Page 1

Osai

- PLC

Osai

- PLC

Page 2

Osai

- PLC

V

ERSION

D

ATE

D

ESCRIPTION OF REVISION

D

RAWN UP BY

C

HECKED BY

00.00 12/09/13 F

01.00 30/10/13 P

IRST DOCUMENT DRAFT

ROCEDURE REVISION

M

BCK/RST F

AGRI MARCELLO

AUSTO ZANARDI

L

ORIS VALSECCHI

CFP0110001/01 - 2 -

Page 3

Osai

- PLC

T

ABLE OF CONTENTS

Introduction ........................................................................................................................... 4

Purpose of document .............................................................................................................. 4

Description of Automation Project Parts .................................................................................... 4

CNC functions and PLC functions ............................................................................................. 5

NC – PLC interaction ............................................................................................................... 5

SW structure of the NC ........................................................................................................... 6

AMP ...................................................................................................................................... 7

Applications by Machining Centre Manufacturer ......................................................................... 7

WIN folder ............................................................................................................................. 8

PLC Structure ......................................................................................................................... 9

Variable Nomenclature .......................................................................................................... 10

TABLES OF SYMBOLS FOR I/O SIGNAL NOMENCLATURE ......................................................... 10

TABLE OF SYMBOLS FOR GLOBAL VARIABLE NOMENCLATURE................................................. 11

TABLE OF SYMBOLS FOR GLOBAL VARIABLE NOMENCLATURE (Volatile only) ........................... 12

NOTES AND EXAMPLES ......................................................................................................... 13

TABELLA DEI SIMBOLI PER NOMENCLATURA ULTERIORI STRUTTURE DATI ............................. 14

Debug PLC ........................................................................................................................... 15

Ricerche Veloci ..................................................................................................................... 17

ulteriori operazioni di debug .................................................................................................. 17

Backup & Restore CN ............................................................................................................ 18

Backup CN ........................................................................................................................... 18

Restore CN .......................................................................................................................... 23

Riferimenti ........................................................................................................................... 27

CFP0110001/01 - 3 -

Page 4

Osai

- PLC

AXES DRIVES

canbus

INVERTER

serial

I

NTRODUCTION

P

URPOSE OF DOCUMENT

This document is meant for assistance support; therefore its aim is simplifying and speeding up

the diagnosis of any machining centre troubles.

For this purpose the following topics will be dealt with:

- Description of the main parts of OSAI automation project

- Description of the CNC and PLC basic structures and related interactions

- Description of PLC Debug operations

- Description of NC OSAI Backup and Restore operations

D

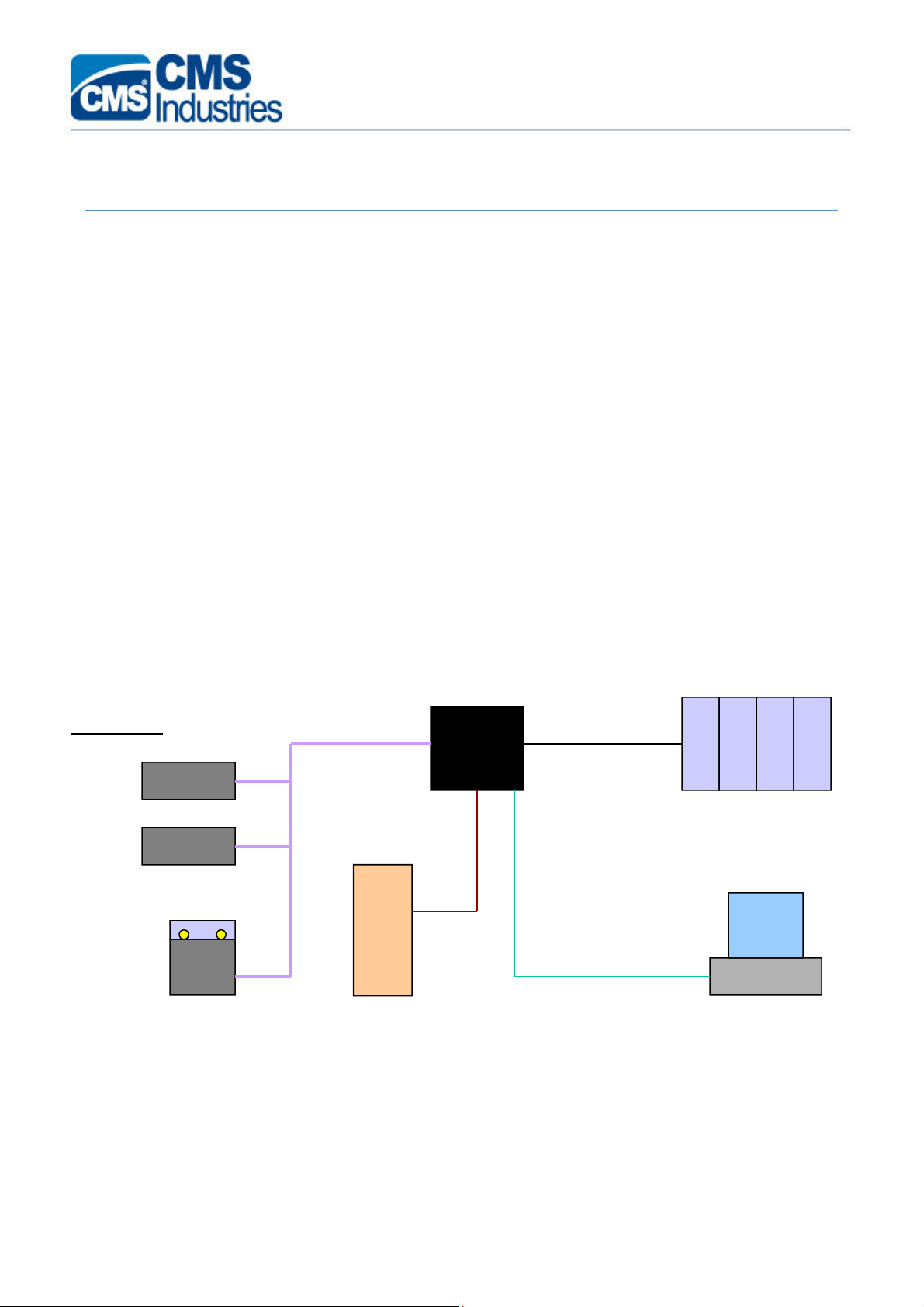

ESCRIPTION OF AUTOMATION PROJECT PARTS

The figure below displays the components of a typical NC OSAI Automation project

Peripherals

mechatrolink

ethernet

PC

OFFICE

CFP0110001/01 - 4 -

Page 5

Osai

- PLC

CNC

FUNCTIONS AND

PLC

FUNCTIONS

The main component of the automation project is the CNC

to as NC from now onwards))

a) Part-Program interpretation and execution

b) Interpolation and axis handling control

c) Management of Process Variables (E, @, L()…)

d) System parameterization

In particular, the NC OSAI integrates also the PLC (

machining centre. The PLC consists of a program written in a programming language called

WinPLUS which, once compiled and transferred into the NC memory, is run by the CPU of the NC

cyclically.

The PLC carries out the following tasks:

a) Manages the “Machine interface logic” , that is, manages all the Inputs/Outputs

(digital/analog, local/remote) of the machine.

b) Informs the machining centre operator about any anomalies, detected via screen

messages or warning lights; attends to stop the machining centre functions temporarily or

definitively based on the seriousness of such anomalies.

c) Enables the workpiece machining process to progress (Part-Program) and checks that at

the beginning and end of each programmed block all necessary conditions exist to be able

to carry on machining.

which carries out the following functions:

(Computer Numerical Control (referred

Programmable Logic Controller

) of the

d) Manages the requests made by the Part-Program via the M,S,T auxiliary functions.

e) Manages the requests made by the machining centre operator:

o selects the operation mode of NC (AUTOMATIC, MDI, JOG, HOMING …)

o starts, stops and resets the machining process

o manages the requests made via Softkey available on the PC OFFICE.

f) Manages the various automatic cycles so that they run concurrently with the machining

process.

g) Acquires process variable values and axis dimensions, checks axis-axis or axis-machine

frame collisions.

