Page 1

Parts Identification

Qty. Description

1 Lateral Runout Kit

1 Printer Bracket Kit

1 Printer Kit

1 Printer Cable

1 115V Power Cord Assembly

1 Duplex Receptacle Bracket

1 115V Female Duplex Receptacle

1 Caution 115V Duplex Receptacle Decal

2 1/4-20 Hex Nylok Nut

1 Danger Laser Decal

1 6-32 Patch Lock Screw

1 1850 Software

1 1800/1850 Operating Manual

1 1800/1850 Parts Identification Manual

1 Temp Instruction - 16 Bit PCB & Metal Arm

Instructions

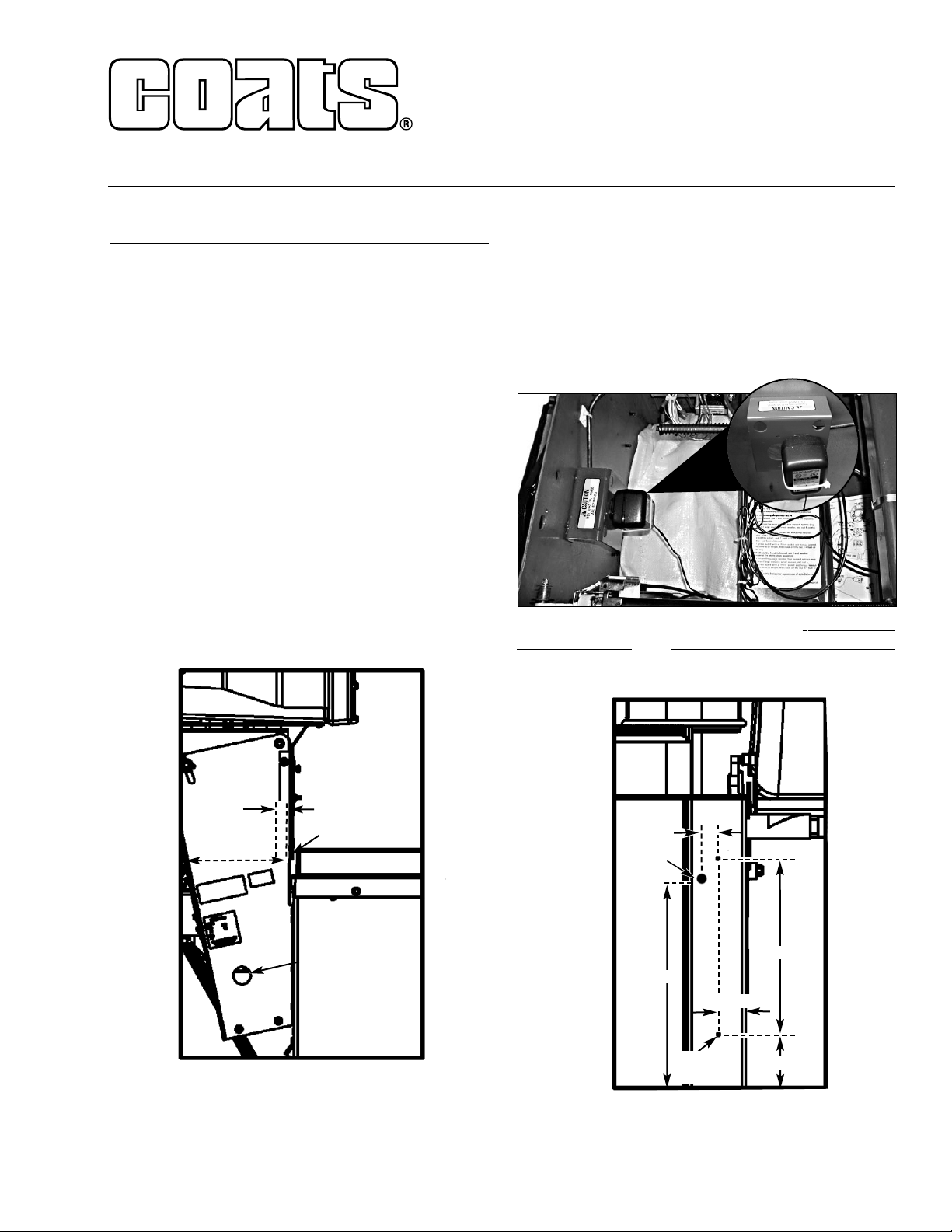

1. Align bottom of printer bracket with bottom of

gauge panel. Position as shown and mark location for

two holes in monitor tower using slots in printer

bracket.

2. Drill two 0.228 diameter holes in monitor tower. Be

sure cabling inside tower is clear.

3. Mount bracket and printer per instructions in

8113881 Printer Kit and 8113883 Printer Bracket Kit

except route Printer Connector Cable through hole at

bottom of monitor tower.

4. Mount the duplex receptacle, bracket, and cable as

shown. Plug in printer adapter and route printer cabling

as shown in picture. Connect cable 80180125 from main

PCB to printer serial connector. Place 8113891 decal on

top of duplex receptacle bracket.

5. Remove weight tray. Locate and drill t

wo 9/32-inch

(0.281) diameter and one 1

1/16-inch (0.687) diameter

holes through front of cabinet per dimensions shown

below.

