintenance

Brake pedal height can be adjusted with the bolt and nut located under the rear

of the brake pedal. The free-play is adjusted with the adjustable plunger on the

end of the brake pedal.

CAUTION:

Use only DOT 4 brake fluid

CAUTION:

Too little brake pedal free-play will allow the brake pads to drag causing the pads

to wear prematurely. Too much free-play will not all the rider to apply the brakes

quickly.

1. Set pedal position first, then

2. Set pedal free play.

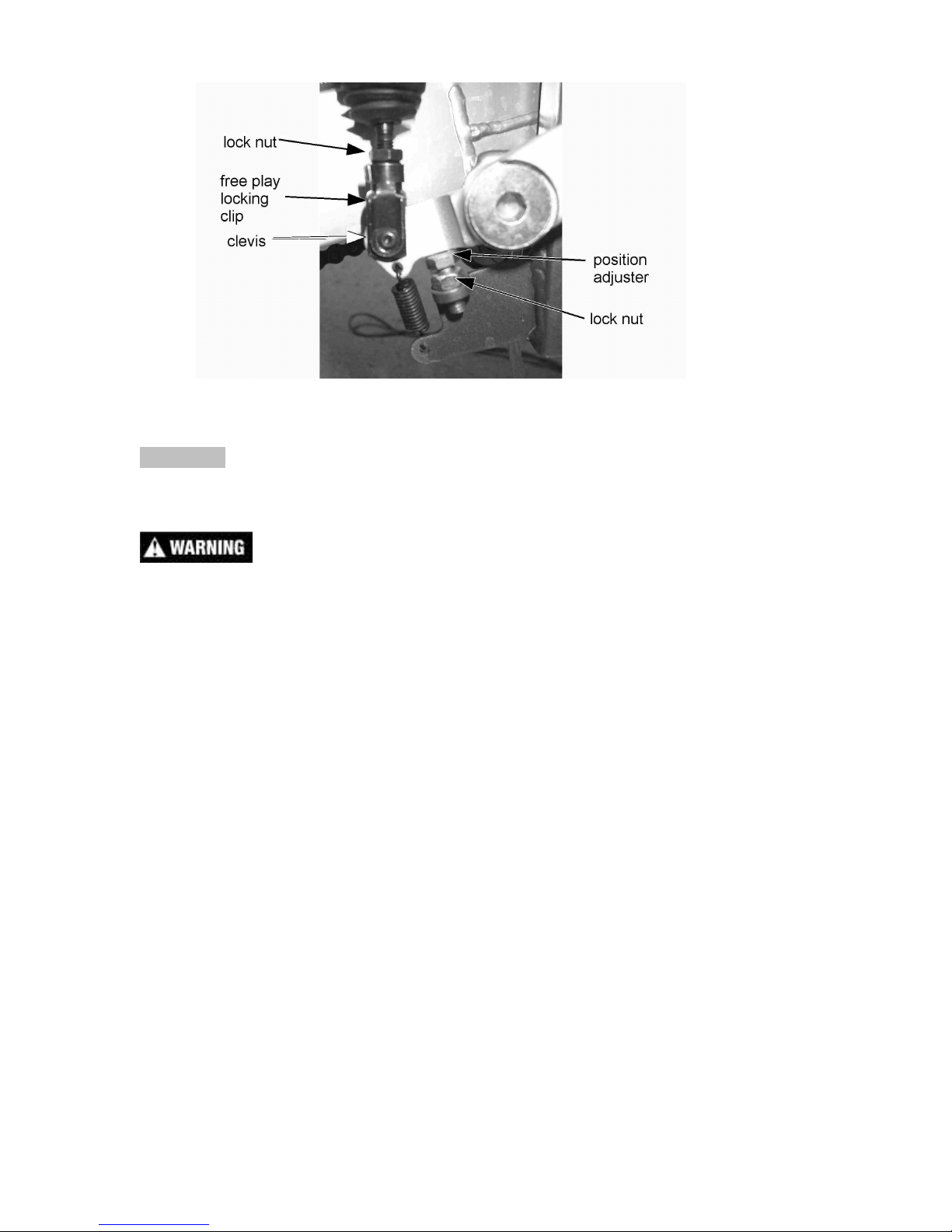

Setting rear brake pedal position (see figure 2b):

1. Loosen the lock nut (10mm wrench).

2. Adjust the brake lever stop (10mm wrench) so that the lever is comfortably

reachable in both:

a. Standing riding position, and

b. Sitting riding position.

3. Tighten the lock nut (10 mm wrench).

13

Page 15

Figure 2b

Setting rear brake pedal free play

CAUTION:

Adequate pedal free play is required so that the brake pads do not wear

prematurely.

Make sure that the free play locking clip is installed such that one must push

forward, toward the front of the bike, to remove. Otherwise the clip is apt to come

undone while riding.

To adjust (see figure 2b):

1. Loosen the lock nut (10mm).

2. Undo the free pl ay locking clip from around the brake adjuster (plunger),

with your hand by pushing it forward.

3. Slide the pin of the locking free play locking clip from the brake lever

4. Adjust as needed by rotating the clevis on the end of the adjuster

(plunger).

NOTE:

Turning the clevis Clockwise will lengthen the adjuster (plunger), removing free

play from the system, and turning the clevis Counter-Clockwise will shorten the

adjuster (plunger) adding free play to the system.

Air Filter Cleaning

Tools recommended for air filter maintenance:

• Flat head screwdriver

• Air filter oil

• 5mm hex key

• Foam filter oil

Your Cobra comes with a pre-filter, or filter skin, to prevent the passing of water

14

Page 16

to the standard air filter. Remove this pre-filter before cleaning and oiling the

standard air filter. The filter skin should be cleaned, with detergent in warm water,

but does not require the application of any oil.

CAUTION:

It is very important to keep it clean and properly oiled with high quality waterresistant foam filter oil. It is also very important to oil your filter consistently each

time because varied amounts of oil will change your carburetor jetting.

Make sure you change your filter after each moto. We recommend carrying

three or more filters in your toolbox.

1 for practice

1 for the each moto

In our testing when filters are properly oiled, no water, dirt or mud can penetrate

through the yellow or red foam to the carburetor inlet. It is important that the filter

does not touch any of the frame components in a rainy, muddy situation. We

offer two different filters. One filter, red in color, is for use in sand and extremely

dusty conditions (part # RCMU0101), and the regular filter, yellow in color, is for

more non extreme conditions (part # RCMU0206).

When washing your bike cover the carburetor/filter with a suitable shield capable

of keeping water from entering the engine. Cobra has a rubber clamp-on plug for

the carburetor (part # RCMU0104).

Fork Oil Replacement

Tools required

• Two 19 mm wrenches or sockets

• 4 & 5 mm hex key (Allen wrench)

• 1” wrench or socket

• 10 wt fork oil

Disassembly procedure

1. Remove the front wheel (19 mm wrench).

2. Remove the brake caliber from the fork leg (4 mm hex key).

3. Loosen the fork caps (1” socket).

4. Remove the fork legs from the triple clamps (5 mm hex key).

5. One leg at a time

a. Remove the fork cap from the leg.

b. Separate the fork cap from the damper rod.

c. Pull out the fork spring.

d. Place upside down over a suitable pan, tray, or container.

e. Work the damper rod up and down several times.

f. Allow to drain completely.

15

Page 17

Assembly procedure

1. Fill the fork leg with 3.5 oz (105 ml) 10 wt fork oil.

2. Measure the fork oil level to the top of the fork tube with the leg collapsed,

and record for tuning purposes.

3. Install the fork spring.

4. Reconnect the damper rod to the fork cap (12 ft-lb, 16 Nm).

CAUTION:

The damper rod is hollow and will break if the nut is over tightened.

5. Reinstall the for cap into the fork leg (5 ft-lb, 6.7 Nm)

6. Reinstall the fork legs into the clamps (6 ft-lb, 8 Nm).

7. Reinstall the brake caliper.

8. Reinstall the front wheel (25 ft-lb, 34 Nm).

16

Page 18

Parts

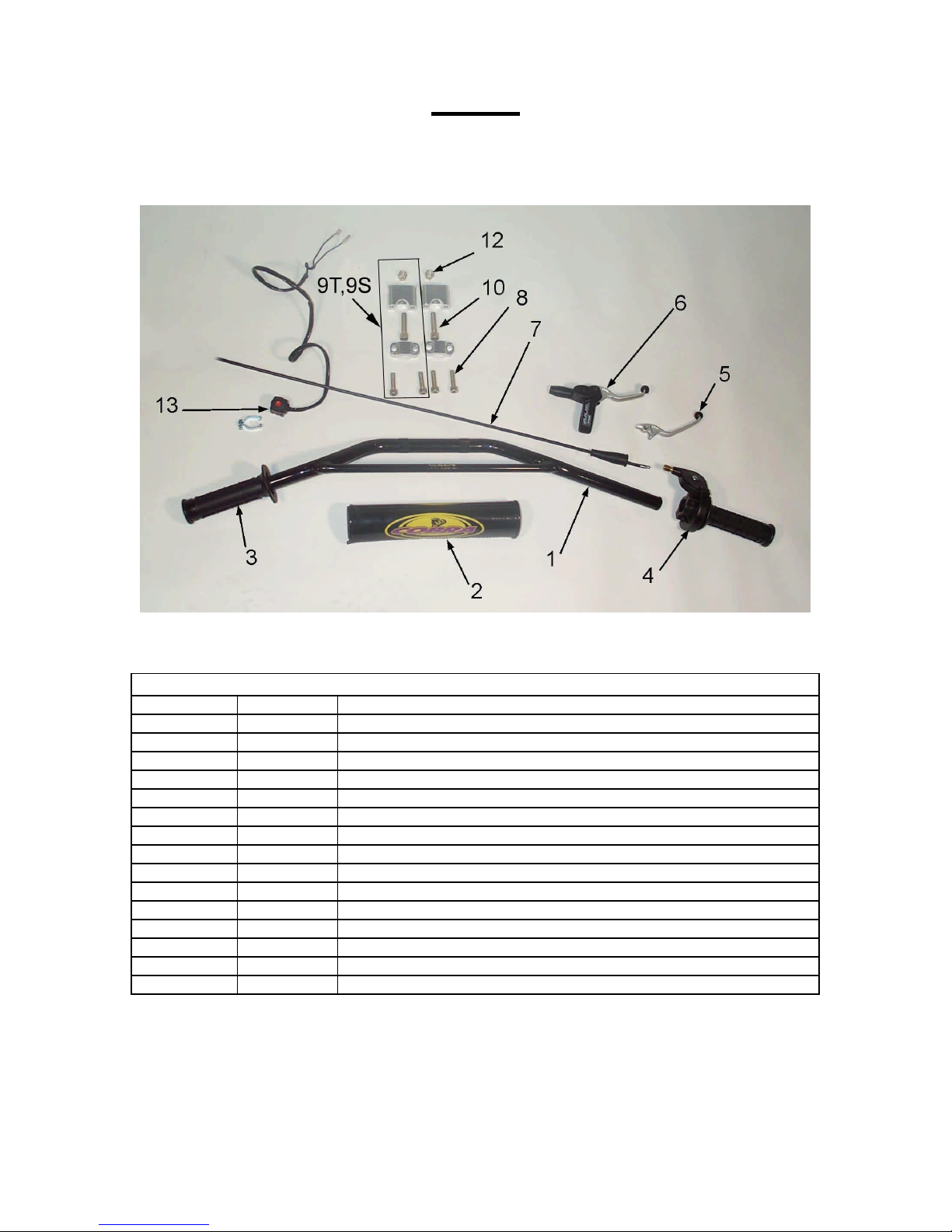

Parts – Bars and Controls

Figure 3

Bars and Controls

REF # PART # DESCRIPTION

1 TCMU 0009 HANDLEBAR - STEEL

2 MCMU0001 OPTIONAL CROSS BAR PAD

3 TCMU0008 GRIPS (SET OF TWO)

4 FCMU0066 THROTTLE ASSEMBLY

NOT SHOWN THROTTLE COVER

5 BCMU0209 ALLOY BRAKE LEVER W/BALL

6 BAMU2002 BRAKE PERCH ASSY W/LEVER & BALL

NOT SHOWN BAKG0004 SHIELDED BRAKE HOSE ASSEMBLY

7 FCMU0067 THROTTLE CABLE

8 HCBC0806 SOCKET HEAD CAP SCREW M8 X 30 (4 PER)

9S TKMU0404 BAR MOUNT KIT, SHORT (2 PER)

