Page 1

FF6000 PORTABLE FLANGE FACER

FEATURES • SETUP & OPERATION

COMPONENTS & ACCESSORIES • TECHNICAL DATA

Cut your dismantling & downtime costs by re-facing flanges and

repairing seal & bearing fits at the work site

This flange facer will substantially

reduce your costs and maintenance

downtime by allowing you to quickly

repair your flanges, seals, and bearing

fits in place without resorting to costly

disassembly and transportation to a

machine shop. This versatile on-site

flange facing machine will also help

to eliminate expensive and timeconsuming recertification procedures

which may be required when critical

valves and flanges are removed for

repair and then re-installed. The job

can be done quickly to get back in

operation with minimum downtime.

An experienced operator can usually

mount the machine in the flange

bore, align it, and start cutting in 30

minutes.

Solid

Single plane chuck provides rigid •

clamping in the bore.

3 inch (76 mm) diameter turning •

bar ensures a rigid tool platform,

even at maximum extension.

A combination of precision ball •

bearings and heavy-duty Timken

Tapered roller bearings for smooth,

chatter-free machining

Effective

• 9.73:1 gear reduction provides 550

ft•lbs (798 N•m) of torque at the

cutter to remove metal fast.

• Radial feed is 0.003 - 0.032 inch

(0.076 - 0.813 mm) per revolution,

infinitely variable, reversible, rack and

pinion system.

• Down feed rates from 0.003 - 0.010

inch (0.076 - 0.0254 mm) per

revolution are provided by the downfeed actuator system.

• Tool holder accepts 1/2 inch or 12

mm square tool bits.

Versatile

Sealed lubrication allows inverted •

operation.

Standard tool head swivels 360 •

degrees in either direction to cut

angles, grooves, chamfers, RTJ, and

weld preps. Use the optional Low

Angle tool holder to cut angles less

than 45 degrees to the flange face.

Down-feed allows turning flange •

edges, and dressing inside flange/

pipe joints,

Optional large bore chuck and •

bar assembly for flanges up to 60

inches (1524 mm) in diameter.

Other options include:•

-

Grinding attachment

- Back facing attachment

- Low-angle tool holder

Portable Machine Tools, Inc.

®

Bringing the solution to you.

Page 2

FF6000 Specifications

Specifications

US Metric

Machine height overall 19.5 inches 495.3 mm

Minimum bore diameter:

with standard single plane chuck

with optional large bore chuck 32.0 inches 812.8 mm

Maximum bore diameter:

with standard single plane chuck

with optional large bore chuck 60.0 inches 1524.0 mm

Minimum flange diameter:

with standard single plane chuck

with optional large bore chuck 32.0 inches 812.8 mm

Maximum flange diameter:

with standard single plane chuck

with optional large bore chuck 60.0 inches 1524.0 mm

Minimum space required inside bore to set up chuck assembly 3.5 inches 88.9 mm

Air motor 1.45 Hp 1.09 kW

Air motor requirements (at maximum power) 90 psi @ 620 kPa @

32 ft

Torque at cutter (at rated Hp) 550 ft-lb 748 N•m

Gear reduction 9.73:1 9.73:1

14.0 inches 355.6 mm

32.0 inches 812.8 mm

14.0 inches 355.6 mm

42.0 inches 1066.8 mm

3

/min 0.91 m3/min

All dimensions

should be considered

reference. Contact

your Climax

Representative for

precision dimensions.

Specifications are

subject to change

without notice.

Turning bar length 25.5 inches 647.7 mm

RPM (Turning Bar) 0 - 22.5 free speed 0 - 22.5 free speed

Shipping weight 634 lbs 289 kg

Shipping Dimensions (Metal Crate) 39 x 26 x 29 inches

991 x 660 x 737 mm

Standard mounting Single plane removable chuck

Cutter One (1) 0.5 inch sq HSS lathe tool bit, furnished

with the machine. NOTE: 12 mm square tool bits

can also be used.

Radial Feed Automatic, infinitely variable reversible 0.003 -

0.032 inch (0.08 - 0.81 mm) per revolution.

