Clrwtr SENTROL Application Notes

SENTROL

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Application Notes

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

ACOUSTIC GLASSBREAK SENSORS

Sentrol has added a number of new ShatterPro™ Acoustic Glassbreak Sensors to

its product line: Sensors that combine high detection rates with high immunity to

false alarms.

ShatterPro

ShatterPro

reliability, flexibility and ease of use. They offer a 25 foot radius range for extented

glassbreak detection. Using patented Pattern Recognition Technology

ShatterPro

of framed glass breaks. It does this by “listening” for the unique sound of glass

breaking at numerous points across the entire frequency spectrum, not just one or

two points.

ShatterPro

24 Hours a day.

Our new ShatterPro

motion-sensitive glassbreak

sensor, was introduced by

Sentrol in February 1995. It is

an acoustic glassbreak sensor

combined with a passive

infrared motion detector (PIR)

for the purpose of detecting

break-ins through glass while

eliminating occupantgenerated false alarms.

Choose the right sensor.

Glassbreak sensors are an important part of an effective perimeter detection

system. An important part of your job is choosing the right sensor for a particular

application or environment. To make it easier, Sentrol offers you a variety of

choices for virtually any glassbreak application. The product comparison chart

below can help you make the decision.

™

II: The Premier Technology.

™

II acoustic glassbreak sensors give you a potent combination of range,

™

™

is designed to eliminate common false alarms and improve detection

™

Plus:

™

Plus, a

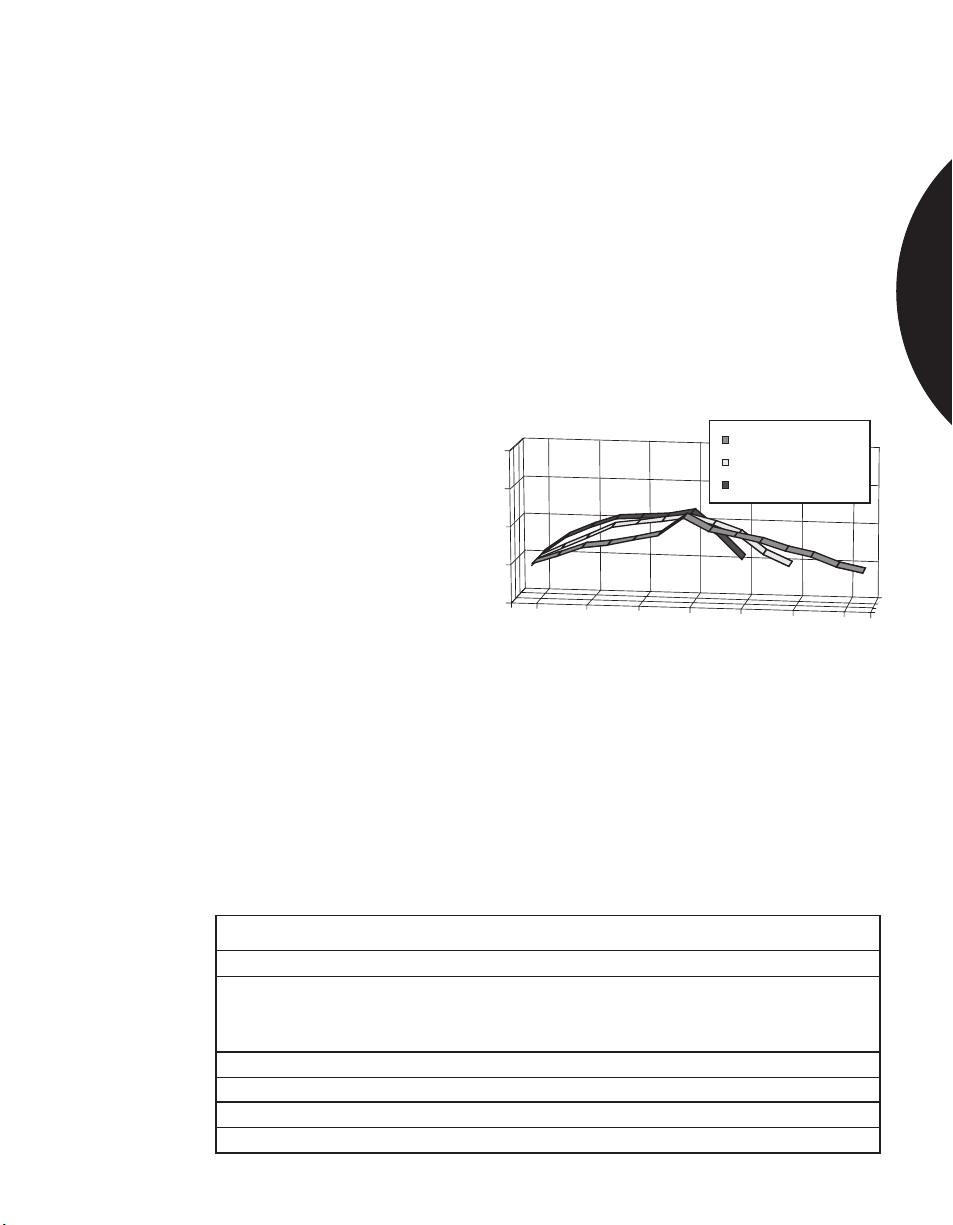

Amplitude

Frequency

, the

Glass Breaking

Pots & Pans Clanging

Doors Slamming

Pattern Recognition Technology™ is designed to eliminate

common false alarm sources and improve detection by

processing the pattern and timing relationships at points

across the entire frequency spectrum.

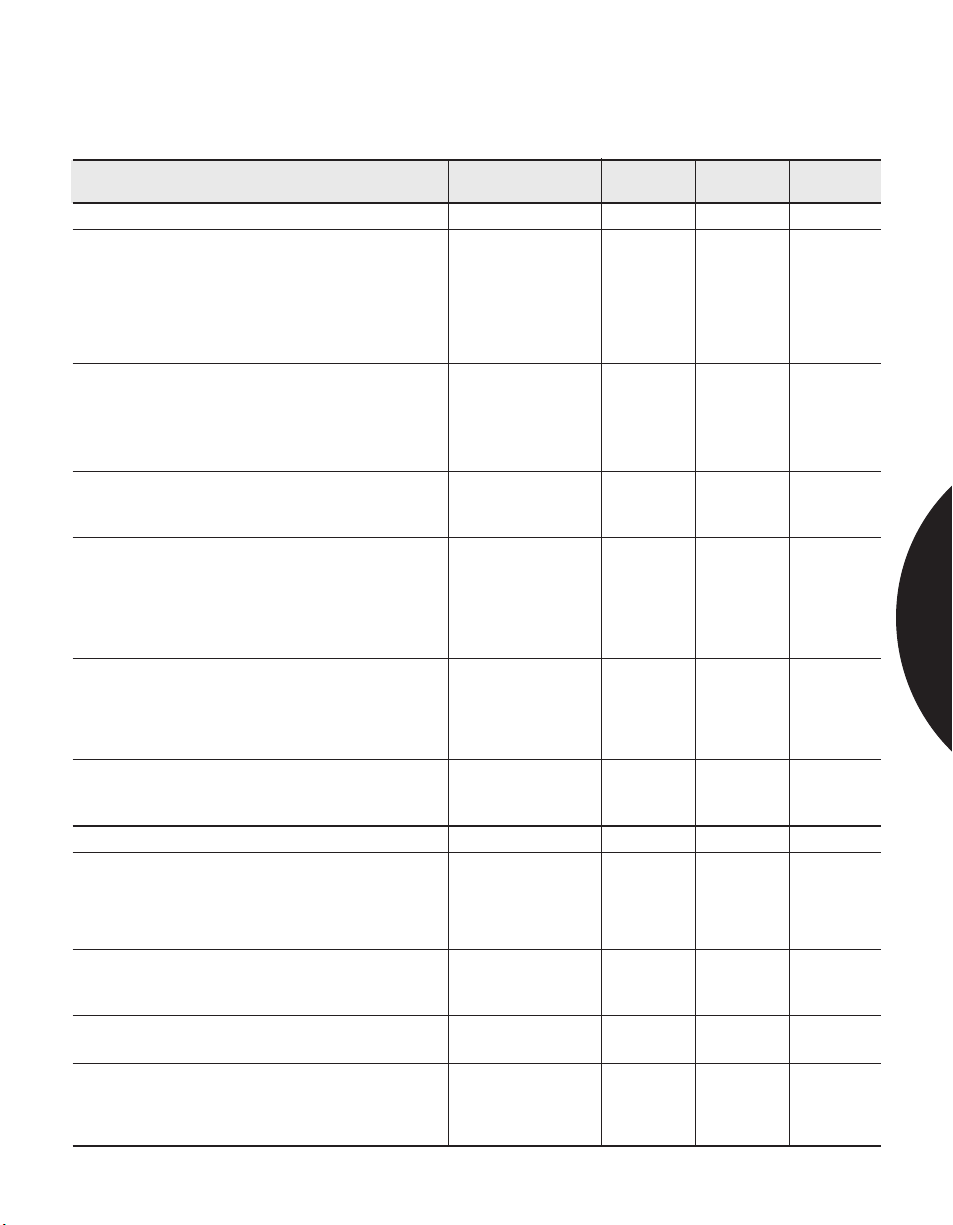

GLASSBREAK SENSORS

Choose the ShatterPro that’s right for you

Model Range Auto test End-user PRT* Occupied area 24-hour application/

ShatterPro II

5810A 25’ • • • •

5820A 25’ • • • •

5825 25’ • • • •

5845 Wireless 25’ • • • •

ShatterPro I

5800 Series 18’ • •

ShatterPro Plus

5885 Series 12’-15’ • • • • •

*Pattern Recognition Technology

to window verification perimeter loop Built in PIR sensor

1.2

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

GLASSBREAK SHOCK SENSORS

Millions of Sentrol shock sensors installed around the world give testimony to our

product reliability. We’ve added some new products to give you more choices at

installation time and more ways to increase your sales.

Reliable, flexible shock sensors.

Breaking glass produces specific shock frequencies which travel through glass and

window frames. When shock sensors “feel” the wave generated by breaking glass,

they signal an alarm. These sensors mount directly on the glass or the frame and

give you a product virtually immune to false alarms. That means they can operate

on windows with heavy drapes or shutters. Shock sensors also provide a visual

deterrent to intruders helping to prevent break-in attempts.

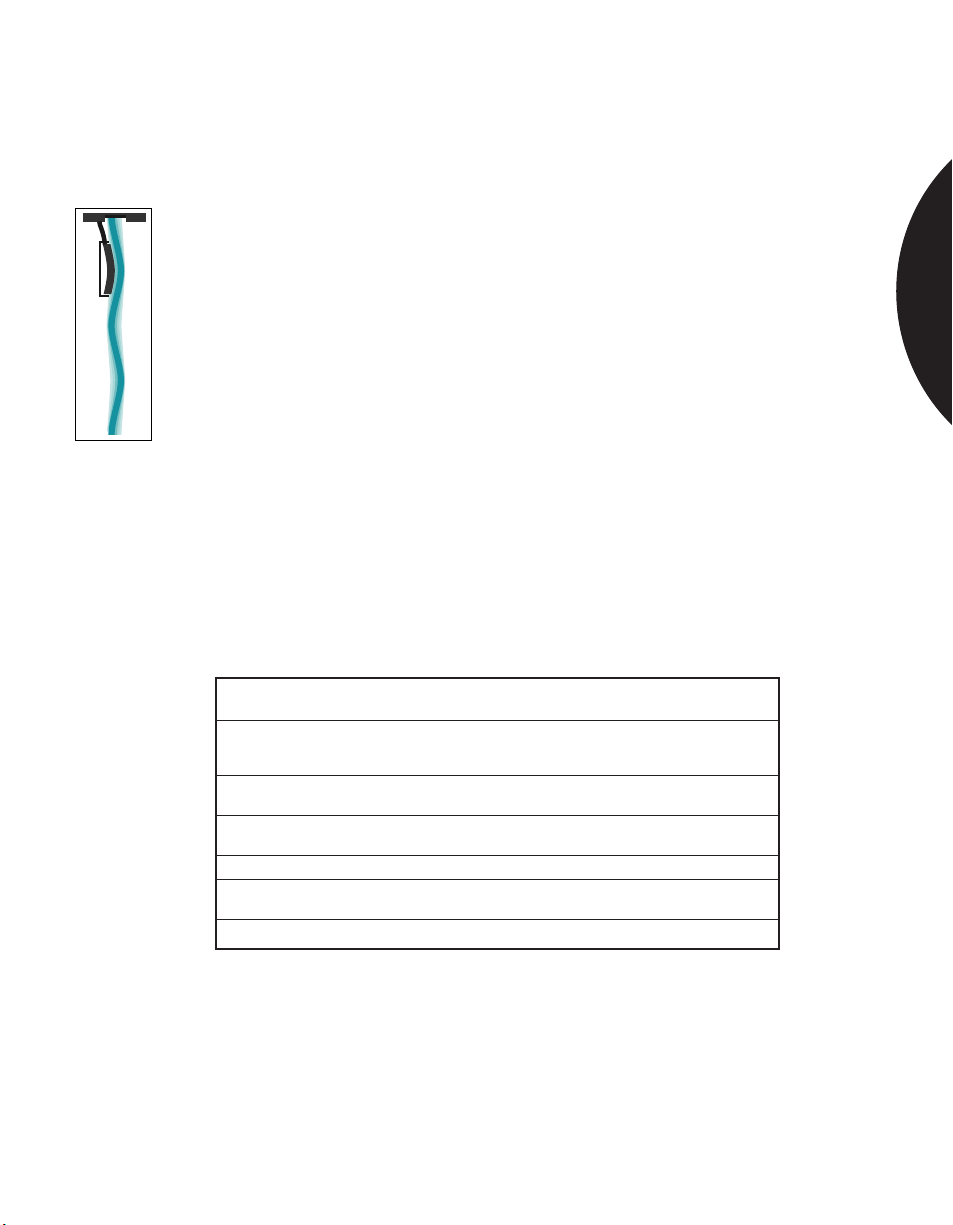

Most of Sentrol’s shock sensors are solid-state, with no mechanical parts to wear

out or fail. We incorporate a piezo transducer specifically tuned to the shock

Sentrol shock

sensors use a piezo

transducer

specifically tuned to

the shock frequency

of glass breaking.

frequency of glass breaking, providing both excellent detection and false alarm

immunity.

