Page 1

Model PM Series Three Axis Mills

PM3000

PM2000

Features

Setup & Operation

Technical Data

CLIMAX

Portable Machine Tools, Inc.

10/98 1

Page 2

Features

Climax's PM Series 3-axis portable milling machines

provide precise and versatile on-the-job milling

capabilities. They are designed to be attached either

to the work piece or to a fabricated frame beside it.

Downtime savings will pay for the machine in a

short time.

• All gears and drives are permanently lubricated

and sealed to allow operation in any position.

• Precision machined dovetail ways and adjustable

gibs provide smooth accurate travel.

Longitudinal travel (bed):

• 20" (508 mm) for PM2000

• 49" (1244.6 mm) for PM3000

• 78" (1981 mm) for PM4000.

A 1 hp electric

motor is standard

equipment; a

pneumatic power

option is available

for flammable

vapor areas.

Cross travel (top slide):

• 8-inch (203 mm)

• Hand-fed with a crank or power-fed with your

3/8 inch drill.

A portable variable speed drill

motor may be

used as a power

cross feed drive

by applying it to

the external stud

provided.

Vertical travel (spindle):

• 3" (76 mm) for all models, controlled by hand

crank.

• The vertical adjusting screw is calibrated for

accurate adjustments and has a locking nut for

zeroing.

Power feed on the

longitudinal axis

provides an infinitely variable feed

rate from 0 to 20

IPM with pushbutton rapid

traverse.

• Push-button rapid traverse saves time between

cuts.

• Adjustable feed stops on the slide are standard.

• Forward, neutral and reverse modes are controlled

by a shift lever. A hand wheel is provided for fine

adjustments.

• Power is delivered by a triple gear reduction

power head with in-line electronic speed control

providing spindle speeds from 280 to 525 rpm.

• Spindle accepts standard 3/4" Weldon-type shank

cutting tools. A 20 mm spindle is available for

metric applications.

The PM-B Series Portable Mill

This 2-axis machine has a blank tool post slide

instead of the top slide assembly, so it

can be modified

to suit the job

site needs.

Longitudinal

travel is the

same as for

the PM series

machines.

Tool post slide travel

is 6.4" (162.5 mm).

