Page 1

Leverless Bead Lifter

Kit 85606689

For use with COATS Tire Changers

This is a supplement to your operating manual and covers the installation and use of the COATS® Leverless

Bead Lifter. If you do not have your original operating manual, please call COATS at 1-800-688-6359 to request

an additional copy.

User Instructions

with Parts Identifi cation

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 85606701 00

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 07/10

Page 2

Qualifying Test For

Machine Compatibility

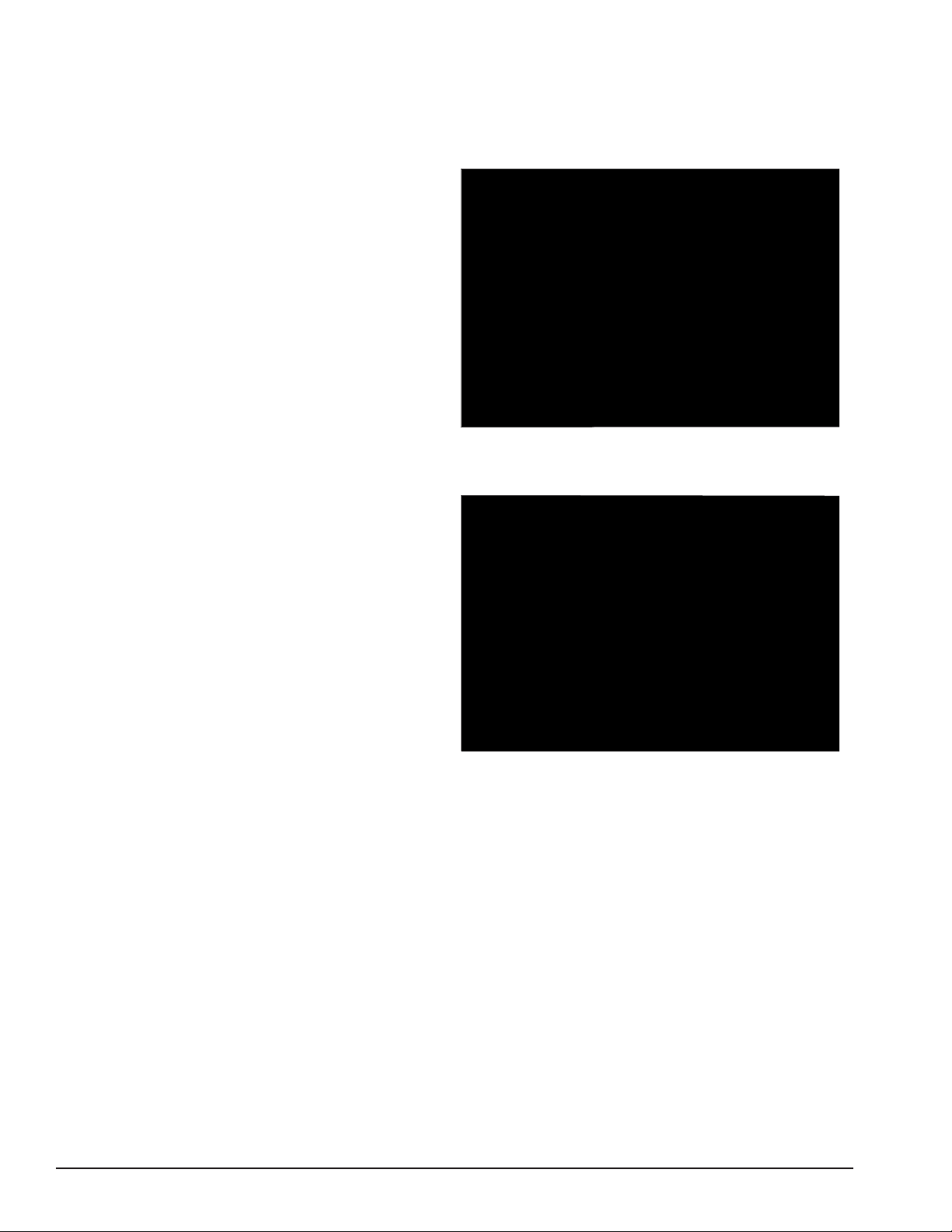

1. Push down on mount/demount head while pulling

up on table top. Record distance — top of clamp to

bottom of mount/demount head.

