Page 1

This is an addendum instruction for the pressure limiter and does not cover the safe operation of the

machine, tire/rim match, or evaluation of safe wheels

and tires, or instructions covering the safe inflation

processes. If you need copies of operating instructions

call 1-800-688-6359 or refer to the internet at

www.ammcoats.com.

Note: Fittings have a sealant coating as purchased. If

absent, be sure to apply teflon tape or thread sealant to

any male threads at installation.

Check connections for zero leakage.

85000817 01 09/08 1 of 2 © COPYRIGHT 2008 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

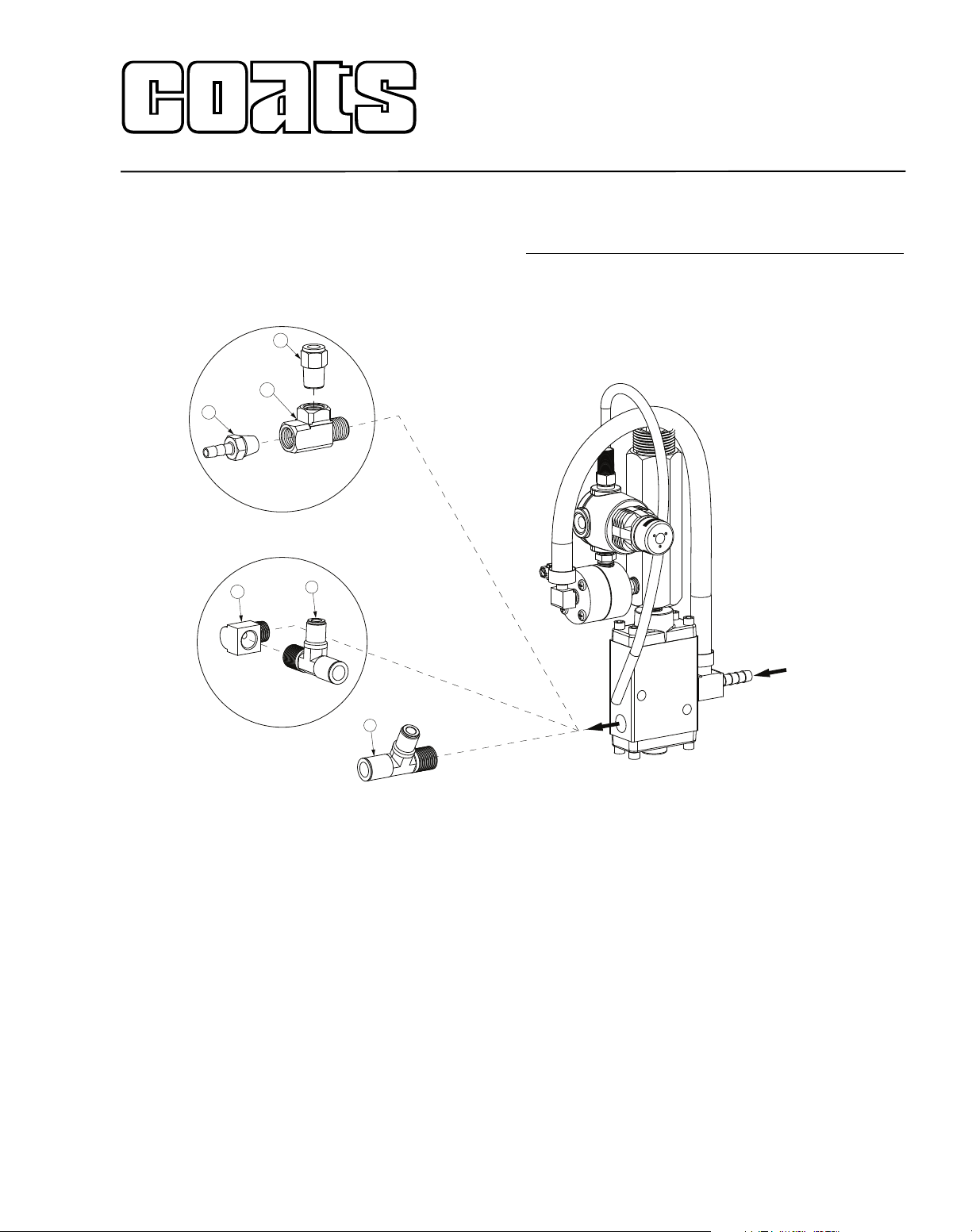

Pressure Limiter Kit 85000816

For use with COATS Model, 40xx, 90xx, Rim

Clamps, RC15, RC20 and APX Tire Changers

Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565 (800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

1

2

5

3

4

1

APX Series

4050

90xx Series

& Rim Clamp

Tire Changers

RC-15 & 20

4040

Middle Port

IN From

1/4-inch Valve

Pressure Limiter Kit Parts List

Ref# Part No. Description

1 8111255 Spl Tee-1/4 NPT x 3/8 x 1/4 Tube

2 8000372 1/4" x 90˚ Street ELL

3 8181987 1/8 NPT x 1/8 Tube Str. Ftg.

4 871101642 1/4 NPT Strt Tee Fitting

5 8000378 1/4" Brass St. Fitting

Page 2

Pressure Limiter Maintenance

Operating a tire changer with a defective,

improperly adjusted, or by-passed pressure

limiter could cause an operator to accidentally over pressurize a tire, resulting in a tire

explosion with severe injury or death to the

operator or bystanders.

Always be sure that the pressure limiter is

present and is operating properly.

Never inflate tire above manufacturer’s recommended pressure after bead is seated.

