Page 1

METERING

FILLING

STATION

MODEL: MFS

(for Models built after June, 1994)

CLEVELAND RANGE INC.

1333 East 179th St.

Cleveland, Ohio

U.S.A. 44110

Toll Free 1-800-338-2204

SE95019 Rev.4

INSTALLATION, OPERATION AND SERVICE MANUAL

Page 2

TABLE OF CONTENTS

Installation Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shipping Damage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Packaged Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Clipper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation Requirements - Compressed Air & Electrical . . . . . . . 1

Installation Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating Instructions General Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pumping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Approximate Volume Setting Instructions . . . . . . . . . . . . . . . . . . . 4

Cleaning Instructions Preproduction Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . 5

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service Parts Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Piston Head Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pump Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Label Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hose Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Thermal Assurance Package (option) . . . . . . . . . . . . . . . . . . . . . 13

Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Piping Assemblies, "O" Rings, Gaskets & Seals. . . . . . . . . . . 15-16

"O" Rings, Gaskets & Seals (shown actual size) . . . . . . . . . . 17-18

Maintenance Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Oil Filling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Air Filter Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . 19

Product Piston Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjustment & Setting of Air Cushion Equipped Pump Heads . . . 20

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pneupak Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . 21

Pneumatic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Air Package Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Air Package Parts Drawing Legend . . . . . . . . . . . . . . . . . . . . . . 24

Point to Point Air Tubing Connections . . . . . . . . . . . . . . . . . . . . 23

Air Tube Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-26

Spare Parts Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Page 3

INSPECTION

Before unpacking visually inspect the unit for

evidence of damage during shipping.

If damage is noticed, do not unpack the unit,

follow shipping damage instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or the

reason for suspecting damage as soon as it is

discovered. This will help in filling out the claim

forms later.

2. As soon as damage is discovered or

suspected, notify the carrier that delivered the

shipment.

3. Arrange for the carrier's representative to

examine the damage.

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

PACKAGED ITEMS

Packaged items that are shipped loose with the

unit include:

(1) 2" Wrench

(1) 3" Wrench

(2) Trash Containers

(1) Assortment of spare "O" Rings

(1) Air Hose Assembly

(2) Food Hose Assemblies

(1) Food Grade Grease

(1) Spring

(1) Bolt

(1) Cleaning Hose

(1) Brush Kit

(1) 3" 90° Elbow

(1) Lug Nut Wrench

ASSEMBLY

The Metering Filling Station is a mobile unit that

requires no assembly to complete unless a clipper

has been shipped with the unit.

It does however ship with a number of loose items

that are required for its use.

These items should be stored in a convenient

location.

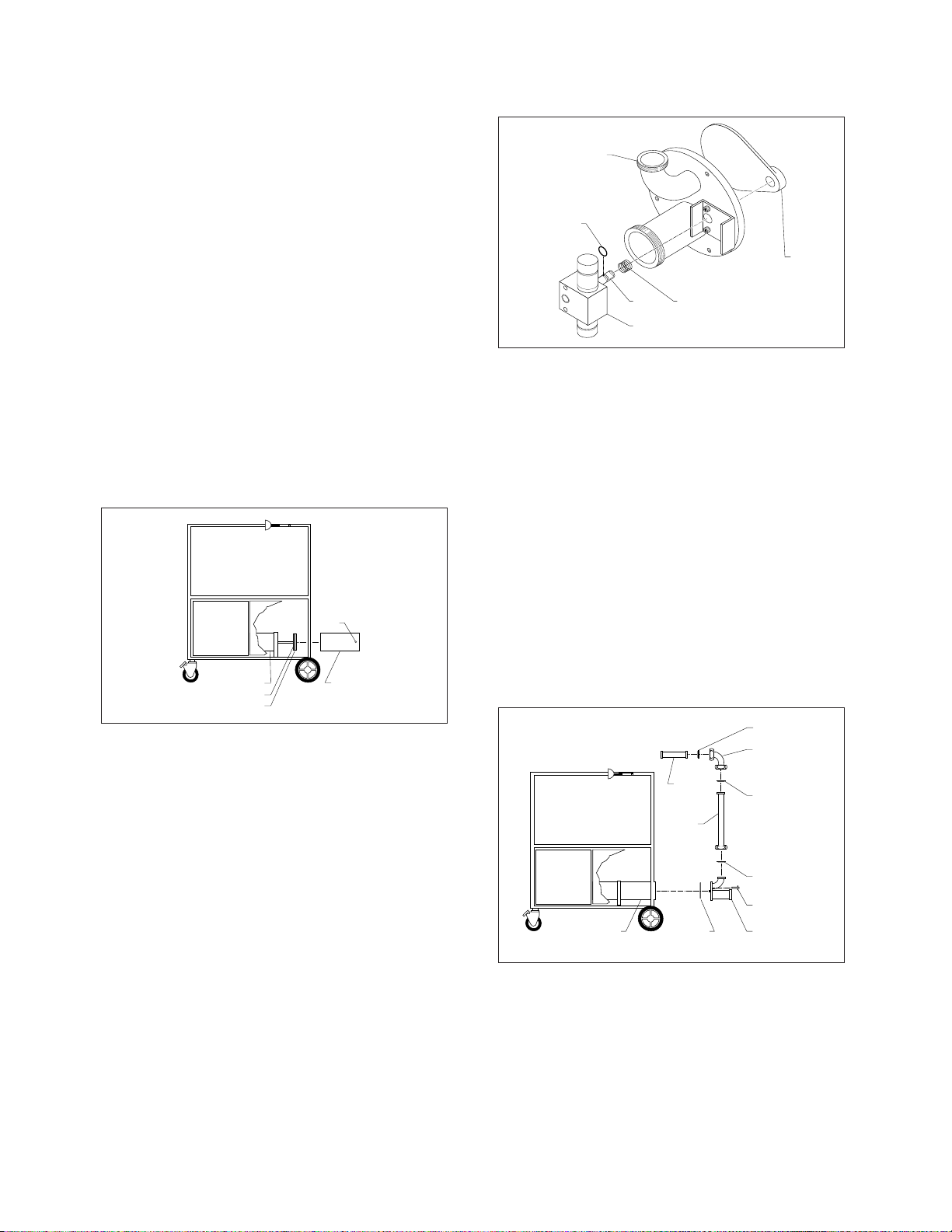

CLIPPER

If a clipper is supplied with the unit, it must be

mounted. Remove it from the box and connect it to

the mounting bar using part #FA11509 bolt

(supplied). Connect one end of the short air hose

(supplied) to the clipper and the other end to the

male quick connect on the end of the MFS.

INSTALLATION

REQUIREMENTS

Compressed Air

This unit requires a constant 25 c.f.m. (cubic feet per

minute) at 90 to 100 p.s.i. (pounds per square inch).

The air must be filtered of oil, moisture and dirt.

The dew point of the supply air must be less than

65°F. The Metering Filling Station is equipped with

its' own air oiler system, therefore, no oil should be

added to the supply air. We recommend the

compressed air system be equipped with a drier,

filter, and automatic water dump on the air

compressor receiver tank. If the distance between

the tank and the unit is less than 100 feet then a

minimum line size of 3/4" is required. A distance of

100 to 300 feet requires a minimum 1" line.

Connect one end of air line (supplied) to the

metering filling station and the other end to the

kettle air outlet fitting.

If you do not have a Cleveland kettle with air

connection built-in then you must attach the

female quick connect (supplied) to your air supply.

