Page 1

MODEL CMA-180

PARTS MANUAL

Rev 2.04

CMA DISHMACHINES

12700 KNOTT AVENUE

GARDEN GROVE, CALIFORNIA 92841

800-854-6417

FAX 714-895-2141

www.cmadishmachines.com

Page 2

TABLE OF CONTENTS

MODEL CMA-180

1. PARTS MANUAL ..........................................................................................3

1.1. EXPLODED VIEW DRAWINGS........................................................................................................... 3

1.1.1 Straight Frame System Assembly............................................................................................ 3

1.1.2 Corner Frame Assembly.......................................................................................................... 4

1.1.3 Drain System Assembly............................................................................................................5

1.1.4 Plumbing System Assembly..................................................................................................... 6

1.1.5 Wash Spray System................................................................................................................. 7

1.1.6 Final Rinse System.................................................................................................................. 8

1.1.7 Door Handle Assembly........................................................................................................... 9

1.1.8 Corner Door Handle Assembly ............................................................................................ 10

1.1.9 Pump System Assembly......................................................................................................... 11

1.1.10 Wash Tank Heater................................................................................................................12

1.1.11 Booster Heater...................................................................................................................... 13

1.1.12 Wiring Harnesses ................................................................................................................. 14

1.1.13 Control Box Assembly .......................................................................................................... 15

1.1.14 Unique Parts For CMA-180TS............................................................................................. 16

1.1.15 Unique Parts For CMA-180TC............................................................................................ 17

2. POWER SWITCH BULB REPLACEMENT INSTRUCTIONS......................18

3. 180 CONVERSION KIT – CORNER TO STRAIGHT #00617.18.................19

4. 180 CONVERSION KIT – STRAIGHT TO CORNER #00617.17.................20

Model CMA-180 Parts Manual Rev. 2.04 3

Page 3

1. Parts Manual

1.1. Exploded View Drawings

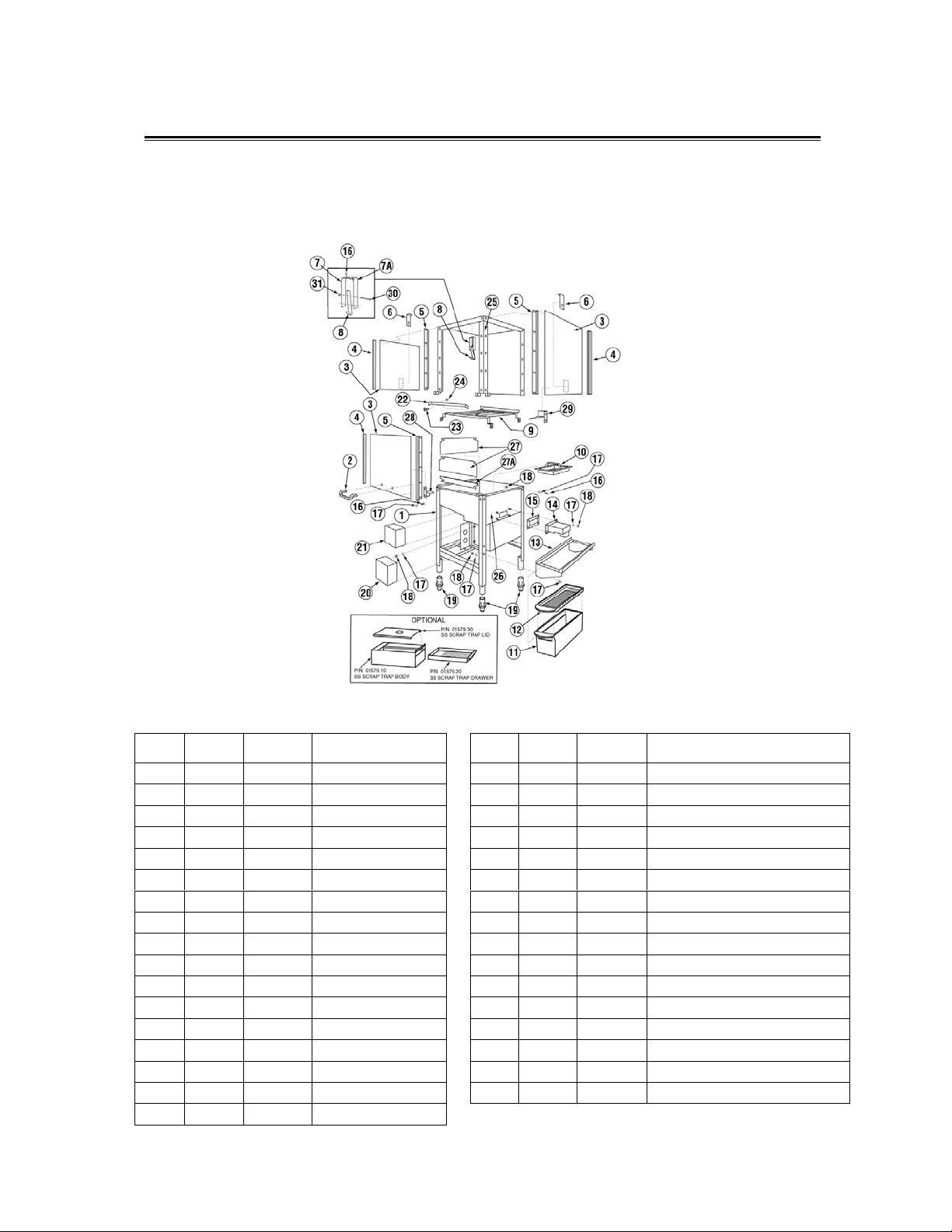

1.1.1 Straight Frame System Assembly

ITEM

NO.