NC – PLC

DIRECT INTERACTON

The NC retentive memory houses a memory area called VARIABILI PLUS which you can access

both from PLC and NC (from Part-Program or by accessing the related variable list). This memory

are is provided with 256 full format variables (subdivided into boolean variables) and 64 floating

point variables.

INTERACTION

CFP0110001/01 - 5 -

Page 6

Osai

- PLC

On the PLC side these memories subdivide into GW memories (bit-to-bit definable, in case) and in

GD memories respectively. On the NC side such variables are seen as variables @ follone by a max

10-character name. Type, name and address are declared in the special section “LOGIC CONF” in

AMP.

For any necessary in-depth details refer to the OSAI “AMP” Manual (code Osai 45006666T).

INDIRECT INTERACTION

The NC has a system memory area called area S; it also reserves part of the M area to interface

with the PLC transparently for the end user.

For instance, to carry out the following operations you need to:

- request for the PLC consent to execute each M,S,T code….

- request for the PLC consent to start moving an axis

- request for the PLC consent to declare an axis movement completed

While waiting for the PLC response, the NC stops the Part-Program execution on the wait

command.

The PLC cyclically controls the area S or area M memories, that are connected with the various NC

controls. After checking the presence of all necessary conditions, it attends to the specific

management and signals the acceptance of the request (ACK) on other memories to enable

continuing the processes under way.

For any necessary in-depth details refer to the OSAI “ WinPLUS Application” Manual (code Osai

45006861T).

SW

STRUCTURE OF THE

This paragraph deals with the organization of the NC files and the description of the most

important ones, with regard to the purpose of this document.

The NC Hard Disk is partitioned into the following 4 logic partitions:

C and D : they are system disks containing the system files relating to the specific NC SW release.

E: this disk is reserved to the machining centre manufacturer, containing all NC parameterization

data.

F: this disk is reserved to the machining centre manufacturer and to the end used; it contains all

workpiece machining cycles (Part-Program) and any other machining centre operating cycles

(paramacro, tool change programs, etc.)

NC

The peculiar files and folder are mentioned below:

E:\AMP : folder where the various AMP (Adjustable Machine Parameters) reside, i.e., the

system characterization files.

CFP0110001/01 - 6 -

Page 7

Osai

- PLC

E:\OEM\EXE : folder where the machining centre manufacturer applications reside (CMSKMG,

CMSCON, CMSRST). These DOS Real Time applications are run by the NC in parallel

with all other activities.

E:\LOG\WIN: folder containing some PLC configuration files, the message files

and the Canbus line configuration files.

F:\CMSKMG : folder containing the CMSKMG application configuration files.

F:\UPP : folder containing the Part-Programs and any auxiliary programs by the machining

centre manufacturer (tool change cycles, workpiece loading/unloading cycles, …)

AMP

By the related utility function it is possible to define up to 4 AMP’s. In most cases one single AMP is

enough for NC characterization. At other times it is necessary to define more than one of them, as

the machining centre can adopt configurations needing different parameterizations (machining

centres equipped with Gantry tables, machining centres where no axes can be added or removed

according to the operations to carry out, …). In this case it will be the end user’s task to select the

necessary AMP each time and restart the NC for activation.

The following features can be defined for each AMP:

- number of processes and related characterizations

- number of axes for each process and related characterization

- process variables

- logic interfacing variables (PLUS Variables)

A

PPLICATIONS BY MACHINING CENTRE MANUFACTURER

Any Applications by the Machining Centre Manufacturer which can be installed on the machining

centre NC are described below

- CMSKMG : this application attends to the serial interface between PLC and spindle Inverter.

It is characterized by the CMSKMG.IMP and CMSKMG.CFG files. In particular the CMSKMG.IMP file

defines the number of the Inverter, the number of electrospindles, the number of tool magazines,

the number of tools and the related coupling of each head.

Also the Machining Centre Manufacturer Applications residing on the PC OFFICE (Els Manager, Tool

Manager,…) use this information.

- CMSRST : application for resetting the electrospindle life, when they are replaced.

- CMSCON : application used for triggering the other applications.

The latest versions of the CMSKMG application are provided with improved diagnostic functions.