Choose the right sensor.

To choose the right shock sensor for a particular application or environment,

see the product comparison chart below.

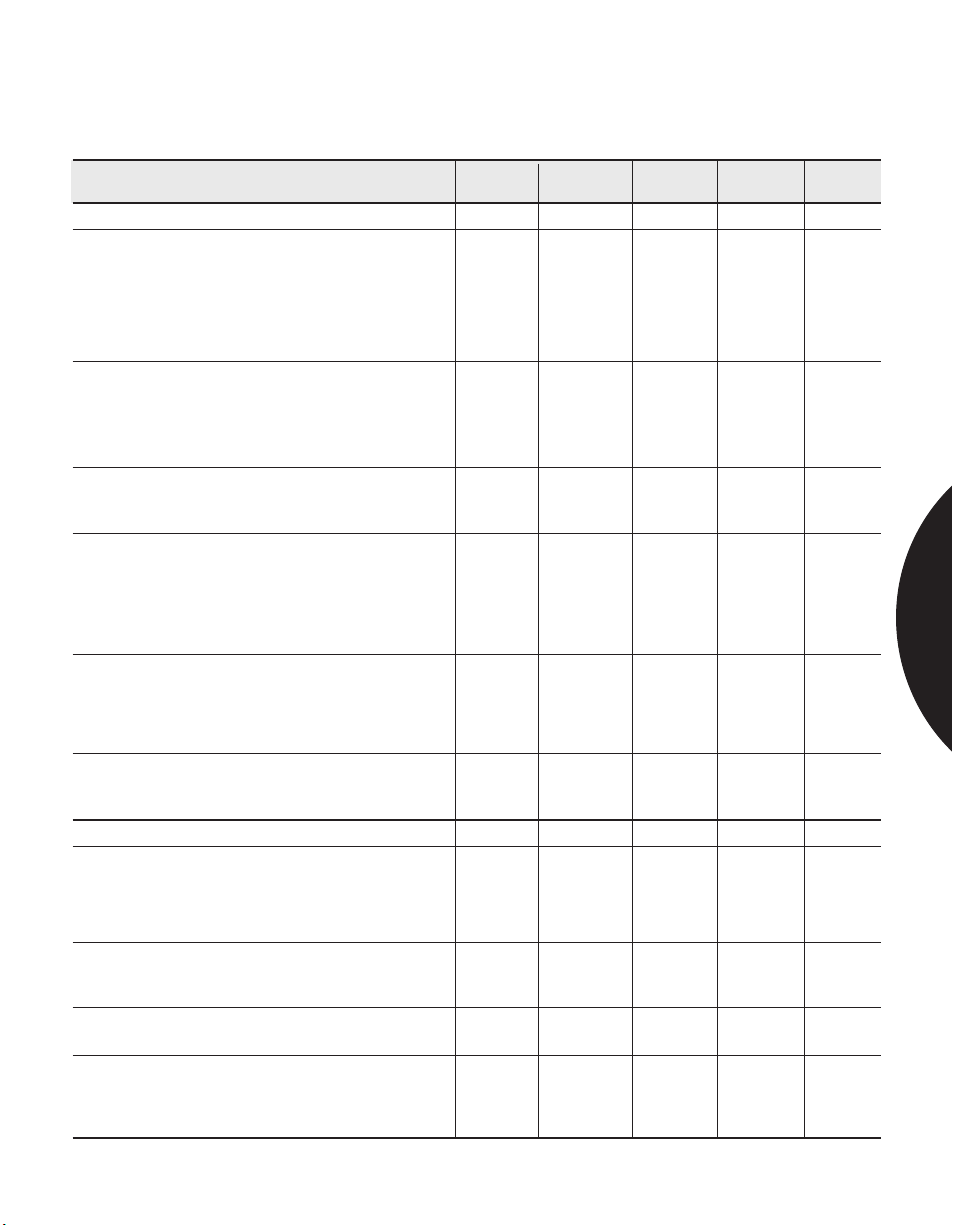

Choose the Shock Sensor that’s right for you.

GLASSBREAK SENSORS

Shock Sensors

Model Coverage Mounting Powered Indicating Reed

5115/20 7’ Glass Self No No

5125 10’ Glass Self Yes No

5135 20’ Glass Wired Yes No

5414 10’ Glass or Frame Self Yes No

5415A 10’ Glass or Frame Self Yes Yes

5425 10’ Glass or Frame Wired Yes No

5428 10’ Glass or Frame Wired Yes Yes

Specialty Shock Sensors

GS600 Varies Glass, Frame, Wired Yes Yes

5422 2’x4’x1’ Metal Enclosure Wired Yes No

Site LED Switch

Wall, or Roof

1.3

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

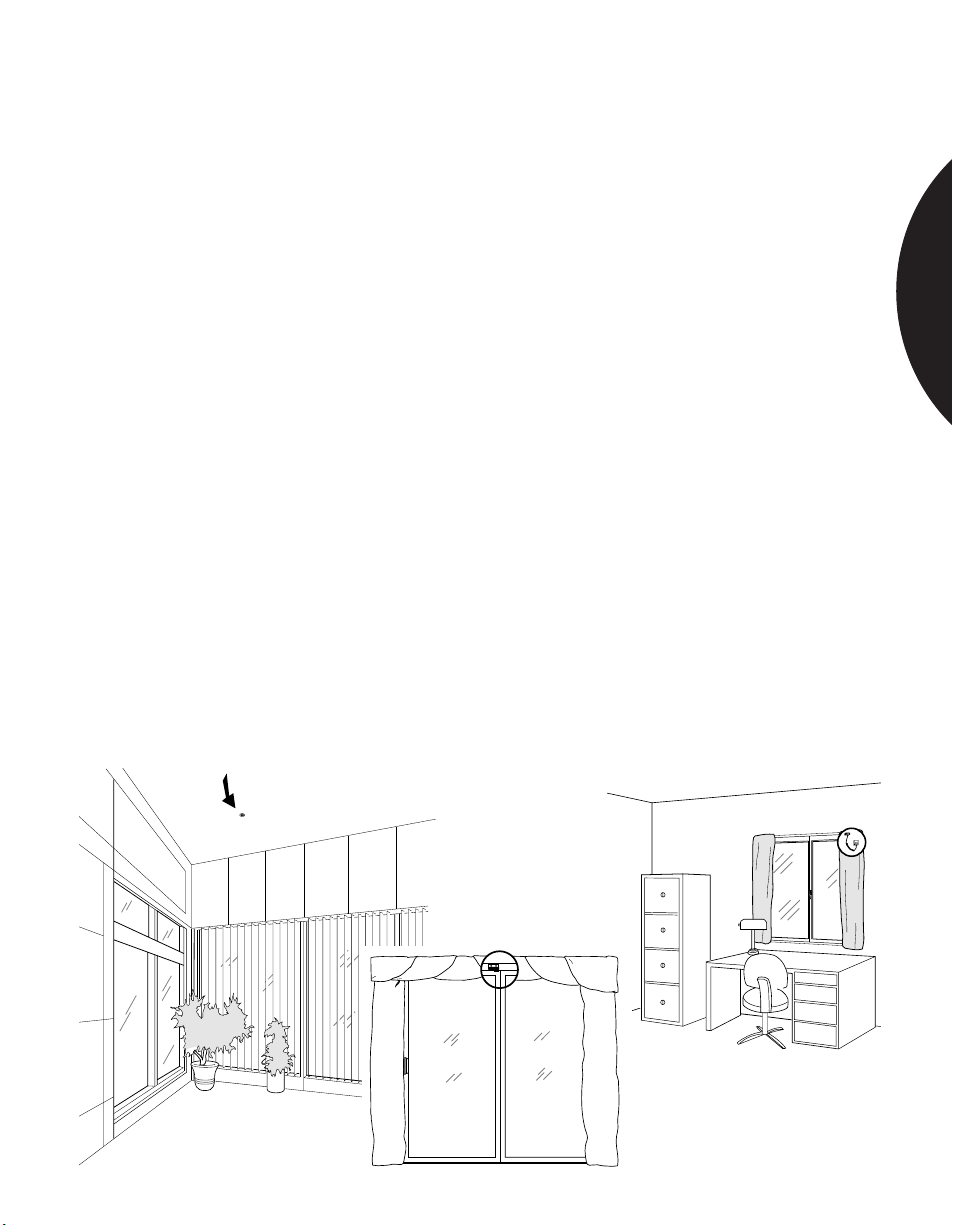

Residential & Commercial Applications

INSTALLING ACOUSTIC GLASSBREAK SENSORS

IN PRE-WIRE APPLICATIONS

APPLICATION

New construction applications offer the opportunity to pre-wire an acoustic

glassbreak sensor, creating an attractive, unobtrusive installation.

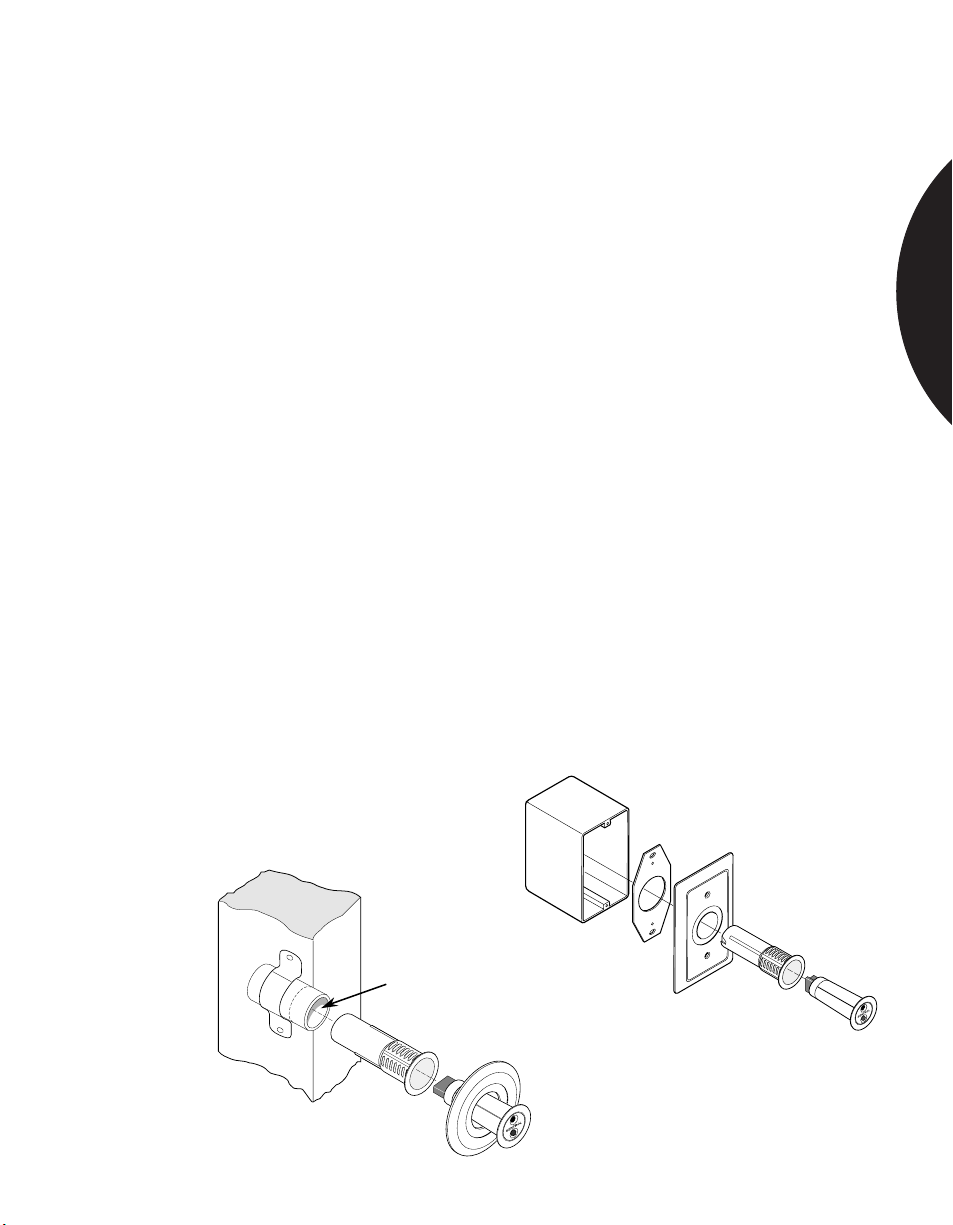

Sentrol’s ShatterPro II can be used in a pre-wire by using the single gang box kit

(5828) or the trim ring. The pre-wire trim ring is almost unnoticeable in pre-wire

installations. Its 2-1/2 in. (6.35 cm) diameter size is almost one third smaller than a

single gang box plate.