1 1 17532.00 Stand 17 52 00924.00 ¼” SS Washer

2 1 00535.30 Front door Handle 18 26 00912.00 ¼”-20 Nylon Lock Nut

3 3 17506.00 Door 19 4 01310.00 Bullet Feet

4 6 00636.17 E Z Door Glide 20 1 17522.50 Wash Tank Heater Cover

5 6 17554.00 Door Guide 21 1 17522.00 Booster Heater Cover

6 2 17552.00 Door Stop 22 1 01505.16 Tray Track Rail

7 1 13915.00 Door Latch Bracket 23 2 00941.00 8/32” x 5/8” Pan Head Screw

7A 1 13915.06 Door Latch Bracket 24 2 03801.00 10/32” Lock Nut

8 1 13701.00 Open Door Latch 25 1 17530.00 Wrapper

9 1 01505.10 Tray Track 26 1 17531.00 Pan

10 2 17510.00 Strainer Basket 27 2 17506.60 Door Panel Splash Guard

11 1 01577.10 Scrap Tray Body 27A 1 17506.65 Door Service Splash Guard

12 1 01577.20 Scrap Trap Drawer 28 1 17506.21 Front Door Safety Bracket

13 1 17579.00 Scrap Trap Holder 29 1 17506.32 Right Door Safety Bracket

14 1 17511.00 Overflow 30 1 00960.00 8-32x1-1/2”pPanhead Screw

15 1 17402.00 Overflow Gasket 31 1 00927.00 8-32 Nylon Lock Nut

16 25 00906.00 ¼”-20 x 1/2” Hex Bolt

NO.

