Page 1

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688-6359 Manual Part No.: 9112095 03

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 4/00

IBS 2000

Interactive Balancing System

®

Installation Instructions

Operating Instructions

Safety Instructions

Maintenance Instructions

READ these instructions before placing unit in

service KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

Page 2

ii • COATS IBS 2000 Interactive Balancing System

Direct Drive

Page 3

COATS IBS 2000 Interactive Balancing System • iii

Table of Contents

Operator Protective Equipment . . . . . . . . .iv

Owner’s Responsibility . . . . . . . . . . . . . . . . .v

Definitions of Hazard Levels . . . . . . . . . . . . .v

Important Safety Instructions . . . . . . . . . . .vi

Before You Begin

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Electrical Requirements . . . . . . . . . . . . . . . . . . . . .1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Standard Accessories . . . . . . . . . . . . . . . . . . . . . .2

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . .2

Installation and Setup

Floor and Space Requirements . . . . . . . . . . . . . . .2

Connect to Power . . . . . . . . . . . . . . . . . . . . . . . . .2

Operating Instructions

Interactive Control Panel . . . . . . . . . . . . . . . . . . . .3

The Planes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

DWLS - Direct Weight Location System . . . . . . . .4

Balancing Modes . . . . . . . . . . . . . . . . . . . . . . . . . .4

Entering Wheel Data . . . . . . . . . . . . . . . . . . . . . . .5

Mounting Wheels

Back Cone Mounting . . . . . . . . . . . . . . . . . . . . . . .6

Front Cone Mounting . . . . . . . . . . . . . . . . . . . . . .6

Alternate Mounting . . . . . . . . . . . . . . . . . . . . . . . .7

Optional Combi-Adapter Mounting . . . . . . . . . . . .7

Selecting Balancing Options

Using the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Reading the Displays . . . . . . . . . . . . . . . . . . .9

Balancing a Wheel

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Changing Wheel Information During Balancing . .10

Changing Balancing Modes and Weight Locations

During Balancing . . . . . . . . . . . . . . . . . . . . . . . . .10

Checking the Balance . . . . . . . . . . . . . . . . . . . . .10

After Balancing Vibration Problems . . . . . . . . . . .10

Match Mount

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Is Match Mount Needed? . . . . . . . . . . . . . . . . . .11

Match Mount Instructions . . . . . . . . . . . . . . . . . .12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .14

Total Accuracy Verification . . . . . . . . . . . . .14

Calibration and Diagnostics

Balancer Calibration . . . . . . . . . . . . . . . . . . . . . . .15

Plane Separation . . . . . . . . . . . . . . . . . . . . . . . . .16

A/D Arm Calibration . . . . . . . . . . . . . . . . . . . . . . .16

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Contents

Page 4

iv • COATS IBS 2000 Interactive Balancing System

Safety

Operator Protective

Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the

place of safe operating practices. Always wear durable

work clothing during tire service activity. Loose fitting

clothing should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands when

handling worn tires and wheels. Sturdy leather work

shoes with steel toes and oil resistant soles should be

used by tire service personnel to help prevent injury in

typical shop activities. Eye protection is essential during tire service activity. Safety glasses with side

shields, goggles, or face shields are acceptable. Back

belts provide support during lifting activities and are

also helpful in providing operator protection.

Consideration should also be given to the use of hearing protection if tire service activity is performed in an

enclosed area, or if noise levels are high.

Failure to follow danger, warning, and caution instructions may lead to serious personal injury or death to operator or

bystander or damage to property. Do not

operate this machine until you read and

understand all the dangers, warnings and

cautions in this manual. For additional

copies of either, or further information,

contact:

Hennessy Industries, Inc.

1601 J.P. Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359

Do it Now

Make sure the instruction and warning decal is clean and clearly visible

to operator.

✓

NOTICE

Read entire manual before assembling,

installing, operating, or servicing this

equipment.

WARNING

Page 5

COATS IBS 2000 Interactive Balancing System • v

Owner’s Responsibility

To maintain machine and user safety, the responsibility of the owner is to read and follow these instructions:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and

Regulations; such as State and Federal OSHA

Regulations and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep

them readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the unit,

and are properly supervised.

• Allow unit operation only with all parts in place

and operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with authorized

or approved replacement parts.

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override safety features.

Definitions of Hazard

Levels

Identify the hazard levels used in this manual with

the following definitions and signal words:

DANGER

Watch for this symbol:

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

Safety

DANGER

WARNING

CAUTION

Page 6

vi • COATS IBS 2000 Interactive Balancing System

Safety

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS

1. Eye and face protection recommendations:

“Protective eye and face equipment is required to

be used where there is a reasonable probability of

injury that can be prevented by the use of such

equipment.” O.S.H.A. 1910.133(a) Protective goggles, safety glasses, or a face shield must be provided by the owner and worn by the operator of

the equipment. Care should be taken to see that

all eye and face safety precautions are followed by

the operator. ALWAYS WEAR SAFETY GLASSES.

Everyday glasses only have impact resistant

lenses, they are not safety glasses.

2. Do not disable hood safety interlock system, or in

any way shortcut safety controls and operations.

3. Be sure that wheels are mounted properly, the

hub nut engages the arbor for not less than four

(4) turns, and the hub nut is firmly tightened

before spinning the wheel.

4. Read and understand this manual before operating. Abuse and misuse will shorten the functional

life.

5. Be sure the balancer is properly connected to the

power supply and electrically grounded.

6. Do not operate equipment with a damaged cord

or if the equipment has been dropped or damaged

– until it has been examined by a qualified serviceman.

7. Do not let cord hang over edge of table, bench, or

counter or come in contact with hot manifolds or

moving fan blades.

8. If an extension cord is necessary, a cord with a

current rating equal to or more than that of the

equipment should be used. Cords rated for less

current than the equipment may overheat. Care

should be taken to arrange the cord so that it will

not be tripped over or pulled.

9. Keep guards and safety features in place and in

working order.

10. Wear proper clothing. Safety toe, non-slip

footwear and protective hair covering to contain

hair is recommended. Do not wear jewelry, loose

clothing, neckties, or gloves when operating the

balancer.

11. Keep work area clean and well lighted. Cluttered

and/or dark areas invite accidents.

