Page 1

Robo-Arm™ LR Accessory

Kit 8560761701 For use with COATS Rim Clamp® Tire Changers

This is a supplement to your operating manual and covers the installation and use of the Robo-Arm LR accessory.

If you do not have your original operating manual, please call COATS at 1-800-688-6359 to request an additional

copy.

Installation Instructions

Operating Instructions

with Parts Identifi cation

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 8560762401 01

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®. and BADA® Automotive Service Equipment and Tools. Revision: 02/12

Page 2

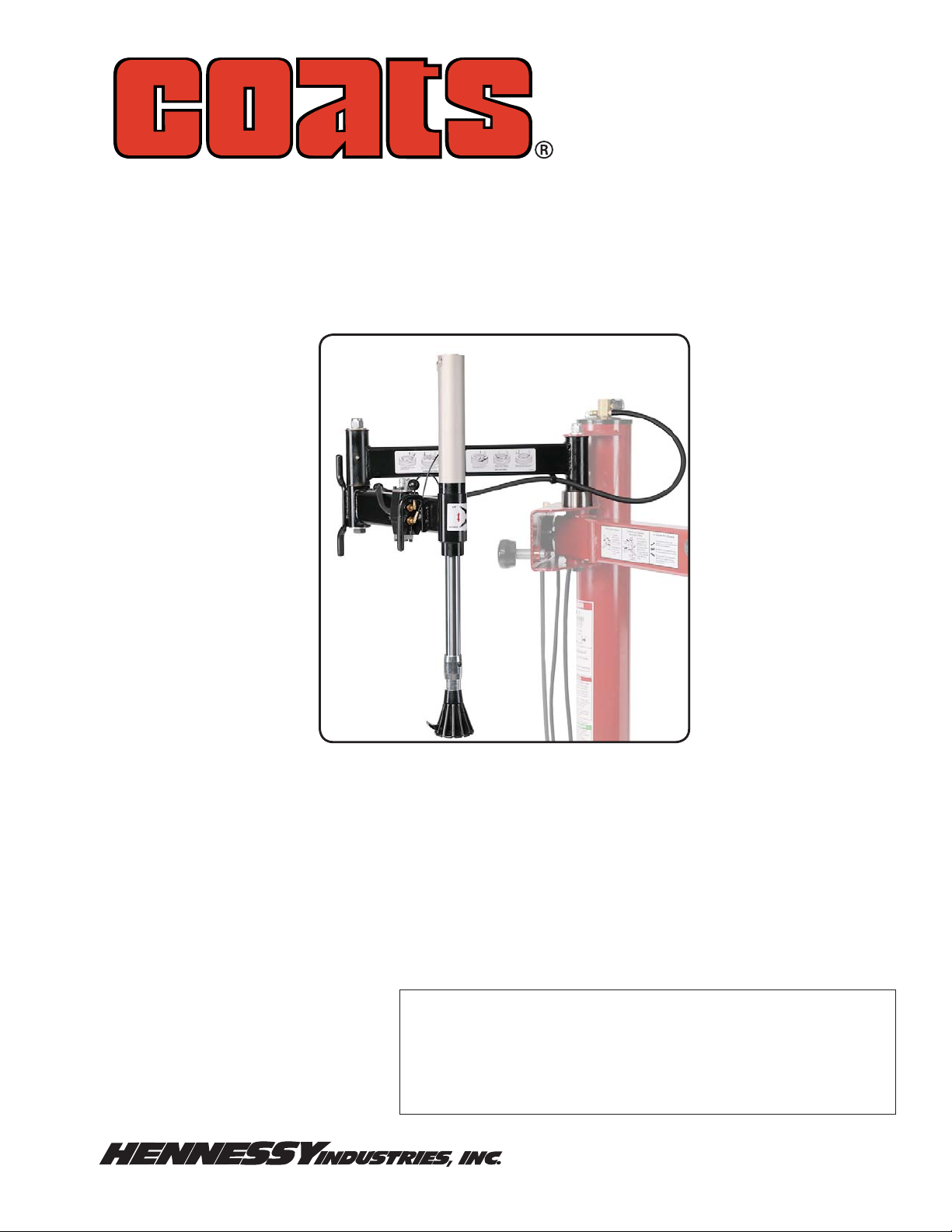

Installation Instructions

1. Before beginning any work, clear the area and posi-

tion the machine for easy access. Disconnect all power

sources, both air and electricity inputs. Allow any stored

air in the reservoir to escape by depressing the inflate

valve.

