Page 1

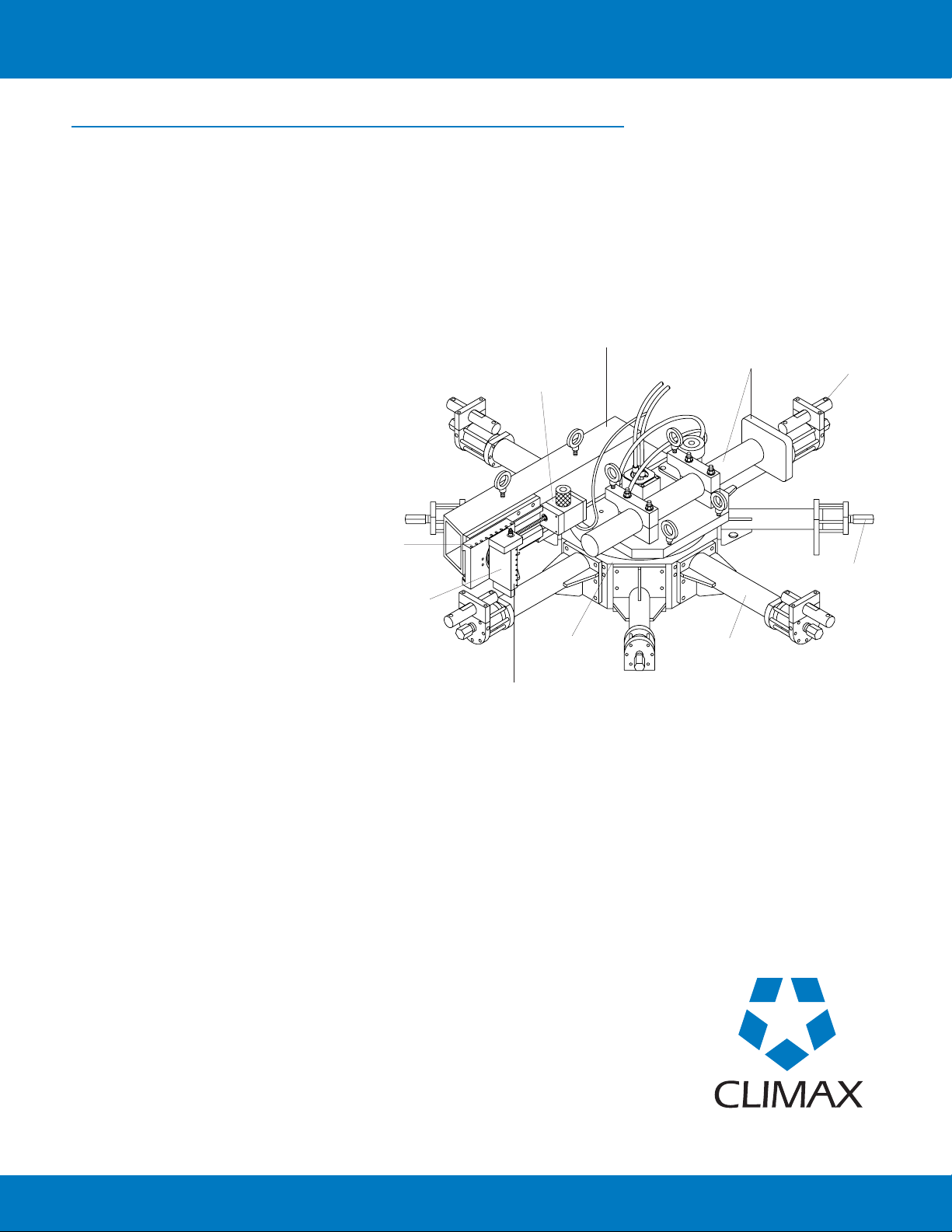

FF8000 PORTABLE FLANGE FACER

Bringing the solution to you.

FEATURES • SETUP & OPERATION

COMPONENTS & ACCESSORIES • TECHNICAL DATA

Versatile

•

Available in ID or OD mount styles.

•

Options include grinding heads, flat

surface mounting, and a mounting

and facing range of up to 10 feet

(3048.0 mm) in diameter.