12. Avoid dangerous environments. Do not use power

tools or electrical equipment in damp or wet locations, or expose them to rain.

13. Avoid unintentional starting. Be sure the balancer

is turned off before servicing.

14. Disconnect the balancer before servicing.

15. Use only manufacturer’s recommended accessories. Improper accessories may result in personal injury or property damage.

16. Repair or replace any part that is damaged or worn

and that may cause unsafe balancer operation. Do

not operate damaged equipment until it has been

examined by a qualified service technician.

17. Never overload or stand on the balancer.

18. Do not allow untrained persons to operate

machinery.

19. To reduce the risk of fire, do not operate equipment in the vicinity of open containers or flammable liquids (gasoline).

20. Adequate ventilation should be provided when

working on operating internal combustion

engines.

21. Keep hair, loose clothing, fingers, and all parts of

body away from moving parts.

22. Use equipment only as described in this manual.

23. Use only manufacturer’s recommended attachments.

Page 7

Before You Begin

Receiving

The shipment should be thoroughly inspected as soon as it is

received. The signed bill of lading is acknowledgement, by the

carrier, of receipt in good condition of the shipment covered by

our invoice.

If any of the goods called for on this bill of lading are shorted

or damaged, do not accept them until the carrier makes a notation of the shorted or damaged goods on the freight bill. Do this

for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or damage

is discovered after receipt and request him to make an inspection. If the carrier will not do so, prepare an affidavit to the effect

that you have so notified the carrier (on a certain date) and that

he has failed to comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER

YOU HAVE GIVEN THE CARRIER A CLEAR RECEIPT.

File your claim with the carrier promptly. Support your claim

with copies of the bill of lading, freight bill, invoice, and photographs, if possible.

Although COATS responsibility ceases upon delivery of the

shipment to the carrier, we will gladly assist in tracing lost shipments. Our willingness to assist in every possible manner does

not make COATS responsible for collection of claims, or replacement of lost or damaged materials.

Electrical Requirements

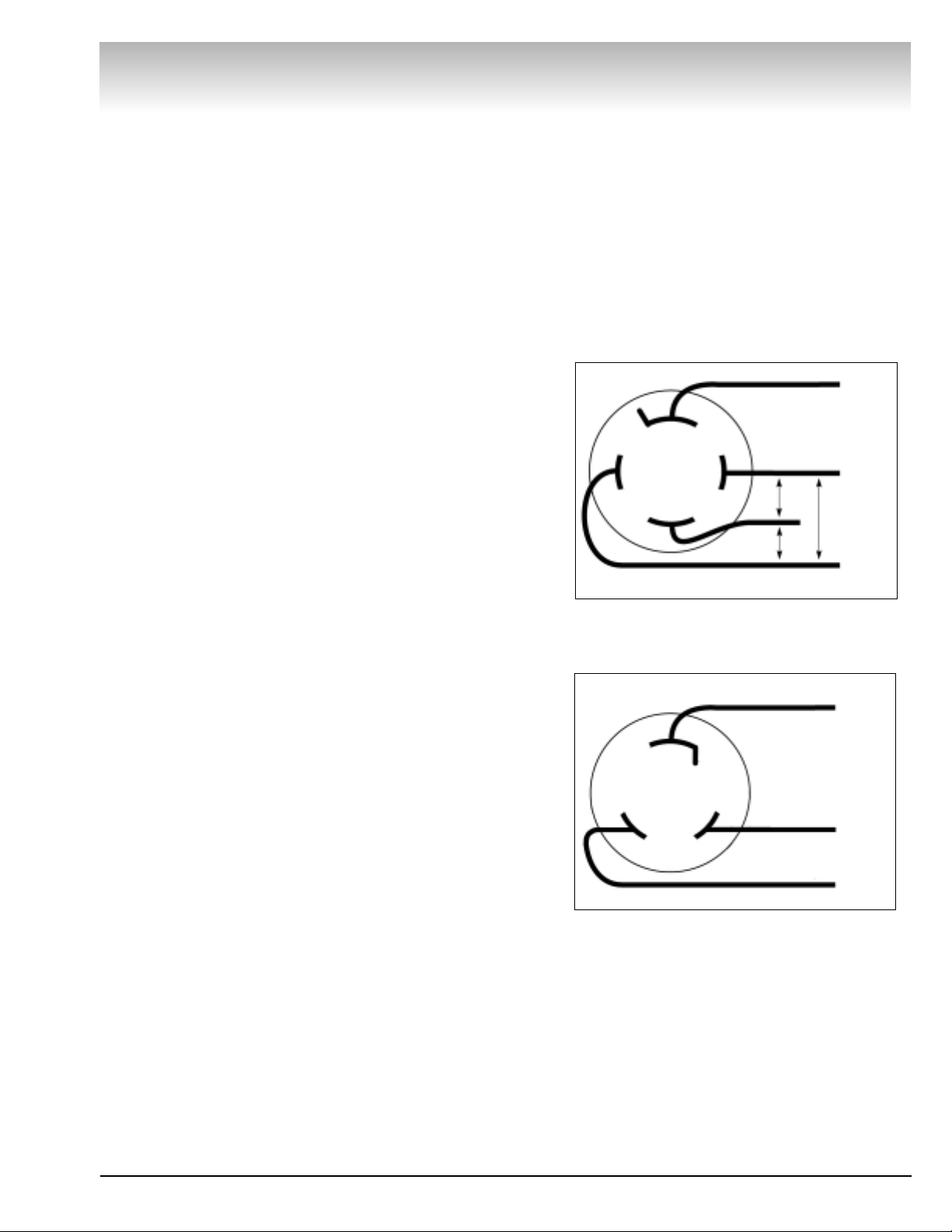

The IBS 2000 requires a 220 VAC, 60Hz, three-phase power

supply with 20 amp fuse or circuit breaker, or a 220 VAC, 60HZ,

single-phase power supply with 20 amp fuse or circuit breaker.

The three-phase balancer is equipped with an approved cord

and a 4-prong grounding plug to fit a Hubbell 2420 or Bryant

71520 grounding receptacle (not included). See figure 1.

The single-phase balancer is equipped with an approved cord

and a 3-prong grounding plug to fit a Hubble 2323 or Bryant

grounding receptacle (not included). See figure 2.

A qualified electrician should install the receptacles in accordance with state and local codes.

