Page 1

Model BB6000 Portable Boring Bar

Machine Features

Setup & Operation

Components &

Accessories

Technical Data

CLIMAX

Portable Machine Tools, Inc.

11/99

Page 2

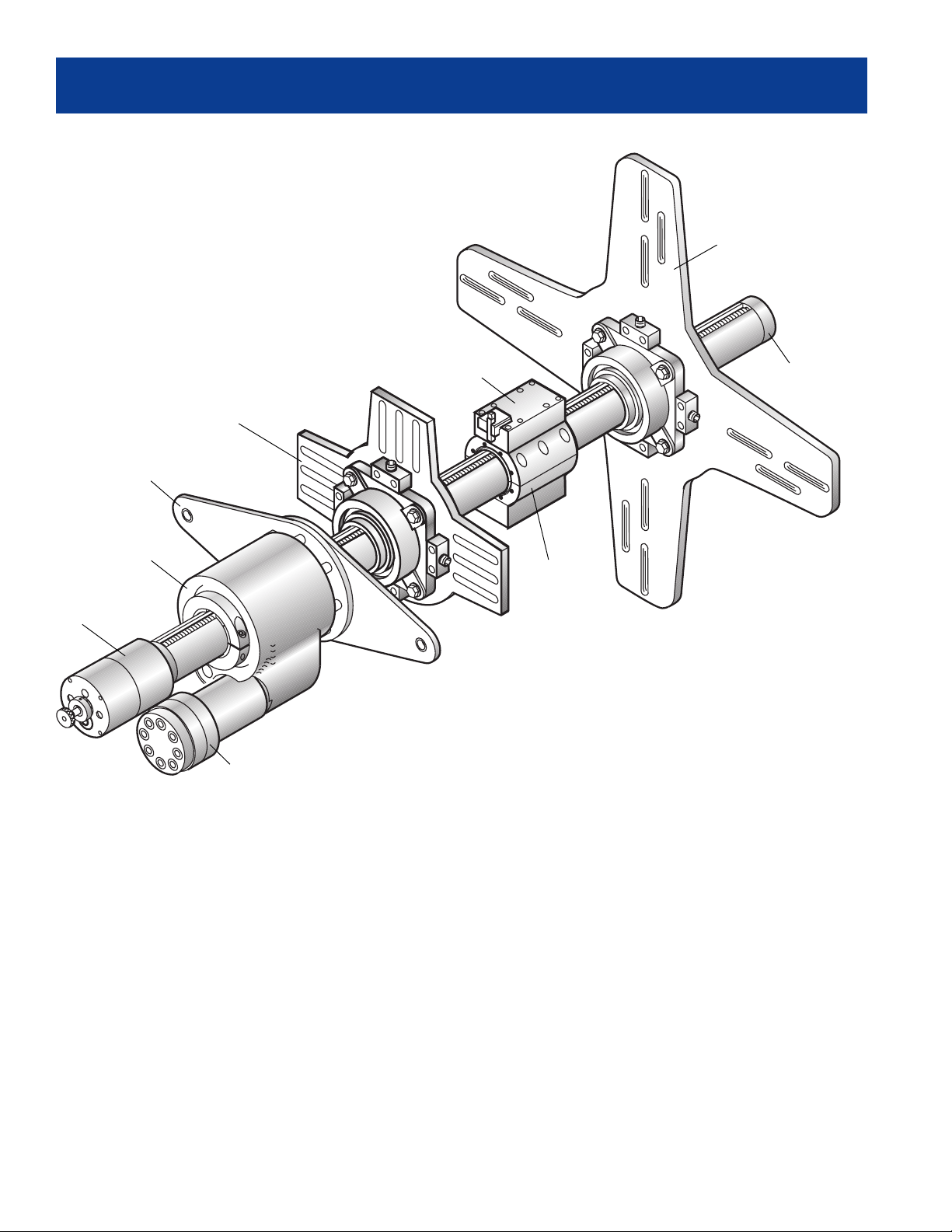

BB6000 Design Features & Benefits

Bore 6-inch to 36-inch diameters on site...

Modular versatility

• The rotational drive unit mounts anywhere on the

bar for maximum setup flexibility.

• Feed unit attaches to either end.

• Optional ID mounting spiders have jacking

screws for centering.

• 3-arm or 4-arm end-mount bearing supports.

• When space is really tight, mount the bearing

cartridge right on the workpiece.