•

Power supply hoses attach to the top

or bottom of the machine with a

rotary union for operation in

horizontal, vertical, or inverted

positions.

Rugged and powerful

•

Large volume hydraulic motor, or

two rotational drive air motors.

•

Produces accurate machining even

at the maximum turning arm

extension.

•

Large diameter, heavy-duty Timken

bearings support the turntable section. The turning arms are large

cross-section tubes that provide rigid,

lightweight mounting for the tool

head.

•

Smooth rotation is ensured by the

adjustable counterbalance arm and

a set of weights provided with the

machine. Properly adjusted, the

FF8000 rotates at a uniform rate,

even when mounted in vertical

flanges.

•

Precise finishes with HSS or

carbide tool bits, even on stainless

steel. Finishes as fine as RMS 16 can

be produced with the optional

grinding head.

•

The turning arms mount on the

machine turntable in dovetail ways

for easy positioning.

•

The 8.0 inch (203.2 mm) travel radial

feed is pneumatically actuated.

•

The tool head/radial feed

mechanism mounts on dovetail ways

at the end of the turning arm, to

re-face to the edge of flanges that

have very little clearance around

them, or cut right up to a shoulder.

Rotating diameter is easily adjustable

in limited clearance applications.

•

The four-inch (101.6 mm) travel

vertical feed is manually controlled

during automatic radial cutting

operations, or may be pneumatically

controlled when cutting grooves or

cutting down vertical surfaces.

•

The tool holder also rotates up to

45° in either direction for cutting

chamfers or J-weld preps.

Get big flange faces back

in working condition - FAST!

Set up fingers

Jacking bolts

Leg assembly

Main body

Vertical slide

Swivel tool

holder

Radial

slide

Feed box

Turning arm

Counterweight

and arm

Portable Machine Tools, Inc.

®

Page 2

FF8000 Specifications

Specifications

US Metric

General Specifications

Tool slide:

Radial travel 10 inches 254.0 mm

Vertical Travel 4 inches 101.6 mm

Swivel -45° to 0 to 45° -45° to 0 to 45°

Tool Feed System:

Automatic feed: pneumatic, reversible 0.003 to 0.20 inches per rev. 0.08 to 0.5 mm per rev.

Manual setup feed (setup only) 0.100 inches per turn of hand wheel 2.5 mm per turn of hand wheel

Tool cutter

3

/4 inch standard square lathe tool bits 20 mm standard square lathe tool bits

Rotational drive assembly:

Final drive reduction 8:1 helical gear 8:1 helical gear

Machining speed 13 rpm at 2.9 Hp 13 rpm at 2.18 kW

Power source:

Pneumatic (standard) 2 motors, 2.9 Hp total 2 motors, 2.18 kW total

Requires 96 ft3/min at 90 psi min. Requires 2.72 m3/min at 620 kPa min.

Hydraulic (optional) 10 Hp hydraulic power unit. 7.46 kW hydraulic power unit

(Hydraulic Power Unit information available upon request. Please contact your Climax representative.)

Machine shipping dimensions:

Main machine (W x D x H) 60 x 34 x 32 inches 1524 x 864 x 813 mm

ID Chuck arm assembly 65 x 43 x 35 inches 1651 x 1092 x 889 mm

(shipped in two crates) 69 x 37 x 32 inches 1753 x 940 x 813 mm

OD chuck arm assembly 65 x 43 x 35 inches 1651 x 1092 x 889 mm

(shipped in two crates) 69 x 37 x 32 inches 1753 x 940 x 813 mm

Hydraulic power unit - 10 Hp 48 x 27 x 36 inches 1219 x 686 x 914 mm

FF8000 Shipping Weights:

