Page 1

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

TFT LCD Preliminary Specification

MODEL NO.: V260B3 – L01

Preliminary

Approved By

TV Head Division

LY Ch en

Reviewed By

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Prepared By

LCD TV Marketing and Product Management Div.

QA Dept. Product Development Div.

Kc_Ko WT Lin

WY Li Delia Lin

1

Version 1.0

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

- CONTENTS -

REVISION HISTORY ------------------------------------------------------- 3

1. GENERAL DESCRIPTION ------------------------------------------------------- 4

1.1 OVERVIEW

1.2 FEATURES

1.3 APPLICATION

1.4 GENERAL SPECIFICATIONS

1.5 MECHANICAL SPECIFICATIONS

2. ABSOLUTE MAXIMUM RATINGS ------------------------------------------------------- 5

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

2.2.2 BACKLIGHT UNIT

3. ELECTRICAL CHARACTERISTICS ------------------------------------------------------- 7

3.1 TFT LCD MODULE

3.2 BACKLIGHT UNIT

3.2.1 CCFL CHARACTERISTICS

3.2.2 INVERTER CHARACTERISTICS

3.2.3 INVERTER INTERFACE CHARACTERISTICS

4. BLOCK DIAGRAM ------------------------------------------------------- 12

4.1 TFT LCD MODULE

5. INTERFACE PIN CONNECTION ------------------------------------------------------- 13

5.1 TFT LCD MODULE

5.2 BACKLIGHT UNIT

5.3 INVERTER UNIT

5.4 BLOCK DIAGRAM OF INTERFACE

5.5 LVDS INTERFACE

5.6 COLOR DATA INPUT ASSIGNMENT

6. INTERFACE TIMING ------------------------------------------------------- 19

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

6.2 POWER ON/OFF SEQUENCE

7. OPTICAL CHARACTERISTICS ------------------------------------------------------- 22

7.1 TEST CONDITIONS

7.2 OPTICAL SPECIFICATIONS

8. DEFINITION OF LABELS ------------------------------------------------------- 26

8.1 CMO MODULE LABEL

9. PACKAGING ------------------------------------------------------- 27

9.1 PACKING SPECIFICATIONS

9.2 PACKING METHOD

10. PRECAUTIONS ------------------------------------------------------- 29

10.1 ASSEMBLY AND HANDLING PRECAUTIONS

10.2 SAFETY PRECAUTIONS

10.3 STORAGE PRECAUTIONS

11. REGULATORY STANDARD -------------------------------------------------------- 30

11.1 SAFETY

12. MECHANICAL CHARACTERISTICS ------------------------------------------------------- 31

2

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

REVISION HISTORY

Version Date

Page

(New)

Ver 1.0 Apr. 15,’09 All All Preliminary Specification was first issued.

Section Description

Preliminary

3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 4

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

1. GENERAL DESCRIPTION

1.1 OVERVIEW

V260B3- L01 is a TFT Liquid Crystal Display module with 4U-CCFL Backlight unit and 1ch-LVDS

interface. The display diagonal is 26”. This module supports 1366 x 768 WXGA format and can display

16.7M colors ( 6-bit+Hi-FRC). The inverter module for backlight is built-in.

1.2 FEATURES

- Optimized Brightness 450nits

- Contrast Ratio (3000:1)

- Fast Response Time (Gray to gray average 8.5ms)

- Color Saturation NTSC 72%

- WXGA (1366 x 768 pixels) Resolution

- DE (Data Enable) Only Mode

- LVDS (Low Voltage Differential Signaling) Interface

- Viewing Angle: 176(H)/176(V) (CR>20) MVA Technology

-Color Reproduction (Nature Color)

1.3 APPLICATION

- TFT LCD TVs

- Optimized Brightness, Multi-Media Displays

1.4 GENERAL SPECIFICATI0NS

Item Specification Unit Note

Active Area 575.769 (H) x 323.712 (V) (26” diagonal) mm

Bezel Opening Area 580.8 (H) x 328.8 (V) mm

Driver Element a-si TFT active matrix -

Pixel Number 1366 x R.G.B. x 768 pixel

Pixel Pitch (Sub Pixel) 0.1405 (H) x 0.4215 (V) mm

Pixel Arrangement RGB vertical stripe -

Display Colors 16.7M color

Display Operation Mode Transmissive mode / Normally Black -

Surface Treatment

Anti-Glare Coating (Haze 11%)

Hard Coating (3H)

-

1.5 MECHANICAL SPECIFICATIONS

Item Min. Typ. Max. Unit Note

Horizontal(H) 625 626 627 mm (1)

Module Size

Note (1) Please refer to the attached drawings for more information of front and back outline dimensions.

Vertical(V) 372 373 374 mm (1)

Depth(D) 31 32 33 mm To Rear

Depth(D) 45.7 46.7 47.7 mm To inverter cover

Weight - 3720 - g

(1)

4

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

2. ABSOLUTE MAXIMUM RATINGS

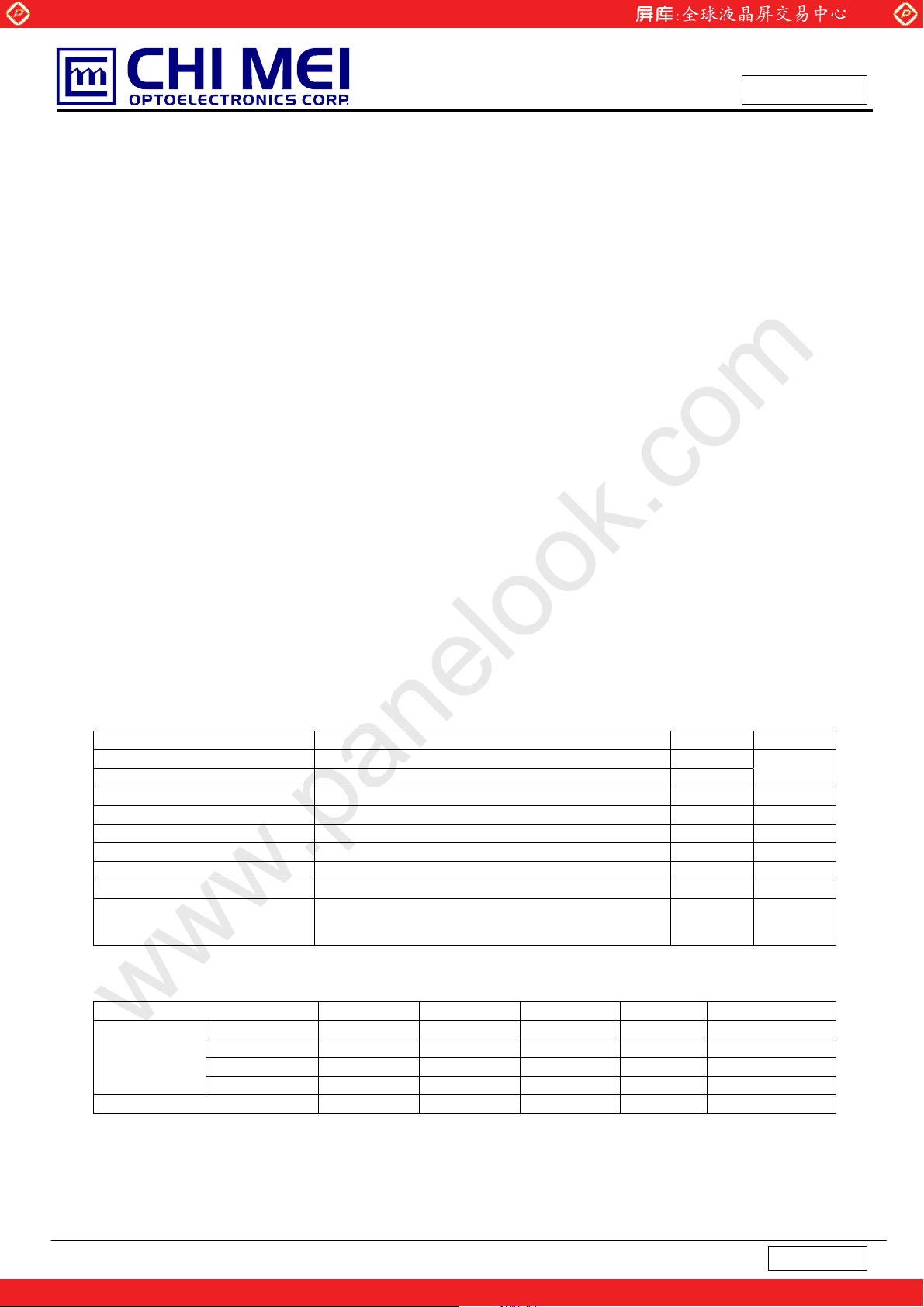

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

Item Symbol

Storage Temperature TST -20 +60 ºC (1)