REQ’D

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

P/N DESCRIPTION

Page 4

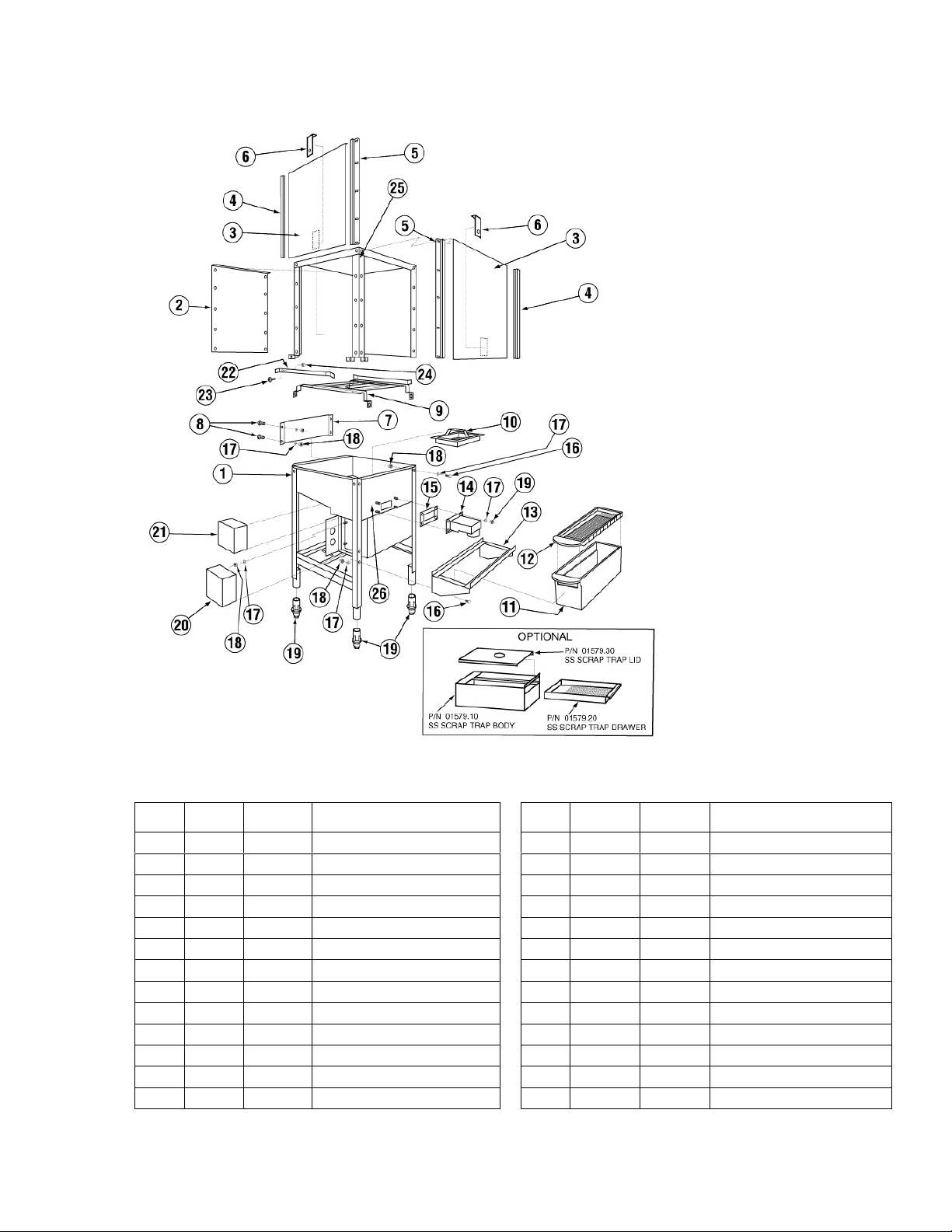

1.1.2 Corner Frame Assembly

ITEM

NO.

1 1 17532.00 Stand 14 1 17511.00 Overflow

2 1 17506.50 Door Panel Corner 15 1 17402.00 Overflow Gasket

3 2 17506.00 Door 16 24 00906.00 ¼”-20 x 1/2” Hex Head Bolt

4 4 00636.17 E Z Door Glide 17 56 00924.00 ¼” SS Washer

5 4 17554.00 Door Guide 18 30 00912.00 ¼”-20 Nylon Lock Nut

6 2 17552.00 Door Stop 19 4 01310.00 Bullet Feet

7 1 17507.10 Air Gap Baffle 20 1 07522.50 Wash Tank Heater Cover

8 4 00905.00 ¼” – 20 x ½ Truss Head Bolt 21 1 17522.00 Booster Heater Cover

9 1 01505.10 Tray Track 22 1 01505.16 Tray Track Rail

10 2 17510.00 Strainer Basket 23 2 00941.00 8/32” x 5/8” Pan Head Screw

11 1 01577.10 Scrap Trap Body 24 2 03801.00 10/32” Lock Nut

12 1 01577.20 Scrap Trap Drawer 25 1 17530.00 Wrapper

13 1 17579.00 Scrap Trap Holder 26 1 17531.00 Pan

Model CMA-180 Parts Manual Rev. 2.04 4

NO.