9T TKMU0403 BAR MOUNT KIT, TALL (2 PER)

10 HCBC3812 SOCKET HEAD CS 3/8-16 X 1-1/2 (2 PER)

12 HCNL3816 LOCK NUT 3/8 - 16 (2 PER)

13 FCMU0033 KILL SWITCH ASSEMBLY

17

Page 19

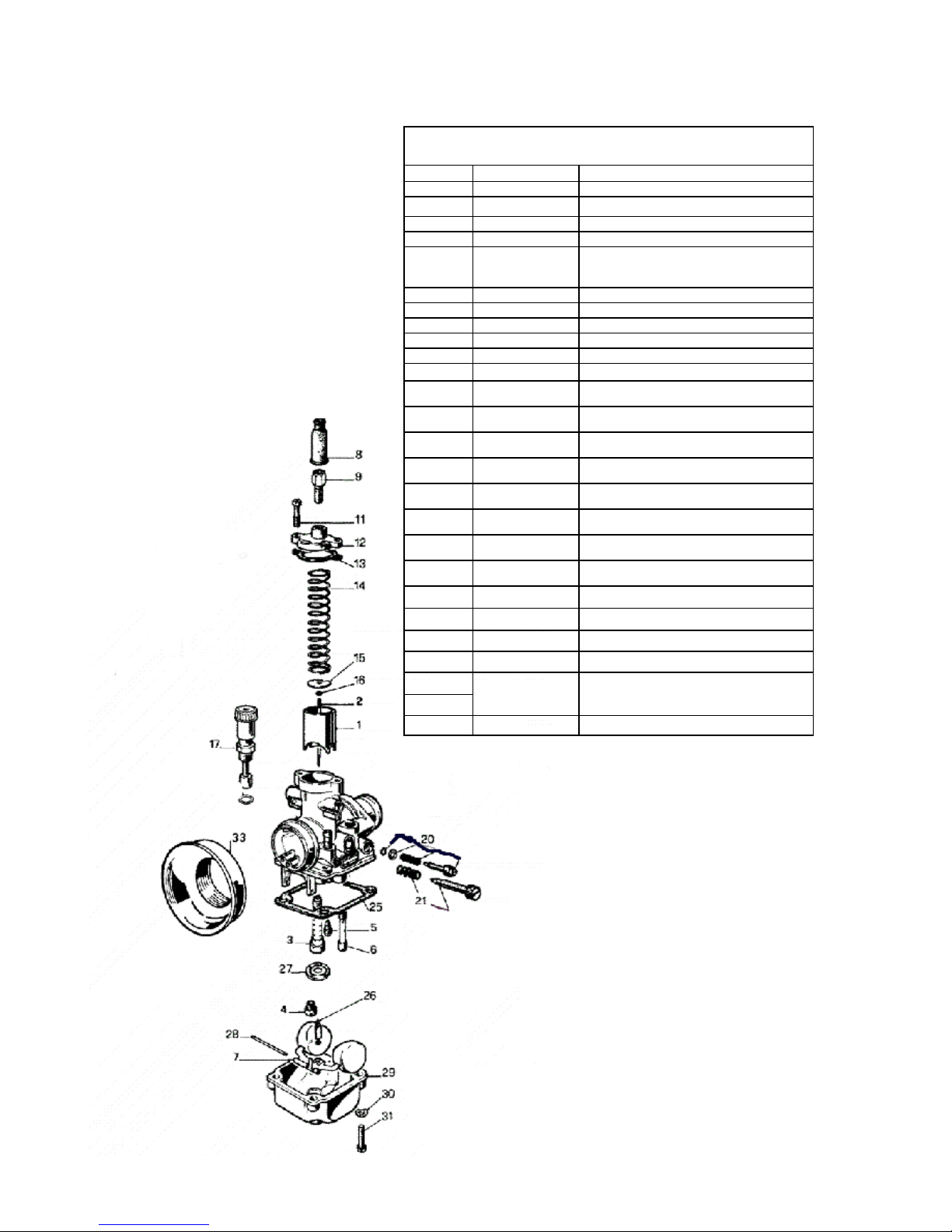

Parts Carburetor

Figure 4

Carburetor

REF. # PART # DESCRIPTION

1 RCMU0305 CARB SLIDE

2 RCMU0601 NEEDLE

3 RCMU0002 ATOMIZER

4 RCMU0095 MAIN JET

5 RCMU0065 PILOT JET

6 CHOKE JET

7 RCMU0301 FLOAT

8 RCMU0102 RUBBER CABLE CAP SEAL

9 RCMU0003 CABLE ADJUSTER

11 RCMU0006 TOP CARB SCREW

12 RCMU0106 CARB TOP

13 ZCMU0007 TOP CARB GASKET

14 RCMU0004 SLIDE SPRING

15 RCMU0205 NEEDLE RETAINER PLATE

16 RCMU0007 NEEDLE CLIP

17 RCMU0204 CHOKE ASS’Y. 2001 CM

20 RCMU0009 FUEL MIXTURE SCREW

21 RCMU0011 IDLE ADJUSTMENT SCREW

25 RCMU0103 FLOAT BOWL GASKET

26 RCMU0107 FLOAT NEEDLE

27 RCMU0012 DIFFUSER

28 RCMU0016 FLOAT RETAINER PIN

29 RCMU0106 FLOAT BOWL

30

RCMU0201 BOTTOM FLOAT SCREW

31

33 RCMU0269 VELOCITY STACK

18

Page 20

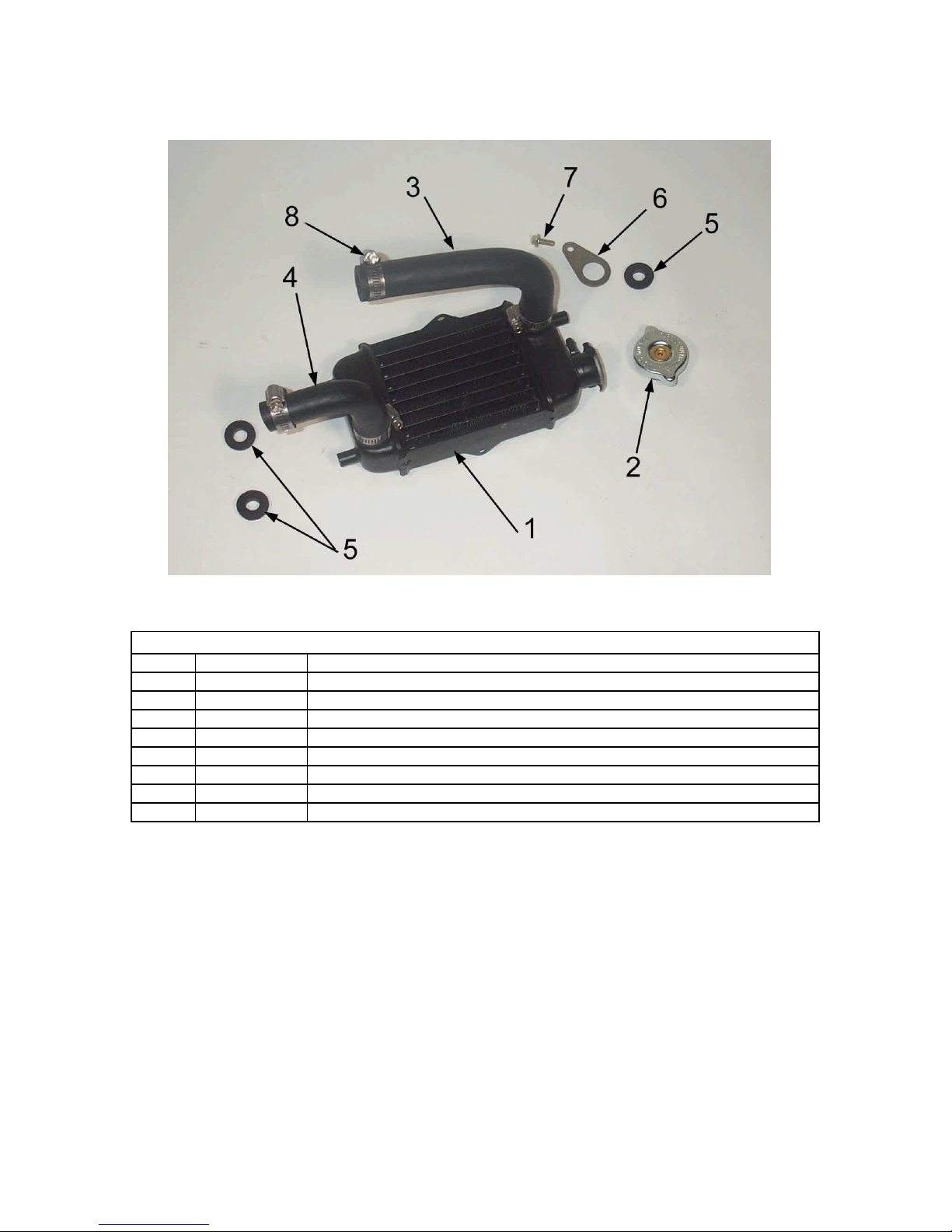

Parts – Coolant System

Figure 5

Coolant System

REF # PART # DESCRIPTION

1 FCMU0045 RADIATOR

2 FCMU0047 RADIATOR CAP

3 ECMU0024 RADIATOR HOSE LARGE, TOP, LEFT

4 MCMUHO01 RADIATOR HOSE, SMALL, BOTTOM, RIGHT

5 MCMUGR03 MOUNTING GROMMET (3 PER)

6 FCMU0006 RADIATOR MOUNTING BRACKET (TEARDROP)

7 HCBF0616 FLANGE HEAD BOLT M6X16

8 MCMUCL02 HOSE CLAMP (4 PER)

19

Page 21

Parts – Electrical System

Figure 6

Electrical System

REF # PART # DESCRIPTION

1 IAMU0001 COIL W/SPARK PLUG CAP

2 ECMU0065 SPARK PLUG, CHAMPION (8339-1)

2H ECMU0067 OPTIONAL HOTTER PLUG (8332-1)

