CMA Dishmachines AHB, AHS, AHC, Scullery, B Owner's Manual

...

Owner’s Manual

Keep with machine for reference

MODELS AH/B/C/S

INSTALLATION & OPERATION

Rev 1.00 B

CMA DISHMACHINES

12700 KNOTT STREET

GARDEN GROVE, CALIFORNIA 92841

800-854-6417

FAX 714-895-2141

TABLE OF CONTENTS

MODEL AH/B/C/S.

1. SPECIFICATIONS ........................................................................................ 3

1.1 MODEL AH/C......................................................................................................................................3

1.2 MODELS B/B ENERGY SAVER ............................................................................................................4

1.3 AH, B AND C OPERATIONAL CYCLE...................................................................................................5

2. GETTING STARTED..................................................................................... 7

2.1. INTRODUCTION TO MODELS AH, B ,C&” S” SERIES...........................................................................7

2.2. RECEIVING AND INSTALLATION...........................................................................................................8

2.2.1. Electrical ....................................................................................................................................8

2.2.2. Plumbing.....................................................................................................................................8

2.2.3. Connecting the Scrap Accumulator and Drain...........................................................................9

2.2.4. Installer’s Checklist....................................................................................................................9

3. OPERATION............................................................................................... 10

3.1. INITIAL SETUP ...................................................................................................................................10

3.1.1. Check….....................................................................................................................................10

3.1.2. Filling the Machine...................................................................................................................10

3.1.3. Chemicals .................................................................................................................................10

3.1.4. Run a Cycle...............................................................................................................................10

3.2. GENERAL...........................................................................................................................................11

3.3. ADDENDUM FOR MACHINES INSTALLED IN THE CITY OFCHICAGO....................................................12

3.4. ELECTRICAL DIAGRAMS....................................................................................................................13

3.4.1. Models AH/ C & B....................................................................................................................13

3.4.2. Solid Bowl.................................................................................................................................14

1. Specifications

,

Electrical and plumbing connections must be made by a qualified service person who will comply with all available

Federal

State, and Local Health, Electrical, Plumbing and Safety codes

1.1 Model AH/C

WATER CONSUMPTION

USA METRIC

PER RACK 1.7 GAL. (6.45 L)

PER HOUR 74 GPH (280.1 LPH)

OPERATING CYCLE

WASH TIME-SEC. 45 45

RINSE TIME-SEC. 30 30

DWELL TIME-SEC. 15 15

TOTAL CYCLE 90 SEC.* 90 SEC.*

*Other cycle times are available

OPERATING CAPACITY

RACKS PER HOUR (NSF Rated) 40 40

WASH TANK CAPACITY 1.7 GAL. (6.45 L)

PUMP CAPACITY 52 GPM (197 LPM)

WATER REQUIREMENTS

REQUIRED MINIMUM TEMP. 120°F (49°C)

RECOMMENDED TEMP. 140°F (60°C)

WATER INLET ¾” 1.9cm

DRAIN CONNECTION 2” 5.1cm

DIMENSIONS

DEPTH 25 ¾” (65.4cm)

WIDTH 25 ¾” (65.4 cm)

HEIGHT 56-57” (142-144.8cm)

HEIGHT (SCULLERY) 66”-67” (168-170 cm)

MAX CLEARANCE FOR DISHES 17”

MAX CLEARANCE FOR DISHES (S) 27”

(43.18 cm)

(68,58”cm)

STANDARD TABLE HEIGHT 34” (86.36 cm)

STANDARD DISH RACKS 19 ¾” x 19 ¾” (50 x 50 cm)

ELECTRICAL RATING

VOLTS

(60-Hz)

115

AMPS

16

WASH PUMP MOTOR 1 HP

SHIPPING WEIGHT

APPROXIMATE 270# (122.5 kg)

APPROXIMATE (SCULLERY) 295# (133.8 kg)

MODEL AH, B & C INSTALLATION & OPERATION MANUAL Rev. 1.01 Page

3

Electrical and plumbing connections must be made by a qualified service person who will comply with all available

,

Federal

State, and Local Health, Electrical, Plumbing and Safety codes

1.2 Models B/B Energy Saver

USA METRIC

WATER CONSUMPTION

PER RACK 1.5/ .96 GAL. (5.7/ 3.63 L)

PER HOUR 118.4/ 76.8 GP H (448/291 LPH)

OPERATING CYCLE

WASH TIME-SEC. 45 45

RINSE TIME-SEC. 30 30

DWELL TIME-SEC. 15 15

TOTAL CYCLE 90 SEC.* 90 SEC.*

*Other cycle times are available

OPERATING CAPACITY

RACKS PER HOUR (NSF Rated) 80 80

WASH TANK CAPACITY 3.0 GAL. (11.4 L)

PUMP CAPACITY (two pumps) 104 GPM (393.68 LPM)

WATER REQUIREMENTS

REQUIRED MINIMUM TEMP. 120°F (49°C)

RECOMMENDED TEMP. 140°F (60°C)

WATER INLET ¾” 1.9cm

DRAIN CONNECTION 2” 5.1cm

DIMENSIONS

DEPTH 25 ¼” (64 cm)

WIDTH 44 ¼” (112 cm)

HEIGHT 55 ½”-56 ½” (141-143.5

HEIGHT (SCULLERY) 65-66” (165-168cm)

MAX CLEARANCE FOR DISHES

MAX CLEARANCE FOR DISHES

(S)

STANDARD TABLE HEIGHT 34” (86.36 cm)

STANDARD DISH RACKS 19 ¾” x 19 ¾” (50 x 50 cm)

ELECTRICAL RATING

WASH PUMP MOTORS (2) 1 HP each

cm)

17”

27"

VOLTS

(60-Hz)

115

(43.18 cm)

