Page 1

8110585 02 06/09 1 of 4 © COPYRIGHT 1991 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Pressure Limiter Kit 8110584

Installation Instructions & Parts List

for RC-15A, RC-15AA, RC-20A, RC-20AA

& 40-40 Tire Changers

Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565 (800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

Installation Instructions

Always DISCONNECT THE ELECTRICAL

POWER before servicing equipment. This

prevents electrical shock or accidental

movement of the systems operated by the

electrical power.

Always DISCONNECT AIR SUPPLY before

servicing equipment. This prevents accidental movement of systems operated by compressed air which may result in personal

injury. BLEED THE AIR SYSTEM by actuating

all the valves.

Before beginning any work, clear the area and position

machine for easy access. Disconnect all power

sources, both air and electricity inputs. Allow any stored

air in the reservoir to escape by depressing the inflate

pedal.

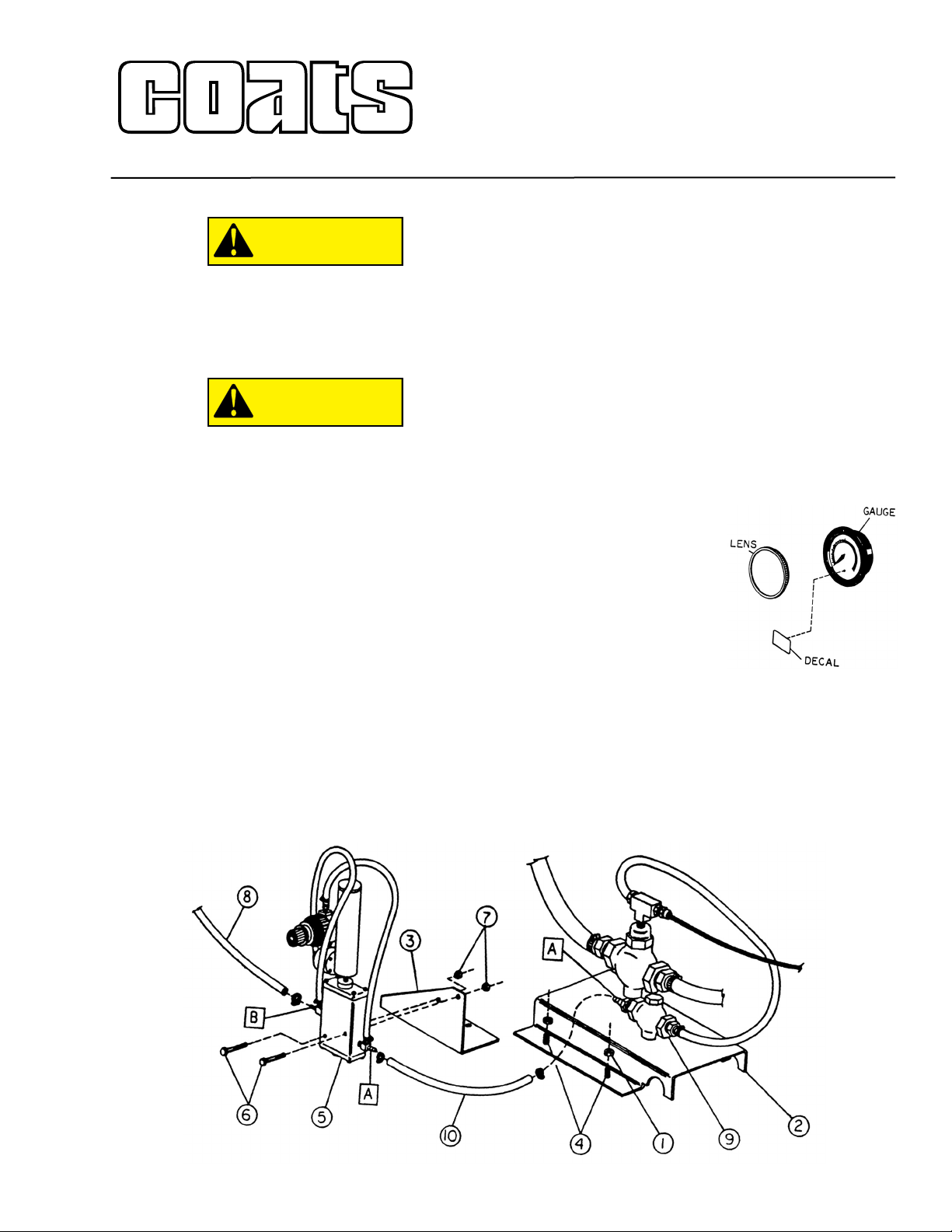

RC-15A and 15AA Pressure Limiter:

1. Remove the side panel.

2. Remove two nuts (ref 1), securing inflation valve

bracket (ref 2) to chassis.

3. Mount pressure limiter bracket (ref 3) to existing

bolts (ref 4) and securely tighten two nuts (ref 1).

4. Install pressure limiter (ref 5) to pressure limiter

bracket (ref 3) using two 1-3/4-inch long bolt (ref 6) and

two nuts (ref 7) provided in kit. Fasten securely.