Tool holder

Three arm

bearing support

Torque arm

Four-arm

bearing support

Boring bar/

leadscrew

Rotational

drive unit

Axial feed

unit

Hydraulic

motor

Compact

The Model BB6000 is the smallest in our line of

traveling head portable boring bars (the smaller

BB3000 and BB5000 models feed by moving the

bar). Boring diameter range is 6" to 36" (152.4 to

914.4 mm). The compact hydraulic rotational drive

unit provides almost 1300 ft•lb of torque.

Compared to competitive machines, the rotational

drive unit provides a high power-to-weight ratio.

Efficient design and cast aluminum housing keep

the rotational drive weight at only 110 lbs. (50 kg),

with the hydraulic motor attached. The compact

mechanical axial feed unit is only a little larger in

diameter than the bar itself.

Split tool

carrier

Powerful

Hydraulic power provides smooth and trouble-free

power transmission to the boring head. Several

hydraulic motors are available to provide a range

of rpm and torque. The Model BB6000 requires a

minimum 5 hp hydraulic power unit.

Rugged, practical design

• Support fixtures feature ball bearings rather than

bronze bushings.

• Split tool carrier is easy to mount on the bar.

• Tool head spacer blocks can be added to

increase the boring diameter.

• The leadscrew is mounted in the boring bar with

roller bearings, not bushings.

• Facing heads, taper boring systems, and other

accessories increase the versatility of the

machine.

• Easy setup and operation.

• High quality, precision design means many years

of trouble-free service.

2 6/00

Page 3

Setup & Operation

Easy setup and

operation help

minimize downtime.

There are several ways to set up the Model

BB6000 depending on the application and

clearances around the work area. If you have to

mount one of the bearing supports on the surface

that needs boring, weld standoffs on the workpiece

to allow access for tool adjustment.

• Insert the bar into the bore, allowing it to rest on

wooden V-blocks.

• Slip the bearing support assemblies onto each

end.

• Lift the bar to bore center and into the support

spiders attached to the workpiece, either

internally or externally.

Face mounted 4-arm mounting spider for up to 36" (914.4mm)

dia. Torque arms prevent rotational drive turning.

Three-arm mounting assembly for up to

20" (508 mm) diameters.

• Make final centering adjustments with the jacking

screws on the bearing plates.

• Once the bar is accurately positioned, slip the

rotational drive unit in place and lock to the bar

with the two locking collars.

• Tie-down arms are provided to secure the

rotational drive and keep it form turning during

boring operations.

• Place the axial feed unit on either end of the bar.

• Install the tool carrier, spacer blocks, and one or

two tool heads.

The machine is ready to make the first boring

pass. Boring operations are simply a matter of

adjusting the boring depth at the cutter, setting the

feed rate, and engaging the feed in forward or

reverse mode. The hydraulic power unit is turned

on and bar rotation is started with the control

pendant.

Speed wrench or portable drill motor can be used to move tool head from either end

of the bar, with or without the axial feed unit attached.

Tool head accepts either HSS tool bits or

carbide insert holders as shown here.

6/00 3

Page 4

Components & Accessories

Modular components allow

you to choose exactly what

you need for your application.

The Model BB6000 Portable Boring Bar is

designed in modules for as wide a range of

applications as possible. Select only those

components you need for your particular situation.

A complete machine must have the following

components to be functional:

1. Rotational drive unit

2. Hydraulic drive motor

3. Axial feed unit

4. Boring bar

5. Tool carrier

6. Boring head

7. Hydraulic power unit

8. Bearing supports (2)

Rotational drive unit

unit mounts anyplace along the bar, and weighs

86 lbs (40 kg) with a 6:1 gear reduction. Clamp

collars lock the unit to the bar securely. Torque

arms keep unit from turning with the bar.

Maximum torque at the bar with the largest

displacement hydraulic motor is almost 1300 ft•lbs

(1768 N•m). Fits any 3.5" (88.9mm) diameter bar.

Compact cast aluminum

Drive motors

motors in various

displacements are available

and provide the smoothest

power transmission for most

boring operations. Standard

SAE flange mount reversible

motors with 2-bolt mounting.

Hydraulic

Tool carrier

may be positioned anywhere

along bar. Way wipers are

provided for carrier and bar

protection. A threaded key

drives the carrier along bar

during boring operations. If

you are using this carrier with

an existing bar, be sure the

key threads are compatible with the leadscrew.