Specifications

• Cycle time . . . . . . . . . . . . . . . . . . . . .4 to 5 seconds (avg.)

• Outside Tire Diameter . . . . . . . . . . . . . . . . .44 inches max.

• Wheel Diameter Range . . . . . . . . . . . . . . .8 to 29.9 inches

• Wheel Width Range . . . . . . . . . . . . . . . . . . .2 to 19 inches

• Balancing Increments . . . . . . . . . . . . . .0.25 or 0.01 ounce

• Resolution (Round Off Mode) . . . . . . . . . .0.01 ounce, 1.4°

• Motor - Modified torque with 900 RPM/1.5 HP rating, forced

air cooling, large housing for heat dissipation, and heavy

duty insulation for high temperature applications.

• Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . .625 pounds

Direct Drive

COATS IBS 2000 Interactive Balancing System • 1

Figure 1 - Three-Phase Wiring Diagram

Three-Phase

Ground

Hot

195-230 V

Between

Hot Wires

Hot

Hot

Figure 2 - Single-Phase Wiring Diagram

Single-Phase

A – Red

B – Black

Green/

Ground

Page 8

2 • COATS IBS 2000 Interactive Balancing System

Direct Drive

Features

• Exclusive Direct Drive System (no belts or pulleys)

• Single-Spin Balancing

• Hood Safety Interlock System

• Extended Mounting Flange for Deeper Wheels

• Dynamic, Static, RV, Match Mount, and Alloy

Balancing Modes

• Interactive Control Panel

• Large, Bright Digital Displays

• Easy-to-Read Weight Position Indicators

• Large Keypad for Data Entry

• Control Pod Adjusts for Optimum Visibility

• Electronics Isolated from Motor Heat

• Automatic Memory and Program Check

• Interactive Display Menu

• Dual Operator Modes (Operator A/B)

• Stop-On-Top for Easier Weight Location

• Automatic Offset and Diameter Data Entry

• Self-Calibrating

• Weight Storage Bins and Accessory Pegs

• No-Bolt-Down Installation

Standard Accessories

• Graduated Cone Assortment (hardened, 3 piece)

• Light Truck Cone

• Hub Nut

• No-Mar Ring

• Rim Width Caliber

• Wheel Weight Pliers

Optional Accessories

• Combi-Adapter for Bolt Hole Mounting

• Extra Large Truck Cone Kit

• 3, 4, and 5 Lug Flange Plate Adapters

• Escort/Lynx Adapter

• Speed Lock Kit

• Side and Rear Storage Trays

• Viper Wheel Kit

• Large Truck Cone and Cup Adapter Kit

• Tacoma Cone

Installation and Setup

A factory trained COATS®Service Technician must

perform the install, setup, and initial test procedures

on your IBS 2000 balancer. Do not attempt to install

and setup the unit yourself. Accurate and reliable operation of your unit depends on proper installation.

Please contact COATS®directly at 1-800-688-9240 for

the Certified Service Partner nearest you.

Do not use the control pod, control pod

arm, faceplate, hood or shaft to lift the balancer.

Floor and Space Requirements

The balancer must be located on a flat floor of solid

construction, preferably concrete. The balancer must

sit solidly on its three feet. If the balancer is not level,

does not sit solidly on its three feet, or is placed on an

unstable floor, the balancer will not function properly

and will produce inaccurate balance readings.

Do not operate the balancer when it is still bolted

down or while it is on the pallet.

Select a location for the balancer that provides a

level, solid floor, and adequate clearance around and

above the balancer. Make sure the location selected

has enough room above and behind the unit so the

hood can be raised completely. The location must also

provide working room for mounting and removing

wheels.

Connect to Power

Your factory trained COATS®Service Technician

should do the final check to verify the power installation before connecting the balancer to a power supply.

Failure due to improper power connection will void the

warranty.

CAUTION

Page 9

Operating Instructions

Interactive Control Panel

Weight Displays

Wheel Position Indicators

Location Indicator LEDs/Selection Buttons

Interactive Display Screen

Mode Display

Keypad

Manual Start Button

The Planes

The IBS 2000 is a 2-plane, microprocessor-based

computer balancer. Any imbalance in a wheel, either

static or dynamic, is resolved into correction planes

where corrective weights can be applied. Refer to

Figure 3 for the preset plane locations. The five weight

location indicators on the control panel correspond to

the 5 planes.

COATS IBS 2000 Interactive Balancing System • 3

Direct Drive

Figure 3 - The Five Planes

Page 10

4 • COATS IBS 2000 Interactive Balancing System

Direct Drive

DWLS - Direct Weight Location System

The IBS 2000 allows the operator to use preset

weight location positions or measured location positions. The measured location positions increase accuracy on alloy wheels and when using hidden weights.

Select between these by using the MODE button.

When using the PRESET measurements, the operator enters the standard A, W, and D measurements.

After these measurements are entered, the computer

based upon wheel profile data stored in the computer

makes corrective weight locations. These calculations

allow the computer to display weight information for

the weight locations selected by the operator. Once

the A, W, and D measurements are entered, the operator may select any of the five weight locations and

the computer will display the calculated weight

amount to be attached at that location.

When using the MEASURED MODE in conjunction

with standard clip-on weights, for BOTH planes, the

operator measures and enters the A, W, and D in the

traditional method by touching the inner rim flange

with the A&D arm and reading the width with the

wheel calipers.

When using the MEASURED MODE in conjunction

with a single clip-on weight and a hidden tape-aweight™ or two hidden tape-a-weights™, the operator measures the specific weight location in which he

wishes to place a weight. The operator selects locations for the weight from plane 1, 2, or 3 by pressing

the button on the display panel adjacent to the plane

of choice. (See figure 3) The operator then uses the

A&D arm to measure the selected location at the

flange or inside the rim.

Note: Always measure from the inner most plane

first, then move outward, away from the balancer. For

example, if the operator selects plane 3 and plane 1

the operator must measure the plane 1 location first,

wait for a confirmation BEEP, and then measure plane

3 again waiting for a confirmation BEEP. These measurements are displayed on the LCD screen as AIN,

DIN, and AOUT, DOUT.

