COATS Kit 85009937 User Manual

Robo-Arm® Kit 85009937

For use with COATS Rim Clamp® Tire Changers

This is a supplement to your operating manual and covers the installation and use of the Robo-Arm®. If you do

not have your original operating manual, please call COATS at 1-800-688-6359 to request an additional copy.

Installation Instructions

Operating Instructions

with Parts Identifi cation

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 85009938 01

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®. and BADA® Automotive Service Equipment and Tools. Revision: 6/14

Installation Instructions

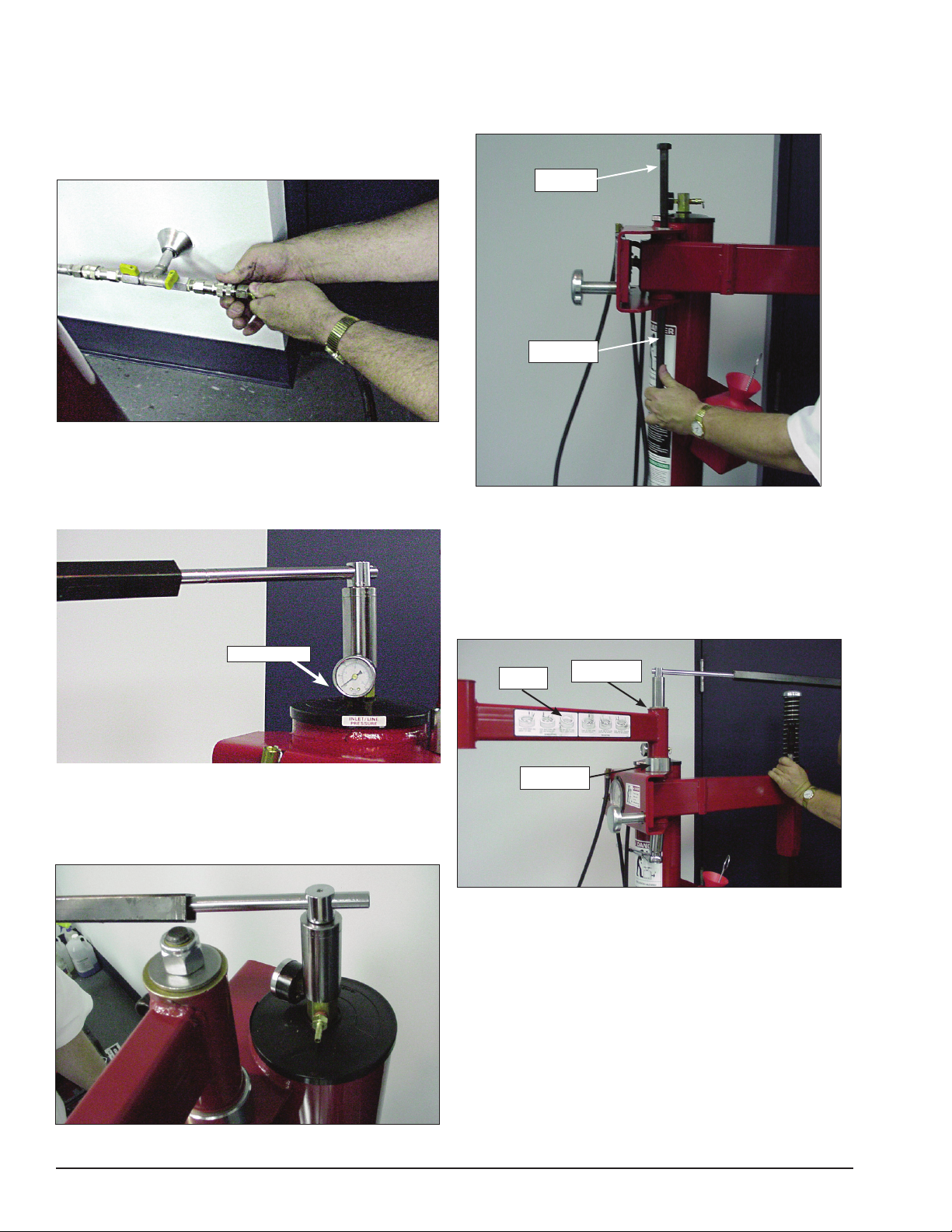

1. Before beginning any work, clear the area and posi-

tion the machine for easy access. Disconnect all power

sources, both air and electricity inputs. Allow any stored

air in the reservoir to escape by depressing the inflate

valve.

Figure 1 - Disconnect power and air sources.

2. Verify the stored air pressure is zero by observing

the air pressure gauge on top of the tower (see photo).

Next with a 1 1/16-inch socket wrench, remove the

manifold with the gauge and safety valve.

4. Next, remove nut on the bolt supporting the swing

arm pivot system. With the new 10 3/4-inches (273 mm)

long bolt push the old bolt out with the new bolt. Make

sure the small washer is on the head of the new bolt.

Old Bolt

New Bolt

Figure 4 - Use new long bolt to push old bolt out.

5. Next, install the large plated spacer, the swing arm

(note position of the decal) with pivot pin spacer, and

the lock nut. Next using large wrenches, tighten the

assembly to 240 ft. pounds torque (very tight). Even

though the bolt is very tight, the assembly should rotate

easy.