4. Next, remove nut on the bolt supporting the swing

arm pivot system. With the new 14-inch (356 mm) long

bolt push the old bolt out. Make sure the small washer

is on the head of the new bolt. Next, install the pivot pin

spacer, the swing arm (note position of the decal) with

pivot pin spacer, large washer and the lock nut.

Pivot Pin

Spacer

Figure 1 - Disconnect power and air sources.

2. Verify the stored air pressure is zero by observing

the air pressure gauge on top of the tower (see photo).

Next with a 1 1/16-inch socket wrench, remove the

manifold with the gauge and safety valve.

Safety Valve

Figure 2 - Remove manifold with gauge and safety valve.

3. Next install the included manifold with the gauge

and safety valve plus a barbed hose fitting. Tighten until

the barbed fitting is located as shown in photo.

Figure 4 - Use new long bolt to push old bolt out.

5. Next, using large wrenches, tighten the assembly

to 240 ft. pounds torque (very tight). If the swing arm

rotation is too tight, loosen the lock nut until the swing

arm assembly rotates with a slight amount of resistance.

Figure 5 - Tighten swing arm to rotate with some resistance.

Manifold with

Gauge and

Safety Valve

Figure 3 - Install manifold, safety valve and barbed fitting.

Barbed

Fitting

2 • Tire Changers

Page 3

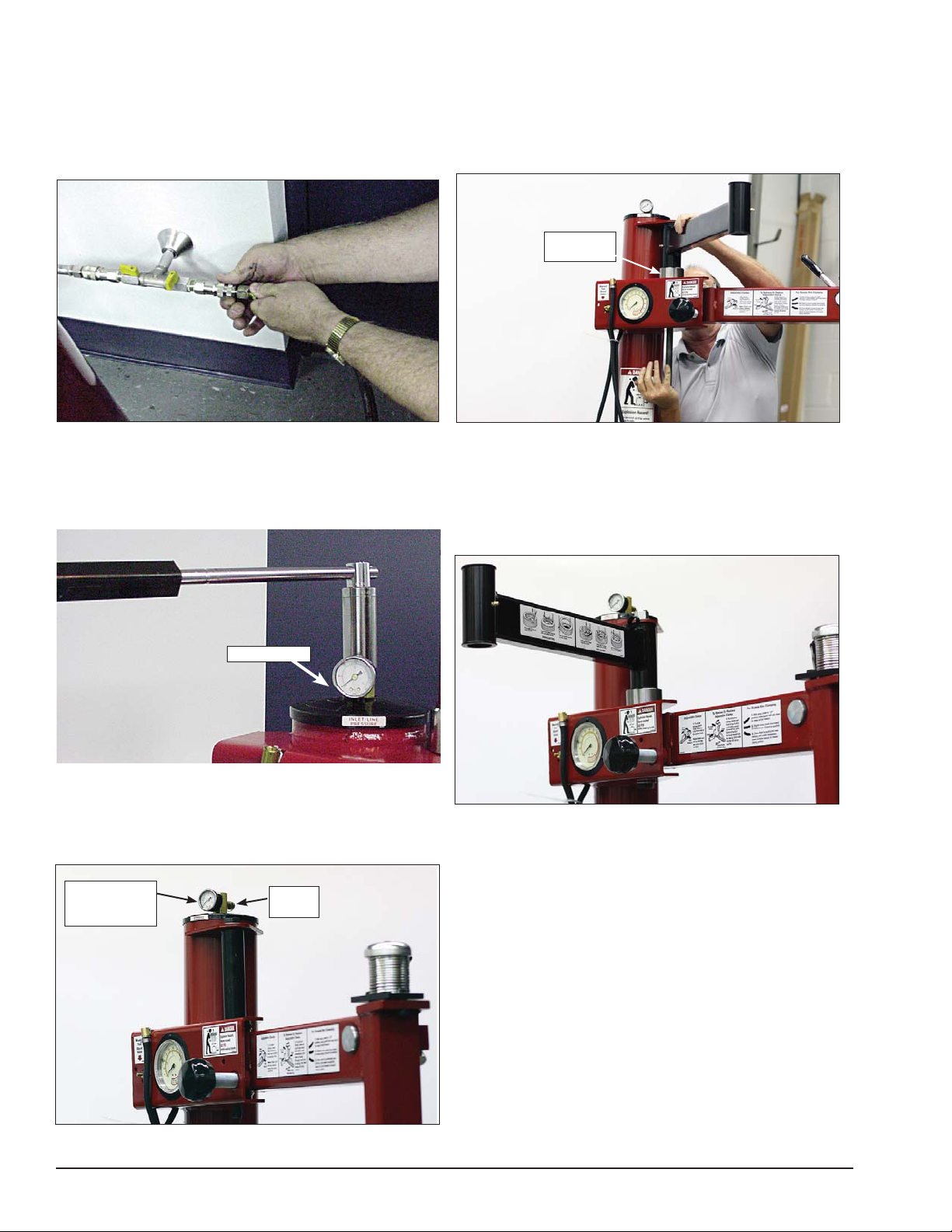

6. Locate arm with valve assembly, install the 10 1/2-

inch (267 mm) long bolt with head through the bottom

side, slide pivot pin over bolt and attach nut with only

one turn.

Figure 6 - Locate and position arm with cylinder.

8. Next, using large wrenches, tighten the assembly

to 240 ft. pound torque (very tight). Again, even though

the bolt is very tight, the assembly should be free to

rotate.

Figure 8 - Tighten the swing arm bolt.

9. Slide the cylinder through the cylinder arm bush-

ing, aligning the cylinder for set screw installation.

Tighten the set screw.

7. Slide the cylinder arm pivot pin through the swing

arm bushing, hold in position, remove nut and place

washer over bolt threads and assemble nut to bolt.

Figure 7 - Hold swing arm in position to install nut to bolt

Set

Screw

Figure 9 - Slide cylinder through cylinder arm bushing.

10. Install the external snap ring.

Figure 10 - Install external snap ring.