Tool down feed Automatic, infinitely variable 0.003 - 0.010 inch

(0.08 - 0.25 mm) per revolution.

page 2

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 3

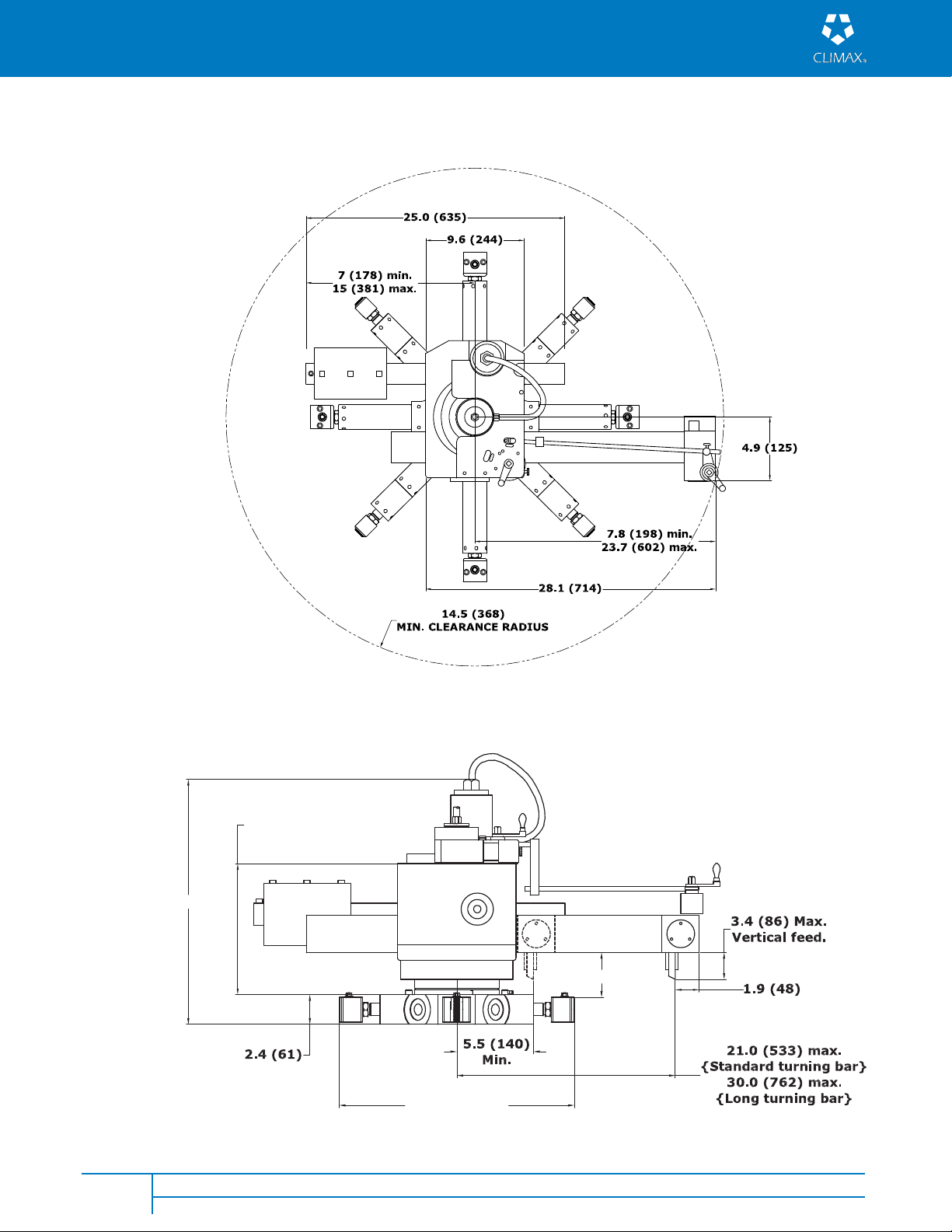

FF6000 Operational Dimensions

Top View

Dimensions in Inch (mm)

19.7 (500)

Side View

10.6 (269)

2.6 (66)

14 (356) min.