Main machine 2,500 lbs 1,134 kg

ID chuck arm assembly 1,695 lbs 769 kg

OD Chuck arm assembly 2,413 lbs 1,095 kg

Hydraulic power unit - 10 Hp 575 lbs 261 kg

ID Mount Machine Specifications

Standard ID mounting diameter 30 - 96 inches 762.0 - 2438.4 mm

Optional ID mounting chuck

extension kit mounting diameter 96 - 120 inches 2438.4 - 3048.0 mm

Standard facing diameter 30 - 96 inches 762.0 - 2438.4 mm

Optional turning extension kit

facing diameter 96 - 120 inches 2438.4 - 3048.0 mm

OD Mount Machine Specifications

Standard OD mounting diameter 42.5 - 109.5 inches 1079.5 - 2781.3 mm

Optional OD mounting extension

kit mounting diameter 96 - 133 inches 2438.4 - 3378.2 mm

Standard facing diameter 30 - 96 inches 762.0 - 2438.4 mm

Optional turning extension kit

facing diameter 96 - 105 inches 2438.4 - 2667.0 mm

All dimensions should be

considered reference.

Please contact your

Climax representative for

precision dimensions.

Specifications subject to change without notice

For help contact: Climax Portable Machine Tools, Inc., 2712 E. 2nd St, Newberg, OR 97132 USA Web: www.cpmt.com

Worldwide Phone: 1.503.538.2185 USA/Canada Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 Email: info@cpmt.com