GLASSBREAK SENSORS

INSTALLATION

RECOMMENDED

PRODUCTS

USING THE TRIM RING

To pre-wire a Recessed ShatterPro, attach a 1 in. (2.54 cm) inside diameter pipe

about 2 1/2" (6.5 cm) long to a stud, in the desired location for the sensor, allowing

the pipe to protrude approximately 3/8 in. (.95 cm) beyond the stud. Run sensor

cable through the pipe. Don’t forget to leave enough slack to pull the wire out

later. (This shows the drywall installer that a security sensor is to be placed in this

location. The drywall installer will then cut a hole through the sheet rock for

the pipe.)

After the drywall is in place, the Recessed ShatterPro II can be inserted into

the pipe. After wiring, insert the 1 in. sleeve into the pipe, and the sensor into

the sleeve. Use the trim ring, if necessary, to cover any irregularities in the

drywall hole.

USING THE SINGLE GANG BOX KIT

This kit includes a plastic front plate, metal plate for alignment and painted

finishing screws.

The 5820A Recessed ShatterPro II acoustic glassbreak sensor, and the 5829 Trim

Ring and 5828 Single Gang Box Kit.

1" I. D. x 2 1/2" long

1.4

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

INSTALLING RECESSED GLASSBREAK SENSORS

WHEN APPEARANCE IS IMPORTANT

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

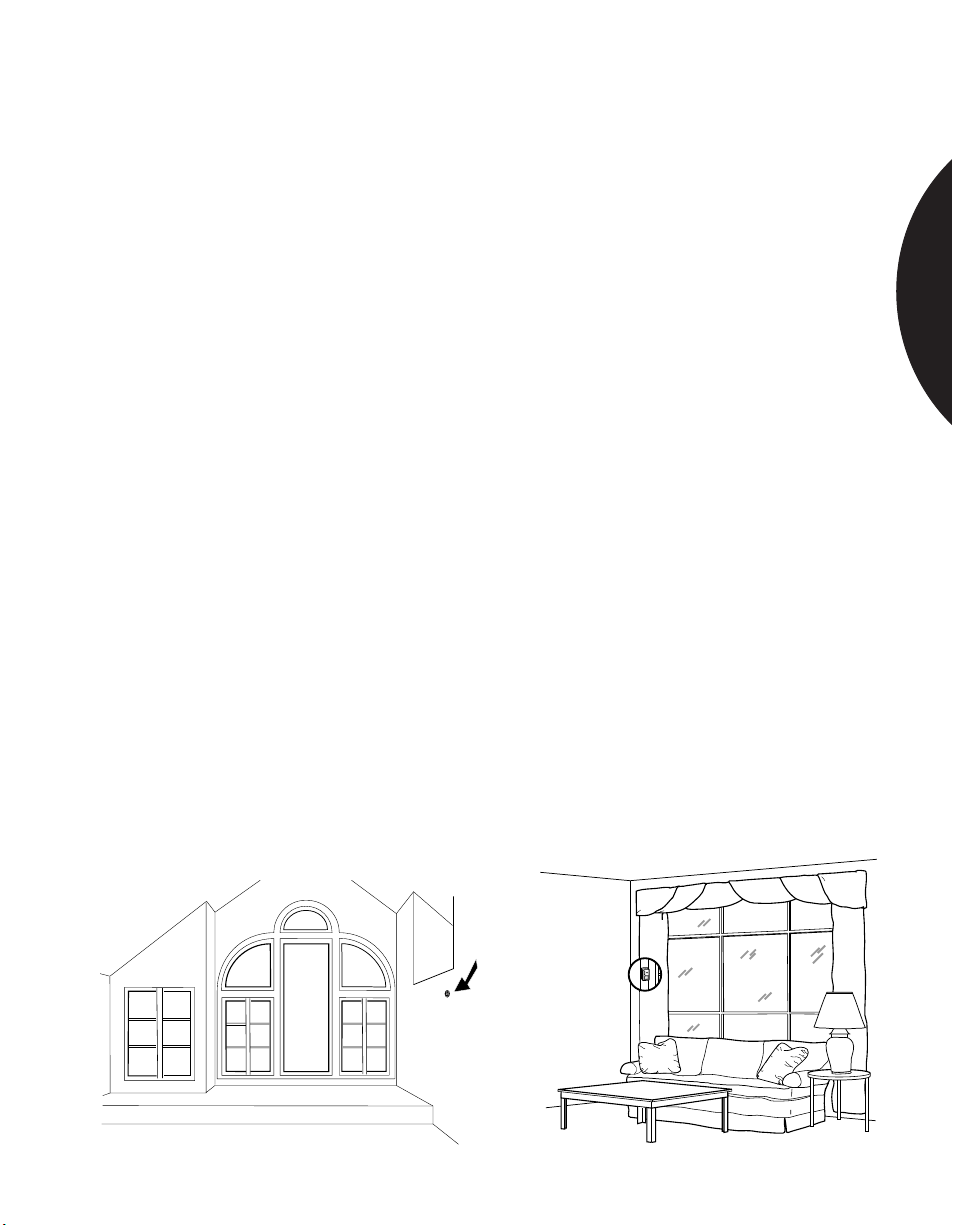

Some customers want their security system to be as inconspicuous as possible.

This is especially true in most residential installations, office entry foyers,

executive offices, and upscale retail stores.

Sentrol’s Recessed ShatterPro II and the Sentrol ShatterSwitch are the least

obtrusive acoustic glass break sensors available.

The Recessed ShatterPro II acoustic sensor recess mounts in a 1 in. (2.54 cm) hole.

See installation instructions on previous page for pre-wired installations.

When installing the Recessed ShatterPro II in existing residences and commercial

facilities, drill a 1 in. hole through the drywall or ceiling tile, in the desired

location. Insert the 1 in. sleeve into the hole, and the sensor into the sleeve. Use

the trim ring, if necessary, to cover any irregularities in the drywall hole. (A hole

saw makes the neatest hole, but a spade bit with cutting tips will usually work also.

A twist drill should be avoided because it tends to tear the sheet rock covering.)

One sensor can protect an entire room. Sensor range is 25 ft. (7.62 m) to the

bottom of the glass in a 360˚ pattern, so the sensor can be ceiling mounted,

mounted on the opposite wall, or on an adjoining wall. When installed, the

Recessed ShatterPro II is little larger than a quarter, and is therefore rarely noticed.

The Sentrol ShatterSwitch is a shorter range sensor which protects up to 10 ft.

(3.05 m) of glass. For a hidden appearance, mount the ShatterSwitch on the

window frame behind curtains or blinds.

For protecting a large glass area, use a 5820A Recessed ShatterPro II. For smaller

areas of glass, a ShatterSwitch 5725T can be used. A ShatterSwitch 5728T with

built in reed switch will also detect the opening of the door or window. An optional

90˚ mounting bracket, part number 5702, may be helpful when mounting the

ShatterSwitch on a narrow window frame.

GLASSBREAK SENSORS

S

E

N

T

R

O

L

1.5

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING BATHROOM WINDOWS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

In residential installations, bathroom windows may have to be protected as part of

a complete perimeter system. Bathrooms are challenging environments for glass

break sensors for two reasons. 1) Humidity can be very high when a shower or tub

is used. 2) Bathrooms are acoustically live rooms — they are typically small, with

bare floors and many sound-reflecting surfaces. Acoustically live rooms have a

greater potential for false alarms when acoustic glassbreak sensors are used.

Humidity can also be a problem for most glassbreak sensors. Sentrol offers a

hermetically sealed shock sensor, the GS610, that works with a separate analyser,

the GS614. Shock sensors have fewer problems than acoustic sensors in high

humidity environments.

Since shock sensors are not “listening,” they are the preferred choice for

acoustically live rooms, such as bathrooms. For best false alarm immunity in

bathrooms, if possible use a hermetically sealed shock sensor mounted on the glass

or a frame mounted shock sensor.

If an acoustic sensor is to be used, select a sensor with range comparable to the

size of the room. In a 10 ft. (3.05 m) bathroom, for example, it is better to use a

sensor with a 10 ft. range than a 25 ft. (7.5 m) range. The 25 ft. sensor is too “hot”

for such a small, acoustically-live room, and would be vulnerable to false alarms.

The GS610 shock sensor, with 12 ft. (4 m) of range, provides excellent false alarm

immunity and humidity tolerance. The GS611 frame mounted shock sensor with

built-in reed switch can protect windows that open. Both sensors work in

conjunction with the GS614 analyser.

The 5810A-W4 reduced sensitivity ShatterPro™ II with advanced Pattern

Recognition Technology™ can also be used in some bathroom applications.

1.6

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING SKYLIGHTS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Skylights can be a vulnerable entry point to many homes and businesses. Many

skylights are made of Plexiglas™, Lexan™, or other type of plastic. This

eliminates the option of using acoustic glassbreak sensors since they are designed

for detecting breaking glass, not plastic.

For protecting plastic skylights, mount a shock sensor in a corner of the skylight

1 in. (2.54 cm) from the frame.

Note: The plastic material in the skylight will absorb much of the shock energy

from a break. The range of a shock sensor on plastic is typically 50% less than the

range on glass. A shock sensor with a 7 ft. (2.13 m) range on glass would generally

have a 3-1/2 ft. (1.07 m) range on a plastic skylight.

When protecting plastic skylights, it is essential to thoroughly test the sensor by

rapping the far opposite corner of the skylight with the handle of an 8"-10"

screwdriver. If the sensor trips to the rap test, its range is sufficient to detect an

actual break-in.

An acoustic glassbreak sensor can be used for glass skylights. The sensor can be

mounted on any wall within range of the skylights, or on the ceiling.

Use a Sentrol 5115/20 shock sensor for plastic skylights if 3-1/2 ft. (1.07 m) of

range is sufficient, or use two sensors mounted in opposite corners if additional

range is required.

For glass skylights, another option is a 5725T ShatterSwitch, if it can be mounted

within range.

1.7

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING ROOMS WITH

CURTAINS AND BLINDS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Many homes and offices have curtains or blinds on at least some of the windows.

Sentrol shock sensors provide glass break detection regardless of the type of

window coverings present. With proper placement, Sentrol’s acoustic sensors may

also be used when blinds and light drapes are present.

Glass mounted or frame mounted shock sensors are unaffected by curtains and

blinds. The sensor should be mounted in the corner of the glass, 1 in. (2.54 cm)

from the frame.

Sentrol’s acoustic ShatterSwitch mounts behind curtains or blinds, and can protect

multiple windows. Mount the ShatterSwitch on the window frame to protect one

or more windows. It will protect a 10 ft (3.05 m) area. However, its range can be

reduced if window coverings are touching the glass.

Sentrol’s acoustic ShatterPro II can be mounted anywhere in a room except on the

frame (as long as the glass to be protected is within its range), and can detect

breaking glass when blinds and light drapes are present. Mount the ShatterPro II

on the ceiling, on an adjoining wall, or on a wall opposite from the glass to be

protected. Mounting the ShatterPro on the same wall as the glass should be

avoided because the signal may be dampened before it bounces back to

the sensor.

Test the range with the 5709C tester held behind the closed curtains or drapes. If

the sensor does not trip, it will be necessary to relocate the sensor closer to the

protected glass, or use additional sensors.

For shock sensor protection, use a 5115/20 or a 5425 shock sensor. For acoustic

glassbreak detection, use a ShatterSwitch 5725T. Or, use a 5728T ShatterSwitch

with built-in reed switch to also detect forced opening of the door or window. For a

larger range, use the ShatterPro II 5810A or the Recessed ShatterPro II 5820A.