Tire Changers • 3

Page 4

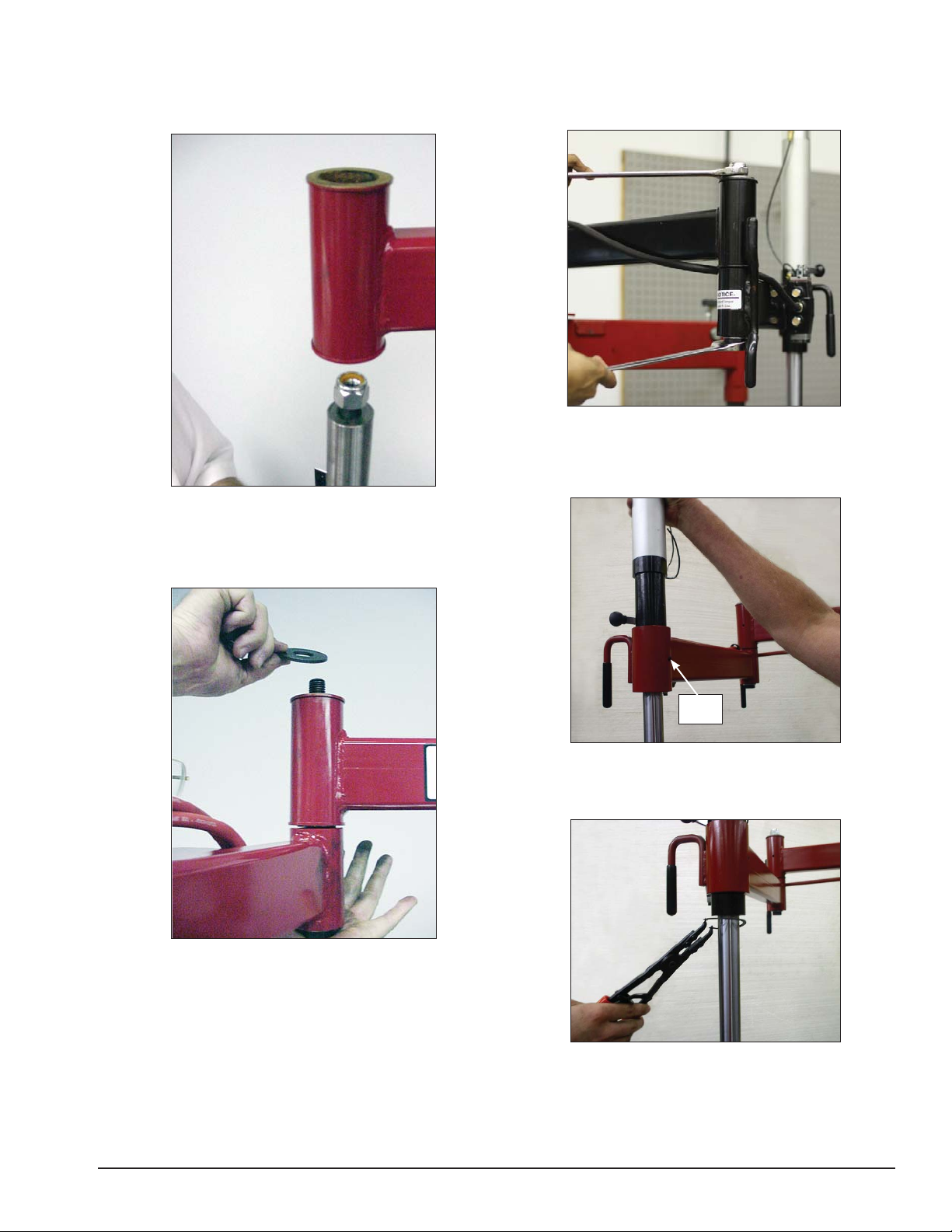

11. Next, install the helper tool onto the extender

shaft using the roll pin.

Roll Pin

Figure 11 - Install helper tool onto extender shaft.

12. Grease the steel ball and place it in the bottom

of the helper tool.

14. Connect 1/8-inch nylon tubes from robo cylinder

to cylinder arm valve fittings, as shown in figure 14.

Attach cable tie around tubes to bottom cylinder fitting.

A

Nylon

Tube

Use Cable

Tie To Nest

Tubing

Nylon

Tube

A

B

B

Figure 12 - Place greased ball in bottom of helper tool.

13. Install the helper tool on the cylinder shaft align-

ing it for set screw installation. Tighten the set screw.

Set Screw

Figure 13 - Install the helper tool on the cylinder shaft.

Figure 14 - Connect nylon tubes.

15. Attach hose clamps to arms. Next, unwrap the

hose from valve, guide through hose clamps; and, with

the hose pushed over the barbed fitting, tighten hose

clamps by pulling clamp tabs off.

C

Figure 15 - Route hose and tighten hose clamps.

Route and

Connect Hose

C

16. Next, reconnect the air pressure source and

check for leaks. Cycle the cylinder on the Robo-Arm™

LR several times to make sure cylinder operates correctly (valve up for cylinder up - valve down for cylinder

down).

4 • Tire Changers

Page 5

Operating Instructions

(with Robo-Arm™ LR)

This unit must be properly operated and properly maintained to help avoid accidents that could damage the

unit and injure the operator or bystanders. This section

of the Operating Instructions manual review basic operations and use of controls. These instructions should be

reviewed with all employees before they are allowed to

work with the machine. Keep these instructions near

the machine for easy reference.

Bead Loosening and Demounting

CAUTION

This machine may operate differently from

machines you have previously operated.

Practice with a regular steel wheel and tire

combination to familiarize yourself with the

machine’s operation and function.

A. Remember to remove all weights from both sides

of the wheel. Weights left on backside of wheel

may cause the wheel to be clamped unleveled.

This may result in the combination mount/demount

head contacting the rim causing scratches. On alloy

wheels, always rotate the wheel one turn after setting the Duckhead to insure proper wheel chucking.

B. Always review with the owner any nicks and

scratches on expensive wheel and tire combinations prior to servicing.

CAUTION

Loosening the beads on a partially or fully

inflated tire is unsafe and causes excess

movement and friction against the bumper

pads and excessive wear on pivots. Deflate

the tire completely to prolong the life of

your machine.

1. Deflate the tire completely by removing the valve

core from the valve stem (figure 1). Be cautious and do

not smoke as a flammable gas could have been introduced into the tire at some time.

Figure 1 - Remove Valve Core to Deflate Tire

CAUTION

Tires are always installed and removed from

the rim’s narrow side.

C. Always loosen the bead on the narrow side of

the wheel’s drop center first (tire removed in figure

2 for clarity).