page 2

Page 3

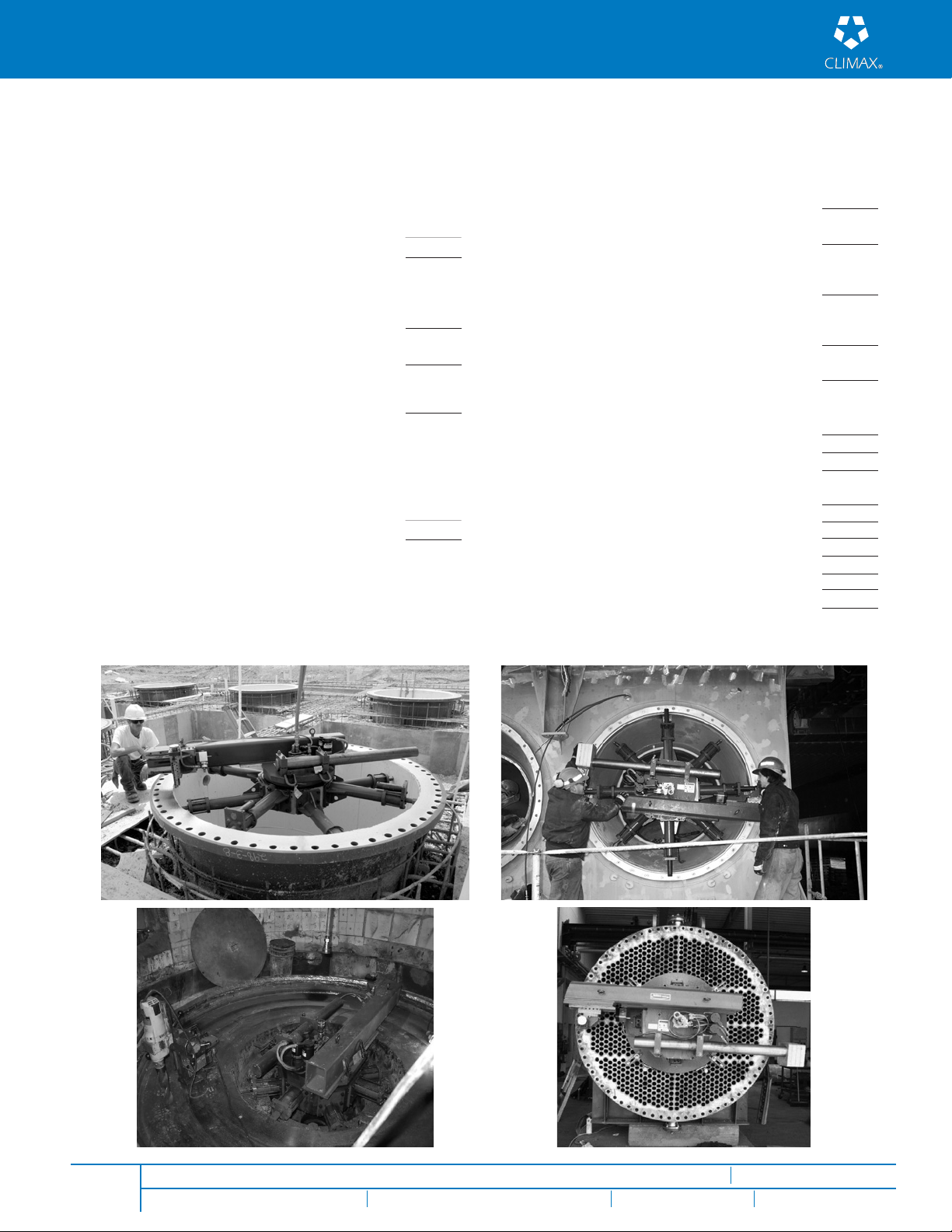

FF8000 Tool Configuration, Application Photos

Basic ID-mount machines

Mounts in 30 - 96 inch (762.0 - 2438.4 mm) ID,

faces 30 - 96 inch diameter.

Pneumatic drive/feed 18447

Hydraulic drive/pneumatic feed 41995

Extensions and Conversions

Extend ID mounting to 120 inches

(3048.0 mm) diameter add 19753

Extend machining to 120 inches

(3048.0 mm) diamete add 33807

Convert ID mount to OD mount,

42.5 - 109.5 inch diameter

(1079.5 - 2781.3 mm) add 17801

Basic OD-mount machines

Mounts on 42.5 - 109.5 inch (1079.5 -

2781.3 mm) outside diameter, faces 30 96 inches (762.0 - 2438.4 mm) diameter.

Pneumatic drive/feed 19581

Hydraulic drive/pneumatic feed 41986

Extensions and Conversions

Extend OD mounting to 133 inches

(3378.2 mm) diameter add 28451

Extend machining to 120 inches

(3048.0 mm) diameter add 33807

Convert OD mount to ID mount,

30 - 96 inch diameter

(762.0 - 2438.4 mm) add 17423

Extend ID mount conversion to

96 0 120 inch diameter

(2438.4 - 3048.0 mm) add 24421

Extend machining to 120 inches

(3048.0 mm) diameter add 33807

Accessories ID or OD

Grinding head 19060

Large steel storage boxes 20213

Tool Kit 17757

Grinding stones

4.0 inch (101.6 mm) dia, 16 grit 19498

4.0 inch (101.6 mm) dia, 60 grit 28295

Tool holder, RH 33996

Tool holder, LH 33997

Carbide insert for tool holder 33998

HSS tool bit, RH 29067

HSS tool bit, LH 29066

Tool Configuration:

Application Photos:

For help contact: Climax Portable Machine Tools, Inc., 2712 E. 2nd St, Newberg, OR 97132 USA Web: www.cpmt.com

Worldwide Phone: 1.503.538.2185 USA/Canada Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 Email: info@cpmt.com

page 3

Page 4

FF8000 Operational Dimensions

Standard ID-Mount

Flange Facer

Side view

Dimensions in Inch (mm)

3.32 (84.3)

30 (762.0) min

96 (2438.4) max

Top view

2.5 (63.5)

26.5 (673.1)

4.38 (111.2)

26.57

(674.9)

9.38

(238.2)

Tool arm length:

Long Std. 40.5 (1028.7)

Short Std. 58.0 (1473.2)

Optional extension arm

71.0 (1803.4)

Turning arm facing diameters:

Optional: 96 - 120

(2038.4 - 3048.0)

Long std.: 47 - 96

(1193.8 - 2438.4)

Short std.: 30 - 61

(762.0 - 1549.4)

For help contact: Climax Portable Machine Tools, Inc., 2712 E. 2nd St, Newberg, OR 97132 USA Web: www.cpmt.com

Worldwide Phone: 1.503.538.2185 USA/Canada Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 Email: info@cpmt.com

page 4

Page 5

FF8000 Operational Dimensions

Standard OD-Mount

Flange Facer

Dimensions in Inch (mm)

Top View

Side View

92.5 (2349.5) without spacers

130.5 (3314.7) with spacers

Spacer

33.25

(844.6)

13.2 (335.3)

