Page 1

8114281 00 05/05 Page 1 of 2 © COPYRIGHT 2005 ALL RIGHTS RESERVED PRINTED IN U.S.A.

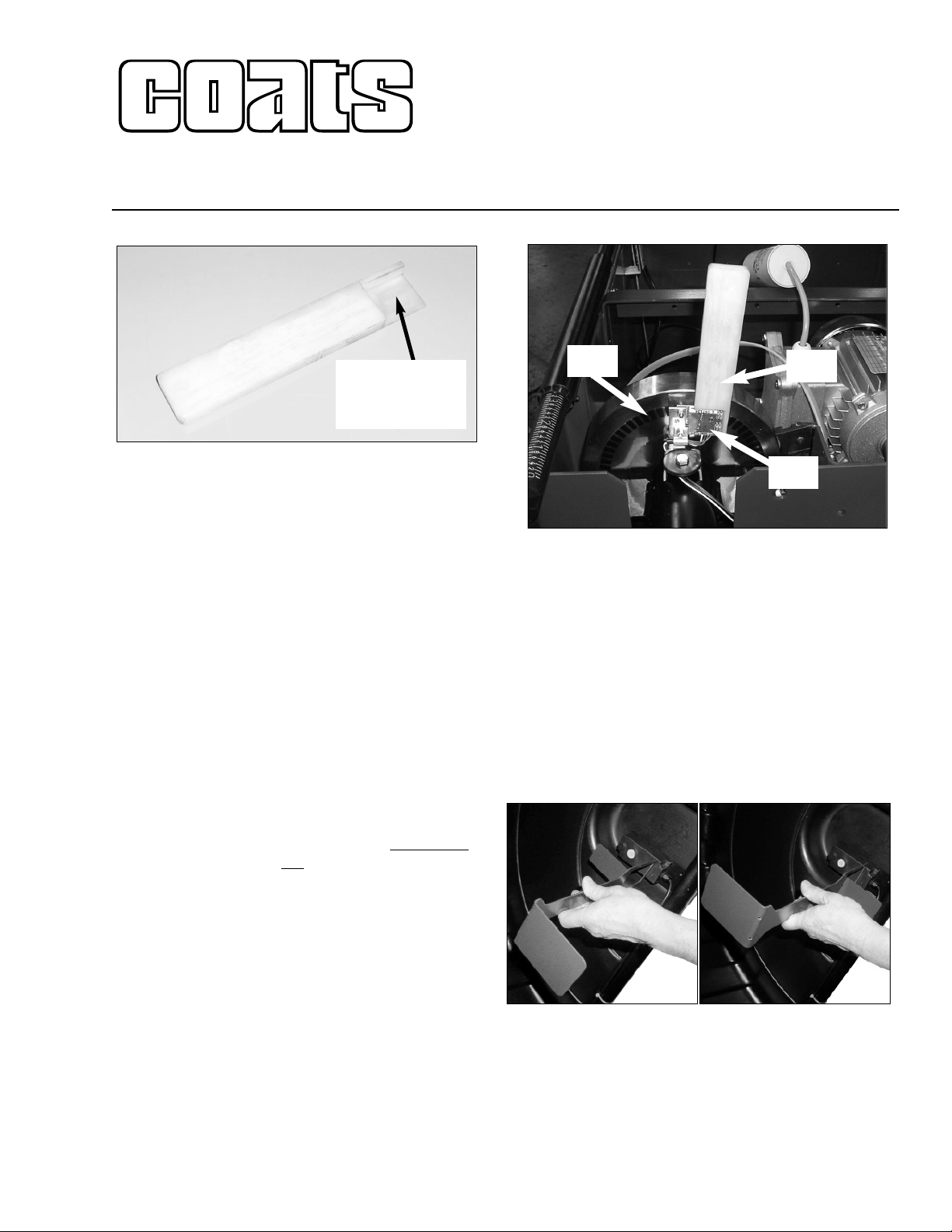

Encoder Gapping Tool

Encoder/Sonar Adjustment

Note: Errors 55, 57, or 59 occur when the value read

by the sonar is insufficent to obtain a correct runout

measurement.

1. Make sure the Radial Runout and Lateral Runout

Sonars are aligned correctly.

2. Set Encoder to pulley gap at 0.040".

To make adjustments to the encoder simply remove

the weight tray. Use the Encoder Gapping Tool and

see if it will fit between the encoder PCB and the

encoder wheel. If not remove the bolt holding the

bracket, place a drop of loctite on the threads.

Reposition the encoder assembly and snug down the

bolt with the Encoder Gapping Tool between the PCB

and wheel (0.040").

Note: 1) Do not use a material that could scratch the

encoder decal. 2) To achive a correct adjustment, position the Tool behind the encoder PCB; to the right

of

the holding bracket and not between the bolt heads.

Check your readings again.

3. Go to Self-Test Screen (Green Screen) and verify

that the Encoder is operating correctly and the Sonar

is reading correctly. Use the Sonar check tool (p/n

8114161) or a tape measure and flat card for a target.

XR 1800/1850 Models

Closest Target (Sonar) Readings: 4-inches = 2450 to 2470

Farthest Target (Sonar) Readings: 14-inches = 8100 to 8300

XR 1750 Model

Closest Target (Sonar) Readings: 4-inches = 3840 to 3880

Farthest Target (Sonar) Readings: 14-inches = 12800 to 13200

Note: If the correct readings cannot be obtained then

replace the sonar.

Notched area for

placement between

the encoder PCB and

the encoder wheel.

Encoder

Decal

Encoder

PCB

Gapping

Tool

Closest Target (Sonar) Reading

Farthest Target (Sonar) Reading

Encoder Gapping Tool

Kit #81142331

for XR Series Wheel Balancers

COATS, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

Page 2

4. For XR 1800/1850 software (version 1.06 and

higher) and XR 1750 software (all versions):

From the Green Screen press button 2 for 2 seconds

and then the Encoder Test Screen will appear.

5. With hood down Press START to run the Encoder

Test. It will work with or without a wheel on the

machine. At the end of the Test Run lines of text will

appear below the graphs:

Line 1: > No. ck encoder: ENCA=64 ENCB=64

Both of these values should be 64, if not, an IN or OUT

encoder adjustment (from the 0.040" gap) is indicated.

Line 2:

XR 1800/1850 Models

> Timing signal: ENCA=2000-3500 ENCB=3500-5000

XR 1750 Model

> Timing signal: ENCA=1500-3000 ENCB=2500-4000

(These numbers will vary within the range and some

even outside of the range. The important thing is to get

rid of Line 3: Error reset.)

If the encoder is not set correctly, a third line of text

will appear:

Line 3: > Error reset ENCA or Error reset ENCB

(If one of the above messages appear: Slightly loosen

the small nuts holding the encoder PCB to the bracket.

For ENCA rotate the PCB slightly upward and for ENCB

rotate the PCB slightly downward. Then re-tighten the

small nuts and rerun the Encoder Test.

Rotate the PCB until the Error reset messages are

eliminated.

6. Now, if any Error 55, 57, or 59 appears then the

problem is most likely a very rough tread pattern or

alignment of the sonar. Move the sonar to a different

spot near the center of the tread.

8114281 00 05/05 Page 2 of 2

© COPYRIGHT 2005 ALL RIGHTS RESERVED PRINTED IN U.S.A.

Loading...

Loading...