REQ’D

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

P/N DESCRIPTION

Page 5

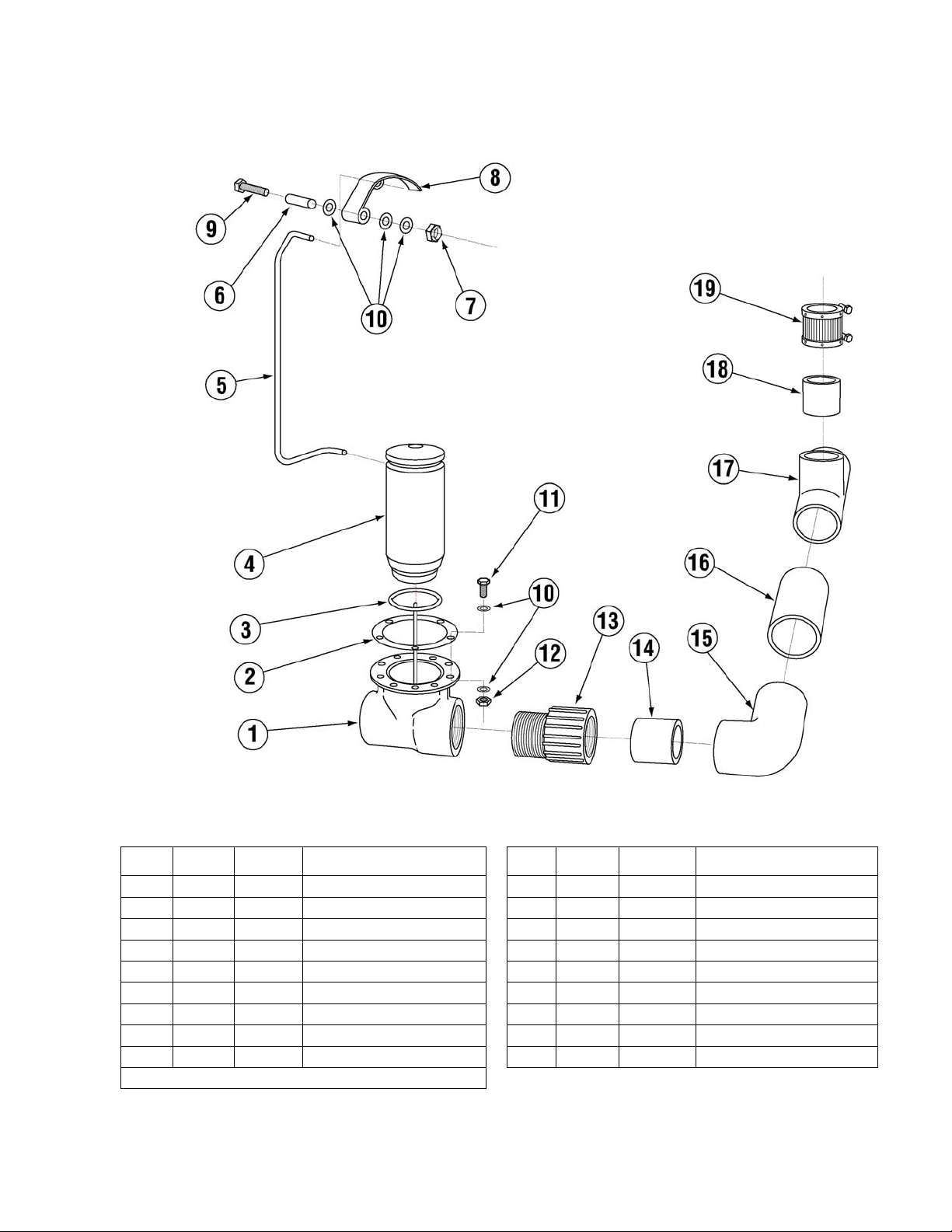

1.1.3 Drain System Assembly

ITEM

NO.

1 1 00113.17 Drain Tee Casting 11 6 00901.00 5/16 –18 x 1” Hex Head Bolt

2 1 00114.00 Drain Tee Gasket 12 6 13805.00 5/16-18 Nylon Lock Nut

3 1 00121.18 Drain Stopper “O” Ring 13 1 01313.00 2” PVC Slip x MIPT Adapter

*4 1 00121.17 Drain Stopper 14 1 05030.17 2” x 4” PVC Tubing

5 1 17581.00 Drain Linkage 15 1 01312.00 PVC Slip x Slip 90 Ell

6 1 17580.50 Drain Linkage Spacer 16 1 05030.27 2” x 6” PVC Tubing

7 1 00912.00 ¼-20 Nylon Lock Nut 17 1 01320.17 2” PVC Tee SxSxS

8 1 17580.00 Drain Lever 18 1 05030.10 2” x 3” PVC Tubing

9 1 00910.00 ¼”-20 x 1 ½” Hex Head Bolt 19 1 01315.17 2” No Hub

* #00121.17 includes #00121.18

NO.

REQ’D

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

P/N DESCRIPTION

Model CMA-180 Parts Manual Rev. 2.04 5

Page 6

1.1.4 Plumbing System Assembly

ITEM

NO.

1A -- 00421.51 Pan Head Screw SS 6-32 x 1/4” 11B -- 03603.20 Water Sol Valve Bonnet ½”

1B -- 00735.60 Vacuum Breaker Brass Bonnet

1C -- 00735.00 Vacuum Breaker Repair Kit ¾” 11D -- 00707.00 Water Sol Repair Kit JE ½”

1D -- 00739.50 Vacuum Breaker Cap

10 1 03603.15 Water Sol Valve 1/2” 220V JE-C

NO.

REQ’D

1 1 00710.50 Vacuum Breaker ¾” Watts 11A 1 00738.15 Water Sol Valve Coil 220V

2 3 13639.00 Nipple SS ¾” Close 13 1 00760.00 Coupling 5/8” x ½” MIP

3 3 13633.00 Elbow FXF Brass ¾” 14 1 13028.00 Ball Valve 3/4”

4 1 13613.00 Nipple ¾” x 5 ½” Brass 15 -- 13028.10 ¾” Ball Valve Repair Kit

5 2 13602.00 Jamb Nut Brass ¾” 16 2 13635.10 Nipple Brass 2/4” x 2”

6 1 13602.45 Pressure Regulator ½” 17 4 00742.00 Nipple ½” x 1 ½”

7 1 00716.10 Brass Tee ¾” x ¾” x ½” FXFXF 18 1 00743.10 Tee ½” FXFXF

8 1 13604.00 Bushing ½” x ¼” Brass 19 1 00780.00 Nipple ½” x 2 ½”

9 1 13605.00 Pressure Gauge 20 - 00705.05 Water Sol Valve ¾” 220V JE

20B - 00705.20 Water Sol Valve Bonnet ¾”

Model CMA-180 Parts Manual Rev. 2.04 6

P/N DESCRIPTION

¾”

Series

ITEM

NO.

11C -- 00786.00 Water Sol Plunger G Style

12 2 41030.10

20A - 00706.00 Water Sol Repair Kit JE ¾”

NO.

REQ’D

P/N DESCRIPTION

½” & ¾” with spring

Elbow 90° ½” FXF

Page 7

1.1.5 Wash Spray System

ITEM

NO.