42.5 (1079.5) min diameter

109.5 (2781.3) max diameter

15 (381.0) min R

48 (1219.2) max R

4.2 (106.7)

4.0 (101.6)

max travel

For help contact: Climax Portable Machine Tools, Inc., 2712 E. 2nd St, Newberg, OR 97132 USA Web: www.cpmt.com

Worldwide Phone: 1.503.538.2185 USA/Canada Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 Email: info@cpmt.com

page 5

Spacer

92.5 (2349.5) without spacers

130.5 (3314.7) with spacers

33.25

(844.6)

13.2 (335.3)

4.2 (106.7)

42.5 (1079.5) min. diameter

109.5 (2781.3) max. diameter

15 (381) min R

48 (1219) max R

4.0 (101.6)

max. travel

Page 6

FF8000 Components and Accessories

No. Description

18447 FF8000 pneumatic ID-mount flange facer

Complete flange facing machine. Mounts inside 30 - 96 inch (762.0 -

2438.4 mm) diameter bores. Faces 30 - 96 inch (762.0 - 2438.4 mm)

diameter flanges. Machine comes complete with main body, two air

motors (2.9 hp/2.18 kW total), pneumatic conditioning unit, chuck

arms for 30 - 96 inch (762.0 - 2438.4 mm) diameter bores, short and

long tool arm supports, swivel tool holder, radial and vertical slide

assemblies, short and long counterweight arms with weights, tool kit,

instruction manual, and wooden storage crate.

41995 FF8000 230V hydraulic/pneumatic ID-mount flange facer

Complete flange facing machine. Mounts inside 30 - 96 inch (762.0 -

2438.4 mm) diameter bores. Faces 30 - 96 inch (762.0 - 2438.4 mm)

diameter flanges. Machine comes complete with main body, hydraulic

motor, pneumatic feed box, chuck arms for 30 - 96 inch (762.0 -

2438.4 mm) diameter bores, short and long tool arm supports, swivel

tool holder, radial and vertical slide assemblies, short and long

counterweight arms with weights, tool kit, instruction manual, and

wooden storage crate.

Hydraulic power unit available separately. Contact your Climax

representative for details.

19753 Extended range ID-mount chuck assembly for 96 - 120 inch

(2438.4 to 3048.0 mm) diameters

Includes hub, upper, lower, and formed leg assemblies.

Use with p/n 18447 or 41995 (FF8000 ID-mount flange facers) to

extend its mounting range to bore diameters from 96 - 120 inches

(2438.4 - 3048.0 mm).

Turning extension kit (33807) must be purchased separately to face

diameters up to 120 inches (3048.4 mm).

17801 OD-mount chuck assembly (OD-mount conversion kit)

Includes OD hub, formed legs, leg tubes, leg clamps and instructions.

Convert part number 18447 or 41995 ID-mount machines to OD

mounting for outside diameters of 42.5 - 109.5 inches (1079.5 -

2781.3 mm). Machine faces 30 - 96 inch (762.0 - 2438.4 mm)

diameter flanges.

28451 OD chuck extension kit (OD-mount extension kit) for 96 - 133

inch (2438.4 - 3378.2 mm) diameters (not shown)

Kit includes leg extensions and mounting hardware only. Use with

part numbers 17801 or 19581 to extend OD mounting range to

96 - 133 inches (2438.4 to 3378.2 mm) in diameter.

Turning extension kit (p/n 33807) must be purchased separately to

face diameters up to 120 inches (3048.4 mm).

NOTE: Drawings are for reference only, are not

to scale, and may not represent actual product.

For help contact: Climax Portable Machine Tools, Inc., 2712 E. 2nd St, Newberg, OR 97132 USA Web: www.cpmt.com

Worldwide Phone: 1.503.538.2185 USA/Canada Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 Email: info@cpmt.com

page 6

Page 7

FF8000 Components and Accessories

No. Description

19581 FF8000 pneumatic OD-mount flange facer

Complete flange facing machine. Mounts on work pieces with outside

diameters from 42.5 - 109.5 inches (1079.5 - 2781.3 mm). Faces 30 96 inch (762.0 to 2438.4 mm) diameter flanges. Machine comes

complete with main body, two air motors (2.9 hp/2.18 kW total),

pneumatic conditioning unit, chuck arms for 42.5 - 109.5 inches

(1079.5 to 2781.3 mm) ODs, short and long tool arm supports, swivel

tool holder, radial and vertical slide assemblies, short and long

counterweight arms with weights, tool kit, instruction manual, and

wooden storage crate.