Operating Ambient Temperature TOP 0 +50 ºC (1), (2)

Shock (Non-Operating) S

Vibration (Non-Operating) V

Note (1) Temperature and relative humidity range is shown in the figure below.

(a) 90 %RH Max. (Ta

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation.

Note (2) The maximum operating temperature is based on the test condition that the surface temperature of

display area is less than or equal to 65 ºC with LCD module alone in a temperature controlled chamber.

Thermal management should be considered in final product design to prevent the surface temperature of

display area from being over 65 ºC. The range of operating temperature may degrade in case of improper

Љ 40 ºC).

NOP

NOP

Min. Max.

Ё

Ё

Value

Unit Note

50 G (3), (5)

1.0 G (4), (5)

thermal management in final product design.

Note (3) 11 ms, half sine wave, 1 time for ± X, ± Y, ± Z.

Note (4) 10 ~ 500 Hz, 10 min, 1 time each X, Y, Z.

Note (5) At testing Vibration and Shock, the fixture in holding the module has to be hard and rigid enough

so that the module would not be twisted or bent by the fixture.

Relative Humidity (%RH)

100

90

80

60

Operating Range

40

20

10

Storage Range

Temperature (ºC)

5

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

8060-20 400 20-40

Version 1.0

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

Item Symbol

Power Supply Voltage Vcc -0.3 13.0 V

Input Signal Voltage VIN -0.3 3.6 V

Min. Max.

2.2.2 BACKLIGHT UNIT

Item Symbol

Lamp Voltage VW

Power Supply Voltage VBL

Control Signal Level

Note (1) Permanent damage to the device may occur if maximum values are exceeded. Functional

operation should be restricted to the conditions described under normal operating conditions.

Note (2) No moisture condensation or freezing.

Condition

Ta = 25

Ё Ё

Value

Te st

к Ё Ё

Ё

Unit Note

(1)

Min. Type Max. Unit Note

0

-0.3

Ё

Ё

3000 V

30 V

7 V

RMS

(1)

(1), (3)

Note (3) The control signals includes Backlight On/Off Control, Internal PWM Control and External PWM

Control.

6

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LCD MODULE

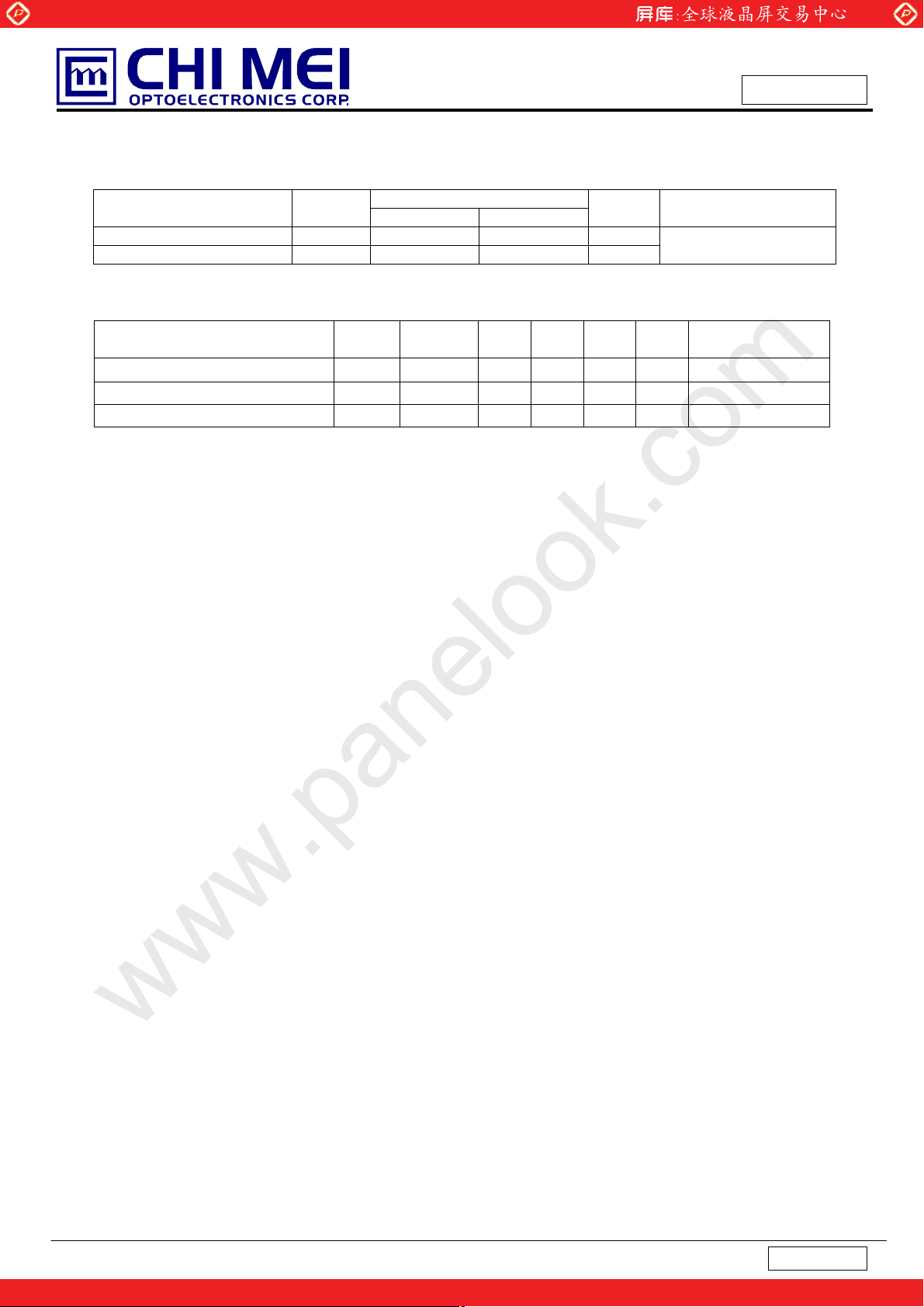

Parameter Symbol

Power Supply Voltage VCC 11.4 12.0 12.6 V (1)

Power Supply Ripple Voltage VRP

Rush Current I

White

Power Supply Current

Differential Input High

LVDS

Interface

Threshold Voltage

Differential Input Low

Threshold Voltage

Common Input Voltage V

Terminating Resistor R

CMOS

interface

Input High Threshold Voltage VIH 2.7

Input Low Threshold Voltage V

Note (1) The module should be always operated within above ranges.

Black

Vertical Stripe

Ta = 25 ± 2 ºC

Value

Min. Typ. Max.