Boring heads

are available in two sets that

cover 6" to 24" (152.4-609.6

mm) and 6" to 36" (152.4-

914.4mm) respectively. Boring

heads mount directly to both

sides of tool carrier with or

without spacers. Use boring

heads alone or in tandem.

Spacers increase boring

diameter. Heads accept .5"

(12mm) square tool bits or 1"

(25.4mm) square indexable

carbide tooling.

Facing head

tool carrier in place of the boring head. The unit

can face from 10.5" to 36" (267-914.4mm) in 4"

(101mm) increments.

Mounting system

mounted bar support systems are available. Selfaligning bearings and jacking screws for centering

allow fast setup. ID mounts are available for 12"

to 36" (304.8-914.4mm) dia. End mounted bearing

support assemblies are available for 12" to 38"

(304.8-965.2mm) mounting diameters.

Split tool carrier

Boring heads

The facing head mounts on the

Combinations of ID or end-

Axial feed unit

automatic feed with manual

feed rate and direction

controls, mounts on either end

of the boring bar. Variable

feed rate from .003"-.020"

(.08-.51mm) per revolution.

Boring bars

dia. with full length lead screws and replaceable

ends. Bar lengths from 5 to 12 ft (1.5-3.7m) with

longer bars available on special order.

4 6/00

Reversible

Chromed bars are 3.5" (88.9mm)

Special adaptations

as tapered boring systems, and bar extension

couplings have been designed to fit particular

customer applications.

Hydraulic power units

piston pump hydraulic power units are available in

5 or 10 hp (3.73 or 7.46 kW) models. These are

compact units designed for portable machining

applications.

One-off accessories such

Variable displacement

Page 5

Bearing support

assembly (three-arm

end mount shown)

Torque arm

Rotational

drive unit

Axial feed

unit

BB6000 Work Sheet

Tool head

assembly

(boring head

shown)

Tool carrier

assembly

Boring bar/

leadscrew

assembly

Bearing

support

assembly

(four-arm

end-mount

shown)

Hydraulic motor

Model BB6000 Portable Boring Bar

To accommodate a wide range of applications, the Model BB6000 is sold as a combination of components. To get a complete machine, you must specify:

Axial feed assembly Boring bar/leadscrew assembly

Rotational drive assembly Hydraulic power unit (not shown)

Bearing support assemblies, ID or Hydraulic motor

end mount (at least two required)

Tool carrier assembly

Tool head assembly: boring or facing

Tool kit (not shown)

Items shown in blue are included in all component packages.

6/00 5

Page 6

BB6000 Worksheet

Component packages:

Component packages include: rotational

drive unit, axial feed assembly, two

three-arm end-mount bearing support

assemblies, tool carrier assembly, 6" to

24" (152.4 to 609.6mm) diameter boring

head set, and tool kit with instruction

manual. Customer must order bar/

leadscrew assembly, hydraulic power

unit, and hydraulic motor separately.

6" -24" boring bar package 23222 ___

6" -36" boring bar package 23223 ___

Components:

Choose a bar/leadscrew assembly, a

hydraulic motor, and a hydraulic power

unit to complete your machine. Other

parts are offered separately for spares.

Component Part number

Mechanical axial feed assembly

1,2

:

23299 ____

Components, continued:

Component Part number

Tool carrier assembly

Tool head assembly:

Boring head set 6"-24" ID 22769

Boring head set 6"-36" ID 22383

Mechanical feed facing head assembly:

Boring bar/leadscrew assembly:

4 ft 25221 ____

5 ft 22107 ____

6 ft 22108 ____

7 ft 22109 ____

8 ft 22110 ____

9 ft 22111 ____

10 ft 22112 ____

11 ft 22113 ____

12 ft 22114 ____

Tool kit

1,2

: 22771 ____

1,2

: 22377 ____

22680 ____

1

2

______

______

Components, continued:

Component Part number

Hydraulic power unit - 10 hp:

3-Ph/230V/60 Hz 24596 ____

3-Ph/460V/60 Hz 24597 ____

3-Ph/550V/50 Hz 24598 ____

3-Ph/575V/60 Hz 24599 ____

3-Ph/440V/50 Hz 24602 ____

3-Ph/220V/50 Hz 24603 ____

3-Ph/380V/50 Hz 24604 ____

3-Ph/200V/50 Hz 24605 ____

Optional remote pendant for 10 hp

electric powered hydraulic power units:

- 1_______

Replacement hydraulic filter element:

25882 ____

Rotational drive assembly

1,2

:

22221 ____

Hydraulic motor:

3

3.6 in

5.6 in

7.3 in

8.9 in

11.3 in

14.3 in

17.9 in

3

3

3

3

3

3

25472 ____

25473 ____

25474 ____

25475 ____

25476 ____

25477 ____

25478 ____

Hydraulic motor fitting kit:

3/8" fittings 25492 ____

1/2" fittings 25495 ____

Bearing support assembly

(at least two recommended):

Three-arm end-mount bearing support

assembly, 20" diameter1: 22072 ____

Three-arm spider only: 22073 ____

Four-arm end-mount bearing support

assembly, 38" diameter2: 22091 ____

Four-arm spider only: 22092 ____

ID-mount bearing support assembly,

22.53": 23228 ____

ID-mount bearing support assembly,

37.53": 23230 ____

Hydraulic power unit - 5 hp:

3-Ph/230V/60 Hz 25318 ____

3-Ph/460V/60 Hz 25319 ____

3-Ph/550V/50 Hz 25320 ____

3-Ph/575V/60 Hz 25321 ____

1-Ph/230V/60 Hz 25322 ____

1-Ph/220V/50 Hz 25323 ____

3-Ph/440V/50 Hz 24592 ____

3-Ph/220V/50 Hz 24593 ____

3-Ph/380V/50 Hz 24594 ____

3-Ph/200V/50 Hz 24595 ____

Optional remote pendant for 5 hp

electric powered hydraulic power units:

- 1_______

6 6/00

1

Included in component package 23222. 2Included in component package 23223.

Page 7

BB6000 Components

No. Description

23222 BB6000 component package - 6" to

24" (152.4 to 609.6mm) diameters

Component package includes:

rotational drive unit, axial feed

assembly, two three-arm end-mount

bearing support assemblies, tool

carrier assembly, 6" to 24" (152.4 to

609.6mm) diameter boring head set,

and tool kit with instruction manual.

Customer must order bar/leadscrew

assembly, hydraulic power unit,

and hydraulic motor separately.

23223 BB6000 component package - 6" to

36" (152.4 to 914.4mm) diameters

Component package includes:

rotational drive unit, axial feed

assembly, two four-arm end mount

bearing support assemblies, tool

carrier assembly, 6" to 36" (152.4 to

914.4mm) diameter boring head set,

and tool kit with instruction manual.

Customer must order bar/leadscrew

assembly, hydraulic power unit,

and hydraulic motor separately.

1,2

23299

Mechanical axial feed assembly

Assembly mounts to either end of

the bar/leadscrew assembly.

Mechanical feed is reversible and

variable, with a feed rate of .003" to

.020" (.076 to .508mm) per

revolution

1,2

22221

Rotational drive assembly

6:1 gear ratio drive assembly

mounts anywhere along the bar.

Adjustable shaft collars hold the

assembly securely to the bar.

Includes torque arms for stability.

Fits 3.5" (88.9mm) diameter bar/

leadscrew assemblies.

Drawings may not represent product.

1

Included in component package 23222.

2

Included in component package 23223.

No. Description

Hydraulic drive motors

Reversible motors with SAE 2-bolt mounting

flange to mount to the rotational drive housing.

Motor ports are 7/8-14 SAE O-ring type. For 50 Hz

power units, reduce the bar rpm by 15%; torque at

the bar remains the same. Torque ratings (at the

bar) are constant.

Power unit specifications:

5 hp - max bar rpm @ 6 gpm (22.7 L/min)

10 hp - max bar rpm @ 10 gpm (37.9 L/min)

25472 Hydraulic motor

displacement 3.6 in

motor rpm: 363 617

motor torque: 253 ft-lb 244 ft-lb

bar rpm: 54 92

25473 Hydraulic motor

displacement 5.9 in

motor rpm: 221 375

motor torque: 430 ft-lb 415 ft-lb

bar rpm: 33 56

25474 Hydraulic motor

displacement 7.3 in

motor rpm: 177 302

motor torque: 544 ft-lb 527 ft-lb

bar rpm: 26 45

25475 Hydraulic motor

displacement 8.9 in

motor rpm: 145 247

motor torque: 663 ft-lb 643 ft-lb

bar rpm: 21 37

25476 Hydraulic motor

displacement 11.3 in

motor rpm: 115 196

motor torque: 850 ft-lb 827 ft-lb

bar rpm: 17 29

25477 Hydraulic motor

displacement 14.1 in

motor rpm: 93 158

motor torque: 1054 ft-lb 1026 ft-lb

bar rpm: 14 23

25478 Hydraulic motor

displacement 17.9 in

motor rpm: 73 125

motor torque: 1330 ft-lb 1292 ft-lb

bar rpm: 11 18

5 hp 10 hp

3

(59.1 cm3) (59.1 cm3)