2C ECMU0066 OPTIONAL COLDER PLUG (8904-1)

3 FCMU0033 KILL SWITCH ASSEMBLY

4 HCBC0516 SCREW, M5 X 16 (2 PER)

5 HCCN0000 5MM CLIP NUT (2 PER)

6 IAMU0002 GROUND WIRE

31 HCWP0001 WASHER FOR STATOR (3 PER)

32 HCBC8312 SOCKET HEAD CS, 8-32X1

33 HCBC0801 SOCKET HEAD CS, 8-32X 1-1/2 (2 PER)

34 HCNS1001 NUT 10MM

35 ECKG0042 PULLEY, WATERPUMP CRANK

59 ICMU0006 ROTOR

60 ICMU0007 STATOR

NOT SHOWN MCKGGR00 GROMMET - STATOR LE AD

NOT SHOWN ICMU0012 ROTOR SHAFT KEY

20

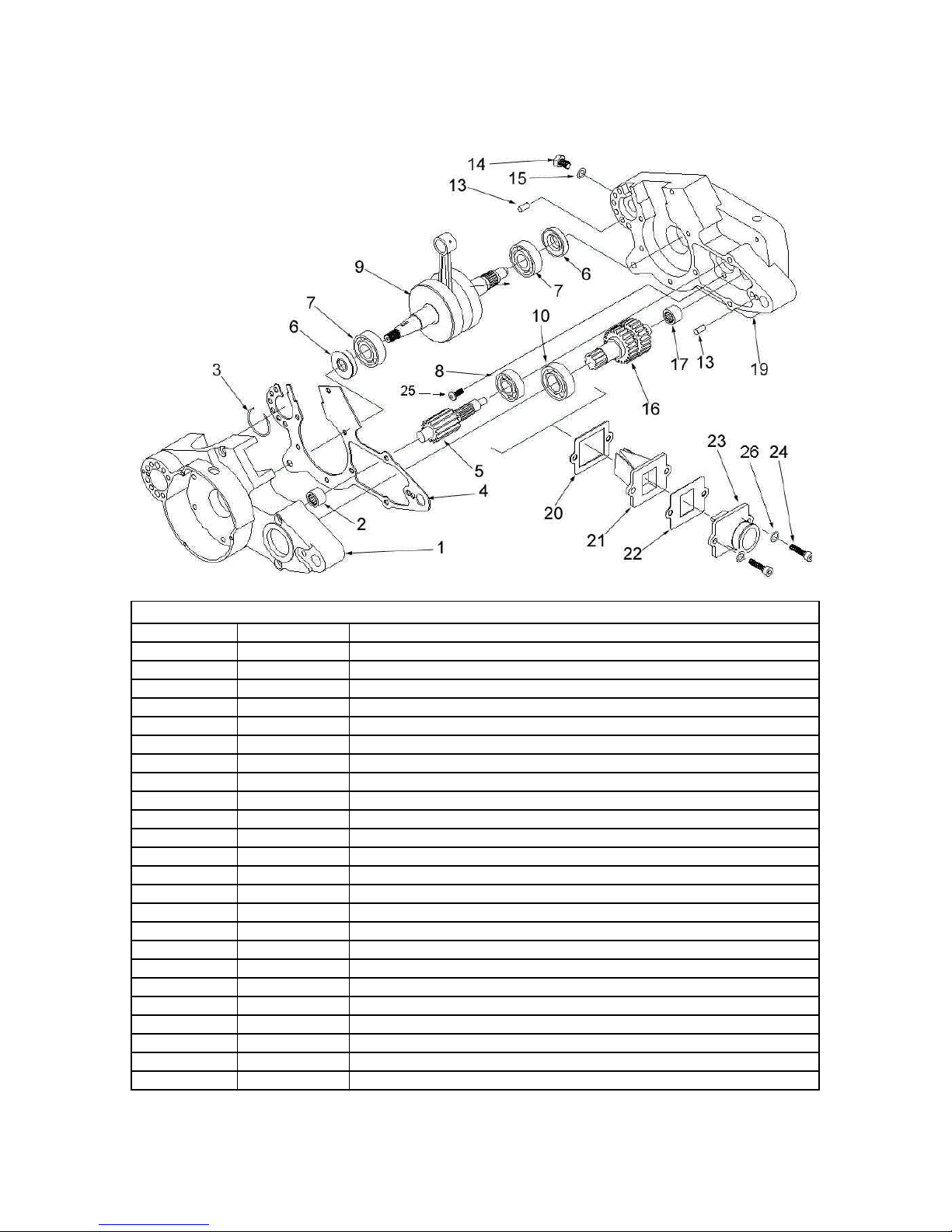

Page 22

Parts – Engine – Bottom End and

Transmission

Figure 7A

Engine Bottom End and Transmission

REF # PART # DESCRIPTION

1 ECKG0017 CRANKCASE, IGNITION SIDE

2 ECMU0020L BEARING, TRANSMISSION PRECISION

3 ECKG0004 SNAP RING, WATER PUMP

4 ZCKG2001 GASKET, CRANKCASE

5 ECMU0106 SECONDARY SHAFT, TRANSMISSION WITH GEAR

6 ECMU0017 SEAL, CRANKSHAFT

7 ECMU0016 BEARING, CRANKSHAFT

8 ECMU0001 BEARING, TRANMISSION SECONDAY SHAFT

9 ECMU0038 CRANKSHAFT

10 ECKGBR01 BEARING, TRANSMISSION OUTPUT SHAFT

13 HCDP1401 DOWEL, ENGINE CASE ALIGNEMENT

14 HCBH0805 M8X12 SCREW

15 HCWC0000 COPPER GASKET

16 ECMU0107 OUTPUT SHAFT, TRANSMISSION WITH GEAR

17 ECMU0020 BEARING, TRANSMISSION PRECISION

19 ECKG0018 CRANKCASE, CLUTCH SIDE

20 ZCMU0032 GASKET, REED TO CASE

21 ECKG0202 REED ASSEMBLY

NOT SHOWN ECKG0205 REED KIT

22 ZCMU0031 GASKET, INTAKE TO REED

23 ECKG0203 INTAKE MANIFOLD

24 HCBC0602 SCREW M6X20

25 HCBB0612 M6X12 BUTTON HEAD SCREW - BEARING RETAINER

26 HCWF0601 6MM FLAT WASHER

21

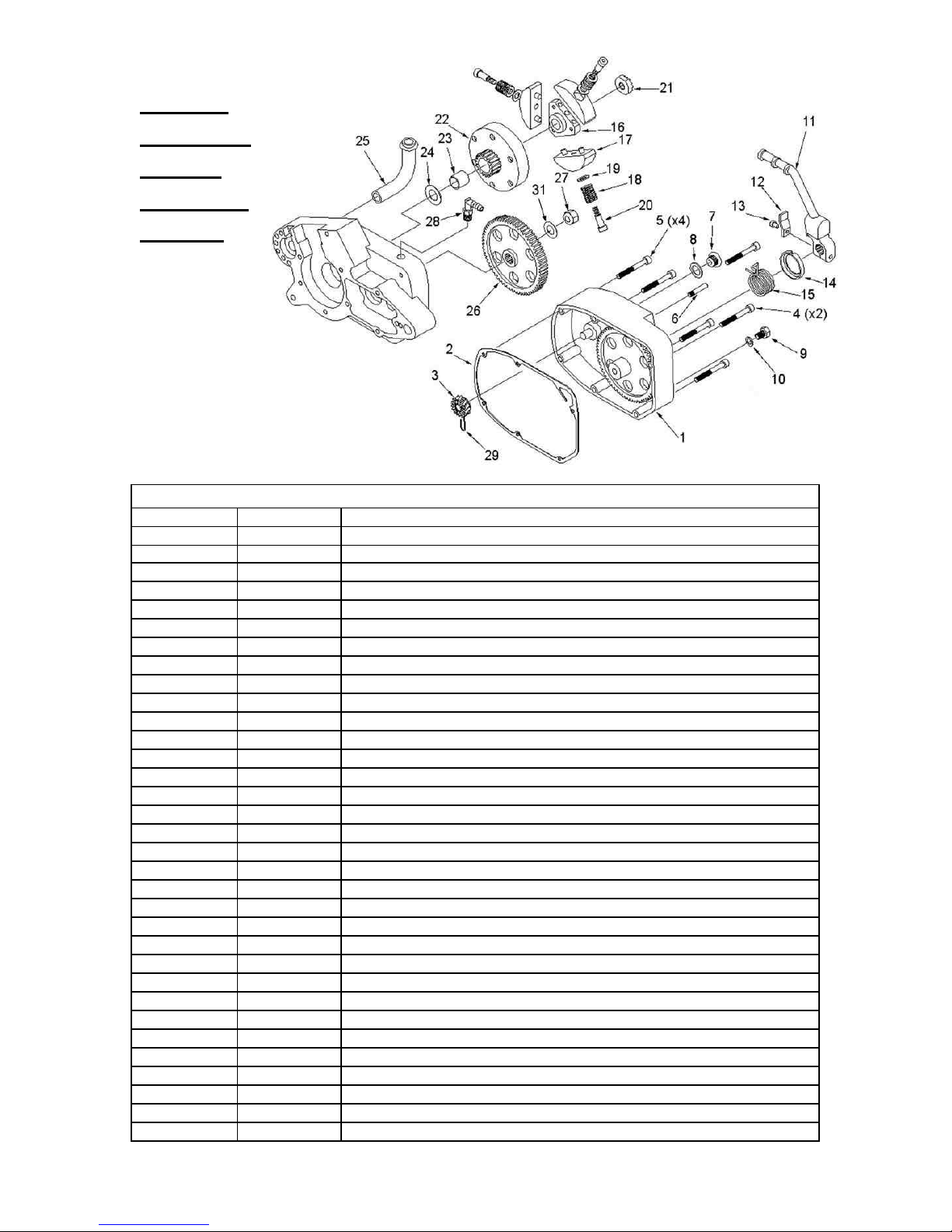

Page 23

Parts –

Engine –

Clutch

and Kick

Starter

Figure 7B

Engine – Clutch and Kick Starter

REF # PART # DESCRIPTION

1 ECMU0128 CLUTCH COVER WITH KICK SHAFT AND GEAR (NO LEVER)

2 ZCMU0030 CLUTCH COVER GASKET

3 ECMU0207 KICKSTART GEAR SMALL

4 HCBC0608 M6X55 SHCS CLUTCH CVR SCREW LNG (2 REQD) CENTER

5 HCBC606 M6X45 SHCS CLUTCH COVER SCREW SHORT (4 REQD)

6 ECMU0068 KICKSTART STOP BOLT

7 ECMUOO37 OIL FILL PLUG

8 ZCMU0001 OIL FILL PLUG GASKET

9 HCBH0805 M8X12 OIL DRAIN SCREW

10 HCWC0000 COPPER GASKET

11 ECDC0046 KICK START LEVER

12 ECMU0164 KICK LEVER STOP BRACKET

13 HCBF0625 M6X25 FLANGE HEAD BOLT

14 ECMU0204 KICK STARTER DUST COVER

15 ECMU0063 KICK RETURN SPRING

16 CCMU0031 CLUTCH ARBOR

17 CAKG0005 CLUTCH SHOE (SET OF 3)

NOT SHOWN CAKG0004 SET OF 3 CLUTCH SHOES WITH SPRINGS, WASHER & BOLT

NOT SHOWN CAKG0002 CLUTCH ASSY W/ ARBOR, SHOES, SPRINGS, WSHR & BOLT

18 CCMU0129 SPRING, CLUTCH (SINGLE PIECE)

19 See Clutch WASHERS, CLUTCH FLAT

NOT SHOWN CAMU0008 SPRINGS, WASHER, & BOLT (COMPLETE SET FOR 3 SHOES)