In this connection the diagnostic file F:\CMSKMG\CMSKMG.LOG has been provided, where a

certain number of signals from the CMSKMG.EXE application is stored. This number depends on

the value of the #DEB parameter present in the file CMSKMG.CFG, which can adopt the following

values:

#DEB 0 : Minimum signal level (default)

CFP0110001/01 - 7 -

Page 8

Osai

- PLC

#DEB 1 : Medium signal level

#DEB 2F: Maximum signal level with output on file CMSKMG.LOG

#DEB 2S: Maximum level with screen output (subject to assignment of video resource to

the CMSKMG.EXE application)

N.B.: folder E:\OEM\AMP1 contains the OEM_CONF.TXT file. This file defines the priority levels

and the video resources associated with the various applications.

By default the video resource is assigned to CMSCON application.

Should any problems arise with the spindle, it is possible to assign the video resource to the

CMSKMG application, to display some additional information which might turn useful during the

diagnostic phase. After making the changes prompted below it is necessary to recompile the AMP

and restart the NC for their acquisition.

Video resource to CmsCon (default) Video resource to CmsKmg

TI 127 512 0 CMSKMG.EXE TI 127 512 1 CMSKMG.EXE

* *

TQ 10 2 TQ 10 2

SM 1 1 SM 1 1

TI 129 512 1 CMSCON.EXE TI 129 512 0 CMSCON.EXE

It is advisable to restore the default configuration any way (#DEB 0 and video resource to the

CMSCON.EXE application) as sending messages implies a waste of extra time at any rate.

WIN

FOLDER

Inside the WIN folder the following files can be found:

- CANBUS line configuration file: CANBUS.DBM and CANBUS.RMP

- PLC message file:

-WINPLUS.ASC (former PLC versions)

-ITA.ASC, ING.ASC, FRA.ASC …… (new PLC versions)

-Initializzation/configuration files for the PLC:

-INITVAR

-INITBANC

-INITZERO

-INIT...

-(WINPLUS.DES is created by the NUMERICAL CONTROL automatically)