(344 N•m) (332 N•m)

3

(96.8 cm3) (96.8 cm3)

(549 N•m) (564 N•m)

3

(119.7 cm3) (119.7 cm3)

(740 N•m) (717 N•m)

3

(146.0 cm3) (146.0 cm3)

(902 N•m) (874 N•m)

3

(185.3 cm3) (185.3 cm3)

(1156 N•m) (1125 N•m)

3

(231.2 cm3) (231.2 cm3)

(1433 N•m) (1395 N•m)

3

(293.6 cm3) (293.6 cm3)

(1809 N•m) (1757 N•m)

3.6 in

5.9 in

7.3 in

8.9 in

11.3 in

14.1 in

17.9 in

3

3

3

3

3

3

3

6/00 7

Page 8

BB6000 Components

No. Description

Hydraulic motor fitting kit

Fitting kit to connect any hydraulic

motor listed above to the hoses from

customer's hydraulic power unit.

Fittings are included with every

Climax hydraulic power unit.

25492 Hydraulic motor fitting kit - 3/8"

fittings Fittings to connect motors

above to power units with 3/8"

female quick disconnect fittings.

Standard for 5 hp units

25495 Hydraulic motor fitting kit - 1/2"

fittings Fittings to connect motors

above to power units with 1/2"

female quick disconnect fittings.

Standard for 10 hp units.

End-mount bearing support

assembly

Bearing support assembly fits onto

the end of the work piece through a

slotted spider. Hold the bar in place

with the self-aligning bearing and

center the bar with the four adjusting

screws. At least two bearing

assemblies are required to

adequately support the bar. Different

styles may be used together.

22072 Three-arm end-mount bearing

support assembly, 20" (508.0 mm)

diameter

Bearing support assembly fits onto

the end of the work piece with

mounting diameters from 12.0" to

20.0" (304.8 to 508.0mm).

22091 Four-arm end-mount bearing

support assembly, 38" (965.2 mm)

diameter

Bearing support assembly fits onto

the end of the work piece with

mounting diameters from 18.0" to

38.0" (457.2 to 965.2 mm).

Support spider only

Because both end-mount bearing

assemblies use the same selfaligning bearing, spiders can be

ordered separately to accommodate

various size work pieces.

22073 Three-arm support spider only

22092 Four-arm support spider only

No. Description

ID-mount bearing support assembly

Bearing support assembly provides

four-way adjustable bar alignment.

Bar is held in place by a self-aligning

bearing. Center the bar by adjusting

the four jacking screws. At least two

bearing support assemblies are

required to adequately support the

bar. Different styles may be used

together.

23228 ID-mount bearing support

assembly, 22.53" (572.3mm) dia.

One bearing + two chucks + jaws to

fit inside bores with ID's from 12" to

22.53" (304.8 to 572.3mm)

23230 ID-mount bearing support

assembly, 37.53" (953.2mm) dia.

Same as above, but includes extra

spacer and jaws to fit inside bores

with ID's from 12" to 37.53" (304.8

to 953.2mm).

1,2

22377

Tool carrier

Split design tool carrier mounts

anywhere along the boring bar. Builtin wipers protect the carrier and bar

from dirt and chips. Boring and

facing heads mount to the tool

carrier with screws and, if required,

spacers. Carrier includes axial

leadscrew nut. Customer must

purchase boring head set and tool

bits separately.

Boring head set

Boring heads mount to the tool

carrier (above) with screws and, if

required, spacers. The range of

diameters the boring head will cut is

determined by the number of

spacers mounted between the tool

carrier and the boring head. Small

tool holders use .5" (12mm) square

HSS tooling. Large tool holders use

1" (25.4mm) square HSS or

indexable carbide tooling. Customer

must purchase tool carrier and tool

bits separately.