20 HCBS5603 BOLT, CLUTCH CENTER (SINGLE PIECE)

21 ECMU0018 NUT, CLUTCH SPECIAL

22 ECMU0133 CLUTCH BASKET, WELDED WITH BUSHING

23 ECMU0003 BUSHING, CLUTCH BASKET

24 ECMU0040 SPACER, CLUTCH BASKET (1 - 3 REQD)

25 ECMU0131 WATER ELBOW

26 ECMU0108 GEAR, PRIMARY TRANSMISSION

27 HCNS1202 NUT, 1/2-20 LEFT HAND THREAD

28 ECDC0105 ELBOW, CASE VENT

29 ECMUSP01 KICK START DOG SPRING (PAPER CLIP)

31 HCWB0042 SPRING WASHER

22

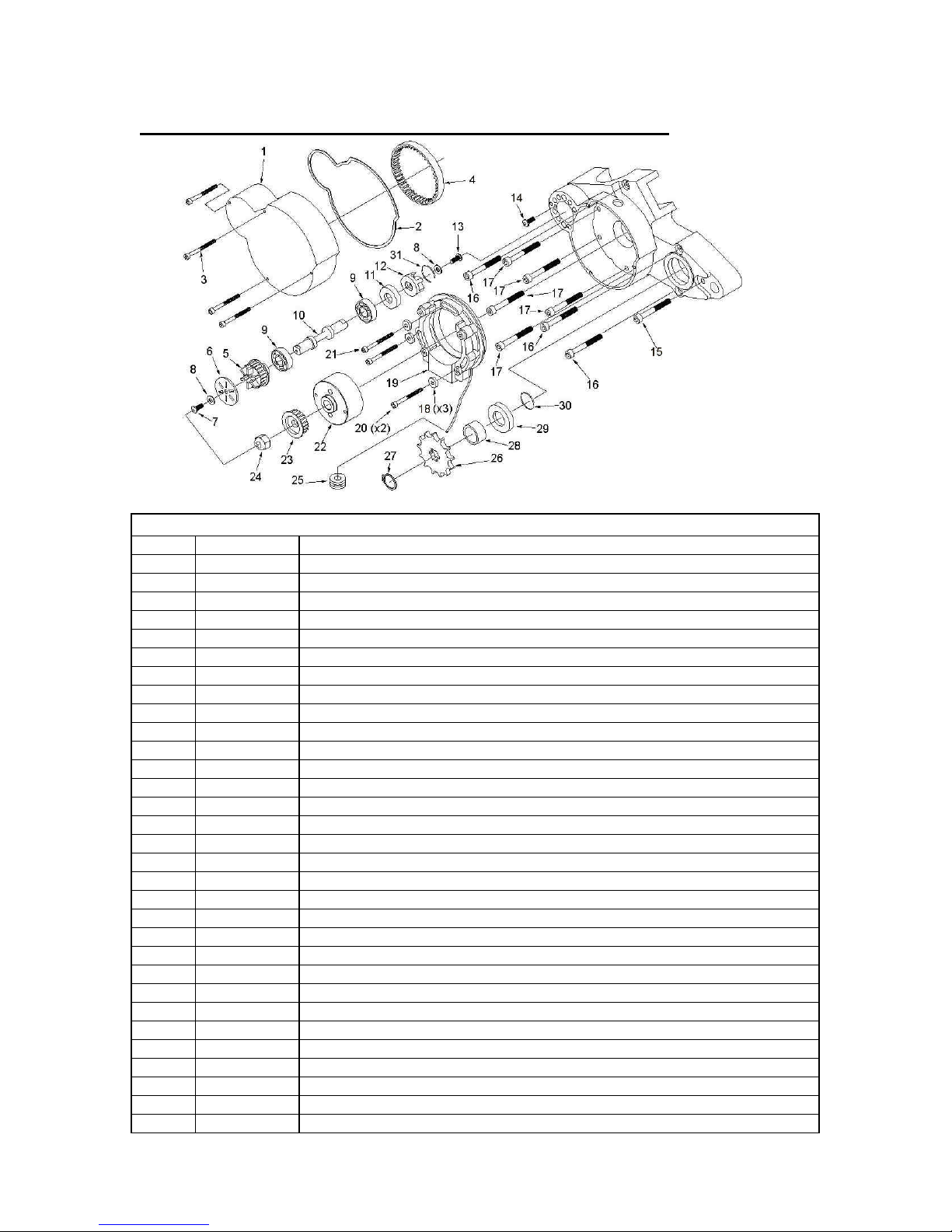

Page 24

Parts – Engine – Ignition and Water Pump

Figure 7C

Engine – Ignition and Water Pump

REF # PART # DESCRIPTION

1 ECKG0001 IGNITION COVER

2 ZCKG0101 IGNITION COVER GASKET

3 HCBC0802 COVER SCREW, SHCS 802X1 -3/4

4 ECKG0070 WATER PUMP BELT

5 ECKG0075 WATER PUMP PULLEY, FAN TYPE - DRIVEN

6 ECMU0080 BELT RETAINER

7 HCBC1033 PULLEY SCREW, SHCS 10-32X3/4

8 HCWF0501 FLAT WASHER

9 ECKG0072 BEARING, WATER PUMP

10 ECKG0141 SHAFT, WATER PUMP

11 ECKG0074 SEAL, WATER PUMP SHAFT

12 ECKG0073 IMPELLER, WATER PUMP

13 HCBB0001 IMPELLER SCREW, SHCS 10-32X1/2

14 HCSS8201 RETAINING SCREW, SHCS 8-32X3/8

15 HCBC0603 CASE SCREW, SHCS M6X30

16 HCBC0606 CASE SCREW, SHCS M6X45 (3 REQD)

17 HCBC0604 CASE SCREW, SHCS M6X35 (5 REQD)

18 HCWP0001 WASHER, STATOR (3 REQD)

19 ICMU0007 STATOR

20 HCBC0801 STATOR SCREW, SHCS 8-32X1-1/2 (2 REQD)

21 HCBC8312 STATOR SCREW, SHCS 8-32X1

22 ICMU0006 ROTOR

23 ECKG0042 WATER PUMP PULLEY, CRANK

24 HCNS1001 NUT 10MM

25 MCKGGR00 GROMMET

26 PCKG0014 SPROCKET, 14T COUNTERSHAFT

27 ECKGSR03 SNAP RING, COUNTERSHAFT SPROCKET

28 ECMU0073 SPACER, SPROCKET

29 ECMU0072 SEAL, COUNTERSHAFT

30 ZCDCOR01 O’RING, COUNTERSHAFT SPACER

31 ECKG004 RETAINER, WATER PUMP ASSEMBLY

23

Page 25

Parts –

Engine – Top

End

Figure 7D

Engine – Top End

REF # PART # DESCRIPTION

1 ECMU0052 CYLINDER

2 ZCKG0002 BASE GASKET

3 ECMU0060 PISTON KIT

5 ECMU0055 PISTON RINGS (2 PER SET)

6 ECMUSR00 SNAP RING FOR PISTON (2 REQ'D)

7 ECKG0012 WRIST PIN

8 ECMU0077 BEARING, WRIST PIN

9 ZCMUOR07 O'RING, EXHAUST FLANGE

10 ECKG0015 EXHAUST FLANGE

11 HCBC0602 M6X20, EXHAUST FLANGE SCREW (2 REQ'D)

12 HCNS1401 NUT, CYLINDER HEAD 1/4-20 (4 REQ'D)

13 HCWF1401 FLAT WASHER, 1/4" (4 REQ'D)

14 ECKG0025 CYLINDER HEAD OUTER

15 ZCMUOR02 O'RING, CYLINDER HEAD LARGE

16 ZCMUOR08 O'RING CYLINDER HEAD SMALL

17 ZCMUOR03 O'RING CYLINDER STUD (8 REQ'D)

18 ECKG1121 CYLINDER HEAD, INSERT

19 ZCMUOR05 O'RING CYLINDER HEAD MEDIUM

20 ECMU0008 STUD, CYLINDER

24

Page 26

Parts – Exhaust System

Figure 8

Exhaust System

REF # PART # DESCRIPTION

1 XCKG2004 2004 KING EXHAUST PIPE

2 ZCMUOR30 HEADER PIPE O-RINGS (2 REQD)

3 XCMU0005 EXHAUST SPRING - SHORT

4 MCMUGR06 PIPE GROMMET MALE

5 MCMUGR07 PIPE GROMMET FEMALE

6 MCMUSP02 PIPE GROMMET SPACER

7 HCWF1478 PIPE GROMMET WASHER (1 ON PIPE, 2 ON SILENCER)

8 HCBF0635 M6X35 FLANGE HEAD BOLT

9 XCDC0003 SILENCER

NOT SHOWN XCMU0018 SILENCER PACKING

10 XCKG0009 PIPE / SILENCER SEAL

11 MCMUGR03 MOUNTING GROMMET (4 REQD TOTAL, 2 PER BOLT)

12 TCKG0001 SPACER (2 PER)

13 HCNF0601 6MM FLANGE NUT (2 REQD)

25

Page 27

Parts – Forks & Triple Clamps

Figure 12

Front Forks and Triple Clamp

REF # PART # DESCRIPTION

1 KAKG0010 FORK COMPLETE, NON-BRAKE SIDE

2 KAKG0009 FORK COMPLETE, BRAKE SIDE

3 KCKG0040 FORK GUARD SET

4 KCKG0040 FORK GUARD SET

5 MCMUZT04 CABLE TIE (2 REQD)

6 HCBB0612 M6X12, BUTTON HEAD SCREW (4 REQD)

7 FAKG0010 TRIPLE CLAMP BOTTOM ASSY, (1 BEARING AND DUST COVER)

8 FCKG0033 TRIPLE CLAMP UPPER

9 HCNJ0101 STEERING HEAD NUT 1X14

10 HCBC0604 SOCKET HEAD CS M6X35 (4 REQD)

11 HCBC0806 CAP SCREW M8X30 (4 REQD)

12S TKMU0404 BAR MOUNT KIT, SHORT (2 REQD)