Electrical

No electrical connection is required unless the unit

comes equipped with a Thermal Assurance

Package (TAP) option. This requires a 115V. 1PH.

grounded outlet.

1

INSTALLATION

Page 4

INSTALLATION CHECKS

(see General Parts Drawing, page 3)

AIR PRESSURE

Complete the following steps with the 3" dia. Food

Product Hose (15) not connected:

1. Connect supply air to metering filling station.

2. Open front Access Doors (17) on metering

filling station.

3. Set Stroke Selection Switch on Control Panel

(1) for "CONSTANT PUMPING".

4. Hold Trigger Lever (10) and read Pressure

Gauge (21) as pump is operating. Pressure

should not drop less than 90 psi or exceed

110 psi.

5. Adjust Pressure Regulator Dial (20) or supply

pressure if required.

Note: If there is no air to unit check:

A/ The kettle's Air Quick Connect is

pushed upward to the "OPEN" position.

Air Quick Connect on Mixer Kettle

B/ Open the back Access Doors (17) and check

that the Main Air Shut Off Valve (22) is

pressed inwards.

SINGLE STROKE

Note: Use 3" gaskets in all hex nut couplings on

food hose.

⇒ First, hand-tighten.

⇒ Then, snug with wrench.

1. Using 3" gasket, connect the 3" dia. Food

Product Hose (15) to metering filling station

and kettle.

2. Add water to kettle and open kettle's product

discharge valve.

3. Open front Access Doors (17) of metering

filling station.

4. Set Stroke Selection Switch on Control Panel

(1) for "SINGLE STROKE".

5. Place bag over Discharge Nozzle (11).

6. Pull and hold Trigger Lever (10).

7. Product piston should go all the way forward,

then return and stop.

8. Release Trigger Lever (10).

9. Repeat test two to four times, product will start

to discharge into bag.

CLIPPER

Refer to clipper operating instruction manual for

safety and operating procedures.

2

OPEN

Page 5

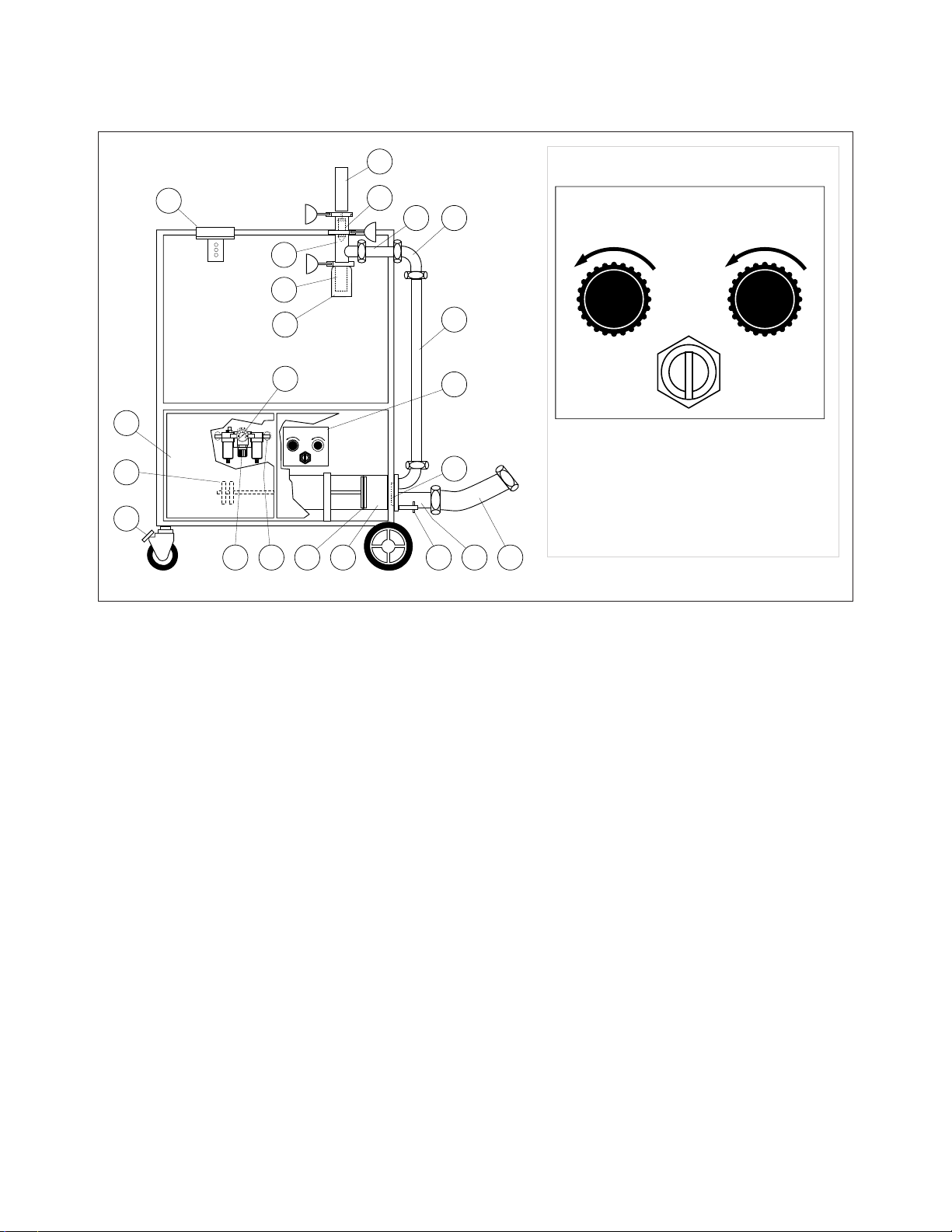

OPERATING INSTRUCTIONS

3

OPERATING CONTROLS

NAME FUNCTION

Discharge speed Adjusts speed of product exiting

the discharge nozzle.

Suction speed Adjusts speed of product being

pulled from kettle and into pump.

Stroke selection Selects operating mode or OFF

when not in use.

General Parts Drawing

ITEM # DESCRIPTION FUNCTION

1. Control Panel . . . . . . . . . . . . . . . Includes: A/ speed adjusters for suction and discharge.

B/ stroke selection switch.

2. Flapper Valve . . . . . . . . . . . . . . Changes direction of product flow.

3. Piston Head

4. Large Lug Nuts . . . . . . . . . . . . . Holds product head to product cylinder.

5. Product Cylinder . . . . . . . . . . . . Cylinder product is drawn into and discharged from.

6. Product Piston . . . . . . . . . . . . . . Moves product within the cylinder.

7. Product Discharge Valve . . . . . . Air cylinder that opens and closes discharge opening

by moving plunger.

8. Plunger . . . . . . . . . . . . . . . . . . . Opens and closes product discharge opening.

9. Discharge Valve Body

10. Trigger Lever . . . . . . . . . . . . . . . Activates pumping action.

11. Discharge Nozzle . . . . . . . . . . . Directs the flow of discharge product.

12. 2" dia. Short Connector Pipe

13. 2" Elbow

14. 2" dia. Long Connector Pipe

15. 3" dia. Food Product Hose . . . . . 3" dia. hose to connect Metering Filling Station hose to kettle.

