Page 1

PL3000 PORTABLE LATHE

Eliminates most of the dismantling needed

to do a simple metal cutting repair job.

The rugged and dependable Climax Model

PL3000 Portable Lathe is a precision

machine tool engineered re-turn large shafts

and roll journals by bolting directly to the

end of the workpiece and rotating around

the shaft.

Heavy duty, powerful, precise

• Heavy solid steel turning bar and

counterbalanced body provide smooth

turning and minimum chatter, even with

the turning bar at maximum reach.

• The motor and planetary ring gear drive

provide enough torque to remove up to

0.125 inch (3.175 mm) of metal so you

can get the job done fast.

• A 3.08 Hp (2.3 kW) electric motor and

a 1.22 Hp (0.91 kW) pneumatic motor

is available.

• Tool reach is 16.0 inches (406.4 mm)

from end of shaft, and up to 22.0

inches (558.8 mm) with optional turning

bar extension.

• Turns shafts from 4.0 - 11.25 inches

(101.6 - 285.75 mm). (This machine

works within a 16.75 inch (425.5mm)

diameter space around the shaft (swing

diameter), and 36 inches (914.4 mm)

from the end of the shaft.)

• Automatic axial feed is variable from

0.003 - 0.011 inches/rev. (0.076 - 0.279

mm/rev.) in 7 increments

Quick and easy to set up

• Mounts on the end of the shaft. Simply

remove the gear or bearing to expose

the end of the shaft.

• The PL3000 can be set up by an

experienced operator in less than an

hour. Drill and tap four mounting holes

on the end of the shaft to attach the

taperedmountingange.

• Adjusting screws allow accurate

centering and alignment even if the

shaft face is no longer square.