CFP0110001/01 - 8 -

Page 9

Osai

- PLC

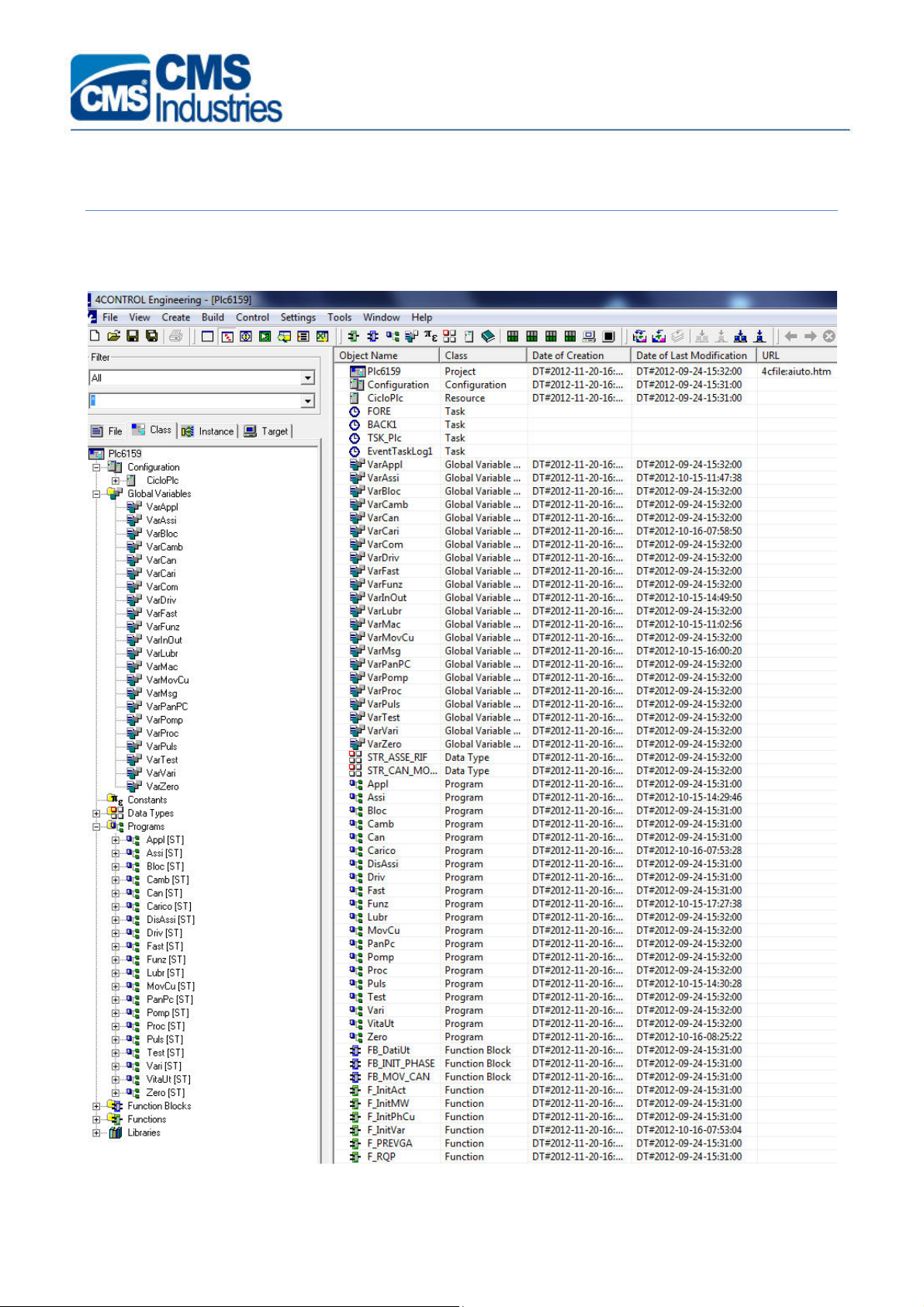

PLC S

The figure below shows an example of PLC application in WinPLUS environment.

TRUCTURE

CFP0110001/01 - 9 -

Page 10

Osai

- PLC

As illustrated by the figure below the PLC is structured into more modules: configuration modules

(CicloPLC.res), variable definition modules (Varxxxx.gvl), code definition modules (xxxx.st) and

other auxiliary modules (constant definition, structure definitions, functions, functional blocks and

various libraries).

In particular:

- CicloPLC.res : lists all the tasks of the PLC project

- VarInOut.gvl : lists the definitions of all I/O’s of the PLC project

- VarMsg.gvl : lists the definitions of all messages of the PLC project

- VarMac.gvl : lists the definitions of the main variables of the machining centre in hand

- VarCom.gvl : lists the definitions of the standard variables shared by all the PLC projects

- Fast.st, Assi.st, Proc.st, Driv.st, Zero.st, Funz.st: these are the main program blocks

V

ARIABLE NOMENCLATURE

The nomenclature of variables has been the target of a great effort of standardization, so as to

simplify the understanding of the various projects. The following tables describe the conventions

adopted.

TABLES OF SYMBOLS FOR I/O SIGNAL NOMENCLATURE

Convention adopted for machine I/O nomenclature.

INPUTS

Derivative, generic, … INP

Flow switch FL

Circuit breaker QF

Motor-protective circuit breaker QM

Braking resistance RR

Selector SA

SYMBOL

Button SB

Luminous button/selector SH

Level sensor SL

Pressure sensor SP

Position sensor SQ

Rotation sensor SR

CFP0110001/01 - 10 -

Page 11

Osai

- PLC

Temperature sensor ST

Thermostat TR

OUTPUTS

Derivative, generic, … OUT

Indicator light, lamp, HL

Instantaneous relay KA

Power contactors KM

Electromagnetic brake YB

Solenoid valve YV

TABLE OF SYMBOLS FOR GLOBAL VARIABLE NOMENCLATURE

Legend: xxxx Name of block where the memory is set

y System memory initials (S or M)

VARIABLE

RANGE

VOLATILE MEMORIES 1 BIT

VOLATILE MEMORIES 8 BIT BYTE

VOLATILE MEMORIES 16 BIT WORD (UNSIGNED)

VOLATILE MEMORIES 16 BIT INT (SIGNED)

VOLATILE MEMORIES 32 BIT DOUBLE WORD (UNS.)