16. Brake . . . . . . . . . . . . . . . . . . . . Locks pump in position.

17. Access Doors

18. Clipper Bracket . . . . . . . . . . . . . Mounting bracket for optional clipper.

19. Adjusting Wheels . . . . . . . . . . . . Used for setting desired pumping volume.

20. Pressure Regulator Dial . . . . . . . Used to regulate air pressure.

21. Pressure Gauge . . . . . . . . . . . . Shows operating pressure.

22. Main Air Shut Off Valve . . . . . . .

Disconnects air supply to unit. (Back side of Metering Filling Station)

18

17

19

16

2220

9

10

11

21

DISCHAR GE

SPEED

FAST SLOW F AST SLOW

2

1

0

9

8

7

SINGLE STROKE CONSTA NT PUMPING

Cleveland

3

4

5

STROKE

6

SELECTI ON

OFF

7

8

12

13

FA ST SL OW FA ST SL OW

14

Cleveland

DI SC HA RG E

SP EE D

ST RO KE

SE LE CT IO N

SI NGLE STR OKE C ONS TANT PUM PING

O F F

SU CT IO N

SP EE D

1

SUCTION

SPEED

2

1

3

0

4

9

5

8

6

7

2

4 36 5 15

Page 6

PUMPING

Note: Use 3" gaskets in all hex nut couplings on

food hose.

⇒ First, hand-tighten.

⇒ Then, snug with wrench.

1. Using 3" gasket, connect one end of the 3"

dia. Food Product Hose (15) to kettle.

2. Position metering filling station for ease of

operation and connect other end of 3" dia.

Food Product Hose (15) - if required use 3"

90° elbow.

3. Connect air hose to kettle and metering filling

station.

4. Open the back Access Doors (17) and check

that the Main Air Shut Off Valve (22) is

pressed inwards.

5. Open front Access Doors (17) of metering

filling station.

6. Set Stroke Selection Switch on Control Panel

(1) for "SINGLE STROKE".

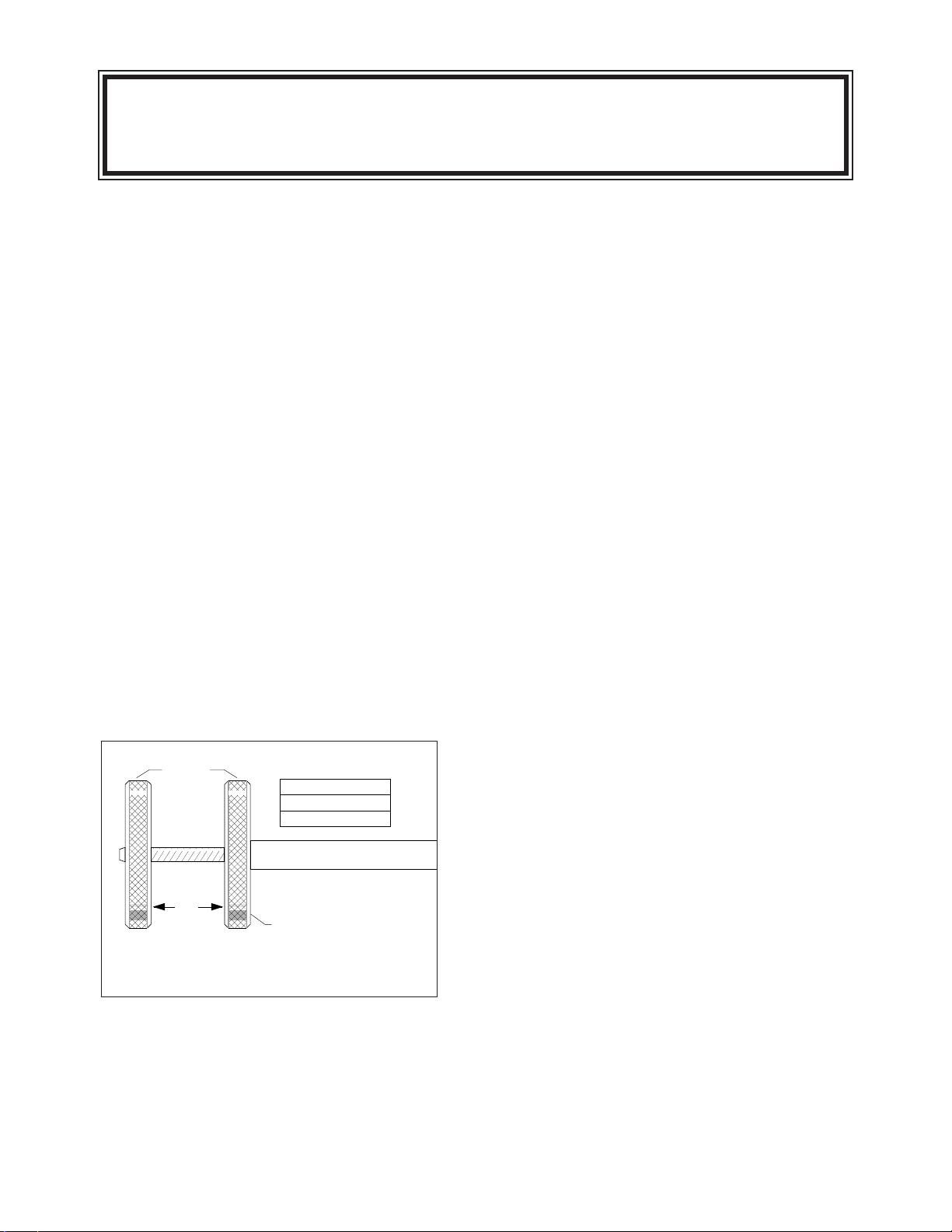

Approximate Volume Setting Instructions

7. Using a ruler, set desired quantity by measuring

between Adjusting Wheels for correct setting.

8. Open product discharge valve on kettle.

9. Place bag over Discharge Nozzle (11).

10. With Stroke Selection Switch on Control Panel

(1) set on "SINGLE STROKE", pull and hold

Trigger Lever (10) against Discharge Nozzle

(11) until pump has stopped; if a second

stroke is required, repeat process.

11. Move bag over to clipper and clip closed

(refer to clipper operating instruction manual).

12. Pump a couple of bags to check volume and

speed.

⇒ To adjust volume, measure between

Adjusting Wheels (19) for correct setting.

⇒ To adjust speed, turn Discharge Speed or

Suction Speed on Control Panel (1) as

required.

⇒ Adjust pump speed faster for thinner

products and slower for thicker.

13. Continue pumping until all product has been

emptied from kettle.

Adjusting

Wheels

A

Locked Position

A Volume

1 1/2" = 1 gallon

3 1/2" = 3 quarts

5 1/2" = 5 quarts

NOTE: Fine tune the distance during start up training.

Make a template for ease of adjustment.

Approximate

4

AS A SAFETY FEATURE THE DISCHARGE NOZZLE (11) WILL

AUTOMATICALLY CLOSE AND THE PUMP WILL REVERSE ANY TIME

YOU RELEASE THE TRIGGER LEVER (10).

Page 7

PREPRODUCTION

SANITIZING PROCEDURE

1. Fill kettle to hemisphere and start the agitator.

2. Add 5.25% bleach to make a 50 ppm solution

- refer to chart.