XR1800 Upgrade to XR1850

Kit 8113887

COATS, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

8113885 01 08/04 Page 1 of 2 © COPYRIGHT 2004 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Route Printer

Connector

Cable Through

Hole

Parallel

with Floor

3/4"

1-1/2"

7-3/8"

15-1/8"

20"

11/16"

(0.687 Dia.)

9/32"

(0.281 Dia.)

2 Holes

2-1/2"

Page 2

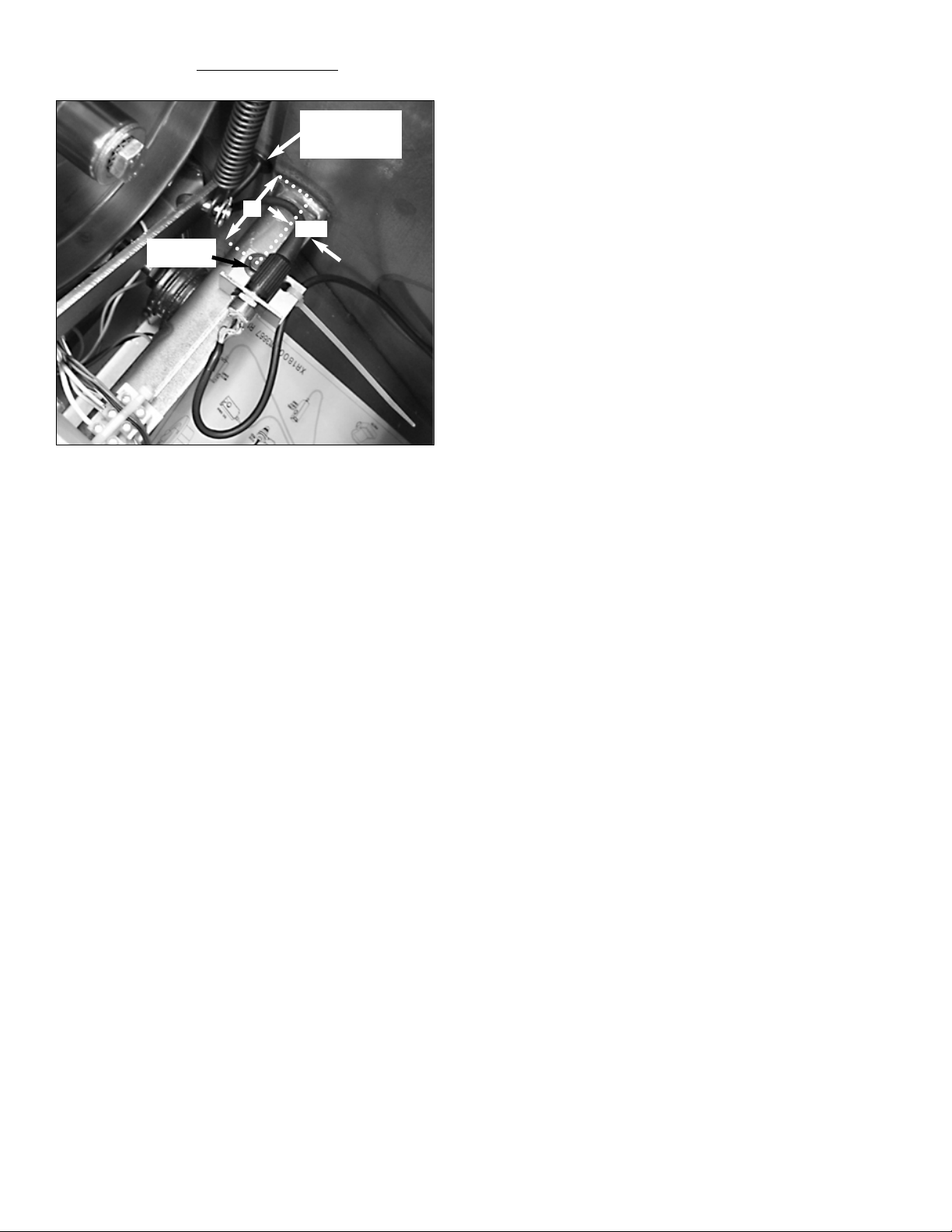

6. Locate and drill one (0.228) diameter hole in flange

of sandplate to mount cable bracket.

7. Mount the lateral runout unit, guard, and wiring per

instructions in the 8113893 lateral runout kit.

8. Replace plastic A&D arm with new metal arm and

washer supplied in kit.

9. Replace main PCB with PCB supplied in kit.

Repack old PCB and return for credit.

10. Power up. Reset NOVRAM. Go to set up menus

and set all functions as desired. Turn printer function

ON. Check to make sure LED on front of printer blinks

every few seconds.

11. Perform machine self calibration with 4-oz.

weight and verify all functions.

12. Perform balance spin and follow instructions on

printer decal to check function of printer.

13. Follow instructions on lateral runout unit and go

to runout graph to verify function of lateral runout. Press

RIM, perform Rim Runout and check printer function

from this screen.

2"

Drill 0.228

Hole

1/2"

Lateral Runout

Cable Entering

Cabinet

8113885 01 08/04 Page 2 of 2 © COPYRIGHT 2004 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Loading...

Loading...