(68,58cm)

AMPS

30

SHIPPING WEIGHT

APPROXIMATE 352# (160 kg)

APPROXIMATE (SCULLERY) 377# (171 kg)

MODEL AH, B & C INSTALLATION & OPERATION MANUAL Rev. 1.01 Page

4

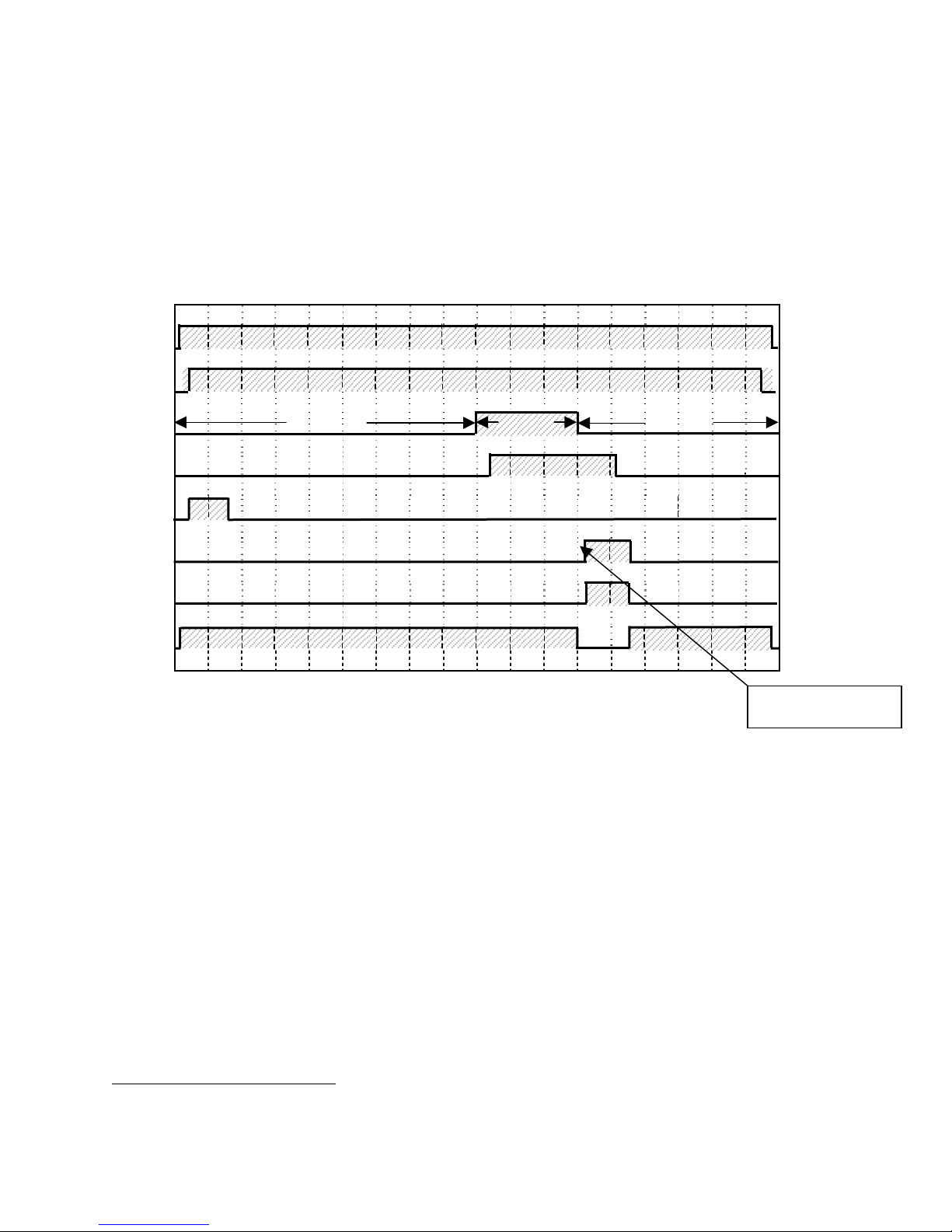

1.3 AH, B and C Operational Cycle*

g

r

W

g

The AH, B and C Operational Cycle have a total cycle time of 90 seconds. The Timing

Diagram and the steps listed below detail the individual functions that are executed during

each Operational Cycle.

Seconds: 0 10 20 30 40 50 60 70 80 90

Cam 1

Cam 2

Cam 3

Cam 4

Cam 5

Cam 6

Cam 7

Cam 8

ASH

DRAIN

RINSE

Start/Stop

Cycle Reset

Drain/Rack

Counter

Flush/Fill

Deter

ent

Sanitize

Rinse Aid

Pump Motor

1. With the machine powered up, closing the doors begins a cycle.

4sec. delay to prevent

chemical dama

a) When the door closes the timer assembly motor is energized through the normally

closed contact of the Start/Stop Relay.

b) Within a couple of seconds cams 1 and 2 close their respective switches. Cam

switch 1 (Start/Stop) maintains power to the timer assembly motor throughout the

90-second cycle. Cam switch 2 (Cycle Reset) energizes the Start/Stop Relay.

c) The Start/Stop Relay, once it is energized by cam switch 2, is held in by its own

normally open contact for as long as the doors remain closed.

2. Cam switch 8 controls the pump motor. The pump motor comes ON at the beginning

of the operational cycle and continues to run until the end of the drain function

(controlled by cam switch 3), at which time it turns off for about eight seconds allowing

time for the machine to refill enough to avoid running the pump dry before the pump

motor restarts and runs to the completion of the operational cycle.

*

“S” series same otherwise noted

e

MODEL AH, B & C INSTALLATION & OPERATION MANUAL Rev. 1.01 Page

5

Loading...

Loading...