Amount of water

Amount (5.25%) of

in the kettle bleach to add

20 gal / 76L. . . . 5 tbsp / 75ml

30 gal / 114L. . . . 7 1/2 tbsp / 113ml

40 gal / 151L. . . . 10 tbsp (5/8 cup) / 150ml

50 gal / 190L. . . . 12 1/2 tbsp. (3/4 cup + 1 tbsp) / 188ml

60 gal / 227L. . . . 1 cup / 225ml

Sanitizing Solution Chart

3. Bring the temperature to 80°F (max.- 100°F)

or lukewarm.

NOTE:

Do NOT allow solution to get hot.

4. Attach the metering filling station to the kettle

and pump on "CONTINUOUS" setting for one

minute.

5. Finish emptying the kettle by disconnecting

the 3" dia. Food Product Hose and letting the

contents of the Metering Filling Station and

kettle drain. Make sure the 3" dia. Food

Product Hose does not drag on the floor.

FLUSHING

Between Recipes

1. To clean between batches of product, flush

kettle and Metering Filling Station with a

warm water and mild detergent solution from

kettle to loosen and remove food particles.

2. Remove product Discharge Nozzle and

replace it with cleaning hose.

3. Place end of cleaning hose over a drain.

4. Switch stroke selector switch to "CONSTANT

PUMPING".

5. Pull and hold trigger lever against discharge

valve nozzle until kettle has been emptied.

6. Add clean water to kettle, and repeat process

to rinse units.

NOTE:

The metering filling station must be

sanitized prior to the daily production run.

5

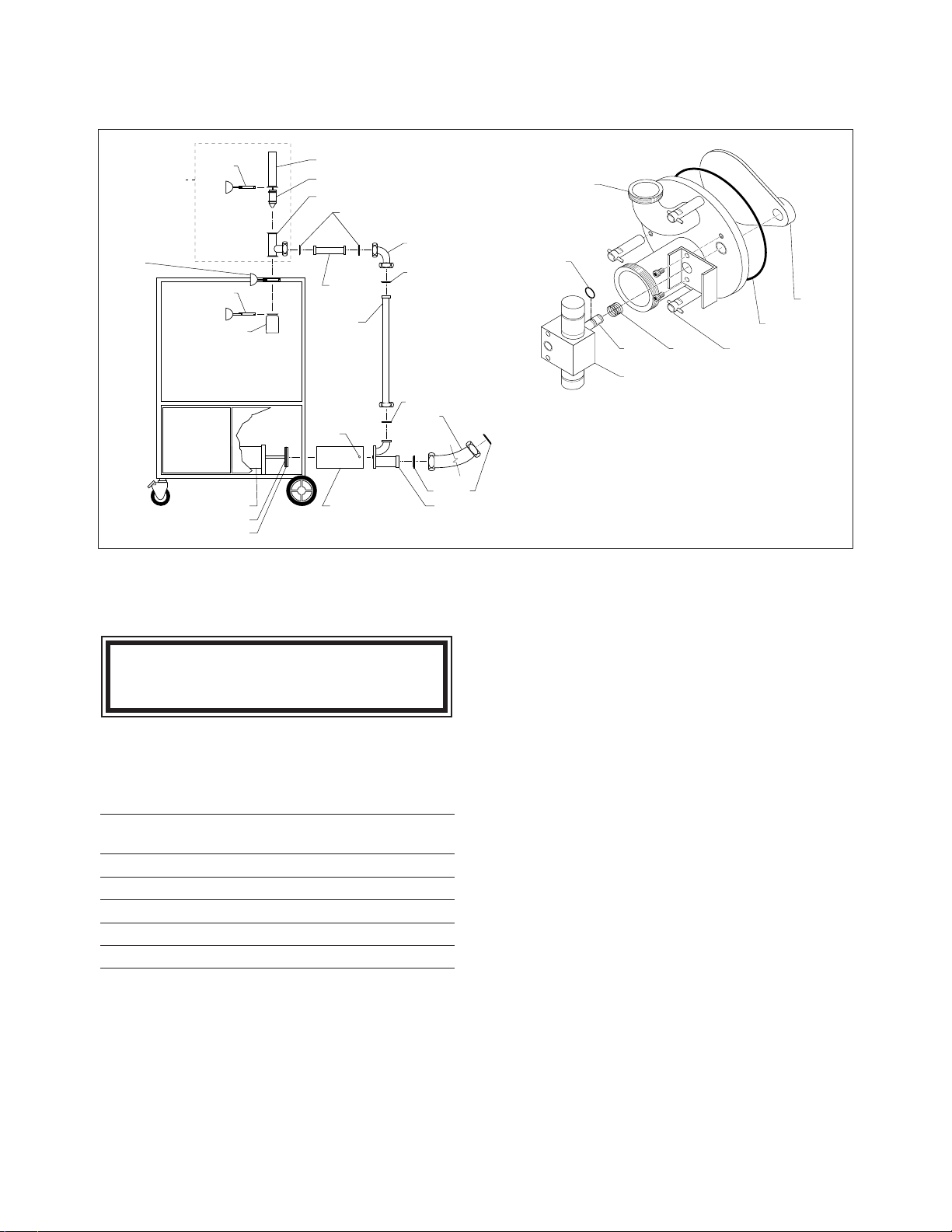

CLEANING INSTRUCTIONS

Flapper Valve

"O" Ring

Spring

Large Lug Nut

Flapper

Rotary Actuator

Cylinder Seal

Shaft

Piston Head

Discharge

Head

Assembly

2" Sani

Clamp

Bracket

Product Piston "O" Ring

2" Sani

Clamp

2" Sani

Clamp

Product

Discharge

Nozzle

Piston Cylinder

Product Piston

Discharge Valve

Plunger

Discharge Valve Body

Gasket

Short

2" dia.

Pipe

Long

2" dia.

Pipe

Push

Pin

Product Cylinder Piston Head Assembly

2" dia. Elbow

Gasket

Gasket

3" dia.

Food

Hose

Gasket

Page 8

DISASSEMBLY

Note: Remove "O" rings using a wooden or

plastic picker; do NOT use a sharp object.

Note: Prepare a properly diluted solution of

authorized cleaning solution in a plastic soak

bucket taken from a freshly filled sink to receive

small parts, gaskets, and "O" rings.

1. Move slide valve on kettle's

air quick connect to down

position to vent air from

metering filling station.

Air Quick Connect on Mixer Kettle

2. Disconnect main air line from Metering Filling

Station.

3. Remove air lines (quick-disconnect fittings)

from Discharge Valve.

4. Undo 2" Sani-Clamp, and remove Discharge

Nozzle.

5. With 2" wrench, loosen nut on Discharge Valve

Body and remove Discharge Head Assembly;

place 2" gasket in warm water to soak.