Ё Ё

RUSH

I

CC

+100

V

LVT H

V

LVTL

1.125 1.25 1.375 V

LVC

T

Ё Ё

Ё

Ё

Ё

0.40 0.50

0.35 0.40

0.45 0.50

Ё Ё

Ё Ё

Ё

100

Ё

0

IL

Ё

300 mV

3.0 A (2)

-100 mV

Ё

3.3 V

0.7 V

Unit Note

A

A

A

mV

ohm

(3)

Note (2) Measurement Conditions:

+12.0V

R1

200K

(Low to High)

(Control Signal)

SW

R2

1K

Vcc rising time is 470us

Q1 AO4409

2N7002

Q2

47K

VR1

C1

10uF

+12V

FUSE

C3

1uF

Vcc

(LCD Module Input)

0.9Vcc

0.1Vcc

GND

470us

7

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

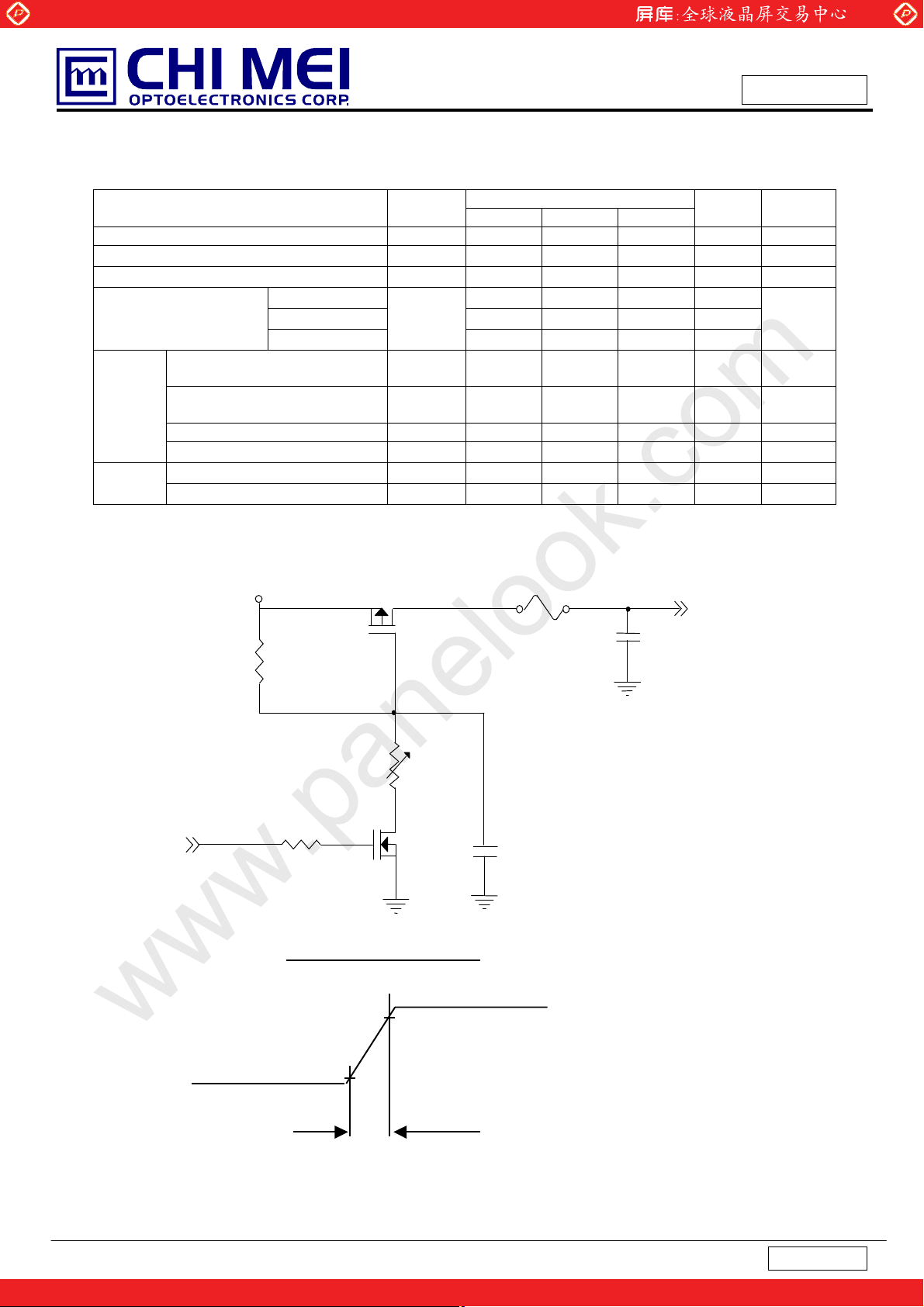

Note (3) The specified power supply current is under the conditions at Vcc = 12 V, Ta = 25 ± 2 ºC, fv = 60

Hz, whereas a power dissipation check pattern below is displayed.