1 1 00303.17 Manifold 9 8 00912.00 Nylon Lock Nut ¼” – 20

*2 1 00360.24 Lower Spray Base Assembly 10 4 00914.10 Hex Head Bolt ¼”-20”x5/8”

**3 1 00361.10 Upper Spray Base Assembly 11 2 00966.10 Hex Head SS Bolt 10-32

4 2 00304.17 Wash Spray Arm 12 4 00363.00 Spray Base Lock Pin

5 4 00308.50 Spray Arm End Plug SS 13 1 00302.00 Spray Base Gasket

6 2 00302.51 Spray Base “O” Ring 14 1 00225.00 Compression Gasket

7 4 00905.00 Truss Head Bolt ¼”-20”x1/2” 15 1 00221.20 1” Comp. Fit.x1”MIP SS

8 12 00924.00 SS Washer ¼” 16 1 00759.17 Base Quick Release W/Nipple

17 2 00341.00 Spray Arm Bearing

**P/N 00361.10 Includes Items 11,12 & 6

*P/N 00360.24 Includes Items 11, 12 & 6

Model CMA-180 Parts Manual Rev. 2.04 7

NO.

REQ’D

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

P/N DESCRIPTION

Page 8

1.1.6 Final Rinse System

ITEM

NO.

1A -- 03623.00 ½” Vacuum Brkr Kit- Watts 11 2 04306.00 Square Manifold Gasket

1B -- 03624.25 ½” Brass Bonnet 12 2 41030.10 ½” 90 deg Ell FxF (Rm)

1C -- 00739.50 ¾” Vacuum Breaker Cap SS 13 1 17401.00 Final Rinse Manifold

1D -- 00421.51 6-32 x ¼” SS Pan Head

3A 1 00436.20 Comp Fitting Nut 17 4 00308.17 Rinse Arm SS End Plug

9A 2 03232.00 1/8” Male Plug 24 1 13607.20 Comp Fitting Sleve

Model CMA-180 Parts Manual Rev. 2.04 8

NO.

REQ’D

1 1 03624.00 ½” Vacuum Breaker Watts 10 1 13306.17 Final Rinse Elbow Assy

2 1 05004.10 3/8” SS Tubing 15 1 00780.00 Nipple Bras ½” x 2 ½”

3 1 13607.10 3/8” Comp x ½” MIP Elbow 16 1 00743.10 ½” Tee F x F x F

4 2 04305.17 Bearing Gasket 18 2 00304.19 Rinse Arm w/Bearing

5 4 00760.00 5/8” Comp x ½” MIP Adapter 19 8 13304.55 SS Final Rinse Spray

6 1 13629.00 ½” S.S. Close Nipple

7 1 13629.82 Nipple SS ½” x 5 ½” 21 8 00926.00 SS Washer 5/16”

8 2 05007.17 5/8” OD .049 Wall 304 SS

9 1 13669.45 Mixing Chamber SS 23 1 13607.00 Water Inlet

P/N DESCRIPTION

Screw Phillips

Tubing

ITEM

NO.

14 2 13642.00 ½” Brass Plug

20 4 00926.00 SS Washer 5/16”

22 4 00912.00 ¼”-20 Nylon Lock Nut

NO.

REQ’D

P/N DESCRIPTION

Jet Ht

Page 9

1.1.7 Door Handle Assembly

ITEM

NO. REQ’D

NO.

1 1 00613.32 Door Handle 10 2 00900.00 Cotter Pin

2 1 01556.50 Right Door Handle Support

3 2 00603.07 Door Spring Extension Rod 12 8 00924.00 ¼” SS Washer

4 2 00602.00 Door Spring 13 8 00912.00 ¼”-20” Nylon Insert Lock Nut

5 2 17552.00 Door Stop 14 4 00610.00 Door Handle Spacer (Small)

6 2 01553.00 Door Handle Link 15 4 00611.00 Door Handle Spacer (Large)

7 2 00606.00 5/16”-18 x 7” Eyebolt 16 2 00607.04 Door Handle Grip

8 2 00913.00 5/16”-18” Nut 17 1 01555.50 Left Door Handle Support

9 2 00926.00 5/16” SS Washer 18 4 00903.00 ¼”-20 x 1 ¾” Hex Screw

P/N DESCRIPTION

1”

ITEM NO.

NO. REQ’D

11 4 00906.00 ¼”-20 x ½” Hex Head screw

P/N DESCRIPTION

Model CMA-180 Parts Manual Rev. 2.04 9

Page 10

1.1.8 Corner Door Handle Assembly

ITEM

NO. REQ’D

2A 1 00619.44 Door Handle Mntg Plate Short 15 4 00611.00 Door Handle Spacer (Lg)

10 1 00900.00 Cotter Pin 23 1 17507.10 Air Gap Corner

11 2 01552.00 Door Stop

12 16 00924.00 ¼” SS Washer

NO.