Narrow Side

Drop Center

Long Side

Figure 2 - Determine Narrow Side of Wheel

E. The clamps on the table top may extend beyond

the table top itself. To avoid damaging the clamps,

move them to their full inward position before positioning a tire for bead loosening.

F. Use extra care in positioning the bead loosener

shoe on larger wheels/tires, and on alloy wheels.

Make sure the shoe rests next to but not on the

rim, and not on the tire sidewall.

Tire Changers • 5

Page 6

2. Pull the bead loosener shoe away from the machine

and roll wheel into position. The valve stem should be

in the 2 o’clock position to accommodate a possible

asymmetric safety hump type rim. Position the bead

loosener shoe against the tire next to, but not on, the

rim. Press the bead loosener foot pedal to actuate the

shoe and loosen the bead. It may be necessary to

loosen the bead in multiple locations around the tire

(figure 3).

Valve Stem

Figure 3 - Position Tire and Bead Loosener Shoe

4. Apply tire manufacturer’s approved rubber lubricant

liberally to entire circumference of both tire beads after

loosening (figure 5).

Figure 5 - Apply Rubber Lubricant to Tire Beads

5. Determine the mounting side of the wheel. The

mounting side is the narrow side of the drop center. See

figure 2 for more information on the drop center.

6. Place tire/wheel assembly on table top with mount-

ing side up (figure 6).

3. Turn the wheel around and repeat loosening pro-

cedure on the other side of the wheel (figure 4). This

should be the long side of the drop center (figure 2).

Figure 4 - Position Tire and Bead Loosener Shoe With Wheel

Turned Around

G. It will be easier to outside clamp the wheel to

the table top if the long side of the rim is loosened

last.

Figure 6 - Place Tire/Wheel Assembly on Table top

7. Use Robo-Arm LR with cone to apply pressure to

aid in clamping rim (figure 7). Use the clamp control

pedal to move the clamps inward (push pedal down)

or outward (toggle pedal up). Clamp steel wheels from

the inside (clamps push outward against wheel). Clamp

mag and custom wheels from the outside (clamps push

inward against the outside rim edge).

Figure 7 - Robo-Arm LR Aids Clamping

6 • Tire Changers

Page 7

8. Check helper foot positioning. Adjust helper foot

reach by rotating the extender up or down. Raise foot

for wide tires or lower foot for narrow tires.

Rotate

Rotate

11. Locate the valve stem just before the demount

head before proceeding (Figure 11).

Valve Stem

Raise For

Wide Tires

Lower For

Narrow Tires

Figure 8 - Using Helper Foot Extender

9. Depress the tire sidewall downward with the

aid of the helper foot providing clearance for the

mount/demount head to be positioned (figure 9). Move

swing arm into place. Increase the horizontal distance

between the demount head and the wheel an additional

1/16 to 1/8 inch with the adjustment knob.

Figure 9 - Helper Foot Depressing Sidewall of Tire

10. Lubricate upper bead liberally (Figure 10).

Demount Head

Figure 11 - Position Valve Stem Under Demount Head

12. Place helper foot opposite the demount head and

push the bead into drop center. Insert bead lifting tool

between knob on demount tool and tire bead (Fig. 12).

Figure 12 - Insert Bead Lifting Tool

13. Rotate lifting tool down over wheel to lift bead

up and over the knob and at the same time remove

helper foot.

14. Hold lifting tool in place, depress the table top

rotation pedal momentarily to jog the wheel a short

distance. Check the wheel and tire to verify that operation is not causing damage. The lifting tool can usually

be removed after jogging the wheel a short distance

(Figure 13). Continue to jog the wheel to allow the tire

sidewall to flex as it crosses the rim edge. Continue

short rotations until top bead is completely demounted.

Figure 10 - Lubricate Upper Bead

Figure 13 - Holding Lifting Tool in Place and Rotate Wheel

Tire Changers • 7

Page 8

15. Demount lower bead. Pay close attention to sen-

sor/transmitter location, and position it just before the

demount tool when starting the lower bead demount

procedure (Figure 14).

Sensor

Figure 14 - Sensor/Transmitter Location

16. Flip down the helper foot hook (figure 15).

Mounting

1. Lubricate both tire beads liberally. Performance

tires will require more lubrication than standard passenger car tires.

2. Mount the lower bead. In most cases, the lower

bead will mount easily.