When using tape-a-weights™ and measuring inside

the rim, we recommend rotating the A&D arm down

so that the tip of the A&D arm is pointing towards the

ground and measuring the lower part of the rim. In

this position, you can see where you are touching for

the measurement. By seeing the position it will be

easier when placing the tape-a-weight after the spin

cycle. Also, traditionally when placing the weight you

would rotate the wheel until the center light flashes,

you are at what we call "Top Dead Center", or at the

location you would attach the weight. There is an alternative, if you marked the Top Dead Center on the rim

and rotate the wheel 180 degrees until you see the

two outermost lights flash the mark is at we call

"Bottom Dead Center". When placing a tape-a-weight

at the bottom of the rim you have a better visual sighting and more accurate placement.

Remember to return the A&D Arm back to it's home

position after use.

Tip! Keep the arm moving until you are ready to take

a reading, the arm will automatically take a reading if

it is not moved. Place the tip or disk at the weight location and hold it firmly in place for two seconds and listen for a confirmation BEEP, move the arm

immediately to the next location and wait again for

two seconds and listen for another confirmation BEEP.

Note: It is good practice when dynamic balancing for

the distance (the W dimension) between the two

weight locations to be as wide apart as physically possible. This will improve the balance of the wheel and

productivity.

Recommendation: Using the PRESET MODE will

provide easy balancing and yield accurate results

when used for the standard clip-on weights. However,

when using the PRESET MODE for tape-a-weights™

you will probably have to make repeated spins to balance the wheel. We encourage you to learn and

become proficient with the use of the MEASURED

MODE. This mode works equally well when measuring for the standard clip-on weights and works particularly well when using a combination of only one-clip

on weight and one tape-a-weight™ or when using

tape-a-weights for both planes. Using the "MEASURED" A and D weight locations, you will balance

wheels with more ease and with increased accuracy.

This will provide your best solution for single spin balancing in all modes and greater customer satisfaction.

Balancing Modes

Select between DYNAMIC and STATIC balancing

modes by pressing the button between their respective LEDs on the control panel.

The DYNAMIC balancing mode calculates separate

corrective weight requirements for the inner and outer

planes of the wheel. The default locations are planes

1 and 5. The specific weight amount and location for

each plane is calculated in a single spin.

The default STATIC balancing mode calculates a single corrective weight requirement for placement at a

point as close to the center of the wheel as possible

(plane 3). The IBS 2000 allows the operator to select

any of the other locations for this weight placement

simply by pressing the corresponding location button

on the display screen. The operator may also opt to

split this single weight between two planes (1 and 5)

Page 11

COATS IBS 2000 Interactive Balancing System • 5

by pressing location button 5 followed by location button 1. Both location LEDs will light, and the static correction weight amount will be split between the two

weight displays. The weights will attach to the same

position on both the inner and outer rim flanges

(directly opposite each other).

RV MODE is used to balance larger wheels that do

not require balancing of increments less than 0.5ounces. This mode is selected by pressing MENU on

the display screen, then selecting SETUP, and choosing RV MODE from the available options in the SETUP

menu.

Entering Wheel Data

Before any wheel can be balanced, the computer

must know its size and position on the arbor. These

measurements are:

A (Wheel Offset) -The distance between the side of

the balancer and the inner edge of the wheel.

D (Wheel Diameter) - This is the diameter of the

wheel at the weight location.

W (Wheel Width) - This is the width of the wheel at

the rim flanges. This is measured with the calipers.

Figure 4 - A/D Arm Measurement Points

The A and D measurements can be entered into the

balancer automatically using the A/D arm. Simply pull

the A/D arm out from the side of the machine and

rotate it until it contacts the desired location on the

wheel. Hold the arm in place until the BEEP is heard

and the measurement data is displayed on the screen.

When measuring to the rim flange, touch the tip of the

A/D arm pointer to the rim flange. When entering

measurements for plane 2 or 3 (MEASURED MODE),

touch the disk around the A/D arm pointer to the location.

Note: The computer reads the automatic diameter

entry as three decimal places (0.000) and rounds the

measurement to two decimal places (0.00). It is not

necessary to convert metric measurements to inches.

Also remember that wheel diameter may vary

depending on rim flange configuration (i.e.: a 14-inch

wheel may display a measurement of 13.6 to 14.3).

For manual entry, enter the inch unit to a single decimal place (0.0). The diameter is included on the tire

sidewall (i.e.; 14, 16, 16.5, etc.).

The A and D measurements may also be entered

manually simply by pressing the corresponding button

on the display screen and entering the number using

the keypad.

To enter the W measurement, touch the button on

the display screen that corresponds to the W measurement and enter the number using the keypad. Take

the width measurement with the calipers. Place the

calipers over the wheel and touch the tips of the

caliper arms to the rim flanges. Read the width on the

scale, see figure 5.

Tip! Watch the display screen. It will show all the

measurements entered or being taken, and any others that are required. If you attempt to balance a

wheel with a measurement missing, the screen will

notify you and prompt you to enter the missing data.

Figure 5 - Measuring Wheel Width with the Calipers

Direct Drive

Use Tip to Measure to

Rim Flange

Use Disk to Measure to

Horizontal Surfaces

Tip

Disk

Page 12

Mounting Wheels

Select the most appropriate mounting method for the wheel

you are balancing. Using the proper method ensures secure

mounting and safe balancer operation, and prevents damage to

the wheel.

On most wheels, the inner side of the wheel hub usually has

the most uniform surface for wheel balancing. Always center

the wheel by the most uniformly shaped side of the hub to

achieve the most accurate balance.

Regardless of mounting type, always make sure that the

wheel is forced firmly against the arbor faceplate and that the

hub nut engages the threaded arbor for at least four complete

turns. To assist in centering the wheel properly, rotate the wheel

on the arbor while tightening the hub nut.

Back Cone Mounting

Most original equipment and steel wheels can be mounted

properly using this method. The wheel is centered on a cone

from the inner side of the hub.

1. Place the cone spring on the arbor with the large end

towards the balancer.

2. Select the cone that best fits the center hole in the wheel.

Slide the cone onto the arbor with the large end towards the

spring.

3. Lift the wheel onto the arbor and center it on the cone.

4. Attach the pressure cup to the hub nut and spin the assem-

bly onto the arbor. Tighten securely.

Front Cone Mounting

A wheel should be centered by the outer side of the hub only

when the inner surface will not provide an accurate surface to

center on.