1 1 00613.04 Door Handle 13 14 00912.00 ¼-20 Nylon Lock Nut

2 1 00619.34 Door Handle Mntg Plate Long 14 4 00610.00 Door Handle Spacer (Sm)

3 1 00603.04 Door Spring Extension 16 2 00903.00 ¼-20 x 1 ¾” Hex Head Bolt

4 2 00602.00 Door Spring 17 9 00926.00 5/16” SS Washer

5 2 17506.00 Door 18 2 00910.00 ¼”-20 x 1/2” Hex Head Bolt

6 2 01553.00 Door Handle Link 19 2 00607.04 Door Handle Cap

7 1 00606.00 5/16”-18 x 7” Eyebolt 20 8 00920.00 5/16-18 x 3/4” Hex Head Bolt

8 9 00913.00 5/16”-18” Nut 21 1 00563.30 Limit Switch Door Bracket

9 10 00905.00 ¼”-20 x 1/2” Truss Head Bolt 22 1 17506.50 Door Panel Corner

P/N DESCRIPTION

ITEM NO.

NO. REQ’D

P/N DESCRIPTION

Model CMA-180 Parts Manual Rev. 2.04 10

Page 11

1.1.9 Pump System Assembly

ITEM

NO. REQ’D

3A 2 00975.00 3/8-16 x 1 ½” Stud 11 2 00924.00 ¼” SS Washer

NO.

1 1 00201.00 Pump Motor 1 HP 8 1 00208.00 Slip Joint Nut Gasket

2 1 03224.00 Small Pump Base 9 1 04204.00 Compression Nut (2.5)

3 6 00921.00 3/8”-16 x 34” Hex Head Bolt 10 2 00906.00 ¼-20 x 1/2” Hex Bolt

4 1 00206.00 Pump Seal Kit 12 2 00912.00 ¼”-20 Nylon Lock Nut

5 1 03226.00 Pump “O” Ring 13 2 00238.00 3/8” Male Plug

6 1 03222.05 Impeller *14 Assy. 00200.10 Pump Assy

7 1 04206.00 Pump Cover 15 1 00208.20 Slip Joint Nut Friction Ring

*P/N 00200.10 Includes Items 1,2,3,4,5 and 6

P/N DESCRIPTION

ITEM NO.

NO. REQ’D

P/N DESCRIPTION

Model CMA-180 Parts Manual Rev. 2.04 11

Page 12

1.1.10 Wash Tank Heater

ITEM

NO.

1A 1 13417.89 Heater Thermostat

Model CMA-180 Parts Manual Rev. 2.04 12

NO.

REQ’D

1 1 13417.65 Wash Tank Heater 5KW 3PH

1 13417.64 Wash Tank Heater 7KW 3PH

2 1 13463.10 Liquid Level Switch

3 1 13463.50 Liquid Level Switch Shield

4 1 17523.51 Hi-Limit Switch - Wash 250 Degrees

5 1 13477.20 7/8” Probe Hole Plug

6 1 13417.45 Wash Tank Heater Gasket

P/N DESCRIPTION

Page 13

1.1.11 Booster Heater

ITEM

NO.

**4 1 13417.67 Immersion Heater 12KW 3PH

4A 1 13417.89 Thermostat 12KW Heater

*6 1 17520.00 Booster Heater Shield*

*For Straight Through Applications Only.

**Includes Gasket #13417.47

Model CMA-180 Parts Manual Rev. 2.04 13

NO.

REQ’D

1 1 17550.00 Booster Tank

2 6 13805.00 Nylon Lock Nut 5/6”-18

3 6 00926.00 Washer SS 5/16”

5 1 17523.51 Hi-Limit Switch-Booster 250 degrees

7 1 13417.47 Booster Heater Gasket

8 1 17560.00 Complete Assembly

P/N DESCRIPTION

Page 14

1.1.12 Wiring Harnesses

ITEM

NO. REQ’D

NO.

1 1 17514.00 Harness (Without Booster)

2 1 17514.17 Booster Wiring Harness

3 -- 00414.17 Harness (Complete)

P/N DESCRIPTION

Model CMA-180 Parts Manual Rev. 2.04 14

Page 15

1.1.13 Control Box Assembly

ITEM

NO.

17A 2 17400.04 30 Amp Terminal Block-Red 30 1 13003.50 Heater Contactor 40 Amp

17B 3 17400.03 60 Amp Terminal Block-Black 31 1 00562.60 Door Roller Switch Connector

17C 4 17400.02 85 Amp Terminal Block-Natural 32 1 00562.00 Door Roller Switch

17D 2 17400.08 30 Amp Terminal Block-Blue 33 1 13426.50 Ground Block

NO.