AE: Mounting the top bead can be very difficult

when mounting new tires on performance and custom

wheels. Proceed slowly and cautiously.

3. Position the valve stem 90 degrees clockwise in

front of the mount/demount tool for top bead mounting. Lift the bead over the rear of the mounting head.

Use the helper tool to hold the bead in the drop center

(Figure 17). Rotate the wheel in short steps and apply

extra lubricant to mount upper bead.

Flip Hook

Down

Figure 15 - Using Helper Foot Hook

17. Position the helper foot hook to lift and hold the

tire at an angle so the lower bead is resting in the drop

center directly across from the demount head, and is

loose below the demount head. Insert bead lifting tool

down over demount tool and below the lower bead. Lift

the lower bead over the demount tool (Figure 13). Hold

the lifting tool in place. Depress the table top rotation

pedal momentarily to jog the wheel short distances to

complete the demounting process.

Valve

Figure 17 - Mount Upper Bead, Use Helper

4. On extremely tight tire and wheel combinations, it

may be necessary to use the bottom of the helper foot

to flip the tire bead over the rim flange (Figure 18)

Figure 18 - Helper Foot to Flip Bead Over Rim Flange

Figure 16 - Lower Bead in Drop Center

8 • Tire Changers

Page 9

Robo-Arm™ LR Maintenance

A. Grease the Robo-Arm LR to maintain smooth rota-

tion. Grease fittings have been provided at the pivot

joints.

B. Check bolt torque periodically at pivot joints. Proper

Torque is 240 ft. lbs.

Maintain Bolt Torque

at 240 ft. lbs.