a. White Pattern

Active Area

c. Vertical Stripe Pattern

b. Black Pattern

Active Area

Active Area

R

R

B

R

B

R R

G

G

G

G

B

B

B

B

R

R

R

G

G

G

G

B

B

B

B

R

R

8

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 9

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

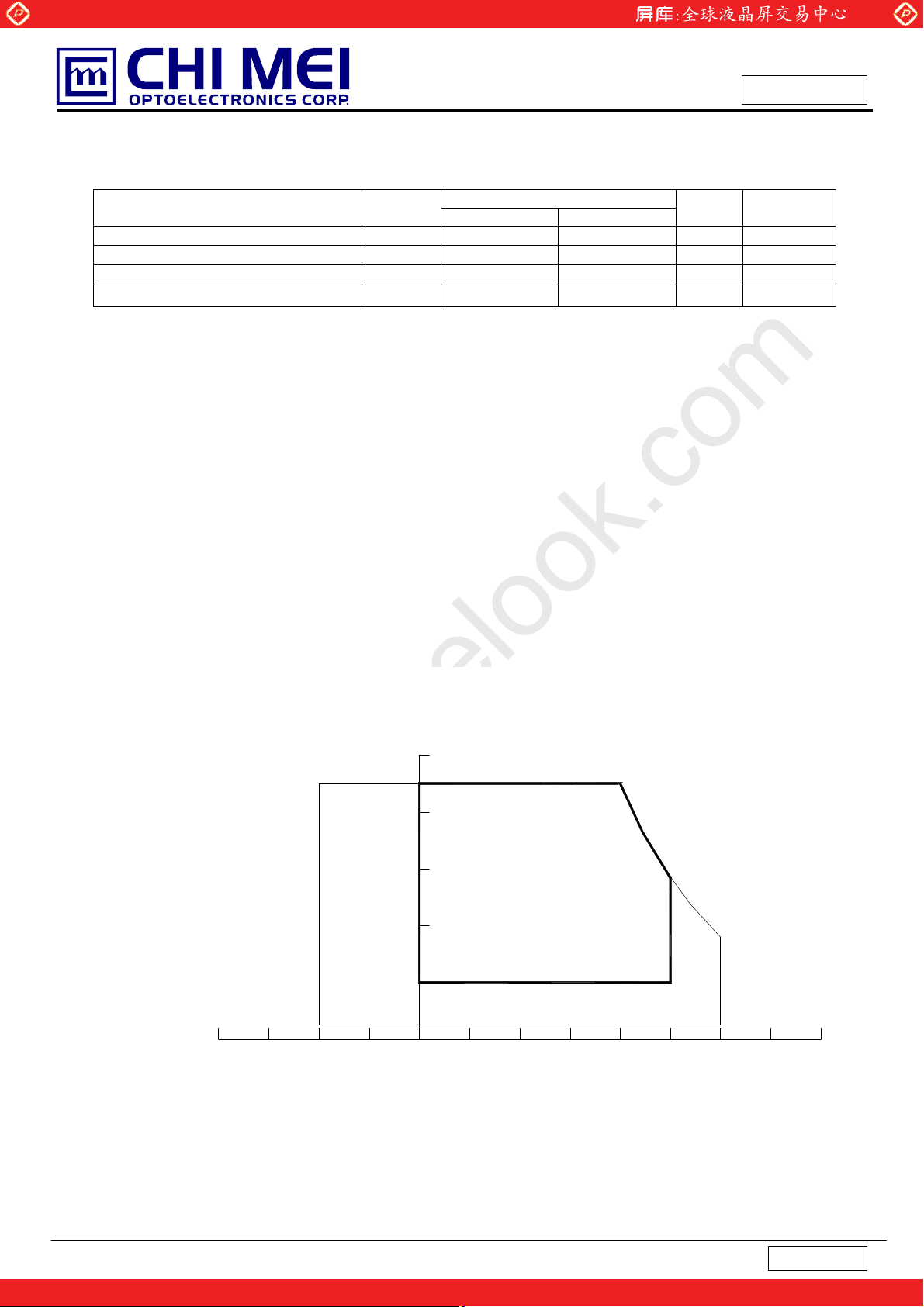

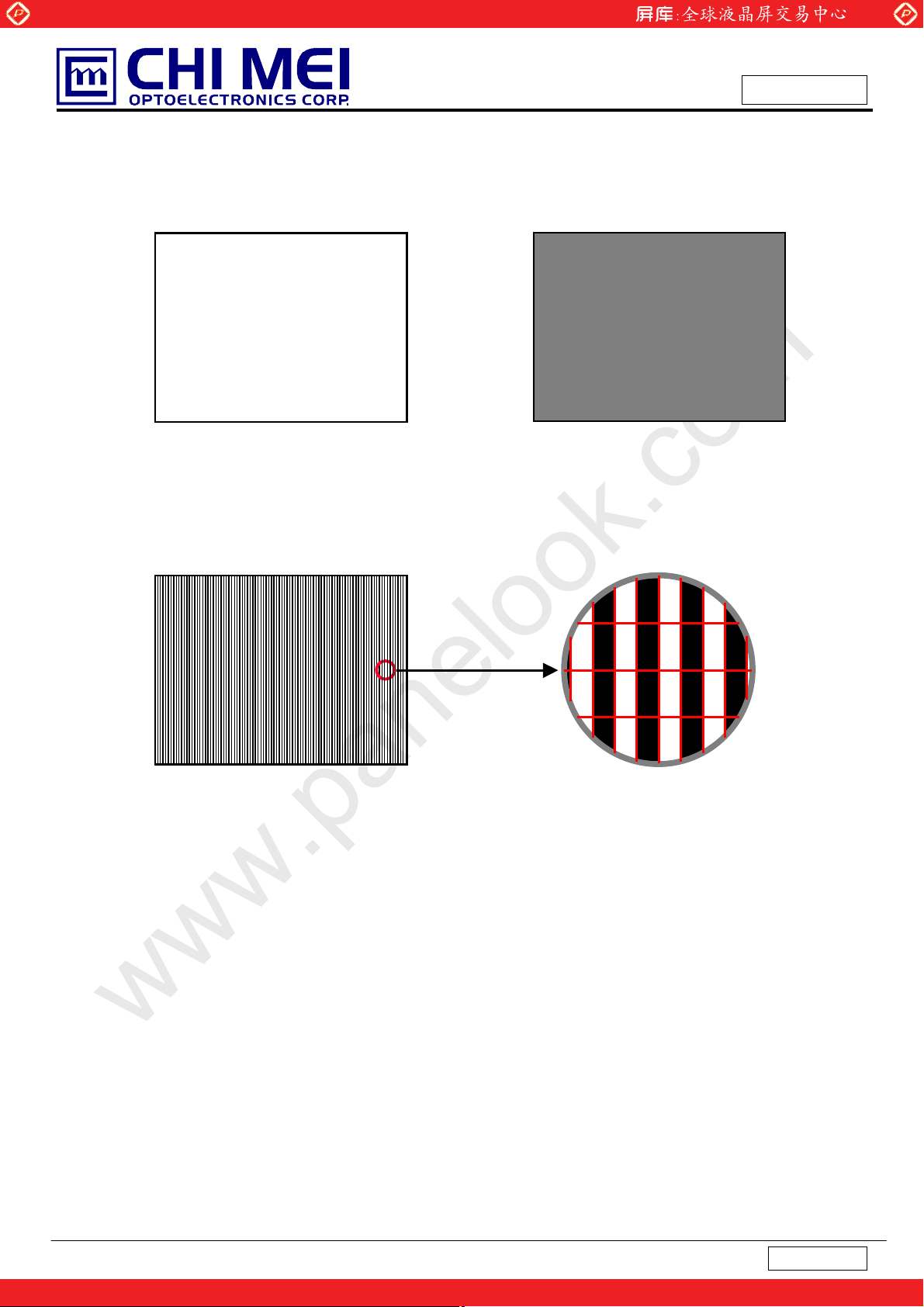

3.2 BACKLIGHT UNIT

3.2.1 CCFL (Cold Cathode Fluorescent Lamp) CHARACTERISTICS (

Parameter Symbol

Min. Typ. Max.

Lamp Input Voltage VL - 1360 - V

Lamp Current IL (8.5) (9.0) (9.5) mA

Lamp Turn On Voltage VS

- -

- Operating Frequency FL 40 - 80 KHz

Lamp Life Time LBL 50,000 - - Hrs (4)

Value

2270

1890

3.2.2 INVERTER CHARACTERISTICS (

Parameter Symbol

Total Power Consumption P

Power Supply Voltage VBL 22.8 24 25.2 VDC

Power Supply Current IBL - 2.08 2.25 A Non Dimming

Input Ripple Noise - - - 912 mV

Oscillating Frequency FW 55 58 61 kHz (3)

Dimming frequency FB 150 160 170 Hz

Minimum Duty Ratio D

Note (1) Lamp current is measured by utilizing AC current probe and its value is average by measuring

- (50) (54) W (5), (6), IL =9.0mA

255

10 20 - % (7)

MIN

Ta = 25 ± 2 ºC)

Val ue

Min. Typ. Max.

Ta = 25 ± 2 ºC)

Unit Note

RMS

RMS

V

Ta = 0 ºC (2)

RMS

Ta = 25 ºC (2)

V

RMS

(1)

Unit Note

VBL=22.8V

P-P

master and slave board.

Note (2) The lamp starting voltage V

should be applied to the lamp for more than 1 second after startup.

S

Otherwise the lamp may not be turned on.

Note (3) The lamp frequency may produce interference with horizontal synchronous frequency of the

display input signals, and it may result in line flow on the display. In order to avoid interference, the

lamp frequency should be detached from the horizontal synchronous frequency and its harmonics

as far as possible.

Note (4) The life time of a lamp is defined as when the brightness is larger than 50% of its original value

and the effective discharge length is longer than 80% of its original length (Effective discharge

length is defined as an area that has equal to or more than 70% brightness compared to the

brightness at the center point of lamp.) as the time in which it continues to operate under the

condition at Ta = 25

Note (5) The power supply capacity should be higher than the total inverter power consumption P

2к and I

= 8.5~ 9.5mArms.

L

. Since

BL

the pulse width modulation (PWM) mode was applied for backlight dimming, the driving current

changed as PWM duty on and off. The transient response of power supply should be considered

for the changing loading when inverter dimming.

Note (6) The measurement condition of Max. value is based on 26" backlight unit under input voltage 24V,

average lamp current 9.3 mA and lighting 30 minutes later.