2. Now, pull up on mount/demount head while push-

ing down on table top. Record distance — top of clamp

to bottom of mount/demount head.

3. Subtract step 1 distance from step 2 distance. If

distance is greater than 3/8-inch then machine is not

compatible.

Note: If the machine is not compatible, please con-

tact COATS® at 1-800-688-9240 for the Certified Service Partner nearest you.

2 • Important: Always read and follow the instructions.

Page 3

Leverless Bead Lifter

Installation

CAUTION

Always DISCONNECT THE ELECTRICAL

POWER before servicing equipment. This

prevents electrical shock or accidental

movement of the systems operated by the

electrical power.

CAUTION

Always DISCONNECT AIR SUPPLY before

servicing equipment. This prevents accidental movement of systems operated by compressed air which may result in personal

injury. BLEED THE AIR SYSTEM by actuating

all the valves.

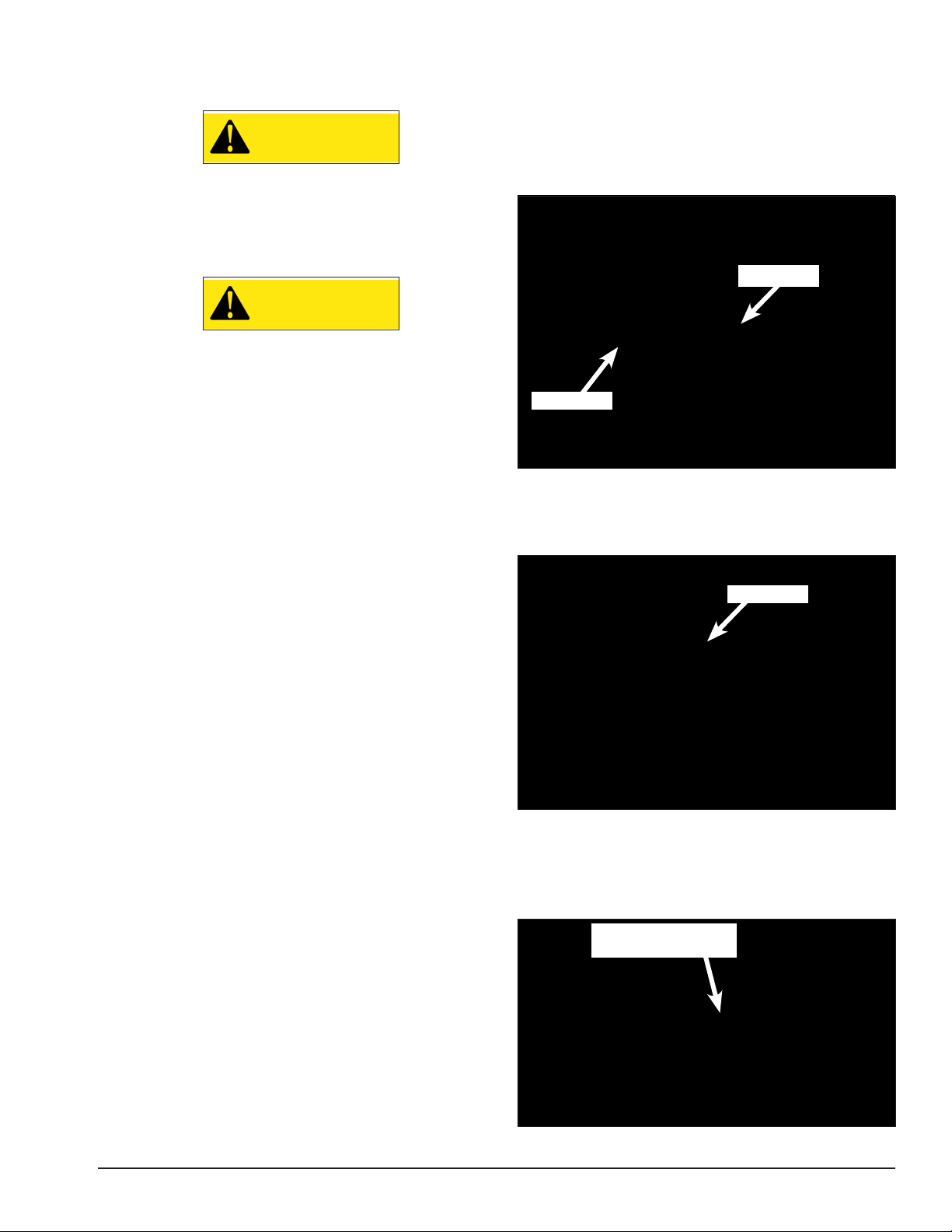

50/70x Series Installation

1. Disconnect the electrical power and air supply

from the machine; empty all residual air.

2. Remove side panel from chassis.

3. Locate and cut rubber hose that is between the

pedal valve and oil injector.

Pedal Valve

Oil Injector

4. Route kit hose assembly through 1-inch hole in

rear of chassis. Place hose clamps on cut hoses, then

connect rubber hoses (from step 3) to tee fitting on kit

hose assembly.

Tee Fitting

5. Route kit hose up the back of the tower. Install

cushion hose clamp around air hose near the fitting.

Then, fasten clamp/hose assembly to top of swing arm

using supplied bolt (or use a self-supplied 1/4-inch selftapping screw).