Pressure limiter is set at 60 PSI. Any

required inflation above 60 PSI should be

performed in an inflation chamber/safety

cage or securely mounted on the vehicle if

an inflation chamber is not available. A tire

explosion may cause personal injury or

death to operator or bystanders.

The pressure limiter helps prevent inflation of standard size or larger tires or tubes beyond 60 PSI to minimize risk of explosion. This device is for the safety of

the operator and bystanders. Proper operation of the

pressure limiter is essential to safe operation of the

machine.

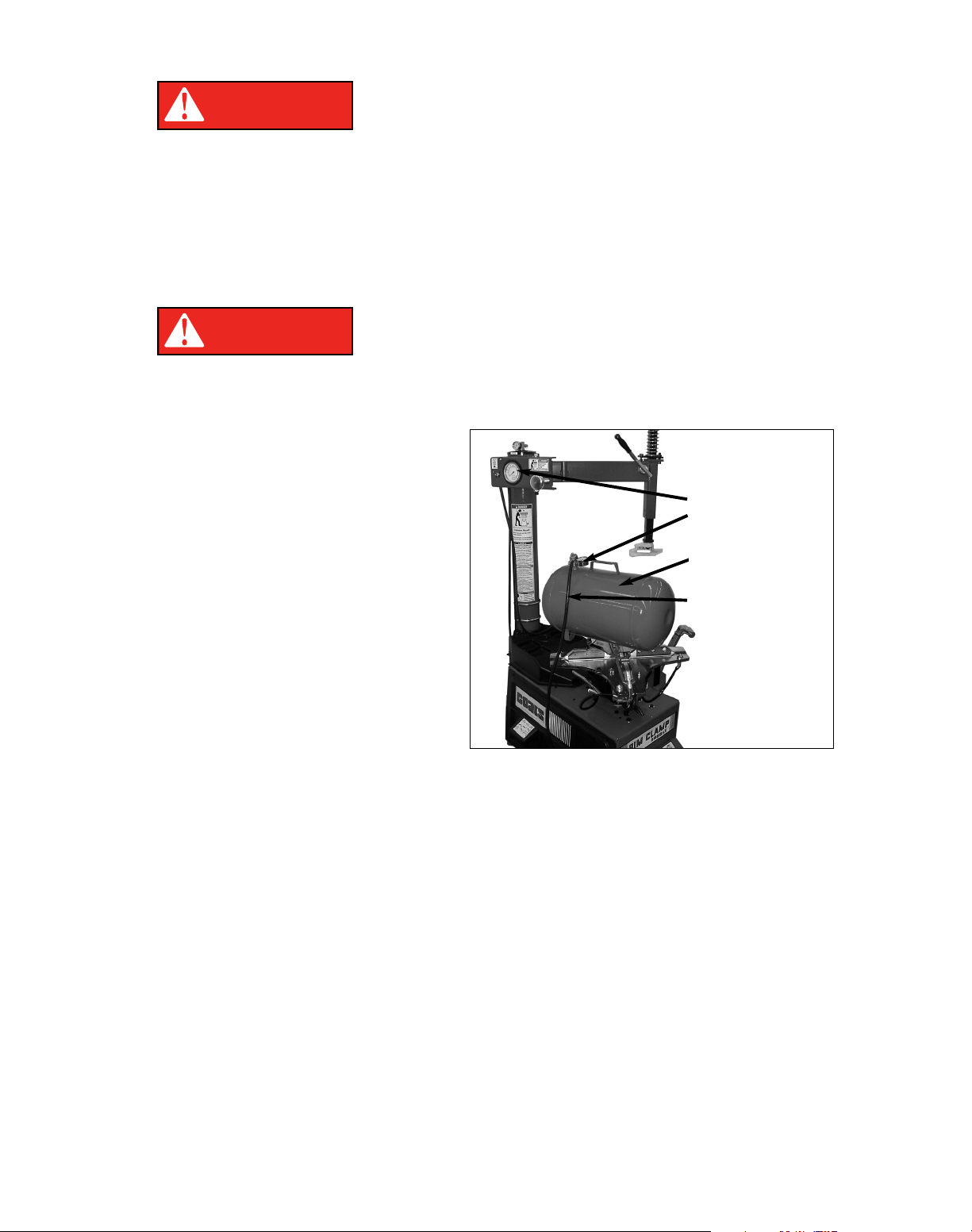

Check operation of the pressure limiter as shown and

described below at least monthly and each time the

machine is serviced:

1. Remove tires and/or wheels from the machine.

2. Connect the inflation hose to an empty service

tank with a pressure gauge (gauge should read 0). Use

a service tank with a pressure rating of at least 100 PSI

and with a pressure relief valve set at the tank’s rated

pressure.

3. Depress inflation pedal to position 1 to start air-

flow through the hose and into the tank. Maintain a

steady pressure for constant flow.

4. Watch the rising pressure on the tank gauge and

the gauge on the machine. Machine gauge should

cycle between check and inflation pressures while tank

gauge climbs steadily. As tank pressure reaches 60

PSI, the pressure limiter should stop the airflow automatically. Both gauges should read 60 PSI ± 5 PSI.

5. Release inflation pedal. Check manual release

valve function by pressing the button and releasing

pressure from the tank until it reaches 50 PSI.

Disconnect inflation hose, and release air inside tank.

6. Replace pressure limiter if it fails to cycle properly

during inflation, if it fails to shut air supply off at 60 PSI,

or if it malfunctions in any other way. Do not operate

machine with a faulty pressure limiter.

DANGER

DANGER

85000817 01 09/08 2 of 2 © COPYRIGHT 2008 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Watch Pressure

on Both Gauges

Tire Changer

Inflation Hose

Connected to Tank

Air Service Tank

Loading...

Loading...