1. Select the cone that best fits the center hole in the wheel.

2. Lift the wheel onto the arbor and slide it back against the

arbor faceplate.

3. Slide the cone onto the arbor and into the center of the

wheel. You will need to lift the tire to seat the cone in the center hole.

4. Spin the hub nut (without pressure cup) onto the arbor.

Tighten it securely against the cone.

Direct Drive

6 • COATS IBS 2000 Interactive Balancing System

Figure 6 - Back Cone Mounting

Figure 7 - Front Cone Mounting

Rim

Spring

Cone

Hub Nut

Pressure Cup

Rim

Hub Nut

Cone

Page 13

Alternate Mounting

If the wheel has a protruding outer hub which will not permit

the use of the pressure cup, or the cup will not permit the hub

nut to engage at least four turns of the arbor, this alternate

method should be used.

1. Place the cone spring on the arbor with the large end

towards the balancer.

2. Select the cone that best fits the center hole in the wheel.

Slide the cone onto the arbor with the large end towards the

spring.

3. Lift the wheel onto the arbor and center it on the cone.

4. Use the small nylon spacer (no-mar ring) or a centering

cone to press against the outer wheel hub.

5. Spin the hub nut (without the pressure cup) onto the arbor.

Tighten securely.

Optional Combi-Adapter Mounting

Use this method for wheels with a center hole that is out of

round, or center holes that do not fit the mounting cones. This

adapter allows the mounting of 3, 4, 5, 6, 8, or 10 lug wheels by

installing 3, 4, or 5 swivel plates on the adapter plate.

1. Assemble the adapter according to the instructions pro-

vided.

2. Attach the adapter to the wheel. The lug nuts must properly

seat in the lug holes and engage at least four full threads for a

secure mounting. Use the wrench provided with the adapter,

and never use air tools or impact wrenches.

3. Lift the wheel onto the balancer and align the adapter base

plate studs with the holes in the arbor faceplate. Secure the

adapter/wheel to the faceplate using the thumb nuts. To properly center the wheel, tighten the thumb nuts in an alternating

pattern while rotating the wheel.

Direct Drive

COATS IBS 2000 Interactive Balancing System • 7

Figure 8 - Alternate Mounting

Cone

Spring

No Mar Ring

Hub Nut

Figure 9 - Optional Combi-Adapter Mounting

Swivel Plate

Swivel Plate Bolt

Washer

(optional)

Faceplate

Nut

Number

Gear

Center

Bushing

Alignment

Mark

Combi Plate

Alignment

Page 14

8 • COATS IBS 2000 Interactive Balancing System

Direct Drive

Selecting Balancing

Options

Using the Menu

Use the menu on the interactive display to access

setup screens, match mount procedures, calibration,

and diagnostics. Open the menu by pressing the

MENU button on the display. The five buttons below

the display will be labeled with their function for each

screen you access.

These buttons typically are (from left to right):

ENTER, PREVIOUS, EXIT, up arrow, and down arrow.

Pressing ENTER toggles your current selection on or

off (or selects the option), PREVIOUS returns you to

the previous screen, and EXIT returns you to the top

of the menu. Use the scroll up and scroll down arrows

to scroll through options and selections. Up and/or

down arrows will be displayed at the top or bottom of

the screen if there is more information above or below

what's shown.

Match Mount - (see pg.11)

Calibration

• Calibrate Balancer - (see pg.14)

• Calibrate Arm - (see pg.15)

Set Up

Round Off -The default weight measurement on the

IBS 2000 is 0.25-ounce. The balancer can be set to a

non-Round Off mode that displays weights in 0.01ounce increments. Select SETUP from the menu,

select ROUND OFF from the list, and press ENTER to

turn this option on or off. Status of this option is

shown in the top of the display as well.

Ounces or Grams - Set the balancer to measure and

display weight amounts in grams. Select SETUP from

the menu, select OUNCE or GRAM from the list, and

use ENTER to select the weight type. Status of this

option is shown in the top of the display as well.

Hood Start - Sets the balancer to start spinning as

soon as the hood is fully lowered. Select SETUP from

the menu, select HOOD START from the list, and use

ENTER to turn this option on or off. Status of this

option is shown in the top of the display as well.

RV Mode - For wheels that do not require balancing

in increments of less than 0.5-ounce. Calculates balancing weights in 0.5 increments only. Select SETUP

from the menu, select RV MODE from the list, and

use ENTER to turn this option on or off.

Stop-on-Top - The IBS 2000 will automatically brake

the wheel to a stop at the end of a spin cycle. The balancer will brake once to slow the wheel and a second

time to stop the wheel with the outer weight position

at or near the top. If no weight is required on the outer

plane, it will brake the wheel to stop based on the

inner weight position. Select SETUP from the menu,

select STOP ON TOP from the list, and use ENTER to

turn this option on or off.

Total Accuracy Verification (TAV) - (see pg.14)

LED Intensity -The LED brightness may be adjusted

to make them easier to read in all lighting environments, bright as well as dark, and those in between.

The last item on the MENU list is LED INTENSITY.

Select this item from the menu and follow the instructions on the display to brighten or dim the LEDs.

Diagnostics - (see pg.17)

Operator A/B - Two operators utilize the balancer

without clearing or changing each others data. This is

handy when one operator is running the Match Mount

procedure and another operator needs the balancer.

For example, if operator A is at a point in the Match

Mount procedure where the wheel is removed from

the balancer, operator B can access the machine by

switching to the other operator memory. When B's

balance is complete, he can toggle the machine back

to A's memory. All of operators A's data is still present, and the Match Mount procedure can be continued without having to start over. Press the

OPERATOR key to toggle between the two operator

memories.

Page 15

COATS IBS 2000 Interactive Balancing System • 9

Reading the Displays

Weight Displays - The two weight displays (one for

the inner plane, and one for the outer plane) are positioned with a wheel cross section diagram. After spinning the wheel, the balancer will calculate the weight

needed and display it in these displays. The display to

the left of the diagram will show the weight to be

applied to the inner plane of the wheel and the display

to the right will show the weight for the outer plane.

Weight Position LEDs - Each weight display

includes weight position LEDs. Located between the

weight display and the diagram, these LEDs indicate

the proper location for weight application. After a spin,

rotate the wheel until the center position indicator

LEDs flash. This indicates that the position specified

by the balancer for weight application is at top-deadcenter.