GLASSBREAK SENSORS

1.8

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

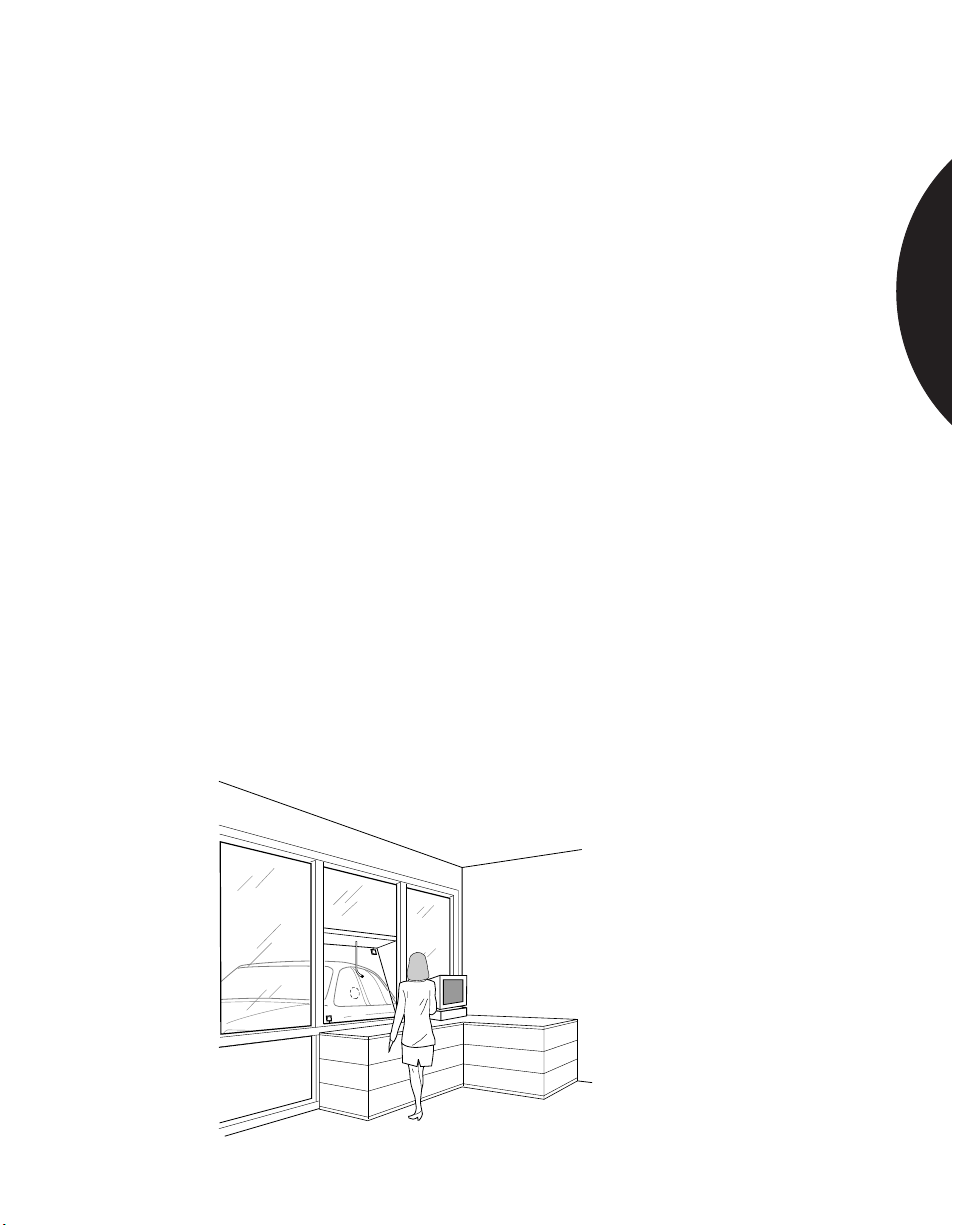

Residential & Commercial Applications

PROTECTING LARGE ROOMS WITH

MULTIPLE WINDOWS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

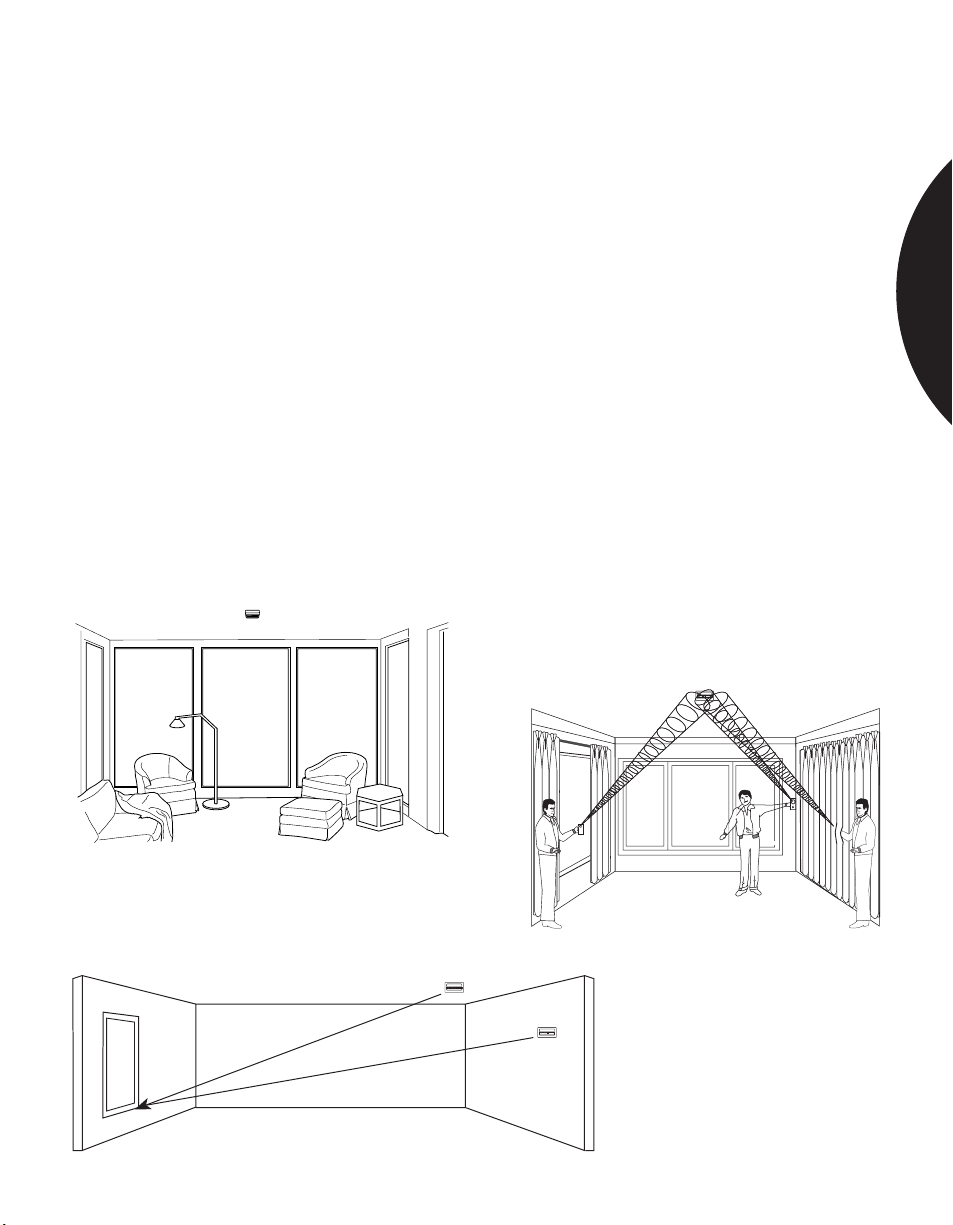

Most large rooms have several windows, often widely spaced from each other.

The most economical way to protect large rooms with multiple windows is with a

single, long range acoustic sensor. However, care should still be taken to match

sensor range to room size. A sensor whose range extends well beyond the

boundaries of the room is acoustically “hot” and vulnerable to false alarms.

For protecting glass on more than one wall, ceiling mounting is most desirable.

Make sure that all protected glass is within the radius coverage of the sensor. For

any glass to be protected by an acoustic sensor, the distance from the bottom of

the window to the sensor must be no more than the sensor’s maximum range.

For protecting one wall of glass, mounting an acoustic sensor on the opposite wall

is best (if all the glass to be protected is within the sensor’s range).

Always confirm range with a Sentrol 5709C hand-held tester.

For glass areas less than 10 ft. (3.05 m) or behind heavy curtains use a Sentrol

5725T ShatterSwitch mounted on the frame. For protecting large glass areas, a

single 5810A ShatterPro II, with its 25 ft. (7.6 m) range, can protect up to four walls

of glass. The 5820A Recessed ShatterPro II mounts in a 1 in. (2.54 cm) hole in the

ceiling, opposite wall or adjacent walls.

GLASSBREAK SENSORS

, Temp wired, Lam

25' (7.5 m) Plate

25' (7.5m) Plate, Temp wired, Lam

1.9

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING SMALL ROOMS WITH GLASS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

False alarms are more likely in small, acoustically live rooms such as small

kitchens, glass entry airlocks, stairwells, small glass offices, and utility rooms. For

best false alarm immunity the range of the sensor should be matched to the size of

the room and glass area to be protected.

Shock sensors offer the best false alarm immunity in acoustically live rooms, and

are the most economical if there is only one window to protect. Acoustic sensors

will provide good false alarm immunity if selected properly.

If it can be avoided, do not install acoustic sensors with large range into small

rooms. A sensor with 25 ft. (7.5 m) diameter range into a 10 ft. (3.05 m) room

increases the risk of false alarm. Choose an acoustic sensor with range comparable

to the size of glass to be protected.

In a small room with just one window, the Sentrol 5115/20 shock sensor provides

economical protection and false alarm free operation in virtually all acoustically

live applications. The 5414 or 5415A frame mount shock sensors are also a good

choice. The 5415A has a built-in reed switch to protect windows that open.

For multiple windows the 5725T (ShatterSwitch) or the 5810A-W4 reduced

sensitivity (ShatterPro II) can be considered for small rooms.

Verify correct sensor placement with the Sentrol 5709C hand-held tester.

To protect just one window, use the 5115/20 shock sensor. For protecting multiple

windows in a small room, use a 5810A-W4 reduced sensitivity ShatterPro II or

multiple shock sensors. The 5415A or 5426 frame mount shock sensors with builtin reed switches can be used to protect windows that open.

L

O

R

T

N

E

S

L

O

R

T

N

E

S

1.10

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

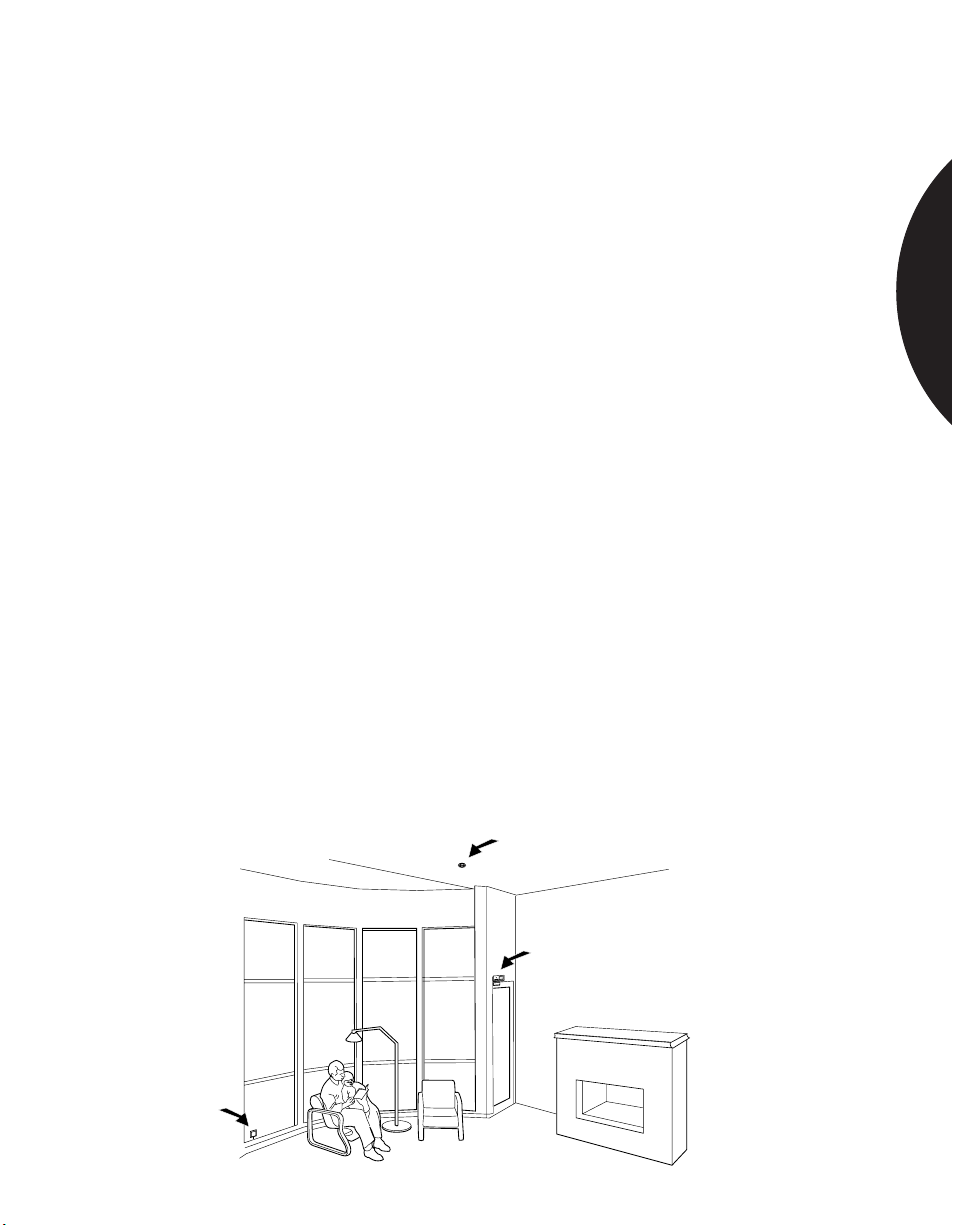

PROTECTING OCCUPIED AREAS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Glassbreak sensors can be armed while rooms are occupied to alert the family

inside a home or the employee working late or on the weekend.

Occupied area protection means sensors are armed when the perimeter loop of the

system is armed. In contrast to 24-hour loops, which are armed continuously, all

day and all night, a perimeter loop containing glassbreak sensors is armed only

when the magnetic contacts on doors are armed — generally, after hours, when

buildings are quieter.