REQ’D

1 1 17503.00 Control Box 17E 2 17400.09 30 Amp Terminal Block-Natural

2 2 00470.10 Toggle Switch Rubber Boot 17F 1 17400.07 60 Amp Terminal Block-Green

3* 1 00409.17 Timer 60 Seconds (4 Cam) 18 1 03408.55 Counter Face Mount 220V

4 1 00631.05 Ice Cube Relay 220V 19 4 00911.00 Pan Head Screw 8-32 x 1/2”

5 6 Ft. 00400.85 Conduit ¾” Sealtite 20 4 00927.00 Lock Nut 8-32

6 6 Ft. 00400.10 Conduit ½” Sealtite 21 1 00421.90 Power Switch

7 2 Ft. 00400.00 Conduit 3/8” Sealtite 22 1 00449.50 Keyless Lock

8 1 00401.85 St-3/4” Straight Connector 23 1 00421.26

9 1 00401.10 St-1/2” Straight Connector 24 1 00404.85 Motor Contactor 208/240V 20A

10 1 00401.00 St-3/8” Straight Connector 25 6 13825.00 Pan Head Screw 8-31 x 1”

11 1 00475.00 Delimer Switch DPDT 15A 26 6 04806.00 #10 Brass Washer

12 1 03470.00 Toggle Switch Momentary (Screw Terminal) 27 2 17503.17 Control Box Sponge Long

13 8 03801.00 Nylon Lock Nut 10-32 27A 2 17503.18 Control Box Sponge Short

14 1 17400.06 Mountain Din Rail 28 1 13003.17 Contactor 60A 3 Pole 220V

15 1 13403.26 Fuse 3A/250V Slow Blow 29 1 03202.00 Thermometer “Wash”

16 2 00941.00 Pan Head Screw 10 -32 x 5/8” 29A 1 03202.00 Thermometer “Rinse”

17 1 17400.17 Terminal Block Assembly 29B -- 03202.00 Thermometer Bracket

* (Optional Timer 2 min.) 34 1 00421.78 Illuminated Plug

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

P/N DESCRIPTION

Rocker Switch Hole Plug

Model CMA-180 Parts Manual Rev. 2.04 15

Page 16

1.1.14 Unique Parts For CMA-180TS

ITEM

NO.

Model CMA-180 Parts Manual Rev. 2.04 16

NO.

REQ’D

1 6 00636.27 Door Guide Material 9 1 17401.20 Final Rinse Manifold

2 3 17506.20 Scullery Door 10 1 00221.20 1”Comp. Fitx1MIP SS

3 6 17554.20 Scullery Door Guide 11 1 00303.27 Manifold

4 1 17530.20 Scullery Wrapper 12 1 00212.50 1-1/2”x1-1/4”Adapter

5 1 00613.22 Door Handle S 13 1 00204.00 Pump Cover Large

6 2 01553.20 Door Handle Link S 14 1 00203.05 Impeller 4-1/2”

7 2 00603.53 Door Spring Extension Rod 15 1 00202.00 Pump Base

8 2 05007.27 Booster Water Line

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

P/N DESCRIPTION

Page 17

1.1.15 Unique Parts For CMA-180TC

ITEM

NO.

NO.

REQ’D

1 1 17506.20 Door Panel Scullery Corner 9 2 05007.27 Booster Water Line

2 6 00636.27 Door Guide Material 11 1 17401.20 Final Rinse Manifold

3 2 17506.20 Scullery Door 13 1 00221.20 1”Comp. Fitx1MIP SS

4 4 17554.20 Scullery Door Guide 12 1 00303.27 Manifold

5 1 17530.20 Scullery Wrapper 13 1 00212.50 1-1/2”x1-1/4”Adapter

6 1 00563.60 Limit Switch Door Bracket 14 1 00204.00 Pump Cover Large

7 2 01553.20 Door Handle Link S 15 1 00203.05 Impeller 4-1/2”

8 1 00613.34 Door Handle S Corner 16 1 00202.00 Pump Base

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

P/N DESCRIPTION

Model CMA-180 Parts Manual Rev. 2.04 17

Page 18

2. Power Switch Bulb Replacement Instructions

NOTE: For Old Style Machines ONLY -- Manufactured prior to May 2002

TO REPLACE BULB

1. Using a 5mm-screw driver dismount the light module from the actuator as shown in

illustration 1 & 2.

2. Replace the burnt bulb with a new one P/N 17421.10 by twisting the bulb 90 degrees.

3. Mount the light module by snapping it onto the actuator as shown in illustration 3.

Model CMA-180 Parts Manual Rev. 2.04 18

Page 19

r

r

f

3. 180 Conversion Kit – Corner to Straight #00617.18

INSTRUCTIONS:

1.

Open dishmachine doors to their highest position so that there is

little spring resistance on the door handle. Remove hardware

holding the door handle to the door linkage. Save all the washers

and spacers. With the door handle in “UP” position, lift spring

and remove from extension rod. Remove the nut attaching the

eyebolt and save all hardware.

2. To remove the door handle, simply unscrew the four bolts holding

the door handle mounting plates and slide the complete assembly

up and off of the cabinet. Use the bolts, nuts and washers to plug

the holes in the back of the cabinet.

3. Remove door panel & hardware from left side of machine, and

install door guides from kit. Remove front door and relocate to

left side of machine. The service door will be used to seal off this

side of machine. Relocate tray track guide to front service doo

side of tray track.

4. Using provided nuts, bolts and washers; mount the left and right

door handle supports on the back of the cabinet. Insert the

eyebolts into the brackets on the back of the dishmachine stand

and screw the nuts on just enough to hold them in place. Hook

both door springs and door spring extension rods on to the doo

handle and secure them with the washers and cotter pins. Then

simply rest the door handle on the door handle supports. (You

may have to lift the door handle to reach the handle supports.)