12T TKMU0403 BAR MOUNT KIT, TALL (2 REQD)

14 HCBC3812 SOCKET HEAD CS 3/8-16 X 1-1/2 (2 REQD)

15 HCNL3816 LOCK NUT 3/8 - 16, (2 REQD)

16 FCMU0103 DUST COVER (2 REQD)

17 FCMU0004 STEERING HEAD BEARING (2 REQD)

18 HCBC0604 SOCKET HEAD CS M6X35 (4 REQD)

19 HCBF0616 FENDER BOLT, M6X16 FLANGE HEAD (4 REQD)

20 FCKG0212 BRAKE LINE HOLDER

21 HCBF0620 M6X20 FLA NGE HEAD BOLT (NUMBER PLATE FASTNR)

26

Page 28

Parts – Forks – Leg Assembly

Figure 13

Fork Leg Assembly

REF # PART # FORK DAMPER ASSEMBLY

1 FORK SPRING STANDARD (12 LB/IN)

2 KCKG1201 FORK SPRING OPTIONAL SOFTER (9 LB/IN)

NOT

SHOWN

NOT

SHOWN KCKG0015 FORK LEG INNER ASSEMBLY, BRAKE SIDE

3 BR KAKG0028 FORK LEG INNER ASEMBLY, NON-BRAKE SIDE

3 NBR KAKG0029 FORK BUSHING, OUTER

4 KCKG0033 SWIPER (PART NUMBER IS A SINGLE PIECE)

5 KCMU0008 SNAP RING

6 KCMUSR23 FORK SEAL (PART NUMBER IS A SINGLE PIECE)

7 KCMU0007 FORK BUSHING, INNER

8 KCKG0020 OUTER FORK TUBE

9 KCKG0121 FORK CAP ASSEMBLY WITH RELIEF

10 KAKG0030 FORK DAMPER ASSEMBLY

KCKG0009 FORK SPRING OPTIONAL STIFFER (15 LB/IN)

27

Page 29

Parts – Forks – Damper Assembly

Figure 14

Figure 15

Damper Cartridge Assembly

REF # PART # DESCRIPTION

1 KCKG0027 FORK DAMPER ROD

2 KCKG0025 CARTRIDGE TOP

3 KCKG0031 TOP OUT SPRINIG

4 KAKG0017 MID VALVE ASSEMBLY (STANDARD)

NOT SHOWN KAKG0016 MID VALVE ASSEMBLY (SOFT/FAST) OPTIONAL

NOT SHOWN KAKG0018 MID VALVE ASSEMBLY (HARD/SLOW) OPTIONAL

5 KCKG0032 FORK SPRING GUIDE

6 HCNJ5601 NUT

7 DAMPER ROD ASSEMBLY WITH MID VALVE

8 KCKG0023 CARTRIDGE TUBE

9 KAKG0014 BASE VALVE ASSEMBLY STANDARD

NOT SHOWN KAKG0013 BASE VALVE ASSEMBLY (SOFT/FAST) OPTIONAL

NOT SHOWN KAKG0015 BASE VALVE ASSEMBLY (HARD/SLOW) OPTIONAL

10 KCKG0024 BOTTOM PLUG

11 ZCKGOR10 BOTTOM PLUG O'RING

28

Page 30

Parts – Forks – Damper – Base Valve Assembly

Figure 16

Forks -Valving, Base Valve Assembly – Std.

REF # PART # DESCRIPTION

1 HCBC0606 M6X45 SOCKET HEAD CAP SCREW

2 KCKG0011 CHECKSTOP

3 KCKG0038 SPRING, BASE VALVE

4 KCKGSH01 CHECKPLATE, 14 X .3

5 KCKG0026 PISTON, FORK VALVE

6 KCKG0035 PISTON SEAL RING, BASE VALVE

7 KCKGSH02 SHIM, 14 X .1

8 KCKGSH03 SHIM, 12 X .15

9 KCKG0036 CONICAL SPACER

10 KCKG0024 BOTTOM PLUG

11 ZCKGOR10 O'RING, BOTTOM PLUG

29

Page 31

Parts – Forks – Damper – Mid Valve Assembly

Figure 17

Forks – Valving, Mid Valve Assembly – Std.

REF # PART # DESCRIPTION

1 HCBC0603 M6X30 SOCKET HEAD CAP SCREW

2 HCWF0601 FLAT WASHER

3 KCKGSH05 SHIM, 8 X .15 (2 REQD)

4 KCKGSH04 SHIM, 12 X .1

5 KCKGSH02 SHIM, 14 X .1

6 KCKG0026 PISTON, FORK VALVE

7 KCKG0035 GLIDRING, MIDVALVE PISTON

8 KCKGSH01 CHECKPLATE, 14 X .3

9 KCKG0038 SPRING - MID VALVE

10 KCKG0011 CHECK STOP

30

Page 32

Parts – Frame – Brake Mounts, Plastic Shield

& Footpegs

Figure 9

Frame – Brake Mounts, Plastic Shield, & Footpegs

REF # PART # DESCRIPTION

1 FAKG0001 FRAME 2004 KING

2 FAKG0009 SUB FRAME 2004 KING

3 HCBF0620 M6x20 FLANGE HEAD CS (2 PER)

4 BCDC0009 BRAKE PIVOT BOLT

5 HCBH0601 M6 X 16 HEX HEAD BOLT

6 HCNS0601 6 MM NUT

7 TCKG0202 MUD GUARD - FRONT OF SHOCK

8 MCMUZT06 6 INCH CABLE TIE (7 PER)

9 TCMU0110 WIDE FOOTPEGS (PAIR)

10 TCMU0106 FOOTPEG SPRING (2 PER)

11 HCBB0803 M8X40 BUTTON HEAD BOLT (2 PER)

12 HCNL0801 8MM LOCK NUT (2 PER)

13 HCWF5601 FLAT WASHER (2 PER)

31

Page 33

Parts – Frame - Exhaust, Radiator, & Engine Mounts

Figure 10

Frame – Pipe, Engine, and Radiator Mounts

REF # PART # DESCRIPTION

1 FAKG0001 FRAME 2004 KING

2 FAKG0009 SUB FRAME 2004 KING

3 MCMUGR06 PIPE GROMMET MALE

4 MCMUGR07 PIPE GROMMET FEMALE

5 MCMUSP02 PIPE GROMMET SPACER

6 HCWF1478 PIPE GROMMET WASHER

7 HCBF0630 FLANGE HEAD BOLT, M6X30

8 HCNF0601 6MM FLANGE NUT

9 FCMU0057 CHAIN ROLLER

10 HCWF1201 WASHER FLAT, CHAIN ROLLER (2 REQ’D)

11 HCCP0002 COTTERPIN 3/32 X 1 (2 REQ’D)

12 HCBH1403 SWINGARM PIVOT BOLT

13 HCNL1402 SWINGARM LOCK NUT (M14 X1)

14 HCBH0880 FRONT ENGINE MOUT BOLT, M8X30 SHCS

15 HCNL0801 8MM LOCKNUT

16 HCHA0003 6MM CLIPNUT

17 FCMU0006 RADIATOR MOUNTING BRACKET (TEARDROP)

18 HCBF0616 FLANGE HEAD BOLT M6X16

19 MCMUGR03 MOUNTING GROMMET (3 FOR RADIATOR, 4 FOR SILENCER)

20 TCKG0001 SPACER

21 HCBF0635 M6X35 FLANGE HEAD BOLT

32

Page 34

Parts - Frame – Subframe, Shock, & Bodywork

Mounts

Figure 11

Frame & Subframe – Plastic and Shock Mounts

REF # PART # DESCRIPTION

1 FAKG0001 FRAME 2004 KING

2 FAKG0009 SUB FRAME 2004 KING

3 HCBB0802 8X20 BUTTON HEAD CAP SCREW (4 PER)

4 HCNL0801 8MM LOCKNUT (4 PER)

5 HCBH1001 M10X40 UPPER SHOCK MOUNT BOLT

6 HCNF0601 6 MM FLANGE NUT

7 HCBB0002 M5X20 BUTTON HEAD CAP SCREW (4 PER)

8 HCWF0501 FLAT WASHER ( 2 REQD PER NUMBER PLATE)

9 HCBH0502 M5 X 16 HEX HEAD CAP SCREW (2 PER)

10 HCWF0601 FLAT WASHER (2 REQD)

11 HCBF0620 M6X20 FLANGE HEAD BOLT

33

Page 35

Parts – Front Brakes

Figure 18

Front Brakes

REF # PART # DESCRIPTION

1 BAMU2002 PERCH ASSEMBLY W/LEVER

2 BCMU0209 ALLOY BRAKE LEVER

3 BAKG0004 BRAKE HOSE WITH SHIELD

4 BCMU0204 BRAKE CALIPER WITH PADS

5 HCBB0612 M6X12 BUTTON HEAD BOLT (2 REQD)

6 BCMU0206 BRAKE ROTOR W/BOLTS

7 BCMU0207 BRAKE ROTOR MOUNTING BOLTS (6 REQD)

8 BCMU0203 BRAKE PADS (SET OF 2)

9 BCKG0008 BRAKE CALIPER MOUNTING BRACKET

10 BCMU0212 BRAKE HOSE MOUNTING SCREW (BANJO BOLT)

11 BCMU0205 BRAKE OIL, 2 OZ BOTTLE

12 BCMU0211 BRAKE OIL, 500 CC BOTTLE

13 BCMU0210 SYSTEM BLEED SYRINGE

14 BKMU0200 BRAKE BLEEDING KIT (2OZ OIL, SYRINGE, FITTINGS, ETC…)

15 FCKG0212 BRAKE LINE HOLDING BRACKET

16 BCMU0213 BLEED HOLE PLUG

17 WCMUZT04 CABLE TIES (2 REQD) TO SECURE BRAKE LINE TO FORK GUARD

18 BCMU0216 MASTER CYLINDER REMOVAL TOOL, TORX WRENCH T08

34

Page 36

Parts – Front Wheel

Figure 19

Front Wheel

REF # PART # DESCRIPTION

1 WAKG2003 FRONT WHEEL COMPLETE

2 WCKG1200 12" FRONT TIRE

3 WCKG1201 12" FRONT TUBE

4 WCKG0011 FRONT AXLE

5 WCMU0023 FRONT WHEEL SPACER, X LARGE

6 WCMU0020 WHEEL BEARING (2 REQD)

7 WCKG0010 WHEEL BEARING SPACER

8 WCMU0001 FRONT WHEEL SPACER, LARGE

9 BCKG0008 BRAKE CARRIER BRACKET

10 HCWF1202 FRONT AXLE WASHER

11 HCNS1201 FRONT AXLE NUT (12MM)

12 BCMU0207 BRAKE ROTOR MOUNTING BOLTS (6 REQD)

13 BCMU0206 BRAKE ROTOR WITH MOUNTING BOLTS

35

Page 37

Parts – Plastic Bodywork & Seat

Figure 20

Plastic and Seat

REF # PART # DESCRIPTION

1 TCMU0016 FRONT FENDER

NOT SHOWN HCBF0616 FRONT FENDER MTG BOLTS (4 REQD)