41986 FF8000 hydraulic/pneumatic flange facer

As above with hydraulic drive/pneumatic feed.

17423 Chuck leg assembly (ID-mount conversion kit)

Includes short, medium, and long leg assemblies, leg end spacers,

short and long setup fingers, short and long jacking bolts, and

instructions.

Convert p/n 19581 & 41986 (FF8000 OD-mount flange facer

assembly) to an ID-mount machine for bore diameters from 30 - 96

inches (762.0 to 2438.4 mm).

This assembly is included with ID-mount machines (p/n 18447 or

41995).

39947 OD mount small diameter kit

Allows mounting down to 24.0 inch (609.6 mm) diameter.

OD mount only.

24421 ID chuck extension kit (ID-mount conversion extension kit) for

96 - 120 inch (2438.4 to 3048.0 mm) diameters (not shown)

Includes upper and lower leg assemblies only.

Use with part number 17423 (ID-mount conversion kit) to extend its

mounting range to 96 - 120 inches (2438.4 to 3048.0 mm).

Turning extension kit (p/n 33807) must be purchased separately to

face diameters up to 120 inches (3048.4 mm).

33807 Turning extension kit for 96 - 120 inches (2438.4 to 3048.0

mm) diameters.

Extension kit allows the flange facer to machine larger diameter.

Mounting chuck extension must be purchased separately to mount

inside 120 inch (3048.0 mm) diameter bores.

NOTE: Drawings are for reference only, are not

to scale, and may not represent actual product.

For help contact: Climax Portable Machine Tools, Inc., 2712 E. 2nd St, Newberg, OR 97132 USA Web: www.cpmt.com

Worldwide Phone: 1.503.538.2185 USA/Canada Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 Email: info@cpmt.com

page 7

Page 8

Portland

Cologne

Chicago

Toronto

Singapore

Houston

Rental Depot

Manufacturing / Sales Facility

International Distributor

World Headquarters

Edmonton

Manchester

Charlotte

Mexico

FF8000 Accessories

No. Description

19060 Grinding and polishing head assembly

Grinding attachment mounts to the vertical slide to smooth

the flange face to a fine finish after machining. Assembly includes

mounting bracket, air grinder, hose for connection to the main

machine air supply, disk pad, and disks.

19498 4.0 inch (101.6 mm) diameter, 16 grit grinding cup

28295 4.0 inch (101.6 mm) diameter, 60 grit grinding cup

20213 Large steel storage container set

For the ID-mount flange facer only.

Large steel storage containers to ship or store the extended-reach

ID-mount flange facer. Set includes one container for the main

machine and one container for accessories. Both containers have steel

construction. lids with full-length piano hinges, latches, and handles.

FF8-.5M1107

Climax Portable Machine Tools Worldwide

Manufacturing, Sales & Rental Facilities

Call Climax for:

Call us. We’ll bring the solution to you.

Corporate Headquarters

Climax Portable Machine Tools, Inc.

2712 E. Second Street

Newberg, Oregon 97132 USA

Worldwide Telephone: 503.538.2185

N. America Toll-Free: 800.333.8311

Fax: 503.538.7600

Email: info@cpmt.com

European Headquarters

Climax GmbH

Am Langen Graben 8

Düren, 52353 Germany

Telephone: (+49) (0) 2421.9177.0

Fax: (+49) (0) 2421.9177.29

Email: cpmt.de@t-online.de

Rentals

With five locations in the

USA, two in Canada, one in Europe,

and one in Asia, you are never far away

from a Climax portable machine tool

.

Special Projects

Climax has been solving complicated on-site

machining problems for our customers since 1964.

On-site Training

Need some refresher courses in setting up

and operating your Climax machine tool?

Portable Machine Tools, Inc.

®

Loading...

Loading...