Page 1

by

Cleveland

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COMBI OVEN-STEAMER

Featuring the

"Advanced Closed

MODEL: c OES-6.20

CAPACITY:

System +3"

ELECTRIC HEATED – Boilerless

Cooking Modes:

n Hot Air n Retherm n "Delta T" slow cooking

n Steam n "Cook & Hold" n "Crisp & Tasty"

n Combi

Cleveland Standard Features:

n

"Advanced closed system" with "Crisp & Tasty" de-moisturizing feature

ficient heating system saves energy and provides fast heat up times

n

Ef

n Fully insulated cooking compartment for maximum energy savings

n

Polished cooking compartment with coved corners for easy cleaning

n Three (3) 26" x 20" wire shelves

n Hinged fan guard and hinged removable pan racks

n

Two (2) speed auto reversing convection fan for even heat distribution

n Space saving, easy to close "Disappearing Door"

n Door latch with safety vent position and wear-free door switch

n Vented, double glass door with integrated door stop and self

draining condensate drip pan

n Easy to change, press-fit door seal

n Oven light with shock resistant safety glass

n Multipoint core temperature probe

n Easy to use electronic controls for all operational functions

n Self diagnostic system with full text message display

n Easy to understand menu icons with bright graphics display

n User friendly selector dial

n Exclusive "Smart Key" for selecting option settings

n Digital controls for temperature, time and core probe settings

n Eight (8) "Press & Go" one step, recipe start buttons

n Cook book library for up to 250 stored recipe programs, each

recipe capable of 20 steps

n

RS 232 connection for controlling one unit with a PC (personal computer)

n Memory module automatically saves unit settings and recipes

n

Manual program override feature for operational settings

n Smooth action hand shower for compartment cleaning

n Injection system for steam

Options and Accessories

p ConvoClean automatic compartment washing system

p PC-HACCP software for establishing "HACCP controls" and automatic

documentation of the cooking process

p Equipment stand(s)

p Equipment stand(s) with Casters

Shall be Cleveland Model: OES-6.20 Combination Convection Oven /

Steamer with simple to operate electronic programmable controls for Hot Air,

Convection Steam, and Combination cooking modes, "

"Delta T" slow-cooking capabilities, "Advanced Closed System" with "Crisp

& Tasty

recipe library, multipoint core temperature probe, "

recipe start buttons, "

auto reversing convection fan, boilerless. "Disappearing Door". Capacity for

seven (7) 18" x 26" full size sheet pans, or fourteen (14) 12" x 20" x 2 1/2" pans.

p Universal pan-rack system to hold full size sheet pans without the use

of wire shelves

p Stacking kit for stacking two (2) OES-6.20 models

p Stacking kit for mounting one (1) OES-6.20 model on top of

one (1) OES-10.20

p Lockable cover over operating controls for prison installations

p USB or RS 485 connection for networking and controlling up to 32

units with a personal computer

p Plate rack for banquet operations

p Plate rack cart

p Thermal cover for plate or pan rack

p ConvoClean compartment cleaning solution

p ConvoCare concentrate for compartment rinse cycle

p "Dissolve" generator descaling solution

p Chicken Grill Rack

p 12" x 20" Wire Baskets for frying products

p Additional 26" x 20" Wire Shelves

p Special Baking Rack System

p 480 volt option

p Kleensteam II W

Seven (7) - 18” by 26” by 1” full size sheet pans* or

Fourteen (14) - 13” by 18” by 1” half size sheet pans* or

Fourteen (14) - 12” x by 20” by 2 1/2” steam table pans

*

On wire racks. Additional wire racks required for maximum capacity.