5. Remove 1/4-inch hose (ref 8) from small valve (ref

9) and connect to port B on pressure limiter (ref 5).

6. Connect 1/4-inch hose 20-inches long (ref 10) sup-

plied in kit to port A on small valve (ref 9) and port A on

pressure limiter (ref 5). Securely tighten using 1/4-inch

hose clamps provided in kit.

7. Check all connections for proper installation and

tightness prior to reconnecting air supply.

8. Check unit for proper operation. Refer to the pres-

sure limiter maintenance section on page 4 of this

instruction.

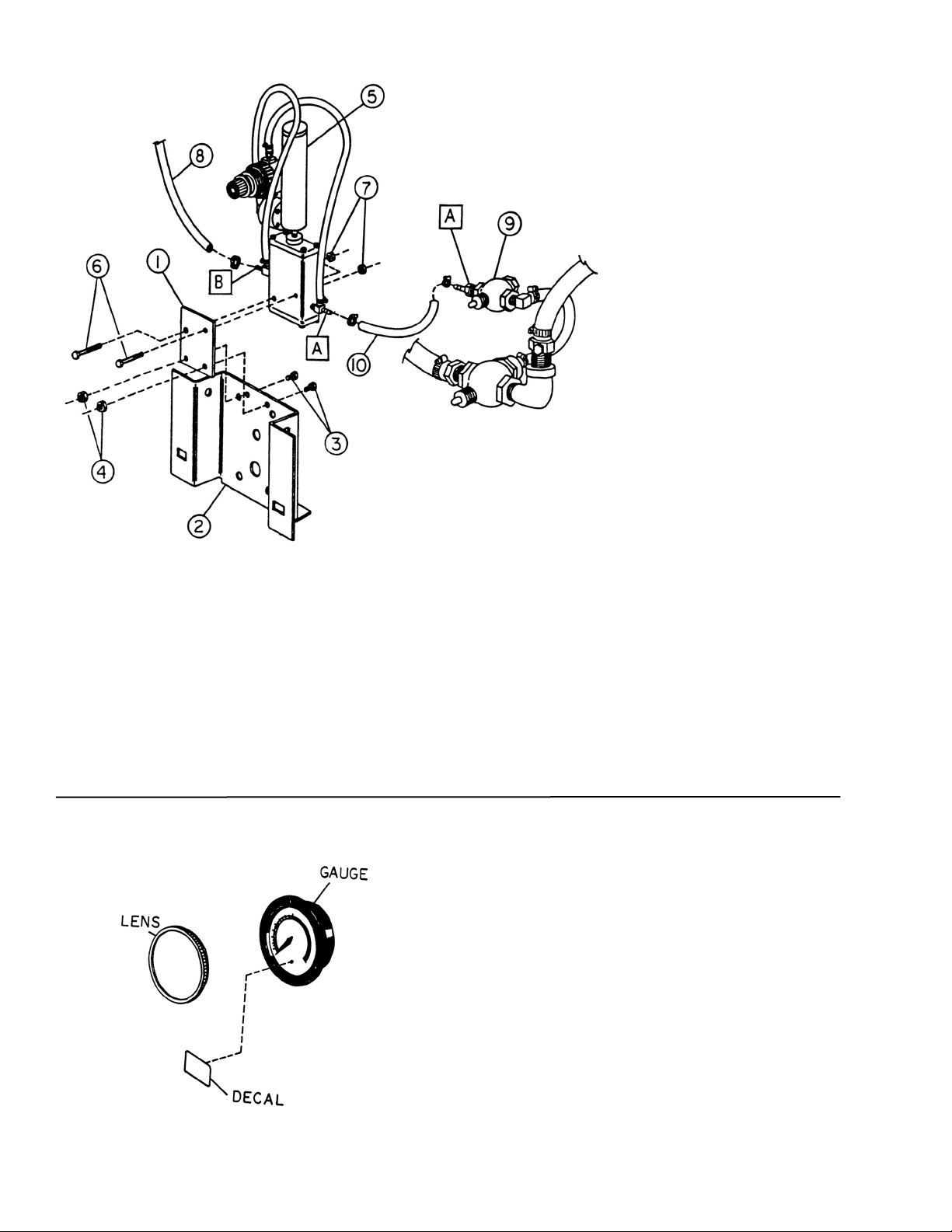

9. Remove lens cover from

air gauge and install new

decal to gauge as shown in

diagram. Reinstall lens cover.

10. Replace side panel.

11. Review proper tech-

nique and operation with the

operators and supervisors.

CAUTION

CAUTION

Page 2

RC-20A and 20AA Pressure Limiter:

1. Remove the side panel.

2. Mount pressure limiter bracket (ref 1) to inflation

bracket (ref 2) using two 1/4-inch bolts 3/4-inch long (ref

3) and two 1/4-inch nuts (ref 4) provided in kit. Tighten

securely.

3. Install pressure limiter (ref 5) to pressure limiter

bracket (ref 1) using two 1/4-inch bolts, 1-3/4-inch long

(ref 6) and two nuts (ref 7) provided in kit. Fasten

securely.