08

2010

PL3

Page 2

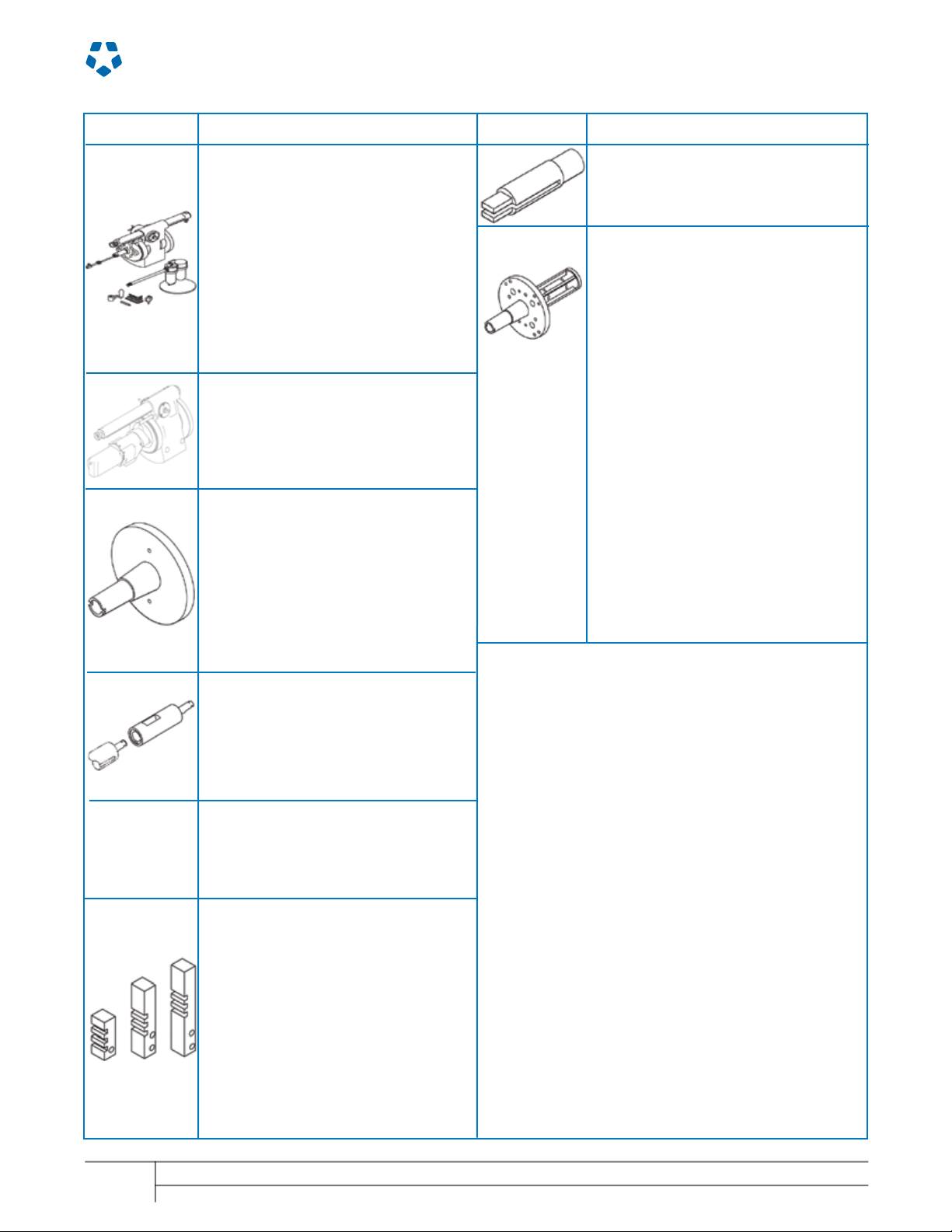

ACCESSORIES

No. Description

10649 PL3000 portable lathe, pneumatic

10649CE CE-Compliant model

Complete lathe machine. Turns shafts and roll journals

8.0 - 11.0 inches (203.2 to 279.4 mm) in diameter.

Machine mounts to the end of the shaft with a blank

tapered mounting flange (included). Also includes

counterbalanced mainbody, pneumatic planetary housing,

1.22 hp (.91 kW) air motor, pneumatic conditioning unit,

16.0 inch (406.4 mm) reach turning bar, abrasive belt

holder, tool kit with 3/8 inch (or 10 mm) square HSS lathe

tool and dial indicator, instruction manual, and wooden

storage crate.

Model PL3000 portable lathe, electric

As above with electric motor and speed control instead of

the air motor and pneumatic conditioning unit.

13872 PL3000 Portable lathe, 120V motor

15524 PL3000 Portable lathe, 230V motor

Tapered mounting flange assembly

Precision machined mounting flange securely mounts the

portable lathe to the end of the shaft. One blank mounting

flange is included with the machine.

10640 Blank tapered mounting flange assembly.

Machine to your mounting configuration.

10642 Machine tapered mounting flange

assembly. Factory machined to your

mounting specifications.

No. Description

10586 Abrasive belt holder

Belt holder mounts to the tool end of the turning bar. Use

with an abrasive belt to produce a fine finish on the shaft.

Abrasive belts not provided.

11784 ID Mounting collet assembly

Allows the PL3000 to be mounted inside work piece

diameters from 4.7 - 10.95 inches (119.4 -278.1 mm).

Assembly includes ID mounting flange, collet body with

fingers and jaws, screw shaft with threaded cones, and

necessary hardware.

28545 ID mounting collet assembly, no jaws

Same as above without fingers or jaws.

ID jaw sets

Jaw set Fits in dia.

28539 0.5 (12.7) 4.7 - 5.95

(119.4 - 151.1)

28540 1.0 (25.4) 5.7 - 6.95

(144.8 - 176.5)

28541 1.5 (38.1) 6.7 - 7.95

(170.2 - 201.9)

28542 2.0 (50.8) 7.7 - 8.95

(195.6 - 227.3)

28543 2.5 (63.5) 8.7 - 9.95

(221.0 - 252.7)

28544 3.0 (76.2) 9.7 - 10.95

(246.4 - 278.1)

10636 Turning bar extension - 22 inch

(558.8 mm) reach

Mount the turning bar extension between the end of the

standard turning bar and the tool housing to extend the

reach of the bar from 16.0 - 22.0 inches (406.4 - 558.8

mm). For longer bar reaches, contact your Climax

representative.

37811 Tooling Pack (not shown)

One HSS 3/8 inch x 3.0 inch side cutting tool

bit, and one HSS

3/8 inch x 3.0 inch top cutting tool bit

in storage case.

Tool holders

Extra tool holders for use with the standard 16.0 inch

(406.4 mm) turning bar and the 22.0 inch (558.8 mm)

turning bar extension. Holders use 3/8 inch or 10 mm

square HSS lathe tool bits.

10643 Tool holder, 4 - 6 inches Used to turn

shafts 4 - 6 inches (101.6 to 152.4 mm)

in diameter

10644 Tool holder, 6 - 8 inches Used to turn s

hafts 6 - 8 inches (152.4 to 203.2 mm)

in diameter.