Note (7) 10% minimum duty ratio is only valid for electrical operation

9

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 10

Global LCD Panel Exchange Center

X

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

LCD Module

HV (Pink)

HV (White)

HV (Pink)

HV (White)

HV (Pink)

HV (White)

HV (Pink)

HV (White)

A

A

A

A

A

A

A

A

Preliminary

1

2

1

2

Inverter

1

2

1

2

3.2.3 INVERTER INTERFACE CHARACTERISTICS

Parameter Symbol

On/Off Control Voltage

Voltage

Voltage

Status Signal

VBL Rising Time Tr1 Ё 30 Ё Ё ms

VBL Falling Time Tf1 Ё 30 Ё Ё ms

Control Signal Rising Time Tr Ё Ё Ё 100 ms

Control Signal Falling Time Tf Ё Ё Ё 100 ms

PWM Signal Rising Time T

PWM Signal Falling Time T

Input impedance RIN Ё 1 Ё Ё

PWM Delay Time T

BLON Delay Time

BLON Off Time T

ON

OFF

MA

MIN

HI 2.0

LO

LO

V

BLON

V

IPWM

V

EPWM

Status

PW MR

PW MF

PW M

Ton Ё 300 Ё Ё ms

T

on1

Ё 300 Ё Ё ms

off

Te st

Condition

Ё Ё Ё 50 us

Ё 100 Ё ms

Ё

Ё

Ё

Ё

Ё

Ё Ё Ё

Ё

Ё 300 ЁЁЁЁ Ё ms

ЁЁ

Val ue

Min. Typ. Max.

2.0

2.85 3.0 3.15 V Maximum duty ratioInternal PWM Control

Ё

Ё

0

0

0

Ё

0

Ё

Ё

Ё

5.0 V

0.8 V

Ё

5.0 V Duty onExternal PWM Control

0.8 V Duty off

0.8 V Abnormal

50 us

Unit Note

VMinimum duty ratio

M˖

10%-90%V

BL

Note (1) The Dimming signal should be valid before backlight turns on by BLON signal. It is inhibited to

change the internal/external PWM signal during backlight turn on period.

Note (2) The power sequence and control signal timing are shown in the following figure. For a certain

reason, the inverter has a possibility to be damaged with wrong power sequence and control

signal timing.

10

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 11

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Note (3) While system is turned ON or OFF, the power sequences must follow as below descriptions:

Turn ON sequence: VBL

Turn OFF sequence: BLOFF

Ш

PWM signal Ш BLON

Ш

PWM signal Ш VBL

Tr1

BL

V

V

V

V

BLON

EPWM

IPWM

0

0

0

0

9

%/

2.0V

0.8V

3.3V

9

2.0V

0.8V

Ton

T

%/

Backlight on duration

Tr

Ext. Dimming Function

T

PWMR

PWM

Floating

T

Ton1

Tf

PWMF

Floating

Int. Dimming Function

Preliminary

Tf1

9

%/

9

Toff

%/

V

W

External

PWM

Period

External

PWM Duty

100%

Minimun

Duty

11

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 12

Global LCD Panel Exchange Center

q

(+/

)

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

4. BLOCK DIAGRAM

4.1 TFT LCD MODULE

RX0(+/-)

RX1(+/-)

RX2(+/-)

RX3(+/-)

RXCLK

-

Vcc

GND

or e

uivalent

INPUT CONNECTOR

(FCI,10041195-001)

CN1

VBL

GND

ERR

BLON

I_PWM

E_PWM

CN1: CI0114M1HR0-LA (CviLux)

TIMING

CONTROLLER

DC/DC CONVERTER &

REFERENCE VOLTAGE

INVERTER CONNECTOR

or equivalent

SCAN DRIVER IC

CN2-CN5:

CP042CP1MR0-LF (CviLux)

or equivalent

Preliminary

TFT LCD PANEL

(1366x3x768)

DATA DRIVER IC

BACKLIGHT

UNIT

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

12

Version 1.0

www.panelook.com

Page 13

Global LCD Panel Exchange Center

y

(3)

(2)

k

k

(2)

(2)

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

5. INTERFACE PIN CONNECTION

5.1 TFT LCD MODULE

CN1 Connector Pin Assignment

Pin No. S

1 VCC Power supply: +12V

2 VCC Power supply: +12V

3 VCC Power supply: +12V

4 VCC Power supply: +12V

5 GND Ground

6 GND Ground

7 GND Ground

8 GND Ground

9 SELLVDS Select LVDS data format

10 NC No connection

11 GND Ground

12 RX0- Negative transmission data of pixel 0

13 RX0+ Positive transmission data of pixel 0

14 GND Ground

15 RX1- Negative transmission data of pixel 1

16 RX1+ Positive transmission data of pixel 1

17 GND Ground

18 RX2- Negative transmission data of pixel 2

19 RX2+ Positive transmission data of pixel 2

20 GND Ground

21 RXCLK- Negative of cloc

22 RXCLK+ Positive of cloc

23 GND Ground

24 RX3- Negative transmission data of pixel 3

25 RX3+ Positive transmission data of pixel 3

26 GND Ground

27 NC No connection

28 NC No connection

29 GND Ground

30 GND Ground

Note (1) Connector Part No.: FCI, 10041195-001 or compatible

mbol Description Note

Preliminary

Note (2) Reserved for internal use. Please leave it open.

Note (3) Ground or OPEN: Normal, High: JEIDA LVDS format

Please refer to 5.5 LVDS INTERFACE (Page 17)