Fa s ten Hos e To Top

Of Swing Arm

Important: Always read and follow the instructions. • 3

Page 4

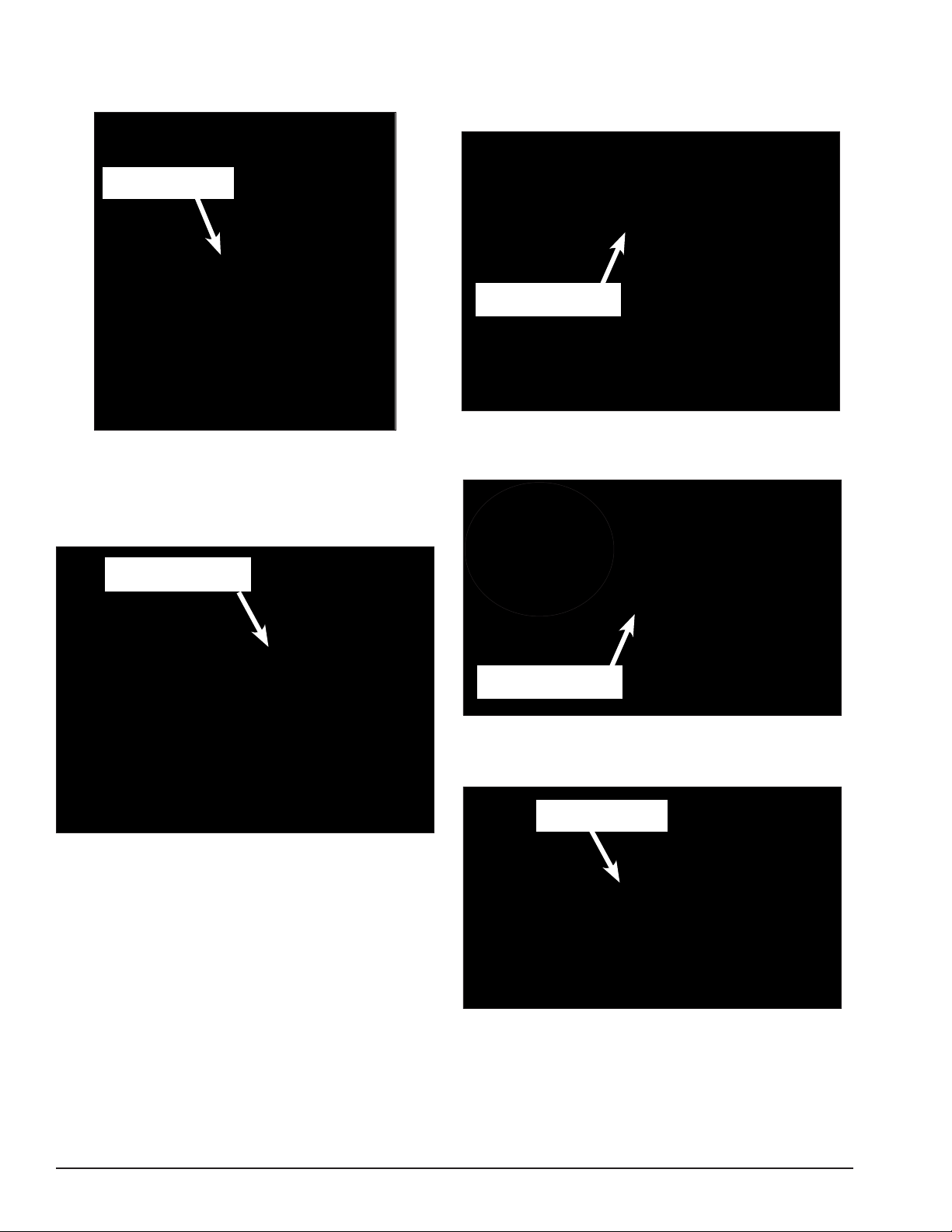

6. Lock the vertical slide shaft and then remove the

mount/demount head, Duckhead® roller mount and

rubber cushion.

Remove Mount/

Demount Head

7. Hold vertical slide shaft down, release lock handle

and remove shaft assembly out the top. Note orientation of flat on the end of shaft.

Note: On units equipped with shoulder screw, use

shim for plastic mount/demount head vertical bar lock.

10. Attach adapter to leverless bead lifter mount/

demount head so that the (2) set screws line up with

the adapter flat. Snug (1) set screw on side to hold

adapter in place.

Align Set Screws

With Adapter Flat

11. Assemble washer set on screw, small washer

first with mating bevels together. Attach leverless bead

lifter assembly to vertical shaft; hand-tight only.

Hold Shaft Down

And Release Lock

8. Remove spring, install short spring from kit and

place shaft assembly back into swing arm. Reassemble

with shaft flat in same orientation.

9. Lock shaft.

Attach Leverless

Bead Lifter To Shaft

12. Connect coil air hose from leverless bead lifter to

the fitting installed on top of swing arm bracket (from

step 5).

Connect Coil Hose

To F itti ng

13. Re-connect air supply to machine. Inspect and

correct leaks if found.

14. Be sure to perform the steps for the Leverless

Bead Lifter Adjustment Procedure on page 7.