Short Form Specifications

Cook & Hold" and

" de-moisturizing feature. Multiple cooking stage programs, stored

Smart Key" for selecting option settings, two (2) speed

ater Filters

Press & Go", one-step

SECT. IIA PAGE 35

0707

Page 2

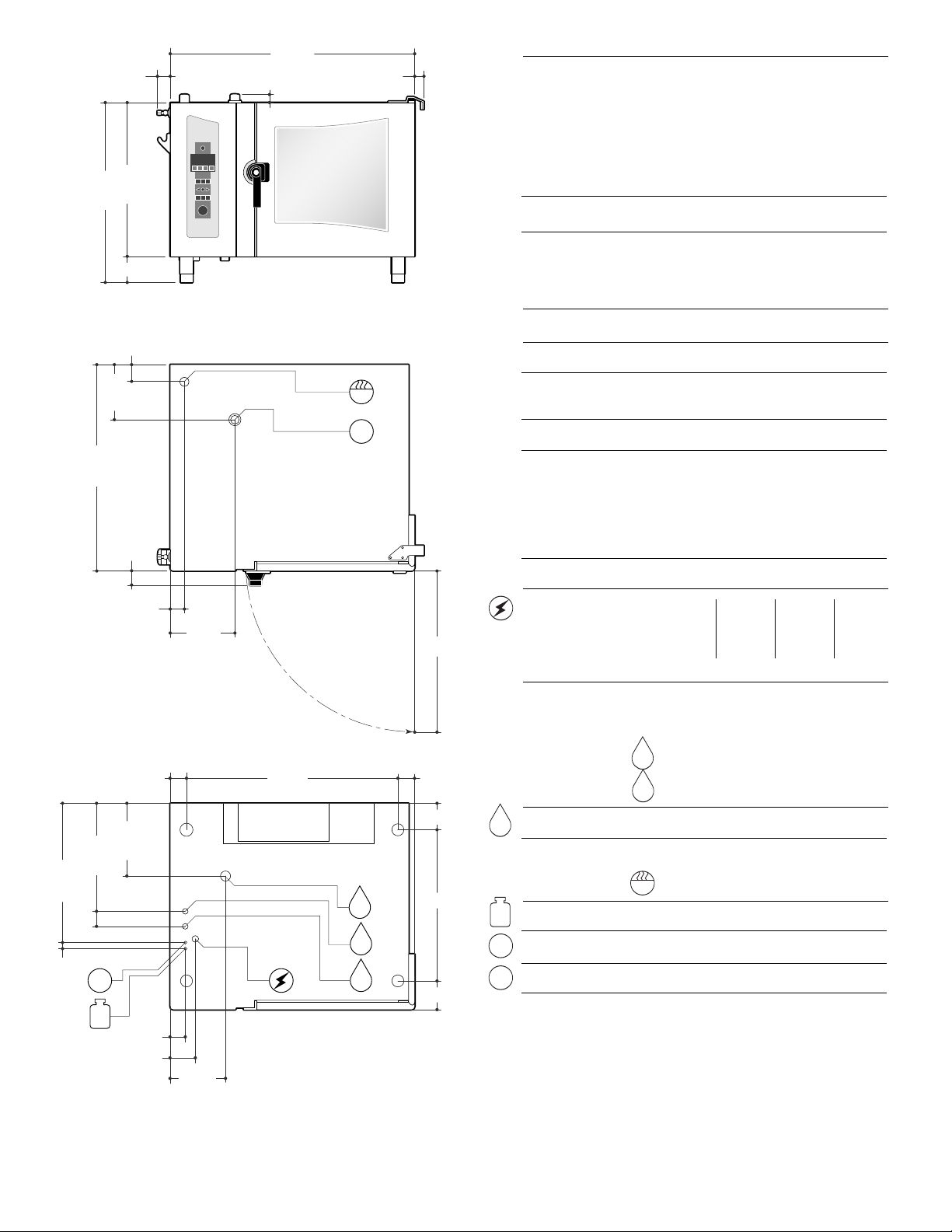

W1

W2

D

RC

W1

W2

D

RC

CS

W1

W2

D

RC

S

CS

AV

47.92"

2.52"

1.58"

30.12"

6.00"

1.82"

36.12"

40.44"

2.80"

12.68"

2.80"

31.50"

3.39"

10.79"

3.23"

14.26"

10.87"

41.42"

3.27"

6.93"

21.19"

2.96"

27.29"

1.19"

29.61"

3.90"

3.00"

4.97"

S

A

V

RC

CS

W1

W2

D

FRONT VIEW

TOP VIEW

BOTTOM VIEW

W1

W2

D

W1

W2

D

W1

W1

W2

W1

W2

D

RC

CS

AV

The "Advanced Closed System" offers the following advantages:

n Saves energy

n Automatic moisture level adjustment

n Low heat and steam emission to the kitchen

n Automatically regulated steam injection

n Enables immediate change into the steam mode

n "Crisp & Tasty" demoisturizing function

Model: OES-6.20

Pan Capacity [

20" x 26") full size wire racks

7 (

4

13" x 18") half size sheet pans - on wire racks 14(12" x 20" x 2 1/2") steam table pans

1

(

12" x 20" x 1") steam table pans

14(

Unit has 7 slide rails at 2.64" (67mm) apart

18" x 26") full size sheet pans - on wire racks

7 (

12" x 20") frying Baskets - (no wire racks needed

14(

]:

)

For Banquet Operations: Optional Plate Rack holds 42 plates

Unit Dimensions:

Shipping Dimensions: Width - 58", Depth - 49", Height - 45"

(including packaging)

Width - 52.26", Depth - 43.24", Height - 36.82"

Shipping Weight: 485 Lbs

Required Clearances:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factory service department for recommendations).

• Installation must comply with all local fire and health codes.

Agency Approvals: UL, UL - Sanitation (NSF Standards)

Electrical Requirements: 208/3/60 240/3/60 440/3/60 480/3/60

Total Connected Load: 16.4 KW 21.6 KW 18.5 KW 22 KW

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Amps per Phase: 45.5 51.8 24.2 26.4

Do not connect to a G.F.I. outlet

Water Connections: Cold Water (drinking water quality)

Flow Pressure:

30 - 60 PSI

Water Inlets: 3/4" GHT-F (Female Garden Hose Connection)

reated Water for Steam Production

T

Untreated Water for Condenser and Hand Shower

Drain Connection: 2" Tube

Venting: Exhaust Hood

*Connection for Cleaning Solution

*Connection for Rinse Cycle

Low Pressure Safety Valve

vailable as an option

*A

Air Vent

required

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers.

SECT

.

IIA P

AGE

36

0707

Loading...

Loading...