Today’s advanced acoustic sensors provide excellent false alarm immunity in

occupied areas if installed on the perimeter loop. Sentrol shock sensors and the

ShatterPro™ Plus 5885 provide 24-hour loop protection without false alarms.

For 24-hour loop protection, mount Sentrol’s 5115/20 shock sensors on the glass to

be protected, 1 in. (2.54 cm) from the corner.

Frame mounted shock sensors such as the 5425 will also provide 24 hour loop

protection without false alarms if sensitivity is set properly. Sentrol also offers a

motion sensitive acoustic glassbreak product, the 5885, for use in 24 hour

applications (see page 24).

For perimeter protection using acoustic sensors, use a ShatterSwitch for protecting

glass areas smaller than 10 ft. (3.05 m). Use Sentrol’s advanced ShatterPro II to

protect large glass areas on the perimeter loop.

To test shock sensors, rap the protected glass with the handle of a screwdriver in

the corner farthest from the sensor. This should trip the sensor. Verify range

coverage of acoustic sensors with the Sentrol 5709C hand-held tester.

For shock sensor protection, the 5115/20 provides the best false alarm immunity

with the 5425 also a good solution. The ShatterSwitch 5725T, the ShatterPro II

5810A, and the Recessed ShatterPro II 5820A provide excellent false alarm

immunity in occupied areas on the perimeter loop. The ShatterPro Plus 5885 is

also recommended for 24 hour acoustic glassbreak coverage.

1.11

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING A SINGLE WINDOW WITH

WIRELESS COMPATIBLE SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

A wireless compatible shock sensor can be used for economical protection of rooms

with a single window. For glass doors or windows which open, use a wireless

compatible sensor with a built-in reed switch.

Sentrol’s 5115/20 wireless compatible shock sensor is a two-wire device which

draws no power, and therefore has no impact on the transmitter’s battery life.

Mount the 5115/20 on the glass, 1 in. (2.54 cm) from the corner. Range is 7 ft.

(2.13 m) radius out from the sensor.

The 5414 or 5415A frame mounted shock sensor can protect two fixed windows in

the same window opening. An internal lithium battery powers the sensor for up to

15 years, so there is no draw on the transmitter battery. Range for the 5414 or

5415A is up to 10 ft. (3.05 m). Frame mounting affects sensor range, so it is

essential to test the sensor by rapping the glass on the side opposite the sensor.

The sensor must trip to the rap test to ensure proper operation. The 5415A

includes a built-in reed switch and a magnet to protect against opening the

window.

For protecting glass doors or windows that open, mount a Wireless ShatterSwitch

acoustic sensor within the window bay. The ShatterSwitch will protect a 10 ft.

(3.05 m) area of glass. Test the sensor’s range using the Sentrol 5709C hand-held

tester.

Note: The Wireless ShatterSwitch shares the battery of the transmitter. Its current

draw of up to 15 micro amps may reduce transmitter battery life by up to 50%.

Since other devices are likely to need battery replacement before the

ShatterSwitch, this is rarely a problem.

Use the Sentrol self-powered 5115/20 for glass-mounted applications, or the

lithium battery powered 5414 shock sensor for frame mounting. Use the 5415A

shock sensor with built-in reed switch to protect windows that open.

For acoustic sensor protection use the Wireless ShatterSwitch 5741. Use the 5742

Wireless ShatterSwitch with built-in reed switch to protect glass doors and

windows that open.

GLASSBREAK SENSORS

L

O

R

T

N

E

S

L

O

R

T

N

E

S

1.12

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING MULTIPLE WINDOWS WITH

WIRELESS COMPATIBLE SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

In many installations it is desirable to protect rooms with several windows. This

can be accomplished economically using one transmitter and a wireless compatible

acoustic sensor.

Sentrol’s Wireless ShatterPro acoustic glassbreak sensor combines excellent false

alarm immunity and consistent detection with wireless compatibility. The Wireless

ShatterPro has a coverage radius of 20 ft. (6.1 m), [40 ft. (12.2 m) diameter] if

ceiling mounted. A single sensor, therefore, can typically protect an entire room.

Mount the transmitter inside the back box of the Wireless ShatterPro 5845, which

hides the transmitter and provides an integrated look. If desired, the transmitter

can also be mounted next the sensor module on the bracket included.

Note: The sensor shares the transmitter battery, which may reduce battery life by

up to 50%. Since other devices are likely to need battery replacement before the

Wireless ShatterPro, this is rarely a problem.

Position the Wireless ShatterPro anywhere in the room except within the frame.

The best location for detection is directly opposite the glass. Since wireless sensor

placement is not determined by wire routing, opposite wall mounting is a more

practical option than with hard wire installations.

Verify sensor range and placement with the 5709C hand-held tester.

For glass areas smaller than 10 sq. ft. (3 sq. m) use the Sentrol’s Wireless

ShatterSwitch 5741. For forced open protection as well, use the 5742 with built-in

reed switch. For glass areas larger than 10 sq. ft., or for an integrated appearance,

use the Wireless ShatterPro 5845.

GLASSBREAK SENSORS

1.13

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

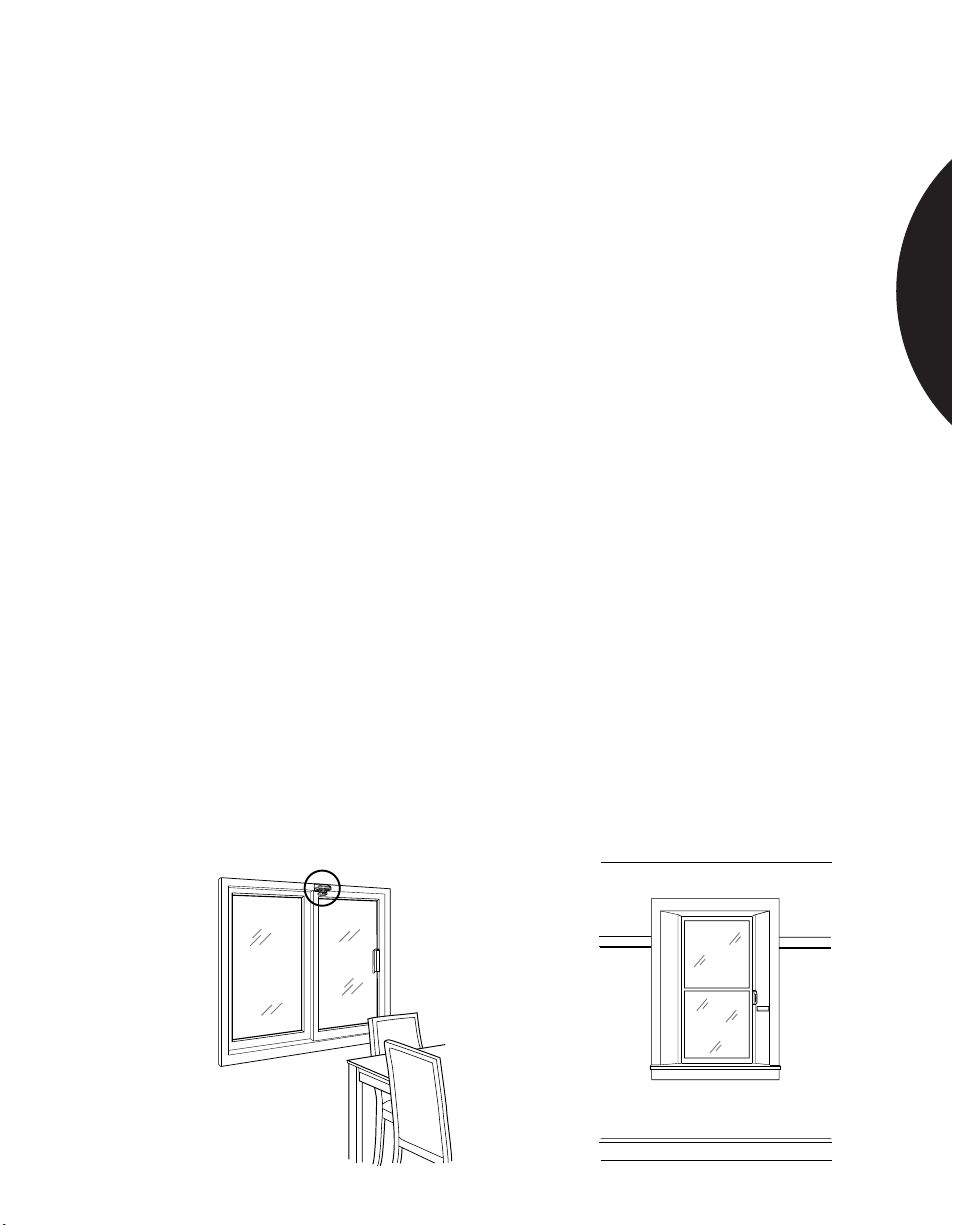

PROTECTING SMALL WINDOWS,

FRENCH DOOR GLASS, FRENCH WINDOWS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Small French door type windows are common in older homes. The glass panels are

typically 6 in. x 9 in. (15.2 cm x 22.9 cm) or larger. Small windows have unique

properties when they break. First, the sound output may be low since there is not

much glass to break. Second, the glass may just pop out of the frame when hit,

rather than breaking. This is particularly true of glass in old wooden frames.

Detection in both cases can be difficult.

Modern French-type windows are usually two large panes of glass with false

dividers between them. The dividers have little effect from a detection

standpoint. Detection of false French windows is the same as with standard size

windows, and no special precautions need to be taken.

The 5725T ShatterSwitch provides good protection of small windows if installed

within 4 ft. of the glass to be protected. Most acoustic sensors are only rated down

to a minimum glass size of 1 ft. x 1 ft. (30.5 cm x 30.5 cm) or larger. If protecting a

smaller window than the sensor’s minimum rated size, the capture rate will

decrease by as much as 50%. The customer should be informed that sensor detection has

been compromised. With small windows, it is best to locate the acoustic sensor close

to the protected glass.

More consistent detection can be achieved using a frame mounted shock sensor.

Often several sensors will be needed to protect a frame of several windows. Take

particular care to thoroughly test sensor range by rapping on the windows farthest

from the sensor. The sensor must trip to the rap test. Use additional sensors on

each side of the glass until a rap to any pane of glass will trip at least one shock

sensor.

For acoustic protection of smaller windows, use a ShatterPro II 5810A or 5820A.

The ShatterPro™ II is not recommended for windows smaller than 1 ft. x 1 ft.

(30.5 cm x 30.5 cm). The 5725T ShatterSwitch can be used if mounted within 4 ft.

of the protected glass.

The 5425 shock sensor can be mounted on the frame to protect multiple panes of

small glass. Several sensors may be required.

GLASSBREAK SENSORS

1.14

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING GLASS DOORS AND

WINDOWS THAT OPEN

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Protecting glass doors and windows that open can be a challenge because of the

difficulty of running wires from the glass to the frame. Glassbreak and forced-open

protection can, however, be achieved with a single detector.

For shock sensor protection, both on-the-glass and frame-mounted sensors can be

used. The 5120C shock sensor ships with 3 ft. (.91 m) of coil cord. The sensor

mounts in a corner on the glass, and the coil cord reaches to a termination on the

frame. As the window or door opens, the coil cord stretches as needed.

Frame-mounted shock sensor models are available which also have a built-in reed

switch with magnet. These sensors provide both glass break detection as well as

forced open detection. Mount the sensor’s magnet on the door or moveable

window, and mount the sensor on the frame as close as possible to the magnet.

For acoustic sensor protection use a Sentrol ShatterSwitch with built-in reed

switch and magnet. This provides coverage of 10 ft. (3.05 m) of glass, including

multiple windows, while detecting forced opening as well. The ShatterSwitch

should be centered at the top of the glass, or as near to center as practical for

magnet location.

Use a 5120C shock sensor with coil cord for on-the-glass protection. The 5426

frame-mount shock sensor with built-in reed switch provides double protection.

The ShatterSwitch is available in standard configuration, part number 5725T, and

also with built-in reed switch, part number 5728T. A 90˚ mounting bracket, part

number 5702, is useful on narrow frames.

GLASSBREAK SENSORS

S

E

N

T

R

O

L

1.15

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Residential & Commercial Applications

PROTECTING INSULATED GLASS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Many modern buildings use windows that contain two panes of glass divided by an

air space for added insulation. This insulated glass can be protected by shock and

acoustic glassbreak sensors. As long as the inside pane of glass breaks, the sensor

will detect the break. It is possible to break the outside pane of glass without

setting off an alarm.

Installation for thermopane windows is the same as for other windows. Shock

sensors should be mounted in the corner or frame mounted. Acoustic sensors

should be mounted so that the protected glass is within range.

Rap test the shock sensors. Test acoustic sensors with the Sentrol 5709C handheld tester.

Use a 5115/20 shock sensor for on-the-glass protection. The 5426 frame-mount

shock sensor with built-in reed switch provides double protection for windows

which open.

Use the 5725T ShatterSwitch, 5728T with built-in reed switch, or 5810A

ShatterPro II for acoustic protection.