VOLATILE MEMORIES 32 BIT DOUBLE INT (SIGNED)

0÷1

0÷255

0÷65535

-32768÷32767

0÷294967295

-2147483648÷2147483647

SYMBOL

MM_xxxx

MB_xxxx

MW_xxxx

MI_xxxx

MDW_xxxx

MDI_xxxx

VOLATILE MEMORIES 64 BIT LONG REAL floating point 64bit precis. MLR_xxxx

VOLATILE MEMORIES TIME MT_xxxxx

RETENTIVE MEMORIES 1 BIT

RETENTIVE MEMORIES 8 BIT BYTE

0÷1

0÷255

RM_xxxx

RB_xxxx

CFP0110001/01 - 11 -

Page 12

Osai

- PLC

RETENTIVE MEMORIES 16 BIT WORD (UNSIGNED)

RETENTIVE MEMORIES 16 BIT INT (SIGNED)

RETENTIVE MEMORIES 32 BIT DOUBLE WORD (UN.)

RETENTIVE MEMORIES 32 BIT DOUBLE INT (SIGN.)

RETENTIVE MEMORIES 64 BIT LONG REAL floating point 64bit precis. RLR_xxxx

VOLATILE MEMORIES 1 BIT NC

VOLATILE MEMORIES 8 BIT NC BYTE

VOLATILE MEMORIES 16 BIT NC WORD (UNSIGNED)

VOLATILE MEMORIES 16 BIT NC INT (SIGNED)

VOL. MEMORIES 32 BIT NC DOUBLE WORD (UNS.)

VOL. MEMORIES 32 BIT NC DOUBLE INT (SIGNED)

0÷65535

-32768÷32767

0÷294967295

-2147483648÷2147483647

0÷1

0÷255

0÷65535

-32768÷32767

0÷294967295

-2147483648÷2147483647

RW_xxxx

RI_xxxx

RDW_xxxx

RDI_xxxx

yM_CN

yB_CN

yW_CN

yI_CN

yD_CN

yDI_CN

VOL. MEMORIES 64 BIT NC LONG REAL floating point 64bit precis. yLR_CN

TABLE OF SYMBOLS FOR GLOBAL VARIABLE NOMENCLATURE (V

VARIABLE

RANGE

MEMORIES 1 BIT

MEMORIES 8 BIT BYTE

MEMORIES 16 BIT WORD (UNSIGNED)

MEMORIES 16 BIT INT (SIGNED)

MEMORIES 32 BIT DOUBLE WORD (UNS.)

MEMORIES 32 BIT DOUBLE INT (SIGNED)

MEMORIES 64 BIT LONG REAL floating point 64bit precis. LOC_MLR

0÷1

0÷255

0÷65535

-32768÷32767

0÷294967295

-2147483648÷2147483647

OLATILE ONLY

)

SYMBOL

LOC_MM

LOC_MB

LOC_MW

LOC_MI

LOC_MDW

LOC_MDI

MEMORIES TIME LOC_MT

CFP0110001/01 - 12 -

Page 13

Osai

- PLC

NOTES AND EXAMPLES

LOCAL VARIABLES

The LOCAL variables differ from the GLOBAL variables in that they can be used only in the module

they are defined for. To distinguish them from the GLOBAL variables the programming department

decided to prefix the variable format type with the string “LOC_” but without indicating the name

of the block xxxx (as they are defined and used always in the same block).

Examples: LOC_MW_RisultatoConversione , LOC_MM_ConversioneInCorso.

CONSTANT

With WinPlus it is advisable to use some symbolic values in the various computational expressions,

i.e. some CONSTANTS, instead of absolute values whose meaning is not easily grasped.

Generic constants defined in the VarCom.gvl module:

KI_PROCESSO1 : INT:= 1 ;

KT_10MS : TIME:= T#10ms ;

Specific constants defined in the VarAssi.gvl module:

KI_ASSI_NUM_BIT_FEED_OVR : INT:= 5 ;

KI_ASSI_NUM_BIT_SPEED_OVR : INT:= 4 ;

NAME OF VARIABLE

Each name of variable is made up by the variable type, the name of the block (with exceptions)

where the variable is set and by a very concise description. The meaning of the action must refer

to logic state 1 (TRUE).