2 TCMU0005 FRONT NUMBER PLATE

NOT SHOWN HCBF0620 FRONT NUMBER PLATE MTG BOLT

3 TCMU0006 FUEL TANK (NO PETCOCK OR CAP)

NOT SHOWN HCBF0620 FUEL TANK MOUNTING BOLT

4 TCMU0203 RADIATOR SHROUDS

NOT SHOWN HCBB0402 RAD SHROUD MTG BOLT, LONG (1 PER SIDE)

NOT SHOWN HCBB0403 RAD SHROUD MTG BOLT, SHORT (1 PER SIDE)

5 TCMU0013 SIDE NUMBER PLATE SET

NOT SHOWN HCBB0002 NUMBER PLATE MTG SCREW (2 PER SIDE)

NOT SHOWN HCWF0501 NUMBER PLATE WASHER (2 PER SIDE)

6 TAMU0012 REAR FENDER ASSEMBLY

NOT SHOWN HCBH0502 REAR FENDER MTG BOLT (2 REQD)

NOT SHOWN HCWF0601 REAR FENDER WASHER (2 REQD)

NOT SHOWN TCMU0012 REAR FENDER NO MUD GUARD

NOT SHOWN TCMU0011 MUD GURAD

7 TCMU0505 SEAT

NOT SHOWN HCNF0601 SEAT MOUNTING NUT

8 TCMU0103 FUEL TANK CAP

9 TCMU0038 FUEL PETCOCK

10 TCMU0108 GRAPHIC KIT

36

Page 38

Parts – Rear Brake

Figure 21

Rear Brake System

REF # PART # DESCRIPTION

NOT SHOWN BAKG0002 BRAKE KIT, MASTR CYLR, CALIPER, PADS AND HOSE

1 BCKG0001 BRAKE PEDAL

2 BCDC0009 BRAKE PIVOT BOLT

3 HCBH0601 M6X16 HEX HEAD BOLT

4 HCNS0601 6 MM NUT

5 BCMUSP01 BRAKE RETURN SPRING

6 BCDCBU01 BUSHING

7 BCDC0004 PUSH ROD, REAR BRAKE

8 HCBF0620 M6X209 FLANGE HEAD BOLT (2 REQD)

9 HCCC0002 BRAKE HOSE CLAMP (2 REQD)

10 HCPP0832 BRAKE HOSE CLAMP FASTENER (2 REQD)

11 BCKG0010 REPLACEMENT BRAKE HOSE

12 HCBF0635 M6X35 FLANGE HEAD BOLT

13 HCBF0620 M6X20 FLANGE HEAD BOLT

14 BCKG0009 BRAKE PADS

15 BCKG0003 BRAKE CARRIER

16 BCKG0006 WHEEL SPACER - FLOATING CARRIER

NOT SHOWN BCKG0011 BRAKE ROTOR

NOT SHOWN HCBB0620 M6X 20 BUTTON HEAD CAP SCREWS (5 REQD)

37

Page 39

Parts – Rear Wheel

Figure 22

Rear Wheel

REF # PART # DESCRIPTION

1 WAKG0009 REAR WHEEL COMPLETE

2 WCMU0275 REAR TIRE, BRIDGESTONE MT320 2.75X10

3 WCMUTU10 TUBE, BRIDGESTONE 10"

4 BCKG0011 BRAKE ROTOR

5 HCBB0620 M6X20 BUTTON HEAD CAP SCREWS (5 REQD)

6 PCMU0139 39T STEEL REAR SPROCKET

7 PCMU0059 RUBBER DAMPERS

8 WCMU0008 WHEEL DAMPING PLATE

9 HCBH0701 M7X35 HEX HEAD BOLT

10 PCMU0001 MASTER LINK 420

11 PCMU0100 CHAIN 420 X 100

12 WCMU0016 REAR AXLE

13 HCPA0002 AXLE HEAD FIXING PLATE

14 BCKG0006 WHEEL SPACER - FLOATING CARRIER

15 BCKG0003 BRAKE CARRIER

16 WCMU0020 WHEEL BEARING

17 WCMU0009 WHEEL BEARING SPACER

18 WCMU0001 WHEEL SPACER

19 HCWF1202 AXLE WASHER

20 HCNS1201 AXLE NUT 12MM

21 WCMU0006 SPACER, SPROCKET DAMPER (4 REQD)

38

Page 40

Parts – Shock

Figure 23

COBRA PART NUMBER DESCRIPTION

SCKGOH01 SPRING CLIP

SCKGOH02 SPACER

SCKGOH03 BALL JOINT

SCKGOH04 SPRING PLATFORM

SCKGOH05 LOCKNUT

SCKGOH06 SLEEVE

SCKGOH07 BUMPER RUBBER

SCKG0H08 SPRING - LIGHT

SCKGOH09 SPRING-MEDIUM-STOCK

SCKGOH10 SPRING-HEAVY

SCKGOH11 ORING FOR BALL JOINT

SCKGOH12 ORING FOR REBOUND ADJUSTER

SCKGOH13 ORING FOR REBOUND ADJUSTER

SCKGOH14 SUPPORT SLEEVE

SCKGOH15 CIRCLIP

SCKGOH16 PIN FOR REBOUND ADJUST

SCKGOH17 ADJUSTMENT KNOB

SCKGOH18 SHAFT FOR END EYE

SCKGOH19 NUT

SCKGOH20 END EYE

SCKGOH21 SCREW FOR KNOB

SCKGOH22 KNOB FOR ADJUSTMENT

39

Page 41

Parts – Swingarm Assembly

Figure 24

Swingarm

REF # PART # DESCRIPTION

1 GAKG2004 SWINGARM ASSEMBLY COMPLETE

2 HCBH1403 SWINGARM PIVOT BOLT

3 HCNL1402 SWINGARM LOCK NUT (M14 X1)

4 GCMU0001 SWINGARM BUSHING (4 PER)

5 GCMU0005 TOP SWINGARM GUARD (CHAIN SLIDER)

6 HCBF0840 FLANGE HEAD BOLT M8X40

7 HCWF5601 FLAT WASHER

8 HCNL0801 8MM LOCK NUT

9 PAKG0001 CHAIN GUIDE ASSEMBLY COMPLETE

10 HCBF1401 1/4 X 20 X 1-1/2" FLAT HEAD SCREW (2 PER)

11 HCNL1401 1/4" LOCKNUT (2 PER)

12 HCBF0620 M6 X 20 FLANGE HEAD BOLT (2 PER)

13 HCCC0002 BRAKE HOSE CLAMP (2 PER)

14 HCPP0832 BRAKE HOSE CLAMP FASTNER (2 PER)

15 HCBH1001 M10 X 40 LOWER SHOCK MOUNT BOLT

16 FCMU0203 WHEEL PULL

17 FCMU0202 WHEEL PULL CAP

18 HCBH0810 WHEEL PULL BOLT M8X65

19 HCWF5601 WHEEL PULL WASHER

20 WCMU0016 REAR AXLE

21 HCPA0002 AXLE HEAD FIXING PLATE

22 HCNS1201 AXLE NUT, 12 MM

23 HCWF1202 AXLE WASHER

24 GCMU0017 OPTIONAL TO P CHAIN SLIDE

25 HCFH0516 FLAT HEAD SCREW

26 HCWF0501 WASHER

27 HCNL0501 LOCK NUT

28 PCKG0004 BOTTOM CHAIN SLIDER

29 FAMU0005 WHEEL PULL ASSEMBLY COMPLETE

30 GCKG0008 SWINGARM PIVOT TUBE SPACER (2 PER)

40

Page 42

Service

Trained technicians with precision gauging and proper assembly fixtures carefully

assemble all Cobra engines to specific clearances. If you feel you have the skills,

and the appropriate tools, to perform the following service tasks please follow the

instructions closely. The part numbers are listed throughout to help you when

ordering parts from your local Cobra dealer.

If you don’t feel comfortable with the service work, simply take your engine out of

the frame and sent it to:

Cobra Precision Engines

11511 Springfield Road

North Lima, Ohio 44452

Cobra has specialized mechanics that will go through the entire engine, replacing

gaskets, bolts, any old part that is worn. The engine will be rebuilt using the

same precision gauging and assembly fixtures as when it was assembled new.

Before leaving, the engines performance will be measured on a dynamometer to

ensure that your engine is operating at its highest potential. All this for one low

nominal fee. Call (330) 549-9603 for details.

Engine Service

One method for determining whether the top end of your engine needs rebuilt is

to perform a WOT (Wide Open Throttle) kicking compression test. Before

performing the procedure please read the caution notes below.

CAUTION:

• There appears to be a wide range of variability in reading compression

gauges across the country.

• The head volume of this Cobra Motorcycle is very small and so requires many

kicks ~20 before you establish the most accurate reading possible.

• Because of the geometry of the spark plug used in this Cobra Motorcycle, the

adapter used with your compression tester must have a similar volume

protru ding into the combustion chamber to establish an accurate value.

• Length of hose on the compression tester will affect the reading. The shorter

the hose length the more accurate your reading will be.

Because of these difficulties in measuring an absolute compression value, a

useful relative value can be achieved by testing your bike’s compression with

your own particular gauge after a new top end or when the bike is new so that

you know what your particular gauge reads on a ‘fresh’ engine. When it has

41

Page 43

dropped to 90% of its original value the engine will be down on power and would

benefit from a rebuild. When it’s dropped to 80% it really needs rebuilt! Using the

table below will help you determine monitor the condition of your top end.

Example

Your Values

Engine is Fresh

Measured Value

110 psi 110 psi * 0.9 = 99 psi 110 psi * 0.8 = 88 psi

Engine Down on Power

Measured Value * 0.9

Engine NEEDS Rebuilt

Measured Value * 0.8

Procedure for Compression Testing

1. Shut off the fuel petcock.

2. Install the compression gauge into the spark plug hole.

3. Hold the throttle to wide open, and kick repeatedly (approximately 20 times)

or until the gauge reading does not increase in value with each kick.

Engine Removal

To service the bottom end and transmission, the engine must be removed from

the frame.

Tools required

• 5/16”, 10, 14, mm socket

• 10, 13, 22 mm wrench

• 10, 17 & 19 mm sockets

• 9/64”, 3,4 & 5 mm hex key (Allen wrench)

• 7 mm nut driver, flat or Phillip, screwdriver for hose clamps

• Spring remover

• Flywheel / clutch puller (#MCMUTL68)

• Clutch nut removal tool (Call local dealer for details).

Procedure

1. Remove the seat (4mm hex key).

2. Turn of the fuel at the petcock and disconnect the fuel line.

3. Remove the tank (5 mm hex key & 10 mm socket).

4. Remove the carburetor from the inlet (flat head or Phillips head screwdriver, 7

mm nut driver).