1.16

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

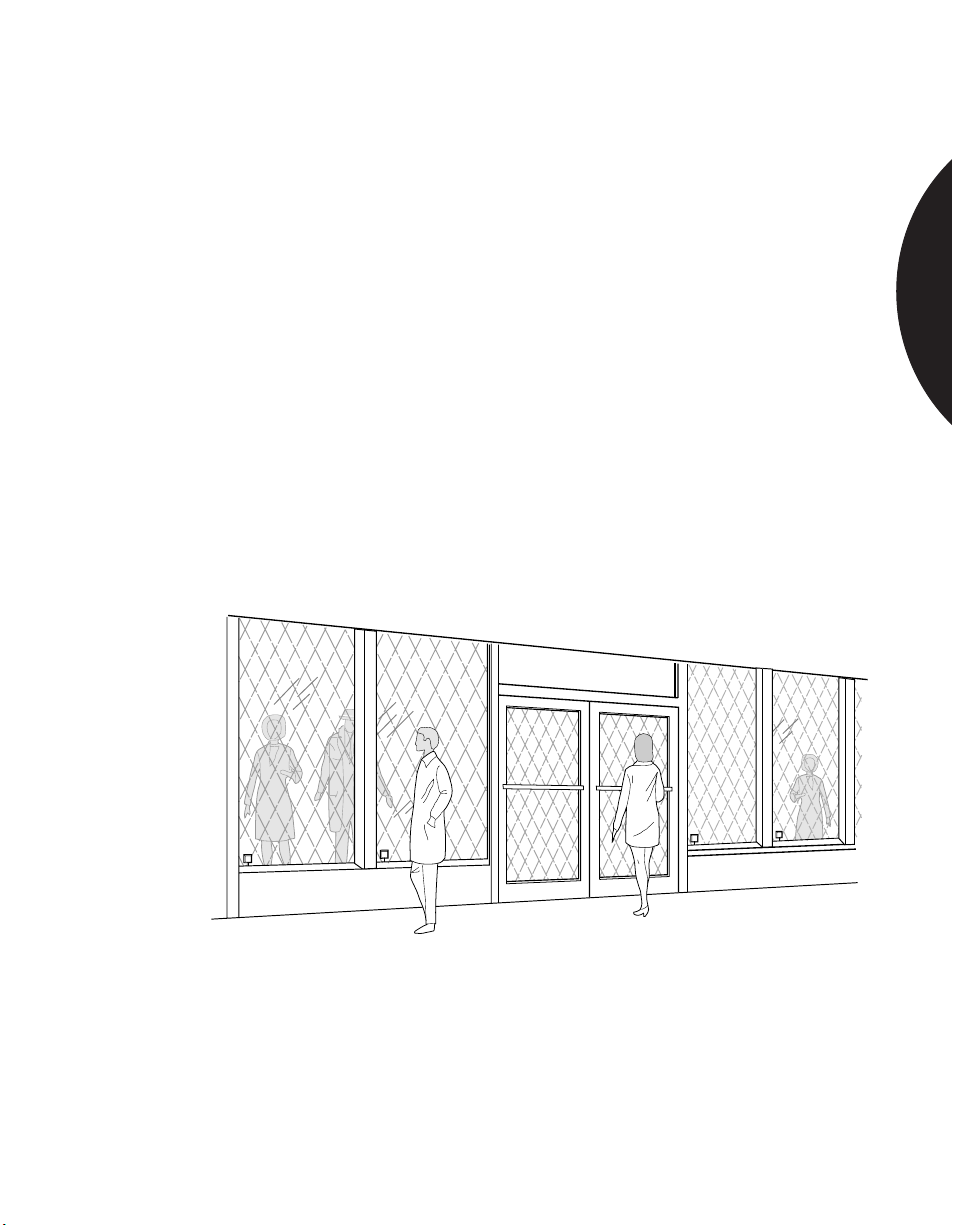

Commercial Applications

PROTECTING STOREFRONT GLASS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Merchants often want glass break protection on their front windows, in order to

have the alarm sound as soon as the glass breaks. While this does not prevent

“smash and grab” losses, it will prevent most burglars from actually entering

the building.

For storefront windows shock sensors are always the best choice. A shock sensor is

visible from the outside, which might deter burglars before the glass is broken.

And shock sensors are less likely to be set off by street noise, or by rolling metal

shutters, than are acoustic sensors. Due to range limitations, however, shock

sensors can be more expensive to install. Multiple sensors may be required to

cover the same glass area that one acoustic sensor can protect.

Acoustic sensors can be successfully used to protect storefront glass if store

personnel are properly trained to not block the glass. Acoustic sensors must be able

to “see” all the glass that they are protecting. If a sensor’s line of sight to the glass

is blocked by store displays or furniture, the sensor is unlikely to detect a break-in

through the blocked glass.

If selecting an acoustic sensor, in stores which do not have window displays, mount

a ShatterPro in the ceiling inside the room. For stores with window displays,

mount a ShatterSwitch directly above the glass.

Use the 5115/20 for on-the-glass shock sensor protection, or use the 5425 for

frame mounting.

For acoustic sensor protection, use a ShatterPro II 5810A, a Recessed ShatterPro

5820A, or a ShatterSwitch 5725T.

New Models Are Here

1.17

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Commercial Applications

PROTECTING STORE WINDOWS

WITH ROLL-UP METAL SHUTTERS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Retail shops in high crime areas will often have roll-up metal shutters to protect

the glass windows at night. The clanging and banging sounds of these shutters can

cause acoustic sensors to false alarm. False alarms can also be caused by people

rattling the shutters, and by other vibrations.

For windows with roll-up shutters, shock sensors provide the best false alarm

immunity. On-the-glass shock sensors have better false alarm immunity than

frame-mounted shock sensors, and are therefore the preferred choice. On-the-glass

sensors are also easily visible from the outside, which may help deter a break-in.

If using acoustic sensors, use only an advanced sensor with excellent false alarm

immunity. Mount the sensor back into the room, away from street and roll-up

shutter sounds. An advanced sensor mounted 15 ft. back from the glass should

provide false-alarm-free operation in most applications.

Use the 5115/20 for on-the-glass shock sensor protection, or use the 5425 for

frame mounting.

Use a ShatterPro II 5810A, or a Recessed ShatterPro II 5820A, for acoustic

sensor protection.

GLASSBREAK SENSORS

1.18

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Commercial Applications

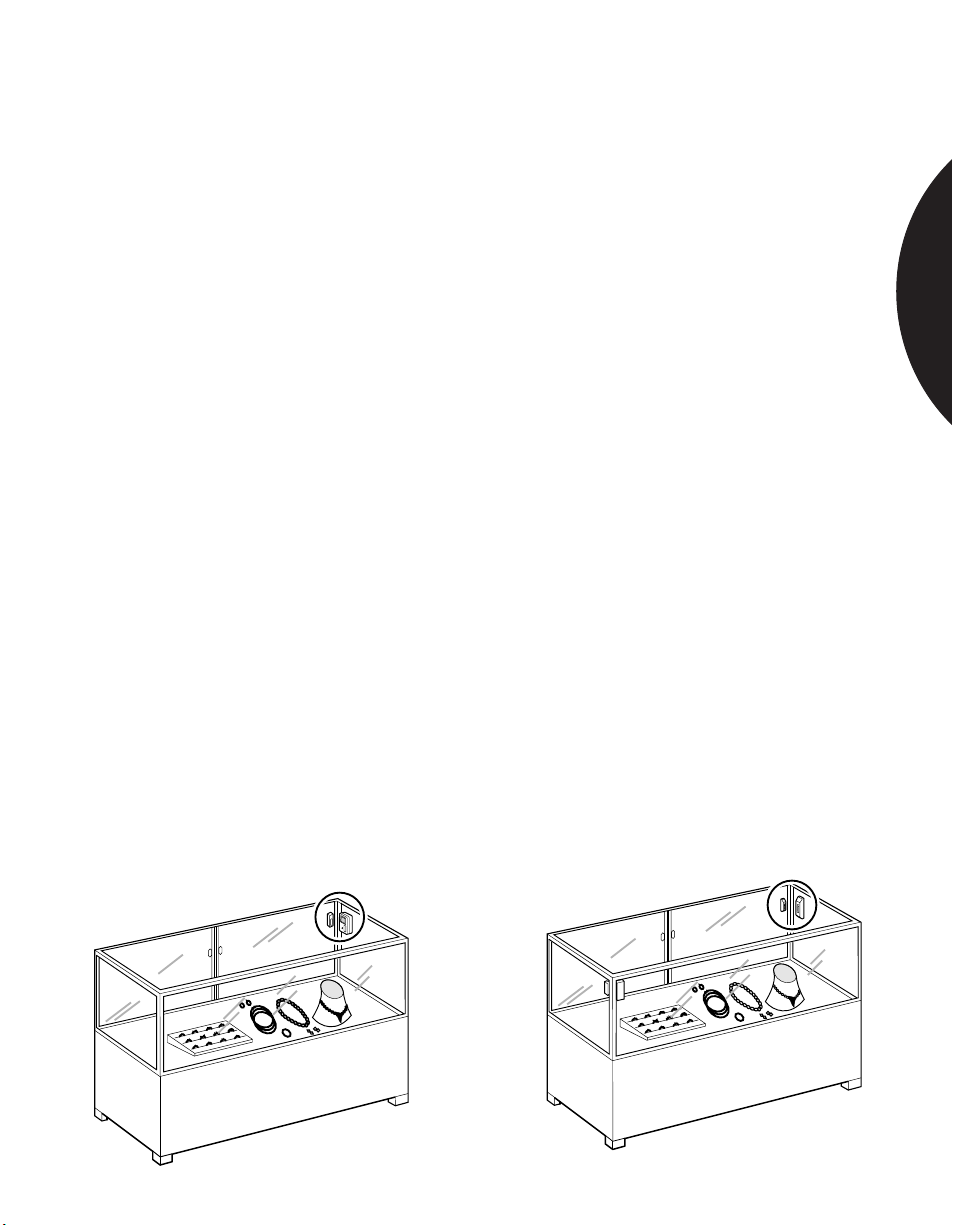

PROTECTING DISPLAY AND JEWELRY CASES

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Museum curators and retailers with glass display and jewelry cases often want the

extra protection of glassbreak sensors inside their cases. Both shock sensors and

acoustic sensors are options for such protection.

Note: Acoustic glassbreak sensors sealed within a glass box are extremely “live,”

and are vulnerable to false alarms if the case is accidentally struck by keys or other

metal objects. For this reason, acoustic sensors are appropriate only if the sensor

will be armed while the premises are not occupied.

For occupied or 24-hour protection of display cases, it is best to use shock sensors.

A frame mounted shock sensor will provide the most economical protection if

there is more than one piece of glass to protect. To prevent sensor tampering, the

glassbreak sensors must be placed inside the case.

Test the installation by rapping the protected glass farthest away from the sensors.

If the shock sensor does not trip to this rap test, it may not trip to an actual break.

Add additional sensors until at least one sensor trips on each rap test.

Note: An actual glass break generates twice as much energy to the shock sensor as

a rap test.

More than one shock sensor may be needed to protect all the glass in a display

case. If, for cosmetic reasons, this is not a viable solution, a single acoustic sensor

may be used. To protect a glass case when a room is not occupied, use an acoustic

sensor with limited range, such as the Sentrol ShatterSwitch , with its 10 ft.

(3.05 m) range. The ShatterPro II is not recommended for display cases because it

is not designed to detect the prying of the case tops.

For acoustic sensor protection, the ShatterSwitch 5725T by Sentrol will generally

protect an entire case. A 5728T with built-in reed switch can be used to detect

forced opening of the access door.

The 5115/20 shock sensor mounts directly onto the glass, and is the best choice if

only one piece of glass is to be protected. For protecting multiple glass walls in the

case, use one or more 5425 shock sensors. Use a 5426 with built-in reed switch to

detect the forced opening of the access door.