2 10/98

Page 3

Applications

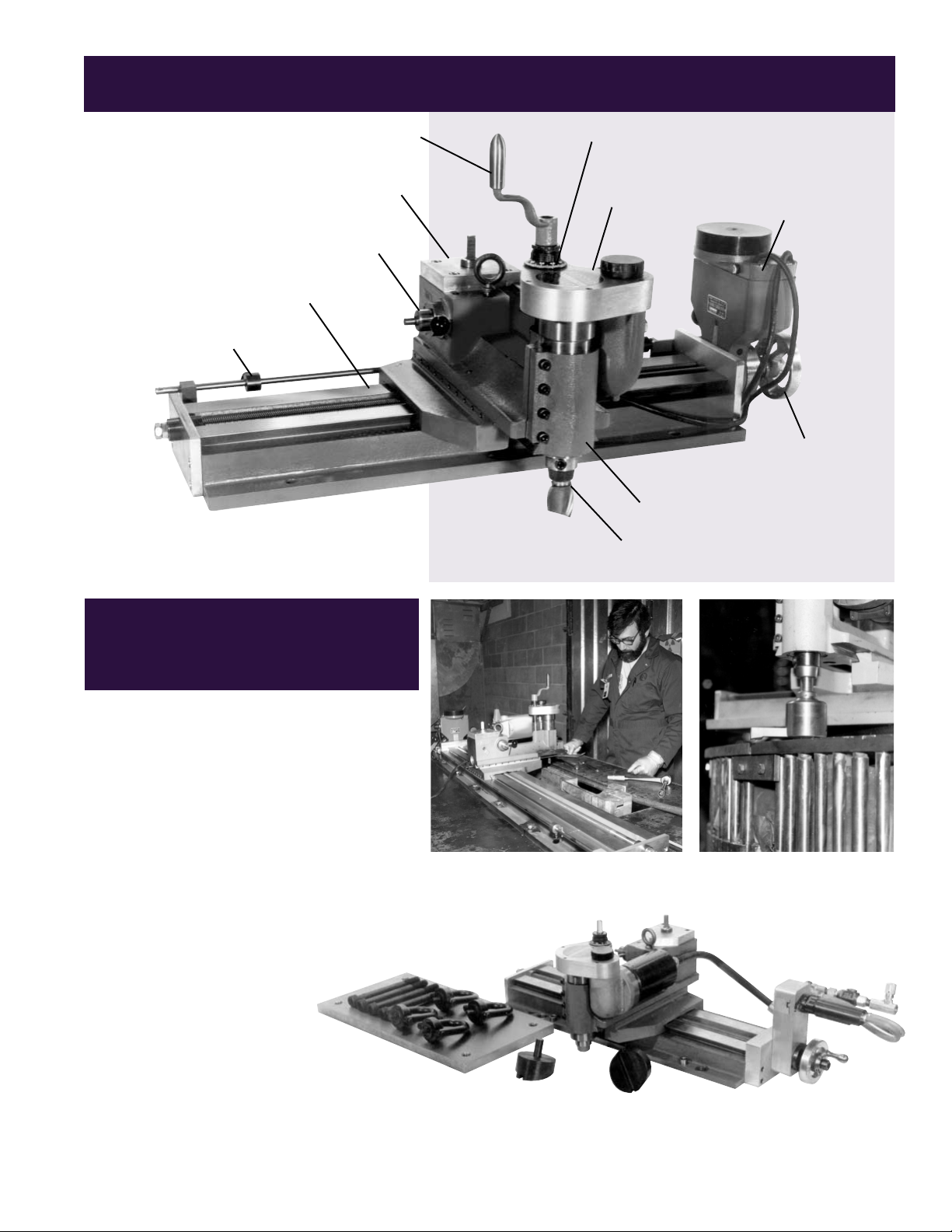

Removable hand crank

Manual feed (cross slide)

Stud for external power feed

source (cross slide)

Precision machined

dovetail ways

Adjustable

feed stop

Model PM2000

Vertical adjusting screw with

zeroing type dial in .001

increments

Triple gear reduction

Power feed

Manual feed

(x-axis)

Adjustable quill clamp

Standard 3/4" Weldon type spindle

A Wide Variety

of Applications

The Climax PM Series are especially

useful for milling large cumbersome

parts. Anyone familiar with basic

machining practices will find these

portable mills simple to operate. Many

customers use the PM Series machines when welding up and remachining worn parts on production

machinery such as stamping presses.

Long motor mount slots are easily

machined, often without dismantling

since the mill can be mounted right on

the part. Aluminum smelter plants have

used a PM2000 with a fly

cutter to quickly face off the

pitted surface of 20-foot

beams used as bus bars.

A PM3000 milling a turbine

diaphragm at Philadelphia

Electric.

Using a PM2000 with a fly

cutter to mill the flange on

a large pump on-site.

A PM2000 with pneumatic motor, shown here with fly

cutters, was used to reface 20 foot bus bars in an aluminum

plant.

10/98 3

Page 4

Setup and Operation

The PM Series is designed to meet the

requirements of a variety of applications and can

be mounted in any position the job calls for - even

upside down. Electronic speed control provides

reduced spindle speeds for harder materials. Gear

box, spindle, quill, and vertical adjusting screw

assembly may be removed as a unit to sharpen or

replace the end mill.

Setup

Setup of the portable mill consists of positioning it

where you want it in relation to the work piece and

clamping or bolting it securely in place. Attach the

base directly to the work piece using the bolt-down

bosses provided or position it next to the work on a

fabricated frame. Mounting rigidity is very

important. The best way to mount the machine is to

weld attachment points right on the work piece.

This eliminates vibration, flexing and other sources

of chatter. If you are using an overhead frame for

mounting the machine upside down, be sure the

frame is rigid enough to handle the weight and side

torque forces of milling operations.

Look to Climax

Climax has over 7,000 portable metal-cutting

machines in service worldwide. Our years of

experience mean we probably have a machine

to solve your maintenance problem; if not, we

can modify an existing machine or design one to

fit your application. Our machines are designed

to get the job done for you accurately and save

you downtime in the process. Give us a call

today... we will be happy to talk with you about

your application.

Operation

Operation of a PM Series mill is similar to any 3axis milling machine. Once the machine is rigidly

mounted, insert the proper cutter in the spindle,

and position for the cut. A rapid travel button allows

for faster milling head positioning. Feed control

varies with the power option. It is possible to

operate both the X and Y-axis feeds at the same

time. After positioning, the gibs should be adjusted

to provide a smooth, even cut. The hand crank

may be used for travel in all three axes.