4 • Important: Always read and follow the instructions.

Page 5

APX Series Installation

1. Tilt tower forward and rotate slide shaft control to

the DOWN position. Do not lock.

2. Disconnect power and air; empty all residual air.

3. Remove the mount/demount head and rubber

bumper.

4. Remove the screw from top of vertical slide cap.

5. Remove rubber stop and hardware from vertical

shaft.

10. Place air coil hose through hole in tower bracket.

Route Coil Hose

Through Hole In

Bracket

Remove Hardware

From Vertical Shaft

6. Slide vertical shaft out the top and rotate it 180

degrees; then re-insert the vertical shaft.

7. Place spring over top of vertical shaft.

8. Replace screw (from step 5) in top cap.

Replace

Screw

11. Cut 1/8-inch tube as shown.

Cut Tubing

12. Assemble (2) cut ends to tee supplied with kit

and push-connect coil hose to tee fitting.

Install Tee

Fitting

Connect Coil

Hose

9. Attach adapter to the leverless bead lifter and

install the assembly to the shaft following the 50/70

series installation steps 10 & 11.

13. Re-connect air supply to machine. Inspect and

correct leaks if found.

14. Be sure to perform the steps for the Leverless

Bead Lifter Adjustment Procedure on page 7.

Important: Always read and follow the instructions. • 5

Page 6

9024 Series Installation

1. Lower vertical slide shaft about 9-inches. and lock

bar. Tighten hex screw to lock bar.

2. Disconnect the electrical power, close the air lever

cock and bleed the air circuit completely.