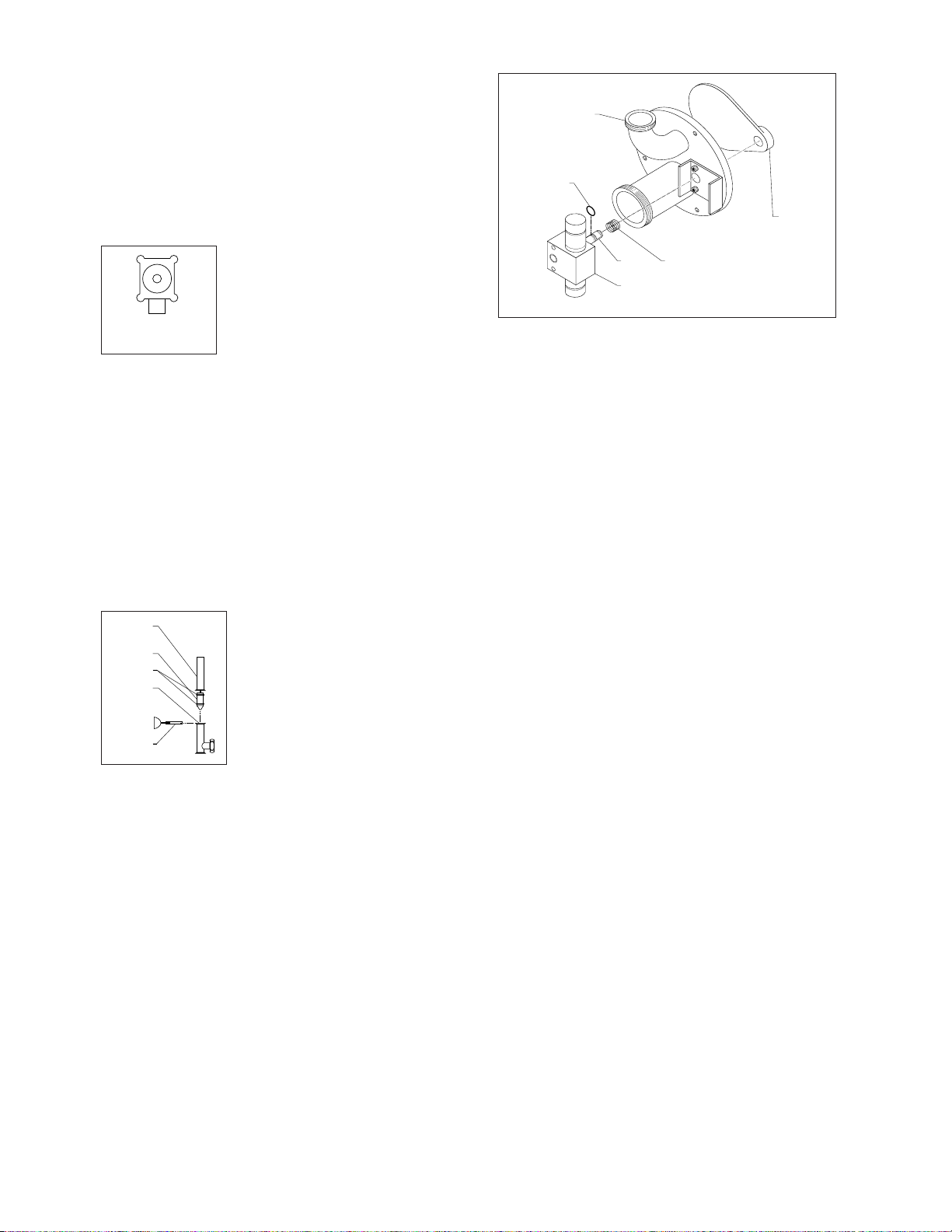

6. To disassemble Discharge

Head Assembly, follow in

order;

⇒ Remove 2" Sani-Clamp that

holds Discharge Head

Assembly together.

⇒ Separate parts by pulling

them apart.

Discharge Head Assembly

⇒ Using a wooden or plastic picker, remove

"O" Rings from plunger.

⇒ Put "O" Rings in warm water to soak; do

NOT submerge discharge valve.

7. With 2" wrench, remove Short 2" dia. Pipe, 2"

dia. Elbow and Long 2" dia. Pipe. Place all

gaskets in soak bucket.

8. Remove two air lines from Rotary Actuator on

Piston Head Assembly.

9. Using lug wrench, unscrew three Large Lug

Nuts, and remove Piston Head Assembly.

10. Dismantle Piston Head Assembly as follows in

order;

Piston Head Assembly

⇒ Push Rotary Actuator toward Piston Head

to remove Flapper, place Flapper in soak

bucket.

⇒ Remove Rotary Actuator, placing small

spring in soak bucket.

⇒ Do NOT submerge Rotary Actuator.

11. Pull product cylinder off product piston.

⇒ Do NOT use pliers or any other tool that

could damage the inside wall of the cylinder.

12. Using plastic or woden picker, remove "O"

ring from Product Piston.

CLEANING

WARNING: Do not submerge Discharge Valve or

Rotary Actuator in water, damage to air cylinders

will result.

⇒ Always turn off equipment power before

using water.

⇒ Never use steel wool for cleaning; particles

may become embedded and rust.

⇒ Clean unit in the following order:

A/ Warm water and mild detergent solution.

B/ Clear rinse.

C/ Properly diluted sanitizing solution (see

Sanitizing Solution Chart) to sanitize after

cleaning.

⇒ Do NOT use chloride cleaners; they may

damage stainless steel surface.

⇒ For difficult cleaning applications, one of

the following can be used: alcohol, baking

soda, vinegar, or a solution of ammonia in

water.

1. Clean all parts (except Discharge Valve and

6

Push yellow tab down to

release air pressure before

disconnecting air hose

Discharge

Valve

Plunger

"O" Rings

Discharge

Valve

Body

2" Sani

Clamps

Piston Head

Flapper Valve

"O" Ring

Flapper

Shaft

Spring

Rotary Actuator

Page 9

Rotary Actuator) with hot soapy water or run

them through the dish washer.

2. Clean the interior of the 2" inch pipes and the

3" dia. food product hose using the brushes

provided.

3. Inspect "O" rings and gaskets for cuts,

distortion, or wear, replace if required.

4. Leave part disassembled overnight.

ASSEMBLY

NOTE: To eliminate any chance of recontamination

of unit, wear sanitary disposable gloves during

reassembly after cleaning.

This startup procedure assumes the unit is fully

disassembled.

1.

Attach Product Cylinder to Piston Cylinder as

follows:

Product Piston/Cylinder Assembly

⇒ Inspect Product Piston "O" Ring (replace if

worn) on Product Piston - lubricate with food

grade grease.

⇒ Push Product Cylinder over Product Piston

and seat firmly in groove (push pin must be

located as illustrated).

2.

Assemble Piston Head Assembly as follows in

order:

Piston Head Assembly

⇒ Inspect Flapper Valve "O" ring on rotary

actuator (replace if worn).

⇒ Lubricate "O" ring with food grade grease and

put on shaft.

⇒ Put Spring on Shaft.

⇒ Slide Rotary Actuator Shaft thru hole in

Piston Head.

⇒ Mount Flapper to Shaft.

3.

Assemble piston and piping as follows in

order:

Note: Use 2" gaskets in all hex nut

couplings.

2" Piping Assembly

⇒ Put Cylinder Seal in place. Lubricate

exposed portion of Cylinder Seal then mount

Piston Head to Product Cylinder, and fasten

in place with large Lug Nuts using lug wrench

for final tightening.

7

Piston Head

Flapper Valve

"O" Ring

Shaft

Spring

Rotary Actuator

Flapper

Push

Pin

Piston Cylinder

Product Piston

Product Piston "O" Ring

Product Cylinder

Gasket

2" dia. Elbow

Short

2" dia.

Pipe

Long

2" dia.

Pipe

Gasket

Gasket

Product Cylinder

Cylinder

Seal

Lug Nut

Piston Head

Page 10

⇒ Attach two 1/4" air lines to Rotary Actuator

(black line on top).

⇒ Reassemble 2" piping (Long 2" dia. Pipe, 2"

dia. Elbow and Short 2" dia. Pipe) on Piston

Head as illustrated using gaskets shown.