Balancing a Wheel

Procedure

The following steps walk through the balancing procedure. Do not proceed with these instructions until

you have read and understand the previous sections

of this guide (mounting, balance modes, and reading

the displays).

1. Turn the balancer on. The power switch is on the

right side of the tower at the side of the unit.

Note: When turned on, the balancer will activate the

same options that were selected when it was last

turned off (hood start, ounce/gram, etc.).

2. Mount the wheel to be balanced. Use the proper

mounting method as described on pages 6 and 7.

Always remove any weights attached to the wheel.

3. Enter the wheel measurements and select bal-

ancing mode (page 4 and 5).

4. Set options (hood start, ounce/gram, operator

A/B).

5. Lower the hood and press START. The wheel will

spin and then brake to a stop.

Note: Spin will start automatically when the hood is

lowered if the hood start option is turned on.

6. Raise the hood.

7. Rotate the wheel until the outer position LEDs

flash.

8. Attach the weight specified in the proper location

at top-dead-center. Refer to the diagrams on the control panel for weight locations.

9. Rotate the wheel until the inner position LEDs

flash.

10. Attach the weight specified in the proper loca-

tion at top-dead-center. Refer to the diagrams on the

control panel for weight locations.

11. Lower the hood and press START to respin the

wheel. The wheel will brake to a stop. The weight displays should now read 0.00. If not, refer to page 10,

Checking the Balance for assistance.

Remember: The more accurate you are in selecting

and positioning the weight, the more often you will

balance wheels with a single spin.

Direct Drive

Page 16

10 • COATS IBS 2000 Interactive Balancing System

Direct Drive

Changing Wheel Information During

Balancing

The information entered into the balancer for A, W,

and D can be changed at anytime during the balancing

procedure. Follow the instructions provided earlier for

entering the measurements manually. The balancer

will recalculate weights and positions based on the

new measurements.

Changing Balancing Modes and Weight

Locations During Balancing

The balancing mode can be changed at anytime and

the balancer will recalculate weight and position

based on the new selection. In PRESET MODE, the

computer will calculate the new weight amount and

location when the operator selects a different weight

location. In the MEASURED MODE, selecting a new

weight location will require new A and D data. Once

entered, the computer will calculate weight amount

and location.

Note: This does not apply when switching to and

from Match Mount. The Match Mount procedure

requires additional steps. Refer to the Match Mount

section of this manual.

Checking the Balance

After applying the weights indicated by the balancer,

respin the wheel. The displays should read 0.00.

If the balancer indicates an additional weight should

be applied in the same location as the first weight, the

first weight is too small. Correct the first weight and

respin.

If the balancer indicates an additional weight should

be applied directly opposite the first weight, the first

weight is too big. Correct the first weight and respin.

If the balancer indicates an additional weight should

be applied at an angle to the first weight, the first

weight was not applied in the correct position. Move

the first weight towards the position indicated for the

second weight or add the second weight as indicated.

After Balance Vibration Problems

If vibration is still present after balancing the wheels

and driving the vehicle on smooth pavement, remove

the wheels and recheck the balance. If a wheel is out

of balance the cause may be:

1. A weight has come off the wheel. Remove the

other weights from the wheel and rebalance.

2. Tire slippage on the wheel. Remove and remount

the tire using proper tire lubricant and inflate to 40

PSI. Do not overinflate. Rebalance the wheel and

reduce air pressure to recommended PSI.

3. Stones or other foreign objects caught in the tire

tread. Remove the objects and repair tire as necessary. Check and rebalance if needed.

If the balancer still indicates the wheels are balanced

to within 0.25-ounces on both inner and outer displays, the problem is not in the balance of the wheels.

Check the following possible sources of vibration:

1. Tire pressure. Bring all tires up to the recom-

mended PSI.

2. Radial or lateral runout in the tire or wheel.

Replace the damaged part.

3. Foreign material inside the tire. Remove the tire

from the wheel, remove the material, and remount.

Remove wheel weights and rebalance the wheel.

4. Imbalanced wheel covers or trim rings. Remove

the wheel covers or trim rings and test drive. If the

vibration is gone, remove the arbor and use the

optional Combi Adapter to mount the wheel to the

balancer. Balance the wheel with the wheel cover or

trim ring attached to the wheel.

5. Incorrectly mounted wheel. Remount correctly.

6. Damaged wheel bolt holes. Replace wheel.

7. Worn universal joints. Replace as required.

8. Drive shaft imbalanced or damaged. Balance,

repair, or replace.

9. Imbalanced brake rotor(s) or drum(s).

10. Suspension out of alignment. Align the vehicle

and replace any damaged or worn parts.

Page 17

COATS IBS 2000 Interactive Balancing System • 11

Match Mount

Description

The Match Mount program assists the user in determining the best possible mating of the tire and wheel,

thereby reducing the amount of additional weight

required for balancing. This mating of tire and wheel

normally allows the least amount of total runout of the

assembly, resulting in better balancing, better ride

conditions, and more satisfied customers. Use Match

Mount when:

• Excessive radial runout is noticed in the tire and

wheel assembly during balancing.

• The customer complains of ride problems.

• The balancer calls for weights in excess of 2ounces on either plane on passenger car tires in the

DYNAMIC MODE.

The Match Mount procedure involves loosening tire beads and the inflation of a tire.

Training is necessary in tire changer operation and the dangers involved during bead

seating and tire inflation before attempting

this stage of the Match Mount procedure.

Read the operators manual supplied with

the tire changer and consult a supervisor.

The 2000 balancer will be idle while the tire is being

rotated on the wheel. During these times, the balancer can be used by another operator without terminating the Match Mount procedure. The second

operator selects the other operator memory, performs

a balance, and then returns the balancer to the previous memory. The original operator can now continue

the Match Mount procedure.

As with any balancing procedure, remove any

weights attached to the wheel and inspect the tire and

wheel before beginning.

Is Match Mount needed?

1. Mount the wheel to the balancer.

2. Select the appropriate operator memory as

required (A or B). Make a note of the memory being

used in the event the memory is changed during the

Match Mount procedure.

3. Enter the A, W, and D measurements and select

the mode that will be used in the final balancing.