A specially modified PM2000 with an air

motor.

4 10/98

Page 5

PM Technical Information

Specifications (Inches/mm)

Specifications subject to change without notice.

For precision dimensions consult your factory representative.

MACHINE SPECIFICATIONS:

Overall length (w/o feed

assembly):

Overall width

Minimum:

Maximum (top slide

extended):

Overall height (std mach)

Minimum:

Maximum:

Overall height (B-series):

Height from mounting

surface to spindle nose

Minimum:

Maximum:

Milling area (single setup):

Longitudinal travel:

Cross slide travel:

PM2000/PM2000-B

36.85 (935.99)

13.22 (335.79)

20.22 (513.59)

13.6 (345.4)

16.6 (421.6)

11.3 (287.0)

0.6 (15.2)

3.6 (91.4)

8.0 x 20.0 (203.2 x 508.0)

20.0 (508.0)

8.0 (203.2)

PM3000/PM3000-B

64.85 (1672.99)

13.22 (335.79)

20.22 (513.59)

13.6 (345.4)

16.6 (421.6)

11.3 (287.0)

0.6 (15.2)

3.6 (91.4)

8.0 x 49.0 (203.2 x 1244.6)

49.0 (1244.6)

8.0 (203.2)

PM4000/PM4000-B

94.85 (2409.19)*

13.22 (335.79)

20.22 (513.59)

13.6 (345.4)

16.6 (421.6)

11.3 (287.0)

0.6 (15.2)

3.6 (91.4)

8.0 x 78.0 (203.2 x 1981.2)

78.0 (1981.2)

8.0 (203.2)

Vertical travel:

Spindle size:

No-load spindle speed

(electric motor):

(air motor*):

(hydraulic motor**):

Blank tool slide length:

Blank tool slide travel:

Working weight

Machine only:

* Air motor requires 105 cubic feet per minute (3m3/min) at 80 psi (550 kPa).

** Configurations including special bed lengths and hydraulic milling heads available upon special request.

3.0 (76.2)

.75"

(20)

280-525 rpm

Up to 900 rpm

Up to 274 rpm

11.0 (279.4)

6.4 (162.5)

332 lb (151 kg)

3.0 (76.2)

.75"

(20)

280-525 rpm

Up to 900 rpm

Up to 274 rpm

11.0 (279.4)

6.4 (162.5)

544 lb (248 kg)

3.0 (76.2)

.75"

(20)

280-525 rpm

Up to 900 rpm

Up to 274 rpm

11.0 (279.4)

6.4 (162.5)

710 lb (323 kg)

10/98 5

Page 6

PM Operational Dimensions

10.18 (258.57)

Model Dim. A Dim. B No. of Dim. C

PM2000 20.0 (508.0) 29.0 (736.6) 6 10. (2)

PM3000 49.0 (1244.6) 58.0 (1473.2) 12 10.0 (254.0)

PM4000 78.0 (1981.2) 87.0 (2209.8) 18.0 (25)

Long. Travel Bed Length Mtg Holes Hole Spacing

.85 (21.59)

2.13 (54.1)

4.0 (101.6)

8.0 (203.2)

travel

13.00 (330.2) min

21.00 (533.4) max

13.6 (345.4) min

16.6 (421.6) max

3.0 (76.2)

vert. travel

3.55

(90.17)

.6 (15.2)

2.18 (55.37)

1.25

(31.75)

4.5 (165.1)

PM Series Portable Mill

.50 (12.7)

8.69 (220.73)

L

C

Spindle

.56 (14.22)

dia.

11.3 (287.0)

A

C

B

4.0

(114.3)

6.7

(170.2)

1.5 (38.1)

Inches (mm)

Specifications subject to

change without notice.

Please refer to the

Technical Information

page for further details.

6.4 (162.5)

tool slide

travel

6.04

(153.42)

6 10/98

2.13

(54.10)

2.30 (58.42)

10.80 (274.32) min

17.20 (432.82) max

.56 (14.22) dia.