227691Boring head set, 6" -24" (152.4-

609.6 mm) ID

223832Boring head set, 6"-36" (152.4 -

914.4mm) ID

8 6/00

Drawings may not represent product.

1

Included in component package 23222.

2

Included in component package 23223.

Page 9

BB6000 Components

No. Description

22680 Mechanical feed facing head

assembly

Facing head assembly mounts to

tool carrier (not included) with

screws and, if required, spacers. The

range of diameters the facing head

will machine is determined by the

number of spacers (not included)

mounted between the tool carrier

and the facing head. When used with

the spacers from the 24" boring head

set (22769), the facing head will

machine 10.5" to 24.0" (266.7 to

609.6 mm). When used with the

spacers from the 36" boring head set

(22383), the facing head will

machine 10.5" to 36.0" (266.7 to

914.4 mm). Stroke is 4" (101.6 mm)

and feed rate is up to .010" (.254

mm) per feed trip. Use multiple trip

mechanisms to increase feed rate.

Facing head uses .5" (12mm) tool

bits. Customer must purchase

boring head set (spacers), tool

carrier and tool bits separately.

Boring bar/leadscrew assembly

3.5" (88.9 mm) diameter chromed

bar with full-length leadscrew. Bar

end caps enable the axial feed

assembly to be mounted to either

end of the bar. Other length bars are

available upon special request.

25221 Boring bar, 4 ft (1.22 m)

22107 Boring bar, 5 ft (1.53 m)

22108 Boring bar, 6 ft (1.83 m)

22109 Boring bar, 7 ft (2.13 m)

22110 Boring bar, 8 ft (2.44 m)

22111 Boring bar, 9 ft (2.75 m)

22112 Boring bar, 10 ft (3.05 m)

22113 Boring bar, 11 ft (3.35 m)

22114 Boring bar, 12 ft (3.66 m)

1,2

22771

Tool kit

Complete set of tools needed to

operate the BB6000 Portable boring

bar.

No. Description

5 hp (3.73 kW) hydraulic power unit

Variable displacement piston pump

power unit comes complete with a 5

gallon (19 liter) reservoir, start/stop

pendant, flow control, pressure

gauge, 20 foot (6 meter) x 3/8"

hydraulic hoses with quick

disconnect fittings, and 7/8-14 SAE

O-ring fittings for hydraulic motors.

Order motors separately

25325 Hydraulic power unit

3-ph/230V/60 Hz/1800 rpm motor.

Pumps 6gpm (22.7 l/min). Full load

13.2 amps.*

25319 Hydraulic power unit

3-ph/460V/60 Hz/1800 rpm motor.

Pumps 6gpm (22.7 l/min). Full load

6.6 amps.*

25320 Hydraulic power unit

3-ph/550/50Hz/1400 rpm motor.

Pumps 6gpm (22.7 l/min). Full load

5.6 amps.*

25321 Hydraulic power unit

3-ph/575V/60 Hz/1800 rpm motor.

Pumps 6gpm (22.7 l/min). Full load

5.5 amps.*

25322 Hydraulic power unit

3-ph/230V/60 Hz/1800 rpm motor.

Pumps 6gpm (22.7 l/min). Full load

22.8 amps.*

25323 Hydraulic power unit

3-ph/220V/50 Hz/1400 rpm motor.

Pumps 5gpm 19.0 l/min). Full load

22 amps.*

24592 Hydraulic power unit

3-ph/440/50 Hz/1400 rpm motor.

Pumps 5gpm (19.0 l/min). Full load

5.5 amps.*

24593 Hydraulic power unit

3-ph/220V/50 Hz/1400 rpm motor.

Pumps 5gpm (19.0 l/min). Full load

14 amps.*

24594 Hydraulic power unit

3-ph/380V/50 Hz/1400 rpm motor.

Pumps 5gpm (19.0 l/min). Full load

8.12 amps.*

24595 Hydraulic power unit

3-ph/200V/50 Hz/1400 rpm motor.

Pumps 5gpm (19.0 l/min). Full load

15.4 amps.*

*Full load amp rating cannot be

used to determine required

generator size. Contact your

generator manufacturer/dealer to

determine required generator size.

Drawings may not represent product.

1

Included in component package 23222.

2

Included in component package 23223.

6/00 9

Page 10

BB6000 Components

No. Description

-1 Remote pendant (motor rpm control

only) for 5 hp (3.73 kW) hydraulic

power unit

Multifunction pendant replaces

standard pendant. Functions include:

Emergency stop, power unit on, jog/

run selector, and slow/fast flow

control. To order add "-1" to the

desired power unit number.