4.

Assemble discharge

head assembly in order as

follows:

Discharge Head Assembly

⇒ Inspect and install "O" Rings (replace if

worn) on Plunger - larger one in top groove -

smaller one in bottom groove.

⇒ Push Plunger into Discharge Valve Body.

⇒ Attach Discharge Valve to Discharge Valve

Body using 2" Sani-Clamp.

⇒ Attach Discharge Nozzle to Discharge

Valve Body using 2" Sani-Clamp.

5.

Attach Discharge Head Assembly as follows:

Discharge Head/2" Piping Assembly

⇒ Mount Discharge Head Assembly on Short

2" diameter Pipe (use Gasket).

⇒ Rotate Discharge Head Assembly into 2"

Sani-Clamp Bracket and fasten clamp.

⇒ Attach two 1/4" air lines to Discharge Valve

(black on top).

SANITIZING

You are now ready to do the preproduction

sanitizing procedure as discussed on page 5 of

this manual.

⇒ Do NOT leave "O" rings in cleaner or

sanitizer.

⇒ When worn, replace "O" rings.

8

Discharge

Valve

Plunger

"O" Rings

Discharge

Valve

Body

2" Sani

Clamps

Discharge Head

Assembly

Gasket

2" Sani

Clamp

Bracket

2" Piping Assembly

Page 11

9

PISTON HEAD ASSEMBLY

ITEM ON. PART NO. DESCRIPTION QTY.

1. - 10. SE00068-1 Pump head assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1. KE53014-1 Rotary actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. FA05002-24 "O" Ring, cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE53056 Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE01302 Lug nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

5. FA11322-1 Hex cap screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

6. KE53659-1 Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. KE53038-1 End plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. KE53016 Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. FA05001-2 "O" Ring, pump head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE53015-1 Valve Paddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5

4

3

2

1

10

9

8

7

6

SERVICE PARTS

WARRANTY

Our Company supports a worldwide network

of Maintenance and Repair Centers. Contact

your nearest Maintenance and Repair Centre

for replacement parts, service, or information

regarding the proper maintenance and repair

of your cooking equipment

In order to preserve the various agency safety

certification (UL, NSF, ASME/Ntl. Bd., etc.),

only factory-supplied replacement parts

should be used. The use of other than factory

supplied replacement parts will void warranty.

Page 12

10

PUMP ASSEMBLY

ITEM ON. PART NO. DESCRIPTION QTY.

1. KE53037 Centre Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE53035 Piston Rod Bearing (Centre Plate) . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. FA05002-6 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE53036 Pneumatic End Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE53034 Piston Rod Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. FA05002-1 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. FA05002-2 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. KE01305 Piston Rod Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE53031 Product Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE54404 Locknut, 1 1/4-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. KE53030 Pneumatic Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. FA22501 Locknut, 1 5/8-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. FA05002-26 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

14. KE01301 Adjustment Rod Weldment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. KE53051 Adjustment Lock Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. KE53039 Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. KE53043 Reach Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

18. FA21026 Hex Nut, 3/8-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

19. KE54401 Backing Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

20. FA11258 Hex. Head Bolt, 1/4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

21. FA32008 Tooth Lockwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

22. FA05002-5 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14 15 8 6 18 5 3 2 10 22

12 14 7

13 11

2120 19

9

Piston Head

Assembly

(See Page 9)

16

17

Page 13

11

LABEL DISPENSER

ITEM ON. PART NO. DESCRIPTION QTY.

1-17 KE01387 Label Dispenser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1. KE53186 Hub Mounting Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE53187 Labeller Back Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE01386 Labeller Front Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE53268 Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE54139 Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE53265 Core Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. KE53266 Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. KE01383 Labeller Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. FA11258 Hexhead Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. FA31029 Lock washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

11. FA21008 Hex Nut, #1/4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. FA19500 Hex Socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. FA11056 Binding Head Screw, #6-32x1/2" lg. . . . . . . . . . . . . . . . . . . . . . . . . . .3

14. FA11260 Hexhead Screw, #1/4-20x1" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. FA11328 Hex Head Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. FA31030 Lock Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. FA21024 Hex Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1

7

5

6

12

5

3

21310

14

9

10

11

15

16

17

8

4

Page 14

12

HOSE ASSEMBLIES

ITEM ON. PART NO. DESCRIPTION QTY.

1. KE01749-1 Food Hose Assembly, 3' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE01749 Food Hose Assembly, 3' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE52399 Acme nut 3" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .see drw.

4. KE52398 Hose Adapter 3" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .see drw.

5. KE54762 Hose Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

6. KE52164 Food Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. FI05083 Threaded Hose Adapter 3" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .see drw.

8. KE01333 Cleaning Hose Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE53099 Cleaning Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. FI05057 Hose Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. FI05255 Hose Adapter 2" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4 3 5 75

1

4

5 43

2

6

6

11 10

8

9

3 5

CLEANING HOSE ACCESSORY

Page 15

13

THERMAL ASSURANCE

PACKAGE (OPTION)

ITEM ON. PART NO. DESCRIPTION QTY.

1. KE53479 Temperature Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE53200 Dialight Assembly (does not include bulb-) . . . . . . . . . . . . . . . . . . . . .1

3. KE53208 Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. FA05002-33 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE53206 RTD Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE53207 Single Circuit Panel, 3 pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. FA05002-28 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. KE54721-2 Watertight Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

9. KE53203 Clipper Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE53210 Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

(not shown) KE01420 RTD Sensor Adapter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1

3

1

2

4

6

5

7

8

9

10

Page 16

14

MISCELLANEOUS PARTS

INSTALLATION, OPERA

TION AND REP

AIR MANUAL

METERING

FILLING

STATION

MODEL: MFS

CLEVELAND RANGE INC.

1333 East 179th St.

Cleveland, Ohio

U.S.A.44110

Toll Free 1-800-338-2204

A

WELBILT

Company

Steam Cooking Specialists

SE90019 Rev.0

KE54166 - Brush Hanger

KE54163

Nylon Brush

for 3" Food

Product Hose

KE54164

12" Nylon Brush

1/2" dia.

KE54165

36" Nylon Brush

for 2" Piping

KE54162

Nylon Scrub Brush

KE01776

Nylon Brush Kit

KE52159

3" Wrench

KE00911

Clipper Hanger

KE01518

Hose for Clipper

3/8" dia.x 6' lg.

KE01947

Lug Wrench

KE52158

2" Wrench

FI05150

3" Elbow, 90˚

Hose for Metering Filling Statiion/Kettle

KE01750

1/2" dia. x 8' 6" lg.

FI05300

3" Elbow, 45˚

KE01316-3

3" Vertical Pipe

SE95019-1 Rev.3

Service Manual

Pan Filler

Mineral

Oil

Mineral Oil

(purchaced locally)

KE54167

Food Grade Grease

KE01314

Trash Container

Support Bar

KE53081

Trash Container

Page 17

15

PIPING ASSEMBLIES,

"O" RINGS, GASKETS & SEALS

(see pages 17-18 for actual size illustrations of "O" Rings)

1

A

2

B

3

4

6

5

D

8

9

10

11 3

13

14

15

17

12

3

18

STANDARD

CONFIGURATION

OPTIONAL

STRAINER

CONFIGURATION

15

16

7

D

D

D

I

F

E

G

F

D

C

C

D

H

H

Piston Head

Assembly

(See Page 9)

Page 18

16

PIPING ASSEMBLIES

ITEM ON. PART NO. DESCRIPTION QTY.