13

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 14

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

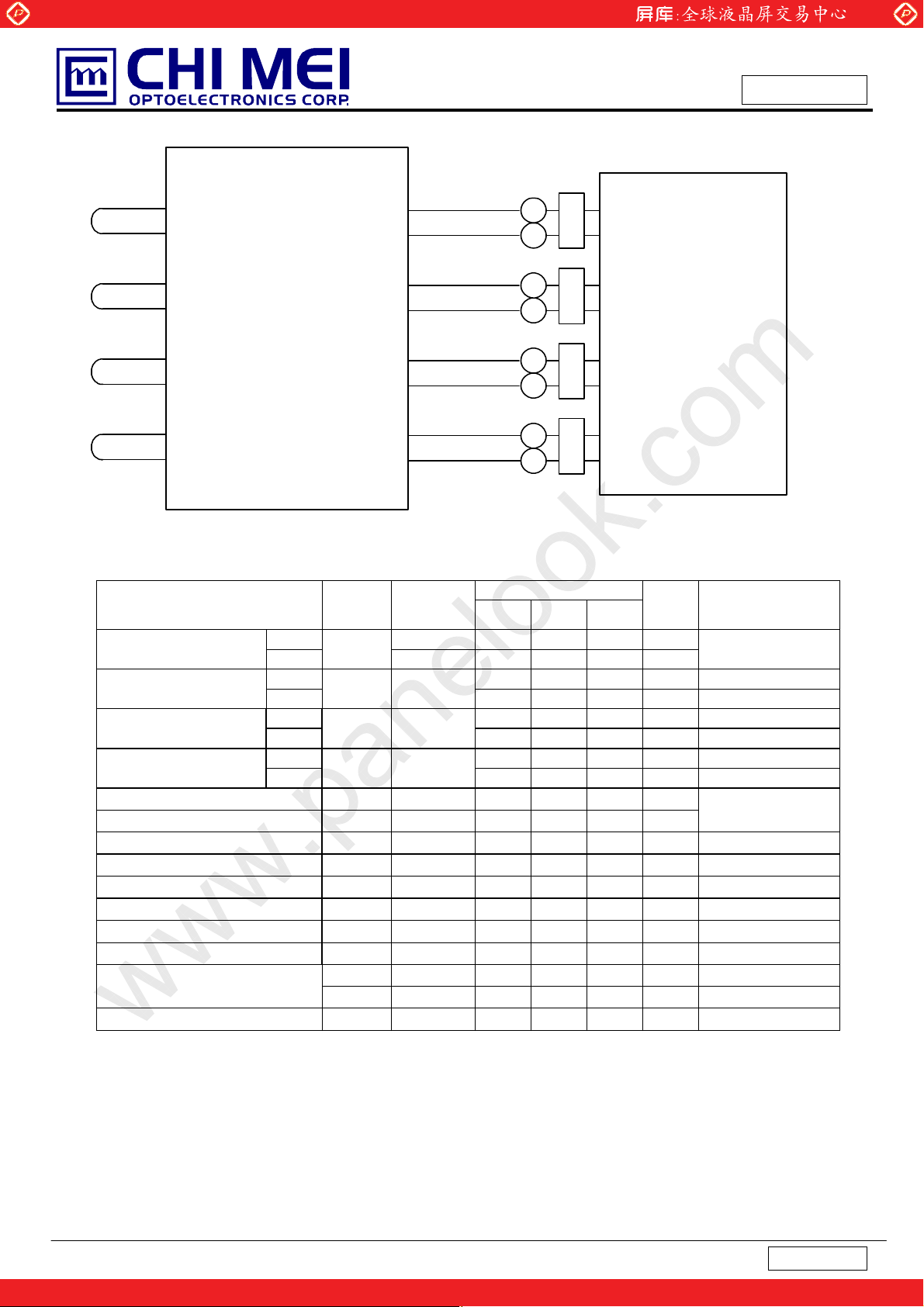

5.2 BACKLIGHT UNIT

The pin configuration for the housing and leader wire is shown in the table below.

Housing : 1.CP0404S0000(CviLux)

Pin No. Symbol Description

1 HV High Voltage Pink

2 HV High Voltage White

Note (1) The backlight interface housing for high voltage side is a model 1. CP0404S0000(CviLux) or

Equivalent.

4 Male Connectors

CP0404S0000(CviLux)

or Equi valent

Wire Color

1.HV(Pink,+)

2.HV(W hite,-)

1.HV(Pink,+)

Preliminary

2.HV(W hite,-)

1.HV(Pink,+)

2.HV(W hite,-)

1.HV(Pink,+)

2.HV(W hite,-)

14

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

5.3 INVERTER UNIT

CN1 : CI0114M1HR0-LA (CviLux) or equivalent.

Pin No. Symbol Description

1

2

3

4

5

6

7

8

9

10

11 ERR

12 BLON BL ON/OFF

13 I_PWM Internal PWM Control

14 E_PWM External PWM Control

Note (1) PIN 13:Intermal PWM Control (Use Pin 13): Pin 14 must open.

Note (2) PIN 14:External PWM Control (Use Pin 14): Pin 13 must open.

Note (3) Pin 13(I_PWM) and Pin 14(E_PWM) can’t open in same period.

VBL +24V Power input

GND Ground

Normal (GND)

Abnormal(Open collector)

Preliminary

CN2-CN5 : CP042CP1MR0-LF (CviLux) or equivalent.

Pin Name Description

1

2

CCFL HOT

CCFL HOT

CCFL High Voltage

CCFL High Voltage

15

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 16

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

5.4 BLOCK DIAGRAM OF INTERFACE

R0-R7

-

B0-B7

DE

Host

Graphics

Controller

LVDS Transmitter

THC63LVDM83A

(LVDF83A)

CN1

Rx0+

-

Rx1+

Rx1-

Rx2+

Rx2-

Rx3+

Rx3-

CLK+

CLK-

51

Ө

100pF

51

Ө

51

Ө

51

51

51

51

51

51

51

100pF

Ө

Ө

100pF

Ө

Ө

100pF

Ө

Ө

100pF

Ө

LVDS Receiver

THC63LVDF84A

RxOUT

Preliminary

R0-R7

G0-G7

B0-B7

DE

DCLK

Timing

Controller

R0~R7 : Pixel R Data

G0~G7 : Pixel G Data

B0~B7 : Pixel B Data

DE : Data Enable Signal

Note (1) The system must have the transmitter to drive the module.

Note (2) LVDS cable impedance shall be 50 ohms per signal line or about 100 ohms per twist-pair line when it is

used differentially.

16

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

5.5 LVDS INTERFACE

SELLVDS = L or Open (VESA)

Preliminary

SELLVDS = H (JEIDA)

R0~R7: Pixel R Data (7; MSB, 0; LSB)

G0~G7: Pixel G Data (7; MSB, 0; LSB)

B0~B7: Pixel B Data (7; MSB, 0; LSB)

DE : Data enable signal

Notes(1) RSVD(reserved)pins on the transmitter shall be “H” or “L”.

17

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 18

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

5.6 COLOR DATA INPUT ASSIGNMENT

The brightness of each primary color (red, green and blue) is based on the 8-bit gray scale data input for

the color. The higher the binary input, the brighter the color. The table below provides the assignment of

color versus data input.

Data Signal

Color

R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

0

Black

Red

Green

Basic

Colors

Gray

Scale

Of

Red

Gray

Scale

Of

Green

Gray

Scale

Of

Blue

Note (1) 0: Low Level Voltage, 1: High Level Voltage

Blue

Cyan

Magenta

Yellow

White

Red(0) / Dark

Red(1)

Red(2)

:

:

Red(253)

Red(254)

Red(255)

Green(0) / Dark

Green(1)

Green(2)

:

:

Green(253)

Green(254)

Green(255)

Blue(0) / Dark

Blue(1)

Blue(2)

:

:

Blue(253)

Blue(254)

Blue(255)

0

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

Red Green Blue

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

1

0

1

1

1

1

0

0

0

0

0

1

1

1

1

1

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1

1

1

1

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

1

1

0

0

1

1

1

1

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

0

1

1

0

:

:

0

1

1

0

1

1

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

1

1

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

1

1

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

1

0

0

:

:

:

:

:

:

:

:

:

:

1

0

1

1

0

1

1

1

1

1

1

1

18

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 19

Global LCD Panel Exchange Center

g

y

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

The input signal timing specifications are shown as the following table and timing diagram.

nal Item Symbol Min. Typ. Max. Unit Note

Si

Frequenc

LVDS Receiver Clock

LVDS Receiver Data

Vertical Active Display Term

Horizontal Active Display Term

Note (1) Since this module is operated in DE only mode, Hsync and Vsync input signals should be set to

Input cycle to

cycle jitter

Setup Time Tlvsu 600

Hold Time Tlvhd 600

Frame Rate

Total Tv

Display Tvd

Blank Tvb 1038 120 Th Tota l T h

Display Thd

Blank Thb 76194 570 Tc -

1/Tc 60 76 82 MH

Trcl

Fr

5

Fr

6

Ё

47 50 53 Hz

57 60 63 Hz

778

768

1442

1366

Ё

Ё Ё

Ё Ё

806 888 Th Tv=Tvd+Tvb

768 768 Th -

1560 1936 Tc Th=Thd+Thb

1366 1366 Tc -

200 ps

ps

ps

Z

low logic level. Otherwise, this module would operate abnormally.

INPUT SIGNAL TIMING DIAGRAM

DE

DCLK

DE

T

h

Tvd

Tv

Tvb

Thd

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

DATA

Valid Display Data (1366 clocks)

19

Version 1.0

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

RXCLK+/-

RXn+/-

Tlvsu

Tlvhd

1T

14

LVDS RECEIVER INTERFACE TIMING DIAGRAM

Tc

3T

14

5T

14

7T

14

9T

14

11T

14

13T

14

Preliminary

20

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 21

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

6.2 POWER ON/OFF SEQUENCE

To prevent a latch-up or DC operation of LCD module, the power on/off sequence should be as the diagram

below.