4. Lower the hood and press START.

5. Wait for the wheel to stop spinning and for the

displays to show weight readings.

• If the balancer indicates that 2-ounces or more will

be required on either plane (in DYNAMIC MODE),

advise the customer/ supervisor to continue with the

Match Mount procedure listed under Match Mount

Instructions. DO NOT attach weights at this point.

Leave the wheel mounted to the balancer.

• If the balancer indicates less than 2-ounces of

imbalance, the Match Mount procedure will not

improve the balance. Continue to balance the wheel

according to the mode selected.

Direct Drive

WARNING

Page 18

Match Mount Instructions

1. Select Match Mount from the LCD menu.

• Hood start is turned off automatically

• Non-round off is turned on automatically

• MM will now be displayed in the upper left corner of the LCD

screen.

• Enter wheel parameters

2. Lower the hood and press START.

• MATCH MOUNT 1 will now be displayed in the upper left

corner of the LCD screen.

3. Raise the hood and rotate the wheel until the valve stem is

at top-dead-center.

4. Press 1 on the touch panel.

• MATCH MOUNT 2 will now be displayed in the upper left

corner of the LCD screen.

5. Press the MORE softkey to read the second page of

instructions on the LCD screen.

6. Remove the wheel from the balancer. Completely deflate

the tire by removing the valve core. After all the air pressure is

exhausted, follow the tire changer manufacturer's instruction for

loosening the tire beads.

A second operator can use the 2000 balancer while the Match

Mount operator performs steps 6, 7, and 8. All data for the

Match Mount procedure will be kept in the Match Mount operator's memory (A or B).

7. Lubricate both tire beads and wheel to aid in rotating the

tire and bead sealing and seating. Always use the tire manufacturers approved rubber lubricant.

8. Rotate the tire 180° on the wheel.

9. Replace the valve core and inflate the tire. Follow the tire

changer manufacturers instructions for inflation.

10. Remount the wheel on the balancer.

Remember: If another operator memory (A or B) has been

selected, reselect the memory being used for the Match Mount

procedure. The balancer will return to the point in the procedure

where the other memory was selected.

11. Press the 2 on the touch panel

• MATCH MOUNT 3 will be displayed in the upper left corner

of the LCD screen.

12. Lower the hood and press START.

13. Wait for the wheel to stop. Raise the hood and rotate the

wheel until the valve stem is at top dead center.

Direct Drive

12 • COATS IBS 2000 Interactive Balancing System

Figure 10 - Rotate the wheel

Figure 11 - Rotate Tire on Wheel

Tire/wheel

assembly rotated

until valve stem

is at top-deadcenter.

Tire rotated 180

degrees on the

wheel.

Figure 12 - Rotate the Wheel

Tire/wheel

assembly rotated

until valve stem

is at top-deadcenter

Page 19

14. Press 4 on the touch panel.

• MATCH MOUNT 4 will be displayed in the upper left corner

of the LCD screen.

15. Rotate the wheel until the weight position LEDs flash.

While the LEDs are flashing, mark the tire at top dead center

and press CONTINUE.

16. Press the MORE softkey to read the second page of

instructions on the LCD screen.

The weight breakdown will now be displayed on the LCD

screen. The weight imbalance due to the wheel (rim) will be displayed above the weight imbalance for the tire. The percent of

the total weight is also given to aid in determining, which has

the greater effect on the imbalance, the tire and/or wheel.

Use these weights to determine the suitability of the rim or

tire. High imbalance may indicate a rim that is out of round or

misformed, or a tire with a bubble or other problem. If the imbalance is excessive, it may be prudent to replace the rim, the tire,

or both. If either is replaced, do not continue with this procedure. Balance the new tire and rim and evaluate the readings for

Match Mount suitability.

17. Remove the wheel from the balancer. Completely deflate

the tire by removing the valve core. After all the air pressure is

exhausted, follow the tire changer manufacturer instructions for

loosening the tire beads.

A second operator can use the 2000 balancer while the Match

Mount operator performs steps 18, 19, and 20. All data for the

Match Mount procedure will be kept in the Match Mount operator's memory (A or B).

18. Lubricate both tire beads and wheel to aid in rotating the

tire and bead sealing and seating. Always use the tire manufacturer's approved rubber lubricant.

19. Rotate the tire until the mark is aligned with the valve

stem.

20. Replace the valve core and inflate the tire. Follow the tire

changer manufacturer instructions for inflation.

Remember: If another operator memory (A or B) has been

selected, reselect the memory being used for the Match Mount

procedure. The balancer will return to the point in the procedure

where the other memory was selected.

21. Remount the wheel on the balancer.

22. Press CONTINUE.

23. The balancer will return to standard balancing mode.

Direct Drive

COATS IBS 2000 Interactive Balancing System • 13

Figure 13 - Rotate the wheel

Tire/wheel

assembly rotated

until weight position lights

flashed. Tire

marked at topdead-center.

Figure 14 - Rotate Tire on Wheel

Figure 15 - Match Mount Completed

Tire rotated so

mark is aligned

with valve stem.

Wheel ready for

balancing

Page 20

14 • COATS IBS 2000 Interactive Balancing System

Direct Drive

Maintenance

The balancer requires only minor maintenance to

keep the unit operating properly.

1. Keep the display clean and clear. Use a vaporizing

cleaner only. Do not use cleaners or solvents which

leave oily or filmy residues behind.

2. Keep the adapters, cones, faceplate, threaded

arbor, pressure cup, and hub nut clean. Grease and

dirt buildup will cause premature wear and inaccurate

balancing. Clean these items at least once a day with

a vaporizing solvent.

3. Clean the weight tray, accessory posts, pegs, and

storage shelves with a vaporizing solvent. Weights

stored in a dirty tray will pick up grease and dirt which

may alter their weight or keep them from securely

attaching to the wheel.

Do not hose down or bucket wash the balancer. Extensive damage to the balancer

will result. Sensitive electronic components, wiring harnesses, and other devices

housed in the balancer are not intended to

be exposed to water.

Exposing the balancer to water, either by

hose pipe or bucket, or by exposure to rain

or snow, may cause risk of shock or electrocution to operator or bystanders. Place,

store, and operate the balancer only in a

dry, sheltered location.