1. KE53270 Air Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE53250 Plunger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE52087 Sani-clamp, 2" Standard Configuration . . . . . . . . . . . .1

Optional Strainer Configuration . . . . . .3

4. KE01385 Discharge Valve Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE54287 Start Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE00905 Actuator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7. KE01384 Discharge Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. KE00920 Short Connector Pipe, 2" Standard Configuration . . . . . . . . . . . .1

9 . KE01974 Elbow, 2" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE01316-1 Long Connector Pipe, 2" Standard Configuration . . . . . . . . . . . .1

11. KE00920-1 Short Connector Pipe, 2" Optional Strainer Configuration . . . . . .1

12. KE01316-2 Long Connector Pipe, 2" Optional Strainer Configuration . . . . . .1

13. SE50415 Strainer Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. SE50413 Strainer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. SE50414 End Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

16. SE50412 Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. KE52344 Sani-clamp, 4" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

18. SE50411 Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

"O" RINGS, GASKETS & SEALS

(see pages 17-18 for actual size illustrations)

ITEM ON. PART NO. DESCRIPTION QTY.

A. FA05002-3 Upper Plunger "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

B. FA05002-7 Lower Plunger "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

C. KE52154 Sani-Clamp Gasket, 2" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

D. KE54810-1 Gasket, 2" Standard Configuration . . . . . . . . . . . .4

Optional Strainer Configuration . . . . . .2

E. KE52347 Sani-Clamp Seal, 4" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

F. FA00340 Housing "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

G. FA00334 Strainer "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

H. KE54810-3 Gasket, 3" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

I. FA05002-26 Product Piston "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Page 19

17

"O" RINGS, GASKETS & SEALS

(shown actual size - see page 12 for part locations)

F

FA00340

Housing "O" Ring

CUTAWAY

VIEW

E

KE52347

Sani-Clamp Seal

CUTAWAY

VIEW

C

KE52154

2" Sani-Clamp

Gasket

CUTAWAY

VIEW

CUTAWAY

VIEW

A

FA05002-3

Upper Plunger

"0" Ring

CUTAWAY

VIEW

B

FA05002-7

Lower Plunger

"0" Ring

D

KE54810-1

2" Gasket

CUTAWAY

VIEW

FA00111

Flapper Valve

"O" Ring

Page 20

18

"O" RINGS, GASKETS & SEALS

(shown actual size - see page 12 for part locations)

I

FA05002-5

Product Piston

"O" Ring

FA05002-26

Pneumatic Piston

"O" Ring

CUTAWAY

VIEW

FA0500-21

(not to scale)

Cylinder Seal

H

KE54810-3

3" Gasket

CUTAWAY

VIEW

G

FA00334

Strainer "O" Ring

CUTAWAY

VIEW

CUTAWAY

VIEW

Page 21

19

Air Regulator

AIR PRESSURE

1. Adjust air regulator or line pressure so that air

pressure gauge reads 90 - 100 psi when unit

is running on continuous cycle (stroke

selector switch is set on "constant pumping").

OIL FILLING PROCEDURE

The lubricator puts one

drop of oil into the air lines

for every ten to fifteen

cycles of the product

piston. This ratio should

be checked weekly and

the oil level should be

checked daily.

Lubricator

1. Drip Adjustment-

⇒ Observe the sight bulb on the top of the

oiler. One drop of oil into the lines for every

ten to fifteen cycles of the product piston.

⇒ If adjustment is necessary turn the

adjustment knob next to the sight bulb

clockwise for more oil, counter clockwise for

less oil.

2. Adding Oil-

Use only mineral oil in th oiler.

⇒ Remove air supply from unit.

⇒ Remove oiler cage and bowl. Fill to line

and replace.

AIR FILTER REPLACEMENT

PROCEDURE

The air filter is designed

to separate a small

amount of dirt and water

from the supply air. This

filter is NOT designed to

clean air straight from the

compressor. You must

install a separate filter

and drier in the supply

line to deliver air with a

dew point of less than

65° F.

Filter

1. Check for water accumulation daily. If water is

present, push button at the bottom of bowl

and allow the water to spray out.

NOTE: If the bowl has to be drained regularly

(more than once a week) then the supply air has

not been sufficiently dried.

2. If the air cartridge is dirty then it should be

replaced.

⇒ Remove air connection from unit.

⇒ Remove cage and bowl.

⇒ Turn disk to the left to remove.

⇒ Install new cartridge.

PISTON TIMING

The amount of delay between the time the product

piston reaches the end of a half stroke and the

reversing of direction can be adjusted.

1. Remove the back panel.

2. The two flow controls are located to the left of

the large shuttle valve on the right.

NOTE: The left flow control controls the delay

after the discharge stroke is completed. The right

flow control controls the the delay after the suction

stroke is completed.

3 Loosen locking nut.

4. Set selector switch to continuous and have

someone hold the tripper switch as you adjust

the delay.

5. Retighten the locking nut.

F

B

Deflector

Filter

Element

Baffle

Lever

Bowl/Guard

Assembly

Filler

Cap

Bowl

MAINTENANCE

Oil Sight Bulb

Oil

Adjustor

Oil

Bowl

low Down Button

Pressure Regulator Dial

Pressure

Gauge

Oil

Bowl

Blow

Down

Button

Page 22

ADJUSTMENT & SETTING OF

AIR CUSHION EQUIPPED

PUMP HEADS

SECTION 1 - Adjustment of Valve Paddle Travel

NOTE: When looking at the pump head (paddle

side), left side paddle travel is affected by the

right side air cylinder travel adjustment set screw

and vice versa.

1. Back off 9/16" lock nut on 3/8" dia. set screw

as shown in Figure 1.

2. Adjust set screw until valve paddle is l/8"

away from inside O-ring land edge as shown

in Figure 2.

3. Secure lock nut.

4. Recheck l /8" distance between paddle and

edge.

5. This side is now set. Follow the same

procedure for the other side.

SECTION 2 - Setting of Air Cushion

NOTE A: Again left side paddle cushioning is

affected by the right side air cylinder cushion set

screw (3/16" dia.) and vice versa as shown in

Figure 1.

NOTE B: Turning set screw in increases air

cushion action and vice versa.

CAUTION: Avoid fingers around paddle travel

area, personal injury may result.

1. Support the head assembly securely and

connect the air lines to the rotary actuator air

cylinders. Activate air to start rotary action.

2. Observe air cushion action at the end of each

swing. Optimum cushion action can best be

described as a controlled deceleration of the

paddle at the end of the swing with complete

elimination of rotational momentum in the

shortest time possible. Adjust set screw to

achieve results on both sides.

TROUBLE SHOOTING GUIDE

(reference drawings at back of manual)

1. If there is no air to unit check:

A/ Check that the kettle's Air Quick

Connect is pushed upward to the

"OPEN" position.

Air Quick Connect on Mixer Kettle

B/ Open the back access doors and check that

the 3 way spool valve (item 16 on page 23-

24) is pressed inwards.

2. Made sure the air regulator (large black knob

on back of panel) is turned on for pressure to

enter system. To be sure enough pressure is

in system, check for min. 60 PSI, otherwise

valves might not shift.

3. Recommended operating pressure is 90 to

100 PSI.

4. If the unit seems to be covered in oil or the oil

is dripping out of the mufflers, then turn

lubricator output down. Correct setting is 1

drop every 10-15 strokes.