Exceptions: the name of the block does not need to be indicated in case of LOCAL variables,

system variables, I/O signals and is omitted in case of variables indicating M/S/T functions.

With WinPlus the name of a variable can be maximum 32-character long.

Per costruirlo unire fra loro TUTTE le parole della relativa descrizione, scrivendo in maiuscolo

l’iniziale di ciascuna parola tranne il tipo di variabile che va scritto interamente in maiuscolo

utilizzando il carattere “_” come separatore.

Ulteriori convenzioni vengono utilizzate per alcuni tipi di variabili utilizzate ad esempio per la

decodifica di softkey , per i messaggi , per i parametri formali delle funzioni o per variabili

rappresentanti maschere di bit.

Negli esempi e nelle note che seguono sono indicati tutti i casi previsti.

Esempi :

Indirizzo (opzionale) Nome Variabile: Tipo

M 1004,04 INP_OkModuloEmergenza Segnale ingresso

CFP0110001/01 - 13 -

Page 14

Osai

- PLC

M 1010,00 SQ_PortaDxAperta Sensore di posizione

M 1130,03 YV_SoffiatoreUtensile Elettrovalvola

M 1355,00 MM_ASSI_AsseXInMovimento Bit Globale da modulo ASSI.ST

MM_VARI_AuxGestioneZone Bit Globale da modulo ASSI.ST

(senza associazione a variabile

pagina vecchia PLUS)

GW 94 RI_CAMB_UtensileMandrino INT Ritentivo da modulo CAMB

MW 2710 MI_ZERO_MskRichiestaZeroAssi INT Globale da modulo ZERO.ST

S 20,07 SM_CN_ResetProcesso1 Bit di sistema

M 143,05 MSG_CAMBIO_CambioUtInCorso Messaggio

M 3801,05 M21 Funzione M

LOC_MI_Contatore INT Locale

TABELLA DEI SIMBOLI PER NOMENCLATURA ULTERIORI STRUTTURE DATI

Per le convenzioni adottate per la nomenclatura di Funzioni , Temporizzatori , Pulse , ecc . riferirsi

alla seguente tabella:

STRUTTURA DATI

FUNZIONE F F_EseguoSomma

BLOCCO FUNZIONE FB FB_DatiUt.

Par. d’Ingresso Funzione FNI_MI FNI_MI_Addendo1

Par. d’uscita Funzione FNO_MI FNO_MI_Risultato

Timer tipo TON TimerTon TimerTon_RitardoInitMotori

Timer tipo TOFF TimerToff TimerToff_Spegnimento

Timer tipo TP TimerTp TimerTp_Soffiatore

Pulse salita Pulse_Up PulseUp_PrimoPowerOn

SIMBOLO

ESEMPIO

Pulse discesa Pulse_Down PulseDownResetCnProc1

Struttura Dati STR_ STR_MOVCU_ArrayCanPhaseCu

Per ulteriori approfondimenti consultare il Manuale OSAI “WinPLUS: Manuale di Programmazione”

(cod.Osai 45006877B).

CFP0110001/01 - 14 -

Page 15

Osai

- PLC

D

EBUG

Una volta scritto il codice è necessario compilare il progetto prima di trasferirlo nel CN (download).

Per compilare il progetto cliccare sull’icona indicata in figura. Con alcune versioni di WInPLUS

l’operazione di compilazione necessita della relativa chiavetta HW.

Nel caso di errori di compilazione provvedere alla relativa correzione.

Per esempio:

PLC

In questo caso cliccando due volte sulla prima riga errata nella lista errori è possibile rintracciare

velocemente il punto in cui l’errore è presente. Apportare le correzioni del caso e ripetere

l’operazione di compilazione. Il risultato che si deve ottenere è il seguente:

CFP0110001/01 - 15 -

Page 16

Osai

- PLC

A questo punto è possibile scaricare il progetto in macchina cliccando sull’icona indicata nella

seguente figura.