Grease Fittings

Tire Changers • 9

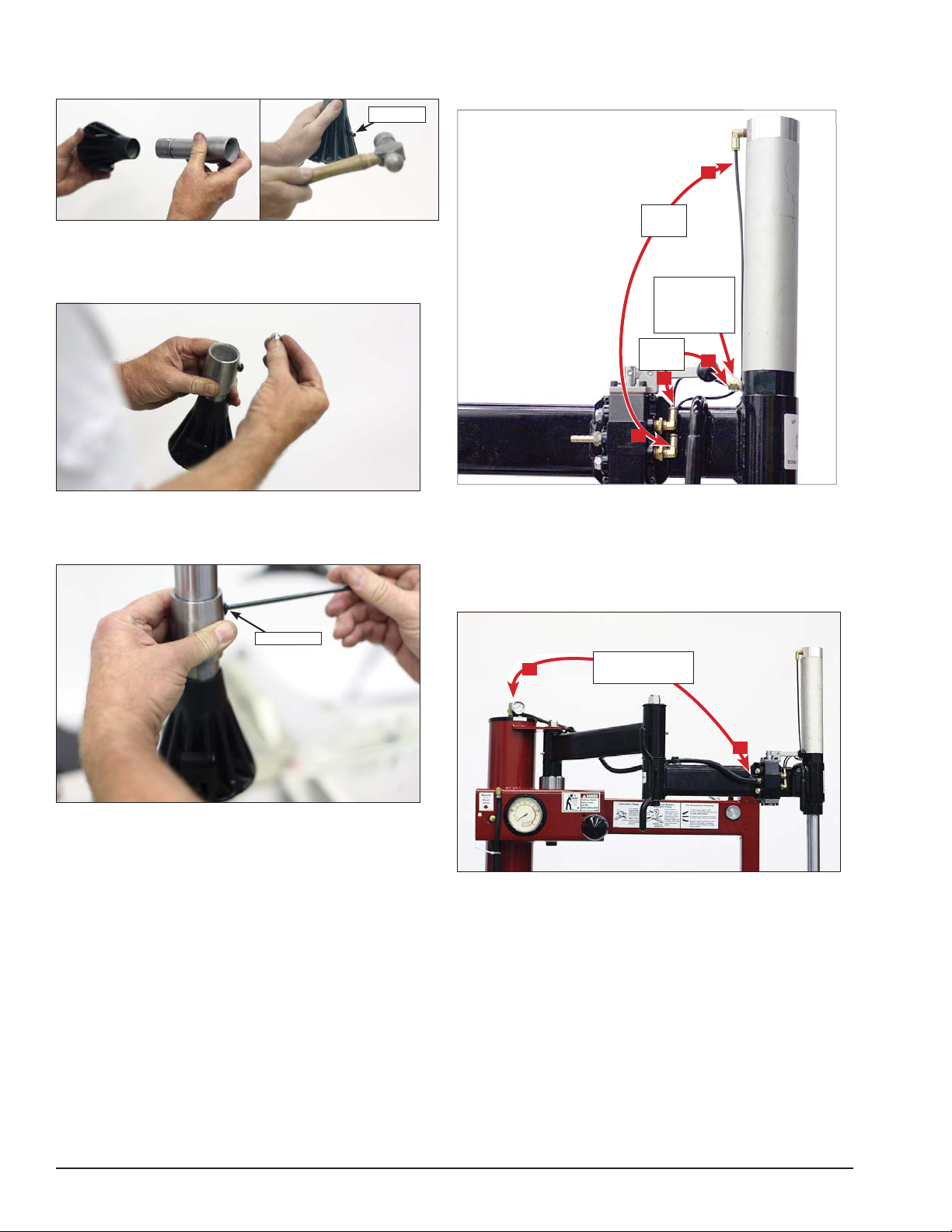

Page 10

Parts Identifi cation

Kit 8560761701 Robo-Arm™ LR Accessory

32

8

36

14

15

9

35

18

34

14

22

23

10

38

7

6

11

17

24

13

39

16

33

21

5

12

19

25

4

41

2

1

3

42

43

44

ITEM PART NO. DESCRIPTION

1 85607622 Plastic Hold Down Foot

2 905563 Roll Pin, 1/4" Dia x 1-1/2"

3 8301017 Dia. Steel Ball, 1/2"

4 7000230 Rubber Hand Grip, 1/2"

5 8183637 2" Ext. Retaining Ring

6 8181983 10-24 x 3/4 Lg. BHSCS

7 *** Robo-Arm LR Valve Assembly

8 85607946 Cyl Assem 2" Dia x 8-inch Stroke

9 8181996 1/4 NPT x 1/8 Tube St. Fitting

10 8106301 1/4-20 x 3/4" HWHST Screw

11 8182044 Neoprene Cushion Clamp

12 8183649 1/4-20 x 5/16" Soc Hd Set Screw

13 8184226 1/4-28 Grease Fitting

14 8182016 3/4-10 Hex Nylock Lock Nut

15 8100994 Flat Washer, 3/4"

16 85607618 Front Arm Weldment

17 85607619 Rear Arm Weldment

18 8181038 Swing Arm Pivot Pin

19 8183703 3/4-10 x 10-1/2” Hex HD Cap Srw

21 8182457 Flat Washer, 3/4 SAE

Torque To

Torque To

240 ft./lb.

240 ft./lb.

