Climax LM6000 User Manual

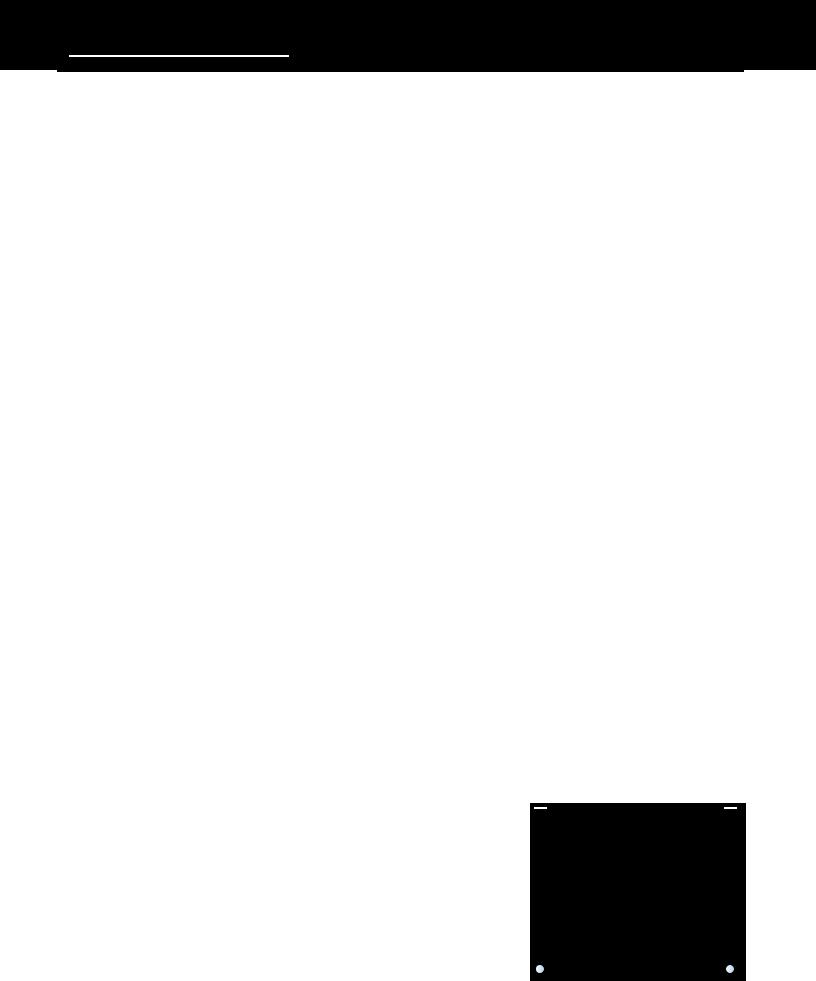

L M 6 0 0 0 L i n e a r M i l l

F e a t u r e s • S e t u p & O p e r a t i o n

C o m p o n e n t s & A c c e s s o r i e s • T e c h n i c a l D a t a

Portable, on-site milling solves difficult repair problems.

The Climax LM6000 Linear Mill has been designed to handle the most demanding field machining conditions. The extra heavy-duty bed is extremely rigid, to provide precision milling within tight tolerances. A robust spindle design and a choice of hydraulic power

units with 25 Hp (18.6 kW) provide you with the power to utilize cutter heads up to 8.0 inches (203.2 mm) in diameter. Even when milling in a vertical orientation, you can get the job done fast. New heavy duty electric feed motors and a unique self-cleaning ball screw drive system provide powerful drive options in

both the X and Y axis (optional Z axis power drive also available). A faster rapid advance feature also allows you to quickly move the milling spindle to the area to be machined, saving you time.

Close tolerance levels

•Extremely rigid welded steel bed structure designed using computerized Finite Element Analysis (FEA). This advanced

process provides maximum rigidity by minimizing sag and torsional twisting to improve conventional & over-head machining operations.