4. Keep the area around the balancer clear. Remove

any tools or other items that are leaning against the

balancer. Keep the area under the balancer clear as

well. Remove any items that may cause the balance to

not sit level.

5. Use only COATS accessories. Accessories from

other manufacturers may not fit or function properly,

and may damage the balancer.

Total Accuracy

Verification

The IBS 2000 includes software that will prompt the

user to check the accuracy of his machine periodically.

The procedure is accomplished as follows:

1. Go to the main menu and select Setup. Press

enter.

2. Arrow through the selections to TAV. Press enter.

3. The menu will now display several "preset" selec-

tions to choose from, or the customer may wish to

SPECIFY (choosing your own). The default is 5000

cycles. Press enter.

4. If SPECIFY (choose your own) is selected, the

menu will prompt to enter the number of cycles

desired. Enter the number and press enter.

5. After the balancer reaches the selected number

of cycles the customer will receive THE MESSAGE.

Do you wish to perform T.A.V.? YES or NO.

6. If NO is is selected, the balancer will return to

normal balancing mode.

7. If YES is selected, the balancer will switch to cal-

ibration.

8. Follow the instructions on the display and per-

form normal calibration.

CAUTION

WARNING

Page 21

COATS IBS 2000 Interactive Balancing System • 15

Calibration and

Diagnostics

This balancer is a precision measuring instrument.

As such, it will require periodic calibration. The need

for calibration is generally identified when the balancer begins to "chase" weights - multiple spins and

multiple weights are required to achieve a "zero" balance. It is important to note, however, that even

though multiple spins and several weights may be

required, the wheel is properly balanced when the balancer indicates as such.

Before performing the calibration procedure, clean

and check the shaft, faceplate, and balancing cones

for damage. Even the slightest amount of dirt or damage can cause inaccurate calibration and balancing.

Balancer Calibration

Balancer calibration is a quick, simple process that

the operator can perform. A 4-ounce calibration

weight and an automotive steel wheel are all that are

required.

1. Select CALIBRATE from the menu, then select

CALIBRATE BALANCER.

2. Mount a 185 x 14 or 195 x 14 wheel, and enter

the standard A, W, and D measurements.

3. Lower the hood to spin the wheel (or press

START if HOOD START is turned off).

4. After the spin, attach a 4-ounce weight to the

wheel at the position indicated by the flashing weight

positioning LEDs.

If the weight cannot be placed in this location

(weights already on the wheel, etc.), place the weight

anywhere on the rim flange, rotate the wheel until the

weight is at top-dead-center, and press * on the keypad.

5. Lower the hood and spin the wheel again.

The display will show CALIBRATION COMPLETE.

Direct Drive

Page 22

16 • COATS IBS 2000 Interactive Balancing System

Direct Drive

Plane Separation

Normally, balancer calibration is all that is necessary

to resolve weight chasing. If, after calibration, the balancer still chases weights, follow these steps:

1. Perform the balancer calibration procedure as

outlined in the previous section.

2. Remove the 4-ounce weight from the calibration

wheel and place the balancer in the non-roundoff

mode.

3. Using clip-on weights and modeling clay (as nec-

essary), fine balance the wheel so that the weight displays show less than 0.02-ounce on both planes.

4. Attach the 4 ounce calibration weight to the inner

plane and spin the wheel.

5.The weight readings should be 3.88 to 4.12 ounce

on the inner plane, and 0.00 to 0.12 ounce on the

outer. If these readings are not obtained, adjust the A

dimension using the touch pad to adjust the readings.

Also, insure that the D reading is correct (i.e.: a 14-inch

tire should read between 13.6 and 14.3). After adjusting the A measurement, note the A and D figures and

follow the A/D arm calibration procedure.

A/D Arm Calibration

As with the balancer calibration procedure, watch

the display screen carefully. It will provide all of the

steps and directions required to perform the procedure. Not all screens may be shown here.

1. Select CALIBRATE ARM from the menu.

2. Press CONTINUE.

3. Review the voltage scales on the display screen.

If the indicator line is not within the area indicated by

the brackets, contact a Service Partner for potentiometer adjustment and press cancel. Otherwise

press continue.

4. Press Continue.

5. Move the arm to the home position, if it is not

already there, then press continue.

6. Mount a 185 x 14 or 195 x 14 wheel and press

continue.

7. Enter the A and D values that were found in step

five of the plane separation procedures.

8. Once the A and D measurements are entered,

pull the A/D arm out and touch the tip to the wheel rim

flange and hold it there while pressing CONTINUE.

9. Rotate the A/D arm around to the lower point at

which it will touch the rim. Hold it in position and press

CONTINUE.

10. The calibration is complete, and the screen will

return to it's main display.

11. Return to Calibrate balancer.

Page 23

COATS IBS 2000 Interactive Balancing System • 17

Diagnostics

There are many parts of the user interface on the

balancer that the operator can check for proper operation. Select DIAGNOSTICS from the menu, and then

chose from the following items:

Piezo Output - While this is not a user reparable

item, your Service Partner may ask you for these readings when placing a service call.

Keypad Test - Should the operator suspect that the

keypad is not functioning or entering data properly, run

the keypad test. The operator will be instructed to

press the individual keys on the keypad, and will display the associated number or function on the screen.

If the displayed item does not match the button

pressed, a service call should be placed. Press any

button 3 times in succession to exit the keypad test.

LCD Test - This test checks the LCD operating RAM

and system to verify that it is operating properly. There

is nothing else required to run this test. Should the

test fail, contact your Service Partner.

LED Test - This test will step through all of the LEDs

on the touch panel. The operator can verify that each

LED is operational simply by watching the LEDs being

tested (as described on the display). When a test is

complete, press CONTINUE to move to the next. If

any LEDs are non-operational, contact your Service

Partner.

Counters - While not a diagnostic function, these

counters are accessed and reset via the DIAGNOSTIC

screen.

The user counter is resettable, and may be helpful to

those who require spin counts.

The calibration counter counts the cycles since the

last calibration. It is not resettable by the user.

The total cycle counter counts all cycles since the

balance was put into operation. This counter is not

resettable.

Software Version - Verify the software version present in the balancer by selecting VERSION.

Direct Drive

Page 24

9112095 03 4/00 © Copyright 1997, 2000 Hennessy Industries and COATS All Rights Reserved Printed in USA

Loading...

Loading...