L

O

R

T

N

E

S

L

O

R

T

N

E

S

1.19

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

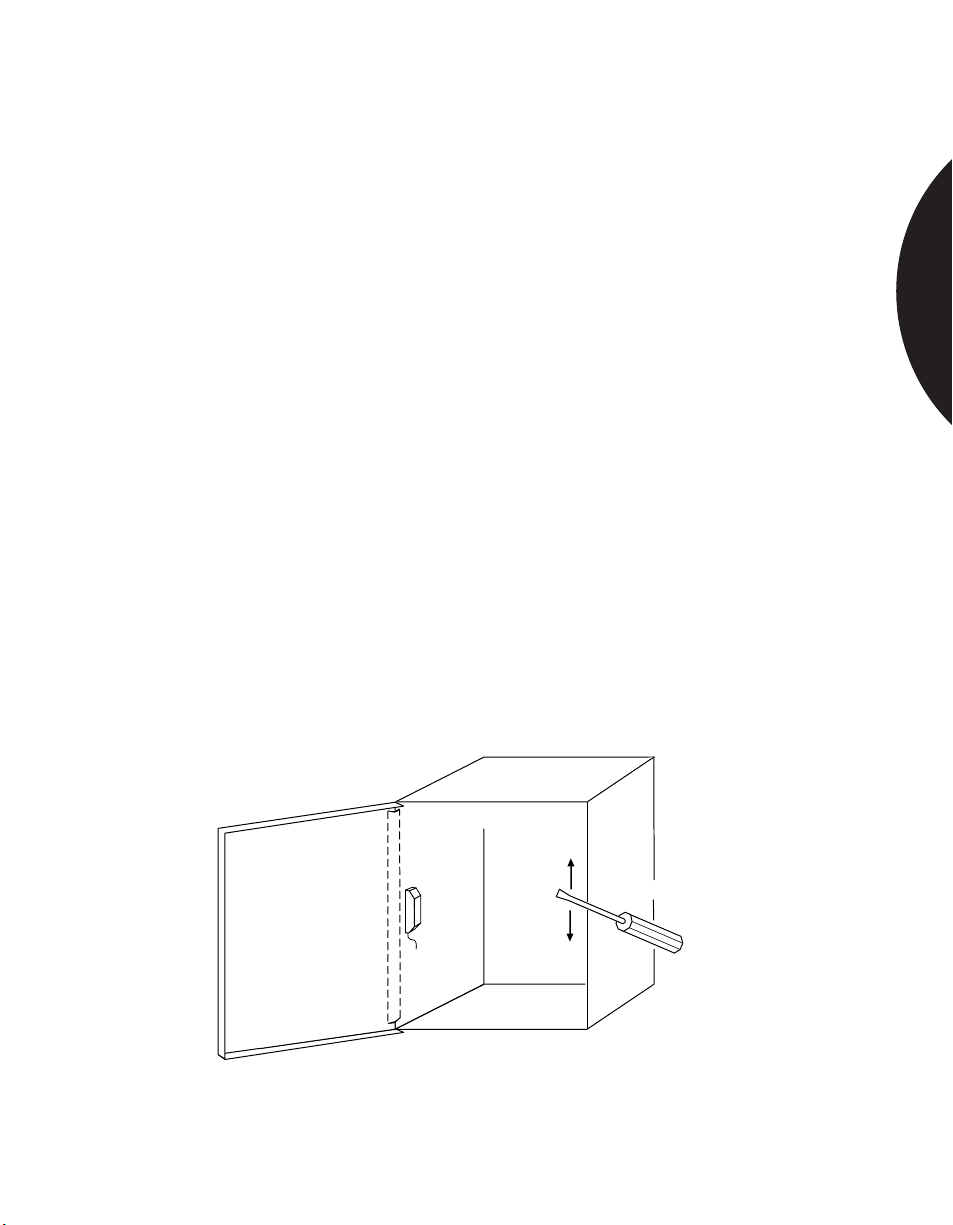

Commercial Applications

PROTECTING METAL ENCLOSURES

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Sentrol’s 5402 shock sensor eliminates the need for costly lined boxes or

placement of security system controls in a vault for UL mercantile applications.

The sensor mounts inside the enclosure on the hinge side of the box for best

response.

Locate the sensor inside the enclosure on the side wall on or near the hinge. If the

hinge runs the length of the side, center the sensor vertically. If the enclosure has

multiple hinges, place the sensor next to the hinge nearest the middle of the

enclosure.

Peel back paper from one side of adhesive tape pad and press it onto back of

sensor. The tape pad must be flat against the plastic case. Use a 50/50 solution of

isopropyl alcohol to clean the mounting area. Dry the mounting area. Peel off the

backing paper from the tape pad and press the sensor against the metal. The tape

will fully adhere within 24 hours.

Wire the sensor to the loop according to wiring instructions.

To test the sensor, view the LED or see if the panel detects the alarm. Then using

the metal shaft of a medium-size screwdriver, lightly scrape back and forth against

the edge of the metal enclosure farthest from the sensor.

If the 5402 does not respond, a second sensor may be required.

Note: The 5402 has an estimated 15 year battery life. Test the sensor biannually

to ensure proper operation. The 5422 is a 4 wire sensor using external power.

5402, 5422

Sensor

Screwdriver

1.20

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Commercial Applications

PROTECTING THICK GLASS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Acoustic sensors and shock sensors are rated for glass thicknesses up to 1/4 in.

(6.4 mm). Some installations may have glass thicker than 1/4 in., yet the customer

still wants glass break detection.

The 5725T ShatterSwitch can be used to protect thicker glass with some reduction

in range. The ShatterPro II is not designed to protect thicker glass. Its

effectiveness will be reduced if protecting thick glass. If ShatterPro II acoustic

sensors are used, the end-user should be warned that capture rate is reduced as much

as 50%.

Shock sensors may be used on thick glass if they are thoroughly tested. Thick

glass absorbs much of the shock energy from a break, and therefore is more of a

challenge for glass break detection.

For on-the-glass shock sensors, mount the sensor in a corner of the glass

approximately 1 in. (2.54 cm) in from the corner. Test the sensor by rapping the far

opposite corner of the glass with a screwdriver handle. The sensor must trip to this

rap test. If the sensor fails to trip, mount additional sensors in the other corners

until at least one sensor trips to rapping the glass at every point on the window.

Frame mounted shock sensors are tested in the same manner. Sensors such as the

5425 have a sensitivity adjustment to increase range of the sensor if needed. For

best false alarm immunity, set sensitivity no higher than half-way. Use additional

sensors as needed.

For shock sensor protection use the 5115/20 mounted on the glass, or the 5425

mounted on the frame. The 5426 shock sensor also has a built-in reed switch with

magnet for detecting forced opening of a door or window. For acoustic sensor

protection, use the 5725T ShatterSwitch and mount within six feet of the farthest

point of the protected glass.

1.21

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Commercial Applications

PROTECTING WINDOWS WITH FILM

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

In sunny climates some commercial windows will have a tinting film attached to

the glass.

Sometimes, commercial windows also have a plastic film attached to the glass to

prevent shattering from impacts or bullets. This “armor-coated” glass can be found

in bank drive-up windows, in some retail stores, and in other vulnerable buildings.

Acoustic sensor range is not effected by tinting film, so any acoustic sensor can be

used.

Shock sensors are also unaffected by tinting film. For on-the-glass sensors, cut

away the film where the sensor will be placed so that the mounting tape is affixed

to the glass itself and not to the film.

Armor-coating will reduce acoustic sensor range by about 50%. This is particularly

true if the armor-coating is applied to laminated glass. If protecting armor-coated

glass, mount the acoustic sensor 50% closer than the specified range, and confirm

coverage with the hand-held tester. Additional sensors may be needed since the

sensors are mounted closer to the glass.

Armor-coated glass will also reduce shock sensor range. When using shock sensors,

thoroughly test the installation by rapping the glass in the far opposite corner of

the glass from the sensor. If the sensor does not trip to the rap test, add additional

sensors at other corners of the window until at least one sensor trips to a rap at any

place on the window.

Any Sentrol shock or acoustic sensor, as long as the installation guidelines above

are followed.

Plate, Tempered

Laminated Glass Tinted Armor Coated

Acoustic Spec. Range 100% 100% 50% or less

Shock Sensors Required 1 1 Double the sensors

1.22

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Commercial Applications

PROTECTING ROOMS WHEN CLEANING CREWS

ARE PRESENT

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Often, the perimeter loop of the security system is armed when cleaning crews are

in a building. If acoustic sensors are armed, they will be listening to all sounds,

including those made by night cleaning crews. Acoustic sensors are most likely to

false alarm to multiple sounds. The cleaning crews produce a combination of

sounds from vacuums, floor polishers, and clattering garbage cans, all of which

combine to cause false alarms for some sensors in some applications.

Shock sensors provide the best false alarm immunity for a building when it is

occupied. Shock sensors are often economically impractical, however, due to the

number of windows to be protected. Also, in applications where appearance is

important, the use of multiple shock sensors may not be an option.

Sentrol’s ShatterPro Plus 5885 provides an acoustic solution to noisy cleaning

crews. The 5885 is a motion sensitive acoustic sensor that combines a passive

infrared sensor with a glassbreak sensor. When a noisy occupant enters the field of

view of the PIR the glassbreak sensor is disabled for 70 seconds. This prevents

false alarms due to loud noises such as vacuums or floor buffers. The glassbreak

sensor is activated after the occupant leaves the field of view. The 5885 makes 24

hour acoustic applications possible.

For false alarm immunity when night cleaning crews are present, the ShatterPro

Plus 5885 will provide trouble-free performance in most applications. Other

reliable solutions are shock sensors like the 5120 or 5414.

GLASSBREAK SENSORS

1.23

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Commercial Applications

PROTECTING PLASTIC WINDOWS

GLASSBREAK SENSORS

APPLICATION

INSTALLATION

RECOMMENDED

PRODUCTS

Many windows in commercial installations are made of Plexiglas™, Lexan™, or

other types of plastic. Unfortunately, this eliminates the use of acoustic glassbreak

sensors, since they are designed to detect breaking glass, not plastic. For protecting

plastic windows, it is safest to use a shock sensor.

Note: The plastic material will absorb much of the shock energy from a break.

The range of a shock sensor on plastic is typically 50% less than the range on glass.

A shock sensor with 7 ft. (2.13 m) of range on glass would generally have 3-1/2 ft.

(1.07 m) of range on a plastic window or skylight.

If you are unsure whether the window to be protected is plastic or glass, look for

scratches. Scratches typically indicate a plastic window.

Mount the shock sensor in a corner of the window, 1in. (2.54 cm) from the frame.

Shock frequencies concentrate in the corners.

When protecting plastic windows, it is essential to thoroughly test the sensor by

rapping the far opposite corner. If the sensor trips to the rap test, the sensor range

is sufficient to detect an actual break-in.

Use a Sentrol 5115/20 shock sensor if 3-1/2 ft. (1.07 m) range is sufficient. Use two

sensors mounted in opposite corners if additional range is required.

1.24

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CHOOSING THE APPROPRIATE PIR

The following chart is intended to help you match the appropriate Sentrol PIR with your particular

installation. The charts on pages 32 and 33 list the specifications for the PIR.

SENTROL PIR RESIDENTIAL

...................................................................................................

Model 6351 35' x 35' room

Sharpshooter

DesignLine

™

™

Wall or corner mounted

90° wide angle

Pet alley, vertical barrier

...................................................................................................

Model 6255 30' x 30' room

SureShot

™

Mounts 1/8" from ceiling

Wall, corner or ceiling

Pet alley, curtain

40' single spot

...................................................................................................

Stairwell coverage

Model 6255FM Pre-wired wall or ceiling

SureShot™ Flush Mount Retro flush mount

...................................................................................................

Model 6155 45' x 45' room

Sharpshooter

™

Wall or corner mounted

Pet alley, curtain

90' long range

Extra wide angle

...................................................................................................

Model 6155CT Cold climates: garages

Sharpshooter™ CT and vacation homes

...................................................................................................

Model 6085 Garages

Sharpshooter™ Wire Cage

...................................................................................................

Model 6155XT Warm climates

Sharpshooter™ XT Unstable environments

(captures within 1˚C contrast)

(uses Quad technology)

...................................................................................................

Model 6165 Compatible with most

Wireless Sharpshooter

(back box for transmitter available)

...................................................................................................

Model 6187CTX

Industrial Sharpshooter

™

wireless systems

Same applications as 6155

™

(operates to –40˚C)

(cast metal housing)

...................................................................................................

Model 6197

Intrinsically Safe PIR

...................................................................................................

Model 6198

Nonincendive PIR

...................................................................................................

COMMERCIAL INDUSTRIAL

35' x 35' room

Wall or corner mounted

90° wide angle

Pet alley, vertical barrier

Mounts 1/8" from ceiling

30' x 30' room

Wall, corner or ceiling

Pet alley, curtain

40' single spot

Stairwell coverage

Pre-wired wall or ceiling

Retro flush mount

45' x 45' room

Wall or corner mounted

Curtain

90' long range

Extra wide angle

Single gang plate w/swivel

Cold climates Cold climates

Unheated property Unheated warehouses

Vandal protection Vandal protection

Gymnasiums

Warm climates Warm climates

Unstable environments

Compatible with most wireless systems

Same applications as 6155

Outdoors to control Outdoors to control

CCTV or local alarm CCTV or local alarm

Warehouses Food processing plants

Locker rooms Underground parking lots

Underground parking lots Dusty environments

Dusty, cold or wet areas Cold or wet areas

Hazardous areas with Hazardous areas

ignitable atmospheres for use in

Government sites Class I, II, & III

Pharmaceutical labs Division 1-2

Oil refineries Groups A, B, C, D, E, F

Grain elevators and G

Hazardous areas; for

use in Class I Division 2

Groups A, B, C, and D

(only)

Introduction

SPACE DETECTION

2.2

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

CHOOSING THE APPROPRIATE PIR

The following chart is intended to help you match the appropriate Aritech PIR with your

particular application.

ARITECH PIR RESIDENTIAL

...................................................................................................

Model AP125/AP126 33' x 40' room

(Form A)/(Form C) Corner or wall mounted

Mirror Optic Wall Mount 5 curtains at 33ft. each

...................................................................................................

Model AP425/426 50' x 65' room

(Form A)/(Form C) Corner or wall mounted

Mirror Optic Wall Mount 7 curtains at 50ft. each

...................................................................................................

Model PR361/PR363 50' diameter-360° coverage

(Form A)/(Form C) Ceiling mount - low profile

Ceiling Mount 9 curtains at 25ft. each

...................................................................................................

Model PR569 (Form C)

Commercial Ceiling Mount

...................................................................................................

Model PR633/643

200 ft Long Range

80 ft Wide Angle

...................................................................................................

Range can be reduced to 20ft.

Mounting height 6'-10'

Mirror mask allows

coverage patterns

Mounting height 6'-10'

Mounting height 7'-12'

COMMERCIAL INDUSTRIAL

33' x 40' room

Corner or wall mounted

5 curtains at 33ft. each

Range can be reduced to 20ft.