5. Swing the door handle downwards to reach the door linkages;

and using the two provided bolts and existing washers and

spacers, attach the door linkages to the door handle. Adjust the

tension in the spring by tightening the nuts under the eyebolt

bracket so that the doors can slide up and down freely. Mount

the provided door handle grips on the ends of the door handle.

6. Eyebolt adjustment nuts should be adjusted to the point the doors

begin to lift from a closed position. Both eyebolts should be

adjusted the same. SEE “Illustration #1” for the proper location o

all door handle hardware for CMA 180-S.

7. “Illustration #2” shows CMA 180-S and CMA 180-C door ha ndle

assembly.

ILLUSTRATION #2

Back

View

ILLUSTRATION #1

ITEM NO.

NO. REQ’D

1 2 00636.17 EZ Glide Door Guide

2 2 00603.07 Door Spring Extension Rod

3 1 00606.00 5/16-18 x 7” Eyebolt

4 1 00613.17 Door Handle

5 2 00913.00 5/16”-18 SS Nut

6 1 01555.50 L.H. Door Handle Support

7 1 01556.50 R.H. Door Handle Support

8 2 00607.04 Door Handle Grip

9 4 00924.00 ¼” SS Washer

10 2 00900.00 Cotter Pin

11 1 17506.00 Service Door

11A 1 00535.30 Door Handle

12 1 13915.00 Door Latch Bracket

12A 1 13915.06 Latch Bracket with Nut

13 1 13701.00 Open Door Latch

14 2 17554.00 Door Glide

15 4 00912.00 ¼” 20 Nylon Lock Nut

16 2 17506.60 Door Splashguard-Straight

17 1 17506.65 Service Door Splashguard-S

18 4 00610.00 Spacer Small

19 4 00962.00 ¼”-20 x 1 SS Hex Head Bolt

20 2 1222.50 Tank Plug

P/N DESCRIPTION

Model CMA-180 Parts Manual Rev. 2.04 19

Page 20

r

r

t

r

r

f

r

4. 180 Conversion Kit – Straight to Corner #00617.17

INSTRUCTIONS:

1. Open dishmachine door to its highest position so that there is

little spring resistance on the door handle. Remove hardware

that holds the door handle to the door linkage. Save all the

washers and spacers. Swing the door handle towards the

back of the dishmachine and dismount it from the door handle

support brackets. Remove the two nuts attaching the eyebolts

and save the door springs.

2. Remove the two (2) door-handle support brackets on the back

of the cabinet and plug the four holes with original hardware.

Remove front door and replace with left door. Remove doo

guides on left side of machine and attaché item No. 9 doo

panel-cover. The left door will now be at the front of the

machine. Remove and relocate service door splashguard to

left side of machine. Remove door latch for service door. The

door latch is not needed on the CMA 180-C.

3. With left door facing the front, door panel on the left, and

service door splashguard in place, we are now ready to install

the door handle.

4. Using provided door handle, door handle mounting plates,

5/16” bolts, nuts and washers; install the door handle as shown

in “Illustration #1”. Match the mounting plate holes to the

cabinet holes and insert all bolts to ensure that the door handle

and mounting plates are aligned. Then secure the mounting

plate with nuts and washers.

Note: You may install one of the mounting plates first, then inser

the door handle pivot post in and mount the other mounting plate

last.

5. Attach the provided extension rod to the back of the doo

handle. Attach one eyebolt to the frame with existing

hardware, along with two springs together. Pivot the doo

handle, positioning handle straight up. You may now connect

loop of 2

forward and down and attach to the door links.

6. Adjust the nut on the eyebolt until the doors be gin to lift then

back off two turns. See “Illustration #2” for proper location o

all door handle hardware included on CMA 180C.

7. “Illustration #3” shows CMA 180-S and CMA 180-C “Doo

Handle Assembly”.

ILLUSTRATION #1

Back View

nd

spring to the door extension rod. Pull handles

ILLUSTRATION #2

ITEM NO.

NO. REQ’D

1 1 00613.04 Door Handle

2 1 00619.34 Door Hdl. Mtng. Plate-Long

2A 1 00619.44 Door Hdl. Mtng. Plate-Short

3 1 00603.04 Door Spring Extension

4 9 00913.00 5/16” – 18” Nut

5 9 00926.00 5/16” SS washer

6 1 00900.00 Cotter Pin

7 2 00607.04 Door Handle Grip

8 8 00920.00 5/16”-18 x ¾” Hex Head Bolt

9 1 17506.50 Door Panel-Cover

10 1 00563.20 Roller Switch Bracket

11 1 17507.10 Air Gap Baffle CMA 180C

ILLUSTRATION #3

Back View

P/N DESCRIPTION

Note: Door handle mounting plates come in two sizes.

Longer is mounted on back-right side.

Model CMA-180 Parts Manual Rev. 2.04 20

Loading...

Loading...