Alla seguente richiesta cliccare su “Si” come indicato in figura:

Ignorare le eventuali segnalazioni di Errore / Warning che vengono emesse al termine

dell’operazione di Download. Verificare che l’operazione si concluda con la scritta “… download

finished” come indicata nella figura seguente:

CFP0110001/01 - 16 -

Page 17

Osai

- PLC

R

ICERCHE VELOCI

I seguenti comandi sono particolarmente utili nelle fasi di debug PLC e diagnostica:

a) “Cerca in files” ⇒ ctrl+i

b) “Vai alla linea” ⇒ ctrl+g--

ULTERIORI OPERAZIONI DI DEBUG

Esistono inoltre i seguenti strumenti di debug che consentono di eseguire operazioni di diagnosi e

debugging più complesse e nel caso di utilizzo dei breakpoint anche pericolose. Il relativo utilizzo è

riservato a personale qualificato.

a) Watchpoint

b) Watch List

c) Breakpoint

CFP0110001/01 - 17 -

Page 18

Osai

- PLC

B

ACKUP & RESTORE

It is possible to save all the files which are on the NC at the same time, without the need to store

them separately.

Please note that the PLC project is on the PC OFFICE and should be saved separately as for all

other applications which are on PC OFFICE.

B

ACKUP

The following procedure describes the steps to be done to save all the data of the NC on the PC:

You must start from the condition

1. CN activated

2. Machine in Emergency stop

CN

CN

• Press UTILITY

• Press BOOT CONTROLLER

• Press MODE

CFP0110001/01 - 18 -

Page 19

Osai

- PLC

• Press SETUP

• Press BOOT

• Press REBOOT

CFP0110001/01 - 19 -

Page 20

Osai

- PLC

• Compare il messaggio “ARE YOU SURE YOU WANT TO BOOT THE CNC”

• Cliccare su YES

Wait for the complete reboot of the system

• Wait until you see the message “CNC IS IN SETUP MODE”

• Press SECURITY shown in figure:

• Press BACKUP and specify the path and name of the backup to be created:

• Create a new folder “BCKxxxx” (xxxx represents the serial number of the machine).

CFP0110001/01 - 20 -

Page 21

Osai

- PLC

• Open the folder you just created, specify the file name and press SAVE

• Select “All the control” tag and press START:

• Wait for the end of the Backup operation, until it is shown the message “Operation

completed successfully!”

• Close the SETUP interface:

Press FILE

Press EXIT

• Into BOOT CONTROLLER interface, select MODE then press NORMAL to restart the CN in

standard mode and resume normal operation of the machine:

CFP0110001/01 - 21 -

Page 22

Osai

- PLC

• Press BOOT, then REBOOT

• Press YES and wait the end of the operation.

• Restart the machine.

CFP0110001/01 - 22 -

Page 23

Osai

- PLC

R

ESTORE

The following procedure describes the operations to load all the data from the PC to the NC:

Requerements:

1. CN activated

2. Machine in Emergency stop

• Press UTILITY

• Press BOOT CONTROLLER

CN

• Press MODE

CFP0110001/01 - 23 -

Page 24

Osai

- PLC

• Press SETUP

• Press BOOT

• Press REBOOT

• It is shown the message “ARE YOU SURE YOU WANT TO BOOT THE CNC”

• Press YES

CN runs the Reboot.

• Wait until it is shown the message “CNC IN SETUP MODE”

CFP0110001/01 - 24 -

Page 25

Osai

- PLC

• Select the SECURITY shown in figure:

• Press RESTORE, select BROWSE… e indicare il percorso ed il nome del file di backup da

ripristinare.

• Select the three options “System area”, “OEM area”, “User area”:

• Press START and wait for the completion of recovery operations CN, which is specified by

the message “Operation completed successfully!”

CFP0110001/01 - 25 -

Page 26

Osai

- PLC

• Close SETUP interface:

Press FILE

Press EXIT

• In the BOOT CONTROLLER interface, select MODE, then press NORMAL to restart the CN

in standard mode and resume normal operation of the machine:

CFP0110001/01 - 26 -

Page 27

Osai

- PLC

• Press BOOT then REBOOT

• Select YES and wait the end of the process.

• Shut down and restart the machine.

R

IFERIMENTI

Documento: install Win e CN v22.doc

Documento: WnBBck.doc

Documento: WnBRst.doc

CFP0110001/01 - 27 -

Loading...

Loading...