Example: "25318-1".

10 hp (7.46 kW) hydraulic power

unit

Variable displacement piston pump

power unit comes complete with a 5

gallon (19 liter) reservoir, start/stop

pendant, flow control, pressure

gauge, 20 ft (6 meter) x 1/2"

hydraulic hoses with quick

disconnect fittings, and 7/8-14 SAE

O-ring fittings for the hydraulic

motor. Order motors separately.

24596 Hydraulic power unit

3-ph/230V/60 Hz/1800 rpm motor.

Pumps 10gpm (37.9 l/min). Full load

26 amps.*

24597 Hydraulic power unit

3-ph/460V/60 Hz/1800 rpm motor.

Pumps 10gpm (37.9 l/min). Full load

13 amps.*

24598 Hydraulic power unit

3-ph/550V/50 Hz/1400 rpm motor.

Pumps 8gpm (30.39 l/min). Full load

6.8 amps.*

24599 Hydraulic power unit

3-ph/575V/60 Hz/1800 rpm motor.

Pumps 10gpm (37.9 l/min). Full load

10.8 amps.*

24602 Hydraulic power unit

3-ph/440V/50 Hz/1400 rpm motor.

Pumps 8gpm (30.39 l/min).. Full

load 5.5 amps.*

24603 Hydraulic power unit

3-ph/220V/50 Hz/1400 rpm motor.

Pumps 8gpm (30.39 l/min). Full load

30 amps.*

24604 Hydraulic power unit

3-ph/380V/50 Hz/1400 rpm motor.

Pumps 8gpm (30.39 l/min). Full load

17.4 amps.*

24605 Hydraulic power unit

3-ph/200V/50 Hz/1400 rpm motor.

Pumps 8gpm (30.39 l/min). Full load

33 amps.*

No. Description

-1 Remote pendant (motor rpm control

only) for 10 hp (7.46 kW) electric

powered hydraulic power unit

Multifunction pendant replaces

standard pendant. Functions include:

Emergency stop, power unit on,

pressure on, pressure off, jog/run

selector, and slow/fast motor speed

control. To order add "-1" to the

desired power unit number.

Example: "24596-1".

25882 Replacement hydraulic filter

element, for 5 hp and 10 hp

hydraulic power units.

10 6/00

*Full load amp rating cannot be

used to determine required

generator size. Contact your

generator manufacturer/dealer to

determine required generator size.

Drawings may not represent product.

1

Included in component package 23222.

2

Included in component package 23223.

Page 11

BB6000 Technical Information

Specifications in inches (mm)

Specifications subject to change without notice.

For precision dimensions consult your factory representative.

Boring diameter:

Standard 6 (152.4) min

36 (914.4) max.

Machine ship weight (approx.): 640 lb (291 kg)

Typical machine consisting of rotational drive assembly

(22221), axial feed assembly (23299), manual boring

head set (22383), two three-arm bearing assemblies

(22072), and 3.5" diameter x 8 foot boring bar (22110).

Components:

Mechanical axial feed assembly:

Feed rate variable, reversible, .003-.020/rev.

(.076-.508/rev)

Rotational drive assembly:

Net weight (w/o motor): 86 lb (40 kg)

Gear ratio: 6:1 gear reduction

(Theoretical values calculated using a 5 hp hydraulic

power unit producing 1200 psi (8268 kPa) continuous,

2000 psi (13780 kPa) intermittent and pumping 6 gpm

(22.7 l/min.).

With 17.9 in3 (293.6 cm3) hydraulic motor (25478):

Boring bar torque: 1292 ft•lb (1757 n•m)

Max boring rpm: 12 rpm @ 6gpm

(12 rpm @ 22.7 l/min)

Boring bar: 3.1 hp (2.3 kW)

Motor, hydraulic:

Displacement: 3.6 - 17.9 in3 (59.1 - 293.6 cm3)

Net weight: 15.5 - 19.2 lb (7.1 - 8.7 kg)

Fittings: 7/8-14 SAE O-ring

Bearing support assembly:

End mount three-arm bearing diameter range:

12-20 (304.8-508.0)

End mount four-arm bearing diameter range:

18-38 (457.2-965.2)

ID-mount bearing ID diameter range:

12-37.53 (304.8-953.3)