0.9V

3

T1

CC

0.1V

T4

Power Off

8

T

cc

CC

0.1V

0.9V

CC

T

2

T

0.5

ЉЉЉЉ

ЉЉЉЉ

0

0

ЉЉЉЉ

1s

T

1

ЉЉЉЉ

T

2

ЉЉЉЉ

T

3

ЉЉЉЉ

ЉЉЉЉ

T4

0V

10ms

50ms

50ms

LVDS Signals

0V

Power On

VALI D

0

ЉЉЉЉ

T

7

ЉЉЉЉ

ЉЉЉЉ

T2

T

8

ЉЉЉЉ

T3

T7

0

Option Signals

(SELLVDS)

Backlight (Recommended)

500ms

100ms

ЉЉЉЉ

ЉЉЉЉ

T5

T

6

50%

5

T

50%

T

6

Power ON/OFF Sequence

Note (1) The supply voltage of the external system for the module input should follow the definition of Vcc.

Note (2) Apply the lamp voltage within the LCD operation range. When the backlight turns on before the LCD

operation or the LCD turns off before the backlight turns off, the display may momentarily become

abnormal screen.

Note (3) In case of Vcc is in off level, please keep the level of input signals on the low or high impedance. If

T2<0,that maybe cause electrical overstress failure.

Note (4) T4 should be measured after the module has been fully discharged between power off and on period.

Note (5) Interface signal shall not be kept at high impedance when the power is on.

21

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 22

Global LCD Panel Exchange Center

y

(

)

(

)

)

(

)

(

)

(4)

)

(7)

k

(4)%(5)

(

)

y

(

)

(

)

y

(

)

(

)

y

(

)

(

)

y

(

)

(68)

(72)

(80)

(88)

(80)

(88)

(80)

(88)

(80)

(88)

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

Item Symbol Value Unit

Ambient Temperature Ta

Ambient Humidity Ha

Supply Voltage VCC 12.0 V

Input Signal According to typical value in "3. ELECTRICAL CHARACTERISTICS"

Lamp Current IL

Oscillating Frequency (Inverter) FW

Vertical Frame Rate

Fr 60 Hz

25±2

50±10

9.0mA ± 0.5

58 ± 3

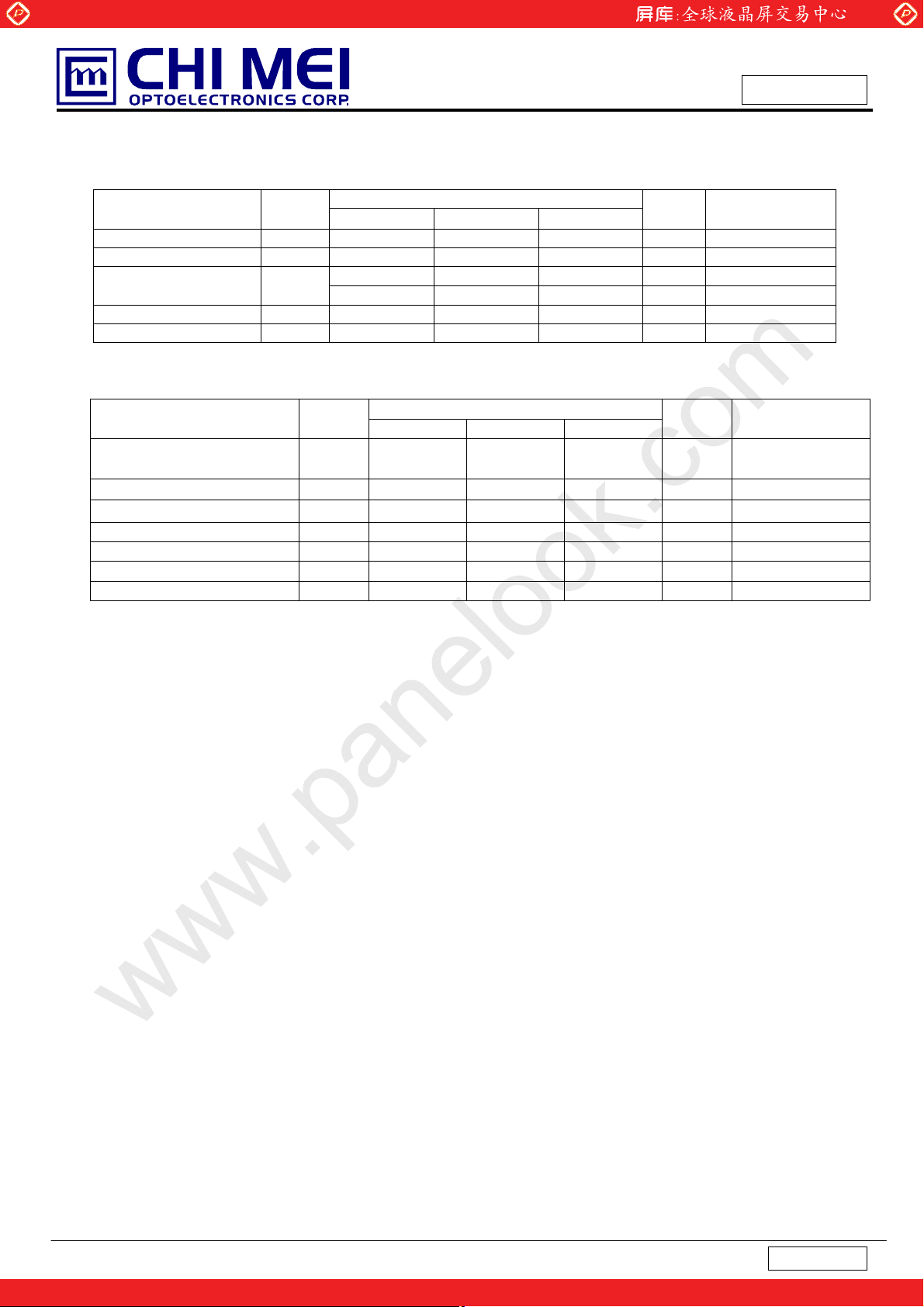

7.2 OPTICAL SPECIFICATIONS

The relative measurement methods of optical characteristics are shown in 7.2. The following items should

be measured under the test conditions described in 7.1 and stable environment shown in Note (6).

Item S

Contrast Ratio CR

mbol Condition Min. Typ. Max. Unit Note

2000

3000

--(2

o

C

%RH

mA

KHz

Response Time Gray to gray

Center Luminance of White L

White Variation

Cross Tal

Color

Chromaticity

Viewing

Angle

Red

Green

Blue

White

Color Gamut CG

Horizontal

Vertical

δW

CT - -

Rx

R

Gx

G

Bx

B

Wx

W

θ

+

-

θ

θ

+

θ

-

θ

=0°, θY =0°

x

Viewing angle at

normal direction.

CR≥20

- (8.5) (14) ms (3)

350

Typ.

-0.03

450

--(1.3

0.646

0.334

0.273

0.596

0.143

0.068

0.280

0.290

-Cd/m

Typ.

+0.03

-%NTSC

2

-

-

-

-

-

-

-

-

Deg. (1)

(6)

22

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Note (1) Definition of Viewing Angle (θx, θy):

Viewing angles are measured by EZ-Contrast 160R (Eldim)

θX- = 90º

x-

6 o’clock

θ

y-

= 90º

y-

Normal

θx = θy = 0º

θy- θy+

θx−

θx+

y+

12 o’clock direction

θ

y+

= 90º

x+

θX+ = 90º

Preliminary

Note (2) Definition of Contrast Ratio (CR):

The contrast ratio can be calculated by the following expression.