4. Remove 1/4-inch hose (ref 8) from small valve (ref

9) and connect to port B on pressure limiter (ref 5).

5. Connect 1/4-inch hose 20-inches long (ref 10) sup-

plied in kit to port A on small valve (ref 9) and port A on

pressure limiter (ref 5). Securely tighten using 1/4-inch

hose clamps provided in kit.

6. Check all connections for proper instal-

lation and tightness prior to recon-

necting air supply.

7. Check unit for proper opera-

tion. Refer to the pressure limiter

maintenance section on page 4 of

this instruction.

8. Remove lens cover from air

gauge and install new decal to gauge

as shown in diagram. Reinstall lens

cover.

9. Replace side panel.

10. Review proper technique and operation with the

operators and supervisors.

8110585 01 2 of 4

40-40 Pressure Limiter:

1. Remove the operator’s side panel from the

machine.

2. Remove front side panel support from chassis by

removing two 3/8-inch self tapping screws. Install new

bracket (ref 1) in same location using the two 3/8-inch

self tapping screws just removed. Tighten securely.

3. Install pressure limiter (ref 2) to pressure limiter

bracket (ref 1) using two 1/4-20 x 1-1/2-inch long bolts

(ref 3) and two 1/4-20 lock nuts (ref 4) provided. Fasten

securely.

4. Disconnect quick coupler. Remove quick coupler

end from 1/4-inch hose (ref 7). Attach 1/4-inch hose (ref

7) to pressure limiter port A. Sercurely fasten all

clamps.

Page 3

5. Attach 37-inch long hose (ref

5) to pressure limiter port B.

Attach quick coupler end to

end of 37-inch long

hose. Securely fasten all clamps.

Reattach quick coupler.

6. Reinstall side

panel.

7. Check unit for proper

operation. Refer to the pressure limiter maintenance section on page 4 of this

instruction.

8. Remove lens cover from air gauge and install new

decal to gauge as shown in diagram. Reinstall lens

cover.

9. Review proper technique and operation with the

operators and supervisors.

Ref# Part No. Description

1 8103649 1/4" Hose x 12" L.G.

2 8109466 Valve

3 8109468 Pressure Repeater

4 8109471 1/8" Close Nipple

5 8109472 1/8" Inline Filter

6 8110325 1/4" NPT Male Run Tee

7 8110496 Volume Chamber

8 8111083 Regulator

9 8111255 Special Tee

10 8182035 Male Straight Fitting

11 8182038 1/4" OD Nylon Tube

12 85606362 14mm Spring Hose Clamp

13 8110497 Fitting - 90º Male Elbow

14 8143169 1/4"-20 Whiz Lock Nut

15 8120408 1/4"-20 x 1 3.4" H.H.C.S.

Pressure Limiter Kit Parts List

8110585 01 3 of 4

Page 4

Pressure Limiter Maintenance

Operating a tire changer with a defective,

improperly adjusted, or by-passed pressure

limiter could cause an operator to accidentally over pressurize a tire, resulting in a tire

explosion with severe injury or death to the

operator or bystanders.

Always be sure that the pressure limiter is

present and is operating properly.

Never inflate tire above manufacturer’s recommended pressure after bead is seated.

Pressure limiter is set at 60 PSI. Any required

inflation above 60 PSI should be performed

in an inflation chamber/safety cage or

securely mounted on the vehicle if an inflation chamber is not available. A tire explosion may cause personal injury or death to

operator or bystanders.

The pressure limiter helps prevent inflation of standard size or larger tires or tubes beyond 60 PSI to minimize risk of explosion. This device is for the safety of

the operator and bystanders. Proper operation of the

pressure limiter is essential to safe operation of the

machine.

Check operation of the pressure limiter as shown and

described below at least monthly and each time the

machine is serviced:

1. Remove tires and/or wheels from the machine.

2. Connect the inflation hose to an empty service

tank with a pressure gauge (gauge should read 0). Use

a service tank with a pressure rating of at least 100 PSI

and with a pressure relief valve set at the tank’s rated

pressure.

3. Depress inflation pedal to position 1 to start air-

flow through the hose and into the tank. Maintain a

steady pressure for constant flow.

4. Watch the rising pressure on the tank gauge and

the gauge on the machine. Machine gauge should

cycle between check and inflation pressures while tank

gauge climbs steadily. As tank pressure reaches 60

PSI, the pressure limiter should stop the airflow automatically. Both gauges should read 60 PSI ± 5 PSI.

5. Release inflation pedal. Check manual release

valve function by pressing the button and releasing

pressure from the tank until it reaches 15 PSI.

Disconnect inflation hose, and release air inside tank.

6. Replace pressure limiter if it fails to cycle properly

during inflation, if it fails to shut air supply off at 60 PSI,

or if it malfunctions in any other way. Do not operate

machine with a faulty pressure limiter.

DANGER

DANGER

8110585 02 06/09 4 of 4 © COPYRIGHT 1991 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Watch Pressure

on Both Gauges

Tire Changer

Inflation Hose

Connected to Tank

Air Service Tank

Loading...

Loading...