Mounting height 6'-10'

50' x 65' room

Corner or wall mounted

7 curtains at 50ft. each

Mirror mask allows

coverage patterns

Mounting height 6'-10'

50' diameter-360° coverage

Ceiling mount - low profile

9 curtains at 25 ft. each

Mounting height 7'-12'

60' diameter-360° coverage 60' diameter-360°coverage

Ceiling Mount Ind./Comm. Ceiling Mount Ind./Comm.

12 curtains at 30 ft. each 12 curtains at 30ft. each

Mounting height 7'-15' Mounting height 7'-15'

Coverage patterns: Coverage patterns:

- Full 360° - Full 360°

- 90° Curtain - 90° Curtain

- ”L“ Turn Pattern - ”L“ Turn Pattern

- Corridor Intersection - Corridor Intersection

200' Long Range 200' Long Range

80' Wide Angle 80' Wide Angle

Wall Mount Wall Mount

12 selectable coverage 12 selectable coverage

patterns patterns

Mounting height 6'-10' Mounting height 6'-10'

SPACE DETECTION

2.3

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

SPECIFICATIONS

6150 6150XT 6160 6170

Series Series Series Series

Electrical

Voltage

3 Volt & 9 Volt Wireless

7 to 16 VDC

7 to 10 VDC

9 to 16 VDC

..............................................................................................................................

..............................................................................................................................

...............................................................................................................................

..................................................................................................................

✔✔

9.5 to 30 VAC/DC

Current

20uA typical

8mA typical, 10mA max

18mA typical, 20mA max 6179

..............................................................................................................................

.................................................................................................................

................................................................................................................

✔✔

50mA max

Alarm Loop Rating

16 VDC, 50mA

..........................................................................................................................

✔✔N/A 6177

30 VAC/DC, 1A; 125 VDC 50mA 6179

Alarm Output

Fail Safe contacts with 10 Ohms in series

Form A, normally closed (SPST) 6155, 6155CT, 6155AL 6155XT

Form C, normally closed and open (SPDT) 6157, 6157CT, 6157AL 6157XT 6177

Form C, no resistance in series 6179

.........................................................................................................

.............................................................................................

.........................................................................................................

Normally high and normally low

Alarm Duration

2 to 5 seconds

............................................................................................................................

✔✔

2 to 5 seconds in walktest mode

5 to 9 seconds in RF mode

.............................................................................................................

0 to 90 seconds retriggerable, adjustable 6179

Cover Tamper Contacts

Normally closed, rating: 50mA, 16-volts, no resistance

................................................................................

✔✔✔✔

Normally closed, rating 50mA, 16-volts, 10 Ohms in series

Environmental

Operating Temperature

0°F to 122°F (-17°C to 50°C) 6155, 6155AL

.............................................................................................................

6157, 6157AL

✔✔✔

-40°F to 122°F (-40°C to 50°C) 6155CT, 6157CT

✔

✔

✔

✔

6177

✔

6177

✔

SPACE DETECTION

Humidity

Dust Proof, Water Resistant

.............................................................................................................

10% to 90% noncondensing ✔✔✔

RFI Immunity

Greater than 10V meter from 0 to 1000 MHz

............................................................................................

✔✔✔✔

Lightning Immunity

2.5KV, 2 joules max energy impulse,

1 msec rise/50 msec decay

...............................................................................................................

Static Discharge 20KV

✔✔ ✔

✔✔✔✔

✔

2.4

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

SPECIFICATIONS

6180 6190 6250 6255FM 6350

Series Series Series Series Series

Electrical

Voltage

3 Volt & 9 Volt Wireless

7 to 16 VDC

7 to 10 VDC

9 to 16 VDC 6197

..............................................................................................................................

..............................................................................................................................

...............................................................................................................................

9.5 to 30 VAC/DC

Current

20uA typical

..............................................................................................................................

8mA typical, 10mA max

18mA typical, 20mA max

50mA max 6197

Alarm Loop Rating

16 VDC, 50mA

30 VAC/DC, 1A; 125 VDC 50mA

Alarm Output

Fail Safe contacts with 10 Ohms in series

Form A, normally closed (SPST) 6198 6255 6255FM 6351, 6352

Form C, normally closed and open (SPDT)

Form C, no resistance in series

Normally high and normally low

Alarm Duration

2 to 5 seconds

2 to 5 seconds in walktest mode

5 to 9 seconds in RF mode

0 to 90 seconds retriggerable, adjustable

Cover Tamper Contacts

Normally closed, rating: 50mA, 16-volts, no resistance

Normally closed, rating 50mA, 16-volts, 10 Ohms in series 6197

Environmental

Operating Temperature

0°F to 122°F (-17°C to 50°C)

-40°F to 122°F (-40°C to 50°C)

Humidity

Dust Proof, Water Resistant

10% to 90% noncondensing

RFI Immunity

Greater than 10V meter from 0 to 1000 MHz

Lightning Immunity

2.5KV, 2 joules max energy impulse,

1 msec rise/50 msec decay

Static Discharge 20KV

..................................................................................................................

.................................................................................................................

................................................................................................................

..........................................................................................................................

.........................................................................................................

.............................................................................................

.........................................................................................................

............................................................................................................................

.............................................................................................................

................................................................................

.............................................................................................................

.............................................................................................................

............................................................................................

...............................................................................................................

✔

✔

6198

6198

✔✔✔

✔✔✔

✔✔ ✔ ✔✔

✔

6197 6257 6257FM 6353

✔✔ ✔✔✔

✔

✔

6198

6198

6197-PIR only

✔✔

6255, 6257 6255FM, ✔

6257FM

6352, 6353

✔✔

✔✔

✔

✔✔

✔✔ ✔ ✔✔

✔✔ ✔ ✔✔

✔✔ ✔ ✔✔

SPACE DETECTION

2.5

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

PIR INSTALLATION GUIDELINES

SPACE DETECTION

Passive Infrared (PIR) motion sensor technology provides one of the most reliable

and cost effective methods for protecting spaces in the home, office or industrial

facility. PIR detectors sense temperature contrasts between a relatively stable

background and hotter or colder objects moving across their fields of view. They

emit no energy of their own. They merely “see” infrared images.

Sentrol, the world leader in security and life safety sensor devices, offers a

complete line of PIRs suitable for every application — residential, commercial,

and industrial. Sentrol PIR detectors fit compactly, aesthetically and unobtrusively

into any environment. This application section is designed to help you select the

appropriate PIR for your particular needs.

IMPORTANT DOs AND DON’Ts FOR ALL INSTALLATIONS —

residential, commercial or industrial.

• Do position the PIR so that any intruder must cross the PIR’s field of view. To

trigger an alarm, an intruder must cross both the positive and negative elements

of one zone of the PIR’s sensor.

• Do pre-test the PIR in the direction of likely intruder motion and walk-test

monthly.

• Do locate the PIR so that valuables are well within its coverage pattern.

• Do terminate each protection zone on a solid object such as a wall or floor

whenever possible. This provides maximum detection.

• Do mask zones around fireplaces because a smoldering log can change

temperature quickly if it bursts into flames.

• Do use an industrial PIR in locations where a standard PIR may be affected by

water, steam or oil.

• Don’t aim PIR detectors at sources of rapid heating or cooling. These include

forced air ducts, space heaters, direct sunlight, strong white lights and mirrors

that can reflect strong lights.

• Don’t obstruct the PIR’s field of view.

SPACE DETECTION

2.6

.........................................................................................................................................................................

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

OTHER INSTALLATION TIPS

Pre-wiring — Pre-wiring allows you to work with the builder in the planning

stage to determine optimum locations for sensors. It will also allow you to avoid

many of the hazards inherent in post-construction installations i.e. drilling through

the electrical cables, plumbing, and duct-work hidden in existing walls.

When wiring after construction, compromises are usually the norm — existing

walls, lighting fixtures, air conditioning ducts, and other obstacles often determine

sensor and control panel locations. Compromises such as these can leave “blind

spots” in security installations.

Pre-wiring also allows you to run extra wires, a practice rarely seen in “post-wired”

systems. Extra wires give the home or business owner the flexibility to easily add

other features at a later date.

Pre-wiring allows you to avoid many of the hazards inherent in post-construction

installations hazards such as water supply pipes, drain-waste-vent pipes, heating

and cooling duct work, venting duct work for kitchens and bathrooms, and high

voltage wiring.

Sensors are now available that will fit into standard outlet boxes just like a light

switch. Sentrol offers two products for prewiring applications. The Flush Mount

SureShot PIR fits into a standard single gang box, remodel box or rough-in plate in

two easy steps. You simply connect the wires to the proper terminals on the back

of the unit, then screw the unit into an outlet box like you would a switch. The

Sharpshooter also has a recessed bezel kit available as an accessory.

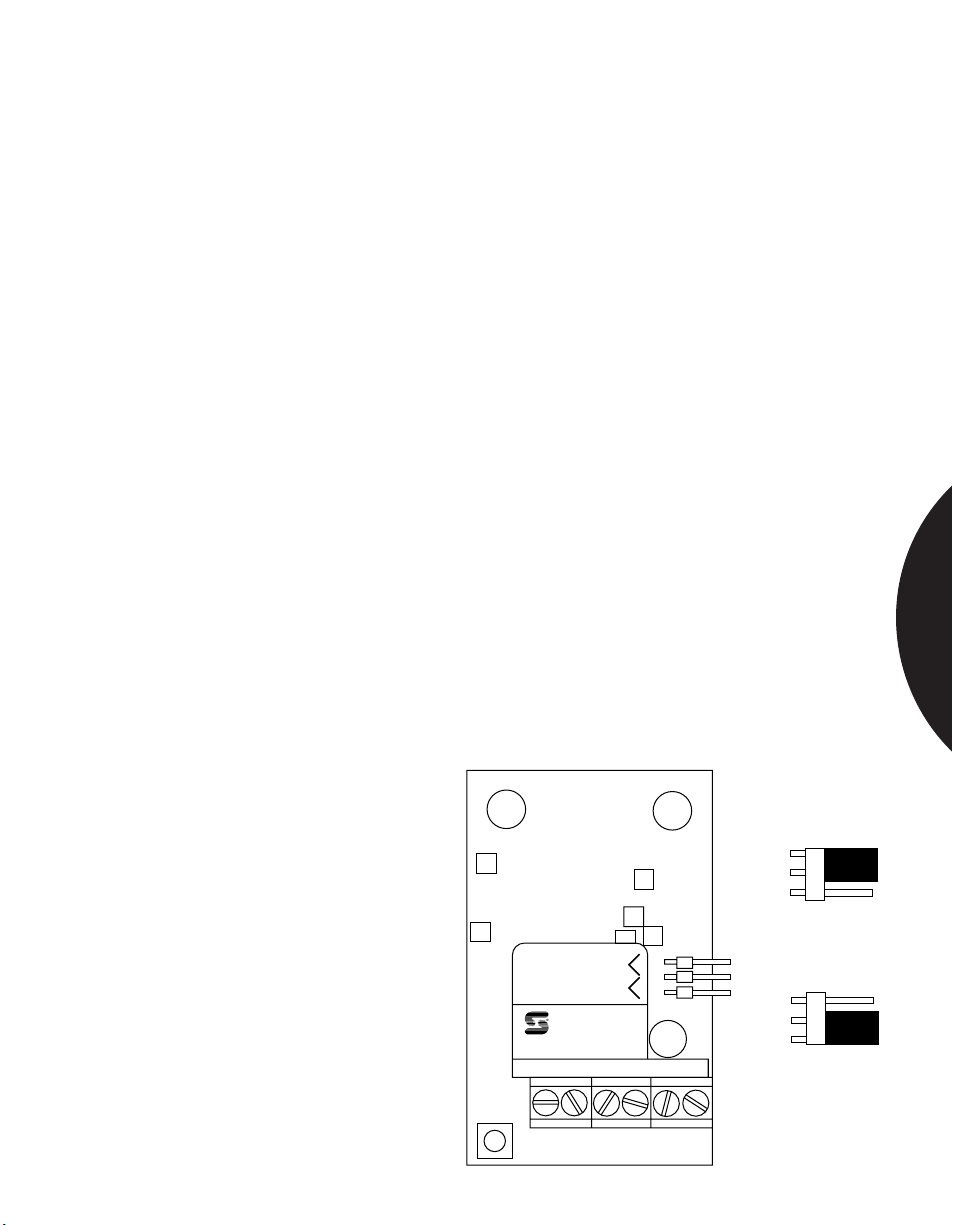

Reducing False Alarms — Sentrol PIRs allow selection of one- or two-zone

detection. Each zone is made up of two fields of view — one positive and one

negative. With one zone selected, an alarm will be indicated when an intruder

moves across one positive and one negative field. With two zones selected, an

intruder must cross the

positive and negative fields

of each of the two zones

before an alarm will be

indicated. Two-zone

detection is recommended

(except when using long

range and curtain lenses) to

reduce chances of false

alarm. One- and two-zone

detection is selected by

simply moving the jumper

as indicated in the diagram.

Two Zones

Remove

(4 pulse)

for

One Zone

Test

(2 pulse)

SENTROL, INC.

SHARPSHOOTER

6155XT

NC COM TAMP TAMP

+–

Two Zone

One Zone

SPACE DETECTION

2.7

Loading...

Loading...