Mounting spiders require 5/8" or smaller bolts

Boring bar:

Ship weight (approx.):

3.5" dia x 5 ft bar (22107): 175 lb (80 kg)

3.5" dia x 12 ft bar (22114): 518 lb (236 kg)

Ship dimensions:

3.5" dia x 12 ft bar: 11 x 13 x 154 (28 x 33 x 392cm)

Hydraulic power unit (10 hp):

Ship weight (approx.): 500 lb (228 kg)

Ship dimensions (approx.):

27 x 33 x 48 (69 x 84 x 122 cm)

Manual boring head assembly:

Tooling: .5" (12mm) square HSS tool bits

1" square indexable carbide

tooling (ass'y requires tool carrier)

Diameter range: 6-36 (152.4-914.4)

Mechanical feed facing head assembly:

Feed rate: automatic, up to .010/rev (.254/rev)

Stroke: 4 (101.6)

Facing diameters:

Using 24" boring head set spacers:

10.5 - 24.0 (266.7 - 609.6)

Using 36" boring head set spacers:

10.5 - 36.0 (266.7 - 914.4)

Tooling: .5" (12mm) and 1" (24mm) square

HSS or 1" square indexable carbide

tooling (ass'y requires tool carrier)

Boring bar:

Chromed, with full-length leadscrew. Bar end caps with

anti-friction leadscrew bearings allow the axial feed

assembly to be mounted to either end of the bar.

Net weight: 3.5" dia. x 5 ft: 175 lb (80 kg)

3.5" dia. x 12 ft: 518 lb (236 kg)

Hydraulic power unit:

Net weight: 5 hp: 400 lb (182 kg)

10 hp: 500 lb (228 kg)

Power sources: 3-phase electric or 1-phase electric

6/00 11

Page 12

BB6000 Operational Dimensions

Specifications in inches (mm)

Specifications subject to change without notice.

For precision dimensions consult your factory representative.

27.25 (692.2)

24.0 (609.6)

3.5 (88.9)

6.0

(152.4)

13.7

(347.9)

Rotational Drive Assembly

11.0 (279.4)

10.0

(254.0)

13.25 (336.6)

5.0 (127.0) dia.

Axial Feed Assembly

9.0

(228.6)

12 6/00

Page 13

10.0

(254.0)

BB6000 Operational Dimensions

Specifications in inches (mm)

Specifications subject to change without notice.

For precision dimensions consult your factory representative.

20.0 (508.0)

12.0

(304.8)

Three-Arm

End-Mount Bearing

Support Assembly

6.0

(152.4)

Four-Arm End-Mount

Bearing Support

Assembly

38.0 (965.2)

18.0 (457.2)

6/00 13

Page 14

BB6000 Operational Dimensions

12.0 (304.8) minimum dia.

14.53 (369.1) maximum dia.

Specifications in inches (mm)

Specifications subject to change without notice.

For precision dimensions consult your factory

representative.

ID-Mount Bearing

Support Assembly

(small chuck)

ID-Mount Bearing

Support Assembly

(large chuck)

14.53 (369.1 minimum dia.

22.53 (572.3) maximum dia.

with short leg kit

37.53 (953.3) maximum dia.

with long leg kit

14 6/00

Page 15

Axial feed

assembly

BB6000 Operational Dimensions

Specifications in inches (mm)

Specifications subject to change without notice.

For precision dimensions consult your factory representative.

Maximum recommended unsupported

bar length is 5 ft. (1.5 m)

7.25

(184.2)

Standoff

5.0

(127.0)

Rotational drive

assembly

Standoff

1,2

1,2

5.0

(127.0)

Hydraulic motor

Total required bar length = 21 (533.4) + distance to bore + (2x standoff length)

End-mount bearing

support assembly

1

Recommended minimum standoff length for boring = 7.5 (190.5)

2

Recommended minimum standoff for facing = 14.0 (355.6)

Boring bar

Boring head and

tool carrier

Determining Required Bar Length

End-mount

bearing

support

assembly

6/00 15

Page 16

CLIMAX

Portable Machine Tools, Inc.

2712 E. Second St., P.O. Box 1210

Newberg, OR 97132-8210 U.S.A.

Worldwide Tel. 503/538-2185

FAX 503/538-7600

Call toll free

800/333-8311

Visit our web page at

http://www.cpmt.com

16 6/00

TD20-.5M10600 Printed in USA

Loading...

Loading...