5. Remove the right side number plate (3mm hex key).

6. Remove the silencer & pipe (spring remover, 5mm hex, & 10mm wrench).

7. Disconnect the ground wire from the reed cage with a 5 mm hex key

(depending on your ultimate repair, you may want to reinstall the fastener in

the inlet.

8. Leaving the coolant lines connected to the engine, remove the radiator from

the frame (5mm hex with 10 mm wrench).

9. Remove the master link from the chain.

10. Remove front engine mount bolt (13 mm socket, 6 mm hex key).

42

Page 44

11. To access the swingarm bolt, remove brake lever (13 mm wrench, 5 mm hex

key).

12. Remove the swingarm bolt (22mm socket & wrench).

NOTE:

Only drive the swingarm bolt far enough to clear the engine, leave it holding the

one side of the swingarm to the frame

13. Remove the engine from the right side of the frame.

14. Locate a suitable container for the engine coolant and remove radiator hoses

from engine (coolant will drain).

NOTE:

If the coolant looks to be free of contaminates it may be reused.

NOTE:

If you are merely performing a top end service skip ahead to Top End

Disassembly Procedure.

Complete Engine Disassembly Procedure

1. Remove the magneto cover (9/64” hex key)

2. Remove the bolt from the water pump shaft (4mm) and slide off the belt cover

and the water pump belt

3. Using a flywheel holding tool and 14 mm socket remove the nut that secures

the flywheel.

4. Using the Cobra flywheel / clutch puller (#MCMUTL68), remove the flywheel

from the crankshaft.

5. Remove the stator (9/64” hex key).

6. Remove the nut holding the large gear to the transmission input shaft (19 mm

socket).

7. Remove the special nut / starter gear that holds on the clutch (special tool

available, contact your local dealer).

8. With the Cobra flywheel / clutch puller (#MCMUTL68), remove the clutch from

the crankshaft (details in Clutch Service portion of this manual).

Top End Disassembly Procedure

1. Remove the cylinder head nuts (5/16”).

2. Remove the outer cylinder head.

3. Remove the inner cylinder head.

43

Page 45

INSPECTION NOTE:

INSPECTION NOTE:

Inspect the cylinder head for deposits and abrasions.

1. If there are deposits they should be removed

a. Black oily deposits (indicating a rich mixture or improper oil

type/quantity) can be removed with solvent

b. Crusty deposits (indicating dirt ingestion) can be removed with

solvent and may require some scraping.

2. Abrasions

a. Pitting or erosion indicates detonation and may require cylinder

head replacement, also

i. Retard the ignition timing

ii. Use a higher octane fuel

b. Missing chunks or indentations indicate broken hardware or

ingested items - replace the cylinder head.

4. Remove the cylinder.

Inspect the cylinder bore for abrasions, deposits, and missing coating.

1. If abrasions: scrapes, scratches, pitting, etc… are found, replace the

cylinder.

2. If deposits are all are found

a. Clean with muratic acid.

b. Once the deposits are removed, inspect for abrasions and missing

surface coating.

i. If there are abrasions or missing coating, replace.

ii. If all looks well, the cylinder may be saved.

Muratic acid can be dangerous. Follow the manufacturers instructions closely.

5. Remove the piston clip with a scribe.

6. Remove the piston pin with a piston pin remover.

INSPECTION NOTE:

Inspect the piston for abrasions and deposits on the top and sides and clean or

replace as necessary.

Splitting the Cases

1. Remove the fasteners holding the two halves of the crankcase together.

2. Separate the cases with a proper case splitting tool.

44

Page 46

CAUTION:

Take caution when handling the crankshaft. It is the main power transfer to the

rest of the engine. If it is out of alignment, it will cause premature failure of your

bearings which can lead to serious damage to the cylinder and the rest of the

engine. Do not try to true the crank yourself. Truing the crank should be done

professionally.

CAUTION:

• If you split the cases, check the gear tooth faces for chapping & signs of

fatigue.

• Check the small needle bearings for fatigue. If the bearings are damaged,

the engine cases should be checked to make sure the needle -bearing casing

didn’t oblong the bearing hole in the case.

• Needle bearings should be replaced every racing season.

Engine assembly

CAUTION:

For any seals that are to be installed, apply a light amount of grease to the seals’

ID and a small amount of Loctite to the OD.

1. Press the three bearings into the respective holes in each case half.

2. Press in the crank seals such that the concave side faces the crank weights.

3. Press in the counter shaft seal (concave side faces inside of transmission)

4. Install the water pump assembly wire ring retainer

5. Press in the water pump assembly

6. Tap both ways axially then verify easy rotation

7. Press crank into right case half

CAUTION:

Insert a 7.05mm (0.278”) shim between the crank throws before pressing on the

crank.

8. Insert the transmission input shaft and install large drive gear as shown in

figures 25 & 26.

NOTE:

If the nut was removed from the input shaft, it will be easier to install and tighten

later.

45

Page 47

Figure 25

46

Figure 26

Page 48

9. Insert dowel pins in the left side case as shown in figure 27.

Figure 8

10. Apply gasket sealer (ThreeBond 1104 gasket material or equivalent) to the

mating surfaces of both crankcase halves.

11. Apply the crankcase gasket to the left crank case half being sure to install the

gasket behind the connecting rod.

12. Assemble the two case halves together with the shim installed between the

crank throws. Be sure to remove the shim after assembly.

13. Insert the screws with the proper lengths at locations shown.

14. Torque to 9 Nm (80 in -lb) in the pattern shown in figure 28.

15. Install the piston with new wrist pin bearing and, pin and clips.

47

Figure 28

Page 49

16. Install the piston rings.

CAUTION:

Be sure to align the piston such that the arrow on the top piston surface points to

the exhaust (front of bike/engine).

17. Apply gasket sealer (ThreeBond #1104, semi -drying liquid gasket material) to

the cylinder deck areas around the coolant passage and cylinder studs as

shown in figure 29.

Figure 29

18. Install the base gasket

19. Install the cylinder being sure that the piston rings are properly aligned with

the indexing pins.

CAUTION:

Never force the cylinder. If resistance is felt, determine the problem and solve it.

20. Install the cylinder studs and o’rings as shown in figure 30.

48

Figure 30

Page 50

21. Install cylin der head insert.

22. Install O’rings as shown in figure 31.

Figure 31

23. Install the cylinder head and torque to 9.2 ft-lb (12 Nm)

24. Install stator reinstalling the grommet and wires (snug the bolts).

25. Install the rotor per Rotor Installation section, under the S3: Ignition portion of

this manual.

26. Install the water pump outlet pipe (apply Ultra black Hi-Temp RTV silicon

gasket maker to the threads before assembly) before installing the clutch and

rotate to a vertical position with the engine resting on a bench

27. Install the clutch per Clutch Installation section in this manual.

28. Install the coolant drain plug with copper washer (11 ft-lb, 15 Nm).

29. Make sure that the exhaust spacer is on the cylinder (53 in -lb, 6 Nm).

30. Install the spark plug with a fresh gasket (to apply the proper torque to the

spark plug when inserting, one must first screw the spark plug in until the

metal gasket ring causes resistance and then turn another 1/8 to ¼ turn).

31. Install reed and inlet manifold with new gaskets (58 in -lb, 6.5 Nm).

49

Page 51

Clutch

Cobra clutch puller assembly:

Clutch puller diagram

Figure 32

Tools recommended for clutch service:

• Universal clutch puller- a universal puller that pulls the clutch, main drive gear

and rotor. (Part # MCMUTL70).

• 5mm T-handle

• Clutch nut removal tool (Call local dealer for details)

• Cobra 3 Shoe Clutch Milk (Part # MCMUGF01)

or Dexron III ATF.

CLUTCH REMOVAL:

1. Drain the engine transmission oil.

2. Remove the pipe and remove the 6 bolts that hold the kick-starter cover on.

3. Remove the clutch nut (not left hand thread) on the end of the crankshaft with

the clutch nut removal tool.

4. Attach the COBRA CLUTCH PULLER. There are three 6mm clutch puller

holes located on the ends of the center hub. (figures 32 & 33) You must use a

draw type puller to remove the clutch.

CAUTION:

Do not use a jaw type puller or use the 6mm tapped holes as jackscrews or you

are likely damage the clutch or drum.

5. If necessary apply heat to the center clutch hub.

CAUTION:

Do not heat the cranksh aft threads or the aluminum shoes.

6. Keep tension on the puller as you are heating it.

Figure 33

The clutch will often pop off under tension from the puller and it will be very hot.

50

Page 52

CLUTCH WASHER STACKUPS:

Once the clutch is removed, and cool to touch, carefully put it into a vice and

remove the center shoulder bolt out of each clutch shoe. You will probably have

to heat the center hub again to remove the bolts. Once you get a bolt loosened,

carefully remove it with the shoe and observe the way the spring washers are

stacked.

CAUTION:

It is very important that the clutch stack be reassembled as it was disassembled

unless new shoes are being installed then it is important to reinstall per figure 34.

CLUTCH ASSEMBLY REFERENCE DRAWING

REF # PART # DESCRIPTION

1 CAKG0004 Set of three shoes, springs, bolts, flat washers & nuts

2 CAMU0008 Set Of three springs, washers, bolts & nuts

3 CAKG0005 Set of three shoes

4 HCBS5603 Single center shoulder bolt

CAUTION:

The ‘4 stack’ clutch spring stack is new for 2004.

Figure 34 Recommended clutch spring stack. Each ‘spring’ stack contains nine springs

(Bellville washers) - six arranged into four ‘flying saucers’, and one turned away against the flat

washer(s). An optional ‘three stack’ will deliver smoother, less aggressive power. For details see

Figure 34b.

51

Figure 34b

Page 53

Clutch shoe wear:

• If the clutch has been slipping and shows signs of glazing, it is best to replace

the shoes. We have found that once the shoes are glazed, even if deglazed

with emery paper or a file, the performance is reduced.

• The best way to prevent glazing is by not gearing too high, changing the oil as

specified and by not blipping the throttle. Every time you blip the throttle, you

are working your clutch springs.

CAUTION:

The clutch produces a tremendous amount of heat and when a rider is blipping

the throttle. This makes the clutch and clutch springs wear out quicker. This also

makes your engine tend to run hotter which decreases engine power and

degrades ignition stator efficiency. It is important to train your rider NOT to be a

throttle 'blipper'.

CAUTION:

Sludge build-up between the spring washers also keeps the clutch shoe from

engaging fully and this will cause the clutch to start to slip. So you will need to

clean the sludge out or just replace the spring washers and bolts with new ones.

How quickly this sludge builds up depends on how often you change your oil

and whether your rider is a throttle ‘blipper’.

REF # PART NO. DESCRIPTION

1 ECMU0017 Crank seal

2 ECMU0040 Clutch to hub spacer

3 ECMU0003 Brass bushing

4 ECMU0033 Clutch Hub w/ brass bushing

5 CAKG0002 Clutch Complete w/ Arbor

6 ECMU0018 Clutch nut

Figure 35, Clutch Assembly Drawing

52

Page 54

CLUTCH ASSEMBLY:

1. After cleaning or replacing the spring washers, reassemble the stack up of

washers.