8.69 (220.73)

10.18 (258.57)

L

C

Spindle

1.25

(31.75)

4.5

(165.1)

A

PM-B Series Portable Mill

5.0 (127.0)

B

11.0

(279.4)

11.3

(287.0)

C

4.0

(114.3)

6.7

(170.2)

1.5 (38.1)

Page 7

Cross slide power feed assembly

Stop rod assembly

PM Series Components

Vertical adjusting shaft

Cross slide assembly

ON/OFF switch

Lifting eye

Bed assembly

Electric power

feed assembly

Adjusting knob

Gear box assembly

Spindle & quill assembly

Quill clamping screws

Vertical adjusting screw assembly

Top slide assembly

Other configurations including hydraulic milling

heads are available upon special request

NO. DESCRIPTION NO. DESCRIPTION

PM2000 Portable Milling Machine

Three-axis milling machine with 20" (508

mm) of longitudinal travel. Machine comes

complete with one end mill, tool kit, speed

control, and instruction manual.

10726 PM2000 -inch, 115V power head,

115V power feed

Machine includes one .75" dia. x

.75" shank end mill, 115V milling

head, and 115V longitudinal feed

and in-line speed control.

10730 PM2000 - metric, 230V power

head, 115V power feed

Machine includes one 20 mm dia. x

20 mm shank end mill, 230V milling

head, and 115V longitudinal feed

and in-line speed control.

11680 PM2000 -inch, air power head, air

power feed

Machine includes one .75" dia. x

.75" shank end mill, 2 hp (1.49 kW)

air milling head**, and .31 hp (.23

kW) air longitudinal feed.

PM3000 Portable Milling Machine

Three-axis milling machine with 49" (1244.6

mm) of longitudinal travel. Machine comes

complete with one end mill, tool kit, speed

control, and instruction manual.

10732 PM3000 -inch, 115V power head,

115Vpower feed

Machine includes one .75" dia. x .75"

shank end mill, 115V milling head,

and 115V longitudinal feed and in-line

speed control.

10736 PM3000 - metric, 230V power head,

115V power feed

Machine includes one 20 mm dia. x 20

mm shank end mill, 230V milling

head, and 115V longitudinal feed and

in-line speed control.

12340 PM3000 - inch, air power head, air

power feed

Machine includes one .75" dia. x .75"

shank end mill, 2 hp (1.49 kW) air

milling head**, and .31 hp (.23 kW) air

longitudinal feed.

NO. DESCRIPTION

PM4000 Portable Milling Machine

Three-axis milling machine with 78" (1981.2

mm) of longitudinal travel. Machine comes

complete with one end mill, tool kit, speed

control, and instruction manual.

10739 PM4000 - inch, 115V power head,

115V power feed

Machine includes one .75" dia. x

.75" shank end mill, 115V milling

head, and 115V longitudinal feed

and in-line speed control.

10743 PM4000 - metric, 230V power

head, 115V power feed

Machine includes one 20 mm dia. x

20 mm shank end mill, 230V milling

head, and 115V longitudinal feed

and in-line speed control.

25419 PM4000 - inch, air power head, air

power feed

Machine includes one .75" dia. x

.75" shank end mill, 2 hp (1.49 kW)

air milling head**, and .31 hp (.23

kW) air longitudinal feed.

17365 PM2000 - B Series, 115V power

feed

Same as machine described above

except it has a tool post in place of

the milling head, and 6" (152 mm)

cross slide travel. Includes 115V

longitudinal feed.

*Other configurations including hydraulic milling heads available upon special request.

**Air motor requires 105 ft

17366 PM3000 - B Series, 115V power feed

Same as machine described above

except it has a tool post in place of the

milling head, and 6" (152 mm) cross

slide travel. Includes 115V longitudinal

feed.

3

/min (3 m3/min) at 80 psi (550 kPa).

17367 PM4000 - B Series, 115V power

feed

Same as machine described above

except it has a tool post in place of

the milling head, and 6" (152 mm)

cross slide travel. Includes 115V

longitudinal feed.

10/98 7

Page 8

CLIMAX

Portable Machine Tools, Inc.

2712 E. Second St., P.O. Box 1210

Newberg, OR 97132-8210 U.S.A.

Worldwide Tel. 503/538-2185

FAX 503/538-7600

Call toll free

800/333-8311

Visit our web page at

http://www.cpmt.com

8 10/98

TD32-1M1098 PRINTED IN U.S.A.

Loading...

Loading...