ITEM PART NO. DESCRIPTION

22 8108968 Air Gauge

23 8182599 Safety Valve

24 8000378 1/4" Brass St. Fitting

25 8183635 Screw, 3/4-10 x 14, HHCS, Gr.5

32 8181997 90º Elbow

33 8184208 Pivot Pin Spacer

34 * Hose, Rubber, 1/4, 58" Black

35 * Plastic Tube, 1/8 x 6"

36 * Plastic Tube, 1/8 x 16"

38 Wire Tie

39 8184059 Manifold Assembly

41 85607692 Extender w/Set Screw

42 8100602 3/16 x 1-1/4 Roll Pin

43 85607688 Plastic Hold Down Foot Hook

44 85607680 Cone

* Hose Reels

LENGTH PART NO. DESCRIPTION

50-ft. 85000375 1/4” ID x 1/2” OD Black Rubber Hose

50-ft. 85000376 1/8” OD x 0.25 Plastic Tube

10 • Tire Changers

Page 11

3

2

1

4

5

3

2

1

4

5

7

45

1

46

2

47

3

48

4

49

5

Robo-Arm LR

ROBO ARM ASSEMBLY VALVE

Assy Valve

ITEM PART NO. DESCRIPTION

45 8000378 Brass Straight Fitting, 1/4 NPT

46 8105615 Small Muffler

47 8185585 3 Position Valve

48 8109481 RDCR Fitting, 1/4 NPT x 1/8 NPT

49 8181997 Male Elbow, 1/8 NPT x 1/8"

Tire Changers • 11

Page 12

8560762401 01 02/12 © Copyright 2011 Hennessy Industries and COATS All Rights Reserved

Loading...

Loading...