18368 Tool holder, 8 - 11 inches Used to turn

shafts 8 - 11 inches (203.2 to 279.4 mm)

in diameter

NOTE: Drawings are for reference only, are not to scale, and

may not represent actual product.

page 2

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 3

SPECIFICATIONS

US Metric

Overall length, electric

std. bar fully retracted 27.0 inches 685.8 mm

std. bar fully extended 43.0 inches 1092.2 mm

Overall length, pneumatic

std. bar fully retracted 31.0 inches 787.4 mm

std. bar fully extended 47.0 inches 1193.8 mm

Overall width 10.5 inches 266.7 mm

Overall height, with the optional 16.0 inches 406.4 mm

Turning Reach (from spindle face)

standard bar 16.0 inches 406.4 mm

standard bar w/ optional extension 22.0 inches 558.8 mm

Shaft dia. max 11.25 inches 285.8 mm

Shaft dia. min

with standard tool holder (18368) 8.0 inches 203.2 mm

with optional tool holder (10644) 6.0 inches 152.4 mm

with optional tool holder (10643) 4.0 inches 101.6 mm

Swing clearance, min. radius 8.375 inches 212.7 mm

Axial feed, automatic 0.003 - 0.011 inches/rev 0.076 - 0.279 mm/rev

Turning bar diameter 2.31 inches 58.7 mm

Cutter 3/8 inch lathe tool bit 10 mm lathe tool bit

Tool depth adjustment, manual 1.125 inches total 28.575 mm total

radial travel in three increments of: 0.375 inches 9.525 mm

Power, electric

120V, 60 Hz continuous 3.08 Hp 2.30 kW

Intermittent 4.80 Hp 3.58 kW

230V, 50 Hz continuous 3.08 Hp 2.30 kW

Intermittent 4.80 Hp 3.58 kW

Torque: 98 ft-lbs (135 N·m) max at 72 rpm bar speed. Bar free speed: 72 rpm max. Gear ratio: 8:1. Variable

speed control with settings 20 - 72 rpm.

Power, pneumatic 1.22 Hp 0.91 kW

[non-reversing, Hp rated at 265 rpm). Torque: 24.2 ft-lbs (32.9 N·m) at full power, 33 rpm. Gear ratio 8:1.

Infinitely variable speed control with needle valve. Air flow required: 90 psi @ 30 ft3/min

(620 kPa @ 0.85 m3/min).]

Operating weight 200 lbs. 90.7 kg

Shipping weight 261 lbs. 118.4 kg

Shipping dimensions L x W x H 33 x 27 x 17 inches 838.2x685.8x431.8 mm

All dimensions should be considered reference. Contact your Climax Representative for precision dimensions. Specifications are subject to change without notice. There are no systems or components

on this machine that are capable of producing hazardous EMC, UV or other radiation hazards. The machine does not use lasers nor does it create hazardous materials such as gasses or dust.

page 3

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 4

OperatiOnal DimensiOns

Electric

page 4

Pneumatic

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 5

Training at the Global Learning Center

Climax has been teaching the fundamentals and fine

points of portable machine tool operation for practically as

long as we’ve been inventing and building the tools.

At the Climax Global Learning Center situated in our

corporate headquarters near Portland, Oregon, we

provide training for machine tool operators on portable

machine tool safety, and machine setup and operation.

Trainees also receive technical tips and tools to improve

operational efficiencies, with the vast majority of every

program devoted to hands-on activities and skill

development.

The Climax instructional team includes specialists in shipbuilding, power generation, civil engineering, bridge re-building,

petrochemical and other industries.

Whether it’s a regularly scheduled course at the Global Learning Center, or custom curriculum conducted at your facility,

your machinists will benefit from courses developed by some of the most respected authorities in the business.

Call us today to register for a regularly scheduled class, or talk to us about how we can customize a training program for

your specialized application.

page 5

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 6

CLIMAX GLOBAL LOCATIONS

Edmonton

World Headquarters

Portland

Houston

Monterrey

Cincinnati

European Headquarters

Manchester

Charlotte

Baton Rouge

Manchester

Cologne

Production Facilities

Rental Locations

International Distributors

Regional Sales & Technical Support Offices

Gdansk

Singapore

Perth

Call Climax for:

On-site Training

Need some refresher courses in setting up

and operating your Climax machine tool?

Special Projects

Climax has been solving complicated

on-site machining and welding problems for

our customers since 1964.

World Headquarters

2712 E. Second Street

Newberg, Oregon 97132 USA

Worldwide Telephone: 1.503.538.2185

N. America Toll-Free: 1.800.333.8311

Fax: 1.503.538.7600

Email: info@cpmt.com

Rentals

With seven locations in North America, two

in Europe and two in Asia, you are never

far away from a Climax portable machine

tool.

Connect with us:

European Headquarters

Am Langen Graben 8

52353 Düren, Germany

Telephone:(+49) (0) 2421.9177.0

Fax: (+49) (0) 2421.9177.29

Email: info@cpmt.de

Copyright © 2012 Climax Portable Machining & Welding Systems. All Rights

Reserved. Climax has taken reasonable measures to ensure the accuracy

of the information contained in this document. However, Climax makes no

warranties or representations with respect to the information contained herein;

and Climax shall not be held liable for damages resulting from any errors or

omissions herein, or from the use of the information contained in this document.

Loading...

Loading...