Contrast Ratio (CR) = L255 / L0

L255: Luminance of gray level 255

L 0: Luminance of gray level 0

CR = CR (5),

CR (X) is corresponding to the Contrast Ratio of the point X at the figure in Note (7).

Note (3) Definition of Gray to Gray Switching Time :

Gray Level 255

100%

90%

Optical

Response

10%

0%

Gray to gray

switching time

Gray Level 0

Gray to gray

switching time

Gray Level 255

Time

The driving signal means the signal of luminance 0%, 20%, 40%, 60%, 80%, 100%.

Gray to gray average time means the average switching time of luminance 0%, 20%, 40%, 60%, 80%, 100%

to each other.

23

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 24

Global LCD Panel Exchange Center

(

)

(

)

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Note (4) Definition of Luminance of White (LC):

Measure the luminance of gray level 255 at center point and 5 points

LC = L (5)

L (X) is corresponding to the luminance of the point X at the figure in Note (7).

Note (5) Definition of Cross Talk (CT):

CT = | Y

– YA | / YA × 100 (%)

B

Where:

Y

= Luminance of measured location without gray level 0 pattern (cd/m2)

A

Y

= Luminance of measured location with gray level 0 pattern (cd/m2)

B

(0, 0)

Active Area

Y

(D/8,W/2)

A, L

Gray 128

Y

(D/2,7W/8)

A, D

Y

Y

D,W

A, U

A, R

(D/2,W /8)

(7D/8,W/2)

(D/4,W/4)

(D/8,W/2)

Y

B, L

Y

(D/2,7W/8)

B, D

0, 0

Active Area

Gray 0

Gray 128

Preliminary

Y

(D/2,W /8)

B, U

Y

(7D/8,W/2)

B, R

(3D/4,3W/4)

(D,W)

Note (6) Measurement Setup:

The LCD module should be stabilized at given temperature for 1 hour to avoid abrupt temperature

change during measuring. In order to stabilize the luminance, the measurement should be

executed after lighting Backlight for 1 hour in a windless room.

LCD Module

LCD Panel

Center of the Screen

Display Color Analyzer

(Minolta CA210)

Light Shield Room

(Ambient Luminance < 2 lux)

Note (7) Definition of White Variation (δW):

Measure the luminance of gray level 255 at 5 points

δW = Maximum [L (1), L (2), L (3), L (4), L (5)] / Minimum [L (1), L (2), L (3), L (4), L (5)]

24

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 25

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

W

W/4

W/2

3W /4

Vertical Line

Horizontal Line

D

D/4 D/2 3D/4

12

5

34

Active Area

X

: Test Point

X=1 to 5

25

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

8. DEFINITION OF LABELS

8.1 CMO MODULE LABEL

The barcode nameplate is pasted on each module as illustration, and its definitions are as following explanation.

V260B3 -L01 Rev. XX

CHI MEI

OPTOELECTRONICS

X X X X X X X Y M D L N N N N

E207943

MADE IN TAIWAN

GEMN

RoHS

CHI MEI

OPTOELECTRONICS

V260B3 -L01 Rev. XX

X X X X X X X Y M D L N N N N

E207943

MADE IN TAIWAN

MADE IN CHINA

LEOO(or CAPG or C ANO)

RoHS

(a) Model Name: V260B3-L01

(b) Revision: Rev. XX, for example: A0, A1… B1, B2… or C1, C2…etc.

(c) Serial ID: X X

Serial ID includes the information as below:

Day: 1~9, A~Y, for 1

X X X X X Y M D L N N N N

Serial No.

Product Line

Year, Month, Date

CMO Internal Use

CMO Internal Use

Revision

CMO Internal Use

(a) Manufactured Date: Year: 1~9, for 2001~2009

Month: 1~9, A~C, for Jan. ~ Dec.

st

to 31st, exclude I ,O, and U.

(b) Revision Code: Cover all the change

(c) Serial No.: Manufacturing sequence of product

(d) Product Line: 1 -> Line1, 2 -> Line 2, …etc.

26

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

9. PACKAGING

9.1 PACKING SPECIFICATIONS

(1) 7 LCD TV modules / 1 Box

(2) Box dimensions : 713(L)x429(W)x453(H)mm

(3) Weight : approximately 30.48 Kg ( 7 modules per box)

9.2 PACKING METHOD

Figures 10-1 and 10-2 are the packing method

LCD TV Module

Anti-Static Bag

Module*7pcs

Cushion(Bottom)

Cushion(Top)

Preliminary

2

4

6

face to face

1

3

5

7

Carton

Carton Label

Figure.9-1 packing method

27

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Sea / Land Transportation

(40ft HQ Container)

Sea / Land Transportation

(40ft Container)

Preliminary

Air Transportation

Figure.9-2 Packing method

28

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

10. PRECAUTIONS

10.1 ASSEMBLY AND HANDLING PRECAUTIONS

(1) Do not apply rough force such as bending or twisting to the module during assembly.

(2) It is recommended to assemble or to install a module into the user’s system in clean working areas.

The dust and oil may cause electrical short or worsen the polarizer.

(3) Do not apply pressure or impulse to the module to prevent the damage of LCD panel and backlight.

(4) Always follow the correct power-on sequence when the LCD module is turned on. This can prevent the

damage and latch-up of the CMOS LSI chips.

(5) Do not plug in or pull out the I/F connector while the module is in operation.

(6) Do not disassemble the module.

(7) Use a soft dry cloth without chemicals for cleaning, because the surface of polarizer is very soft and

easily scratched.

(8) Moisture can easily penetrate into LCD module and may cause the damage during operation.

(9) High temperature or humidity may deteriorate the performance of LCD module. Please store LCD

modules in the specified storage conditions.

(10) When ambient temperature is lower than 10ºC, the display quality might be reduced. For example, the

response time will become slow, and the starting voltage of CCFL will be higher than that of room

temperature.

10.2 SAFETY PRECAUTIONS

(1) The startup voltage of a backlight is over 1000 Volts. It may cause an electrical shock while assembling

with the inverter. Do not disassemble the module or insert anything into the backlight unit.

(2) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth. In

case of contact with hands, skin or clothes, it has to be washed away thoroughly with soap.

(3) After the module’s end of life, it is not harmful in case of normal operation and storage.

10.3 STORAGE PRECAUTIONS

When storing modules as spares for a long time, the following precaution is necessary.

(1) Do not leave the module in high temperature, and high humidity for a long time.

It is highly recommended to store the module with temperature from 0 to 35

condensation.

(2) The module shall be stored in dark place. Do not store the TFT-LCD module in direct sunlight or fluorescent

кat normal humidity without

light.

29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 30

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

11. REGULATORY STANDARDS

11.1

SAFETY

Information Technology equipment

Audio/Video Apparatus

Regulatory Item Standard

UL UL 60950-1: 2003

cUL CAN/CSA C22.2 No.60950-1-03

CB IEC 60950-1:2001

UL

UL 60065: 2003

cUL CAN/CSA C22.2 No.60065-03

CB

IEC 60065:2001

Preliminary

30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 31

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

12. MECHANICAL CHARACTERISTICS

Preliminary

ڻႝηިҽ ԖϦљ

ڻႝηިҽ ԖϦљ

CHI MEI

CHI MEI

31

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 32

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

Preliminary

ڻႝηިҽԖϦљ

ڻႝηިҽԖϦљ

CHI MEI

CHI MEI

32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Page 33

Global LCD Panel Exchange Center

www.panelook.com

Issued Date: 15, Apr 2009

Model No.: V260B3 – L01

No.

Preliminary

ڻႝηިҽԖϦљ

ڻႝηިҽԖϦљ

CHI MEI

CHI MEI

33

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 1.0

www.panelook.com

Loading...

Loading...