5. If the pump valve (item 68 on page 23-24 -

the large Airtec valve) does not shift during

operation or is slow in shifting, make sure the

two Legris flow controls are not adjusted right

in. If so, then back them off.

6. If pump cylinder is too slow then adjust large

Aro flow controls (item 12 on page 23-24) to

desired speed.

7. If a leak develops around the air valve 5 bank

manifold (item 16 on page 23-24), tighten the

screws on top of valve and tighten manifold

socket head bolts as these can loosen over

time.

NOTE: Be careful with socket head bolts - do not

tighten too much or clamps will bend on manifold

increasing the leak.

8. If cylinder cycles one way but not back,

check that the limit valves (item 53 on page

23-24) are hitting to make sure contact is

made and signal is sent to either port 19 or 26

of the 5 station valve bank.

9. If cylinder still does not cycle, check or

replace control valve assembly (item 67 on

page 23-24 - top and middle valve) of the 5

station valve bank.

20

Figure 1 Figure 2

1/8" 1/8"

Cushion

Adjustment

Set Screw

Travel

Adjustment

Set Screw

OPEN

Page 23

21

PNEUPAK TROUBLE

SHOOTING GUIDE

1. No air, then turn red sleeve valve on.

2. Make sure that the air regulator (large black

knob on back of panel) is turned on for

pressure to enter system. To be sure enough

pressure is system, check for min. 60 PSI,

otherwise valves might not shift.

3. Recommend 80 to 90 PSI operating pressure.

4. If the unit seems to be covered in oil, or the oil

is dripping out of the mufflers, then turn

lubricator output down.

5. Problems within the complete system can

result if too mush oil is in the air lines and

valves. This could cause the valves not to

shift completely. Recommended oil to be used

as lubricant is a Tellus 32 or ISO32. If oil is

incompatible with Buna-N seals, the seals

may swell and cause the valves and cylinders

to stick.

6. If the pump valve (large Airtec valve) does not

shift during operation or is slow in shifting;

make sure that the two Legris flow controls

are not adjusted right in. If so, then back off.

7. If pump cylinder is too slow then adjust large

Aro flow controls to desired speed.

8. If a leak develops around the air valve 5 bank

manifold; tighten the screws on top of valve

and tighten manifold socket head bolts as

these may loosen over time.

NOTE: Be careful with socket head bolts --- Do

not tighten too much or clamps will bend on

manifold increasing the leak.

9. If pump cylinder cycles one way but not back;

check that the limit valves are actuated to

make sure contact is made and signal is sent

to either port 19 or 26 of the 5 station valve

bank.

10. If cylinder still does not cycle, check or

replace valve 1 & 3 (top and middle valve) of

the 5 station valve bank.

11. If leakage is detected around the selector

switch then check to see if debris is hindering

proper valve actuation. If this is not the case,

then replace the selector switch.

BASIC OPERATION

Single Cycle Operation

Turn the selector switch to the single cycle. It will

then do the following when the start switch is hit:

■ Shifts valve No. 2 second from the top which

turns off valve No. 1 and takes the signal

away from Pt. 24.

■ Single cycle valve is now turned on. It gives a

one shot of air to valve No. 3 which shifts, and

turns on Group A.

■ The pump valve now shifts (Airtec Valve) Pt. 1

and valve No. 4 & 5 shifts Pt. 11 &12. This

actuates Air Cylinder & Rotary Actuator.

■ When the pump reaches its full stroke, it hits

LV1. This shifts valve No. 3 back through Pt.

19 which turns on Group B which shifts the

pump valve (Airtec Valve) at Pt. 2 and shifts

the valves NO. 4 & 5 back through Pt. 22 & 23

which actuates the Air Cylinder and Rotary

Actuator to complete the single cycle.

Constant Pumping Path:

Turn the selector switch to constant pumping

cycle. It will then do the following when the start

switch is hit:

■ Valve No. 2 shifts which in turn shifts valve

No. 1 through Pt. 31. This turns on valve No. 3

through Pt. 24 if LV2 is actuated which turns

on Group A.

■ The pump valve now shifts (Airtec Valve) Pt. 1

and valve No., 4 & 5 shifts Pt. 11 & 12 to

actuate Air Cylinder and Rotary Actuator.

■ When pump reaches the full stroke it hits LV1.

This shifts back Valve No. 3 through Pt. 19

which turns on Group B which shifts pump

valve (Airtec Valve) at Pt. 2 and shifts back

valve No. 4 & 5 through Pt. 22 and Pt. 23

which actuates the Air Cylinder and Rotary

Actuator.

■ When the pump completes the first cycle, LV2

is hit again and turns valve No. 1 back on and

shifts valve No. 3 again through Pt. 24 and

starts another cycle all over again.

■ This will continue until the selector switch is

turned off which turns off the air to valve No. 2

and stops supplying valve No. 1, which will

not turn on valve No. 3 to start another cycle.

Page 24

22

PNEUMATIC SCHEMATIC

Page 25

AIR PACKAGE PARTS DRAWING

23

Page 26

24

AIR PACKAGE PARTS DRAWING LEGEND

Page 27

25

POINT TO

POINT

AIR TUBING

CONNECTIONS

Page 28

26

POINT TO POINT AIR TUBING CONNECTIONS

(continued)

Page 29

27

SPARE PARTS LIST

ITEM ON. DESCRIPTION QTY. QTY.

DOMESTIC OVERSEAS

Consumables

KE54810-3 Gasket, 3", Food Hose 10 50

KE54810-1 Gasket, 2", Piping Assembly 10 50

KE53056 Spring, Pump Head 2 10

KE54167 Food Grade Grease 1 10

FA05002-24 "O" Ring, Flapper Valve 5 20

FA05002-3 "O" Ring, Upper Plunger Seal 10 50

FA05002-2 "O" Ring, Pump Head 10 50

FA05002-7 "O" Ring, Lower Plunger Seal 10 50

FA05002-26 "O" Ring, Product Piston Head 10 50

Spare Parts

FA05002-6 "O" Ring, Rear Seal 1 2

FA05002-1 "O" Ring, Front Seal 1 2

KE01302 Lug Nut 1 2

KE54278 Removable Panel Stop 1 2

KE53266 Spring, Label Dispenser 1 2

KE53014-1 Rotary Actuator --- 1

KE01712 Air Cylinder, Discharge Head --- 1

KE01518 Hose for Clipper --- 1

KE01750 Hose for MFS to Kettle --- 1

KE54286 Air Limit Switch --- 1

KE54295 Air Flow Control --- 1

SE00090 Control Valve Assembly --- 1

SE00091 Pump Valve Assembly --- 1

OPTIONAL STRAINER PARTS

Consumables

FA05002-28 End Assembly 5 10

FA00334 "O" Ring 5 10

KE52347 Gasket, 4", Sani-Clamp 5 10

KE52154 Gasket, 2", Sani-Clamp 5 10

Spare Parts

SE50412 Pin 1 2

KE52087 Sani-Clamp, 2" 1 2

KE52344 Sani-Clamp, 4" 1 2

OPTIONAL THERMO ASSURANCE PACKAGE PARTS

Consumables

FA00008 "O" Ring 5 20

Spare Parts

KE53206 RTD Sensor 1 1

KE53200 Bulb 1 2

KE53203 Clipper Lockout Valve --- 1

Loading...

Loading...