•Rigidity allows machining to very tight tolerance levels.

Powerful

•New heavy duty spindle design and a choice of hydraulic power units with 25 Hp (18.6 kW) allow use of cutter heads of up to 8.0 inches (203.2 mm) in diameter for fast aggressive milling even in the vertical orientation.

This high level of machining power means you will finish your jobs much faster.

Compact Design

•While designing more power and rigidity into the LM6000, we have also reduced the mill’s vertical dimension, which means you can apply the power of the LM6000 to previously inaccessible work areas.

•Feed boxes for each axis are mounted using a clamping system that requires only one screw to mount. The feed may be rotated and clamped in any position in 360° to avoid work area obstacles.

•Feeds for the X and Y axes may be mounted on either end of the bed or ram.

Accurate and precise

•Both X & Y axis utilize hardened square ways. The square ways are precision ground and hardened for accuracy and long life.

•Main bed and ram feature large diameter precision ball screws for accuracy and long nut life.

•Ball nuts are lubricated by the oiling system that is integral to the saddle plates, and are protected from chips and contamination by a 3 step sealing system.

•Chromed & precision-ground Heavy-Duty Quill.

B r i n g i n g t h e s o l u t i o n t o y o u .

Specifications

Specifications

Travel/Standard |

Travel/Metric |

Main bed travel lengths (X-axis) 48.0 inches |

1219.2 mm |

72.0 inches |

1828.8 mm |

96.0 inches |

2438.4 mm |

120.0 inches |

3048.0 mm |

144.0 inches |

3657.6 mm |

RAM assembly (Y-axis) travel, inverted or overhead machining (Riser required)

Ram length 36 inch (609.6 mm) |

24.0 inches |

609.6 mm |

Ram length 48 inch (914.4 mm) |

36.0 inches |

914.4 mm |

Ram length 60 inch (1219.2 mm) |

48.0 inches |

1219.2 mm |

RAM assembly (Y-axis) travel, standard setup (Measurements are from center of spindle to edge of bed)

Ram length 36 inch (609.6 mm) |

14.5 inches |

368.3 mm |

Ram length 48 inch (914.4 mm) |

26.5 inches |

673.1 mm |

Ram length 60 inch (1219.2 mm) |

26.5 inches |

673.1 mm |

NOTE: Max. recommended Y-axis travel with 60 inch (1219.2 mm) ram partially offset. When the ram is centered, the travel is 16.25 inches (412.75 mm) each side.

Spindle assembly (Z-axis) |

|

|

Travel |

4.0 or 8.0 inches |

101.6 or 203.2 mm |

Power options |

Hydraulic or Pneumatic |

|

Hydraulic Power Units |

25 Hp |

18.6 kW |

Maximum cutter diameter |

8.0 inches |

203.2 mm |

Tool attachment (spindle taper) |

#40 or #50 taper NMTB |

|

Power feed assemblies |

|

|

Heavy duty electric feed available for X, Y, Z-axis.

X & Y axis power feed utilize self-cleaning ball screw for long service life.

Manual hand wheels are provided for any axis without a power feed (Z-axis feed uses ACME leadscrew).

Feed Rate |

1.0 - 20.0 inches/min. |

25.4 - 508.0 mm/minute |

Rapid advance (horizontal or vertical) |

20.0 inches/min. |

508.0 mm/minute |

Machine control center |

|

|

Single pendant control panel (integrated with the Climax Hydraulic Power Unit) provides power control to all three axes and spindle. Includes instant rapid advance button. Optional control panel available to control 3-axis feed only, for use with customer-supplied Hydraulic Power Unit.

All dimensions should be considered reference. Contact your Climax Representative for precision dimensions.

Specifications are subject to change without notice.

There are no systems or components on this machine that are capable of producing hazardous EMC, UV or other radiation hazards.