CAUTION:

It is important to reassemble the washer stack to that recommended or to your

own specialized stack.

CAUTION:

It is also important that all three shoes are stacked the same. (See figure 34)

2. Clean the threads of the stack bolt and the clutch with contact cleaner

removing all old thread locking material.

3. Apply high strength (red) thread lock material to the stack bolt and tighten as

tight as possible without stripping the Allen head.

CAUTION:

Avoid allowing excess thread lock material to contact the spring washers and the

clutch or the clutch is likely to malfunction.

4. Use fine emery paper on the center hole of the clutch and on the tapered

section of the crankshaft.

5. Apply a small amount of wicking / bearing retainer (green) thread lock agent

to the center tapered section of the crankshaft and taper of clutch arbor.

CAUTION:

Lean the bike / engine such that any excess thread lock agent goes away from

the bushing in the clutch drum.

6. Put the clutch back in.

7. Apply high strength (red) thread locking agent to the threads and install the

nut and torque to 40 ft-lb (54Nm) with the special socket (see figure 35).

CAUTION:

Use high strength (red) thread locker on the threads of the clutch nut. If you are

using an impact socket, just zap it lightly with an air wrench to tighten it because

there are only about 4 threads inside the nut and they can be easily stripped. If

you are tightening it by hand, you can very carefully use a 3/4" piece of wooden

dowel rod inside the exhau st port to block the piston so you can tighten the nut.

Do not use something harder than your aluminum piston and do not crush the top

of the piston into the ring.

53

Page 55

INSPECTION NOTE:

a. There must be in / out play in installed clutch, 1.0 mm (0.04”)

maximum.

b. Excess in/out will cause early crank seal failure.

c. A blue clutch drum is worn out from excessive slippage or improper

lubrication.

d. Should be no looseness in clutch shoes.

8. Install the clutch cover taking care to put the two longer bolts in their proper

locations and tightening in the order specified in figure 36. (5mm hex key, 5.8

ft-lb, 7.8 Nm).

CAUTION:

Prior to tightening the six clutch cover bolts, press the kick lever down to ensure

proper kick gear alignment.

9. Put pipe back on and add oil (235 ml (8.0 oz) Cobra 3 Shoe Clutch Milk (Part

# MCMUGF01) or Dexron III ATF.

Ignition

Stator care

Stator failure will result from running the bike hot. Following is a list of things that

will make your engine run hot.

1. The timing should not exceed the maximum specifications listed.

2. Improper carburetor jetting.

54

Figure 36

Page 56

3. Improper spark plug heat range. Never run a hotter plug than the specified

spark plug.

4. Clutch slippage. See “CLUTCH” section for causes of slippage.

CAUTION:

• Because of the amount of heat generated by the clutch and engine during

extended periods of riding, it is advisable to remove the ignition cover

afterward to allow the ignition to cool off. The heat transfers through the cases

and can damage the stator as it cools off because of lack of airflow around

the stator. Spray the stator and rotor with CRC 3-36 or WD -40 and let it drip

dry or blow it off a little with an air nozzle.

• Ignition will overheat if the gap between the rotor and stator is not large

enough. There should be even clearance as the rotor rotates relative to the

stator.

• Non -resistor spark plug caps should be used. Resistor caps will result in a

weaker spark that will reduce performance.

• Make sure ground wires are secure.

• Make sure connections are free of dirt.

CAUTION:

If the engine is hot, it is EXTREMLY important to take the ignition cover off, put a

fan on it to let it cool, and spray it with CRC 3-36 or WD -40. Proper stator care is

important for the durability of the ignition system. (Stator- Part # ICMU0007)

The proper ignition timing for this model of is at 0.045” before Top Dead Center

(that means 0.045” before the piston reaches the highest point of it’s travel in the

cylinder).

CAUTION:

Advancing the ignition timing will cause the engine to run hotter, in-turn causing

power loss, shortened clutch life, and possibly lead to premature stator failure,

and can also cause detonation which can lead to premature piston and ring

failure.

Tools recommended for timing service:

• Compact motorcycle dial indicator

• Universal clutch puller- a universal puller that pulls the clutch, main drive gear

and rotor. (Part # MCMUTL70).

TIMING YOUR IGNITION:

1. Remove the spark plug cap, and sparkplug.

2. Insert the dial indicator into the spark plug hole.

3. Remove the four 8/32” X 1 ¾” bolts from the ignition cover.

4. Remove the water pump belt from the rotor and water pump shaft.

5. Turn the crankshaft counterclockwise until it reaches top dead center.

55

Page 57

6. Set the dial indicator to zero

7. Turn the crankshaft clockwise until the dial indicator reaches 0.045” (1.14mm)

from top dead center.

8. Line up the lines on the stator and the rotor (figure 37). Otherwise loosen the

three 10X32 bolts to adjust the stator.

0.045”

before

TDC

Figure 37, Lining up the line on the rotor

with the line on the stator.

Figure 38, Using a dial indicator to measure piston

height for setting ignition timing.

ROTOR INSTALLATION:

1. Use wicking / bearing retainer (green) thread locker on the inside of the rotor,

and on tapered part of crankshaft.

CAUTION:

It is recommended that you apply the proper thread locking primer to the

components that are to receive thread locking material per the manufacturers

instructions.

2. Eyeball the lines on the rotor and stator then press the rotor onto the

crankshaft firmly (figure 37).

3. Torque the nut on the rotor to 40 ft-lb (54 Nm).

4. Recheck the timing following the procedure of timing your ignition.

5. Install the water pump belt back on.

6. Bolt the ignition cover back on.

7. Put the spark plug back in, and firmly stick the spark plug cap onto the spark

plug.

Cooling System

The water pump in the engine keeps the radiator fluid in circulation throughout

the motor. The air stream running through the radiator cools the radiator fluid.

Therefore dirty radiators additionally reduce the cooling effect.

56

Page 58

Cobra has tested numerous brand name automotive and racing coolant /

antifreeze solutions and has found Liquid Performance Propylene Glycol based

Mini Coolant / Antifreeze to have the greatest effect on reducing cylinder head

temperatures.

Radiator fluid removal:

1. Remove the coolant drain plug (A) on the front of the engine case (figure 39).

A

Figure 39

To remove radiator cap:

1. Turn the cap counter clockwise to the first stop and wait there for a few seconds.

2. Push the cap down and turn it further in the same direction and remove the cap.

NOTE: Inspect the old coolant for visual evidence of corrosion and abnormal smell.

Fill the radiator up to the bottom of the radiator filler neck with coolant. Install the cap,

turning it clockwise about ¼ turn.

Tools recommended for impeller service:

• Flat head screwdriver

• 5mm hex key

• 13mm- hex wrench

• 1/8” hex key

• 9/64” hex key

• 3/32” hex key

• Propane torch

• 3/8” diameter x 8” long steel rod

• Hammer

COBRA IMPELLER SERVICE INSTRUCTIONS

1. Remove exhaust pipe and gas tank (you will be using a propane torch in step 12.

2. Remove radiator cap and drain engine coolant by removing the 13mm- hex head

coolant drain plug.

3. If the impel ler is damaged or broken completely back flush the coolant system to

ensure no solid pieces are in the system.

4. Remove foot brake.

5. Drain engine transmission oil by removing drain screw using a 13mm- hex

wrench. (item 2 in the figure below).

57

Page 59

6. Remove kick-starter cover using a 5mm hex key. (item 3 six places)

7. Remove clutch and basket.

8. Unscrew water elbow fitting. (Figure 40)

Figure 40

8. Remove ignition cover using a 9/64” hex key (four places)

9. Remove belt retainer screw using a 1/8” hex key. (Figure 41 - item 1)

10. Remove belt retainer, water pump belt and water pump fan pulley.

11. Remove bearing retainer screw using a 3/32” hex key. (Figure 41 – item 2)

Figure 41

12. Heat engine case around area of impeller lightly with a small Burnsmatic propane

torch. Using a 3/8” diameter x 8” long steel rod, tap impeller assembly out of

engine as shown in figure 42.

Figure 42

CAUTION:

Too much heat can be detrimental to the engine cases.

13. The shaft assembly is serviceable. Use a 1/8” hex key to remove impeller

retainer screw. Remove impeller, seal and both bearings. Check shaft for wear in

the area of the seal. If there is any sign of wear (like a groove) replace the shaft.

58

Page 60

Figure 43

Clean all threads and use green (wicking / bearing retainer) thread locker on the belt

Temp RTV silicon gasket maker to the threads of the water

Do not mix Propylene Glycol based coolant / antifreeze solutions with Ethylene

14. Reinstall new bearings, seal and impeller. Clean all threads and use green

(wicking / bearing retainer) thread locker.

15. Using a liberal amount of grease on the outside seal, bearings and inside of

case, reinstall bearing assembly by using a 0.500” ID by 1.000” OD steel tube 2”

long and tap on end of tube per figure 44.

Figure 44

16. Re-assemble in same order of disassembly.

CAUTION:

retainer screw.

NOTE:

Apply Ultra black Hipump 90° elbow fitting before assembly.

NOTE:

Refill the coolant system with Liquid Performance

Propylene Glycol based Mini Coolant / Antifreeze.

CAUTION:

Glycol based coolant / antifreeze solutions.

59

Page 61

Fuel & Air System

Carburetor:

Tools recommended for carburetor service:

• Small flat head screwdriver

• WD-40

• 8mm socket

REF. # PART # DESCRIPTION

Figure 45

KING Carburetor Ref. Drawing

1 RCMU0305 CARB SLIDE

2 RCMU0601 NEEDLE

3 RCMU0002 ATOMIZER

4 MAIN JET

5 PILOT JET

6 CHOKE JET

7 RCMU0301 FLOAT

8 RCMU0102 RUBBER CABLE CAP SEAL

9 RCMU0003 CABLE ADJUSTER

10

11 RCMU0006 TOP CARB SCREW

12 RCMU0106 CARB TOP

13 ZCMU0007 TOP CARB GASKET

14 RCMU0004 SLIDE SPRING

15 RCMU0205 NEEDLE RETAINER PLATE

16 RCMU0007 NEEDLE CLIP

17 RCMU0204 CHOKE ASS’Y. 2001 CM

20 RCMU0009 FUEL MIXTURE SCREW

21 RCMU0011 IDLE ADJUSTMENT SCREW

25 RCMU0103 FLOAT BOWL GASKET

26 RCMU0107 FLOAT NEEDLE

27 RCMU0012 DIFFUSER

28 RCMU0016 FLOAT RETAINER PIN

29 RCMU0106 FLOAT BOWL

30

RCMU0201 BOTTOM FLOAT SCREW

31

33 RCMU0269 VELOCITY STACK

60

Page 62

Your Cobra is equipped with an adjustable carburetor. Some fine-tuning may be

needed according to weather condition and altitude. Proper jetting is very

important for engine performance and engine life. Serious damage to the engine

can occur if not properly adjusted.

IDLE ADJUSTMENT:

On the left side of the carburetor, there are two adjustment screws. The larger

screw with the knurled head is the idle adjustment screw. To raise the idle, turn