32 (813) max.

page 3

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 4

FF6000 Components and Accessories

Part number Description

6471-S1 FF6000 Flange Facer Package

Complete flange facing machine fits 14 - 32 inch (355.6 - 812.8 mm) diameter bores and faces

flanges 14 - 42 inches (355.6 - 1066.8 mm) in diameter.

Machine includes mechanical radial and down feed assemblies (base unit p/n 49595), 8-jaw

adjustable single plane chuck assembly, setup fingers, 1.45 Hp (1,01 kW) air motor (p/n 36923),

pneumatic conditioning unit, ½ inch HSS tool bit, tool kit, instruction manual, and durable metal

container.

Automatic mechanical radial feed is infinitely variable 0.003 - 0.032 inches (0.08 - 0.81 mm) per

revolution.

Automatic mechanical tool down feed is infinitely variable 0.003 - 0.010 inches (0.08 mm- 0.25

mm) per revolution.

For Facing Larger Bores:

58388 Large bore chuck and bar assembly

Use in place of the standard single plane chuck assembly to fit bores 32 - 60 inches (812.8 -

1524.0 mm) in diameter. Includes chuck core arms, 5 inch (127.0 mm) spacers, extention legs

and hardware, large diameter face turning bar and counterweight assembly.

Other Components and Accessories:

19073 Grinding attachment

Designed to be used after facing to evenly grind work pieces with uneven surfaces and or hard

spots. Mounts directly to the end of the turning arm in place of the tool head. Includes 1.5 Hp

(1.05 kW), 7500 rpm air motor and pneumatic connection hardware.

42025 Back-facing attachment

Accessory for facing the back side of flanges.

42010 Low angle tool holder

Right angle tool holder that mounts in the standard tool head, allows cutting angles less than 45

degrees to the flange face.

14648 Tool kit

Includes HSS & Carbide tool bits, crank handle, and all wrenches r

and operation.

equired for machine setup

page 4

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 5

FF6000 Setup and Operation

This model is so fast and easy to set up that an experienced

operator can usually mount the machine in the flange bore,

align it, and start cutting in 30 minutes.

Measure the

bore diameter.

This will be

1

determine the

jaw length.

2

foot.

used to

Select the

appropriate

jaw length and

Indicate, level

and tighten

jaws.

4

5

Install tool bit.

Connect to

power.

Install setup

fingers, and

place in the

3

bore.

page 5

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 6

FF6000 Applications

Face

Backface

(optional)

O-ring Groove Counterbore

page 6

ID Chamfer

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

OD Chamfer

Page 7

FF6000 Application Photos

Track loader frame bearing mount repair.

page 7

Shovel base repair.

Climax Portable Machine Tools, Inc. 2712 E. Second Street, Newberg, OR 97132 USA Web site: www.cpmt.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: Info@cpmt.com

Page 8

Climax Portable Machine Tools, Inc.

Climax Portable Machine Tools Worldwide

Manufacturing, Sales & Rental Facilities

Edmonton

Portland

World Headquarters

Houston

Chicago

Monterrey

Call Climax for:

Rentals

With seven locations in North

America, two in Europe, and

two in Asia, you are never far

away from a Climax portable

machine tool

.

London

Cologne

Manchester

Charlotte

Bengaluru

Singapore

Rental Depot

Manufacturing / Sales Facility

International Distributor

Special Projects

Climax has been solving

complicated on-site machining

problems for our customers

since 1964.

On-site Training

Need some refresher courses in

setting up and operating your

Climax machine tool?

Call us. We’ll bring the solution to you.

FF6000-.ELEC1109

Corporate Headquarters

Climax Portable Machine Tools, Inc.

2712 E. Second Street

Newberg, Oregon 97132 USA

Worldwide Telephone: 1.503.538.2185

N. America Toll-Free: 1.800.333.8311

Fax: 1.503.538.7600

Email: info@cpmt.com

European Headquarters

Climax GmbH

Am Langen Graben 8

Düren, 52353 Germany

Telephone: (+49) (0) 2421.9177.0

Fax: (+49) (0) 2421.9177.29

Email: info@cpmt.de

Portable Machine Tools, Inc.

www.cpmt.com

®

Copyright © 2009 Climax Portable Machine Tools, Inc. All Rights Reserved.

Loading...

Loading...