3. Release hex screw of pipe locking knob. Insert kit

spring and hex washer and tighten hex screw back on.

6. Insert the other end of the hose into the T-union

previously installed (step 4).

7. Using two hose clamps from kit, attach the hose

at the end of the guide placed behind the post. Cut the

over length and secure with ties.

Use Hose

Clamps To

Route Hose

4. Cut the black hose, as in picture, and insert the

union delivered with the kit.

Install

Union

5. Place the plate, complete with unions, on the

locking plate screw. Attach nut and tighten. Then insert

hose into the L-shaped union.

Attach Plate

8. Remove the mount/demount head. Then release

the tool locking screw using hex wrench. Keep screw

and washers.

9. Next install the leverless bead lifter to the shaft

following the 50/70 series installation step 11.

10. Insert the quick union into the free end of the

coil hose and then insert this quick union into the

female union on the plate (from step 5).

11. Re-connect air supply to machine. Inspect and

correct leaks if found. Open the air lever cock to send

pressure to circuit.

12. Move the bar lock selector to middle position.

You will hear an air bleed.

13. Release the hex bush screw to release the oper-

ating arm.

14. Be sure to perform the steps for the Leverless

Bead Lifter Adjustment Procedure on page 7.

6 • Important: Always read and follow the instructions.

Page 7

Leverless Bead Lifter

Adjustment Procedure

1. Use a 17-inch diameter wheel for adjustments.

This covers the normal range of 14 to 21-inch wheels.

2. Set mount/demount head to 1/8 to 3/16-inch

above wheel.

1/8" to 3/16"

5. Loosen (2) set screws on adapter 1/4 turn.

6. Tighten screw holding leverless bead lifter assem-

bly to vertical shaft; torque to 20-26 ft-lbs.

Torq ue To

20-26 ft-lbs.

7. Tighten set screws (4) — (2) on adapter and (2) on

mount/demount head.

8. Tighten (1) set screw on side of mount/demount

head

3. Align mount/demount head to match curvature of

wheel.

Align Mount/

Demount Head

With Wheel

Curature

4. Snug (2) set screws in adapter. Then snug (2) set

screws in mount/demount head making sure mount/

demount head to wheel relationship doesn’t change.

9. Tighten (1) set screw through access hole on

leverless bead lifter.

Tighten Set

Screw

(2) Adapter

Set Screws

(2) Mount/Demount

Head Set Screws

Important: Always read and follow the instructions. • 7

Page 8

Leverless Bead Lifter

Operation

This accessory is normally used in the servicing of

single piece automotive and most light truck tire/wheel

assemblies.

Demounting

Follow tire changer operating instructions provided

for demounting a standard wheel assembly, except:

1. After deflating and bead loosening, clamp the

wheel to the table top. Position leverless arm until

mount/demount head plastic contacts wheel.

3. Tighten swing arm adjustment screw until it con-

tacts arm.

4. Lube leverless tool.

7. Push control handle up, retracting leverless tool.

Note: Use helper arms if equipped.

8. Rotate tire to remove top bead.

9. Position valve stem as shown in step 5.

10. Repeat #6

Note: To aid bead lubing, lower leverless tool slightly

to move bead away from wheel.

5. Position valve stem approximately as shown to

prevent damage to TPMS (Tire Pressure Monitoring

System) sensor.

6. Push control handle down to lower leverless tool

under tire bead while pulling leverless handle to hold

leverless bead lifter against the wheel.

Note: If leverless tool does not hook under tire bead,

reverse rotation. Re-position valve stem while pushing

bead opposite leverless bead lifter into drop center.

11. While holding tire up into drop center, lift tire to

hook the bead on leverless tool, push control handle up

to lift bead over rim.

12. Rotate to remove tire.

8 • Important: Always read and follow the instructions.

Page 9

Mounting

13. Lube beads.

14. Place tire on wheel.

15. Position leverless bead lifter arm so tire bead is

above tail of mount/demount head and position valve

stem just in front of where bead crosses rim.

Valve

Stem

16. Rotate wheel to mount lower bead.

17. To mount top bead, position valve stem just in

front of where bead crosses rim and be sure the tire is

on top or the mount/demount head tail.