Safety Valve

Figure 2 - Remove manifold with gauge and safety valve.

3. Next install the included manifold with the gauge

and safety valve plus a barbed hose fitting. Tighten until

the barbed fitting is located as shown in photo.

Decal

New Bolt

Figure 5 - Tighten swing arm to rotate.

New Bolt

Figure 3 - Install manifold, safety valve and barbed fitting.

2 • Tire Changers

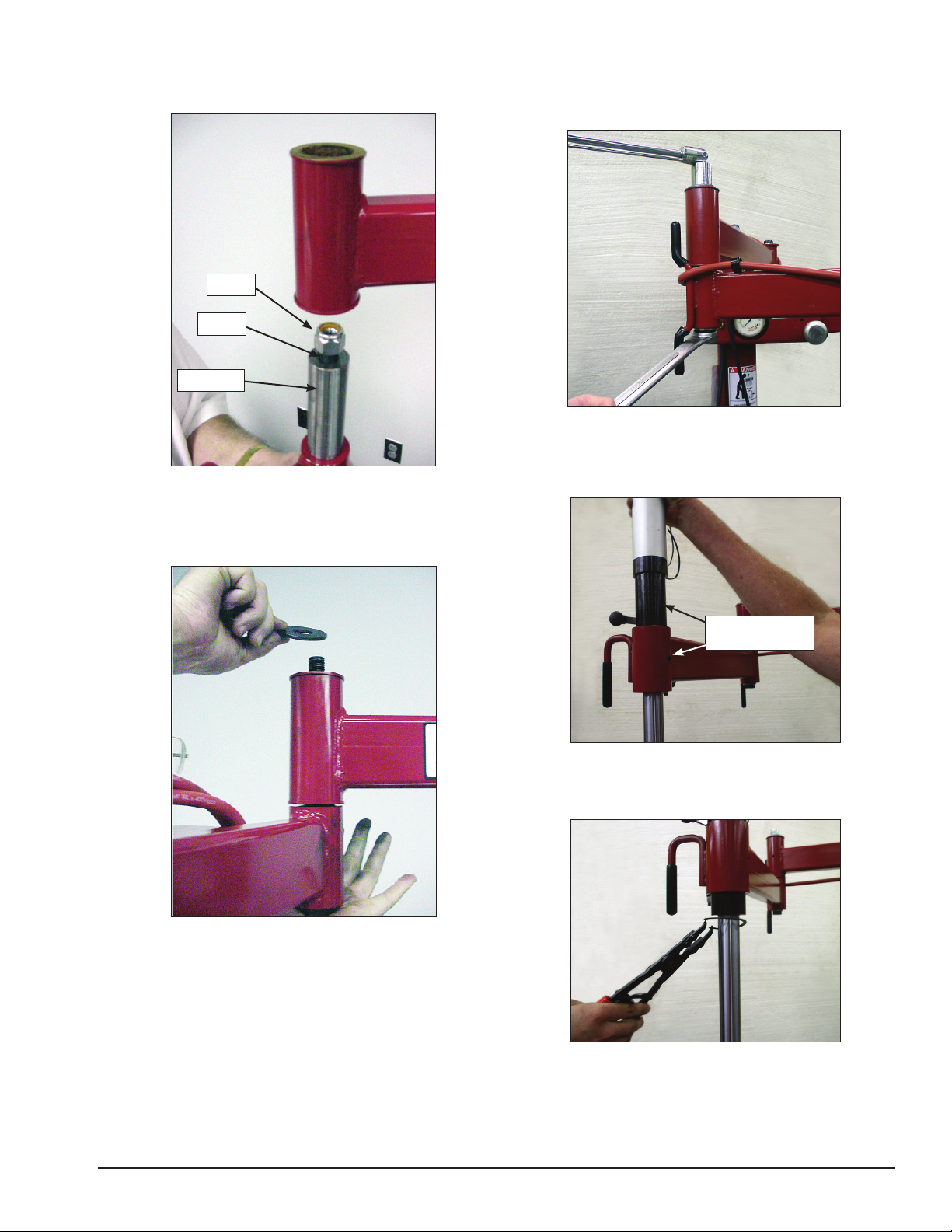

6. Locate arm with cylinder, install 7-inch bolt with

head through the bottom side, slide pivot pin over bolt

and attach nut with only one turn.

Nut

Bolt

Pivot Pin

Figure 6 - Locate and position arm with cylinder.

7. Slide the cylinder arm through the swing arm bushing, hold in position, remove nut and place washer over

bolt threads and assemble nut to bolt.

8. Next, using large wrenches, tighten the assembly

to 240 ft. pound torque (very tight). Again, even though

the bolt is very tight, the assembly should be free to

rotate.

Figure 8 - Tighten the swing arm bolt.

9. Slide the robo cylinder through the cylinder arm

bushing, aligning the robo cylinder for set screw installation. Tighten the set screw.

Figure 7 - Hold swing arm in position to install nut to bolt

Align To Install

Set Screw

Figure 9 - Slide cylinder through cylinder arm bushing.

10. Install the external snap ring.

Figure 10 - Install external snap ring.

Tire Changers • 3

Loading...

Loading...