The machine does not use lasers nor does it create hazardous materials such as gasses or dust.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

page 2 |

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com |

|||||

|

|

|

|

|

||

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com |

||||||

|

||||||

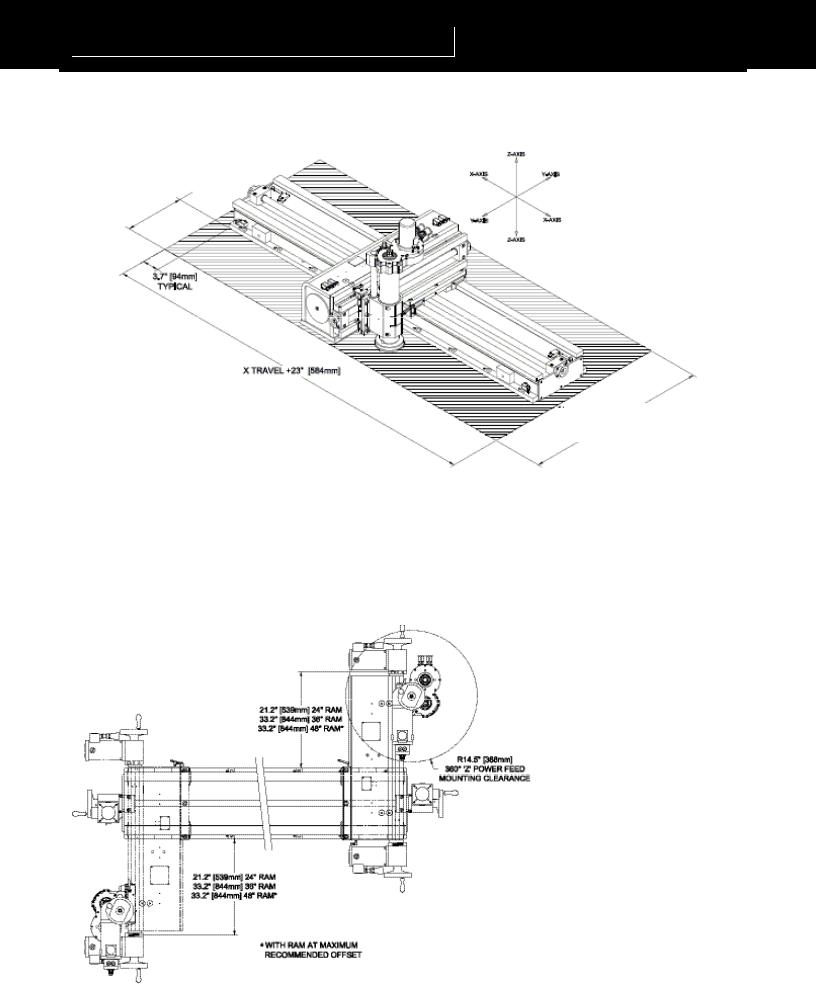

Operational Dimensions

Milling Area Dimensions

Dimensions in Inch (mm)

14.5 (368.3) (with 24” RAM)

26.5 (673.1) (with 36” RAM)

**26.5 (673.1) (with 48” RAM)

44.7 (1135.4) (with 24” RAM)

88.5 (2247.9) (with 36” RAM) ** 88.5 (2247.9) (with 48” RAM)

**Dimensions shown are with RAM at MAXIMUM RECOMMENDED OFFSET

Total area around mill base that can be milled by offsetting the Ram on both sides, and by rotating the Ram 180º. When milling overhead, the entire area may be milled.

(Dimensions shown are to the centerline of the spindle)

Overhead view (with Ram at maximum recommended offset)

The Ram (Y-Axis) may be offset to either side of the bed, and clamped. Dovetail clamps allow the Ram to be locked in any position. The Ram may also be rotated 180º for increased flexibility.

The optional Z-axis power feed may be rotated to any 360º position, and clamped in place.

page 3 |

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com |

|

|

||

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com |

||

|

Loading...

Loading...