18. Slightly lower leverless tool to push bead down;

hold opposite side of tire down into drop-center.

Valve

Stem

19. Rotate wheel to mount upper bead.

20. Inflate, unclamp per standard instructions.

Important: Always read and follow the instructions. • 9

Page 10

Parts Identifi cation

Leverless Bead Lifter

Item No Part No. Description

1 84297851 Handle

2 87019215 Valve Box

3 84399954 Screw 8x20

4 84395374 Nut M8

5 83030571 Spiral Hose 6x4, L=1500

6 84198285 5-way Valve

7 82006996 Valve

8 84198618 Union 1/8"

9 84399829 Washer 8 (8, 4x16x1,5)

10 84399900 Self-locking Nut M8

11 84393957 Screw 10x12

12 84399864 Seeger Ring D.12

13 84395530 Screw 12x2

14 84395529 Screw 12x16

15 83019305 Back Slide

16 83019198 Touchless Mounting Tool

17 84299720 Clamp 188x4,5

18 83019202 Connection Plate

19 84399434 Screw 12x20

20 84398637 Washer ID 12x21x2,5

21 83017334 Bush 12/18/8,2

Item No Part No. Description

22 83017302 Ferrule 12/18/6,5

23 83019212 Tool Pin

24 83019214 Connection Rod

25 84393753 Screw 5x8

26 83019306 Tool Front Slide

27 83019210 Pin

28 83019213 Touchless Tool

29 83010284 Knob D.14x45 M5

30 83019211 Cylinder Pin

31 83019561 Support Plate

32 84194004 Union MR 41 6 M6

33 84199161 Plug 1/8"

34 84199610 Silencer 1/8"

35 84399957 Screw 6x8

36 82031707 Cylinder Unit

37 84399976 Nut M8

38 84298822 O-ring D.68, 26x3, 53

39 84399865 Self-locking Nut M12

40 84198856 Piston D.75

41 83031708 Cylinder Shaft

10 • Important: Always read and follow the instructions.

Page 11

Item No Part No. Description

42 83019208 Special Screw 8x1, 25x180

43 83019204 Special Screw M8X1, 25x164

44 83031709 Cylinder Liner L=125

45 83015024 Flange

46 83199601 Scraper

47 83019467 Back Flange D.75 SO Side Hole

M6

48 87019199 Tool Holder

49 83019959 Hose 6x6 L=240

51 84396878 Steel Shim 12x25x0,5

52 83031595 Threaded Tab

53 83032778 Hose D.6x12 L=7,5 Ft (2300mm)

54 83031235 Spring

55 84397560 Screw 5x16

56 84399292 Washer 5 (5,3x10x1)

57 84398987 Self-locking Nut M5

58 84193590 Hose Clamp 15x15

59 84197390 Clamp D.8x13 H9

60 84199026 Union

61 84198894 Coupling 1/4"

62 84198298 Quick Union 1/4"

63 84193591 Clamp D.16 with Nut

Item No Part No. Description

64 84193592 Coupling 10-1/4

65 84198630 Union 1/4”

66 83030807 Adapter

67 84395804 Washer G Type 14,2x35x5

68 84395805 Washer C Type 10, 2x21x4

69 84393850 Screw 3/8”-16 L=2,5” UNC

70 83030792 Balance Spring

71 83019471 Washer

72 84399967 Nut M10

73 84194089 Quick Union Mod.5053-1/8 F

74 83019607 Quick Fastening Plate

75 84198618 Union 1/8"

76 84194088 Quick Union

77 84198993 Quick Union 1/8"

78 83019962 Hose 6x4 Black L=1500

79 84198172 Connection

80 84198778 Quick Union 1/8"

81 84193574 Straight Union S 6510 6-18

82 84193577 T-Union TT200 1/8

83 84193575 Reduction 1/8 M5

84 84193576 Straight Union M5

70X Series

9024 Series

APX Series

Important: Always read and follow the instructions. • 11

Page 12

85606701 00 07/10 © Copyright 2010 Hennessy Industries and COATS All Rights Reserved Printed in USA

Loading...

Loading...